埃索美拉唑的合成工艺研究ppt课件

- 格式:ppt

- 大小:1.36 MB

- 文档页数:31

埃索美拉唑镁肠溶片的制备张建岭;张菊红【摘要】Objective To prepare Esomeprazole Magnesium Enteric-coated Tablets,and analyse its quality.Methods The enteric-coated Esomeprazole Magnesium pellets were prepared by fluid bed coating technology. The Esomeprazole Magnesium enteric-coated tablets were prepared by direct compression of the enteric-coated pellets and suitable excipients. The self-made tablets compare its drug release in vitro,the resistance to acid and stability with the marketing tablets. Results: All the criteria of the self-made tablets were found to be in line with the quality standard specification. Conclusion The preparation process was simple ,feasible and replicableand the problem of Esomeprazole Magnesium′s stability was resolved effectively.%目的:制备埃索美拉唑镁肠溶片并对自制片进行质量分析。

方法:采用流化床包衣法制备埃索美拉唑镁肠溶微丸,然后选用适宜辅料采用直接压片法对微丸压片,并将自制片与市售片进行药物体外药物释放度、耐酸力及稳定性的比较。

埃索美拉唑镁肠溶片制备工艺研究邹达亮;张佳;汤媛媛;糜志远【摘要】筛选埃索美拉唑镁肠溶片的最优处方并评价制剂质量.用单因素试验和正交试验对处方进行筛选和优化;采用高效液相色谱法测定其溶出度和主药含量及有关物质.筛选出的最优处方为:埃索美拉唑镁微丸33%,微晶纤维素8.3%,淀粉8.3%,交联聚维酮33%,10%聚乙烯吡咯烷酮K-30乙醇溶液8.3%,乳糖8.3%,硬脂酸镁0.8%.实验表明崩解时限<2 min,在pH6.8的磷酸缓冲液中45 min的累积释放率>80%.研究表明,所筛选的处方合理,制成的埃索拉唑镁肠溶片质量稳定可控,工艺可行且重复性好.%The paper is aimed at optimizing the formula of esomeprazole magnesium enteric-coated tablets and evaluating the quality.Orthogonal L9(34) test was designed to optimize the prescription.HPLC method was used to detect dissolution of esomeprazole magnesium enteric-coated tablets and established to determine the content of esomeprazole magnesium and the related substances.It has been found that the optimized prescription assembly was 33% of esomeprazole magnesium pellets,8.3% of microcrystalline cellulose,8.3% of starch,33% of cross-linked povidone,8.3% of povidone,8.3% of loctose,0.8% magnesium stearate.The test showed that disintegration time was lessthan 2 min.The accumulated release of the pellets and the tablets in phosphate buffer(pH6.8) within 45 mins were over 80%.Results showedthat the optimal prescription is feasible.The quality of prepared esomeprazole magnesium enteric-coated tablets issteady and controlled.The pharmaceutical procedure is feasible and reproducible.【期刊名称】《湖北工业大学学报》【年(卷),期】2017(032)002【总页数】4页(P47-50)【关键词】埃索美拉唑镁;肠溶片;制药工艺【作者】邹达亮;张佳;汤媛媛;糜志远【作者单位】湖北工业大学生物工程与食品学院,湖北武汉 430068;湖北工业大学生物工程与食品学院,湖北武汉 430068;湖北工业大学生物工程与食品学院,湖北武汉 430068;湖北工业大学生物工程与食品学院,湖北武汉 430068【正文语种】中文【中图分类】R944.4埃索美拉唑镁(esomeprazole magnesium trihydrat,EMZ-Mg)是瑞典AstraZeneca公司研发的(S)-(-)-型单一对映体的镁盐制剂。

埃索美拉唑镁肠溶微丸的制备与质量控制摘要:目的:制备埃索美拉唑镁肠溶微丸,建立质量控制方案。

方法:应用流化床包衣法(底喷),成功制备出埃索美拉唑镁肠溶微丸,进行溶出度、耐酸力测定,评价埃索美拉唑镁肠溶微丸的质量。

结果:pH值6.8的人工肠液中,自制埃索美拉唑镁肠溶微丸的溶出度>86%,pH值1.2的氯化氢溶液中(模拟胃液环境),自制埃索美拉唑镁肠溶微丸的累积溶出度<2%。

结论:人工肠液中,自制埃索美拉唑镁肠溶微丸的溶出较完全,人工胃液中,自制埃索美拉唑镁肠溶微丸的耐酸力较好,该制备工艺可靠,药物质量理想,可推广。

关键词:埃索美拉唑镁肠溶微丸;制备工艺;质量控制埃索美拉唑镁主要应用于胃食管反流性疾病的临床治疗中,但容易被酸性物质所催化降解,为避免其被胃酸破坏、降低疗效,需要进行包衣处理,也就是制备埃索美拉唑镁肠溶微丸。

1.材料与方法1.1材料与仪器1)材料:埃索美拉唑镁三水合物、滑石粉、空白糖丸、羟丙基甲基纤维素(HPMC)、羟丙基纤维素(HPC)、柠檬酸三乙酯、乙腈。

2)仪器:小型流化床包衣机、磁力搅拌器、恒流泵、智能溶出仪、分析天平、高效液相色谱仪。

1.2埃索美拉唑镁肠溶微丸的制备工艺1)载药微丸的制备。

以3% HPMC水溶液为黏合剂,并加入埃索美拉唑镁,从而制备为混悬液。

在小型流化床包衣机中对空白糖丸进行加工,应用底喷工艺,将其制成载药丸心,工艺参数:雾化压力0.1兆帕至0.11兆帕、床温30±1摄氏度、平衡状态下的喷液流速每分钟1.5毫升。

载药丸心制备完成后,流化干燥30分钟。

2)隔离微丸的制备。

取处方量的HPC、滑石粉溶于水中,制备隔离包衣液,浓度为3.5%。

在小型流化床包衣机中应用底喷工艺进行包衣处理,工艺参数:雾化压力0.1兆帕、床温37摄氏度、喷液流速每分钟3.5毫升。

包衣完成后,流化干燥30分钟。

载药微丸包衣的目的是,由于埃索美拉唑镁在酸性环境下容易发生分解,因此需要将埃索美拉唑镁制备为肠溶剂,但使用的是弱酸性的肠溶包衣材料,所以应进行隔离包衣处理,避免肠溶材料与埃索美拉唑镁发生化学反应[1]。

Scalable Process for the Premix of Esomeprazole†Lekkala Amarnath Reddy,‡Golla China Malakondaiah,‡Alieti Sanjay Reddy,‡Boluguddu Vijaya Bhaskar,‡Vurimidi Himabindu,§Apurba Bhattacharya,‡and Rakeshwar Bandichhor*,‡Center of Excellence,Integrated Product De V elopment,Inno V ation Plaza,Dr.Reddy’s Laboratories Ltd.,Bachupalli, Qutubullapur,R.R.District500072Andhra Pradesh,India,and Center for En V ironment,Institute of Science and Technology, Jawaharlal Nehru Technological Uni V ersity,Kukatpally,Hyderabad500072,IndiaAbstract:An efficient,scalable process for the premix of unstable esome-prazole base is described that allows accessibility to the stableamorphous form of esomeprazole1.IntroductionPrazoles are known as proton pump inhibitors that mecha-nistically inhibit gastric acid secretion and are thus used as anti-ulcer agents.1,2The new proton pump inhibitor(PPI),esome-prazole Mg(Nexium),developed by AstraZeneca is the S-isomer of omeprazole,thefirst PPI developed as a single optical isomer and used for the treatment of acid-related diseases.3Esomeprazole1as shown in Figure1is found to be a more effective PPI than omeprazole4due to the fact that it has superior pharmacokinetic properties and less variability in effectiveness as compared to omeprazole.Esomeprazole shares a similar mechanism of action,side-effect profile,and precautions with currently available proton-pump inhibitors.The better efficacy of esomeprazole may be attributed to the active moiety that is the enantiomerically pure(S)-isomer of omeprazole.Earlier we have reported a resolution process for the synthesis of the magnesium salt of S-omeprazole through a transition metal complex using a combination of D-(-)-diethyl tartrate,Ti(O i Pr)4,and L-(+)-mandelic acid as resolving agents.5 In continuation of our work,we opted to stabilize an unstable form of esomeprazole base to achieve a pharmaceutically acceptable formulation.Certain pharmaceutically active ingredients are acid labile, and thus,they create a myriad of problems during in V i V o absorption.Therefore,formulating such an acid-labile com-pound in the oral pharmaceutical dosage form to allow compatibility to the acidic environment of the stomach imposes a great challenge.For example,a few substituted benzimidazole derivatives have poor stability.In particular,these compounds tend to decompose rapidly and acquire color under moist or acidic to neutral conditions.When these compounds are formulated for oral administration,they require specific coating to avoid exposure to the gastric acid of the stomach.In order to achieve effective enteric coating,granulation or pellet formation techniques are practiced that prohibit the active pharmaceutical ingredient(API)from being soluble in water under acidic or neutral conditions and allow the API to be soluble in alkaline conditions.However,the material used in enteric coatings is often acidic,which can cause the decomposi-tion of the acid-labile compounds.Such decomposition occurs even during the enteric coating process,which results in the coloration of the surface of the core.In order to avoid such problem,an inert sub coating,which is not acidic,is often required between the core and enteric coating,which brings the intricacy and adds the cost of the formulation in the manufacturing process of acid-labile compounds.For substances that are labile in acidic media,but have better stability in neutral to alkaline media,it is often advantageous to add alkaline as the inactive constituents in order to increase the stability of the active compound during manufacturing and storage.In particular,substituted benzimidazole derivatives such as omeprazole and esomeprazole are not only unstable in acidic condition but also in neutral solid state.Thus,in order to enhance the storage stability,an alkaline base such as sodium bicarbonate is added to the formulation,and/or the substituted benzimidazole derivatives are converted to their alkaline salts, which are usually more stable than the free species.It is also known that such alkaline base has adverse effects on patients who suffer from hypertension,heart failure,etc.†Communication number:IPDO IPM-00183.*Corresponding author.Telephone:+914044346430.Fax:+9140 44346164.E-mail:rakeshwarb@.‡Dr.Reddy’s Laboratories Ltd.§Jawaharlal Nehru Technological University.(1)For reviews,see:(a)Pellissier,H.Tetrahedron2006,62,5559.(b)Bentley,R.Chem.Soc.Re V.2005,34,609.(c)Fernandez,I.;Khiar, N.Chem.Re V.2003,103,3651.(d)Legros,J.;Dehli,J.R.;Bolm,C.Ad V.Synth.Catal.2005,347,19.(2)For reviews,see:(a)Sachs,G.;Shin,J.M.;Howden,C.W.Aliment.Pharmacol.Ther.2006,23,2.(b)Tonini,M.;Giorgio,R.D.;Ponti,F.D.Expert Opin.Ther.Patents2003,13,639.(3)Baker,D.E.Re V.Gastroenterol.Disord.2001,1,32.(b)Cotton,H.;Elebring,T.;Larsson, E.M.;Li,L.;So¨rensen,H.;Unge,S.V.Tetrahedron:Asymmetry2000,11,3819.(c)Larsson,E.M.;Stenhede, U.J.;So¨rensen,H.;Unge,S.V.;Cotton,H.EP0773940B1,1997.(d) Federsel,H.J.;Larsson,E.M.In Asymmetric Catalysis on Industrial Scale:Challenges,Approaches and Solutions;Blaser,H.U.,Schmidt,E.,Eds.;Wiley-VCH:Weinheim,2004;p413.(4)(a)Rabasseda,X.;Cole,P.Drugs Today2001,37,767.(b)Graul,A.;Castaner,R.;Castaner,J.Drugs Future1999,24,1178.(5)(a)Raju,S.V.N.;Purandhar,K.;Reddy,P.P.;Reddy,G.M.;Reddy,L.A.;Reddy,K.S.;Sreenath,K.;Mukkanti,K.;Reddy,.Process Res.De V.2006,10,33.(b)Reddy,L.A.;Kondaiah,G.C.M.;Srihari,K.B.;Bhattacharya,A.;Bandichhor,R.;Himabindu,V.;Reddy, P.P.;Anand,.Process Res.De V.2008,12,66.Figure1.Structure of esomeprazole1.Organic Process Research&Development2009,13,1122–11241122•Vol.13,No.6,2009/Organic Process Research&Development10.1021/op9001406CCC:$40.75 2009American Chemical Society Published on Web09/25/2009Various stabilizing agents are disclosed for benzimidazole derivatives in the core tablets.6The findings also show that such compounds are stable in the presence of basic inorganic salts of magnesium,calcium,potassium,and sodium.The stability is further consolidated by separating the acid-labile prazoles from the acidic components of the enteric coat by an intermedi-ate coating (subcoating).At our end,we have unsuccessfully attempted to formulate the amorphous form of the free base of 1by employing the basic,or neutral or acidic coating or subcoating excipients.This observation prompted us to embark on studies of preparation of premix to stabilize the amorphous form of 1.Premix is a well-defined mixture of API and a set of additives that help in retaining the stability of the formulated drug product.The premix process of esomeprazole base is not yet reported.Herein,we describe an efficient,scalable,unprec-edented process for the premix of unstable esomeprazole base by understanding the role of water which was not studied in detail in earlier disclosures 6h and employing organic base and neutral components that allows us to stabilize the esomeprazole base 1.Result and DiscussionDuring formulation,it was found that esomeprazole base can undergo degradation due to its unstable nature at ambient conditions as well as at lower temperatures.To overcome this problem,we decided to make the API more stable at 2-8°C,by mixing it with additives such as mannitol 4and meglumine 5in the preparation of esomeprazole 1premix.This innovative approach provides a stabilized premix for the pharmaceutical formulations of acid-labile APIs.Esomeprazole base 1as an oily residue is prepared by following the novel resolution process published earlier by us 5and shown in Scheme 1.Esomeprazole 1generates many impurities under acidic conditions.In our early attempts,we prepared the esomeprazole base 1as a solid amorphous polymorph from its oily residue by employing acetone and water (1:2).In this experiment thechiral purity was enhanced from 97%to 99.8%.However,we encountered difficulty in drying the wet solid at less than 30°C,as the compound started changing its color from off white to cream,and simultaneously the material also changes its morphological behavior as it turned out to be a sticky mass instead of free-flowing powder.In order to prepare premix,we have screened different pharmaceutically acceptable water-soluble sugar derivatives such as mannitol,lactose,fructose,sorbitol,xylitol,maltodextrin,dextrates,dextrins,and lactitol,and we found that the sugar derivative alone is not sufficient to obtain the stable premix (Table 1).In fact ingredients 4and 5with other additives were employed in the formulation of commercialized batches of omeprazole tablets.7Thus,4and 5were considered to be nontoxic and clinically safe to use in our premix preparation of 1.By considering the first principle of acid/base reaction it can be visualized that the use of base may enhance the stability;therefore,we screened different pharmaceutically acceptable water-soluble bases,such as meglumine,lysine,N ,N ′-diben-zylethylenediamine,chloroprocain,choline,diethanolamine,ethylenediamine,procaine (except meglumine 5;results with other bases are not included)along with mannitol 4as the structures are shown in Figure 2.Interestingly,stable esomeprazole premix was obtained with meglumine base along with mannitol in appropriate solvents.We have tried different combinations of meglumine and mannitol along with esomeprazole to get the stable premix.Noticeably,a 50:47:3ratio of esomeprazole,mannitol,and meglumine offered a stable premix.Interestingly,it was observed that the dry esomeprazole base is fragile under the conditions that we applied for the preparation of premix of 1.However,in the presence water the isolation of stable premix of 1was possible.This observation prompted us to investigate the role of water in the premix formation event.At first,we attempted the preparation of premix by using dried material (dried under vacuum at 25-30°C)1at lower temperatures(6)(a)Nohara,A.;Maki,Y.U.S.Patent 4,628,0981986.(b)Lovgren,K.I.;Pilbrant,A.G.;Yasumura,M.;Morigaki,S.;Oda,M.;Ohishi,N.U.S.Patent 4,786,505,1998.(c)Lovgren,K.I.;Pilbrant,A.G.;Yasumura,M.;Morigaki,S.;Oda,M.;Ohishi,N.U.S.Patent 4,853,230,1989.(d)Makino,T.;Tabata,T.;Hirai,S.U.S.Patent 5,045,321,1991.(e)Makino,T.;Tabata,T.;Hirai,S.U.S.Patent 5,093,132,1992.(f)Lundberg,P.J.;Lovgren,K.U.S.Patent 6,013,281,2000.(g)Makino,T.;Tabata,T.;Hirai,S.U.S.Patent 5,433,959,1995.(h)Kolhe,U.D.;Krishna,D.M.;Dixit,A.A.;Deshmukh,A.M.;Rajput,N.D.;Mohan,M.S.;Reddy,M.S.;Kumar,M.K.;Purender,K.;Reddy,A.S.WO 2004/093875A1,2004.Scheme 1.Synthesis of esomeprazole starting fromomeprazole Table 1.Different ratios of 1,4,5and various solvents used for premix preparation 1(%)4(%)5(%)solventresult1585-(CH 3)2CO and cyclohexane unstable 2575-(CH 3)2CO and cyclohexane unstable 5050-(CH 3)2CO and cyclohexane unstable 61.5308.5(CH 3)2CO and cyclohexane unstable 97-3(CH 3)2CO and cyclohexane gummy 50473(CH 3)2CO and cyclohexane stable a 50473MeOH and cyclohexane gummy 50473CH 2Cl 2and cyclohexane gummy 50473EtOAc and cyclohexane gummy 50473(CH 3)2CO gummy 50473MeOH gummy 50473EtOAc gummy 50473CH 2Cl 2gummy 50473cyclohexanegummya∼49%1,∼48%4,∼3%5.Figure 2.Structures of mannitol 4and meglumine 5.Vol.13,No.6,2009/Organic Process Research &Development•1123(10-20°C)which afforded degradation byproducts.In otherexperiments,water was removed by extracting the product indichloromethane followed by evaporation of solvent,andeventually the base1was subjected to premix preparation thatafforded the gummy mass.Considering the aforementionedobservations,we proceeded to prepare the premix with wetsolid,and surprisingly,we obtained esomeprazole premix as afree-flowing solid.As a result,we anticipate the hydrogenbonding between additives4,5,and1up to great extent.Thetypical procedure involves the dissolution of around75%(water)wet1in acetone followed by addition of additives,distillationof solvent up to around60-70%and codistillation withcyclohexane afforded the material as a free-flowing powder ofpremix of1(Table1).Polymorphism Studies.During the synthesis,we observed that amorphous nature of the esomeprazole base was retained.Interestingly the impression of3%of meglumine in the premixwas not detected in the PXRD.However,the mannitol XRDremained unchanged.The X-ray powder diffraction results havebeen obtained on a Rigaku D/Max-2200model diffractometerequipped with horizontal goniometer inθ/2θgeometry.TheCu K R(1)1.5418Å)radiation was used,and the sampleswere scanned between3-45°2θ.Stability Studies.Stability studies of esomeprazole premix were conducted under the following two different stabilityconditions:(1)Accelerated stability conditions at40°C(2°C and relative humidity(RH):75%(5%.(2)Cold storage stability conditions at2-8°C.We have observed that esome-prazole premix was stable at cold storage stability conditions(condition2).The stability was judged by color description,HPLC purity,esomeprazole base content in the premix,and XRD.The detailsare summarized in Table2.The level of water content duringthefirst month of the stability test was found to be slightlyhigher(1.73%)than the initial content(1.61%w/w).Thisamount of moisture intake did not affect the nature of samplesince no extra peak in XRD has been detected,indicating thatthe esomeprazole base in the premix of1is amorphous in natureeven after2years.ConclusionWe have developed a robust and scalable process for thepreparation of the stable premix of1and successfully demon-strated with concurrent pilot-plant scale.The polymorphic study was performed to generate irrefutable evidence for the amor-phous nature of the premix of1being identical to that of its free base.We have also conducted the stability studies to document the storage conditions for the premix of1,which was found to have a stability profile better than that of the free base of1,and it helped us to formulate the premix of1as tablets with a wide range of excipients.Experimental SectionPreparation of Esomeprazole Base Wet Solid(1)(50-80% Water Content).To a solution of esomeprazole residue(10 kg,28.9mol)in acetone(50L)was added DM water(100L), and the mixture was stirred for30min.The pH of the mass was adjusted to12-13with40%caustic lye solution(1.2L) at25-30°C,and the mixture was stirred for30min.Thereafter, activated carbon(1kg)was charged,the solution stirred for30 min,and the reaction mass wasfiltered through a leaffilter having a Celite bed.Moreover,the leaffilter was washed with a solution of acetone(13L)and demineralized water(25L). Subsequently,pH was adjusted slowly to7.0-8.0with acetic acid,and the mass was cooled to0-5°C.After stirring the solution for2h at0-5°C,the solid material was separated,filtered,washed with demineralized(DM)water(50L),and spun dried for4h.The wet solid[15kg;99.9%(HPLC)]8was used immediately for the next step.Preparation of Esomeprazole1Premixed with4and5. To a solution of esomeprazole base wet solid(15kg,70%water content)in acetone(22.5L)was added activated carbon(0.5 kg).After stirring for30min,the mass wasfiltered through sparkler and online cartridgefilters.Thereafter,thefilter bed was washed with acetone(13.5L),and a combined solution of mannitol4(3.88kg)and meglumine5(0.27kg)was added. After stirring for30min,cyclohexane(54L)was added,and the solution was distilled up to60-70%at20-30°C under vacuum.Subsequently,cyclohexane(45L)was charged,the solution distilled again at20-30°C under vacuum followed by further addition of cyclohexane(27L)and stirred for30 min at20-30°C.A free-flowing material suspended in cyclohexane wasfiltered and washed with another lot of cyclohexane(13.5L),and then dried at30-35°C under vacuum to afford1premix in90%(over all35%)yield(7.15 kg)and99.85%purity(HPLC);9[water content:1.0%,esome-prazole base content:∼49%(that corresponds to90%yield),∼48%4and∼3.0%5].AcknowledgmentWe thank the management of the Dr.Reddy’s Laboratories Ltd.for supporting the work.Received for review June5,2009.OP9001406(7)Lundberg,P.J.;Lovgren,K.U.S.Patent6,013,281,2000.(8)HPLC data:Chiral pack AD50mm×4.6mm or equivalent,flow rate0.5mL/min with a UV detector at280nm,load20µL,run time30min at25-30°C.(9)HPLC Data:HI-CHROM TBB,flow rate1.0mL/min with a UVdetector at280nm,load22µL,run time50min at25-30°C.Table2.Assessment of the stability of the premix of1duration of analysiscolordescriptionHPLCpurity(%)%of esomeprazolebase in premix of1initial light-yellow solid99.8249.21st month no change99.8647.12nd month no change99.8547.33rd month no change99.8047.66th month no change99.8247.99th month no change99.8347.612th month no change99.8247.718th month no change99.8147.424th month no change99.7847.0aa There is no change in the amorphous nature of the premix of1after the24th month as is evident in the powder-XRD experiment.1124•Vol.13,No.6,2009/Organic Process Research&Development。

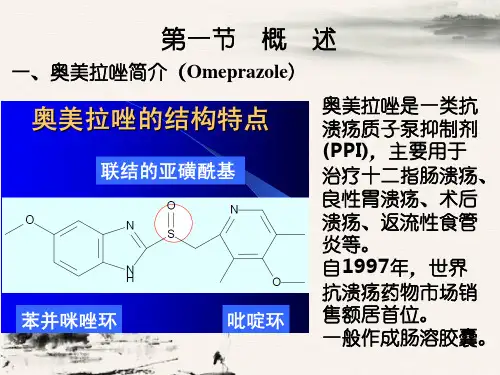

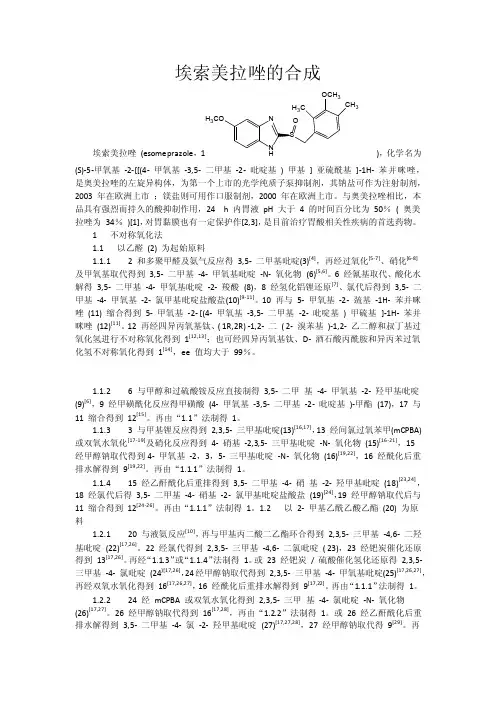

埃索美拉唑的合成埃索美拉唑 (esomeprazole ,1H 3CO H S OCH 3OCH 3H 3C),化学名为(S)-5-甲氧基 -2-[[(4- 甲氧基 -3,5- 二甲基 -2- 吡啶基 ) 甲基 ] 亚硫酰基 ]-1H- 苯并咪唑,是奥美拉唑的左旋异构体,为第一个上市的光学纯质子泵抑制剂,其钠盐可作为注射制剂,2003 年在欧洲上市 ;镁盐则可用作口服制剂,2000 年在欧洲上市。

与奥美拉唑相比,本品具有强烈而持久的酸抑制作用,24 h 内胃液 pH 大于 4 的时间百分比为 50% ( 奥美拉唑为 34% )[1],对胃黏膜也有一定保护作[2,3],是目前治疗胃酸相关性疾病的首选药物。

1 不对称氧化法1.1 以乙醛 (2) 为起始原料1.1.1 2 和多聚甲醛及氨气反应得 3,5- 二甲基吡啶(3)[4],再经过氧化[5-7]、硝化[6-8]及甲氧基取代得到 3,5- 二甲基 -4- 甲氧基吡啶 -N- 氧化物 (6)[5,6]。

6 经氰基取代、酸化水解得 3,5- 二甲基 -4- 甲氧基吡啶 -2- 羧酸 (8),8 经氢化铝锂还原[7]、氯代后得到 3,5- 二甲基 -4- 甲氧基 -2- 氯甲基吡啶盐酸盐(10)[9-11]。

10 再与 5- 甲氧基 -2- 巯基 -1H- 苯并咪唑 (11) 缩合得到 5- 甲氧基 -2- [(4- 甲氧基 -3,5- 二甲基 -2- 吡啶基 ) 甲硫基 ]-1H- 苯并咪唑 (12)[11]。

12 再经四异丙氧基钛、( 1R,2R) -1,2- 二 ( 2- 溴苯基 )-1,2- 乙二醇和叔丁基过氧化氢进行不对称氧化得到 1[12,13];也可经四异丙氧基钛、D- 酒石酸丙酰胺和异丙苯过氧化氢不对称氧化得到 1[14],ee 值均大于 99%。

1.1.2 6 与甲醇和过硫酸铵反应直接制得 3,5- 二甲 基 -4- 甲氧基 -2- 羟甲基吡啶(9)[6],9 经甲磺酰化反应得甲磺酸 (4- 甲氧基 -3,5- 二甲基 -2- 吡啶基 )-甲酯 (17),17 与11 缩合得到 12[15]。