物流英语Chapter4

- 格式:ppt

- 大小:118.00 KB

- 文档页数:32

Chapter11.Why is logistics important to meet customer’s requirements?The purpose of logistics is “to meet customers’ requirements”, with one being that logistics strategies and activities should be based upon customers’ wants and needs rather than the wants, needs and capabilities of other parties. Since different customers have different logistical needs and wants, a-size-fits-all logistics approach result in some customers being over-served while others are underserved.2.The definition of logisticsLogistics is part of supply chain process that plans, implements, and controls the efficient, effective forward and reverse flow and storage of goods services, and related information between the point of origin and the point of consumption in order to meet c ustomers’ requirements.3.What is the difference between effectiveness and efficiency?a)Broadly speaking, effectiveness can be thought of as” how well does a company do whatthey say they’re going to do.”b)In contrast, efficiency can be thought of as how well (or poorly) company resources are usedto achieve what a company promises it can do.4.Why is reverse logistics important?Reverse logistics is also likely to gain additional attention in the future because online purchases tend to have higher return rates than other types of purchases.5.What is the core concept of logistics?The development of logistics customer service is the core concept of modern logistics. From a customer service point of view, logistics is defined by scholars as: to the right cost and the right conditions, to ensure the right customer at the right time and right place, for the right product for availability, namely, the concept of logistics 6Rs.6.What is the importance of logistics?Logistics costs account for almost 10% of the Gross Domestic Product7.How do enterprise gain extra competitive advantages through logistics?a)The customer service level can beat his opponent, an important weapon to gain acompetitive advantage. Because products, prices and promotions can certainly offer customers value added, but the brutal competition make products and prices, promotions easily imitated by competitors.b)Defects and late deliveries are symptoms of quality problems in supply chain processes thatare all too apparent to the end-customer. Such problems negatively influence that customer’s loyalty.c)Time measures how long a customer has to wait in order to receive a given product orservice. Lead time means the time it take from the moment a customer places an order to the moment that customer receives the goods he or she specified. The time advantage is variously described as speed or responsiveness inpractice.Chapter21.The definition of warehouseThe warehouse is a point in the logistics system where a firm stores or holds raw materials, semi-finished goods, or finished goods for varying period of time.2.Why does warehouse add cost to the productsHolding goods in a warehouse stops or interrupts the flow of goods, adding cost to the product or products.3.The functions of warehousea)The warehouse serves several value-adding roles in a logistics system.b)The second function of warehousing may be, customer order product mixing.c)The third function of warehouse is to provide service.d)The fourth function of warehousing is protection against contingencies such astransportation delays, vendor stock-outs, or strikes.e)The fifth function of warehousing is to smooth operations in the manufacturing process.4.The goals of warehousingThe objective is to efficiently receive inventory, possibly store it until required by the market, assemble it into complete orders, and initiate movement to customer.5.The goals of handingThe overall objective of material handing is to eventually sort in bound shipments into unique customer assortments. The three primary handing activities are receiving, in-storage handing, and shipping.6.The definition of shippingShipping consists of order verification and transportation equipment loading.7.The focus of storage: individual characteristics8.Which factors influent storage logisticsThe most important product variables to consider in a storage plan are product volume, weight and storage requirements.Similarly, the storage plan should take into consideration product weight and special characteristics.9.The different between active storage and extended storagea)Warehouse that directly serve customers typically focus on active short-term storage.b)In contrast, warehouse use extended storage for speculative, seasonal, or obsoleteinventory.10.The definition of active storageStorage for basic inventory replenishment is referred to as active storage11.The feature of active storageActive storage must provide sufficient inventory to meet the periodic demands of the service area. For active storage, materials handling processes and technologies need to focus on quick movement and flexibility with relatively minimal consideration for extended and dense storage.12.The definition of extended storageRefers to inventory in excess of that required for normal replenishment of customer stocks.13.The feature of extended storageExtended storage uses materials handling processes and technologies that focus on maximum space utilization with minimal need for quick access.14.Product suit for extended storageSeasonal items, erratic demand items, product conditioning, goods are purchased on a speculative basis, the goods used to realize special discounts.15.Elements of WMSInbounding management, shelf operation, storage management, pickout operation, quality inspection and outbounding management.16.The focus of holding inventoriesA firm might want inventories at some level in their operations and they would also want to keep them at a minimum.17.The definition of inventoryInventory refers to stocks of anything necessary to do business.18.Why should firms control inventory some levelEach type represents money tied up until the inventory leaves the organization and is paid for. For this reason it is undesirable to hold greater stocks than necessary. On the other hand, inadequate levels of stock create danger of production hold-ups or failure to meet customer demand.19.The true costs of carrying inventoryThe true costs of carrying inventory include the direct costs of storage, insurance, taxes, etc. but also the cost of money tied up in inventory20.The goal of inventory managementBest practice inventory management involves simultaneously attempting to balance thecosts if inventory with the benefits of inventory.21.Why should we have inventory? The purposes of inventorya)The most important reason for having inventory is the convenience of having thingsavailable as and when required.b)Another factor is the possibility of cost reduction by taking advantage of bulk discountsfrom suppliers.c)We may also hold stocks as a buffer against things going wrongd)Inventory is required if an organization is to realize economies of scale in purchasing,transportation, or manufacturing.e)Balancing supply and demandf)Inventory makes it possible for each of a firm’s plants to specialize in the products that itmanufactures.g)Inventory is held as protection from uncertainties; that is. To prevent a stockout in the caseof variability in demand or variability in the replenishment cycle.Chapter31.Principles of choosing transportation modela)Speed of deliveryb)Certainty of timingc)Avoidance of damaged)Avoidance of loss though pilferagee)Ancillary servicesf)Freedom from interruption2.Pros and cons of each transportation models3.The definition of containerContainers are essential big boxes into which firms place small loads4.The feature of containerThe container permits economic and efficient transfer of unitized loads among different modes of transportation5.Advantage of containerizationa)The use of container, though an improvement over the conventional mode, does notdispense with the individual packing required for the cargo, and the cost of packing remains unreduced.b)The above clearly show that containerized traffic is far more efficient than the traditionalmode of transportation.c)The other advantages derivable from containerized traffic comprise minimization of lossesand simpler packaging.6.The cause of the high investmenta)First, the carriage if containers necessitates specific accommodations in the ship.b)Second, the manufacture or purchase of containers involves a considerable sum of money,especially when the number required is taken into account.c)Third, to meet the specific requirements for container ships, a special type of terminaldifferent form traditional berths is required.7.What the definition of intermodal transportation?Intermodal transport service refers to the use of two or more carriers of different modes in the through movement of a shipment.8.What are the respective features of piggyback fishyback and bridyback?a)Rail-truck, called piggyback. Piggyback adds the truck’s accessibility to the low cost of railservice.b)Truck-water refer to as fishyback. Fishyback couples motor accessibility with the low cost ofwater carriage.c)Birdyback, the combinations of air-truck. Birdyback combines the accessibility of motor withthe speed of the airline.9.What are the problems of intermodal transportation servicea)Carriers are reluctant to participate. Once one carrier can transport the commodity in theentire distance through its own lines, the carrier is still hesitant to coordinate with other carriers.b)Another problem with intermodal services is the transfer of freight from one mode toanother. This creates time delays and adds to transportation costs.10.What the feature of intermodal transportationIntermodal services maximize the primary advantages inherent in the combined modes and minimize their disadvantages.11.Why do enterprises need intermodal transportation?a)The basic reasons are the various modes’ service characteristics and costs.b)By manipulating the modes, a logistics manager can overcome a given mode’s servicedisadvantage and retain the mode’s basic advantage, usually low cost.Chapter41.Definition of packagingPackaging is the technique of preparing goods for distribution (methods of packaging using packaging machines or devices by hand. Marketing, production and legality. Attracting attention)2.Function of packagingContainment; production and preservation; communication3.Containers of packagingBarrel; crate; wire bound box4.Techniques of packagingBlister packaging; fin seal packaging; shrink wrapping; CAP5.Methods of packagingProtection from corrosion; protection from damage6.What’re the respective feature of consumer packaging and industrialpackaging?a)Consumer packaging (interior packaging), which mainly aims at containing the goods,promoting the sale of it and facilitating use of it, is of little value to logistics operation.b)Industrial packaging (exterior packaging) has a significant impact on the cost andproductivity of logistics.7.What functions should industrial packaging perform to meet logisticsrequirements?a)First, it should protect the goods from damage during handing, storing and transportation.b)Second, it should promote logistical efficiency.c)The third important logistical packaging function is communication or information transfer.8.What information can be provided in the packaging?Identify; traceability; instructions9.The definition of traceabilityTraceability is defined as ”the ability to trace the history, application or location of an entity by means of recorded identifications.”Chapter51.When do exchange occur?Exchange takes place when there is a discrepancy between the amount, type, and timing of goods available and the goods needed. If a number of individuals or organizations within the society have a surplus of goods that someone else needs, there is basis for exchange.2.What’s the goal of distribution management?The extent to which a channel of distribution creates an efficient flow of products from the producer to the consumer is a major concern of management.3.How do manufactures market their products?a)Select the appropriate channel structure.b)Choose the intermediaries to be used and establish policies regarding channel members.c)Devise information and control systems to ensure that performance objectives are met.d)Due to the dynamic nature of the business environment, management must monitor andevaluate the performance of the distribution channel regularly and frequently.4.What is a channel of distribution?A channelof distribution can be defined as the collection of organization units, either internal or external to the manufacture, which performs the functions involved in product marketing.5.What’re the marketing functions?They include buying, selling, transporting’ storing, grading, financing, bearing market risk, and providing marketing information.6.What’re the channel structure affects?a)Control over the performance of functionsb)The speed of delivery and communicationc)The cost of operations7.What’s the difference between direct channel and indirect?a)While a manufacture-to-user channel usually gives management great control over theperformance of marketing functions, distribution costs are higher, making it necessary for the firm to have substantial sales volume or market concentration.b)With indirect channel, the external institutions or agencies (warehouse holder, wholesalers,retails) assume much of the cost burden and risk, but the manufacturer receives less revenue per unit.8.Definition of DCDistribution centers are the place store goods for short amounts of time during their journeys between points of production and to wholesale or retail outlets.9.Function of DCa)The sorting function and storageb)The function of the distribution center is integrating supplier resources, customer resourcesand product resources, it can also save transportation routes.10.What does sorting mean?The sorting function, meaning that they are the point at which goods are concentrated, and from this concentration a new and different assortment of goods is selected and moves forward to be dispersed to the next level.11.What are the step of sorting functiona)The functions involve taking, a heterogeneous supply of products and sorting them intostocks that are homogenous;b)Bringing together similar stocks from different sources;c)Breaking a homogenous supply into smaller lots;d)Building up assortments of small lots for reshipment, usually to retailers.Chapter61.Definition of ITCITC is the use of electronicprocess media for the collection, analysis and evaluation of data, and the transfer of information from one point to another.2.What’re functions of ITC in logisticsFlows of information in logistics and supply chains are as fundamental as the flows of goods and materials and people. Such information flows occur not only internally within companies, butalso between external suppliers, contractors, and customers.All the flows of physical goods, people and material are triggered by ITC. The whole logistics and supply chain process is kept moving by the supply of information and communication.The timing and quality of the information affects the quality of decision-making. Good information enables good decisions to be made. Inadequate or incorrect information leads to poor decisions.3.Why is information important in logistics managementa)First, satisfying, in fact pleasing, customers have become something of a corporateobsession.b)Second, information is a crucial factor in the managers’ abilities to reduce inventory andhuman resources requirements to a competitive level.c)Finally, information flows play an essential role in the Strategic Planning for and deploymentof resources.4.What’re the 3 levels of information required in logistics and how are the 3levels of information functionedStrategic, tactical and operational level.The strategic levels are mainly involved with medium-to-long-term planning. This level requires information on the following areas, typically for the senior managers in a business. It include: information about alternative suppliers; information of product ranges; information of stockholding; information of own-account operation or third party contractors; information of buying or leasing vehicles and demographic patterns.The operational level is mainly involved with shorter-term to minute-by-minute decisions such as dealing with contingencies and changes. This level requires information for typically the first line management and operatives in a business.These three levels overlap in a business. The information flows from top to bottom and also flows internally and externally.ICT will facilitate all these fundamental triggering, coordinating and controlling functions in logistics.5.Definition of E-CommerceElectronic commerce is the term used to describe the wide range of tools and technology utilized to conduct business in paperless environment.6.What activities does EC includea)Commercial transactions conducted by Internet, telephone and fax.b)Electronic banking and payment systems.c)Trade in digitized goods and services.d)Electronic purchasing and restocking systems (supply chain management).e)Business-to-business exchange of data.f)Delivery of goods and/or services purchased (order fulfillment), and customer service7.What’re the benefits of ECa)The benefits of E-Commerce include facilitation of information-based business processes forreaching and interacting with customers, online order taking, online customer service, etc.b)E-commerce also reduces costs in managing orders and interacting with a wide range ofsuppliers and trading partners, areas that typically add significant overheads to the cost of products and services.8.Make some explanation to ECa)E-commerce is a way of marketing and selling your products through the Internet.b)E-commerce can be defined as modern business methodology that addresses the needs ofthe organization, merchants and consumers to cut costs while improving the quality of goods and services and speed of service delivery.9.What benefits are included in EDIa)Quick access to informationb)Better customer servicec)Reduced paperworkd)Increased productivitye)Cost efficiencyf)Competitive advantage10.Definition of Bar coding and scanningBar coding and electronic scanning are identification technologies that facilitate information collection and exchange, allowing supply chain members to track and communicate movement details quickly with a greatly reduced probability of error.Chapter71.What’s supply chainEncompasses all activities associated with the flow and transformation of goods from the raw materials stage (extraction), through to the user, as well as the associated information flows.2.What’s supply chain managementThe pipeline for the efficient and effective flow of product/ materials, services, information, and financials from the supplier’s suppliers through the various intermediate organizations/ companies out to the customer’s customers or the system of connected logistics network between the original vendors and the ultimate final consumer.3.As a consumer, are you part of supply chainThere are five components in the supply chain involving supplier, producer, wholesaler, retailer and customer4.What’s the goal of supply chain managementThe goal and objectives of individual supply chain participants should be compatible with the goal and objectives of other participants in the supply chain5.What are the contents included in SCMThere are many contents in supply chain management such as supply chain planning, supply chain enterprise applications, supply chain operations, procurement product lifecycle management, logistics and supply chain strategy.6.What are the barriers to supply chain managementa)Regulatory and political considerationsb)Lack of top management commitmentc)Reluctance to share, or use, relevant datad)Incompatible information systemse)Incompatible corporate cultures7.What are the primary methods organizations can pursue when attemptingto integrate their supply chain?Broadly speaking, organizations can pursue three primary methods when attempting to integrate their supply chains.a)One method is through vertical integration, where one organization owns multipleparticipants in supply chainb) A second possible method of supply chain coordination involves the use of formal contractsamong various participantsc) A third method of supply chain coordination involves informal agreements among thevarious organizations to pursue common goal and objectives, with control being exerted by the largest organization in the supply chain.8.What are the dements for the successful implementation of a supplychain’s strategic alliance programa)Trustb)Long-term relationshipsc)Information sharingd)Total risk, profit sharinge)Individual strengths of organizations9.The goal of strategic allianceAs we all know that different functions or groups within any organization must work together to achieve a wide range of common goals-from the reduction of product cost and improved product quality and delivery to the development of innovative new products.Chapter81.What are the new trends of logistics? Make interpretation about themGreen logistics, 3PL, reverse logistics. Four party logistics2.What are the advantages of enterprises cooperation in the supply chaina)Cooperation is the essence of supply chain. All members of supply chain cooperate andband together to create more value than that of each member can do, and to realize the whole value of supply chain, which is far greater than the simple sum of every link value. b)Cooperative efforts and collaborations between these enterprises make it easier to realizethe whole benefit of supply chain and to improve their competitive abilityc)The relationships among these members or enterprises have direct link to the efficiency andbenefit of supply chain3.What are the advantages of 3PLa)Allows flexibility to expand and contract inventory levelsb)Enhanced technology and supply chain visibilityc)Improved customer service offeringsd)Allows companies to focus on core competenciese) A more strategic and scientific approach to logistics challengesf)Lower or eliminate capital expenditures associated with equipment and facilities4.Definition of green logisticsa)Aform of logistics which is calculated to be environmentally and often socially friendly inaddition to economically functional.b)Pollution, congestion, resource depletion, means that the logistics industry is still not very“green”c)Government intervention promoting greater environmental regulation appears inevitable.Global, continental, national and local environmental legislation is already taking hold.5.Definition of 3PLThird party logistics or “3PL”is the integration of a company’s warehousing, transportation, and related lo gistics services through an outsourced or “third party” partnership6.Definition of reverse logisticsReverse logistics is the management of all the activities involved in goods, demand information, and money flowing in the opposite direction of the primary logistics flow7.Definition of fourth party logisticsThe fourth party logistics provider is a supply chain integrator that assembles and manages the resources, capabilities, and technology of its own organization with those of complementary service providers to deliver a comprehensive supply chain solution.。

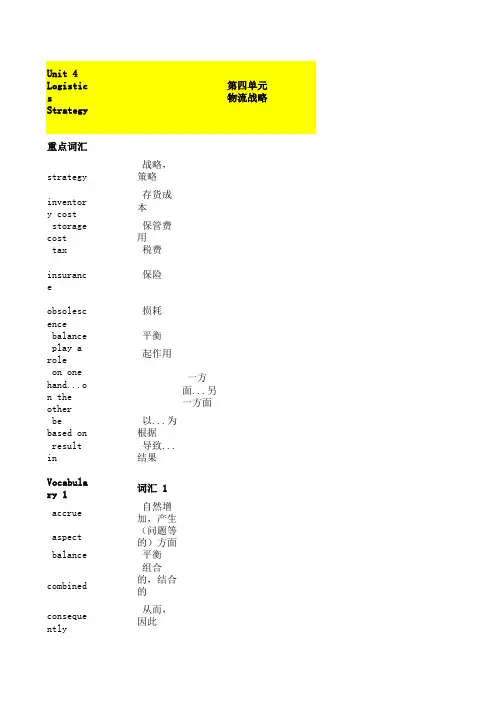

Unit 4 Logistics Strategy第四单元 物流战略重点词汇strategy 战略,策略inventory cost 存货成本storage cost 保管费用tax 税费insurance 保险obsolescence 损耗balance 平衡play a role 起作用on one hand...on the other 一方面...另一方面be based on 以...为根据result in 导致...结果Vocabulary 1词汇 1accrue 自然增加,产生aspect(问题等的)方面balance 平衡combined 组合的,结合的consequently 从而,因此deterioration 变坏,退化,堕落economical 节约的,经济的exposure 暴露,揭露fewer 较少的formulation 用公式表示identify 识别,鉴别incur 招致invest 投(资)levy 征收logic 逻辑,逻辑性lot 批量maintain 维持,维修normally 正常地,通常地obsolescence 损耗overstock 库存过剩peg 钉;固定,限制precise 精确的,准确的prime 主要的,最好的private 私人的,私有的quantity 量,数量risk 冒险,风险size 大小,尺寸specify 指定,详细说明,列入清单view 看作,认为Vocabulary 2词汇 2abandon 放弃,遗弃fan 扇子,鼓风机JIT=just in time 准时制junkyard 丢弃旧汽车的地方mercury 水银,汞model 样式,型号Monterey 蒙特里(美国加州西部城市) necessarily 必要地pickup 皮卡,一种小型货车plug 塞子,插头retire 退休,引退Sam 萨姆(男子名)site 地点,场所spark 火花spark plug 火花塞vintage 制造年期windshield 挡风玻璃workshop 车间,工场Supplementary Vocabulary补充词汇discount 折扣minimum 最小值stockpile 积蓄,库存supply 供给yard 院子,堆场。

第九章实物配送Part I实物配送实物配送的概念实物配送作业包括对顾客订单的处理和交付。

实物配送是市场营销和销售绩效必不可少的一部分,因为配送使产品可获得性及时、经济。

赢得和留住顾客的总体过程可大致分为交易产生和实物履行活动。

交易产生活动是指做广告和销售,实物配送执行实物履行活动。

配送运行周期典型的实物配送运行周期包括5个相关活动,包括:订单传递、订单处理、订单拣选、订单运输和交付客户。

基本的实物配送运行周期的如图所示:从物流的角度看,实物配送将公司与客户联系起来。

实物配送将营销和制造的目的整合为一体。

营销和生产制造之间(的界面)会有冲突。

一方面,市场营销致力于满足顾客。

在大多数企业,向顾客提供货物可使市场营销和销售受到最小的限制。

这常意味着市场营销和销售宁愿保持多条生产线和高库存,而不管每件产品实际的潜在收益。

这样,顾客的任何需求,无论大小都能得到满足。

实物配送的期望是达到零缺陷的服务,并支持关注顾客的市场营销工作。

实物配送相关作业的重要性实物配送是为了满足客户需求——这一事实意味着与配送相关的操作将会比制造支持活动和采购运行周期的特性更具有不稳定性。

减少实物配送操作的不协调性和简化交易有必要关注客户如何订购产品。

首先,必须尽力改善预测精确度。

第二,应该起动一个与客户相协调的订单管理程序,尽可能减少不确定性。

第三,也是最后一点,实物配送运行周期应该设计得尽可能具有柔性和响应性。

顾客启动实物配送运行理解实物配送运行周期动态的关键是要记住是顾客通过订货启动了这一过程。

销售企业的物流响应能力构成了总营销战略中最重要的竞争力之一。

配送的类型三种类型的配送方式可以用来实现顾客对产品的可获得性:(1)集约型配送;(2)选择性配送;(3)独家配送。

集约型配送在集约型配送中,产品卖给尽可能多的零售商或者是批发商。

集约型配送适需要集约型配送的工业产品包括铅笔、纸夹、透明胶带、档案夹、选择性配送另一方面,在选择性配送中,产品的销售渠道的数量是有限的,但是未达到独家配送的程度。