ASME IX BASE METALS中英对照QW-403

- 格式:pdf

- 大小:881.56 KB

- 文档页数:5

PROCEDURE QUALIFICATION RECORDS工艺评定记录(PQR)Procedure Qualification Record No工艺评定记录编号Date日期Apr. 11, 2009WPS No. 焊接工艺规程编号Welding Process(es) 焊接方法Page 1 of 2Fillet-Weld Test 角焊缝试验(QW-180) NA 不适用Result -- Satisfactory: 结果是否满意:Yes是No否Penetration into Parent Metal: 熔透母材:Yes是No否Macro -- Results宏观检测结果Other Tests其它试验None 无Type of Test 试验类型Deposit Analysis 熔敷金属成分Other 其它........................................................................................................................................................................................................................ Welder’s Nam e 焊工姓名Clock No. 上班考勤卡编号Stamp No. 钢印号Tests Conducted by试验执行机构Laboratory Test No. 实验室试验编号We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance with the requirements of Section IX of the ASME BOILER AND PRESSURE VESSEL CODE.兹证明本报告所述均属正确,并且试验是根据ASME规范第IX卷的要求进行试件的准备、焊接和试验的。

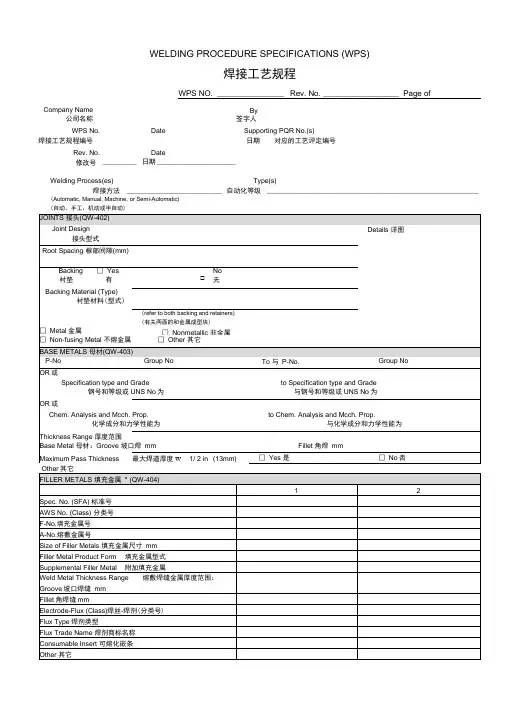

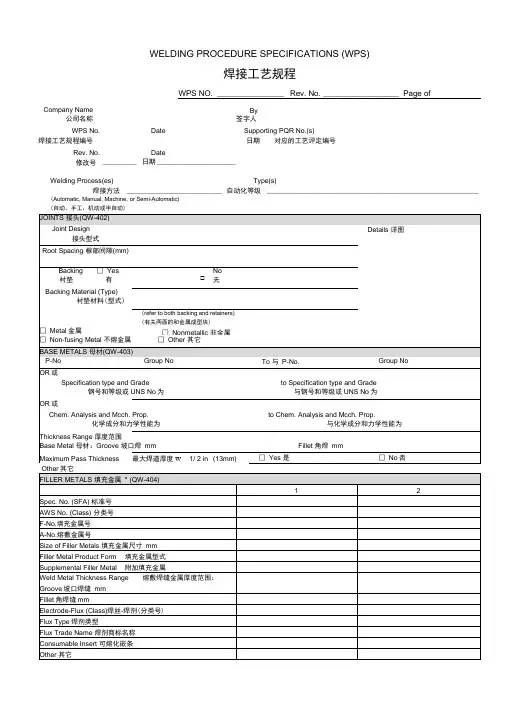

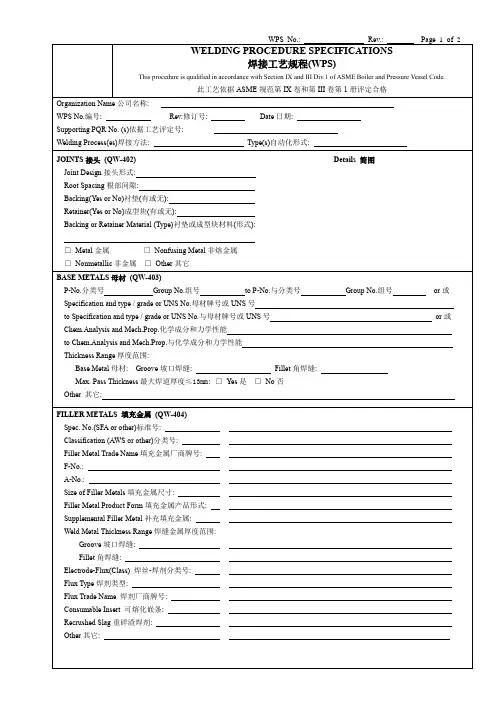

WELDING PROCEDURE SPECIFICATIONS (WPS)焊接工艺规程WPS NO. _______________ Rev. No. _________________ Page ofBy 签字人DateSupporting PQR No.(s) 日期 对应的工艺评定编号Date__________ 日期 _______________________ Welding Process(es) Type(s) 焊接方法 ____________________________ 自动化等级 ______________________________________________________________(Automatic, Manual, Machine, or Semi-Automatic) (自动、手工、机动或半自动)Company Name公司名称 WPS No.焊接工艺规程编号Rev. No.修改号*Each base metal-filler metal combination should be recorded individually.WELDING PROCEDURE SPECIFICATIONS (WPS)焊接工艺规程WPS NO. _________________ Rev. No. ___________________ Page ofPulsing Current 脉冲电流Heat Input ( Max.)热输入(最大)Tungsten Electrode Size and Type ( Pure Tungsten,2Thoriated etc.)钨极尺寸和型号(纯钨,2%钍钨极等) Mode of Metal Transfer for GTAW (FCAW) ( Spray Arc, Short Circuiting Arc, et 熔滴过渡型式(射流或短路)Electrode Wire Feed Speed Rang 送丝速度范围 ______________________________________________________________________________________Other 其它TECHNIQUE 焊接技术(QW-410)Stri ng or Weave Bead 直进焊或摆动焊 ______________________________________________________________________________________ Orifice or Gas Cup Size 嘴孔或喷嘴尺寸 mmInitial and Interpass Cleaning打底焊道和中间焊道的清理方法(Brushing, Grinding, etc.)( 刷理或打磨等等) ______________________Method of Back Gouging背面清根方法Oscillati on 横摆方法 ________________________________________________________________________________________________________ Con tact Tube to Work Dista nee 导电嘴至工件距离 ____________________________________________________________________________ Multiple or Single Pass 多道焊或单道焊 (Per Side)( 每侧) _________________________________________________________________ Multiple or Single Electrodes 多丝焊或单丝焊Travel Speed 焊接速度(Range)(范围) _________________________________________________________________________________Peening 锤击Use of thermal processes 使用热工艺 _______________________________________________________________________________________ Other 其它对于每一母材-填充金属的组合均需分别填表Date 日期。

DHME 压力容器焊接手册(ASME规范)焊接科-焊接技术系2007年目录第一章 总则1.1目的1.2适用范围1.3参考文献第二章 设计规范2.1 编制WPS2.2 评定PQR2.3 设备焊接坡口设计第三章 采购要求3.1 焊接材料采购技术要求3.2 焊接材料选择指南第一章 总则1.1目的作为焊接ASME规范容器的参考基准。

1.2 适用范围本手册适用于按照ASME规范建造的压力容器焊接的设计、采购、检验等。

1.3参考文献1)ASME规范第VIII-1卷。

2)ASME规范第VIII-2卷。

3)ASME规范第IX卷。

4)ASME规范第II-C卷。

第二章 设计规范2.1 焊接工艺规程WPS2.1.1 工艺评定用焊接工艺规程工件焊接前,应编制工艺评定用焊接工艺规程(格式如正式的焊接工艺规程),评定试件应按工艺评定用焊接工艺规程焊接。

此焊接工艺规程在工艺评定合格前,不得用于正式产品焊接。

2.1.2 合格的焊接工艺规程工艺评定合格后,根据工艺评定的记录(电流、电压、焊接速度等),修改工艺评定用焊接工艺规程而编制出合格的焊接工艺规程。

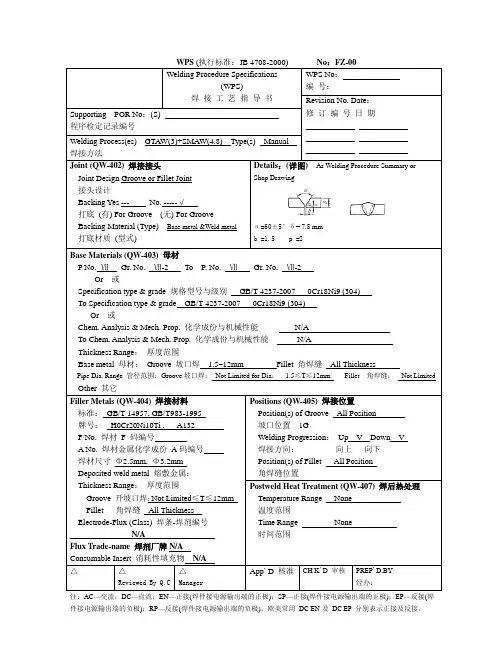

2.2 焊接工艺规程的格式及填表方法如下:焊接工艺规程WELDING PROCEDURE SPECIFICATIONS (WPS)Company Name 公司名称 (1) Reviewed By:签字人 (2) Welding Procedure Specification No.WPS 编号 (3) Date 日期 (4) Supporting PQR No.(s)所依据的PQR编号 (5) Revision No.修改文件号 (6) Date 日期 (7)Welding Process(es) 焊接方法 (8) Type(s)自动化等级(自动,手工,机动或半自动) (9) (Automatic, Manual, Machine, or Semi-Auto.)* Each base metal-filler metal combination should be recorded individually对于每一种母材—填充金属的组合均需分别填表焊接工艺规程WELDING PROCEDURE SPECIFICATION (WPS)WPS No. Rev.POSITION QW-405 焊接位置Position(s) of Groove 坡口的位置 (31) Welding Progression: Up 向上 (32) Down 向下 (32) Position(s) of Fillet 角焊缝位置 (33) POSTWELD HEAT TREATMENT QW-407 焊后热处理Temperature Range 温度范围 (37) Time Range 时间范围 (38)Preheat QW-406 预热Preheat Temp. Min.预热温度最小 (34) Interpass Temp. Max.层间温度最大 (35) Preheat Maintenance预热的保持方式 (36) (Continuous or special heating where applicable should be recorded) GAS QW-408 气体Percent Composition 百分组成Gas(es) (Mixture) Flow Rate气体 (混合保护气体) 流量Shielding 保护气体 (39) Trailing尾部保护气体 (40) Backing背面保护气 (41)ELECTRICAL CHARACTERISTICS QW-409电特性Current AC or DC 交流或直流 (42) Polarity极性 (43)Amps(Range) 安培(范围) (44) Volts(Range)伏特(范围) (45)(Amps and Volts range should be recorded for each electrode size,position, and thickness, etc. This information may be listed in a tabularform similar to that shown below.)(安培和伏特范围应按每种焊丝尺寸,位置和厚度等分别记录,可按以下表的方式记录)Tungsten Electrode Size and Type (46)钨极规格和类型 (Pure Tungsten,2%Thoriated etc.)(纯钨极或2%钍钨极等) Mode of Metal Transfer for GMAW (47)金属过渡方式(GMAW) (Spray arc,short circuiting arc,etc)(射流或断路等) Electrode wire feed speed range (48)送丝速度范围TECHNIQUE QW-410String or Weave Bead无摆动焊或摆动焊 (49) Orifice or Gas Cup Size嘴孔或喷嘴尺寸 (50) Initial and Interpass Cleaning (Brushing,Grinding,etc)打底焊道和中间焊道的清理方法(清理和打磨等等) (51) Method of Back Gouging背面清理方法 (52) Oscillation摆动 (53) Contact Tube to Work Distance导电嘴—工件距离 (54) Multiple or Single Pass (Per side)多道焊或单道焊(每边) (55)Multiple or Single Electrodes多丝焊或单丝焊 (56) Travel Speed(Range)焊接速度(范围) (57) Peening锤击 (58) Other其它 (59)焊层 焊接方法 填充金属Filler Metal电流Current电压范围焊接速度范围其它例如:备注,说明,加热丝,施焊技术,焊炬角度等等Weld Layer(s) Process 种类Class直径Dia.极性Type Polar安培Amp RangeVolt Range TravelSpeedRangeOther(e.g. Remarks,Comments,Hot WireAddition, Technique, Torch Angle,Etc.)(60)PREPARED BY 编制 DATE日期 APPROVED BY 批准 DATE日期(1) 公司名称 如“大连日立机械设备有限公司”(2) 签字人 通常由DHME质保部-质保科长签字(3) WPS 编号 DHME编号规则AWPS+年号+流水号(4) 日期(5) PQR编号 支持工艺规程的PQR,编号规则APQR+年号+流水号(6) 修改文件号 从0开始(7) 日期(8) 焊接方法 SMAW+SAW或GTAW(9) 自动化等级 焊接方法的自动化程度,如:SMAW:手工GMAW&FCAW:半自动SAW:机动或自动GTAW:手工或自动(10) 接头 接头形状单面V形,双面V形,单面U形,双面U形,角焊缝,坡口焊缝&角焊缝,堆焊焊缝(11) 衬垫 记为 “√”,双面焊作为有垫板对待(12) 衬垫材料 如SA516-70,或母材及焊缝金属(13) 母材分类号 查QW-422,或AWS B2.1(14) 母材组号 查QW-422,或AWS B2.1若无冲击试验要求,此处可不填写“N/A”(15) 规格型号和等级 母材的型号和等级SA240-304(16) 化学成分和力学性能 母材的化学成分和力学性能填入无P-No.的母材的化学成分和力学性能(17) 坡口焊,母材厚度范围 按照QW-450(18) 角焊,母材厚度范围 按照QW-202.1,QW-451.3,QW-451.4,通常为“不限”(19) 坡口焊的管径范围 管件焊接时,填入管径(20) 角焊的母材厚度范围 通常为“不限”(21) 填充金属的ASME SFA号,或AWS A号 如“5.1”等或“GB/T5117”(22) 填充金属的等级 如“E7016”如“ER70S-2”(23) 填充金属的F-No. 按QW-432,无分类号填入“-”(24) 填充金属的A-No. 按QW-442,可按熔敷金属的化学分析结果、标准值、质量证明书(应注意焊接方法,焊接条件应与产品一致)(25) 填充金属尺寸 填充金属的尺寸(26) 坡口焊缝金属厚度 根据评定的结果填写(27) 角焊缝焊缝金属厚度 通常为“不限”(28) 焊丝-焊剂(等级) 填写焊丝和焊剂的型号,如“F7A2-EH14”(29) 焊剂牌号 当有冲击试验要求时,填写焊剂的“商品牌号”,如“G-80”当焊接高合金时,如奥氏体不锈钢时,必须填写焊剂的“商品牌号”,如“AT-SJ601”(30) 熔化性填充 当使用熔化性嵌条时,填写嵌条的类型,商品名称(31) 坡口的位置 坡口焊的位置,应按照评定结果,1G-6G(32) 焊接行进方向 3G,3F,5G,6G位置时必须填写,按照评定结果,“√”(33) 角焊缝位置 角缝焊接的位置,应按照评定结果,1F-4F(34) 预热温度 最低的预热温度,按照评定结果,堆焊时应分层填写,QW-406.1,QW-281.2(e) (35) 层间温度 最高的层间温度,按照评定结果, QW-406.3,QW-281.2(e)(36) 预热的保持方式 填入预热保持方法,需要消氢处理时,填入后热规范(37) 焊后热处理温度范围 按照焊接工艺评定,或“-”(38) 焊后热处理保温时间 焊后热处理的保温时间范围,按照评定结果(有冲击试验要求时),或“-” (39) 保护气体的类别,混合比,气体流量 按照评定结果(40) 尾部保护气体的类别,混合比,气体流量按照评定结果(41) 背面保护气体的类别,混合比,气体流量 按照评定结果(42) 电流 DC或AC(43) 电流极性 RP与SP,EN与EP,DC+与DC-,AC无极性之分(44) 焊接电流范围(45) 电弧电压范围(46) 钨极类型和尺寸 按照ISO6848,SFA-5.12(47) GMAW的金属过渡形式 短路过渡,颗粒过渡,喷射过渡(48) 送丝速度范围QW-409.8 以送丝速度代表电流控制时,填入送丝速度(49) 焊接技巧QW-409.10 直焊,摆动,直焊或摆动(50) 喷孔或喷嘴尺寸QW-410.3 GMAW,GTAW,PAW喷嘴的尺寸(51) 层道清理方法QW-410.5 打磨,打磨或刷(52) 背面清理方法QW-410.6 碳弧气刨,打磨,机加工(53) 机械摆动的参数QW-410.7 当采用机械摆动装置时,填入摆动的频率和幅度(54) 导电嘴-工件距离(干伸长)QW-410.8 SAW:30-40cmGMAW&FCAW:10-25cm(55) 多道焊或单道焊QW-410.9 填入“单道”或“多道”(56) 电极数 如:SAW:单丝SAW:双丝(57) 焊接速度(58) 锤击QW-410.5 填入“是”,“否”(59) 其它(60) 焊接规范 填入评定合格的焊接规范2.2 焊接工艺评定记录PQR焊接工艺评定记录PQR的格式和填写规则如下:焊接工艺评定记录PREHEAT QW-406预热Preheat Temp.预热温度 (25) Interpass Temp.层间温度 (26) Other其它 (27) 侧) (43) Single or Multiple Electrodes多丝焊或单丝焊 (44) Other其它 (45)焊接工艺评定记录PROCEDURE QUALIFICATION RECORD (PQR) PQR NO.Tensile Test QW-150 拉力试验Specimen No.试样号 Width宽Thickness厚Area面积UltimateTotal Load NUltimateUnit Stress MPaType of Failure& Location(46) (47) (48) (49) (50) (51) (52)Guide-Bend Tests QW-160 导引弯曲试验Type and Figure No. 类型和编号 Result 结果(53) (54)Toughness Test QW-170 韧性试验Specimen No. Notch Location Notch Type Test Temp.Impact Values Lateral Exp.侧向膨胀 Drop Weight 落锤试验试样号 缺口位置 缺口类型 试验温度冲击值 % Shear mm Break 断裂 No Break 不断裂(55) (56) (57) (58) (59) (60) (61) (62) (63)Fillet-Weld Test 角焊缝试验Result-Satisfactory: Yes No (64) Penetration into Parent Metal: Yes No 结果满意 是 否 熔透母材: 是 否 Macro-Results (65) 低倍检查结果Other Tests其它试验Type of test试验类型 (66) Deposit Analysis熔敷金属成分 (67) Other其它 (68) Welder's Name 焊工姓名 (69) Clock No.工号 (70) Stamp钢印 (71) Tests conducted by:执行人 (72) Laboratory Test No.实验室试验编号 (73) We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance with the requirements of Section Ⅸ of the ASME Code.MANUFACTURER 制造厂 PREPARED BY 编制 DATE 日期 CERTIFIED BY 证明 DATE 日期 REVIEWED BY 签字 DATE 日期PQR填写规则:序号内容详细(1)公司名(2) PQR编号(3)日期评定合格日期(4) WPS编号及版号用于施焊评定试件的WPS(5)焊接方法(6)自动化等级 SMAW:手工GTAW:手工、自动SAW:机械化GMAW&FCAW:半自动(7)接头评定试件的坡口形式及焊道层、道布置(8)材料标准如“SA-516”(9)型号和等级“70”(10) P-No. 按QW-422(11) P-No. 按QW-422(12)试件厚度(13)试件直径(14)其它(15) SFA标准如“5.1”(16) AWS等级如“E7016”(17)填充金属F-No. 如“6”(18)焊缝金属A-No. 如“1”,可根据SFA标准、质量证明书、化学分析报告等依据(19)填充金属规格如“Φ4.0”(20)其它(21)焊缝金属厚度如“6.0mm”,对于每种焊接方法,应分别测量。

ASME IX Q235C焊接工艺规程WPS__________ 有限公司焊接工艺规程(WPS)公司名称:Company Name__________ 有限公司编制 Prepared审批rovedWPS NO.WPS-1801 版本 REV.A 日期 Date20__.01.30 PQR No PQR-1801 焊接方法Welding ProcessGMAW 自动化程度TYPE(S)半自动焊 Semi-automatic welding 接头 JOINTS (QW-402)详图:接头型式:坡口对接或角焊缝 Joint Design:Groove or Fillet根部间隙:见接头图 See Sketchthe root spacing 衬垫 Backing :GMAW:有或无With or Without 定位块 Retainers :有或无With or Without接头型式按图纸要求 Joint design may be per licable drag requirement 母材Base Metals(QW-403)材料标准号 Base Metal Specification :GB/T 700-20__6 ;材料等级Grade :Q235C 评定的厚度范围:Thickness Range: 母材Base Metal:坡口焊缝Groove:16-20__mm角焊缝Fillet:所有 All最大焊道厚度 Ma_imum pass thickness :≤13mm焊接方法 Welding ProcessGMAW 填充金属 Filler Metals(QW-404)SFA No.SFA-5.18/AWS A5.18 ER70S-6 F-No.6 A-No.1 填充金属尺寸 Size of Filler Metals Φ1.2mm 焊丝-焊剂标准和型号Flu_/wire specification classGB/T 8110,ER50-6 评定的焊缝金属厚度范围 Weld Metal Thickness Range: 坡口焊缝 Groove Ma_:20__mm 角焊缝 Fillet 所有 All 焊接位置POSITIONS (QW-405)坡口焊缝位置 Position(s) of Groove1G 角焊缝焊缝位置 Position(s) of Fillet1F,2F 焊接方向 Welding Progression:向上 Up向上 Up预热 PREHEAT (QW-406)预热温度和预热方式Preheat Temperature and Preheat MethodMinimum100℃;火焰或电加热 Flame or Electric最高层间温度Interpass Temperature, Ma_imum300℃ 预热保持时间和温度Preheat Maintenance 不要求 Not required焊后热处理 POSTWELD HEAT TREATMENT(QW-407)None 温度范围 Temperature Range / 时间范围 Time Range / 气体 GAS (QW-408)N/A气体 Gas(es) 混合比量 Mi_ture 流量 Flow Rate 焊接保护气 Shielding Ar+CO 278-82Ar+18-22CO 215-25 L/Min 尾部保护气 Trailing 无 No -- -- 背面保护气 Backing 无No -- -- 焊接技巧 TECHNIQUE(QW-410)直进焊或摆动焊 String or Weave Bead 摆动或直进焊 Weave Bead or string 嘴孔或喷嘴尺寸 Orifice or Gas Cup SizeΦ16-22mm 打底焊道和中间焊道的清理方法 Initial and Interpass Cleaning 刷或打磨 Brushing or Grinding 背面清根方法 Method of Back Gouging 需要时,采用气刨、机械加工、凿或打磨的方法 Arc-gouging, machining, chipping or grinding, when licable 导电嘴至工件距离 Tube-work distance 10-20mm 每侧多道焊或单道焊 Multiple or Single Pass (Per Side) 多道焊 Multiple pass 多丝焊或单丝焊 Multiple or Single Electrodes 单丝焊 Single Electrode锤击有无 Penning 有或无 With or without。

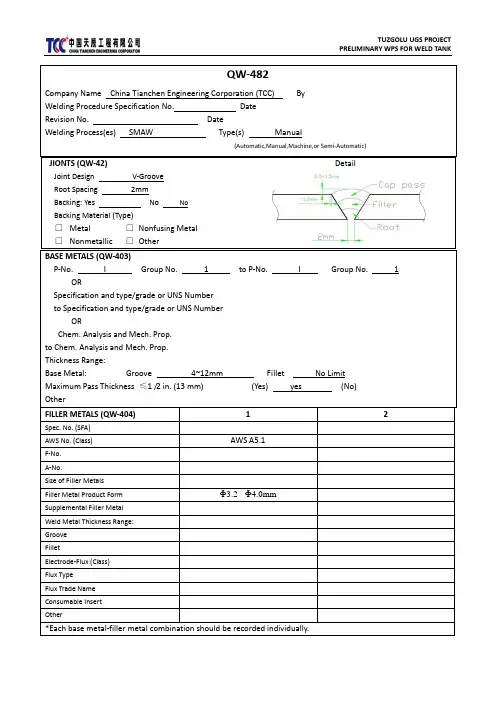

QW-482Company Name China Tianchen Engineering Corporation (TCC) ByWelding Procedure Specification No. DateRevision No. DateWelding Process(es) SMAW Type(s) Manual(Automatic,Manual,Machine,or Semi-Automatic)JIONTS (QW-42) DetailJoint Design V-GrooveRoot Spacing 2mmBacking: Yes No NoBacking Material (Type)□Metal □Nonfusing Metal□Nonmetallic □OtherBASE METALS (QW-403)P-No. I Group No. 1 to P-No. I Group No. 1 ORSpecification and type/grade or UNS Numberto Specification and type/grade or UNS NumberORChem. Analysis and Mech. Prop.to Chem. Analysis and Mech. Prop.Thickness Range:Base Metal: Groove 4~12mm Fillet No LimitMaximum Pass Thickness ≤1 /2 in. (13 mm) (Yes) yes (No)OtherFILLER METALS (QW-404) 1 2 Spec. No. (SFA)AWS No. (Class) AWS A5.1F-No.A-No.Size of Filler MetalsFiller Metal Product Form Ф3.2 - Ф4.0mmSupplemental Filler MetalWeld Metal Thickness Range:GrooveFilletElectrode-Flux (Class)Flux TypeFlux Trade NameConsumable InsertOther*Each base metal-filler metal combination should be recorded individually.QW-482 (Back)WPS No. Rev.POSITIONS (QW-405)Position(s) of Groove 4G Welding Progression: Up √Down Position(s) of Fillet 4G Other POSTWELD HEAT TREATMENT (QW-407) Temperature Range —Time Range —Other —PREHEAT (QW-406)Preheat Temperature, Minimum —Interpass Temperature, Maximim —Preheat Maintenance —Other GAS (QW-408)Percent CompositionGas(es) (Mixture) Flow RateShieldingTrailingBackingOtherELECTRICAL CHARACTERISTICS (QW-409)Weld Pass(es) ProcessFiller MetalCurrentType andPolarityAmps(Range)(A)WireFeedSpeedEnergy orPower(J/mm)Volts(V)TravelSpeed(mm/min)Other Classification DiameterRoot Filler Cap SMAWSMAWSMAWA5.1 E7018A5.1 E7018A5.1 E70183.2mm3.2/4.0mm3.2/4.0mmDC (+)DC (+)DC (+)90-130120-190120-1801900-20001970-25902000-259018-2618-2618-2650-10050-15050-140Pulsing Current Heat Input (max.)Tungsten Electrode Size and TypeMode of Metal Transfer for GMAW (FCAW)OtherTECHNIQUE (QW-410)String or Weave BeadOrifice, Nozzle, or Gas Cup SizeInitial and Interpass Cleaning (Brushing, Grinding, etc.) Glassing Machine or Wire BrushMethod of Back Gouging Scarfing or Glassing MachineOscillation SwingContact Tube to Work DistanceMultiple or Single Pass (Per Side) SingleMultiple or Single ElectrodesElectrode SpacingPeeningOther。

浙江嘉善鑫海精密铸件有限公司ZHEJIANG LINJIA CHANGLONG VALVE CASTING CO.,LTD焊接工艺评定记录PROCEDURE QUALIFICATION RECORDS (PQR)TENSILE TEST(QW-150)〈拉伸试验〉嘉善鑫海精密铸件有限公司ZHEJIANG LINJIA CHANGLONG VALVE CASTING CO.,LTD焊接工艺评定记录PROCEDURE QUALIFICATION RECORD (PQR)GUIDED BEND TEST (QW-160) 〈引导弯曲试验〉TOUGHNESS TESTS(QW-170)〈韧性试验〉FILLET WELD TEST (QW-180) 〈角焊缝试验〉Result-Satisfactory: ■ Yes □No Penetration Into Parent Metal: ■ Yes □No 结果:合格□不合格熔透母材:■合格□不合格Macro-Results (宏观试验): N/AOTHER TEST (其它试验)Type of Test(试验类型): PT(1008PT112) RT(1008RT0807) Deposit Analysis(金相及成分分析):C:0.22, Si:0.38, Mn:0.85, P:0.021, S:0.014, Cr:0.075, Ni:0.071, Mo:0.032, Cu:0.030, V:0.001 (L183) Other(其它): N/AWelder’s Name(焊工姓名):季忠敏 Clock No.(证件号): 33252219721222473 Test Conducted by(试验执行人):季忠敏 Stamp No.(钢印号): L184 Laboratory Test No.(试验编号):CS-01/CS-05-1 CS-01/CS-05-2 CS-01/CS-05-3 CS-01/CS-05-4 CS-01/CS-05-5 CS-01/CS-05-6We certify that the statements in this record are correct and that the test welds were prepared,welded and tested in accordance with the requirements of Section Ⅸ of the ASME Code.我们确保此焊接工艺的准备、焊接和试验均按照ASME规范第Ⅸ卷进行。

WELDING PROCEDURE SPECIFICATIONS (WPS)焊接工艺规程WPS NO. _______________ Rev. No. _________________ Page ofBy 签字人DateSupporting PQR No.(s) 日期 对应的工艺评定编号Date__________ 日期 _______________________ Welding Process(es) Type(s) 焊接方法 ____________________________ 自动化等级 ______________________________________________________________(Automatic, Manual, Machine, or Semi-Automatic) (自动、手工、机动或半自动)Company Name公司名称 WPS No.焊接工艺规程编号Rev. No.修改号*Each base metal-filler metal combination should be recorded individually.WELDING PROCEDURE SPECIFICATIONS (WPS)焊接工艺规程WPS NO. _________________ Rev. No. ___________________ Page ofPulsing Current 脉冲电流Heat Input ( Max.)热输入(最大)Tungsten Electrode Size and Type ( Pure Tungsten,2Thoriated etc.)钨极尺寸和型号(纯钨,2%钍钨极等) Mode of Metal Transfer for GTAW (FCAW) ( Spray Arc, Short Circuiting Arc, et 熔滴过渡型式(射流或短路)Electrode Wire Feed Speed Rang 送丝速度范围 ______________________________________________________________________________________Other 其它TECHNIQUE 焊接技术(QW-410)Stri ng or Weave Bead 直进焊或摆动焊 ______________________________________________________________________________________ Orifice or Gas Cup Size 嘴孔或喷嘴尺寸 mmInitial and Interpass Cleaning打底焊道和中间焊道的清理方法(Brushing, Grinding, etc.)( 刷理或打磨等等) ______________________Method of Back Gouging背面清根方法Oscillati on 横摆方法 ________________________________________________________________________________________________________ Con tact Tube to Work Dista nee 导电嘴至工件距离 ____________________________________________________________________________ Multiple or Single Pass 多道焊或单道焊 (Per Side)( 每侧) _________________________________________________________________ Multiple or Single Electrodes 多丝焊或单丝焊Travel Speed 焊接速度(Range)(范围) _________________________________________________________________________________Peening 锤击Use of thermal processes 使用热工艺 _______________________________________________________________________________________ Other 其它对于每一母材-填充金属的组合均需分别填表Date 日期。

ASME,IX,Q345B焊接工艺评定报告PQR-1907XXXXXXXXXX有限公司焊接工艺评定报告(PQR)公司名称:CompanyNameXXXXXXXXXX有限公司PQRNoPQR-1907日期Date2019.09.02WPSNO.WPS-1907焊接方法WeldingProcessSAW自动化程度TYPE(S)机械化焊Machine接头JOINTS(QW-402)衬垫Backing:无Without成型块Retainers:无Without母材BaseMetals(QW-403)材料标准号BaseMetalSpecification:GB/T3274;材料等级Grade:Q345B与to材料标准号BaseMetalSpecification:GB/T3274;材料等级Grade:Q345B相焊;试件厚度BaseMetalThickness:40mm;试件直径BaseMetalDiameter:/最大焊道厚度Maximumpassthickness:13mm焊接方法WeldingProcessSAW填充金属FillerMetals(QW-404)SFANo.SFA5.17F7P0-EH14F-No.6A-No.1焊丝/焊剂商标牌号Wire/Fluxdesignation/tradenameH10Mn2/HJ431焊丝/焊剂生产厂家Wire/FluxManufacturer常州市运河焊材有限公司/池州市秋浦焊剂厂焊丝/焊剂标准和型号Wire/FluxspecificationclassGB/T14957/GB/T5293F5P0-H10Mn2填充金属尺寸SizeofFillerMetals5.0mm评定的焊缝金属厚度WeldMetalThickness:40mm焊剂类型Fluxtype中性Neutral可熔化嵌条ConsumableInsert--回用重碎渣Recrushedslag不使用Without附加填充金属Supplemental不使用Without合金元素成分Alloyflux不使用Without合金焊剂成分Alloyelements不使用Without焊接位置POSITIONS(QW-405)焊接位置Position(s)1G焊接方向WeldingProgression:--预热PREHEAT(QW-406)预热温度和预热方式PreheatTemperatureandMethod100℃,电加热Electric最高层间温度InterpassTemperature,Maximum300℃预热保持时间和温度PreheatMaintenanceNone焊后热处理POSTWELDHEATTREATMENT(QW-407)温度范围TemperatureRange590-600℃时间范围TimeRange3.5h气体GAS(QW-408)N/A气体Gas(es)混合比量Mixture流量FlowRate焊接保护气Shielding------尾部保护气Trailing------背面保护气Backing------焊接技巧TECHNIQUE(QW-410)直进焊或摆动焊StringorWeaveBead直道焊StringBead嘴孔或喷嘴尺寸OrificeorGasCupSize--打底焊道和中间焊道的清理方法InitialandInterpassCleaning打磨Grinding背面清根方法MethodofBackGouging气刨+打磨Arc-gougingandgrinding每侧多道焊或单道焊MultipleorSinglePass(PerSide)多道焊MultiplePass多极焊或单极焊MultipleorSingleElectrodes单极焊SingleElectrode锤击有无Peening无None导电嘴到工件距离Tube-workdistance25-30mm电特性ELECTRICALCHARACTERISTICS (QW-409)焊层WeldLayers焊接方法Process填充金属FillerMetal电流Current电压VoltRange(V)焊接速度TravelSpeedRange(mm/min)热输入HeatInput(J/mm)备注Remarks种类Class直径Dia.(mm)类型和极性Polar安培Amp.RangeAllSAWH10Mn2+HJ4315.0直流反接DCEP500-80028-34350-5001680-4663注Note:QW-403.13,QW-407.4;QW-408.10,QW-410.11,QW-410.64Notapplicab le.拉伸试验(QW-150)TensileTest试样号*SpecimenNo宽厚WidthThickness(mmmm)面积Area(mm2)极限总载荷UltimateTotalLoad(kN)极限单位应力TensileStrength(MPa)破坏性质和位置TypeofFailureLocationPQR-1907-I139.6618.98752.75402.72535塑性断于母材Ductile,BasemetalPQR-1907-I239.4618.86744.22394.43530塑性断于母材Ductile,Basemetal*QW-462.1(a)导向弯曲试验(QW-160)GuidedBendTest类型和图号TypeandFigureNo结论ResultPQR-1907-1侧弯Sidebend, QW-462.2按QW-163(4T,180)试验合格AcceptedpreQW-163(4T,180)PQR-1907-2侧弯Sidebend,QW-462.2按QW-163(4T,180)试验合格AcceptedpreQW-163(4T,180)PQR-1907-3侧弯Sidebend,QW-462.2按QW-163(4T,180)试验合格AcceptedpreQW-163(4T,180)PQR-1907-4侧弯Sidebend,QW-462.2按QW-163(4T,180)试验合格AcceptedpreQW-163(4T,180)冲击试验(QW-170)ToughnessTest试样号SpecimenNo缺口位置NotchLocation缺口型式NotchType试样尺寸Specimensize试验温度TestTemp冲击功ImpactValues(J)结论ResultPQR-1907I1焊缝WeldV10105520℃128合格AcceptedPQR-1907I2103PQR-1907I3122PQR-1907I4热影响区HAZ136PQR-1907I5153PQR-1907I6154角焊缝试验FilletWeldTest(QW-180)N/A结果是否满意Result---Satisfactory:是Yes否No;熔透母材PenetrationintoParentMetal:是Yes否No宏观检测结果Macro-Result其它试验OtherTests试验类型TypeofTest超声检测UT:UT-PQR1907-01,Accepted熔敷金属成分DepositAnalysisN/A其它OtherN/A焊工姓名WeldersNameXXXX上班考勤号ClockNo--钢印号StampNo01试验执行人TestConductedby:xxxxxx实验室实验编号LaboratoryTestNo2019-LX0355/0356/0357兹证明本报告所述均属正确,并且试验是根据ASME规范第IX卷的要求进行试样的准备、焊接和试验的。

Contract Title合同名称Shanghai Secco Petrochemicals Company Limited上海赛科石油化工有限责任公司Integrated Project Management Team一体化项目管理组Caojing, Shanghai, P R China中国上海漕泾Document Title文件名称standard for piping welding管道焊接标准DOCUMENT NUMBER文件编号SD-00-TSC-MS-0025English language is the "original" language and if inconsistencies exist between English and Chinese versions, the English version takes precedence and the English version is the legally binding version.原本以英文书就,如果英文和中文版本之间存在不一致,以英文版本为准,英文版本具有法律约束力。

A00 The Chinese translation done on A00(从A00版开始有中文翻译)29/11/02A00 APPROVED AT 18/06/02 ES 18/06/02 MC 18/06/02 HYC 19/06/02 P02 Reviewed by SJEC YJC 04/06/02P01 Reviewed by SEI YQZ 30/05/02 ZBJ 30/05/02P00 FOR REVIEW AT 03/05/02 MC 03/5/02 MC 03/05/02Issue Rev Issue or Revision Description Origin by D ate CheckbyDate ApprovebyDate ApprovebyDateThis Document is Owned by 本文件持有人Henry Chen (HC) IPMT AuthorityIPMT授权批准硬拷贝为非受控文件STANDARD FOR PIPING WELDING管道焊接标准TABLE OF CONTENTS目录1.0 SCOPE范围2.0 Supplier RESPONSIBILITY供货商职责3.0 REGULATIONS规则3.1 C ODES规范3.2 R EFERENCE S PECIFICATIONS参考规范4.0 FABRICATION制配4.1 W ELDING P ROCESSES AND R ESTRICTIONS焊接方法和限定4.2 F ILLER M ETALS填充金属4.3 C LAD P LATE AND O VERLAY W ELDING包层板和堆焊4.4 W ELD O VERLAY P ROCEDURE Q UALIFICATIONS堆焊工艺评定4.5 G ENERAL W ELDING R EQUIREMENTS总的焊接要求4.6 P REHEAT AND I NTERPASS T EMPERATURE焊前预热和层间温度4.7 P OST W ELD H EAT T REATMENT (PWHT)焊后热处理5.0 ADDITIONAL REQUIREMENTS补充要求5.1 R EPAIR修补5.2 B ASIC R EQUIREMENTS FOR W ORKING D URING U NFAVORABLE W EATHER C ONDITIONS对工作期间不适宜的气候条件的基本要求6.0 INSPECTION AND TESTING检验和试验6.1 W ELD Q UALITY AND W ELD I NSPECTION焊缝质量和焊缝检查6.2 V ISUAL T ESTING外观检查6.3 I N-P ROCESS E XAMINATION中间检查6.4 G ENERAL N ON-D ESTRUCTIVE E XAMINATION (NDE)R EQUIREMENTS总的无损检验要求6.5 M AGNETIC P ARTICLE T ESTING (MT)磁粉检验(MT)6.6 L IQUID P ENETRANT T ESTING (PT)液体渗透检验(PT)6.7 R ADIOGRAPHIC T ESTING (RT)射线检验(RT)6.8 U LTRASONIC T ESTING (UT)超声波检验(UT)6.9 W ELD H ARDNESS T ESTING焊缝硬度试验6.10 F ERRITE C ONTROL铁素体控制6.11 P OSITIVE M ATERIAL I DENTIFICATION (PMI)精确材料鉴定6.12 P IPE W ELDS:E XTENT OF E XAMINATION管道焊接:检验范围7.0 REQUIREMENTS FOR SUPPLIER OR SUB-CONTRACTOR DOCUMENTS对供货商及分包商的文件要求7.1 QA / QC Plan QA / QC计划7.2 W ELDING P ROCEDURE S PECIFICATIONS (WPS'S)焊接工艺规定(WPS'S)7.3 P ROCEDURE Q UALIFICATION R ECORDS (PQR'S)工艺评定记录7.4 W ELD M ATRIX T ABLE焊缝矩阵表7.5 W ELD M APPING焊缝图7.6 NDE P ROCEDURES无损检验流程7.7 PWHT P ROCEDURES 焊后热处理流程1.0 SCOPE范围This standard covers the minimum welding requirements to be met for shop andfield fabricated piping including piping components such as valves, weld overlayedflanges and piping specialty items. The requirements for the welding of pipingwhich are supplied as part of an equipment package are outside the scope of thisstandard该标准涉及车间及现场制配管道应予满足的最低的焊接要求,包括管件,诸如阀门、堆焊法兰和某些管道专业内容,作为整套设备构成部分的管道的焊接要求不适用于该标准。

中某一P-No.改变为另一P-No.,或改变为任何其他母材。

如接头是由不同P-No.的两母材焊接而成,则即使两者已分别作过评定,工艺评定仍应按P-No.的组合来进行。

QW-403.2 The maximum thickness qualified is the thickness of the test coupon. QW-403.3 For full penetration single-sided welds without backing, where the meas-urement of penetration can be made by visual or mechanical means, requalification is re-quired when the base metal thickness is more than 20% thicker than that qualified when thetest coupon thickness is 1 in. (25 mm) and under, and more than 10% thicker when the testcoupon thickness is over 1 in. (25 mm). Where the measurement of penetration cannot bemade, requalification is required when the base metal thickness is more than 10% thicker thanthat qualified when the test coupon thickness is 1 in. (25 mm) and under, and more than 5%thicker when the test coupon thickness is over 1 in. (25 mm).评定的最大厚度是试件的厚度对于无衬垫单面焊全焊透焊缝,如可能用目视或机械方法测定溶深时,当试件厚度不大于1in.(25mm),母材比评定厚度大20%以上;或试件厚度为1in.(25mm)以上,母材比评定厚度大10%以上,则需重新进行评定。

如溶深不能测定,当试件厚度不大于1in.(25mm),母材比评定厚度大10%以上;或试件厚度为1in.(25mm)以上,母材比评定厚度大5%以上,则需重新进行评定。

QW-403.3○15(a)For full penetration single-sided welds without backing wherethe verification of penetration can be made, an increase of more than 20% in base metalthickness when the test coupon thickness is less than or equal to 1 in. (25 mm), and more than10% in base metal thickness when the test coupon thickness is greater than 1 in. (25 mm).对于確認已達到全焊透支无衬垫单面焊焊缝,且试件厚度不大1 in. (25 mm),母材厚度比评定厚度大20% 以上;或试件厚度为1 in. (25 mm)以上,母材厚度比评定厚度大10% 以上(b)For all other welds, an increase of more than 10% in base metalthickness when the test coupon thickness is less than or equal to 1 in. (25 mm), and more than5% in base metal thickness when the test coupon thickness is greater than 1 in. (25 mm). 对于其他之焊缝,试件厚度不大1 in. (25 mm),母材厚度比评定厚度大20% 以上;或试件厚度为1 in. (25mm) 以上,母材厚度比评定厚度大5% 以上QW-403.4Welding procedure qualifications shall be made using a base metal of the same type or grade or another base metal listed in the same group (see TableQW∕QB-422) as the base metal to be used in production welding. When joints are to be madebetween base metals from two different groups, a procedure qualification must be made forthe applicable combination of base metals, even though procedure qualification tests havebeen made for each of the two base metals welded to itself.焊接工艺评定应当采用与实际焊接生产所用母材具有相同的型号、等级,或相同组号的另一种母材(见表QW∕QB-422)。

如接头是由两种不同组号的母材组合而成的,则即使两者分别各自做过工艺评定,亦必须按这种组合来进行工艺评定。

QW-403.5 Welding procedure specifications shall be qualified using one of the following:焊接工艺评定应使用:(a)the same base metal (including type or grade) to be used in pro-duction welding使用与产品焊接相同的母材(包括型号或等级);或(b)for ferrous materials, a base metal listed in the same P-NumberGroup Number in Table QW∕QB-422 as the base metal to be used in production welding对于铁基材料,使用与产品焊接有相同P-No.和组号的母材(QW∕QB-422 表所列);或(c) for nonferrous materials, a base metal listed with the same P-Number UNS Number in Table QW∕QB-422 as the base metal to be used in production weld-ing对于非铁基材料,使用与产品焊接有相同P-No.和UNS No.的母材(见表QW∕QB-422所列)。

For ferrous materials in Table QW∕QB-422, a procedure qualifi-cation shall be made for each P-Number Group Number combination of base metals, even though procedure qualification tests have been made for each of the two base metals welded to itself. If, however, two or more qualification records have the same essential and supple-mentary essential variables, except that the base metals are assigned to different Group Num-bers within the same P-Number, then the combination of base metals is also qualified. In ad-dition, when base metals of two different P-Number Group Number combinations are quali-fied using a single test coupon, that coupon qualifies the welding of those two P-Number Group Numbers to themselves as well as to each other using the variables qualified. This var-iable does not apply when impact testing of the heat-affected zone is not required by other Sections.对于在表QW∕QB-422中所列的铁基材料,应对每种不同P-No.和组号的组号进行工艺评定,即使这二种母材各自己分别进行过工艺评定,仍应按每个P-No.和组号的组合进行工艺评定;但是,倘若有二个或更多评定记录表明除了母材是在同一P-No.下有不同的组号,且有相同的重要变素和附加重要变素,则该母材组合与可看作已通过评定。

此外,如两种不同P-No.和组号的母材是采用同一试件进行评定的,则这个试件不但对这两个P-No.和组号的母材两者相互焊接做了评定,同时也对它们两者采用评定的变素自身相焊做了评定。

当其他卷不要求热影响区的冲击试验时,不应用本变素。

QW-403.6 The minimum base metal thickness qualified is the thickness of the test coupon T or 5∕8 in. (16 mm), whichever is less. However, where T is less than 1∕4 in.(6 mm), the minimum thickness qualified is 1∕2T. This variable does not apply when a WPS is qualified with a PWHT above the upper transformation temperature or when an austenitic or P-No.10H material is solution annealed after welding. 评定的母材最小厚度为试件厚度T或5∕8in.(16mm),取两者中较小值。