WPS焊接工艺规程

- 格式:pdf

- 大小:1.07 MB

- 文档页数:42

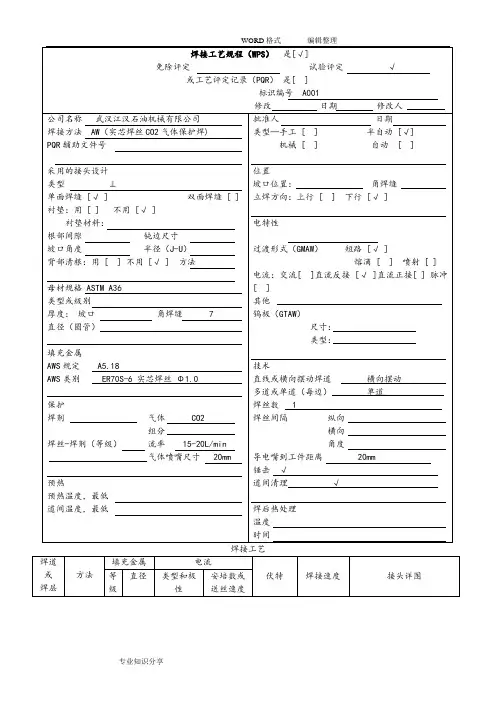

焊接工艺规程(WPS)

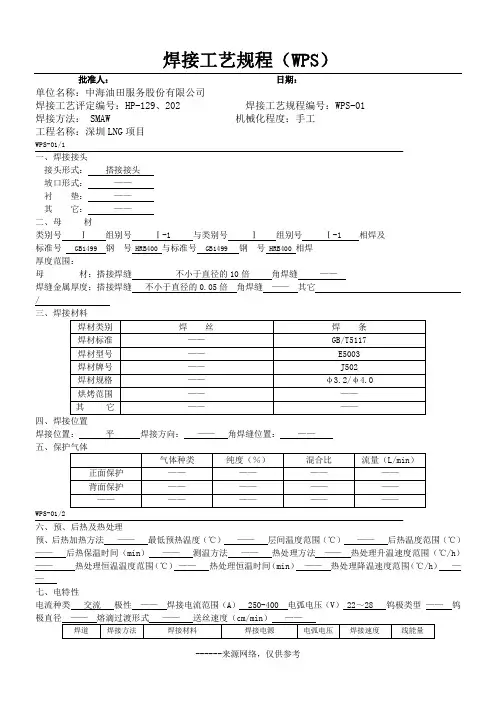

批准人:日期:

单位名称:中海油田服务股份有限公司

焊接工艺评定编号:HP-129、202 焊接工艺规程编号:WPS-01

焊接方法: SMAW 机械化程度:手工

工程名称:深圳LNG项目

WPS-01/1

一、焊接接头

接头形式:搭接接头

坡口形式:——

WPS-01/2

六、预、后热及热处理

预、后热加热方法——最低预热温度(℃)——层间温度范围(℃)——后热温度范围(℃)——后热保温时间(min)——测温方法——热处理方法——热处理升温速度范围(℃/h)——热处理恒温温度范围(℃)——热处理恒温时间(min)——热处理降温速度范围(℃/h)——

七、电特性

电流种类交流极性——焊接电流范围(A) 250-400 电弧电压(V) 22~28 钨极类型——钨

------来源网络,仅供参考

八、技术、质量要求:

1.钢筋笼焊接前,必须先进行钢筋材质及焊接质量送检,合格后,方可进行钢筋笼加工制作。

2.钢筋笼制作是在现场特制平台上进行的,钢筋笼平台是用120mm工字钢焊成的平面框架结构。

其纵横垂直,

周正水平,整体稳固。

3.50%。

或者

5.

6.

7.

8.

9.

10.

11.

接。

WPS-2/3

九、焊接接头简图

编制:日期审核:日期

WPS-3/3

------来源网络,仅供参考。

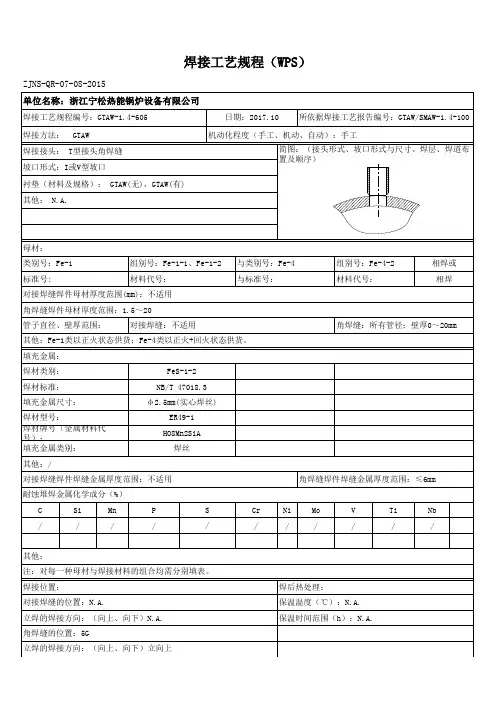

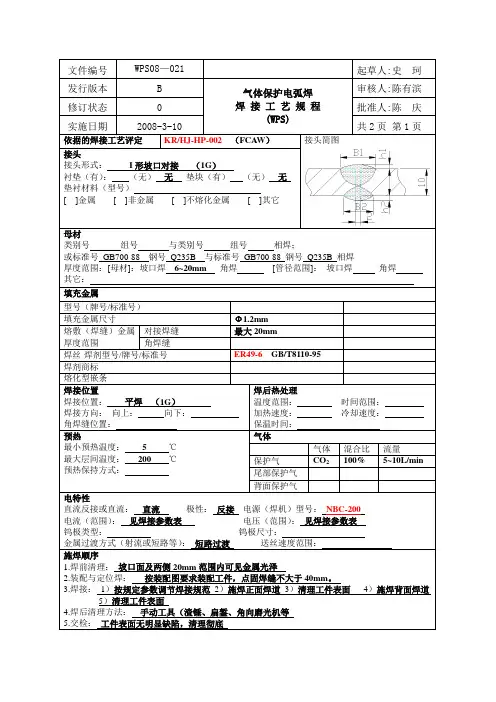

文件编号WPS08—021 起草人:史珂发行版本 B 气体保护电弧焊焊接工艺规程(WPS) 审核人:陈有滨修订状态0 批准人:陈庆实施日期2008-3-10 共2页第1页依据的焊接工艺评定KR/HJ-HP-002(FCA W)接头简图接头接头形式:I形坡口对接(1G)衬垫(有):(无)无垫块(有)(无)无垫衬材料(型号)[ ]金属[ ]非金属[ ]不熔化金属[ ]其它母材类别号组号与类别号组号相焊;或标准号GB700-88 钢号Q235B 与标准号GB700-88 钢号Q235B 相焊厚度范围:[母材]:坡口焊6~20mm 角焊[管径范围]:坡口焊角焊其它:填充金属型号(牌号/标准号)填充金属尺寸Φ1.2mm熔敷(焊缝)金属厚度范围对接焊缝最大20mm 角焊缝焊丝-焊剂型号/牌号/标准号ER49-6GB/T8110-95 焊剂商标熔化型嵌条焊接位置焊接位置:平焊(1G)焊接方向:向上:向下:角焊缝位置:焊后热处理温度范围:时间范围:加热速度:冷却速度:保温时间:预热最小预热温度:5℃最大层间温度:200 ℃预热保持方式:气体气体混合比流量保护气CO2100% 5~10L/min 尾部保护气背面保护气电特性直流反接或直流:直流极性:反接电源(焊机)型号:NBC-200电流(范围):见焊接参数表电压(范围):见焊接参数表钨极类型:钨极尺寸:金属过渡方式(射流或短路等):短路过渡送丝速度范围:施焊顺序1.焊前清理:坡口面及两侧20mm范围内可见金属光泽2.装配与定位焊:按装配图要求装配工件,点固焊缝不大于40mm。

3.焊接:1)按规定参数调节焊接规范2)施焊正面焊道3)清理工件表面4)施焊背面焊道5)清理工件表面4.焊后清理方法:手动工具(渣锤、扁錾、角向磨光机等5.交检:工件表面无明显缺陷,清理彻底文件编号WPS08—022 山东科瑞石油装备有限公司起草人:史珂发行版本 B 气体保护电弧焊焊接工艺规程(WPS) 审核人:陈有滨修订状态0 批准人:陈庆实施日期2008-3-10 共2页第1页依据的焊接工艺评定KR/HJ-HP-002(FCA W)接头简图接头接头形式:V形坡口对接衬垫(有):(无)无垫块(有)(无)无垫衬材料(型号)[]金属[ ]非金属[ ]不熔化金属[ ]其它母材类别号组号与类别号组号相焊;或标准号钢号与标准号钢号相焊厚度范围[母材]:坡口焊不限角焊[管径范围]:坡口焊角焊其它:填充金属型号(牌号/标准号)填充金属尺寸Φ1.2mm熔敷(焊缝)金属厚度范围对接焊缝不限角焊缝焊丝-焊剂型号/牌号/标准号ER49-6 GB8110-95 焊剂商标熔化型嵌条其它焊接位置焊接位置:平焊(1G)焊接方向:向上:向下:角焊缝位置:焊后热处理温度范围:时间范围:加热速度:冷却速度:保温时间:预热最小预热温度: 5 ℃最大层间温度:200 ℃预热保持方式:气体气体混合比流量保护气CO2100% 5~10L/min 尾部保护气背面保护气电特性直流或直流:直流极性:反接电源(焊机)型号:NBC-200电流(范围):见焊接参数表电压(范围):见焊接参数表钨极类型:钨极尺寸:金属过渡方式(射流或短路等):送丝速度范围:施焊顺序1.焊前清理:坡口面及两侧20mm范围内可见金属光泽2.装配与定位焊:按装配图要求装配工件,点固焊缝不大于40mm。

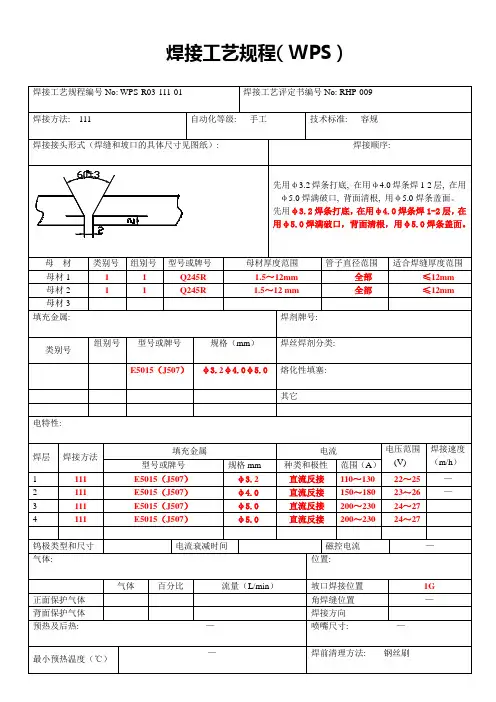

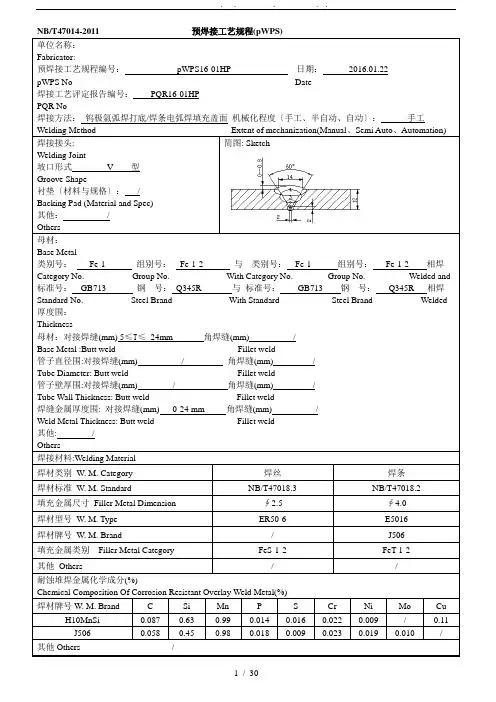

NB/T47014-2011 预焊接工艺规程(pWPS)单位名称:Fabricator:预焊接工艺规程编号:pWPS16-01HP 日期:2016.01.22pWPS No Date焊接工艺评定报告编号:PQR16-01HPPQR No焊接方法:钨极氩弧焊打底/焊条电弧焊填充盖面机械化程度〔手工、半自动、自动〕:手工Welding Method Extent of mechanization(Manual、Semi Auto、Automation) 焊接接头:简图: SketchWelding Joint坡口形式V 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-1 组别号:Fe-1-2 与类别号:Fe-1 组别号:Fe-1-2 相焊Category No. Group No. With Category No. Group No. Welded and 标准号:GB713 钢号:Q345R 与标准号:GB713 钢号:Q345R 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:Thickness母材:对接焊缝(mm) 5≤T≤24mm 角焊缝(mm) /Base Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm) / 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) / 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm) 0-24 mm 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material焊材类别W. M. Category 焊丝焊条焊材标准W. M. Standard NB/T47018.3 NB/T47018.2填充金属尺寸Filler Metal Dimension ∮2.5 ∮4.0焊材型号W. M. Type ER50-6 E5016焊材牌号W. M. Brand / J506填充金属类别Filler Metal Category FeS-1-2 FeT-1-2其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo Cu H10MnSi 0.087 0.63 0.99 0.014 0.016 0.022 0.009 / 0.11 J506 0.058 0.45 0.98 0.018 0.009 0.023 0.019 0.010 /单位名称:Fabricator: 焊接工艺指导书:/ 日期:2016.01.22WPS No Date焊接工艺评定报告编号:pWPS16-02HPPQR No焊接方法:钨极氩弧焊〔GTAW〕机械化程度〔手工、半自动、自动〕:手工Welding Method Extent of mechanization(Manual、Semi Auto、Automation)焊接接头:简图: SketchWelding Joint坡口形式V 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-8 组别号:Fe-8-1 与类别号:Fe-8 组别号:Fe-8-1 相焊Category No. Group No. With Category No. Group No. Welded and 标准号:GB24511 钢号:06Cr19Ni10 与标准号:GB24511 钢号:06Cr19Ni10 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:8mmThickness母材:对接焊缝(mm) 8mm 角焊缝(mm)不限Base Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm) / 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) / 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm) 8mm 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material 06Cr19Ni10焊材类别W. M. Category 焊丝/焊材标准W. M. Standard NB/T47018.3 /填充金属尺寸Filler Metal Dimension ∮2.0 /焊材型号W. M. Type / /焊材牌号W. M. Brand H08Cr21Ni10Si /其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo Cu H08Cr21Ni10Si 0.013 0.52 2.18 0.018 0.011 19.87 9.80 0.02 0.02单位名称:Fabricator: J焊接工艺指导书:/ 日期:2016.01.22WPS No Date焊接工艺评定报告编号:pWPS16-03HPPQR No焊接方法:钨极氩弧焊打底/焊条电弧焊盖面机械化程度〔手工、半自动、自动〕:手工Welding Method Extent of mechanization(Manual、Semi Auto、Automation)简图: Sketch焊接接头:Welding Joint坡口形式V 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-1 组别号:Fe-1-2 与类别号:Fe-8 组别号:Fe-8-1 相焊Category No. Group No. With Category No. Group No. Welded and 标准号:GB713 钢号:Q345R 与标准号:GB24511 钢号:06Cr19Ni10 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:8mmThickness母材:对接焊缝(mm) 8mm 角焊缝(mm) 不限Base Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm) / 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) / 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm) 8mm 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material Q345R/06Cr19Ni10焊材类别W. M. Category 焊丝焊条焊材标准W. M. Standard NB/T47018.3 NB/T47018.2填充金属尺寸Filler Metal Dimension ∮2.0 ∮4.0焊材型号W. M. Type E309-16 /焊材牌号W. M. Brand H12Cr24Ni13 A302其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo Cu H12Cr24Ni13 0.052 0.58 1.82 0.024 0.006 23.62 12.9 0.02 0.03单位名称:Fabricator:.焊接工艺指导书:/ 日期:2016.01.22WPS No Date焊接工艺评定报告编号:pWPS16-04HPPQR No焊接方法:钨极氩弧焊〔GTAW〕机械化程度〔手工、半自动、自动〕:手工Welding Method Extent of mechanization(Manual、Semi Auto、Automation)简图: Sketch焊接接头:Welding Joint坡口形式L 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-1 组别号:Fe-1-1 与类别号:Fe-1 组别号:Fe-1-2 相焊Category No. Group No. With Category No. Group No. Welded and 标准号:GB9948 钢号:20 与标准号:GB713 钢号:Q345R 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:2mm/12mmThickness母材:对接焊缝(mm) 30mm 角焊缝(mm) 不限Base Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm)∮19mm 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) 2 mm 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm)≥2mm 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material 20/Q345R焊材类别W. M. Category 焊丝/焊材标准W. M. Standard NB/T47018.3 /填充金属尺寸Filler Metal Dimension ∮2.5 /焊材型号W. M. Type / /焊材牌号W. M. Brand H10MnSi /其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo Cu H10MnSi 0.087 0.63 0.99 0.014 0.016 0.022 0.009 / 0.11 其他Others /NB/T47014-2011 预焊接工艺规程(pWPS)单位名称:Fabricator:焊接工艺指导书:/ 日期:2016.01.22WPS No Date焊接工艺评定报告编号:pWPS16-05HPPQR No焊接方法:钨极氩弧焊〔GTAW〕机械化程度〔手工、半自动、自动〕:手工Welding Method Extent of mechanization(Manual、Semi Auto、Automation)焊接接头:简图: SketchWelding Joint坡口形式L 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-1 组别号:Fe-1-1 与类别号:Fe-8 组别号:Fe-8 -1 相焊Category No. Group No. With Category No. Group No. Welded and 标准号:GB9948 钢号:20 与标准号:GB24511 钢号:06Cr19Ni10 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:2mm/30mmThickness母材:对接焊缝(mm) 2mm 角焊缝(mm) 不限Base Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm)∮19mm 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) 2mm 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm)≥2mm 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material 20/06Cr19Ni10焊材类别W. M. Category 焊丝/焊材标准W. M. Standard NB/T47018.3 /填充金属尺寸Filler Metal Dimension ∮2.0 /焊材型号W. M. Type / /焊材牌号W. M. Brand H12Cr24Ni13 /其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo Cu H12Cr24Ni13 0.052 0.58 1.82 0.024 0.006 23.62 12.9 0.02 0.03 其他Others /单位名称:Fabricator:焊接工艺指导书:/ 日期:2016.01.22WPS No Date焊接工艺评定报告编号:pWPS16-06HPPQR No焊接方法:钨极氩弧焊〔GTAW〕机械化程度〔手工、半自动、自动〕:手工Welding Method Extent of mechanization(Manual、Semi Auto、Automation)简图: Sketch焊接接头:Welding Joint坡口形式L 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-8 组别号:Fe-8-1 与类别号:Fe-8 组别号:Fe-8-1 相焊Category No. Group No. With Category No. Group No. Welded and 标准号GB13296-2013 钢号:06Cr19Ni10 与标准号:GB24511 钢号:06Cr19Ni10 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:2mm/30mmThickness母材:对接焊缝(mm) 30mm 角焊缝(mm) 不限Base Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm)∮19mm 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) 2mm 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm)≥2mm 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material 06Cr19Ni10焊材类别W. M. Category 焊丝/焊材标准W. M. Standard NB/T47018.3 /填充金属尺寸Filler Metal Dimension ∮2.0 /焊材型号W. M. Type / /焊材牌号W. M. Brand H08Cr21Ni10Si /其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo Cu H08Cr21Ni10Si 0.013 0.52 2.18 0.018 0.011 19.87 9.80 0.02 0.02 其他Others /单位名称:Fabricator:焊接工艺指导书:/ 日期:2016.01.22WPS No Date焊接工艺评定报告编号:pWPS16-07HPPQR No焊接方法:焊条电弧焊〔SMAW〕机械化程度〔手工、半自动、自动〕:手工Welding Method Extent of mechanization(Manual、Semi Auto、Automation)简图: Sketch焊接接头:Welding Joint坡口形式L 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-1 组别号:Fe-1-1 与类别号:Fe-1 组别号:Fe-1-2 相焊Category No. Group No. With Category No. Group No. Welded and 标准号:GB9948 钢号:20 与标准号:GB713 钢号:Q345R 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:3.5mm/12mmThickness母材:对接焊缝(mm) 12mm 角焊缝(mm) 3.5mmBase Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm)∮57mm 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) 3.0mm 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm)≥12mm 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material 20/Q345R焊材类别W. M. Category 焊条焊条焊材标准W. M. Standard NB/T47018 NB/T47018填充金属尺寸Filler Metal Dimension ∮3.2 ∮4.0焊材型号W. M. Type E5016 E5016焊材牌号W. M. Brand J506 J506其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo V J506(∮3.2) 0.071 0.45 0.97 0.017 0.011 0.052 0.012 0.007 0.005 J506(∮4.0) 0.058 0.45 0.98 0.018 0.009 0.023 0.019 0.010 0.004 其他Others /单位名称:Fabricator:焊接工艺指导书:/ 日期:2016.01.22WPS No Date焊接工艺评定报告编号:pWPS16-08HPPQR No焊接方法:焊条电弧焊〔SMAW〕机械化程度〔手工、半自动、自动〕:手工Welding Method Extent of mechanization(Manual、Semi Auto、Automation)简图: Sketch焊接接头:Welding Joint坡口形式L 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-8 组别号:Fe-8-1 与类别号:Fe-8 组别号:Fe-8-1 相焊Category No. Group No. With Category No. Group No. Welded and 标准号GB13296-2013 钢号:06Cr19Ni10 与标准号:GB24511 钢号:06Cr19Ni10 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:3.0mm/8mmThickness母材:对接焊缝(mm) 8mm 角焊缝(mm) 不限Base Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm)∮57mm 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) 3.0mm 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm)≥3mm 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material 06Cr19Ni10焊材类别W. M. Category 焊条焊条焊材标准W. M. Standard NB/T47018.2 /填充金属尺寸Filler Metal Dimension ∮3.2 ∮4.0焊材型号W. M. Type E308-16 E308-16焊材牌号W. M. Brand A102 A102其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo Cu A102 0.05 0.71 1.22 0.025 0.010 19.77 9.77 0.05 0.03 其他Others /单位名称:Fabricator:焊接工艺指导书:/ 日期:2016.01.22WPS No Date焊接工艺评定报告编号:pWPS16-09HPPQR No焊接方法:焊条电弧焊〔SMAW〕机械化程度〔手工、半自动、自动〕:手工Welding Method Extent of mechanization(Manual、Semi Auto、Automation)简图: Sketch焊接接头:Welding Joint坡口形式V 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-1 组别号:Fe-1-1 与类别号:Fe-1 组别号:Fe-1-1 相焊Category No. Group No. With Category No. Group No. Welded and 标准号GB/T8163 钢号:20 与标准号:GB/T8163 钢号:20 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:3.5mmThickness母材:对接焊缝(mm)≥3mm 角焊缝(mm) 不限Base Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm)∮57mm 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) 3.0mm 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm) / 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material 20焊材类别W. M. Category 焊条焊条焊材标准W. M. Standard NB/T47018.2 /填充金属尺寸Filler Metal Dimension ∮3.2 ∮4.0焊材型号W. M. Type E5016 E5016焊材牌号W. M. Brand J506 J506其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo V J506(∮3.2) 0.071 0.45 0.97 0.017 0.011 0.052 0.012 0.007 0.005 J506(∮4.0) 0.058 0.45 0.98 0.018 0.009 0.023 0.019 0.010 0.004 其他Others /单位名称:Fabricator:焊接工艺指导书:/ 日期:2016.01.22WPS No Date焊接工艺评定报告编号:pWPS16-10HPPQR No焊接方法:焊条电弧焊〔SMAW〕机械化程度〔手工、半自动、自动〕:手工Welding Method Extent of mechanization(Manual、Semi Auto、Automation)简图: Sketc焊接接头:Welding Joint坡口形式V 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-8 组别号:Fe-8-1 与类别号:Fe-8 组别号:Fe-8-1 相焊Category No. Group No. With Category No. Group No. Welded and 标准号GB13296-2013 钢号:06Cr19Ni10 与标准号:GB13296-2013 钢号:06Cr19Ni10 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:3.0mm/3.0mmThickness母材:对接焊缝(mm) 3.0mm 角焊缝(mm) 不限Base Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm)∮57mm 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) 3.0mm 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm) / 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material 06Cr19Ni10焊材类别W. M. Category 焊条焊条焊材标准W. M. Standard NB/T47018.2 NB/T47018.2填充金属尺寸Filler Metal Dimension ∮3.2 ∮4.0焊材型号W. M. Type E308-16 E308-16焊材牌号W. M. Brand A102 A102其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo Cu A102(∮3.2) 0.05 0.71 1.22 0.025 0.010 19.77 9.77 0.05 0.03 A102(∮4.0) 0.049 0.700 1.190 0.026 0.009 19.71 9.70 0.050 0.050 其他Others /NB/T47014-2011 预焊接工艺规程(pWPS)单位名称:Fabricator:焊接工艺指导书:/ 日期:2016.01.22WPS No Date焊接工艺评定报告编号:pWPS16-11HPPQR No焊接方法:埋弧焊〔SAW〕机械化程度〔手工、半自动、自动〕:半自动Welding Method Extent of mechanization(Manual、Semi Auto、Automation)焊接接头:简图: SketchWelding Joint坡口形式I 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-1 组别号:Fe-1-2 与类别号:Fe-1 组别号:Fe-1-2 相焊Category No. Group No. With Category No. Group No. Welded and 标准号GB713 钢号:Q345R 与标准号:GB713 钢号:Q345R 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:12mmThickness母材:对接焊缝(mm) 12mm 角焊缝(mm) 不限Base Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm) / 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) / 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm)≥12mm 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material Q345R焊材类别W. M. Category 焊丝/焊剂/焊材标准W. M. Standard NB/T47018.4 /填充金属尺寸Filler Metal Dimension ∮4.0 /焊材型号W. M. Type F5A0 /焊材牌号W. M. Brand H10Mn2 HJ431 /其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo Cu H10Mn2 0.082 0.045 1.65 0.009 0.009 0.023 0.006 / 0.115 其他Others /NB/T47014-2011 预焊接工艺规程(pWPS)单位名称:Fabricator:焊接工艺指导书:/ 日期:2016.01.22WPS No Date焊接工艺评定报告编号:pWPS16-12HPPQR No焊接方法:埋弧焊〔SAW〕机械化程度〔手工、半自动、自动〕:半自动Welding Method Extent of mechanization(Manual、Semi Auto、Automation)焊接接头:简图: SketchWelding Joint坡口形式I 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-8 组别号:Fe-8-1 与类别号:Fe-8 组别号:Fe-8-1 相焊Category No. Group No. With Category No. Group No. Welded and 标准号GB24511 钢号:06Cr19Ni10 与标准号:GB24511 钢号:06Cr19Ni10 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:8mmThickness母材:对接焊缝(mm) 8mm 角焊缝(mm) /Base Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm) / 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) / 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm) 8mm 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material 06Cr19Ni10焊材类别W. M. Category 焊丝/焊剂/焊材标准W. M. Standard /T47018.2 /填充金属尺寸Filler Metal Dimension ∮4.0 /焊材型号W. M. Type F308 /焊材牌号W. M. Brand H08Cr21Ni10Si / SJ101 /其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo Cu H08Cr21Ni10Si 0.013 0.52 2.18 0.018 0.011 19.87 9.80 0.02 0.02 其他Others /单位名称:Fabricator:焊接工艺指导书:/ 日期:2016.01.22WPS No Date焊接工艺评定报告编号:pWPS16-13HPPQR No焊接方法:焊条电弧焊〔SMAW〕机械化程度〔手工、半自动、自动〕:手工Welding Method Extent of mechanization(Manual、Semi Auto、Automation)简图: Sketch焊接接头:Welding Joint坡口形式V 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-1 组别号:Fe-1-2 与类别号:Fe-1 组别号:Fe-1-2 相焊Category No. Group No. With Category No. Group No. Welded and 标准号GB713 钢号:Q345R 与标准号:GB713 钢号:Q345R 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:12mmThickness母材:对接焊缝(mm) 12mm 角焊缝(mm) /Base Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm) / 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) / 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm)≥12mm 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material Q345R焊材类别W. M. Category 焊条焊条焊材标准W. M. Standard NB/T47018.2 NB/T47018.2填充金属尺寸Filler Metal Dimension ∮3.2 ∮4.0焊材型号W. M. Type E5016 E5016焊材牌号W. M. Brand J506 J506其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo V J506(∮3.2) 0.071 0.45 0.97 0.017 0.011 0.052 0.012 0.007 0.005 J506(∮4.0) 0.058 0.45 0.98 0.018 0.009 0.023 0.019 0.010 0.004 其他Others /单位名称:Fabricator:焊接工艺指导书:/ 日期:2016.01.22WPS No Date焊接工艺评定报告编号:pWPS16-14HPPQR No焊接方法:焊条电弧焊(SMAW) 机械化程度〔手工、半自动、自动〕:手工Welding Method Extent of mechanization(Manual、Semi Auto、Automation)简图: Sketch焊接接头:Welding Joint坡口形式V 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-8 组别号:Fe-8-1 与类别号:Fe-8 组别号:Fe-8-1 相焊Category No. Group No. With Category No. Group No. Welded and 标准号:GB24511 钢号:06Cr19Ni10 与标准号:GB24511 钢号:06Cr19Ni10 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:8mmThickness母材:对接焊缝(mm) 8mm 角焊缝(mm) 不限Base Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm) / 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) / 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm) 8mm 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material 06Cr19Ni10焊材类别W. M. Category 焊条焊条焊材标准W. M. Standard NB/T47018.2 NB/T47018.2填充金属尺寸Filler Metal Dimension ∮3.2 ∮4.0焊材型号W. M. Type E308-16 E308-16焊材牌号W. M. Brand A102 A102其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo Cu A102(∮3.2) 0.05 0.71 1.22 0.025 0.010 19.77 9.77 0.05 0.03 A102(∮4.0) 0.049 0.700 1.190 0.026 0.009 19.71 9.70 0.050 0.050 其他Others /单位名称:Fabricator:焊接工艺指导书:/ 日期:2016.01.22WPS No Date焊接工艺评定报告编号:pWPS16-15HPPQR No焊接方法:焊条电弧焊(SMAW) 机械化程度〔手工、半自动、自动〕:手工Welding Method Extent of mechanization(Manual、Semi Auto、Automation)简图: Sketch焊接接头:Welding Joint坡口形式V 型Groove Shape衬垫〔材料与规格〕:/Backing Pad (Material and Spec)其他:/Others母材:Base Metal类别号:Fe-1 组别号:Fe-1-2 与类别号:Fe-8 组别号:Fe-8-1 相焊Category No. Group No. With Category No. Group No. Welded and 标准号:GB713 钢号:Q345R 与标准号:GB24511 钢号:06Cr19Ni10 相焊Standard No. Steel Brand With Standard Steel Brand Welded 厚度围:8mmThickness母材:对接焊缝(mm) 8mm 角焊缝(mm) 不限Base Metal :Butt weld Fillet weld管子直径围:对接焊缝(mm) / 角焊缝(mm) /Tube Diameter: Butt weld Fillet weld管子壁厚围:对接焊缝(mm) / 角焊缝(mm) /Tube Wall Thickness: Butt weld Fillet weld焊缝金属厚度围: 对接焊缝(mm) 8mm 角焊缝(mm) /Weld Metal Thickness: Butt weld Fillet weld其他: /Others焊接材料:Welding Material 16MnR /06Cr19Ni10焊材类别W. M. Category 焊条焊条焊材标准W. M. Standard NB/T47018.2 NB/T47018.2填充金属尺寸Filler Metal Dimension ∮3.2 ∮4.0焊材型号W. M. Type E309-16 E309-16焊材牌号W. M. Brand A302 A302其他Others / /耐蚀堆焊金属化学成分(%)Chemical Composition Of Corrosion Resistant Overlay Weld Metal(%)焊材牌号W. M. Brand C Si Mn P S Cr Ni Mo Cu A302(∮3.2) 0.037 0.894 1.281 0.023 0.013 23.97 12.84 0.264 0.023 A302(∮4.0) 0.057 0.88 1.24 0.028 0.009 23.73 12.38 0.21 0.05 其他Others /。

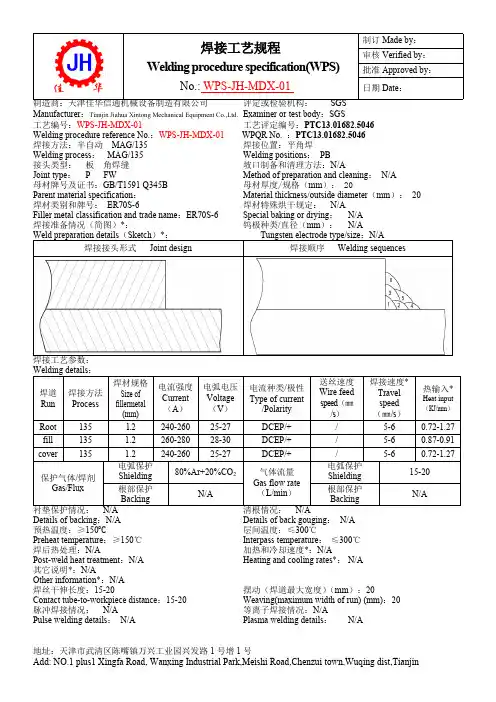

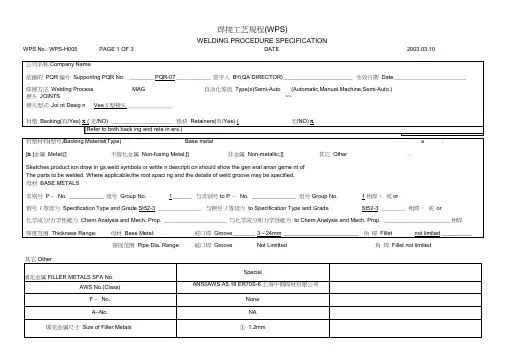

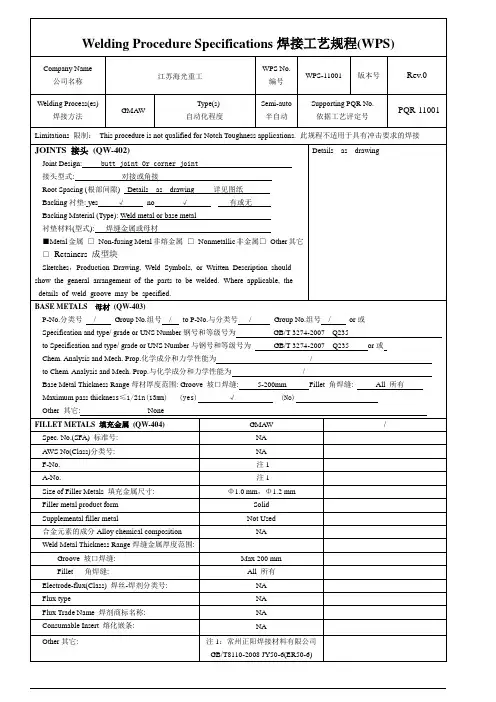

Prepared by 编制: Date: Approved by 批准: Date:Prepared by 编制: Date: Approved by 批准: Date:WPS No./Rev.: WPS-11003/Rev.0Prepared by 编制: Date: Approved by 批准: Date:WPS No./Rev.: WPS-11004/Rev.0Prepared by 编制: Date: Approved by 批准: Date:WPS No./Rev.: WPS-11005/Rev.0Prepared by 编制: Date: Approved by 批准: Date:WPS No./Rev.: WPS-11006/Rev.0Prepared by 编制: Date: Approved by 批准: Date:WPS No./Rev.: WPS-11007/Rev.0Prepared by 编制: Date: Approved by 批准: Date:WPS No./Rev.: WPS-11008/Rev.0Prepared by 编制: Date: Approved by 批准: Date:Prepared by 编制: Date: Approved by 批准: Date:Procedure Qualification Records焊接工艺评定记录(PQR) Company Name公司名称江苏海光重工PQR No./编号PQR-11001Welding Process(es)焊接方法GMAWTypes自动化等级Semi-auto半自动WPS No./ Rev.依据规程号WPS-11001/0JOINTS 接头(QW-402) Groove design of Test Coupon 试件坡口设计BASE METALS 母材(QW-403)Material Spec. 材料标准号: GB/T3274Type or Grade 型号或等级: Q235B+ Q235BP-No. / Group No. / to P-No. / Group No. / Thickness of Test Coupon 厚度: 50mm Diameter of Test Coupon 直径: NA Maximum pass thickness ≤13mm Other 其它: 无None FILLER METALS 填充金属(QW-404)SFA Specification标准号:NAAWS Classification分类号: NA合金元素的成分Alloy chemical composition NA Filler Metal F-No. 注1Weld Metal Analysis A-No. 注1Size of Filler Metals填充金属尺寸: φ1.0;1.2mm Weld Metal Thickness 焊缝金属厚度: 50mmFiller metal product form NASupplemental filler metal Not UsedElectrode flux classification NA flux type NA Flux Trade Name NA Other 其它:注1:常州正阳焊接材料有限公司GB/T8110-2008 JY50-6(ER50-6) POSITIONS 焊接位置(QW-405)Position of Groove 坡口位置: 3GWeld Progression (Uphill, Downhill) 焊接方向: NA Other 其它:PREHEAT 预热(QW-406)Preheat Temp.预热温度: 10℃Inter pass Temp.层间温度: 180℃Other 其它: POSTWELD HEAT TREATMENT 焊后热处理(QW-407) Temperature 温度: 610℃±15℃Time时间: 3小时hOther 其它:GAS 保护气体(QW-408) (GTAW)Percent Composition百分比组成Gas(es)气体Mixture混合比Flow Rate流量Shielding 保护气: CO2&Ar 80%:20% 15-25L/Min Trailing尾部保护: No NA NABacking背部保护: No NA NAOther NoneELECTRICAL CHARACTERISTICS 电特性(QW-409)Current 电流AC or DC: DC 直流Polarity 极性: EP 正接Amps 安培: See below见下表V olts 伏特: /Tungsten Electrode Size钨极尺寸: NAMode of metal transfer GMAW(FCAW): Globular Transfer 融滴过渡TECHNIQUE 焊接技术(QW-410)Travel Speed 焊接速度:String or Weave Bead 有无摆动: Weave 摆动Oscillation 摆动方式: NASingle or Multiple Pass (Per side) 单道焊或多道焊(每侧): single单道Single or Multiple Electrodes单丝焊或多丝焊:Initial and Inter pass Cleaning 打底或层间清理: Brushing and Grinding Method of Back Gouging 背面清理方法: NAClosed to out chamber:闭室焊到室外焊NAOther其它: None 无Weld Layer(s)焊层Process焊接方法Filler Metal填充金属Current电流V olt电压(V)Travel Speed焊接速度(mm/min)其它Other Class种类Dia.直径(mm)Type Polar.极性Amp.电流(A)1 GMAW ER50-6 1.0 DCEP 195-200 20-22 / NA 2-3 GMAW ER50-6 1.0 DCEP 205-210 26-27 /others GMAW ER50-6 1.2 DCEP 260-265 32-33 /PQR No. PQR-11001/Rev.0Tensile Test 拉伸试验(QW-150)Fillet-Weld Test 角焊缝试验(QW-180)Result-Satisfactory (Yes or No ) 结论是否合格: Yes NA No NAPenetration into Parent Metal (Yes or No ) 母材是否熔透: Yes NA No NAMacro-Results宏观检查结果: NAOther Tests 其它试验Type of Test 试验类型: NONEDeposit Analysis 焊缝成分: NONEOther 其它: NONEWelder’s Name 焊工姓名: lv Wenfei 吕文飞Clock No. Stamp No. 钢印号: B213Laboratory Test No. 试验室编号: PMZ-QC-PCTR-110801Tests conducted by 试验执行人: 郑丽华Zheng Lihua Test Equipment No.试验设备编号:PMZ2-0004We certify that the statements in this record are correct and that the test welds were prepared, welded ,and tested in accordance with the requirements of Section IX of the ASME Code.兹证明本报告所述均属正确,并且试件是根据ASME规范第IX卷的要求进行试件的制备、焊接和试验的。

接头制备要求:1、管道采用火焰或等离子切割,加工后使用砂轮机打磨除去氧化皮,保证无裂纹、重皮、毛刺、凸凹、缩口、熔渣等现象。

2、焊件坡口及内外表面在焊接前要求进行清理,。

3、坡口组对:内壁错边量不超过管壁厚度的10%,且不应大于2mm 。

4、定位焊缝:应采用与根部焊道相同的焊接材料和工艺;定位焊缝的长度、厚度和间距应能保证焊缝在正式焊接过程中不致开裂。

焊接的工卡具其材质宜与母材相同或同一类别号,拆除工卡具时不应损伤母材,拆除后应将残留焊疤打磨修整至与母材表面齐平。

熔渣及影响焊接的表面层打磨平整。

焊接工艺规程页数 1 of 3工程名称:产品名称(施焊部位) 工艺管道 产品设计温度范围 - 产品工作介质 -焊接工艺规程(WPS )编号 WPS20201-201-GY-004 版次 - 日期2021.04.24 所依据的焊接工艺评定报告(PQR )编号PQR2020063 版次 - 日期2020.12.16焊接方法 GTAW+SMAW 操作类型(手工,自动,半自动) 手工 焊接施工执行标准 GB/T50236-2011 其他 无 焊接接头:接头型式 对接 简图 (接头型式、坡口形式和尺寸、焊层/焊道布置及顺序示意图): 衬垫(有) 无 (无) 衬垫材质、型式及规格 --母材:材料标准号 GB/T9948-2013 型号或牌号 20,ANTI-SCC 与 材料标准号 GB/T9948-2013 型号或牌号 20,ANTI-SCC 相焊 厚度范围:坡口焊 7.04mm-14.08mm 角焊 母材厚度不限 管道直径范围:坡口焊 不限 角焊 不限 其他 无填充金属焊接材料标准号 NB/T47018.3-2017NB/T47018.3-2017型号 ER50-G E4315 牌号CHG-SHA CHE427SHA 尺寸Φ2.5 Φ3.2/Φ4.0烘干温度/时间 - 按照焊材说明书进行烘烤。

焊缝熔敷金属厚度 0~5mm 0~9mm 其他GTAWSMAW焊接位置:坡口对接焊缝位置 45°固定焊(6G ) 角焊缝位置 全位置 焊接方向(向上、向下) 向上其他 无 预热:最小预热温度 20℃(室温) 最大层间温度 250℃ 后热温度和时间 -加热方式及其他 -焊接工艺规程页数 3 of 3 3、焊接操作注意事项:焊件表面不得有电弧擦伤,并不得在焊件表面引弧和试验电流;焊接时应采取合理的施焊方法和施焊顺序;焊接过程中应保证起弧和收弧处的质量,收弧时应将弧坑填满;焊缝多层多道焊时,焊接接头应错开;焊接过程中,焊丝的加热端应置于保护气体中;需预拉伸或预压缩的管道焊缝,组对时所使用的工卡具应在整个焊缝焊接完毕并经检验合格后方可卸载。

公司名称 ________________焊接方法 AW (实芯焊丝CO2气体保护焊) PQF 辅甫助文件号采用的接头设计类型 _______________ I __________________________________________ 单面焊缝[V ] 双面焊缝[]衬垫:用[]不用[V ]衬^垫材料:1 J 十/l/J /ll ♦■ 根部间隙----- 钝边尺寸 -------------坡口角度 半径(J-U )母材规格ASTM A36 -------------------------------------- 类型或级别 -------------------------------------------------厚度:坡口 -------------------- 角焊缝 7直径(圆管) ----------------------------------------------填充金属AWSB 定 -------------------------------------------------- AWS 类别 ER70S-6 实芯焊丝①过渡形式(GMA ) 短路[V ]熔滴[] 喷射[]电流:交流[]直流反接[V ]直流正接[] 脉冲[]其他 ----------------------------------------------------- 钨极(GTA )尺寸: 类型:焊丝数 1—焊丝间隔 纵向 横向角度焊接工艺规程(WPS ) 是[V ]免除评定试验评定V或工艺评定记录(PQR ) 是[]标识编号A001修改 -------------- 日期 ------------ 修改人 --------------背部清根:用[]不用[V ] 方法批准人 ____________________________ 日期 _________________焊接工艺------------------------------ 气体喷嘴尺寸 20mm 预热预热温度,最低 ___________________________________________ 道间温度,最低 ___________________________________________导电嘴到工件距离 20mm锤击 V道间清理 -------------- V ——焊后热处理温度 ------------------------------------------------------焊接工艺组分横向焊丝-焊剂(等级)流率焊接工艺------------------------------ 气体喷嘴尺寸预热预热温度,最低350-400 C角度 ------------------------------导电嘴到工件距离 锤击一“道间清理 ------------------V焊后热处理温度 ------------------------------------------------------组分横向焊丝-焊剂(等级)流率焊接工艺----------------------------- 气体喷嘴尺寸预热预热温度,最低350-400C角度 -------------------------------导电嘴到工件距离 锤击一“道间清理 ----------------- V焊后热处理温度 -------------------------------------------------------组分横向焊丝-焊剂(等级)流率焊接工艺----------------------------- 气体喷嘴尺寸预热预热温度,最低350-400C角度 -------------------------------导电嘴到工件距离 锤击一“道间清理 --------------- V ——焊后热处理温度 -------------------------------------------------------焊丝-焊剂(等级)流率 8-13L/min焊接工艺------------------------------ 气体喷嘴尺寸 20mm预热预热温度,最低 ___________________________________________角度 -------------------------------导电嘴到工件距离 20mm锤击一“道间清理 ----------------- V焊后热处理温度 -------------------------------------------------------焊丝-焊剂(等级)流率 8-13L/min焊接工艺------------------------------ 气体喷嘴尺寸 20mm预热预热温度,最低 ___________________________________________角度 -------------------------------导电嘴到工件距离 20mm锤击一“道间清理 ----------------- V焊后热处理温度 -------------------------------------------------------焊丝-焊剂(等级)流率 8-13L/min焊接工艺------------------------------ 气体喷嘴尺寸 20mm预热预热温度,最低 ___________________________________________角度 -------------------------------导电嘴到工件距离 20mm锤击一“道间清理 ----------------- V焊后热处理温度 -------------------------------------------------------焊丝-焊剂(等级)流率 8-13L/min焊接工艺------------------------------ 气体喷嘴尺寸 20mm预热预热温度,最低 ___________________________________________角度 -------------------------------导电嘴到工件距离 20mm锤击一“道间清理 ----------------- V焊后热处理温度 -------------------------------------------------------焊丝-焊剂(等级)流率 8-13L/min焊接工艺------------------------------ 气体喷嘴尺寸 20mm预热预热温度,最低 ___________________________________________角度 -------------------------------导电嘴到工件距离 20mm锤击一“道间清理 ----------------- V焊后热处理温度 -------------------------------------------------------组分横向焊丝-焊剂(等级)流率 8-13L/min焊接工艺------------------------------ 气体喷嘴尺寸 20mm预热预热温度,最低 ___________________________________________角度 -------------------------------导电嘴到工件距离 20mm锤击一“道间清理 ----------------- V焊后热处理温度 -------------------------------------------------------。