凹版油墨标准(英文版)

- 格式:doc

- 大小:181.00 KB

- 文档页数:13

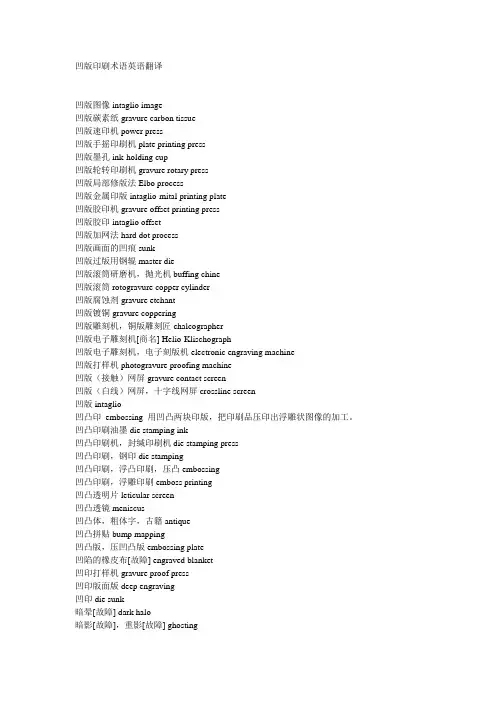

凹版印刷术语英语翻译凹版图像intaglio image凹版碳素纸gravure carbon tissue凹版速印机power press凹版手摇印刷机plate printing press凹版墨孔ink-holding cup凹版轮转印刷机gravure rotary press凹版局部修版法Elbo process凹版金属印版intaglio-mital printing plate凹版胶印机gravure offset printing press凹版胶印intaglio offset凹版加网法hard dot process凹版画面的凹痕sunk凹版过版用钢辊master die凹版滚筒研磨机,抛光机buffing chine凹版滚筒rotogravure copper cylinder凹版腐蚀剂gravure etchant凹版镀铜gravure coppering凹版雕刻机,铜版雕刻匠chalcographer凹版电子雕刻机[商名] Helio-Klischograph凹版电子雕刻机,电子刻版机electronic engraving machine凹版打样机photogravure proofing machine凹版(接触)网屏gravure contact screen凹版(白线)网屏,十字线网屏crossline screen凹版intaglio凹凸印embossing 用凹凸两块印版,把印刷品压印出浮雕状图像的加工。

凹凸印刷油墨die stamping ink凹凸印刷机,封缄印刷机die stamping press凹凸印刷,钢印die stamping凹凸印刷,浮凸印刷,压凸embossing凹凸印刷,浮雕印刷emboss printing凹凸透明片leticular screen凹凸透镜meniscus凹凸体,粗体字,古籍antique凹凸拼贴bump mapping凹凸版,压凹凸版embossing plate凹陷的橡皮布[故障] engraved blanket凹印打样机gravure proof press凹印版面版deep engraving凹印die sunk暗晕[故障] dark halo暗影[故障],重影[故障] ghosting包本covering 在书芯上裹封皮。

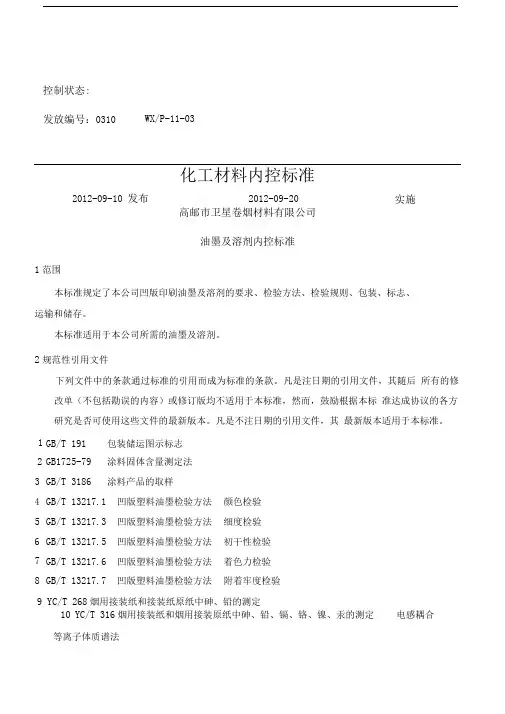

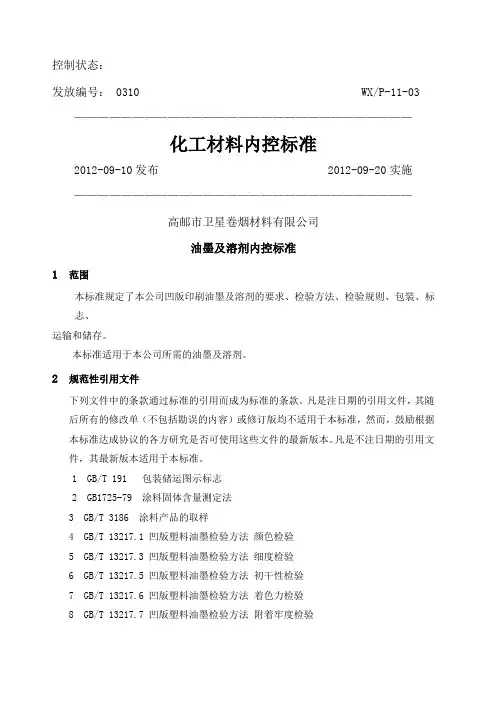

WX/P-11-03化工材料内控标准高邮市卫星卷烟材料有限公司油墨及溶剂内控标准1范围本标准规定了本公司凹版印刷油墨及溶剂的要求、检验方法、检验规则、包装、标志、 运输和储存。

本标准适用于本公司所需的油墨及溶剂。

2规范性引用文件下列文件中的条款通过标准的引用而成为标准的条款。

凡是注日期的引用文件,其随后 所有的修改单(不包括勘误的内容)或修订版均不适用于本标准,然而,鼓励根据本标 准达成协议的各方研究是否可使用这些文件的最新版本。

凡是不注日期的引用文件,其 最新版本适用于本标准。

10 YC/T 316烟用接装纸和烟用接装原纸中砷、铅、镉、铬、镍、汞的测定电感耦合等离子体质谱法控制状态:GB/T 191 包装储运图示标志GB1725-79 涂料固体含量测定法GB/T 3186涂料产品的取样GB/T 13217.1 凹版塑料油墨检验方法 颜色检验 GB/T 13217.3 凹版塑料油墨检验方法 细度检验 GB/T 13217.5 凹版塑料油墨检验方法 初干性检验 GB/T 13217.6 凹版塑料油墨检验方法 着色力检验GB/T 13217.7 凹版塑料油墨检验方法 附着牢度检验3 4 5 6 7 8 1 2 9 YC/T 268烟用接装纸和接装纸原纸中砷、铅的测定发放编号:03102012-09-10 发布 2012-09-20实施11YC/T 279烟用接装纸中砷、铬、镍的测定14YC/T207卷烟条与盒包装纸中挥发性有机物的测定顶空-气相色谱法15GB/T 14436工业产品保证文件总则16YQ15-2012中国烟草总公司企业标准烟用材料许可使用物质名单3要求3.1产品的技术指标应符合表1的规定表1 物理指标注:各油墨品种的固含量应符合合同规定。

3.2油墨使用的物质须符合国家、烟草行业许可使用名录要求。

油墨在生产过程中,严禁使用苯溶油墨及金属络染料;禁止添加邻苯二甲酸酯类增塑剂;所用乙醇溶剂必须符合GB10343 的要求。

凹版油墨标准控制状态:发放编号: 0310 WX/P-11-03—————————————————————————————化工材料内控标准2012-09-10发布 2012-09-20实施—————————————————————————————高邮市卫星卷烟材料有限公司油墨及溶剂内控标准1范围本标准规定了本公司凹版印刷油墨及溶剂的要求、检验方法、检验规则、包装、标志、运输和储存。

本标准适用于本公司所需的油墨及溶剂。

2规范性引用文件下列文件中的条款通过标准的引用而成为标准的条款。

凡是注日期的引用文件,其随后所有的修改单(不包括勘误的内容)或修订版均不适用于本标准,然而,鼓励根据本标准达成协议的各方研究是否可使用这些文件的最新版本。

凡是不注日期的引用文件,其最新版本适用于本标准。

1 GB/T 191 包装储运图示标志2 GB1725-79 涂料固体含量测定法3 GB/T 3186 涂料产品的取样4 GB/T 13217.1 凹版塑料油墨检验方法颜色检验5 GB/T 13217.3 凹版塑料油墨检验方法细度检验6 GB/T 13217.5 凹版塑料油墨检验方法初干性检验7 GB/T 13217.6 凹版塑料油墨检验方法着色力检验8 GB/T 13217.7 凹版塑料油墨检验方法附着牢度检验9 YC/T 268 烟用接装纸和接装纸原纸中砷、铅的测定10 YC/T 316烟用接装纸和烟用接装原纸中砷、铅、镉、铬、镍、汞的测定电感耦合等离子体质谱法11 YC/T 279 烟用接装纸中砷、铬、镍的测定12 Q/HY.CJ.166-2012烟用接装纸中邻苯二甲酸酯类化合物的测定气质联用法13 Q/HY.CJ.165-2012烟用接装纸中甲醛的测定超高效液相色谱法14 YC/T207 卷烟条与盒包装纸中挥发性有机物的测定顶空-气相色谱法15 GB/T 14436 工业产品保证文件总则16 YQ15-2012中国烟草总公司企业标准烟用材料许可使用物质名单3要求3.1产品的技术指标应符合表1的规定表1 物理指标指标颜色细度µm粘度s(25℃)固含量%着色力%初干性%附着牢度%纸张凹版油墨近似标样≤12≥25≥2095~10025~50≥93注:各油墨品种的固含量应符合合同规定。

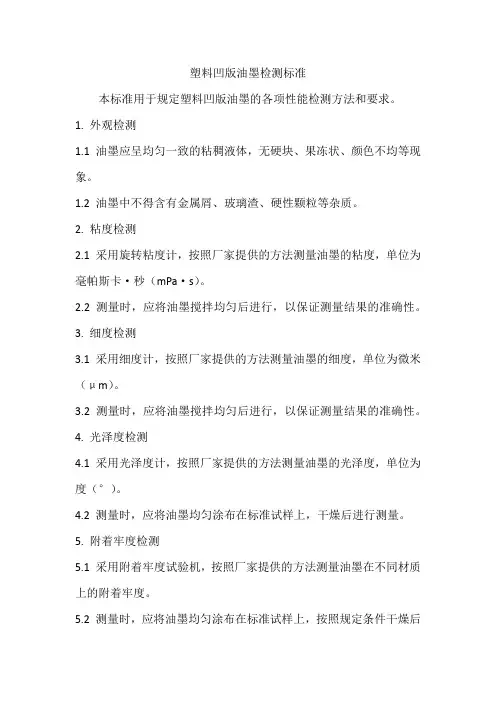

塑料凹版油墨检测标准本标准用于规定塑料凹版油墨的各项性能检测方法和要求。

1. 外观检测1.1 油墨应呈均匀一致的粘稠液体,无硬块、果冻状、颜色不均等现象。

1.2 油墨中不得含有金属屑、玻璃渣、硬性颗粒等杂质。

2. 粘度检测2.1 采用旋转粘度计,按照厂家提供的方法测量油墨的粘度,单位为毫帕斯卡·秒(mPa·s)。

2.2 测量时,应将油墨搅拌均匀后进行,以保证测量结果的准确性。

3. 细度检测3.1 采用细度计,按照厂家提供的方法测量油墨的细度,单位为微米(μm)。

3.2 测量时,应将油墨搅拌均匀后进行,以保证测量结果的准确性。

4. 光泽度检测4.1 采用光泽度计,按照厂家提供的方法测量油墨的光泽度,单位为度(°)。

4.2 测量时,应将油墨均匀涂布在标准试样上,干燥后进行测量。

5. 附着牢度检测5.1 采用附着牢度试验机,按照厂家提供的方法测量油墨在不同材质上的附着牢度。

5.2 测量时,应将油墨均匀涂布在标准试样上,按照规定条件干燥后进行测量。

6. 硬度检测6.1 采用硬度计,按照厂家提供的方法测量油墨的硬度,单位为肖氏硬度。

6.2 测量时,应将油墨均匀涂布在标准试样上,干燥后进行测量。

7. 耐冲击检测7.1 采用耐冲击试验机,按照厂家提供的方法测量油墨的耐冲击性能。

7.2 测量时,应将油墨均匀涂布在标准试样上,按照规定条件干燥后进行测量。

8. 耐摩擦检测8.1 采用摩擦试验机,按照厂家提供的方法测量油墨的耐摩擦性能。

8.2 测量时,应将油墨均匀涂布在标准试样上,干燥后进行测量。

控制状态:发放编号: 0310 WX/P-11-03 —————————————————————————————化工材料内控标准2012-09-10发布 2012-09-20实施—————————————————————————————高邮市卫星卷烟材料有限公司油墨及溶剂内控标准1范围本标准规定了本公司凹版印刷油墨及溶剂的要求、检验方法、检验规则、包装、标志、运输和储存。

本标准适用于本公司所需的油墨及溶剂。

2规范性引用文件下列文件中的条款通过标准的引用而成为标准的条款。

凡是注日期的引用文件,其随后所有的修改单(不包括勘误的内容)或修订版均不适用于本标准,然而,鼓励根据本标准达成协议的各方研究是否可使用这些文件的最新版本。

凡是不注日期的引用文件,其最新版本适用于本标准。

1 GB/T 191 包装储运图示标志2 GB1725-79 涂料固体含量测定法3 GB/T 3186 涂料产品的取样4 GB/T 13217.1 凹版塑料油墨检验方法颜色检验5 GB/T 13217.3 凹版塑料油墨检验方法细度检验6 GB/T 13217.5 凹版塑料油墨检验方法初干性检验7 GB/T 13217.6 凹版塑料油墨检验方法着色力检验8 GB/T 13217.7 凹版塑料油墨检验方法附着牢度检验9 YC/T 268 烟用接装纸和接装纸原纸中砷、铅的测定10 YC/T 316烟用接装纸和烟用接装原纸中砷、铅、镉、铬、镍、汞的测定电感耦合等离子体质谱法11 YC/T 279 烟用接装纸中砷、铬、镍的测定14 YC/T207 卷烟条与盒包装纸中挥发性有机物的测定顶空-气相色谱法15 GB/T 14436 工业产品保证文件总则16 YQ15-2012中国烟草总公司企业标准烟用材料许可使用物质名单3要求3.1产品的技术指标应符合表1的规定表1 物理指标3.2油墨使用的物质须符合国家、烟草行业许可使用名录要求。

油墨在生产过程中,严禁使用苯溶油墨及金属络染料;禁止添加邻苯二甲酸酯类增塑剂;所用乙醇溶剂必须符合GB10343的要求。

Chapter 2 Creation and Input in Digital Prepress (创作与输入数字印前)Digital Image Types (数码图像类型)File Formats (文件格式)Digital Image Input (数字图像输入)Digital Photography (数码摄影)Key Terms (关键点)Chapter 3 Assembly in Digital Prepress (数码印前工序)Page Layout (版式)Digital Halftones (数字半色调)Color Management (颜色管理,色彩处理)Chapter 4 Output in Digital Prepress (数字化印前输出)PostScript (页描述语言)Portable Document Format(文同文件)I mposition and Trapping (要求和方法)Output to Film (输出影像)Digital Proofing (数码样)Computer to Plate (ctp直接制版)Chapter 5 Offset(平版印刷)Presses and Printing (胶印机印刷)IntroductionOffset Presses OperationStarting Up and Proofing (启动与打样)Printing Process Color on Sheet-Fed Offset Presses(单张纸胶印机的印刷过程中的色彩)Quality Control Devices (质量控制计划/ 质量控制手段)Common Press Concerns (普通印刷问题)A Troubleshooting Checklist(故障排除单)Chapter 6 Gravure Printing(凹版印刷)The Gravure Industry (凹印行业)Basic Gravure Concepts (基本凹印概念)Cylinder(圆柱体)Construction(建筑,解释)and Preparation(滚筒的结构与制备)Gravure Presswork(凹版印刷)Chapter 7 Flexographic, Ink-Jet, and Digital Printing(柔性版、喷墨、数码印刷)Chapter 8 Paper and Ink (纸张油墨)Introduction to Paper (纸张简介)Classifying Paper (纸张分类)Determining Paper Needs (确定文件需要)Sample Paper Estimating Problem(样张测试问题)Introduction to Ink (油墨简介)Properties of Ink(墨性)Ingredients in Ink (油墨的成分)Calculating Ink Usage(计算机油墨的使用)Ink Specifications and Standards(油墨的特性及标准)Lithographic Inks(平版油墨)Screen Printing Inks (网版印刷油墨)Letterpress Inks(凸版油墨)Flexographic Inks(柔性油墨)Gravure Inks(奥班油墨)Chapter 9 Finishing Operations (精加工)Cutting (裁切)Folding (折页)Assembling (配页)Binding (装订)In-Line Finishing (在线整理)Chapter 10 Quality Management (质量管理)Defining Quality (决定性品质)Motivation for a Customer- Defined Quality Orientation(为客户定义的质量定位)Part 1一、Regardless of the printing process used, however, there is a sequence of production steps that all printing follows. This sequence consists of the following steps:●Image design●Image generation●Image conversion●Image carrier preparation●Image transfer●Finishing二、In the image design variables(可变化的)such as type style, visual position, type size, balance, and harmony(风格,视觉定位,类型,大小,平衡,和谐)are all considered. After the customer approves the design, the image must be generated and made into a final form.三、Commercial PrintingIf a commercial printer does not have all of the equipment or skilled staff to perform a whole job, parts of the job, such as die cutting(模切), foil stamping(烫箔), or binding(装订), he may be subcontracted to (发包给/发送给)trade shops. 四;专有名词image design(形象设计)in-plant printing(企业内部印刷)image conversion(图像转换)image conversion(凸版印刷)image carrier(图像载体)lithography(平板印刷)gravure(凹版印刷)finishing(精加工)image transfer(图像转移)Chapter 2Creation and Input in Digital Prepress(印前)一、专有名词graphical user interface(图形用户界面)raster image(位图)single-pass digital camera(单反相机)resolution independent(与分辨率无关的)pixel(像素)interpolation(插入)resolution(决议)lossless(无损)vector images(矢量图)drum scanner(滚筒扫描仪)dynamic range(灰黑比可调范围)bit depth(色彩深度)gray scale(灰调)Chapter 3 Assembly in Digital Prepress (数码印前工序)一、专有名词page layout(版面涉及)font usage(字体使用)image editing(图像编辑)color correction(颜色校正)be addressed to(寄往)workflow(工作流程)an integral part of(必不可少的一部分)Chapter 4Output in Digital Prepress一、专有名词PostScript(附录)flatbed platesetter(平版制版机)late binding(后期装订)film image recorder(图片记录器)Portable Document(便携式文档)digital halftone proofer(数字半色调检查器)PDF Format (pdf格式)photopolymer plate(感光聚合物印版)PDF publishing(pdf出版)。

凹版印刷术语英语翻译凹版图像intaglio image凹版碳素纸gravure carbon tissue凹版速印机power press凹版手摇印刷机plate printing press凹版墨孔ink-holding cup凹版轮转印刷机gravure rotary press凹版局部修版法Elbo process凹版金属印版intaglio-mital printing plate凹版胶印机gravure offset printing press凹版胶印intaglio offset凹版加网法hard dot process凹版画面的凹痕sunk凹版过版用钢辊master die凹版滚筒研磨机,抛光机buffing chine凹版滚筒rotogravure copper cylinder凹版腐蚀剂gravure etchant凹版镀铜gravure coppering凹版雕刻机,铜版雕刻匠chalcographer凹版电子雕刻机[商名] Helio-Klischograph凹版电子雕刻机,电子刻版机electronic engraving machine凹版打样机photogravure proofing machine凹版(接触)网屏gravure contact screen凹版(白线)网屏,十字线网屏crossline screen凹版intaglio凹凸印embossing 用凹凸两块印版,把印刷品压印出浮雕状图像的加工。

凹凸印刷油墨die stamping ink凹凸印刷机,封缄印刷机die stamping press凹凸印刷,钢印die stamping凹凸印刷,浮凸印刷,压凸embossing凹凸印刷,浮雕印刷emboss printing凹凸透明片leticular screen凹凸透镜meniscus凹凸体,粗体字,古籍antique凹凸拼贴bump mapping凹凸版,压凹凸版embossing plate凹陷的橡皮布[故障] engraved blanket凹印打样机gravure proof press凹印版面版deep engraving凹印die sunk暗晕[故障] dark halo暗影[故障],重影[故障] ghosting包本covering 在书芯上裹封皮。

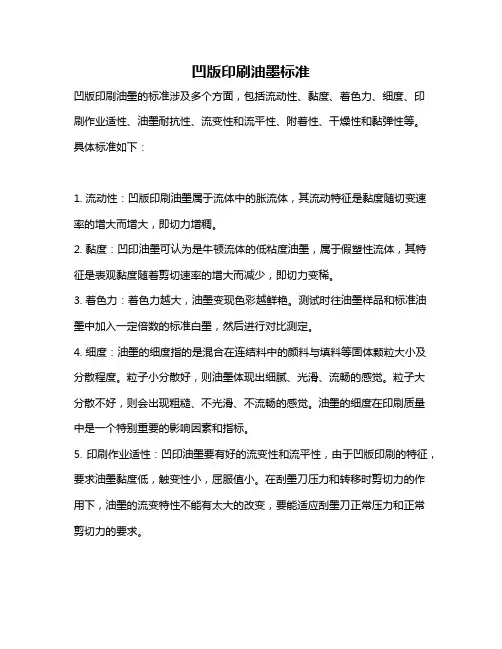

凹版印刷油墨标准凹版印刷油墨的标准涉及多个方面,包括流动性、黏度、着色力、细度、印刷作业适性、油墨耐抗性、流变性和流平性、附着性、干燥性和黏弹性等。

具体标准如下:1. 流动性:凹版印刷油墨属于流体中的胀流体,其流动特征是黏度随切变速率的增大而增大,即切力增稠。

2. 黏度:凹印油墨可认为是牛顿流体的低粘度油墨,属于假塑性流体,其特征是表观黏度随着剪切速率的增大而减少,即切力变稀。

3. 着色力:着色力越大,油墨变现色彩越鲜艳。

测试时往油墨样品和标准油墨中加入一定倍数的标准白墨,然后进行对比测定。

4. 细度:油墨的细度指的是混合在连结料中的颜料与填料等固体颗粒大小及分散程度。

粒子小分散好,则油墨体现出细腻、光滑、流畅的感觉。

粒子大分散不好,则会出现粗糙、不光滑、不流畅的感觉。

油墨的细度在印刷质量中是一个特别重要的影响因素和指标。

5. 印刷作业适性:凹印油墨要有好的流变性和流平性,由于凹版印刷的特征,要求油墨黏度低,触变性小,屈服值小。

在刮墨刀压力和转移时剪切力的作用下,油墨的流变特性不能有太大的改变,要能适应刮墨刀正常压力和正常剪切力的要求。

6. 油墨耐抗性:指的是固化后的墨膜在受外界因素侵袭时,保持膜的色彩、图文清晰及各种品种不变的性能。

常见的有光泽度、耐光性、耐摩擦、耐水性、耐溶剂型、耐酸碱性、耐油脂等。

7. 流变性和流平性:凹印油墨要有好的流变性和流平性,由于凹版印刷的特征,要求油墨黏度低,触变性小,屈服值小。

在刮墨刀压力和转移时剪切力的作用下,油墨的流变特性不能有太大的改变,要能适应刮墨刀正常压力和正常剪切力的要求。

8. 附着性:油墨要有适合承印材料要求的附着性,对薄膜而言,油墨要先润湿后吸附,即油墨的表面张力小于材料表面张力或油墨的内聚力小于油墨与材料之间的附着力,这样两者之间的接触角小于90°,油墨的润湿性好;其次油墨分子与薄膜分子之间的极性牵引力要尽可能大,油墨的附着性好。

9. 干燥性:一方面受其溶剂种类、性质的影响,另一方面受机器干燥装置的影响。

书山有路勤为径;学海无涯苦作舟常用油墨术语集锦三(中英对照)网孔版塑料油墨screen printing ink for plastic materials 适用于网孔版印刷塑料材料的油墨。

网孔版印刷线路板耐腐蚀油墨etch-resist screen printing ink for printed circuit board 适用于各种网孔版印刷机印制线路板,能耐三氯化铁等的腐蚀,并易于用稀碱液清洗干净的油墨。

网孔版紫外线固化阻焊油墨ultru-violet curing solder proof screen printing ink 适用于各种网孔版印刷机印制线路板,能耐波峰式焊接或浸焊,并在清洗助焊剂时不起泡,不变色并不沾焊锡的紫外线固化油墨。

网孔版陶瓷滤波器耐腐蚀油墨ceramic electric filter etch-resistscreen printing ink 适用于网孔版印刷陶瓷滤波器,能耐浓硝酸腐蚀并易于用有机溶剂清除的油墨。

网孔版调频油墨screen printing ink for frequency modulation 适用于网孔版印刷陶瓷滤波器,能起调频滤波作用的油墨。

凹版油墨雕刻凹版印刷intaglio ink 适用于雕刻凹版印刷纸币和有价证券等的油墨。

照相凹版油墨photogravure ink 适用于照相凹版印刷书刊插页、画报、邮票等的油墨。

照相凹版苯型油墨aromatic based photogravure ink 以芳香为主要溶剂的照相凹版油墨。

照相凹版汽油型油墨aliphatic based photogravure ink 以链为主要专注下一代成长,为了孩子。

网孔版紫外线固化阻焊油墨ultru-violet curing solder proof screen printing ink 适用于各种网孔版印刷机印制线路板,能耐波峰式焊接或浸焊,并在清洗助焊剂时不起泡,不变色并不沾焊锡的紫外线固化油墨。

网孔版陶瓷滤波器耐腐蚀油墨ceramic electric filter etch-resist screen printing ink 适用于网孔版印刷陶瓷滤波器,能耐浓硝酸腐蚀并易于用有机溶剂清除的油墨。

网孔版调频油墨screen printing ink for frequency modulation 适用于网孔版印刷陶瓷滤波器,能起调频滤波作用的油墨。

雕刻凹版印刷intaglio ink 适用于雕刻凹版印刷纸币和有价证券等的油墨。

照相凹版油墨photogravure ink 适用于照相凹版印刷书刊插页、画报、邮票等的油墨。

照相凹版苯型油墨aromatic based photogravure ink 以芳香为主要溶剂的照相凹版油墨。

照相凹版汽油型油墨aliphatic based photogravure ink 以链为主要溶剂的照相凹版油墨。

照相凹版水性油墨water based photogravure ink 可用水稀释的照相凹版油墨。

凹版塑料薄膜油墨gravure ink for plastic film 适用于凹版轮转印刷机在经预处理的聚烯薄膜等表面印刷的油墨。

凹版热复合塑料薄膜油墨gravure ink for hot-laminating plastic film 适用于凹版印刷机印刷经预处理的聚烯或聚酯等薄膜并能满足热复合工艺的油墨。

凹版冷复合塑料薄膜油墨gravure ink for cold-laminating plastic film 适用于凹版印刷机印刷经预处理的聚烯或聚酯等薄膜并能满足冷复合工艺的油墨。

凹版聚氯乙烯薄膜油墨gravure ink for polyvinyl chloride film 适用于凹版印刷机印刷聚氯乙烯薄膜的油墨。

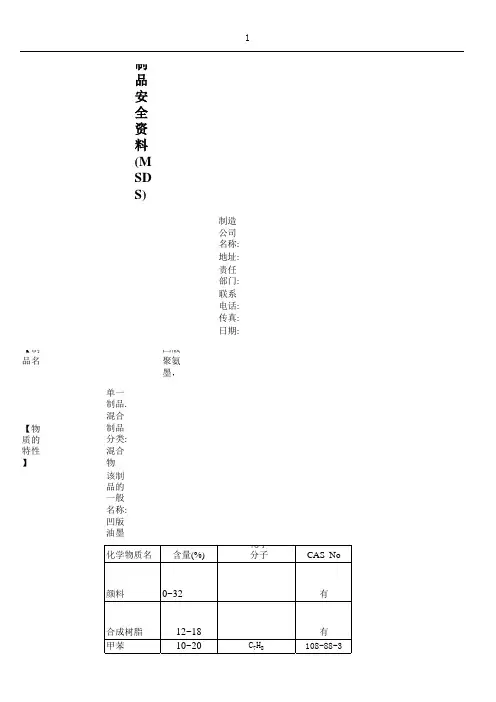

XXXXXX油墨有限公司化学品安全技术说明书修订日期:2013-01-22 SDS编号:产品名称:凹版塑料薄膜油墨版本:第一部分化学品及企业标识化学品中文名:凹版塑料薄膜油墨化学品英文名:企业名称:XXXXXXX油墨有限公司企业地址:XXXXXXXXXXXX邮编:XXXXXXXXXX 传真:XXXXXXXXXX联系电话:XXXXXXXXXXX电子邮件地址:XXXXXXXXXXXXX企业应急电话:XXXXXXXXXXXX国家事故应急咨询电话:XXXXXXXXXXXXXX产品推荐及限制用途:塑料薄膜印刷第二部分危险性概述紧急情况概述:易燃液体。

有毒,对中枢神经系统有麻醉作用。

GHS危险性类别:根据化学品分类、警示标签和警示性说明规范系列标准(参阅第十五部分),该产品属于易燃液体,类别3;急性毒性,类别3(吸入、食入)。

标签要素:象形图:警示词:危险危险信息:易燃液体。

防范说明:预防措施:远离热源/火花/明火/热表面。

—禁止吸烟。

采取防止静电措施。

只能使用不产生火花的工具。

容器和接收设备接地/连接,使用防爆电器/通风/照明/设备。

保持容器密闭。

戴防护手套/穿防护服/防护眼镜/防护面罩。

操作后彻底清洗。

作业场所不得进食、饮水或吸烟。

仅在室外或通风良好处操作。

事故响应:火灾时,使用抗溶性泡沫、干粉、二氧化碳、雾状水等灭火。

如果接触:立即呼叫中毒控制中心或就医。

如皮肤(或头发)接触:立即脱掉所有被污染的衣服。

用水冲洗皮肤/淋浴。

食入:漱口。

皮肤接触:用大量肥皂水和水清洗。

立即脱去所有被污染的衣服。

被污染的衣服须经洗净后方可重新使用。

如吸入:将患者转移到空气新鲜处,休息,保持利于呼吸的体位。

安全储存:保持容器密闭。

储存于阴凉、通风的库房。

上锁保管。

废弃处置:建议用焚烧法处置。

危险性说明:物理化学危险:易燃液体。

与氧化剂发生剧烈反应,有引起火灾、爆炸的危险。

健康危害:对中枢神经系统有麻醉作用;急性中毒:短时大量吸入出现上呼吸道刺激,症状有咳嗽、头昏、头痛、恶心、虚弱、视觉障碍。

油墨术语热固着油墨heat-set printing ink红外线固着油墨infrared setting printing ink热熔油墨hot melt printing ink湿固着油墨moisture-set printing ink蒸汽固着油墨steam-set printing ink蜡固着油墨wax setting printing ink热固化油墨thermo curing printing ink紫外线固化(UV)油墨ultra-violet curing printing ink电子束固化油墨electron-beam curing ink热转移油墨heat transfer printing ink贴花油墨decal process printing ink陶瓷贴花油墨ceramic decal printing ink导电油墨electrically conduc- tive printing ink磁性油墨magnetic printing ink光学记号判读油墨optical mark recogni- tion ink (OMR ink)光学字符判读油墨optical character recognition ink (OCR ink)安全油墨safety ink隐显油墨sympathetic ink防伪油墨anti-forgery ink发泡油墨foaming ink盲文印刷油墨printing ink for braille隆凸油墨embossing ink防霉油墨fungicidal ink芳香油墨perfumed ink耐油脂油墨grease proof printing ink耐洗烫油墨indelible printing ink可洗去油墨washable printing ink金属油墨metallic printing ink金墨gold ink (bronze ink)银墨silver ink珠光墨pearl lusting printing ink荧光油墨fluorescent ink平光油墨(无光油墨) mat ink (dull ink)发光油墨luminous ink双色调油墨double tone ink二片罐油墨printing ink for two piece can三色版油墨three colours process ink玻璃油墨glass printing ink玻璃纸油墨cellophane printing ink金属箔油墨printing ink for metal-foil软管油墨collapsible tube printing ink软管滚涂油墨collapsible tube roller coating印铁滚涂油墨tin-plate roller coating复写纸油墨carbon paper ink圆珠笔油墨ball pen ink盖销油墨ink for stamping号码机油墨ink for numbering machine涂盖墨ink for masking无水胶印油墨waterless offset ink凸版转印油墨letterset printing ink静电复印油墨electrostatic printing ink干法静电复印色调剂xerographic toner湿法静电复印油墨液electrofax liquid toner喷射印刷油墨jet printing ink石印制油墨lithographic drawing ink落石墨copyable ink(电子元件)标记油墨electronic coponent marking ink导线油墨wire marking ink网孔版油墨screen printing ink誊写油墨stencil ink水型誊写油墨water based stencil ink网孔版金属油墨screen printing ink for metal网孔版塑料油墨screen printing ink for plastic materials网孔版印刷线路板耐腐蚀油墨etch-resist screen printing ink for printed circuit board网孔版紫外线固化阻焊油墨ultru-violet curing solder proof screen printing ink网孔版陶瓷滤波器耐腐蚀油墨ceramic electric filter etch-resist screen printing ink网孔版调频油墨screen printing ink for frequency modulation雕刻凹版印刷intaglio ink照相凹版油墨photogravure ink照相凹版苯型油墨aromatic based photogravure ink照相凹版汽油型油墨aliphatic based photogravure ink照相凹版水性油墨water based photogravure ink凹版塑料薄膜油墨gravure ink for plastic film凹版热复合塑料薄膜油墨gravure ink for hot-laminating plastic film凹版冷复合塑料薄膜油墨gravure ink for cold-laminating plastic film凹版聚氯乙烯薄膜油墨gravure ink for polyvinyl chloride film凹版醇型油墨alcohol based gravure ink石印油墨lithographic printing ink胶版油墨offset printing ink胶印亮光油墨high gloss offset ink胶版树脂油墨resinous offset ink胶版卷筒纸油墨web-fed-offset ink胶版单张纸油墨sheet-fed offset ink胶版四色油墨four colors process offset ink胶版快固着油墨quick-set offset ink胶版印铁油墨offset tin-printing ink胶版印铁耐蒸油墨sterilization resistance offset tin-printing ink 珂罗版油墨collotype printing ink凸版书刊油墨letterpress ink for publication凸版彩色油墨letterpress color ink凸版轮转书刊油墨rotary letterpress ink for publication凸版轮转印报油墨rotary letterpress news ink凸版彩色报刊油墨rotary letterpress color news ink铜版油墨copper plate printing ink凸版塑料薄膜油墨letterpress printing ink for plastic films柔性版油墨flexographic printing ink调墨油varnish树脂调墨油resinous varnish防潮油water proof varnish照光油over-printing varnish调金油gold varnish冲淡剂reducer维利油white lake白油laketine稀释剂diluent去粘剂viscosity reducer增稠剂densifier (bodying-agent)防结皮剂anti-skinning agent防沾脏剂anti-set-off agent干燥剂dryer白燥油paste dryer钴燥油cobalt dryer抗干燥剂drying retarder色、颜色colour彩色colours消色(无彩色)achromatic colours孟塞尔颜色系统Munsell colour system色调(色相)hue明度lightness饱和度saturationCIE颜色系统CIE colour system三刺激值tristimulus values彩度chroma色度chromaticity色度坐标chromaticity coordinates色差colour difference色差仪colorimeter反射密度仪reflection densitometer色偏hue error灰度grayness效率efficiency色强度colour strength原色primary colour三原色three primary colours二次色secondary colour复色compound colour补色complementary colour面色toptone底色undertone墨色masstone着色力tinctorial strength标样master standard墨性the properties of ink身骨body流平levelling丝头stringing粘性tack粘性仪inkometer粘性增值increasing value of tack飞墨misting斜率slope平行板粘度仪(铺展仪) parallel plate viscosimeter 截距intercept屈服值yield value落棒式粘度仪fall rod viscosimeter触变性thixotropy锥板旋转式粘度仪cone and plate viscosimeter 粘弹性viscoelasticity粘度viscosity牛顿流体Newtonian fluid塑性流体plastic fluid假塑性流体pseudoplastic fluid膨胀性流体(胀流型流体) dilatant fluid流动性fluidity流动度测定仪spread-o-metter固着setting印刷适性仪printability tester干燥drying流平性levelling property透明性transparence光泽gloss光泽仪glossmeter细度fineness刮板细度仪grindometer初干性initial dryness附着牢度adhesion粘胶牢度tape adhesion热粘连blocking under warming冷冻牢度toughness after freeze耐光light fastness耐蜡wax resistance耐热heat resistance耐摩擦rub resistance耐蒸煮steam resistance胶化livering斑点mottle粉化chalking堆墨piling蹭脏set-off晶化crystallization脱墨stripping不下墨ink retreating from fountain roller 浮脏tinting起油腻greasing起脏scumming糊版pasting plate透印strike-through罩光渗化bleeding when overprinting粘页blocking针孔pinholing细网点消失image detail disappearing充填不良poor filling。

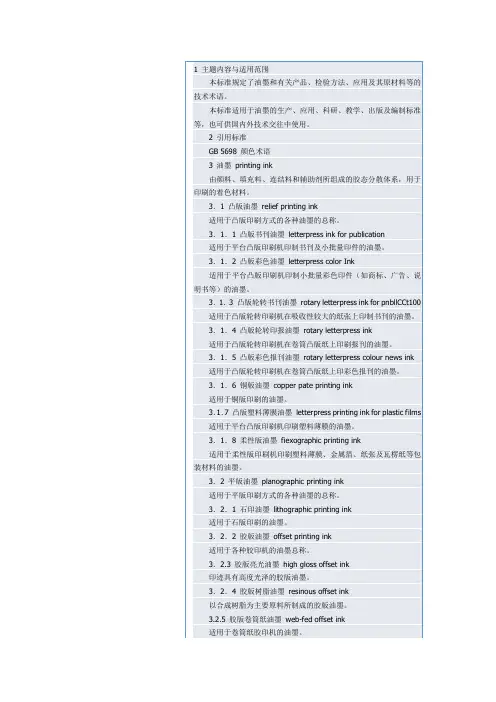

凹版复合塑料薄膜油墨1. 主题内容与适用范围本标准规定了氯化聚丙烯型的凹版复合塑料薄膜油墨的产品分类、技术要求、试验方法、检验规则及标志、包装、运输、贮存。

本标准适用于在凹版轮转印刷机上使用的凹版复合塑料薄膜油墨,该油墨用于经处理的双向拉伸聚丙烯的里面印刷。

2. 引用标准GB/T 13217.1 凹版塑料油墨检验方法 颜色检验GB/T 13217.3 凹版塑料油墨检验方法 细度检验GB/T 13217.4 凹版塑料油墨检验方法 粘性检验GB/T 13217.5 凹版塑料油墨检验方法 初干性检验GB/T 13217.6 凹版塑料油墨检验方法 着色力检验GB/T 13217.7 凹版塑料油墨检验方法 附着牢度检验ZAB 17005 印刷油墨产品分类、命名和型号3. 产品分类按产品颜色分为白、黄、蓝、红、黑五种。

4. 技术要求4.1 产品各项技术指标必须符合表1规定。

表1 型号产品名称 质 量 指 标颜色 着色力% 细度µm 粘度SA54 101 凹版复合塑料薄膜白墨 近似标样 95-110 ≤25 25-70A54 223 凹版复合塑料薄膜中黄墨A54 442 凹版复合塑料薄膜天蓝墨A54 664 凹版复合塑料薄膜深红墨A54 801 凹版复合塑料薄膜黑墨 4.2 产品各项性能要求必须符合表2规定。

表2` 型号 产品名称 性 能 要 求初干性mm附着牢度 % 表面张力 N/cm 溶剂残留量 mg/m2A54 101 凹版复合塑料薄膜白墨20-50 ≥85 ≥38×10(-5次方) ≤30 A54 223 凹版复合塑料薄膜中黄墨A54 442 凹版复合塑料薄膜天蓝墨A54 664 凹版复合塑料薄膜深红墨A54 801 凹版复合塑料薄膜黑墨 5. 试验方法5.1 颜色按GB/T 13217.1进行检验,不同之处如下。

5.1.1 原检验方法中3.1低密度聚乙烯薄膜,改用双向拉伸聚丙烯薄膜。

Control Status:Issued ID:0310 WX/P-11-03 —————————————————————————————The internal control standards of chemicalmaterialPublication Data:2012-09-10 Implement Data:2012-09-20 Gaoyou satellite Cigarette Materials Co.The internal control standards of solvent and inks1ScopeThis standard provides the requirements, test methods, inspection rules, packaging, labeling, transportation and storage of gravure inks and solvent of our company .This standard applies to inks and solvents required by our Company.2Criteria for quotations and referencesThe provisions in following documents become the provisions of these specifications though quotation. As for all the quoted documents given clear indication of date, all revised papers attached to them (excluding the corrected content) or recensions do not apply to these specifications. However, all parties that reached an agreement according to these specifications are encouraged to study whether to use the up-to-date editions of these documents. As for the quoted documents not given clear indication of date, their up-to -date editions apply to these specifications.1 GB/T 191 Packaging Pictorial logo2 GB1725-79 Determination method of coating solids3 GB/T 3186 The s ampling of paint products4 GB/T 13217.1 Examination method of gravure plastic ink: Color examination5 GB/T 13217.3 Examination method of gravure plastic ink: Fineness examination6 GB/T 13217.5 Examination method of gravure plastic ink: The primary dryingexamination7 GB/T 13217.6 Examination method of gravure plastic ink: Tinting strengthexamination8 GB/T 13217.7 Examination method of gravure plastic ink: Adhesion fastness test9 YC/T 268 Determination of arsenic, lead of tipping paper and tipping base paper of cigarette.10 YC/T 316 Determination of Arsenic, lead, cadmium, chromium, nickel, mercury of tipping paper and tipping base paper of cigarette: inductively coupled plasma mass spectrometry11 YC/T 279 Determination of Arsenic, chromium, nickel of tipping paper of cigarette.12 Q/HY.CJ.166-2012 Determination of Phthalate esters of tipping paper of cigarette:GC-MS13 Q/HY.CJ.165-2012 Determination of methanal of tipping paper of cigarette: UltraPerformance Liquid Chromatography14 YC/T207 Determination of volatile organic compounds of the cigarette and wrappingpaper of boxes: Headspace - Gas Chromatography15 GB/T 14436 General Provisions of industrial products guarantee documents16 YQ15-2012 China National Tobacco Corporation corporate standardsThe list of substances which permission to use in the material for cigarette3RequirementProduct technical indicators shall conform to the Table 1Table 1 physical indexIndex Color FinenessµmViscositys(25℃)solidcontent%TintingStrength%Initialdryness%Adhesionfastness%The paper gravure inks Approximatestandardsamples≤12≥25≥2095~100 25~50 ≥93Note: The solids content of each ink varieties should meet the requirements of the contract. 3.2 Substance used in ink must comply the requirements of countries, tobacco industry licensed use list. in the production process of ink, prohibited to use of benzene soluble inks and metal complex dyes; prohibit adding phthalate plasticizers; ethanol solvent used must comply with the requirements of GB10343.3.3 Health indicators of ink using scraping sample test, the health indicators of product shall comply with Table 2,3,4.Table 2 Heavy metalItemArsenic(㎎/㎏)Lead(㎎/㎏)Mercury(㎎/㎏)Cadmium(㎎/㎏)Chromium(㎎/㎏)Nickel(㎎/㎏)The papergravure inks≤0.6≤3.0≤0.6≤0.6≤10.0≤6.0Note: For special and less dosage ink, heavy metals in accordance with the requirements of the special provisions, such as purple, red ink arsenic content is below 3ppm. Chromium content is below 30ppm.Table 3 VOCs表4邻苯二甲酸酯类ItemUnitIndexdimethyl phthalate ppm not detectablediethyl phthalate ppmDiisobutyl phthalate ppm not detectable dibutyl phthalate ppmnot detectablePhthalate (2 - methoxy) ethyl ester ppm Phthalate (4 - methyl - 2 - amyl) ethyl esterppm Phthalate (2 -) ethoxy ethyl esterppm diamyl phthalateppmName of indexUnitIndexV olatileOrganic Compoundsbenzene mg/m 2 Not detectablemethylbenzene mg/m 2 ≤0.12 ethylbenzene mg/m 2 ≤0.12 xylene mg/m 2 ≤0.12 methyl alcohol mg/m 2 ≤0.8normal propyl alcohol mg/m 2 ≤2.5isopropyl alcohol mg/m 2 n-butyl alcohol mg/m 2 propylene glycol monoethyl ether mg/m 2 formaldehyde g/kg ≤0.010 propylene glycol monomethyl ether mg/m 2 ≤1.8 n-butyl acetate mg/m 2 ≤0.5 ethyl acetate mg/m 2 Total ≤2.5n-propyl acetate mg/m 2 acetic acid isopropylester mg/m 2 acetone mg/m 2 Total ≤2.0butanonemg/m 2 4-methyl-2-pentanonemg/m 2cyclohexanone mg/m 2Dihexylphthalate ppmButyl benzyl phthalate ppmPhthalate (2 - butoxy) ethyl ester ppmDicyclohexyl phthalate ppmPhthalate (2 -) ethyl ester ppmDiphenyl phthalate ppmDi-n-octyl ortho-phthalate ppmDiisonoyl adipate ppmDiisononyl phthalate ppmNote:other individual event ≤20ppm,total ≤50ppm,in which special and less dosage ink, the requirements of phthalate esters in accordance with the special provisions, such as: purple, black ink dimethyl phthalate, di-iso-butyl phthalate, phthalic carboxylic acid ester content should be below 10ppm.4SamplingSampling according to GB / T 3186 provisions of paint products.5Testing standard5.1ColorInspection according to GB / T 13217.1.5.2FitnessInspection according to GB / T 13217.3.5.3ViscosityInspection according to GB / T 13217.4-2008.5.4Coating Solid contentInspection according to GB1725-79 Coating solid content measurement。