展望兴031B型真空贴合机用户手册

- 格式:ppt

- 大小:2.48 MB

- 文档页数:12

使用说明INSTRUCTION MANUAL为使您正确使用本机,须对本机的各种功能充分了解,以便安全操作。

To get the most out of the many functions of this machine and operate it in safety,it is necessary to use this machine correctly.使用前请仔细阅读使用说明书,我们希望您能长期愉快地使用本机,请保存好说明书,以备查阅。

Please read this Instruction Manual carefully before use.We hope you will enjoy the use of your machine for a long time.Please remember to keep this manual in a safe place.1.无论您何时使用本机,须了解基本的安全事项,包括但不限于下列事项。

Observe the basic safety measures,including,but not limited to the following ones, whenever you use the machine.2.通读所有说明,并保存好使用说明书。

如果需要,请随时翻阅。

Read all the instructions,including,but not limited to this Instruction Manual before you use the machine,in addition,keep this Instruction Manual so that you may read it at anytime when necessary.3.使用本机前,必须弄清与本机有关安全规定、标准在您的国家是否适用。

Use the machine after it has been ascertained that it conforms with safetyrules/standards valid in your country.4.使用本机前或使用本机时,所有安全装置必须配备齐全。

00000151515PLSTG-6000型吸管粘贴机用户手册上海普丽盛轻工设备有限公司目录一、安全生产注意事项 (2)二、贴管机工作原理 (2)三、贴管机的构成 (3)(一)、分盒装置 (3)1、工作原理 (3)2、安装调整 (3)(二)贴管总成 (4)1、工作原理 (4)2、主要结构及特点 (4)2.1贴管装置 (4)2.2支架调整机构 (9)四、气动控制系统 (10)五、熔胶机的使用 (11)六、贴管机常见故障与排除 (12)七、包装和运输 (13)(一)包装要求 (13)(二)运输要求 (13)八、贴管机电器控制系统 (14)(一)、电器控制原理图 (14)(二)、电器控制原理图的说明 (17)一、安全生产注意事项1、本机为高温高压设备,操作者必须具有机、电、气压等基础知识,并具有一定的操作技能方能上岗;2、操作人员需经培训;3、注意识别危险标志;4、若被烫伤,不可把伤口放进冷水里降温,更不可用力将伤口上热熔胶取走,应用适当的防烫伤药品涂之,并送医院治疗;5、接总电源线时,一定要区分好零线(N),否则会烧毁设备;6、若设备起火,请马上切断电源,切忌用水救火,以防被过热水蒸气烫伤;7、严格按照本使用说明书进行操作。

二、贴管机工作原理(见图1 贴管机工作原理示意图)砖形盒在输送带上快速运行,进入分盒装置,由于输送带的速度比分盒装置同步带的线速度较快,砖形盒出来后被分隔成一定的间距,经过喷胶装置被喷上两点热熔胶,再经过贴管装置被贴上一只吸管,然后继续运行进入下一道工序。

图1 贴管机工作原理示意图1、熔胶主机2、输送带3、砖型盒4、分盒装置5、喷胶装置6、贴管装置7、光电开关三、贴管机的构成:主要由分盒装置、熔喷胶机构、贴管总成三个相对独立的机构所组成。

(一)分盒装置:1、工作原理:输送带运行时,利用调速带与砖形盒的磨擦力大于输送带与砖形盒底部的磨擦力,使砖形盒以较慢的速度与调速带同速前进,而下一个砖形盒以同样的过程进入调速带工作区,和调速带同步前进,碰到前一个砖形盒并将之推出,使之和输送带同步前进,进入下一道工序。

Fagor Automation S. Coop.20i-M / 30i-M20i-M B / 30i-M B安装/操作手册手册代码: 14460053手册版本: 0605软件版本: 4.xx目录1数显表概述 (3)1.1前面板 (3)1.2开启与关闭数显表 (4)2数显表的操作 (5)2.1显示方式 (5)2.2增量方式, 绝对方式与机床零 (6)2.2.1示例 (7)2.2.1.1绝对方式 (7)2.2.1.2增量方式 (8)2.3机床零点的选择与搜索 (9)2.3.1零点搜索的顺序 (9)2.4带刀具时的操作 (10)2.4.1输入刀具尺寸 (10)2.4.2加工过程中的刀具补偿 (10)2.4.3工件零点的刀具补偿 (10)2.5特殊操作 (11)2.5.1比例系数 (11)2.5.2工件中心定位 (12)2.6刀具补偿操作示例 (12)2.6.1内型腔 (12)2.6.2外型腔 (13)2.7进入特殊功能方式 (14)2.7.1直线和圆周孔加工 (15)2.7.1.1选择加工平面 (15)2.7.1.2圆周孔加工 (15)2.7.1.3执行圆周孔加工 (16)2.7.1.4直线孔加工 (17)2.7.2坐标锁定 (HOLD) (17)2.7.3计算器 (18)2.7.3.1计算器的操作 (18)2.7.3.2数据的调用和预置 (19)2.7.4工件角度测量 (20)2.7.5腔体加工 (21)3数显表安装 (22)3.1嵌入式安装 (22)3.2后面板 (23)3.3一般技术特性 (24)3.4连接 (24)3.4.1反馈系统的连接 (24)3.5快捷设置 (25)3.5.1进入快捷设置模式 (25)3.5.2操作方式. (25)3.5.3电源与机床的连接 (26)3.6安装参数 (26)3.7影响轴位置显示的参数 (28)4附录 (35)4.1CE 认证 (35)4.1.1遵守标准 (35)4.1.2安全条件 (36)4.1.3保修条款 (38)4.1.4产品返回条款 (38)4.2错误代码 (39)4.3维护 (40)(2/40) - Installation/Operation - 20i-M / 30i-M - V0605V0605 - 20i-M / 30i-M - 安装/操作手册 - 数显表概述- (3/40)1 数显表概述1.1前面板每个轴可显示8位14.1mm 高的LED 字符及符号位(-).LED 显示及控制键:ABS 当数显表工作在绝对方式下时,此灯亮;当数显表工作在增量方式下时,此灯灭。

XXXXXXX有限公司DTH-650/1300贴合分切机作业指导书一、概述:该机是手机、电脑、液晶显示器等电子标签行业胶带类粘贴产品的专用复合设备。

收放卷均采用磁粉张力控制。

可复合单、双面胶,具有收底纸功能,可多条同时复合并具有局部贴合功能。

二、主要规格及技术参数机器型号DTH-320 DTH-4202.1 卷筒纸最大宽度320 420mm2.2 最大放纸卷直径φ500mm φ500mm2.3 贴合速度35 m/min 35m/min2.4 贴合精度±0.25mm ±0.25mm2.5 主电机0.5KW 0.5KW2.6 两组总功率 1.5KW 1.5KW2.7 三组总功率2KW 2KW三、结构和工作原理简介3.1 本机由放卷机构、传动机构、牵引贴合机构、收卷机构,张力控制装置及电器控制等部分组成。

3.2本机作用是:将原材料与另外一种材料贴合并收卷,其工作原理是将所需贴合的材料固定在放料轴上,放料轴的一端有磁粉张力控制器来恒定原材料的所需张力,用一对橡胶辊贴和牵引原材料和所需帖和材料,经各导辊导引到收卷轴,收卷成品。

3.3原料在牵引走料过程中发生了偏移,手动调节纠偏手轮左右移动放料轴,能纠正原料偏移。

3.4收放卷时,根据卷料直径的大小,调节卷料装置上的磁粉离合器或磁粉制动器张力电流大小。

由于卷径大,要求扭矩大,卷径小,要求扭矩小。

因此,卷大,磁粉离合或制动器张力电流调大。

卷小,磁粉离合或制动器张力电流调小。

保证贴合材料速度、张力一致,收卷材料内外径张力均匀。

四、ZX-168预置编程型长度控制器(一)、主要技术参数1、范围:累加方式0-999999M2、误差正负一个脉冲3、输入频率小于50赫兹4、输入接口霍尔开关或接近开关6、预置输出方式继电器(0.5/250VAC)7、停电处理停电储存数据大于5年8、工作电源交流220V 50/60HZ(二)、长度信号拾取方式长度控制器要求霍尔开关拾取的转数,拾取结构因机器的不同而有不同的方法,要求是,该结构能准确反映出料,不能有打滑、空转现象。

XPF贴片机操作指导书1. 目的文件讲述了FUJI XPF贴片机的基本使用方法和操作指导,工程部和生产部必须按照此文件,以获得高品质的零件贴装。

2.范围本文件适用用于公司所有的 XPF贴片机。

3.权责3.1 生产部负责按该文件的内容来执行。

3.2 工程部负责维护、监督生产部正确操作。

4. 定义无5.内容5.1开机程序打开控制计算机(FUJICAM PC)并连接电缆到机器。

在FUJICAM PC故障或不使用时,可直接连接进行(5.1.1)5.1.1在机身前右下方顺时针旋转交流输入开关90°,将电源开关置“┃”位置。

5.1.2按压“SYSTEM ON”按钮开机。

5.1.3等待机器激活,此过程约几分钟直到显示LOG ON窗口,并显示初始化完成。

5.1.4利用显示的键盘输入操作员名及密码,按LOG ON进入主画面。

5.1.5释放所有紧急按钮,关闭防护门,检查机器活动区域无异物。

5.1.6按压“READY ON”按钮,机器伺服系统可以工作。

5.2 产前准备(此部分由生产部负责)5.2.1技术员根据生产部门提供的生产型号,在主屏按[PRODUCTION],然后按[SELECTPROGRAM]显示机器程序,选择对应程序,按[DOWN LOAD]调出程序。

5.2.2核对程序的送料器排位设置无误。

在主屏按[PLOGRAM],然后按[EDITOR]编辑机器程序,选择[FEEDER SETUP]调出程序送料器排位,用MI核对程序的送料器排位设置无误。

5.2.3检查送料器安装无误。

要求送料器类型正确,物料安装正确到位,送料器安装到MFU上正确到位。

5.2.4核对程序的吸嘴设置无误,在主屏按[PROGRAM],然后按[EDITOR]编辑机器程序,选择[MOZZLE]调出程序吸嘴排位,核对程序的吸嘴设置无空缺及无不合用。

5.2.5 设置机器的吸嘴及吸嘴中心测定。

5.2.5.1回到主屏按[NOZZLE EXCHANGE SIDE1]或[NOZZLE EXCHANGE SIDE2],[START],机器贴装头移动到机器前边或后边,根据吸嘴排位要求更换吸嘴,在主屏按[PRODUCTION],然后按[NOZZLE EDITOR],再按[SET ALL PROGRAM NOZZLES]设置机器的吸嘴。

说明非常感谢您使用鹰眼电子科技有限公司的CO B—E201A系列产品,在安装、操作、维修或检查本产品之前请务必要彻底阅读本说明书。

本手册内容和规格可能会根据机器版本(包括硬件和软件)而更变,恕不另行通知。

未经鹰眼电子科技有限公司许可,本手册任何部分都不可以任何形式或者通过电子或机械方法复制。

目录1.安全措施- - - - - - - - - - - - - - - - - - - - - - 3 -2.界面操作- - - - - - - - - - - - - - - - - - - - - - 4 –2-1. 主界面操作- - - - - - - - - - - - - - - - - - - - - 4 –2-2. 参数设定面板- - - - - - - - - - - - - - - - - - - - 4 –2-3. 运动控制面板- - - - - - - - - - - - - - - - - - - - 12 –2-4. 界面调试操作- - - - - - - - - - - - - - - - - - - - 13 –3.控制面板介绍- - - - - - - - - - - - - - - - - - - - - - 16 –3-1.电源控制面板- - - - - - - - - - - - - - - - - - - - 16 –3-2. 点胶快捷键面板介绍- - - - - - - - - - - - - - - - - 17 –3-3.参数控制面板- - - - - - - - - - - - - - - - - - - - - 17 –3-3-1.气路系统- - - - - - - - - - - - - - - - - - - - - - 18 –3-3-2. 温控系统- - - - - - - - - - - - - - - - - - - - - 18 –备注:设备易损件及其使用寿命- - - - - - - - - - - - - - - 19 –4.常见故障及其排除方法- - - - - - - - - - - - - - - - - - 20 –5.机台的保养方法- - - - - - - - - - - - - - - - - - - - - 21 –6.相对应标准件清单- - - - - - - - - - - - - - - - - - - - 22 –7.整机检修问题备忘录- - - - - - - - - - - - - - - - - - - 24 -1.安全措施1-1.机器搬运及安装注意事项:1.由于机器比较重,建议在搬运时要由4人以上进行。

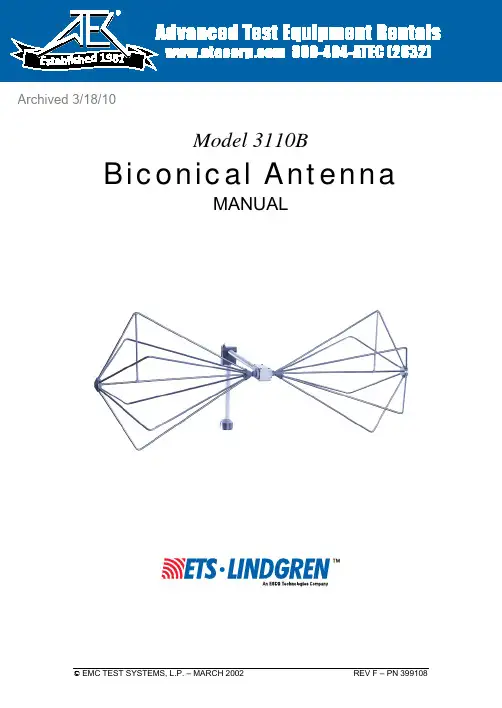

1981Archived 3/18/10Model 3110BBiconical AntennaMANUAL© EMC TEST SYSTEMS, L.P. – MARCH 2002 REV F – PN 399108MODEL 3110B BICONICAL ANTENNA© EMC TEST SYSTEMS, L.P. – MARCH 2002REV F – PN 399108EMC Test Systems, L.P. reserves the right to make changes to any product described herein in order to improve function, design or for any other reason. Nothing contained herein shall constitute EMC Test Systems, L.P. assuming any liability whatsoever arising out of the application or use of any product or circuit described herein. EMC Test Systems, L.P. does not convey any license under its patent rights or the rights of others.© Copyright 2002 by EMC Test Systems, L.P. All Rights Reserved.No part of this document may be copied by any means without written permission from EMC Test Systems, L.P.E-MAIL & INTERNET ************************USA1301 Arrow Point Dr., Cedar Park, TX 78613 P.O. Box 80589, Austin, TX 78708-0589 Tel 512.531.6400 Fax 512.531.6500FINLANDEuroshield OY Mekannikontie 1 27510, Eura, Finland Tel 358.2.838.3300 Fax 358.2.865.1233SINGAPORELindgren RF Enclosures Asia-Pacific 87 Beach Road#06-02 Chye Sing Building Singapore 189695Tel 65.536.7078 Fax 65.536.7093Archived 3/18/10MODEL 3110B BICONICAL ANTENNA© EMC TEST SYSTEMS, L.P. – MARCH 2002 REV F – PN 399108Table of ContentsINTRODUCTION ........................................................................................................................................ 1 ASSEMBLY INSTRUCTIONS ................................................................................................................... 1 MOUNTING INSTRUCTIONS .................................................................................................................. 2 APPLICATION ............................................................................................................................................ 3 TYPICAL DATA .......................................................................................................................................... 4 SPECIFICATIONS ...................................................................................................................................... 6 MAINTENANCE ......................................................................................................................................... 7 WARRANTY STATEMENT . (8)Archived 3/18/10© EMC TEST SYSTEMS, L.P. – MARCH 2002REV F – PN 399108INTRODUCTIONThe ETS-Lindgren EMCO brand Model 3110B BiconicalAntenna is specifically designed for radiated emissionstesting. This high performance, receive only, antennaoperates with in a frequency range of 30 to 300 MHz.The biconical elements are made from aluminum rods andare welded into a fixed assembly. The elements mount ontoa balun network which is fabricated of aluminum and thenecessary impedance-matching components. Its lightweightconstruction provides for ease in portability and storage. ASSEMBLY INSTRUCTIONSThe Model 3110B consists of the following (shippedunassembled):1 ea. Balun2 ea. Biconical Elements2 ea. Belleville Washers (In a small plastic bag)1 ea. Mounting ClampStep 1.After carefully unpacking all of the components, take oneof the belleville washers and slide it onto the threadedscrew end of one of the biconical elements.Step 2.Line up the screw threads with the receptacle hole on thebalun and turn the biconical element until it is firmlysecured in the balun. Be careful not to cross-thread thisconnection or permanent damage to the joint could occur.© EMC TEST SYSTEMS, L.P. – MARCH 2002 1 REV F – PN 399108Mounting InstructionsMODEL 3110B BICONICAL ANTENNA2 © EMC TEST SYSTEMS, L.P. – MARCH 2002REV F – PN 399108Step 3. Repeat Steps 1 and 2 with the other washer and biconicalelement .Now you are ready to mount the antenna on a tripod for testing.MOUNTING INSTRUCTIONSThe mounting clamp of the Model 3110B uses standard 7/8x14 threads and comes with a 1/4x20 thread adapter for versatility when connecting to an ETS tripod or most other tripods for support.After the mounting clamp is attached to a tripod, unscrew the latch and open the clamp. Insert the balun of the 3110B into the clamp and close the top over the balun. Move the screw latch to the closed position and tighten, so the balun is held securely. The cable can now be attached to the output connector.Archived 3/18/10MODEL 3110B BICONICAL ANTENNA Application© EMC TEST SYSTEMS, L.P. – MARCH 20023REV F – PN 399108APPLICATIONThe Model 3110B is ideally suited for swept site attenuation measurements per ANSI and FCC specifications. Also, the Model 3110B can be used for horizontal as well as vertical site attenuation measurements. A 20 dB pre-amp is recommended in line with the receive antenna to minimize the required transmitted power and to reduce the possibility of saturation of the transmitting antenna. The maximum continuous input power to the Model 3110B is 250 mW.When the 3110B is used vertically, the same element orientation need not be maintained from measurement to measurement. The Model 3110B exhibits excellent symmetrical performance and test repeatability is assured by the balun design.Each antenna is calibrated during manufacturing. The results of the calibration are tabulated and included with this manual as gain and antenna factor vs frequency for use in Specification Compliance Testing. Typical data for the Model 3110B can be found in the next section.Archived 3/18/10Typical DataMODEL 3110B BICONICAL ANTENNA4 © EMC TEST SYSTEMS, L.P. – MARCH 2002REV F – PN 399108TYPICAL DATA306090120150180210240270300510152025d B 1/mFrequency (Mhz)Model 3110B Antenna Factor306090120150180210240270300-20-15-10-55101 m3 m10 md BFrequency (Mhz)Model 3110B GainArchived 3/18/10MODEL 3110B BICONICAL ANTENNA Typical Data© EMC TEST SYSTEMS, L.P. – MARCH 20025REV F – PN 39910830609012015018021024027030035791315Frequency (Mhz)Model 3110B VSWR306090120150180210240270300406080100120140160180200d e g r e e s Frequency (Mhz)Model 3110B Half Power BeamwidthArchived 3/18/10SpecificationsMODEL 3110B BICONICAL ANTENNA6 © EMC TEST SYSTEMS, L.P. – MARCH 2002REV F – PN 399108SPECIFICATIONSElectricalFrequency Range 30 to 300 MHzVSWR Ratio (AVG) 2.0:1Maximum Continuous Power 250 mW Peak Power NA Impedance 50 ςConnectorType N femalePhysicalWidth 132.1 cm52.0 inDepth 55.9 cm22.0 inDiameter 52.0 cm20.5 inWeight 2.7 kg6.0 lbNOTE: ETS-Lindgren recommends using a 6DB pad attached to the end of the antenna, otherwise high VSWR may occur.Archived 3/18/10MODEL 3110B BICONICAL ANTENNA Maintenance© EMC TEST SYSTEMS, L.P. – MARCH 20027REV F – PN 399108 MAINTENANCETo ensure reliable and repeatable long-term performance,annual recalibration of your antenna by ETS-Lindgren’sexperienced technicians is recommended. Our staff canrecalibrate almost any type or brand of antenna. Please callto receive a Service Order Number prior to sending anantenna to us for calibration.For more information about our calibration services or toplace an order for antenna calibration visit our calibrationwebsite at /.Archived 3/18/10Warranty Statement MODEL 3110B BICONICAL ANTENNA8 © EMC TEST SYSTEMS, L.P. – MARCH 2002 REV F – PN 399108 WARRANTY STATEMENTEMC Test Systems, L.P., hereinafter referred to as the Seller, warrants that standard EMCO products are free from defect in materials and workmanship for a period of two (2) years from date of shipment. Standard EMCO Products include the following:Antennas, Loops, HornsGTEM cells, TEM cells, Helmholtz CoilsLISNs, PLISNs, Rejection cavities & NetworksTowers, Turntables, Tripods, & ControllersField Probes, Current Probes, Injection ProbesIf the Buyer notifies the Seller of a defect within the warranty period, the Seller will, at the Seller’s option, either repair and/or replace those products that prove to be defective.There will be no charge for warranty services performed at the location the Seller designates. The Buyer must, however, prepay inbound shipping costs and any duties or taxes. The Seller will pay outbound shipping cost for a carrier of the Seller’s choice, exclusive of any duties or taxes. If the Seller determines that warranty service can only be performed at the Buyer’s location, the Buyer will not be charged for the Seller’s travel related costs.This warranty does not apply to:Normal wear and tear of materialsConsumable items such as fuses, batteries, etc.Products that have been improperly installed, maintained or usedProducts which have been operated outside the specificationsProducts which have been modified without authorization Calibration of products, unless necessitated by defectsTHIS WARRANTY IS EXCLUSIVE. NO OTHER WARRANTY, WRITTEN OR ORAL, IS EXPRESSED OR IMPLIED, INCLUDING BUT NOT LMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE REMEDIES PROVIDED BY THIS WARRANTY ARE THE BUYER’S SOLE AND EXCLUSIVE REMEDIES. IN NO EVENT IS THE SELLER LIABLE FOR ANY DAMAGES WHATSOEVER, INCLUDING BUT NOT LIMITED TO, DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY. Note: Please contact the Seller’s sales department for a Return Materials Authorization (RMA) number before shipping equipment to us.Archived 3/18/10。