Mooring-Control for Winches(恒张力控制)

- 格式:pdf

- 大小:557.84 KB

- 文档页数:12

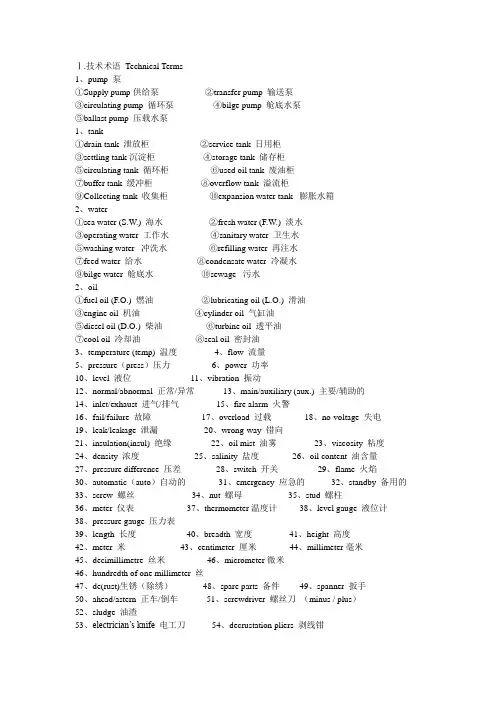

I .技术术语Technical Terms② transfer pump 输送泵④bilge pump舱底水泵②service tank日用柜④storage tank储存柜⑥ used oil tank 废油柜⑧ overflow tank 溢流柜⑩ expansion water tank 膨胀水箱②fresh water (F.W.)淡水④ sanitary water 卫生水⑥ refilling water 再注水⑧condensate water 冷凝水⑩sewage污水② lubricat ing oil (L.O.) 滑油④ cylinder oil 气缸油⑥ turbine oil 透平油⑧ seal oil 密封油3、temperature (temp) 温度5、pressure( press)压力10、level 液位13、main/auxiliary (aux.) 主要/辅助的36、meter 仪表38、pressure gauge 压力表39、length 长度42、45、decimillimetre 丝米37 、thermometer 温度计40、breadth 宽度46、micrometer 微米38、level gauge 液位计41、height 高度44 、millimeter 毫米46、hundredth of one millimeter 丝47、de(rust)生锈(除绣)48、spare parts 备件49、spanner 扳手50、ahead/astern 正车/倒车51、screwdriver 螺丝刀( minus / plus )52、sludge 油渣53、electrician ' s kn电工刀54、decrustation pliers 剥线钳14、inlet/exhaust 进气/排气16、fail/failure 故障19、leak/leakage 泄漏21、insulation(insul) 绝缘24、density 浓度27、pressure difference 压差30、automatic ( auto)自动的33、screw 螺丝15、fire alarm 火警17、overload 过载20、wrong-way 错向22、oil mist 油雾25 、salinity 盐度28、switch 开关18、no-voltage 失电23 、viscosity 粘度26、oil content 油含量29、flame 火焰31、emergency 应急的32、standby 备用的34、nut 螺母35、stud 螺柱1、pump 泵①Supply pump供给泵③ circulati ng pump 循环泵⑤ballast pump压载水泵1、tank①drain tank泄放柜③ settling tank 沉淀柜⑤circulating tank 循环柜⑦buffer tank缓冲柜⑨Collecting tank 收集柜2、water①sea water (S.W.)海水③ operating water 工作水⑤ washing water 冲洗水⑦ feed water 给水⑨ bilge water 舱底水2、oil① fuel oil (F.O.)燃油③ engine oil 机油⑤ diesel oil (D.O.) 柴油4、flow 流量6 、power 功率11、vibration 振动12、normal/abnormal 正常/异常meter 米43、centimeter 厘米n .(主机主要部件) Main Parts for M/Ein .机舱布置图 Engine room arrangement2、 intermediate shaft 中间轴4 、propeller shaft 螺旋桨轴6、 aft seal head tank 后密封油箱 8、stern tube L.O. drain tank 艉管滑油泄放柜 10、L.O. drain tank12、rust preventer tank 防锈剂柜 14、 Low sea chest 低位海水门15、 L.O. transfer pump 16、 bilge pump 舱底泵17、 M/E lub oil pump 18、 M/E S.W. cooling pump 主机海水泵 19、 sludge pump 油渣泵 20、ejector pump for F.W.G 造水装置工作水泵21、 stern tube L.O. pump 艉轴管滑油泵22、H.F.O. Transfer pump 燃油输送泵 23、 ballast pump 压载泵24、bilge & G.S. pump 舱底总用泵25、 Fire & G .S. pump 消防总用泵 26、Provision Ref. Unit S.W. pump 伙食冷藏海水 泵27、 aux. S.W. Cooling pump 辅海水泵 28、L.O. purify cleaning tray 滑油分油机洗池 29、 L.O. purify. Operating water tank 滑油分油机工作水箱30、 L.O. purify. Heater 滑油分油机加热器 31、diesel generator 柴油发电机组 32、 D/G F.W. Cooler 柴油发电机淡水冷却器 33、boiler feed water pump 锅炉给水泵I 、 engine frame 机架 3、piston 活塞 5、bedplate 机座7、cylinder cover/head 气缸盖 9、turbocharger 增压器 II 、 air cooler 空气冷却器 13、 oil sprayer 喷油器 15、 exhaust valve 排气阀 17、 cylinder liner 气缸套2 、 cylinder 气缸 4 、 crosshead 十字头 6 、crankshaft 曲轴8、 connecting rod 连杆 10、driving chain 传动链 12、scanvage box 扫气箱 14、 oil nozzle 喷油嘴 16、 sealing ring 密封环 18、 piston rod 活塞杆1、main engine /M.E. 主机 3、bearing 轴承5、stern tube 艉管7、FWD seal head tank 前密封油箱 9、chemical cleaning tank 化学清洗柜 11、 sludge oil trap 油渣收集柜13、 oily water separator 油水分离器 34、 cascade tank 热井 36、 inspection tank 凝水检查柜 38、 distilling plant 造水装置 40、 control air dryer 控制空气干燥器 42、 main air vessel 主空气瓶35、aux.condenser 大气冷凝器37、filter 过滤器39、control air vessel 控制空气瓶41、air compressor 空压机 43、M/E F.O. heater 主机燃油加热器44、 purif room exh fan 分油机室抽风机 45、sludge tank 油渣柜46、 drinking water hydrophone tank 饮水压力柜 47、 calorifier 热水柜48 、 drinking water sterilizer 饮水消毒器49、 emergency air compressor50 、stern tube gravity oil tank 艉管重力油柜51、 antifouling system power unit 53、 overhead crane 机舱行车防污系统电源箱 52、 ECR. Unit cooler 集控室空冷机 54、boiler feed water test kit 炉水试验台 55、 cylinder oil measuring tank 气缸计量柜 56 、sink 洗池 57、 gas welder 气焊机58、E.L. welder 电焊机65、 sewage treatment unit 生活污水处理装置 66、 composite boiler 燃油 /废气组合锅炉IV .Others1、shipyard船厂 2、 shipbuilding 造船3、berth/slipway 船台4、 marine diesel engine 船用柴油机5、bulk-cargo carrier 散装货船6、container ship 集装箱船7、oil tanker 油船 8 、 tonnage 吨位9、merchant ship 民用船 10、military ship (warship) 军用船 11、 drawing 图纸 12、 hull 船外壳13、 bow/stern 船艏 /船尾 14、port/starboard 左舷 /右舷 15、 deadweight 载重量 16 、 displacement 排水量 17、 freeboard 干舷 18 、 deck 甲板 19、 keel 龙骨 20、 anchor 锚 21、 rudder 舵22、 bottom 底23、 supersrtucture 上层建筑 24、side25、 weld 焊 26、 painting 油漆 27、 assemble 装配 28、 launching 29、 sea trial 试航30、 delivery 交船31、 tightness test 密性试验 32、 after service 售后服务 33、 approval 认可 34、 blue collar worker 蓝领 35、 maker36、 rules and regulations 规则、规范37、 chief engineer 轮机长 38 、chief officer 大副 39、 clerk 事务员 40、 foreigner 41、 fore peak 艏尖舱 42、 aft peak 尾尖舱 43、 frame 肋骨44、cabin 舱室45、 wheel house 驾驶室 46 、shaft tunnel 轴隧 47、 beam 横梁48、 manhole 人孔49、 bulbous bow 球鼻艏 50 、sea chest 海水门 51、 bulkhead 隔舱壁 52、 dry cargo hold 干货舱 53、 provision store 食品库 54 、passageway 走廊、通道55、 refrigerating chamber 冷藏室V 甲板机械 Deck Machi nery1、deck 甲板2、anchor chain (cable ) 锚链3、chain locker 锚链舱4、 windlass 起锚机5、mooring hole 导缆孔6、 bollard 带缆桩7、cargo winch 起货绞车8、 hand rail 栏杆9、hawse pipe 锚链筒10、 hatchcover 舱口盖63、 grinder 砂轮机 64、 cupboard 橱 67、 forced draft fan 锅炉强力风机 69、 waste oil service tank 废油日用柜 71、 spark arrester 消音器68、 incinerator 焚烧炉 70、 supply ventilating fans 送风机13、 derrick 吊杆15、 mooring winches 系泊绞车 17、 vertical ladder 直梯 19、 side scuttle 舷窗21、 rudder shaft 舵轴 22、乜.管系 for piping1、Exhaust air system 排气系统Exhaust pipe for M.E (Generators / boiler / emergency generators ) 主机 / 发电机 / 锅炉 / 应急发电机 ② cooli ng sea water (CSW) 海水冷却水② heavy diesel oil (HDO)④oil sludge 废油(污油)② Lub. oil transferring② starting air 起动空气 ④ remote control air 遥控空气② the ballast system 压载水 ④ the steam system 蒸汽 ⑥ the fire-fighting system 消防 空气测量注入 ⑧ the level system 液位 8、 drainage valve sets 9、 vacuum 真空表 10、thermometer 温度计12、 copper tube 铜管14、funnel 漏斗16、 induction port 吸口 18、shim (washer) 垫片 20、connection 接口22、 threaded connection 螺纹接头 24、flowmeter 流量计 26、 pipe wrench 管子钳 14、cargo hook 吊货钩16、wire cable 钢索 18、wire steel 钢丝卷筒 20、rudder stock 舵杆 flag staff 旗杆23、 ventilator 通风筒2、 Cooling Water System ① cooli ng fresh water (CFW)3、 fuel oil system 燃油系统① light diesel oil ③ fuel oil purifyi ng 燃油净化 ⑤ fuel oil transferring 燃油输送 4、 Lubricating oil system ① L.O for M.E(ge nerator / stern tube)5、 Compressed air system ① high / low pressure air ③ con trol air⑤miscellanous air 杂用空气 6、 Ship systems① the bilge system 舱底水 ③ the water supply system 供水 ⑤ the drainage system 排水 ⑦ the air measuri ng and filli ng system7、 filter / filter gauze (screen) 9、pressure gauge 压力表 11、 steel tube 钢管13、 observation glass 观察镜 15、 hose 软管 17、 bracker 支架 19、 flange 法兰21、 stainless steel pipe 不锈钢管 23、 sleeve pipe 套管 25、 radiator 散热器冷却水系统 淡水冷却水2、 non-return valve 止回阀4、 butterfly valve 蝶阀6、 remote-control butterfly valve 遥控蝶阀28、pipe cutter 管子割刀30、vice 老虎钳32 、torch 手电筒四主要阀件铭牌Main valve list1、slush valve 截止阀3、through-way valve 直通阀5、sluice valve 闸阀7、 quick closing valve 速关阀 9、 reducer valve 减压阀 11、 copper valve 铜阀 13、 cast iron valve 铸铁阀 15、 safety valve 安全阀 17、 thermostatic valve 恒温阀 19、 exhaust valve 排气阀 21、 fire valve 消防阀 8、 self-closing valve 自闭阀 10、 ball valve 球阀 12、 steel valve 钢阀18、 induction valve 进气阀 20、 drain valve 排泄阀22、 three-way valve 三通阀23、 valve material① cast iron 铸铁④ bronze 青铜 ②cast steel 铸钢 ⑤ brass 黄铜③ sta ini esssteel ⑥ copper 紫铜⑦ nodular cast iron 球墨铸铁 忸.电力设备 electrical equipment 1. emergency (diesel / tacho- / shaft) generator 应急(柴油 / 测速/ 轴带)发电机 2. servo (governor) motor 伺服(调速)马达3. ignition (current / voltage) transformer 点火变压器(电流 /电压互换器)4. converter 变流器5. frequency changer 变频器6. charger 充电器7. rectifier 整流器8. uninterrupted power source (UPS) 不间断电源装置 9. battery or storage battery 蓄电池或蓄电池组10. main (emergency / power section) switchboard 主(应急 /电力区)配电板 11. generator (feeder) panel 发电机(馈电)屏 12. charging & discharging panel 充放电板13. (radio / low voltage / internal communication) power distribution board 无线电(低压 / 船内通信 / 电力)分电箱14. power unit for cathodic protection 阴极保护电源箱 15. test panel 电工试验板 16. shore connection box 岸电箱17. junction box (with fuse) 接线箱(带熔断器) 18. control console (panel) 控制台,集控台 19. main engine control stand 主机控制台 20. motor starter 电动机起动器 21. control box (panel) 控制箱(板)22. main engine safety (air conditioning) control box 主机安全系统(空调)控制箱 23. control box for singal light 信号灯控制箱 24. steering gear source box 舵机电源箱 25. contactor 接触器 26. relay 继电器27. control (pressure / change over) switch 控制(压力 / 转换)开关 28.magnetic valve 电磁阀11、 14、 stainless steel valve 不锈钢阀16、 temperature adjusting valve 温度调节阀29. resistor 电阻器30. push button 按钮31. temperature transducer 温度变换器32. oil mist detector 油雾探测器33. fuse 熔断器34. Ammeter 电流表voltmeter 压力表35.power meter 功率表36.37. power factor meter 功率因数表38. watt-hour meter 电度表frequency meter 频率表39.40. flow meter 流量表speed indicator 转速表41.42. ohm meter 欧姆表43. welder 电焊机44. lathe 车床45. drilling machine 钻床46. planning machine 刨床47. grinding machine 砂轮机48. electric heater 电热器electric refrigerator 电冰箱49.50. electric fan 电风扇51. air conditioner 空调washing machine 洗衣机52.53. fresh water sterilizer 引水消毒器54. stator 定子55. rotor 转子neutral wire 零线(中性线)56.57. winding 绕组58. coil 线圈IX.illu min ati on equipme nt 照明设备1. port (starboard) light 左右舷灯2. mast桅灯(stern艉灯/ anchor锚灯/ steering操舵灯/ signal信号灯/ flashing闪光灯/ towing 拖船灯/ daylight signal 白昼信号灯/ pendant 舱顶灯/ fluorescent pendant 荧光舱顶灯/ ceiling 蓬顶灯/passage corner 走道角灯/ desk 台灯/ wall 壁灯/ berth 床头灯/ room's nameplate 舱室铭牌灯/ chart table 海图灯/ flameproof 防爆灯/ flood 泛光灯(强光灯)/ search 聚光灯(探照灯)) light3. switch 开关4. plug 插头5. socket 插座6. socket box 插座箱X.Navigation equipment 导航设备1. gyrocompass 电罗径2. magnetic compass 磁罗径3. feedback unit 反馈装置4. echo-sounder 回声测深仪5. log 计程仪6. master (slave) clock 母(子)钟7. radar 雷达8. radio direction finder 无线电测向仪/ 卫星导航)接9. Loran (radio navigation / satellite navigation) receiver 劳兰(无线电导航收机10. VHF radio telephone transceiver 甚高频电话收发信机11. facsimile 传真机12. television set 电视机13. video camera 电视摄像机oxygen 氧气acetylene 乙炔nitrogen 氮气inter gas 惰性气体epoxy 环氧的resin 树脂chock 楔子垫木soapy water 肥皂水anemometer 风速计manometer 压力(压强)表,气压表straight edge 直尺feeler gauge 塞尺steel scale 钢尺dial gauge 千分表micrometer 外径千分尺vernier caliper 游标卡尺spanner 扳手wrench 扳手screw driver 螺丝刀hammer 锤子clinometer 测斜仪chain block 手拉葫芦mandatory 命令、强制的Chlorinator 氯化器syphon=siphon 弯管,存水管,虹吸管blind 盲板booklet of piping procedure 工序,过程,步骤gymnasium 健身房galley 船上厨房motorcycle safety helmet 安全帽life belt 安全带glove 手套respirator 口罩overall 工作服uniform electric torch 手电筒flashlight eyeglass 眼镜elevator 电梯plank 厚木板stage 大舞台expressions 公式formula (复数formulae)plus 加,正minus 减,负multiply 乘divide by用…除equal to 等于sb entrust sb with sth 委托某人reply to 答复promise 许诺explanation 解释说明answer to 答案typist 打字员triangle 三角形quadrangle 四边形四角形pentagon 五角形inflator 打气筒tyre 轮胎wheel 车轮off duty 下班on duty 上班overtime 加班Slipway 、shipway 船台I. Lighting alignment for shafting & rudder system 轴舵系照光对中2.Stern tube boring 艉轴管镗孔3.Stern tube bush 艉轴衬套4.Stern boss 艉轴壳5.forced fitting inspection 压入配合检验6.oil jack (千斤顶)油泵7. (propeller shaft & stern tube bush )radial clearance (艉轴和艉管衬套)径向间隙8. axial clearance 轴向间隙9.Stern tube seals sealing 艉轴密封10. propeller installation force fitting 压配II. pull-up length 压进距离12. p ull-up force 推进力13.oilpressure for boss 扩涨油压14. Z ero point 零点15. Shrinkage 过盈量16. c leanness 光洁度17. t aper 圆锥,斜度18. superposition 重合19. intersect 相交20. p erpendicularity 垂直度21. v ertical 垂直的22. h orizontal 水平的23. nut of stern shaft 艉轴螺栓24. r udder 舵25. r udder blade 舵叶26. r udder stock 舵杆27. r udder pintle 舵销28. r udder tiller 舵柄29. r udder bush 舵承30. r udder horn 挂舵臂31. securing key 定位销,定位键32. p rotecting cover 保护帽33. g rease 牛油34. r udder angle 舵角35. f ull angle 满舵36. rudder blade ' s stOOp跳块37. temperature sensor 温度传感器38. inlet outlet 进出39. tolerance 公差,允许量40. wear down gauge 磨损规41. stern tube main chamber 大腔42. high pressure chamber 高压腔43.low pressure chamber 低压腔Engine Room 机舱1. Cleaning check:Storage oil tank of steering gear 舵机储存油箱(方形)Expansion oil tank of mooring winch 绞机膨胀油箱(圆形)Storage oil tank of mooring winch 绞机储存油箱Storage oil tank of windlass 锚机储存油箱(方形)Expansion oil tank of windlass 锚机膨胀油箱(圆形)Hydraulic oil tank of hatch cover 舱口盖液压油箱2. flushing of winch piping 绞机管路投油1. D/G pouring epoxy chock 发电机浇环氧2. holding down bolt 地脚螺栓3. deflection of crankshaft 曲轴甩档4. piston 活塞5. cylinder 气缸6. turbocharger 涡轮增压器7.1.Force measurement of M/E stay bolts 紧固螺栓2. piston rod and connection rod bolts 活塞杆和连杆螺栓3. bolts in drive end of crank 曲轴大端螺栓4. piston —piston rod —crosshead—connection rod —crank —crankshaft活塞活塞杆十字头连杆曲柄曲轴5. cam 凸轮6. camshaft 凸轮轴7. M/E chain cable 主机链条8. flooding test of M/E return oil pipes 压水试验9. propeller cap —propeller —stern tube seals—stern tube bush—stern shaft —intermediate shaft 导流帽螺旋桨艉密封艉管衬套艉轴中间轴—intermediate bearing —flywheel (thrust shaft)中间轴承飞轮推力轴10. c oupling reamer holes 联轴节铰制孔11. t urning gear 盘车机12. spring 弹簧1.main air compressor 主空压机2. alignment of coupling flange 联轴节对中3. gap 裂面4. sag 位移1.steering gear 舵机2. ram roller bearing 舵机活塞杆轴承3. neck bush & cylinder 舵机活塞颈衬套和活塞缸体4. dimension measurement 尺寸测量1.fore draft valve 艏吃水阀2.speed log 计程仪3. echo sounder 测深仪Quay、shipside、wharf 、dock 码头。

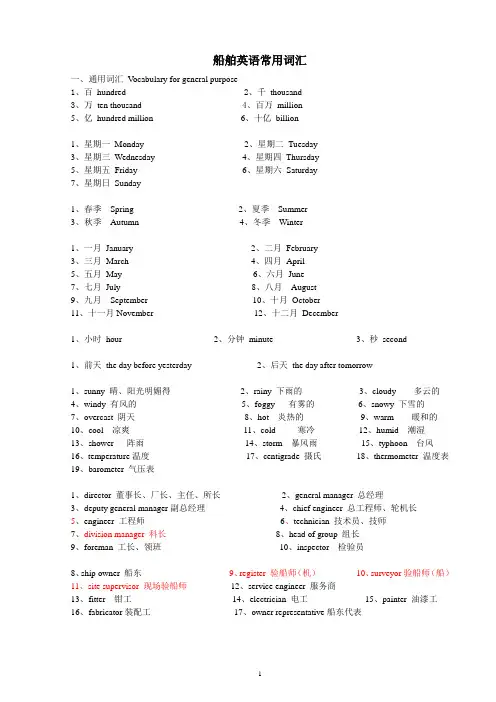

船舶英语常用词汇一、通用词汇V ocabulary for general purpose1、百hundred2、千thousand3、万ten thousand4、百万million5、亿hundred million6、十亿billion1、星期一Monday2、星期二Tuesday3、星期三Wednesday4、星期四Thursday5、星期五Friday6、星期六Saturday7、星期日Sunday1、春季Spring2、夏季Summer3、秋季Autumn4、冬季Winter1、一月January2、二月February3、三月March4、四月April5、五月May6、六月June7、七月July 8、八月August9、九月September 10、十月October11、十一月November 12、十二月December1、小时hour2、分钟minute3、秒second1、前天the day before yesterday2、后天the day after tomorrow1、sunny 晴、阳光明媚得2、rainy 下雨的3、cloudy 多云的4、windy 有风的5、foggy 有雾的6、snowy 下雪的7、overcast 阴天8、hot 炎热的9、warm 暖和的10、cool 凉爽11、cold 寒冷12、humid 潮湿13、shower 阵雨14、storm 暴风雨15、typhoon 台风16、temperature温度17、centigrade 摄氏18、thermometer 温度表19、barometer 气压表1、director 董事长、厂长、主任、所长2、general manager 总经理3、deputy general manager副总经理4、chief engineer 总工程师、轮机长5、engineer 工程师6、technician 技术员、技师7、division manager 科长8、head of group 组长9、foreman 工长、领班10、inspector 检验员8、ship owner 船东9、register 验船师(机)10、surveyor验船师(船)11、site supervisor 现场验船师12、service engineer 服务商13、fitter 钳工14、electrician 电工15、painter 油漆工16、fabricator装配工17、owner representative船东代表二.技术术语Technical Terms1、pump 泵①Supply pump供给泵②transfer pump 输送泵③circulating pump 循环泵④bilge pump 舱底水泵⑤ballast pump 压载水泵1、tank①drain tank 泄放柜②service tank 日用柜③settling tank沉淀柜④storage tank 储存柜⑤circulating tank 循环柜⑥used oil tank 废油柜⑦buffer tank 缓冲柜⑧overflow tank 溢流柜⑨Collecting tank 收集柜⑩expansion water tank 膨胀水箱2、water①sea water (S.W.) 海水②fresh water (F.W.)淡水③operating water 工作水④sanitary water 卫生水⑤washing water冲洗水⑥refilling water 再注水⑦feed water给水⑧condensate water 冷凝水⑨bilge water 舱底水⑩sewage污水2、oil①fuel oil (F.O.) 燃油②lubricating oil (L.O.) 滑油③engine oil 机油④cylinder oil 气缸油⑤diesel oil (D.O.) 柴油⑥turbine oil 透平油⑦cool oil 冷却油⑧seal oil 密封油3、temperature (temp) 温度4、flow 流量5、pressure(press)压力6、power 功率10、level 液位11、vibration 振动12、normal/abnormal 正常/异常13、main/auxiliary (aux.) 主要/辅助的14、inlet/exhaust 进气/排气15、fire alarm 火警16、fail/failure 故障17、overload 过载18、no-voltage 失电19、leak/leakage 泄漏20、wrong-way 错向21、insulation(insul) 绝缘22、oil mist 油雾23、viscosity 粘度24、density 浓度25、salinity 盐度26、oil content 油含量27、pressure difference 压差28、switch 开关29、flame 火焰30、automatic(auto)自动的31、emergency 应急的32、standby 备用的33、screw 螺丝34、nut 螺母35、stud 螺柱36、meter 仪表37、thermometer温度计38、level gauge 液位计38、pressure gauge 压力表39、length 长度40、breadth 宽度41、height 高度42、meter 米43、centimeter 厘米44、millimeter毫米45、decimillimeter 丝米46、micrometer微米46、hundredth of one millimeter 丝47、de(rust)生锈(除绣)48、spare parts 备件49、spanner 扳手50、ahead/astern 正车/倒车51、screwdriver 螺丝刀(minus / plus)52、sludge 油渣53、electrician’s knife 电工刀54、decrustation pliers 剥线钳三.(主机主要部件)Main Parts for M/E1、engine frame 机架2、cylinder 气缸3、piston 活塞4、crosshead 十字头5、bedplate 机座6、crankshaft 曲轴7、cylinder cover/head 气缸盖8、connecting rod 连杆9、turbocharger 增压器10、driving chain 传动链11、air cooler 空气冷却器12、scanvage box 扫气箱13、oil sprayer 喷油器14、oil nozzle 喷油嘴15、exhaust valve 排气阀16、sealing ring密封环17、cylinder liner 气缸套18、piston rod 活塞杆四.机舱布置图Engine room arrangement1、main engine /M.E. 主机2、intermediate shaft 中间轴3、bearing 轴承4、propeller shaft 螺旋桨轴5、stern tube艉管6、aft seal head tank 后密封油箱7、FWD seal head tank前密封油箱8、stern tube L.O. drain tank 艉管滑油泄放柜9、chemical cleaning tank 化学清洗柜10、L.O. drain tank 滑油泄放柜11、sludge oil trap 油渣收集柜12、rust preventer tank 防锈剂柜13、oily water separator油水分离器14、Low sea chest 低位海水门15、L.O. transfer pump 16、bilge pump 舱底泵17、M/E lub oil pump 18、M/E S.W. cooling pump 主机海水泵19、sludge pump 油渣泵20、ejector pump for F.W.G 造水装置工作水泵21、stern tube L.O. pump 艉轴管滑油泵22、H.F.O. Transfer pump 燃油输送泵23、ballast pump 压载泵24、bilge & G.S. pump 舱底总用泵25、Fire & G.S. pump 消防总用泵26、Provision Ref. Unit S.W. pump伙食冷藏海水泵27、aux. S.W. Cooling pump 辅海水泵28、L.O. purify cleaning tray 滑油分油机洗池29、L.O. purify. Operating water tank 滑油分油机工作水箱30、L.O. purify. Heater滑油分油机加热器31、diesel generator 柴油发电机组32、D/G F.W. Cooler 柴油发电机淡水冷却器33、boiler feed water pump 锅炉给水泵34、cascade tank 热井35、aux. condenser 大气冷凝器36、inspection tank 凝水检查柜37、filter 过滤器38、distilling plant 造水装置39、control air vessel 控制空气瓶40、control air dryer控制空气干燥器41、air compressor 空压机42、main air vessel 主空气瓶43、M/E F.O. heater 主机燃油加热器44、purif room exh fan分油机室抽风机45、sludge tank 油渣柜46、drinking water hydrophone tank 饮水压力柜47、calorifier 热水柜48、drinking water sterilizer 饮水消毒器49、emergency air compressor应急空压机50、stern tube gravity oil tank艉管重力油柜51、antifouling system power unit防污系统电源箱52、ECR. Unit cooler 集控室空冷机53、overhead crane 机舱行车54、boiler feed water test kit 炉水试验台55、cylinder oil measuring tank气缸计量柜56、sink 洗池57、gas welder 气焊机58、E.L. welder 电焊机59、universal machine 组合机床60、driller 立式钻床61、bench 钳桌台62、vice台虎钳63、grinder 砂轮机64、cupboard 橱65、sewage treatment unit 生活污水处理装置66、composite boiler 燃油/废气组合锅炉67、forced draft fan 锅炉强力风机68、incinerator焚烧炉69、waste oil service tank 废油日用柜70、supply ventilating fans 送风机71、spark arrester消音器五.Others1、shipyard 船厂2、shipbuilding 造船3、berth/slipway 船台4、marine diesel engine 船用柴油机5、bulk-cargo carrier 散装货船6、container ship 集装箱船7、oil tanker 油船8、tonnage 吨位9、merchant ship 民用船10、military ship (warship) 军用船11、drawing 图纸12、hull 船外壳13、bow/stern 船艏/船尾14、port/starboard 左舷/右舷15、deadweight 载重量16、displacement 排水量17、freeboard 干舷18、deck 甲板19、keel 龙骨20、anchor 锚21、rudder 舵22、bottom 底23、supersrtucture 上层建筑24、side 舷侧25、weld 焊26、painting 油漆27、assemble 装配28、launching下水29、sea trial 试航30、delivery 交船31、tightness test 密性试验32、after service 售后服务33、approval 认可34、blue collar worker 蓝领35、maker 36、rules and regulations 规则、规范37、chief engineer 轮机长38、chief officer大副39、clerk 事务员40、foreigner 外国人41、fore peak 艏尖舱42、aft peak 尾尖舱43、frame 肋骨44、cabin 舱室45、wheel house 驾驶室46、shaft tunnel 轴隧47、beam横梁48、manhole 人孔49、bulbous bow球鼻艏50、sea chest 海水门51、bulkhead 隔舱壁52、dry cargo hold 干货舱53、provision store 食品库54、passageway 走廊、通道55、refrigerating chamber 冷藏室六、甲板机械Deck Machinery1、deck 甲板2、anchor chain(cable)锚链3、chain locker 锚链舱4、windlass 起锚机5、mooring hole 导缆孔6、bollard 带缆桩7、cargo winch 起货绞车8、hand rail 栏杆9、hawse pipe 锚链筒10、hatchcover 舱口盖11、hatch coaming舱口围板12、control cabin操纵室13、derrick 吊杆14、cargo hook 吊货钩15、mooring winches 系泊绞车16、wire cable 钢索17、vertical ladder 直梯18、wire steel 钢丝卷筒19、side scuttle舷窗20、rudder stock 舵杆21、rudder shaft 舵轴22、flag staff 旗杆23、ventilator 通风筒七、.管系for piping1、Exhaust air system 排气系统Exhaust pipe for M.E(Generators / boiler / emergency generators)主机/ 发电机/ 锅炉/ 应急发电机2、Cooling Water System 冷却水系统①cooling fresh water (CFW) 淡水冷却水②cooling sea water (CSW) 海水冷却水3、fuel oil system 燃油系统①light diesel oil ②heavy diesel oil (HDO)③fuel oil purifying 燃油净化④oil sludge 废油(污油)⑤fuel oil transferring 燃油输送4、Lubricating oil system①L.O for M.E(generator / stern tube) ②Lub. oil transferring5、Compressed air system①high / low pressure air ②starting air 起动空气③control air ④remote control air 遥控空气⑤miscellanous air 杂用空气6、Ship systems①the bilge system舱底水②the ballast system 压载水③the water supply system 供水④the steam system 蒸汽⑤the drainage system 排水⑥the fire-fighting system 消防⑦the air measuring and filling system 空气测量注入⑧the level system 液位7、filter / filter gauze (screen) 8、drainage valve sets9、pressure gauge 压力表9、vacuum真空表10、thermometer 温度计11、steel tube 钢管12、copper tube 铜管13、observation glass 观察镜14、funnel 漏斗15、hose 软管16、induction port 吸口17、bracket 支架18、shim (washer) 垫片19、flange 法兰20、connection 接口21、stainless steel pipe 不锈钢管22、threaded connection 螺纹接头23、sleeve pipe 套管24、flowmeter 流量计25、radiator 散热器26、pipe wrench 管子钳27、spanner 扳手28、pipe cutter 管子割刀29、scraper 刮刀30、vice 老虎钳31、screwdriver 螺丝刀32、torch 手电筒八、主要阀件铭牌Main valve list1、slush valve 截止阀2、non-return valve 止回阀3、through-way valve 直通阀4、butterfly valve 蝶阀5、sluice valve 闸阀6、remote-control butterfly valve 遥控蝶阀7、quick closing valve 速关阀8、self-closing valve 自闭阀9、reducer valve 减压阀10、ball valve 球阀11、copper valve 铜阀12、steel valve 钢阀13、cast iron valve 铸铁阀14、stainless steel valve 不锈钢阀15、safety valve 安全阀16、temperature adjusting valve 温度调节阀17、thermostatic valve 恒温阀18、induction valve 进气阀19、exhaust valve排气阀20、drain valve 排泄阀21、fire valve 消防阀22、three-way valve 三通阀23、valve material①cast iron 铸铁②cast steel铸钢③stainless steel ④bronze 青铜⑤brass黄铜⑥copper紫铜⑦nodular cast iron球墨铸铁九、.电力设备electrical equipment1.emergency (diesel / tacho- / shaft) generator应急(柴油/ 测速/ 轴带)发电机2.servo (governor) motor 伺服(调速)马达3.ignition (current / voltage) transformer点火变压器(电流/电压互换器)4.converter 变流器5.frequency changer 变频器6.charger 充电器7.rectifier 整流器8.uninterrupted power source (UPS)不间断电源装置9.battery or storage battery蓄电池或蓄电池组10.main (emergency / power section) switchboard 主(应急/电力区)配电板11.generator (feeder) panel 发电机(馈电)屏12.charging & discharging panel 充放电板13.(radio / low voltage / internal communication) power distribution board无线电(低压/ 船内通信/ 电力)分电箱14.power unit for cathodic protection阴极保护电源箱15.test panel 电工试验板16.shore connection box 岸电箱17.junction box (with fuse) 接线箱(带熔断器)18.control console (panel) 控制台,集控台19.main engine control stand主机控制台20.motor starter 电动机起动器21.control box (panel) 控制箱(板)22.main engine safety (air conditioning) control box主机安全系统(空调)控制箱23.control box for singal light信号灯控制箱24.steering gear source box 舵机电源箱25.contactor 接触器26.relay 继电器27.control (pressure / change over) switch 控制(压力/ 转换)开关28.magnetic valve 电磁阀29.resistor 电阻器30.push button 按钮31.temperature transducer 温度变换器32.oil mist detector 油雾探测器33.fuse 熔断器34.Ammeter 电流表35.voltmeter 压力表36.power meter 功率表37.power factor meter 功率因数表38.watt-hour meter 电度表39.frequency meter 频率表40.flow meter 流量表41.speed indicator 转速表42.ohm meter 欧姆表43.welder 电焊机lathe 车床44.drilling machine 钻床45.planning machine 刨床46.grinding machine 砂轮机47.electric heater 电热器48.electric refrigerator 电冰箱49.electric fan 电风扇50.air conditioner 空调51.washing machine 洗衣机52.fresh water sterilizer 引水消毒器53.stator 定子54.rotor 转子55.neutral wire 零线(中性线)56.winding 绕组57.coil 线圈十、.illumination equipment 照明设备1.port (starboard) light 左右舷灯2.mast 桅灯(stern艉灯/ anchor锚灯/ steering操舵灯/ signal信号灯/ flashing 闪光灯/ towing 拖船灯/ daylight signal 白昼信号灯/ pendant 舱顶灯/ fluorescent pendant 荧光舱顶灯/ ceiling 蓬顶灯/passage corner 走道角灯/ desk 台灯/ wall 壁灯/ berth 床头灯/ room’s nameplate 舱室铭牌灯/ chart table 海图灯/ flameproof 防爆灯/ flood 泛光灯(强光灯)/ search 聚光灯(探照灯)) light3.switch开关4.plug插头5.socket 插座6.socket box 插座箱十一、.Navigation equipment 导航设备1.gyrocompass 电罗径2.magnetic compass 磁罗径3.feedback unit 反馈装置4.echo-sounder 回声测深仪5.log 计程仪6.master (slave) clock 母(子)钟7.radar 雷达8.radio direction finder 无线电测向仪9.Loran (radio navigation / satellite navigation) receiver劳兰(无线电导航/ 卫星导航)接收机10.VHF radio telephone transceiver 甚高频电话收发信机11.facsimile 传真机12.television set 电视机13.video camera 电视摄像机oxygen 氧气acetylene 乙炔nitrogen 氮气inter gas 惰性气体epoxy 环氧的resin 树脂chock楔子垫木soapy water 肥皂水anemometer 风速计manometer 压力(压强)表,气压表straight edge 直尺feeler gauge 塞尺steel scale 钢尺dial gauge 千分表micrometer 外径千分尺vernier caliper 游标卡尺spanner 扳手wrench 扳手screw driver 螺丝刀hammer 锤子clinometer 测斜仪chain block 手拉葫芦mandatory 命令、强制的Chlorinator 氯化器syphon=siphon 弯管,存水管,虹吸管blind 盲板booklet of piping procedure 工序,过程,步骤gymnasium 健身房galley 船上厨房motorcycle safety helmet 安全帽life belt 安全带glove 手套respirator 口罩overall 工作服uniformelectric torch 手电筒flashlighteyeglass 眼镜elevator 电梯plank 厚木板stage 大舞台expressions 公式formula(复数formulae)plus 加,正minus 减,负multiply 乘divide by 用…除equal to 等于sb entrust sb with sth 委托某人reply to 答复promise 许诺explanation 解释说明answer to 答案typist 打字员triangle 三角形quadrangle 四边形四角形pentagon 五角形inflator 打气筒tyre 轮胎wheel 车轮off duty 下班on duty 上班overtime 加班Slipway、shipway船台1.Lighting alignment for shafting & rudder system 轴舵系照光对中2.Stern tube boring 艉轴管镗孔3.Stern tube bush 艉轴衬套4.Stern boss艉轴壳5.forced fitting inspection压入配合检验6.oil jack(千斤顶)油泵7.(propeller shaft & stern tube bush)radial clearance (艉轴和艉管衬套)径向间隙8.axial clearance 轴向间隙9.Stern tube seals sealing 艉轴密封10. propeller installation force fitting压配11.pull-up length压进距离12.pull-up force 推进力13.oilpressure for boss 扩涨油压14.Zero point 零点15. Shrinkage 过盈量16.cleanness光洁度17.taper圆锥,斜度18. superposition 重合19. intersect 相交20.perpendicularity 垂直度21.vertical垂直的22.horizontal 水平的23. nut of stern shaft艉轴螺栓24.rudder 舵25.rudder blade 舵叶26.rudder stock 舵杆27.rudder pintle 舵销28.rudder tiller 舵柄29.rudder bush 舵承30.rudder horn 挂舵臂31. securing key 定位销,定位键32.protecting cover 保护帽33.grease牛油34.rudder angle 舵角35.full angle 满舵36. rudder blade’s stopper防跳块37.temperature sensor 温度传感器38. inlet outlet 进出39. tolerance 公差,允许量40.wear down gauge 磨损规41.stern tube main chamber 大腔42.high pressure chamber 高压腔43.low pressure chamber 低压腔Engine Room 机舱1.Cleaning check:Storage oil tank of steering gear 舵机储存油箱(方形)Expansion oil tank of mooring winch 绞机膨胀油箱(圆形)Storage oil tank of mooring winch 绞机储存油箱Storage oil tank of windlass 锚机储存油箱(方形)Expansion oil tank of windlass 锚机膨胀油箱(圆形)Hydraulic oil tank of hatch cover 舱口盖液压油箱2.flushing of winch piping 绞机管路投油1.D/G pouring epoxy chock 发电机浇环氧2.holding down bolt 地脚螺栓3.deflection of crankshaft 曲轴甩档4.piston 活塞5.cylinder 气缸6. turbocharger 涡轮增压器7.1.Force measurement of M/E stay bolts 紧固螺栓2.piston rod and connection rod bolts 活塞杆和连杆螺栓3.bolts in drive end of crank 曲轴大端螺栓4.piston—piston rod—crosshead—connection rod—crank—crankshaft活塞活塞杆十字头连杆曲柄曲轴5.cam 凸轮6.camshaft 凸轮轴7.M/E chain cable 主机链条8.flooding test of M/E return oil pipes 压水试验9.propeller cap—propeller—stern tube seals—stern tube bush—stern shaft—intermediate shaft导流帽螺旋桨艉密封艉管衬套艉轴中间轴—intermediate bearing—flywheel (thrust shaft)中间轴承飞轮推力轴10.coupling reamer holes 联轴节铰制孔11.turning gear 盘车机12. spring 弹簧1.main air compressor主空压机2.alignment of coupling flange 联轴节对中3.gap 裂面4.sag 位移1.steering gear舵机2. ram roller bearing 舵机活塞杆轴承3. neck bush & cylinder 舵机活塞颈衬套和活塞缸体4. dimension measurement 尺寸测量1.fore draft valve艏吃水阀2.speed log 计程仪3.echo sounder 测深仪Quay、shipside、wharf、dock码头11。

Ⅰ.技术术语Technical Terms1、pump 泵①Supply pump供给泵②transfer pump 输送泵③circulating pump 循环泵④bilge pump 舱底水泵⑤ballast pump 压载水泵1、tank①drain tank 泄放柜②service tank 日用柜③settling tank沉淀柜④storage tank 储存柜⑤circulating tank 循环柜⑥used oil tank 废油柜⑦buffer tank 缓冲柜⑧overflow tank 溢流柜⑨Collecting tank 收集柜⑩expansion water tank 膨胀水箱2、water①sea water (S.W.) 海水②fresh water (F.W.) 淡水③operating water 工作水④sanitary water 卫生水⑤washing water 冲洗水⑥refilling water 再注水⑦feed water 给水⑧condensate water 冷凝水⑨bilge water 舱底水⑩sewage 污水2、oil①fuel oil (F.O.) 燃油②lubricating oil (L.O.) 滑油③engine oil 机油④cylinder oil 气缸油⑤diesel oil (D.O.) 柴油⑥turbine oil 透平油⑦cool oil 冷却油⑧seal oil 密封油3、temperature (temp) 温度4、flow 流量5、pressure(press)压力6、power 功率10、level 液位 11、vibration 振动12、normal/abnormal 正常/异常13、main/auxiliary (aux.) 主要/辅助的14、inlet/exhaust 进气/排气15、fire alarm 火警16、fail/failure 故障17、overload 过载 18、no-voltage 失电19、leak/leakage 泄漏20、wrong-way 错向21、insulation(insul) 绝缘22、oil mist 油雾 23、viscosity 粘度24、density 浓度 25、salinity 盐度26、oil content 油含量27、pressure difference 压差28、switch 开关 29、flame 火焰30、automatic(auto)自动的31、emergency 应急的32、standby 备用的33、screw 螺丝 34、nut 螺母35、stud 螺柱36、meter 仪表 37、thermometer温度计38、level gauge 液位计38、pressure gauge 压力表39、length 长度 40、breadth 宽度41、height 高度42、meter 米 43、centimeter 厘米 44、millimeter毫米45、decimillimetre 丝米 46、micrometer微米46、hundredth of one millimeter 丝47、de(rust)生锈(除绣)48、spare parts 备件 49、spanner 扳手50、ahead/astern 正车/倒车 51、screwdriver 螺丝刀(minus / plus)52、sludge 油渣53、electrician’s knife 电工刀 54、decrustation pliers 剥线钳Ⅱ.(主机主要部件)Main Parts for M/E1、engine frame 机架2、cylinder 气缸3、piston 活塞4、crosshead 十字头5、bedplate 机座6、crankshaft 曲轴7、cylinder cover/head 气缸盖8、connecting rod 连杆9、turbocharger 增压器10、driving chain 传动链11、air cooler 空气冷却器12、scanvage box 扫气箱13、oil sprayer 喷油器14、oil nozzle 喷油嘴15、exhaust valve 排气阀16、sealing ring密封环17、cylinder liner 气缸套18、piston rod 活塞杆Ⅲ.机舱布置图Engine room arrangement1、main engine /M.E. 主机2、intermediate shaft 中间轴3、bearing 轴承4、propeller shaft 螺旋桨轴5、stern tube艉管6、aft seal head tank 后密封油箱7、FWD seal head tank前密封油箱8、stern tube L.O. drain tank 艉管滑油泄放柜9、chemical cleaning tank 化学清洗柜 10、L.O. drain tank11、sludge oil trap 油渣收集柜12、rust preventer tank 防锈剂柜13、oily water separator油水分离器14、Low sea chest 低位海水门15、L.O. transfer pump 16、bilge pump 舱底泵17、M/E lub oil pump 18、M/E S.W. cooling pump 主机海水泵19、sludge pump 油渣泵20、ejector pump for F.W.G 造水装置工作水泵21、stern tube L.O. pump 艉轴管滑油泵22、H.F.O. Transfer pump 燃油输送泵23、ballast pump 压载泵24、bilge & G.S. pump 舱底总用泵25、Fire & G.S. pump 消防总用泵26、Provision Ref. Unit S.W. pump伙食冷藏海水泵27、aux. S.W. Cooling pump 辅海水泵28、L.O. purify cleaning tray 滑油分油机洗池29、L.O. purify. Operating water tank 滑油分油机工作水箱30、L.O. purify. Heater滑油分油机加热器31、diesel generator 柴油发电机组32、D/G F.W. Cooler 柴油发电机淡水冷却器33、boiler feed water pump 锅炉给水泵34、cascade tank 热井35、aux.condenser 大气冷凝器36、inspection tank 凝水检查柜37、filter 过滤器38、distilling plant 造水装置39、control air vessel 控制空气瓶40、control air dryer控制空气干燥器41、air compressor 空压机42、main air vessel 主空气瓶43、M/E F.O. heater 主机燃油加热器44、purif room exh fan分油机室抽风机45、sludge tank 油渣柜46、drinking water hydrophone tank 饮水压力柜47、calorifier 热水柜 48、drinking water sterilizer 饮水消毒器49、emergency air compressor 50、stern tube gravity oil tank艉管重力油柜51、antifouling system power unit防污系统电源箱52、ECR. Unit cooler 集控室空冷机53、overhead crane 机舱行车 54、boiler feed water test kit 炉水试验台55、cylinder oil measuring tank气缸计量柜 56、sink 洗池57、gas welder 气焊机58、E.L. welder 电焊机59、universal machine 组合机床60、driller 立式钻床61、bench 钳桌台62、vice台虎钳63、grinder 砂轮机64、cupboard 橱65、sewage treatment unit 生活污水处理装置66、composite boiler 燃油/废气组合锅炉67、forced draft fan 锅炉强力风机68、incinerator焚烧炉69、waste oil service tank 废油日用柜70、supply ventilating fans 送风机71、spark arrester消音器Ⅳ.Others1、shipyard 船厂2、shipbuilding 造船3、berth/slipway 船台4、marine diesel engine 船用柴油机5、bulk-cargo carrier 散装货船6、container ship 集装箱船7、oil tanker 油船 8、tonnage 吨位9、merchant ship 民用船10、military ship (warship) 军用船11、drawing 图纸12、hull 船外壳13、bow/stern 船艏/船尾14、port/starboard 左舷/右舷15、deadweight 载重量 16、displacement 排水量17、freeboard 干舷 18、deck 甲板19、keel 龙骨20、anchor 锚21、rudder 舵22、bottom 底23、supersrtucture 上层建筑24、side25、weld 焊 26、painting 油漆27、assemble 装配 28、launching29、sea trial 试航 30、delivery 交船31、tightness test 密性试验 32、after service 售后服务33、approval 认可 34、blue collar worker 蓝领35、maker 36、rules and regulations 规则、规范37、chief engineer 轮机长 38、chief officer大副39、clerk 事务员 40、foreigner41、fore peak 艏尖舱 42、aft peak 尾尖舱43、frame 肋骨 44、cabin 舱室45、wheel house 驾驶室 46、shaft tunnel 轴隧47、beam横梁 48、manhole 人孔49、bulbous bow球鼻艏 50、sea chest 海水门51、bulkhead 隔舱壁 52、dry cargo hold 干货舱53、provision store 食品库 54、passageway 走廊、通道55、refrigerating chamber 冷藏室Ⅴ甲板机械Deck Machinery1、deck 甲板2、anchor chain(cable)锚链3、chain locker 锚链舱4、windlass 起锚机5、mooring hole 导缆孔6、bollard 带缆桩7、cargo winch 起货绞车8、hand rail 栏杆9、hawse pipe 锚链筒 10、hatchcover 舱口盖11、hatch coaming舱口围板12、control cabin操纵室13、derrick 吊杆14、cargo hook 吊货钩15、mooring winches 系泊绞车16、wire cable 钢索17、vertical ladder 直梯18、wire steel 钢丝卷筒19、side scuttle舷窗20、rudder stock 舵杆21、rudder shaft 舵轴22、flag staff 旗杆23、ventilator 通风筒Ⅵ.管系for piping1、Exhaust air system 排气系统Exhaust pipe for M.E(Generators / boiler / emergency generators)主机/ 发电机/ 锅炉/ 应急发电机2、Cooling Water System 冷却水系统①cooling fresh water (CFW) 淡水冷却水②cooling sea water (CSW) 海水冷却水3、fuel oil system 燃油系统①light diesel oil ②heavy diesel oil (HDO)③fuel oil purifying 燃油净化④oil sludge 废油(污油)⑤fuel oil transferring 燃油输送4、Lubricating oil system①L.O for M.E(generator / stern tube) ②Lub. oil transferring5、Compressed air system①high / low pressure air ②starting air 起动空气③control air ④remote control air 遥控空气⑤miscellanous air 杂用空气6、Ship systems①the bilge system舱底水②the ballast system 压载水③the water supply system 供水④the steam system 蒸汽⑤the drainage system 排水⑥the fire-fighting system 消防⑦the air measuring and filling system 空气测量注入⑧the level system 液位7、filter / filter gauze (screen) 8、drainage valve sets9、pressure gauge 压力表9、vacuum真空表10、thermometer 温度计11、steel tube 钢管12、copper tube 铜管13、observation glass 观察镜14、funnel 漏斗15、hose 软管16、induction port 吸口17、bracker 支架18、shim (washer) 垫片19、flange 法兰20、connection 接口21、stainless steel pipe 不锈钢管22、threaded connection 螺纹接头23、sleeve pipe 套管 24、flowmeter 流量计25、radiator 散热器26、pipe wrench 管子钳27、spanner 扳手28、pipe cutter 管子割刀29、scraper 刮刀30、vice 老虎钳31、screwdriver 螺丝刀 32、torch 手电筒Ⅶ主要阀件铭牌Main valve list1、slush valve 截止阀2、non-return valve 止回阀3、through-way valve 直通阀4、butterfly valve 蝶阀5、sluice valve 闸阀6、remote-control butterfly valve 遥控蝶阀7、quick closing valve 速关阀8、self-closing valve 自闭阀9、reducer valve 减压阀10、ball valve 球阀11、copper valve 铜阀12、steel valve 钢阀13、cast iron valve 铸铁阀14、stainless steel valve 不锈钢阀15、safety valve 安全阀16、temperature adjusting valve 温度调节阀17、thermostatic valve 恒温阀18、induction valve 进气阀19、exhaust valve排气阀20、drain valve 排泄阀21、fire valve 消防阀22、three-way valve 三通阀23、valve material①cast iron 铸铁②cast steel铸钢③stainless steel④bronze 青铜⑤brass黄铜⑥copper紫铜⑦nodular cast iron球墨铸铁Ⅷ.电力设备electrical equipment1. emergency (diesel / tacho- / shaft) generator应急(柴油/ 测速/ 轴带)发电机2. servo (governor) motor 伺服(调速)马达3. ignition (current / voltage) transformer点火变压器(电流/电压互换器)4. converter 变流器5. frequency changer 变频器6. charger 充电器7. rectifier 整流器8. uninterrupted power source (UPS)不间断电源装置9. battery or storage battery蓄电池或蓄电池组10. main (emergency / power section) switchboard 主(应急/电力区)配电板11. generator (feeder) panel 发电机(馈电)屏12. charging & discharging panel 充放电板13. (radio / low voltage / internal communication) power distribution board无线电(低压/ 船内通信/ 电力)分电箱14. power unit for cathodic protection阴极保护电源箱15. test panel 电工试验板16. shore connection box 岸电箱17. junction box (with fuse) 接线箱(带熔断器)18. control console (panel) 控制台,集控台19. main engine control stand主机控制台20. motor starter 电动机起动器21. control box (panel) 控制箱(板)22. main engine safety (air conditioning) control box主机安全系统(空调)控制箱23. control box for singal light信号灯控制箱24. steering gear source box 舵机电源箱25. contactor 接触器26. relay 继电器27. control (pressure / change over) switch 控制(压力/ 转换)开关28. magnetic valve 电磁阀29. resistor 电阻器30. push button 按钮31. temperature transducer 温度变换器32. oil mist detector 油雾探测器33. fuse 熔断器34. Ammeter 电流表35. voltmeter 压力表36. power meter 功率表37. power factor meter 功率因数表38. watt-hour meter 电度表39. frequency meter 频率表40. flow meter 流量表41. speed indicator 转速表42. ohm meter 欧姆表43. welder 电焊机44. lathe 车床45. drilling machine 钻床46. planning machine 刨床47. grinding machine 砂轮机48. electric heater 电热器49. electric refrigerator 电冰箱50. electric fan 电风扇51. air conditioner 空调52. washing machine 洗衣机53. fresh water sterilizer 引水消毒器54. stator 定子55. rotor 转子56. neutral wire 零线(中性线)57. winding 绕组58. coil 线圈Ⅸ.illumination equipment 照明设备1. port (starboard) light 左右舷灯2. mast 桅灯(stern艉灯/ anchor锚灯/ steering操舵灯/ signal信号灯/ flashing 闪光灯/ towing 拖船灯/ daylight signal 白昼信号灯/ pendant 舱顶灯/ fluorescent pendant 荧光舱顶灯/ ceiling 蓬顶灯/passage corner 走道角灯/ desk 台灯/ wall 壁灯/ berth 床头灯/ room’s nameplate 舱室铭牌灯/ chart table 海图灯/ flameproof 防爆灯/ flood 泛光灯(强光灯)/ search 聚光灯(探照灯)) light3. switch开关4. plug插头5. socket 插座6. socket box 插座箱Ⅹ.Navigation equipment 导航设备1. gyrocompass 电罗径2. magnetic compass 磁罗径3. feedback unit 反馈装置4. echo-sounder 回声测深仪5. log 计程仪6. master (slave) clock 母(子)钟7. radar 雷达8. radio direction finder 无线电测向仪9. Loran (radio navigation / satellite navigation) receiver劳兰(无线电导航/ 卫星导航)接收机10. VHF radio telephone transceiver 甚高频电话收发信机11. facsimile 传真机12. television set 电视机13. video camera 电视摄像机oxygen 氧气acetylene 乙炔nitrogen 氮气inter gas 惰性气体epoxy 环氧的resin 树脂chock楔子垫木soapy water 肥皂水anemometer 风速计manometer 压力(压强)表,气压表straight edge 直尺feeler gauge 塞尺steel scale 钢尺dial gauge 千分表micrometer 外径千分尺vernier caliper 游标卡尺spanner 扳手wrench 扳手screw driver 螺丝刀hammer 锤子clinometer 测斜仪chain block 手拉葫芦mandatory 命令、强制的Chlorinator 氯化器syphon=siphon 弯管,存水管,虹吸管blind 盲板booklet of piping procedure 工序,过程,步骤gymnasium 健身房galley 船上厨房motorcycle safety helmet 安全帽life belt 安全带glove 手套respirator 口罩overall 工作服uniformelectric torch 手电筒flashlighteyeglass 眼镜elevator 电梯plank 厚木板stage 大舞台expressions 公式formula(复数formulae)plus 加,正minus 减,负multiply 乘divide by 用…除equal to 等于sb entrust sb with sth 委托某人reply to 答复promise 许诺explanation 解释说明answer to 答案typist 打字员triangle 三角形quadrangle 四边形四角形pentagon 五角形inflator 打气筒tyre 轮胎wheel 车轮off duty 下班on duty 上班overtime 加班Slipway、shipway船台1.Lighting alignment for shafting & rudder system 轴舵系照光对中2.Stern tube boring 艉轴管镗孔3.Stern tube bush 艉轴衬套4.Stern boss艉轴壳5.forced fitting inspection压入配合检验6.oil jack(千斤顶)油泵7.(propeller shaft & stern tube bush)radial clearance (艉轴和艉管衬套)径向间隙8.axial clearance 轴向间隙9.Stern tube seals sealing 艉轴密封10. propeller installation force fitting压配11.pull-up length压进距离12.pull-up force 推进力13.oilpressure for boss 扩涨油压14.Zero point 零点15. Shrinkage 过盈量16.cleanness光洁度17.taper圆锥,斜度18. superposition 重合19. intersect 相交20.perpendicularity 垂直度21.vertical垂直的22.horizontal 水平的23. nut of stern shaft艉轴螺栓24.rudder 舵25.rudder blade 舵叶26.rudder stock 舵杆27.rudder pintle 舵销28.rudder tiller 舵柄29.rudder bush 舵承30.rudder horn 挂舵臂31. securing key 定位销,定位键32.protecting cover 保护帽33.grease牛油34.rudder angle 舵角35.full angle 满舵36. rudder blade’s stopper 防跳块37.temperature sensor 温度传感器38. inlet outlet 进出39. tolerance 公差,允许量40.wear down gauge 磨损规41.stern tube main chamber 大腔42.high pressure chamber 高压腔43.low pressure chamber 低压腔Engine Room 机舱1.Cleaning check:Storage oil tank of steering gear 舵机储存油箱(方形)Expansion oil tank of mooring winch 绞机膨胀油箱(圆形)Storage oil tank of mooring winch 绞机储存油箱Storage oil tank of windlass 锚机储存油箱(方形)Expansion oil tank of windlass 锚机膨胀油箱(圆形)Hydraulic oil tank of hatch cover 舱口盖液压油箱2.flushing of winch piping 绞机管路投油1.D/G pouring epoxy chock 发电机浇环氧2.holding down bolt 地脚螺栓3. deflection of crankshaft 曲轴甩档4.piston 活塞5.cylinder 气缸6. turbocharger 涡轮增压器7.1.Force measurement of M/E stay bolts 紧固螺栓2.piston rod and connection rod bolts 活塞杆和连杆螺栓3.bolts in drive end of crank 曲轴大端螺栓4.piston—piston rod—crosshead—connection rod—crank—crankshaft活塞活塞杆十字头连杆曲柄曲轴5.cam 凸轮6.camshaft 凸轮轴7.M/E chain cable 主机链条8.flooding test of M/E return oil pipes 压水试验9.propeller cap—propeller—stern tube seals—stern tube bush—stern shaft—intermediate shaft 导流帽螺旋桨艉密封艉管衬套艉轴中间轴—intermediate bearing—flywheel (thrust shaft)中间轴承飞轮推力轴10.coupling reamer holes 联轴节铰制孔11.turning gear 盘车机12. spring 弹簧1.main air compressor 主空压机2.alignment of coupling flange 联轴节对中3.gap 裂面4.sag 位移1.steering gear 舵机2. ram roller bearing 舵机活塞杆轴承3. neck bush & cylinder 舵机活塞颈衬套和活塞缸体4. dimension measurement 尺寸测量1.fore draft valve艏吃水阀2.speed log 计程仪3.echo sounder 测深仪Quay、shipside、wharf、dock码头。

目录content1.总则general description (5)2.舵机试验steering gear test (5)3.锚机试验windlass test (8)4.系泊绞车试验mooring winches test (10)5.救生艇、救助艇及其相关装置lifeboat, rescue boat and appliance (12)6.物料吊试验provision crane test (14)7.苏伊士运河灯吊杆试验 suez canal searchlight davit test (15)8.舷梯试验 accommodation ladder (15)9.引水员梯试验pilot ladder (17)10.门、窗、盖试验 test of doors,window and cover (18)11.机舱行车试验E.R crane test (20)12.机修设备试验 workshop equipments test (20)13.燃油及滑油快关阀试验F.O and L.O quick-closed test (21)14.污水处理装置试验 sewage treatment test (22)15.舱底水油水分离器试验 bilge oil-water seperator (22)16.焚烧炉试验incinerator test (23)17.制淡装置试验F.W generator test (24)18.分油机试验 oil separator test (24)19.空压机及空气瓶试验 test of air compressor and air reservoir (25)20.机舱水雾灭火系统试验test for E.R water mist fire extinguishing system (27)21.生活供水系统试验 water supply system test (27)22.机械通风系统试验 mechanical ventilation system test (28)23.CO2灭火系统试验 CO2 fire extinguish system test (29)24.水消防系统试验 water fire fighting system test (29)25.阀门遥控系统试验 valve remoting system test (31)26.压载系统试验 ballast system test (31)27.液位、温度遥测系统试验level and temperature remote system test (32)28.舱底水系统试验 bilge water system test (33)29.淡水冷却系统试验 F.W cooling system test (34)30.海水冷却系统试验sea water cooling system test (34)31.油渣输送系统试验 oil sludge transferring system test (35)32.滑油输送及主机润滑系统试验 L.O transferring and M.E lubrication test (35)33.燃油储藏及输送系统试验F.O stori ng and transferring system test (36)34.燃油日用系统及供油单元试验F.O daily system and oil-supply unit test (37)35.锅炉试验 boiler test (38)36.主推进系统试验 main propulsion system test (41)37.主电站试验 main power station test (44)38. 应急电站试验emergency power station test (68)39.照明系统试验 lighting system test (72)40.内部通讯和报警系统试验intercommunication and alarm test (73)41.导航设备试验navigation equipment test (75)42.无线电设备试验radio equipments test (86)43.检测和报警系统(自动化系统)实验Detectingand alarm system (automation system)test (88)44.其它电气设备试验 other electrical equipments (88)45.货舱进水系统试验Cargo hold water ingress system test (89)46.克令吊试验 Crane t est (90)47.舱口盖试验 Hatch cover test (93)48.甲板疏水和卫生排泄系统试验Deck drainage system& ER room drainage system甲板疏排水系统和机舱疏排水系统 (94)Item that are missing: 缺少的项目(根据实船调试、报验情况而定)1. Distribution panels 分配盘2. Engineer watch call system and Officer extension alarms system轮机员值守呼叫系统和官员延伸报警系统3. Transformers 变压器4. Insulation Resistance 绝缘电阻5. Dead Man alarm system 冗员报警系统6. Loading computer 装载计算机(按厂家服务商要求)7. Alarm Columns in E/R机舱报警灯柱8. Dead Ship 瘫船(在航行试验中进行)9. Sequential Start System顺序启动系统10. Air Condition Plant空调装置(按杰奥空调厂家服务商要求)11. Fire System for Paint Store 油漆储存间消防系统12. Miscelaneos Items (lifting eyes,lifting beams) 杂项(吊耳,吊梁)13. Changeover ST-BY pumps test辅助-备用泵切换测试14. Storage Battery Discharge \ Charge test to be provided蓄电池冲放电测试15. Accomodations Cabins 居住舱16. Furniture夹具17. Galley Equipment厨房设备(参照厂家资料效用)18. Fans of Accomodations,Bosun Store. 居舱,水手长储存间风机(效用)19. Emergency Fire Pump,General Service pumps % Ballast Pumps 应急消防泵,通用日用泵压载泵(参照原理图效用)20. Emergency General Alarm and Public Adress System应急通用报警和公共广播系统21. Sanitary Equipment卫生间设备(参照厂家资料效用)22. Instalattions of ICCP and Antifouling system in E/R 机舱内的阴极保护装置和防腐蚀系统(参照厂家资料检查)23. Spare Parts for Crew deck and engine船员甲板和轮机备件1.总述GENERAL DESCRIPTION1.1本试验程序根据上海船舶研究设计院编制的试验大纲和《GB3471-1995钢质海船系泊和航行试验大纲》编制。

浅谈卷取设备中张力控制系统发展现状摘要:张力控制是纺织,造纸等行业应用最为广泛的一项技术,它实现的好坏直接关系到产品的生产效率的高低和质量的优劣。

本文对张力控制领域的间接法、直接法张力控制原理进行介绍,并梳理恒张力控制系统的国内外发展现状,为进一步研究提供了相关参考资料。

关键词:卷曲设备;张力控制;专利分析;技术发展一、引言张力控制,比较通俗的讲,就是要控制卷取物体时保持物体相互拉长或者绷紧的力。

早期的工业应用中,张力控制并未引起人们足够的重视。

直到人们对卷取材料的质量和表面质量提出越来越严格要求的时候,张力控制技术才逐渐被各国电气工程师重视起来,特别是张力应用最广泛的纤维、造纸、塑料薄膜、电线、印刷品、磁带等轻工业中,带材或线材的收放卷张力对产品的质量起着至关重要的作用。

二、张力控制系统的概念以及基本原理在纺织、造纸等轻工业行业中,在加工过程中或者是加工完成之后,最后的一道工序一般就是将加工物卷绕成筒状。

在这一过程中,卷绕的好坏将是决定产品质量的关键,卷的太紧,容易使织物变形,拉断,卷的太松又容易使卷取不紧凑,不利于搬运和运输,因而为了达到使卷绕紧凑,保证产品的质量,都要求在卷绕过程中,在织物上建立一定的张力,并保持张力为一恒定值,能够实现这一功能的系统,就叫做张力控制系统。

目前应用的张力控制系统,根据其测量控制的原理结构,主要有以下三种:1.间接法张力控制系统2.直接法张力控制系统3.兼有间接法和直接法的复合张力控制系统2.1间接法张力控制原理间接法张力控制,也就是通过调节驱动力的及时大小来实现张紧力的调节。

比较通俗的讲,是一个开环扰动的控制系统,即按照现场张力与实际设定值之间的偏差来进行调节,通过间接地改变张力执行部件的激励电流、磁场等电气参数来动态补偿现场的干扰量。

电动机通过减速机构输出控制收卷轴的卷取速度:卷取速度快,相应地张力就大,卷取速度慢,张力显示就小。

因而只要借助于一定的检测设备,检测出现场的扭转角速度或者是卷径,在保证电机激励磁通不变的情况下,动态修正激励电流即可以实现在卷径和速度变化情况下现场张力的恒定。

辅机到280 934-945Sediment残渣demister汽水分离器agitate 搅拌ispp---200及以上iapp---400及以上生活污水(sewage)3海里以外,机舱污水(bilge water)不包括生活污水。

消毒器(disinfector)特殊区域12海里以上可排食物钻井平台上的食物在12海里以外包装材料25海里以外含油污水50海里以外STCW保证足够休息ibc--solas 惰性系统排出的惰性气体含氧量不超过5% 惰性系统在洗油舱前最大含氧量为8%应急舵机三个月检查一次ISM>SMS>SMCtacit acceptance procedure 默认接受程序闪点--释放蒸汽形成可燃混合气的最低温度,反应挥发性(volatility),柴油闪点最低燃点(fire point)--释放蒸汽并持续燃烧的最低温度。

系统操作温度考虑浊点(cloud point)和倾点。

倾点低于浊点。

闪点低于燃点。

压缩机load----stopplate----cooling jacket water and oil溶解的固体物--TDS粘度计维持粘度油雾探测器用于曲轴箱垃圾记录簿保存2年油类记录簿保存3年,最后一次记录后保存三年启动空气管会爆炸加热缸套水使启动容易大管轮主机二管轮辅机三管轮锅炉人工呼吸每分钟12--15次油柜预留1%--3%供膨胀,温度对于预留空间很重要。

2长4短时堵漏报警33解除7短1长弃船乱钟(间隔少于十秒)着火乱钟加4声敲击机舱着火滤器在排出侧polish 三螺杆泵最适于油水分离器给水关离合器---停主机convection对流船上无法移除油类灭火二氧化碳最适于灭B、C类火,卤素(halon)、干粉可灭C类火二氧化碳灭火剂每年称一次重量,用过一次就要排空。

干粉(dry chemical)和水灭火要注意防止复燃。

大量油着火用泡沫灭火剂(foam)soda-acid extinguisher 酸碱灭火器充每年一次油漆间或细碎的油布(paint locker)最可能自燃快速清洁滤器在消防栓(fire hydrant)处183mm直径的通岸接口口径。

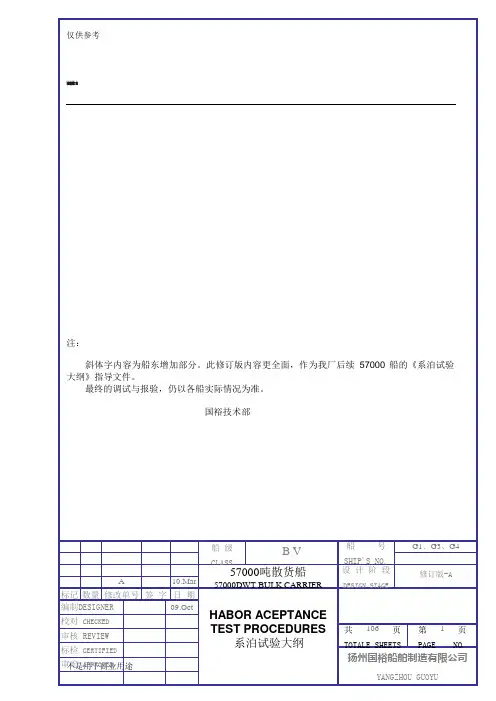

注:斜体字内容为船东增加部分。

此修订版内容更全面,作为我厂后续57000船的《系泊试验大纲》指导文件。

最终的调试与报验,仍以各船实际情况为准。

国裕技术部标记数量修改单号签字日期编制DESIGNER校对CHECKED审核 REVIEW标检CERTIFIED 船级CLASS船号SHIP'S NO.设计阶段DESIGN STAGE共页TOTALE SHEETS第页PAGE NO.106 1A 10.Mar09.OctB V57000吨散货船57000DWT BULK CARRIERHABOR ACEPTANCETEST PROCEDURES系泊试验大纲G1、G3、G4修订版-A目录content1.总则general description (5)2.舵机试验steering gear test (5)3.锚机试验windlass test (8)4.系泊绞车试验mooring winches test (10)5.救生艇、救助艇及其相关装置lifeboat, rescue boat and appliance (12)6.物料吊试验provision crane test (14)7.苏伊士运河灯吊杆试验 suez canal searchlight davit test (15)8.舷梯试验 accommodation ladder (15)9.引水员梯试验pilot ladder (17)10.门、窗、盖试验 test of doors,window and cover (18)11.机舱行车试验E.R crane test (20)12.机修设备试验 workshop equipments test (20)13.燃油及滑油快关阀试验F.O and L.O quick-closed test (21)14.污水处理装置试验 sewage treatment test (22)15.舱底水油水分离器试验 bilge oil-water seperator (22)16.焚烧炉试验incinerator test (23)17.制淡装置试验F.W generator test (24)18.分油机试验 oil separator test (24)19.空压机及空气瓶试验 test of air compressor and air reservoir (25)20.机舱水雾灭火系统试验test for E.R water mist fire extinguishing system (27)21.生活供水系统试验 water supply system test (27)22.机械通风系统试验 mechanical ventilation system test (28)23.CO2灭火系统试验 CO2 fire extinguish system test (29)24.水消防系统试验 water fire fighting system test (29)25.阀门遥控系统试验 valve remoting system test (31)26.压载系统试验 ballast system test (31)27.液位、温度遥测系统试验level and temperature remote system test (32)28.舱底水系统试验 bilge water system test (33)29.淡水冷却系统试验 F.W cooling system test (34)30.海水冷却系统试验sea water cooling system test (34)31.油渣输送系统试验 oil sludge transferring system test (35)32.滑油输送及主机润滑系统试验 L.O transferring and M.E lubrication test (35)33.燃油储藏及输送系统试验F.O stori ng and transferring system test (36)34.燃油日用系统及供油单元试验F.O daily system and oil-supply unit test (37)35.锅炉试验 boiler test (38)36.主推进系统试验 main propulsion system test (41)37.主电站试验 main power station test (44)38. 应急电站试验emergency power station test (68)39.照明系统试验 lighting system test (72)40.内部通讯和报警系统试验intercommunication and alarm test (73)41.导航设备试验navigation equipment test (75)42.无线电设备试验radio equipments test (86)43.检测和报警系统(自动化系统)实验Detectingand alarm system (automation system)test (88)44.其它电气设备试验 other electrical equipments (88)45.货舱进水系统试验Cargo hold water ingress system test (89)46.克令吊试验 Crane t est (90)47.舱口盖试验 Hatch cover test (93)48.甲板疏水和卫生排泄系统试验Deck drainage system& ER room drainage system甲板疏排水系统和机舱疏排水系统 (94)Item that are missing: 缺少的项目(根据实船调试、报验情况而定)1. Distribution panels 分配盘2. Engineer watch call system and Officer extension alarms system轮机员值守呼叫系统和官员延伸报警系统3. Transformers 变压器4. Insulation Resistance 绝缘电阻5. Dead Man alarm system 冗员报警系统6. Loading computer 装载计算机(按厂家服务商要求)7. Alarm Columns in E/R机舱报警灯柱8. Dead Ship 瘫船(在航行试验中进行)9. Sequential Start System顺序启动系统10. Air Condition Plant空调装置(按杰奥空调厂家服务商要求)11. Fire System for Paint Store 油漆储存间消防系统12. Miscelaneos Items (lifting eyes,lifting beams) 杂项(吊耳,吊梁)13. Changeover ST-BY pumps test辅助-备用泵切换测试14. Storage Battery Discharge \ Charge test to be provided蓄电池冲放电测试15. Accomodations Cabins 居住舱16. Furniture夹具17. Galley Equipment厨房设备(参照厂家资料效用)18. Fans of Accomodations,Bosun Store. 居舱,水手长储存间风机(效用)19. Emergency Fire Pump,General Service pumps % Ballast Pumps 应急消防泵,通用日用泵压载泵(参照原理图效用)20. Emergency General Alarm and Public Adress System应急通用报警和公共广播系统21. Sanitary Equipment卫生间设备(参照厂家资料效用)22. Instalattions of ICCP and Antifouling system in E/R 机舱内的阴极保护装置和防腐蚀系统(参照厂家资料检查)23. Spare Parts for Crew deck and engine船员甲板和轮机备件1.总述GENERAL DESCRIPTION1.1本试验程序根据上海船舶研究设计院编制的试验大纲和《GB3471-1995钢质海船系泊和航行试验大纲》编制。

—MARINEDrives and motors for electrically driven deck machinery and offshore winches• Working in close cooperation with winch manufacturers,we've incorporated our extensive experience into the drivesthat work with various marine and offshore winch types.• Pair our drives with our LV marine motors for a one-stop supplierthat is backed by a global service and support network.2M A R I N E B R O CH U R E—Performance. Speed. Reliability. Safety.Everything counts.With the help of application expertise gained over many years, we’ve developeddrives and motors that enable precise, smooth, dependable, and safe winch operation, while reducing wear on the ropes and winch. Because everything counts.Anchoring/mooring winchesThe built-in winch control program of our ACS880 drives includes features like anchor control, hand mooring mode, automooring mode, clutch control mode, mechanical brake control, and master-follower operation (for controlling multiple winches). 1 Winch control is included in the drive – no need for external controllers (located in the winch cabinet of the electrical room)2 Full control of speed and torque without a shaft encoder3 Automooring is possible without a load cell sensor4 Multiple control stands connect directly to the driveDeck machinery winch solution with +N5100 software option1234Deck machinery winches are used for anchor handling with a chain or for mooring by maintaining rope tension.The main benefits of an electrically driven winch include precise, smooth, dependable and safe winch operation. In addition, the electrical winch control reduces wear on the ropes and the winch.Deck machinery solutions typically have an open loop motor control (without an encoder) and S2-30% motor duty without motor cooling (IC-410). The open loop motor control is an advantage especially in harsh environment due to simpler installation with fewer parts. *)*) The performance of the winch needs to be verified and approved between ABB and the winch manufacturer. In the case of hoisting machinery, a closed loop control with a motor encoder is required.D R I VE S A N D M OTO R S FO R EL EC TR I C A L LY D R I V EN D ECK M ACH I N ER Y A N D O FFSH O R E W I N CH E S 3Offshore machinery winch solution with +N5800 software optionTugboat towing winchesEscort and push mode operations for safe tugboat control. HMIActive Heave Compensation (AHC)AHC is built into the drive for controlling the remotely operated vehicle (ROV) and launch and recovery system (LARS) winches. The MRU is connected directly to the drive via an Ethernet interface.Offshore machinery winches are used for applications such as:• Towing (escort tow & push tasks)• Fish trawling (dragging & pulling tasks based on true line force)• Umbilical & tether cable management• Active Heave Compensation (AHC) for LARS & oceanographic operationsOffshore machinery solutions always require an encoder on the motor shaft or drum main shaft. Furthermore, the drive rating needs to be oversized to compensate for intermittent peak performance requirements. Since these applications require the motor to constantly perform close to 0 rpm, the motor duty and cooling options need to be considered. *)*) The performance of the winch drive needs to be verified and approved between ABB and the winch manufacturer.4M A R I N E B R O CH U R E—ACS880 drives with built-in winch control software Minimize your engineering timeOur marine-certified ACS880 drives provide reliable operation and performance where it’s needed the most. Offering accurate speed and torque control for a wide range of motor types, they are suitable for new installs and retrofits of existing winches.ACS880 drives are available in the 0.55 to 6000 kW range and voltages of 400, 440, 500 and 690 V. Enclosure class options include: IP20, IP21, IP22, IP42, IP54 and IP55.Removable memory unitStores the drive’s software and settings for fast and easy commissioning and maintenance.ACS880 marine winch control software ordering codes • For deck machinery, anchoring/mooring and multi-motor/master-follower winches: +N5100• For offshore, tugboat and AHC winches: +N5800 (limited release)Understanding the effects of harmonic distortionAny distorted voltage and current waveform that deviates from the ideal sinusoidal waveform has the potential to damage electrical components, which can result in costly repairs and equipment downtime. All non-linear loads connected to the electrical supply in industrial and commercial facilities insert waveform distortions called harmonics on the power distribution system. Commonnon-linear loads include solid-state motor soft starters, standard variable speed drives, computers, LED lighting, welding supplies, and uninterruptible power supplies. Harmonics negatively affect power networks and connected equipment. The higher the harmonic content, the higherthe line current, which means higher losses in the network, including its components like transformers, switches, circuit breakers, and cables. In addition, the increased line current means that the power network equipment overheats, which leads to premature failure. Furthermore, harmonics witha distorted current mean there is also a risk of connectedequipment malfunctioning and failing.—A pure sinusoidal voltage and current does not contain any harmonics.—A voltage and current that deviate from the sine form contain harmonics.D R I VE S A N D M OTO R S FO R EL EC TR I C A L LY D R I V EN D ECK M ACH I N ER Y A N D O FFSH O R E W I N CH E S5 Helping to keep the vessel’s network cleanNow, the ultra-low harmonic and regenerative ACS880drives are also available with marine type approvals.Both of these drive types help to keep the vessel’selectrical network clean from unwanted disturbancesby producing exceptionally low harmonic content.Furthermore, the ACS880 regenerative drives help tosimplify the installation by eliminating the need foran external braking resistor.Key benefits of ACS880 ultra-low harmonicand regenerative drives• The total harmonic current distortion is typically<3% in a nominal situation in an undistorted network.In partial loads, the harmonic content is also low.• Unity power factor. Network power factorcorrection is also possible.• The active supply unit in the drive can boost theoutput voltage, which ensures reliable operationand guarantees full motor voltage, even whenthe supply voltage is below nominal• No need for external filters, multi-pulsearrangements or special transformersWith ACS880 regenerative drives you’ll also get these:• 100% of the power can be regenerated continuously • Significant energy savings compared to other braking methods• No need for external braking devices, which makes drive installation simple and requires less cabinet space —ACS880 ultra-low harmonic and regenerative drives are now available with marine type approvals.—ACS880 ultra-low harmonic and regenerative drives Keeping the network clean while saving energy6M A R I N E B R O CH U R E—Low voltage marine motors for winchesMade to last in demanding conditionsOur range of open-deck motors are designed to withstand salt, humidity, and waves washing over the deck. They deliver reliably high performance foryour winches, day after day.Key benefits of ABB’s low voltage brake motors for winches:• Our motors are designed to comply with stringent safety criteria while providing the highestreliability. At the same time, special attention is paid to marine classification requirements.• ABB Marine Process Performance brake motors consist of three flexible designs for customized configurations: 1) totally enclosed non-ventilated TENV (IEC 410); 2) totally enclosed fan cooledTEFC (IEC 411); 3) enclosed forced ventilated TEFV (IEC 416).• IP56 open deck protection (highest protection class for motors, standard IP56 is not adequate).• Built-in marine IP67 brake options from all major brake manufacturers.• Selection of encoders designed for harsh marine and offshore conditions.• Wide range of painting systems, including the NORSOK-approved system.• Availability of a watertight enclosure IP67 open deck-type terminal box.• Robust, low-temperature-resistant designs can be supplied for vessels that operate inArctic or Antarctic waters. Ex-protected versions are also available.D R I VE S A N D M OTO R S FO R EL EC TR I C A L LY D R I V EN D ECK M ACH I N ER Y A N D O FFSH O R E W I N CH E S7 Typical electrically driven winch motor performance (with an induction motor)Available motor technologies for winches – induction, permanent magnet, SynRM and PMaSynRM motors3A U A 0000157570 R E V D E N 10.1.2022© Copyright 2022 ABB. All rights reserved.Specifications subject to change without notice.—For more information, please contact your local ABB representative or visit/drives/segments/winches/motors-generators/segments/marine。

【百科】常用海事英文总汇-ENGLISH FOR MARINE2015-01-28宁波海事点击上方蓝色小字“宁波海事”关注我们致力于提供更高效的海事服务;更便捷的沟通渠道;更专业的航运、海事资讯。

微信公共平台帐号:nbmsa01正文Deadweight 载重量Capacity 舱容(载重吨位)freeboard 干舷general provisions 通则(总则)general description 一般规定main dimensions and particulars主尺度trim 浮态stability 稳性model test 船模试验complements 定员rules, regulations and certificates 规范规则和认证owner’s furnished equipment 船东需提供的设备materials and equipment 材料和设备inspection and inclining test 检验和倾斜试验trials and tests at sea 海上试航试验vibration and noise 振动和噪音plans for approval 送审图纸finished drawings 完工图name plates and idetification 铭牌和标记dry docking 进坞delivery 交船hull construction 船体结构welding and construction test 焊接和结构试验deck height 甲板高sheer 脊弧camber 梁拱Main hull 主船体Bottom construction 船底结构Side Shell Structure舷侧结构Bulkheads 舱壁Deck Structure 甲板结构Engine Room Structure机舱结构Bulwark 舷墙Ship’s Ends船端Superstructure and deck house 上层建筑和甲板室miscellaneous 其它foundations 基座bulwark 舷墙bilge keel 舭龙骨Chain Lockers锚链舱Hawse Pipe 锚链管Sea Chest海水箱Bottom Plugs船底塞Fish plate挡油板(接合板,鱼尾板)Funnel & Hull Markings烟囱和船体标志Rudder set 舵corrosion protection 油漆与防腐Surface Preparation表面处理Application of Painting涂漆工作Paint Schedule油漆明细表Cathode Protection阴极保护Deck machinery 甲板机械Ship’s outfittings 外舾装设备General for deck machinery 甲板机械概述Steering gear 舵机Bow thruster首側推(船首推进器)Windlass 锚机Mooring winches 绞缆机(停泊,绞车)Anchoring and mooring outfits 锚系泊设备Anchoring System锚系统Mooring System系泊系统Lifting equipment 起升设备Hose Handling Crane(装卸吊车)软管吊Provision Hoist Davit食物吊MASTS AND POSTS桅杆ACCESS HATCHES AND MANHOLES小舱盖、人孔盖Cargo Tank Hatches货油舱盖Cargo Tank Hatches货油舱盖Wing Tank (Water Ballast) Manholes边压载舱人孔盖Small Hatches 小舱盖Manholes 人孔Tank Cleaning Hatch 洗舱舱口盖Ladders 扶梯Accommodation Ladders 舷梯Weather Ladders 室外梯(露天梯)Cargo Tank Ladders 货舱梯Wing Tanks (Ballast Tanks) Ladders 边(压载)舱扶梯Miscellaneous Ladders & Steps 其它梯、踏步handrails 栏杆,扶手storm rails 风暴扶手catwalk 步桥awning 天幕life saving appliances 救生设备Life Boat & Rescue Boat 救生艇和救助艇Life Rafts & Working Raft救生筏Life Buoys 救生圈Life Jackets 救生衣Life Saving Appliances救生装置Personnel Protection个人防护用品ship’s identification 船体标志spare parts 备件,附件Deck Machinery甲板机械Deck Department甲板部Inventory 备品,附件Boatswain’s & Carpenter’s Shop水手长储藏室及木工间Box, Board & Frame 箱、板、框ACCOMMODATION舱室设备,舱室布置Fire protection防火绝缘BULKHEAD LING & OVERHEAD CEILING舱壁衬里和天花板Deck covering甲板敷料INSULATION FOR LIVING QUARTERS居住区绝缘shelves 木搁架LADDERS & DOORS IN ACCOMMODATION室内梯及门Deck Ladder & Stairways甲板梯和楼梯Doors in Accommodation舱室门Steel Doors to Open Decks开敞甲板钢质门Wheelhouse Doors驾驶室门Locks and Keys锁和钥匙Windows and scuttles方窗和舷窗Wheel house Windows驾驶室窗Portholes 舷窗(射击孔)Galley, Pantry and Laundry Equipment厨房、配餐室及洗衣间设备Schedule of Furniture家具明细Upholstery室内装饰EQUIPMENT FOR LIQUID CARGO SYSTEM货油系统设备CARGO HANDLING SYSTEM货油装卸系统Cargo and Slop/Stripping Pumps货油泵与扫舱泵Arrangement of Loading and Discharging System货油装卸系统的布置Drip Trays集油盘Pipe Hose Support软管支架HEATING SYSTEM FOR CARGO AND SLOP TANK货油舱和污油水舱加热系统CARGO TANK GAS / VENTING SYSTEM货油舱透气系统AUXILIARY SYSTEM AND EQUIPMENT FOR CARGO货油辅助系统和设备Cargo Tank Sounding System货油舱测深系统Temperature Alarm温度报警Pressure Measuring System压力测量系统Tank Cleaning System洗舱系统Valve Remote Control System阀门遥控系统Gas Detection System 货油蒸汽探测系统Cargo/Gas Sampling Device油气取样装置OIL DISCHARGE MONITORING SYSTEM排油监控系统CARGO CONTROL ROOM货油控制室HULL PIPING船舶管路Branching of Pipes支管系Pipe Bending管道弯曲Pipe Coating管道的涂镀处理Pipe Fittings and Components管路附件和元件Pipe Supports管架Pipe Insulation管道隔热BALLAST SYSTEM压载系统Water ballast pumps压载水泵Ballast piping system压载管系BILGE SYSTEM舱底水系统Oily bilge pump日用舱底泵Oily water separator油水分离器DRAINAGE SYSTEM排水系统AIR AND SOUNDING SYSTEM空气和测深系统Air Pipes空气管Sounding Pipes测深管OIL FILLING SYSTEM油注入系统Heavy Fuel Oil重燃油Lub. Oil / D.O tanks滑油/柴油舱柜FIRE FIGHTING AND DECK WASH SYSTEM消防和甲板冲洗系统Sea Water Fire and Deck Wash System水灭火和甲板冲洗系统Foam Fire Extinguishing System泡沫灭火系统CO2 Fire Extinguishing System二氧化碳灭火系统Fire and General Alarm System火灾报警系统REFRIGERATED SYSTEM冷却系统VENTILATION AND AIR CONDITIONING SYSTEM通风与空调系统Ventilation and Air Conditioning System For Accommodation居住区的通风及空调系统Engine Control Room机控室Engine Room Ventilation轮机舱通风Ventilation of Spaces Other Than Accommodation居住区以外的通风布置SANITARY SYSTEM WITH DISCHARGES DRAINAGE SYSTEM卫生疏水系统Application of pipe and valves阀件与管道的使用Sanitary Supply System卫生用水供给系统Sanitary Discharge System卫生用水放泄系统FRESH WATER SYSTEM淡水系统Domestic Fresh Water System - Cold日用淡水系统–冷COMPRESSED AIR PIPE FOR DECK USE 甲板用压缩空气管PIPE INSULATION管道绝热MACHINERY DESCRIPTION机械设备说明PRINCIPAL PARTICULARS OF MACHINERY推进柴油机Main Engine主机Reduce gear box for propulsion减速齿轮箱Flexible coupling高弹性联轴器Shafting and Propeller轴系及螺旋桨Electric Generating Plant发电装置Heating Plant加热装置Air Compressors压缩空气装置Oil Purifier分油机Ventilation Fans通风风机Heater Exchangers热交换器Tanks舱柜MISCELLANEOUS MACHINERY其他机械设备Engineer’s Work Shop And Working Tools机修间及工作工具Machine Overhauling Equipment机械维修设备Ventilation of Machinery Space机舱通风Oily Water Separator油水分离器Sewage Treatment Plant生活污水处理装置Incinerator焚烧炉PIPING SYSTEM FOR MACHINERY动力管系Fuel Oil System燃油系统Lub. Oil System滑油系统Cooling Water System冷却水系统Sea Chests海水箱Valves阀件MISCELLANEOUS EQUIPMENT其他设备Funnel And Up-take烟囱Fire Extinguishing System In Engine Room机舱消防系统Platforms, Hand Rails, Ladders and Gratings平台,栏杆扶手,梯子及格栅Engine Store机舱储藏间Painting In Engine Room机舱油漆间Name Plate铭牌PIPING MATERIALS管材INSULATION AND LAGGING绝缘包扎Piping Insulation管系的绝缘Machinery Insulation机器绝缘GAUGES 仪表AUTOMA TION AND INSTRUMENTA TION自动化Automatic Control of Aux. Machinery辅机的自动控制Steam Generating Plant蒸汽产生设备Centralised Instrumentation集中仪表Alarm System报警系统SPARE PARTS AND TOOLS备件和工具ELECTRIC PART电气CABLE电缆Cable application电缆选择Cable Installation电缆敷设PRIMARY SOURCE一次电源Generator发电机Secondary Source二次电源Operation And Control Of Generator发电机的运行及控制Generator’s Interlocking 发电机连锁SWITCHBOARDS配电板Main Switchboard主配电板Emergency Switchboard应急配电板Shore Connection Box 岸电箱DISTRIBUTION SYSTEM 配电系统Electric Distribution电力分配Section And Distribution Board电力、照明分配电箱POWER SYSTEM 电力系统Motor 电动机Starters 起动器Emergency Stop Device 应急切断Important Pumps Auto-change Control重要泵自动转换控制The Control of Steering Gear 舵机控制Wheelhouse Control Console驾控台Test Switchboard 试验板Engine Control Console机舱集控台Cargo Oil Control Console货油控制台LIGHTING SYSTEM 照明系统Navigation Lights And Signal Lights 航行灯和信号灯INTERIOR COMMUNICATION, ALARM & MEASURING内部通信、报警和测量Interior Communication 内部通信Alarm System报警系统Measuring System 测量系统ELECTRIC NAUTICAL EQUIPMENT 航行设备RADIO EQUIPMENT 无线电设备Radio Console无线电台VHF Radio TelephoneVHF 无线电话INMARSAT B + C Ship Earth Station INMARSAT B+C卫星船站SAFETY EQUIPMENT 安全设备V oyage Data Recorder (VDR) 航行数据记录仪(VDR)SSAS(船舶安全报警系统)AIS(自动识别系统)Outfitting舾装engine girder 机座纵桁web 梁腹,腹板rider plate 内龙骨面板,中内龙骨面板chine bar 折角圆钢。

锚绞机恒张力液压系统原理A constant tension hydraulic system is essential for the operation of an anchor winch. 这种系统能够确保绞盘在工作过程中始终保持恒定的张力,从而保证船舶在锚地停泊时的稳定性。

The hydraulic system works by using hydraulic fluid to transmit power from the pump to the winch. 液压系统利用液压传动来实现动力的传递。

When the anchor winch is in use, the hydraulic pump generates high-pressure fluid, which is then directed towards the winch motor. 在绞盘使用过程中,液压泵产生高压液体,然后将其传送至绞盘马达。

This high-pressure fluid is used to turn the winch drum, allowing the cable or rope to be wound in or let out with a constant tension. 这种高压液体驱动绞盘滚筒旋转,使绞盘能够在放出或回收缆绳时保持恒定张力。

Without a constant tension hydraulic system, it would be difficult to control the speed and tension of the cable or rope as it is being wound or unwound. 若没有恒张力液压系统,很难控制缆绳在放出或回收时的速度和张力。

In addition to providing constant tension, the hydraulic system also helps in controlling the speed at which the cable or rope is wound or unwound. 除了提供恒张力外,液压系统还有助于控制绞盘在放出或回收缆绳时的速度。

—5.6 Winch controlwith variable frequency driveABB’s winch control program enables the ABB variable frequency drive (VFD) range to be used in different winching control configurations on board ships, offshore platforms and in harbors.Dedicated drives for marine and offshore appli-cationsABB variable frequency drives are certified for marine applications, enabling continuous speed and torque control of:• Anchor winches• Mooring winches• Ro-Ro (roll on, roll off) quarter ramp winches • Towing winchesBuilt-in brake choppers connect the DC bus voltage to an external resistor which converts braking en-ergy into heat. Low harmonic drives meet the strict-est harmonic standards; no additional filtering equipment is needed to ensure power supply qual-ity. Regenerative drives can recover energy from a process and feed it back into the network, thus sav-ing energy.A key feature of the ABB variable frequency drive is its direct torque control (DTC) motor control platform.— Passenger shipDTC enables the drive to deliver full torque at zero speed, with or without the need for a feedback en-coder. This is an advantage because the harsh envi-ronment on a vessel’s open deck can often damage an encoder or interfere with the feedback signal to the motors.Avoiding hydraulic system inefficienciesABB variable frequency drive with special inbuilt winch control program is a profitable solution com-pared to the traditional and costly hydraulic winch controller. The VFD solution for winch control has significantly lower maintenance costs and perfor-mance inefficiency together with better overall sys-tem reliability.Compared to hydraulic control of winch systems, an AC drive provides substantial power and en-ergy savings when continuous running of a hy-draulic pump is not required. Additionally, hydrau-lic systems use oils which pose a pollution risk to the environment. An AC drive based electrical winch control system can eliminate this risk. Winch interface for control standsThe winch can be controlled from control stands located on port, starboard and upper deck of the vessel. The electrical interface supports either traditional inputs and outputs (I/O) or fieldbus gateways commanded by a programmable logic controller (PLC). Four control stands can be sup-ported: three via digital I/O and a fourth via a fieldbus gateway.Anchor controlReady-made control logic provides speed control of the anchor, whether it is being raised or low-ered. Slip detection and anchor-in protection are also provided as safeguards for anchor move-ments.Mooring controlWhen mooring a vessel to a harbour or pier, the tension within the mooring ropes can be con-trolled either manually or automatically.Hand-mooring: The control logic can be config-ured to allow the operator to control the winch manually from the harbour using continuous speed control. The logic also allows for high speed slack rope when letting out the ropes, thereby speeding up operating time in the hand-mooring control mode.• Peak torque protection prevents damage to the rope. It detects severe tightening of the rope and immediately sends a signal to adjust the speed, thereby protecting the rope and the winch system from overload.Auto-mooring: Following the hand-mooring pro-cedure, and with the rope already pre-tensioned, auto-mooring can be enabled. This is a speed control application with torque limitation which provides smooth continuous mooring. Pre-de-fined auto-mooring modes are available as fol-lows:• Time control – auto-mooring rope tension con-trol is based on a programmable re-mooring time interval.• Load cell sensor – auto-mooring rope tension con-trol is based on real measured status.• Constant on – auto-mooring rope tension con-trol is always on, without closing the mechani-cal brake and stopping the winch motor.The rope tension set-point can be a fixed internal parameter value or it can be sent via external digi-tal- and analog input signals. The actual rope ten-sion can also be defined without any sensor with the help of unique torque measuring logic. Power controlThe power control function limits the speed of the winch depending on the load. With a very light load, for example, the winch can run at high speed whereas, if there is a heavy load then the speed can be limited. The speed is adjusted according to a series of cross points located on the forward and reverse power curves. These cross points, each of which has a speed and torque connection, can be identified by the user, by way of power control parameters within the winch control pro-gram.Ro-Ro controlRo-Ro quarter ramp control logic is used for rais-ing or lowering the ship’s vehicle access ramp. Special protection is provided to slow down the speed and torque before parking the access ramp in the upper end position.With the Ro-Ro access ramp in the loading posi-tion, the special holding and tension control mode can be used.Mechanical brake control logic and torque mem-oryThe winch control program features integrated brake control logic to control the winch motor’s external disk or drum brake. The brake control logic utilizes torque memory and pre-magnetiz-ing to open and close the mechanical brake safely and reliably.The brake control logic, together with the DTC-controlled winch motor, enables the drive to hold the winch machinery stationary until the mechan-ical brake takes over.Adaptive programmingFunction block programming within the drive en-ables the user to change or modify the ready-made winch control program application to their customized platform.Master-follower for winch motors working to-getherWhen several winch motors are connected to the same machinery, the ready-made master-follower arrangement supports the speed and torque con-trol mode with load sharing mode.Motor heatingThe drive’s DC injection function can be enabled by the winch operator to provide controlled winch motor heating. This function keeps winch motors dry when they are in standby mode and is benefi-cial for open-deck motors.Major benefits from installing a variable fre-quency drive• The ideal solution for retrofits – the existing winch motor, motor cable and operator control can be reused.• Space saving on the deck – simplified winch ar-rangement.• Lower noise level.• Reduced maintenance costs – Soft starting re-duces startup current peaks. Smooth continu-ous speed and torque control reduce stress on the whole mooring system.• DTC (Direct Torque Control) eliminates the need for a pulse encoder, increasing the reliability of the winch system.• Safe and accurate anchor and mooring winch con-trol throughout the whole speed range.• Cost reduction compared to closed loop sys-tems.• Environmentally friendly solution – Oil-free op-eration with fully electronic equipment.• Reduction of mechanical wear.• External programmable logic controller (PLC) not needed because the winch control program includes winch operation and protection func-tions.• Multi I/O functionality allowing three different control stands to be connected directly to the drive.• Anchor-in or anchor-slowdown protection re-duces the speed as the anchor approaches its end position. Slip protection operates between the winch drum and winch motor.• The peak torque protection in hand-mooring function detects severe tightening of the rope enabling immediate speed adjustment to pro-tect the rope and the winch system from over-load.• Mechanical brake control with torque memory.• Easy start-up and maintenance of drive system.• Adjustable auto-mooring provides accurate rope tension control and eliminates the need for load cells on the ropes.—Case m/s Mariella, Viking LineCost efficient winch retrofit using variable fre-quency drive“The old system is breaking the motors, when we are in the harbour, when we have torque control; it’s going on and off all the time. It’s full ahead or nothing.” says Jonas Rautelius, the ship’s electri-cian describing the existing three-speed mooring control system.When the ship arrives in port, the ship’s winches keep it secure to the dock so that the passengers can safely board and depart the ship. The ship’s six winches, in operation since 1985, use a three-speed control system with three winding, direct-on-line (DOL) motors and an external mooring controller and load sensor in the gearbox. Existing controlUsing this system to moor the ship, winch opera-tors watch the rope until it is taut, adjusting the speed of the winch accordingly. Each speed change made to the winch (low, middle, or high speed) results in a direct-on-line start of one of the motor’s windings. DOL starting and the high torque demands of the mooring operation place substantial stress on the winch system. As a re-sult, rotors on the winch motors would periodi-cally break. In addition, the age of the winches makes finding spare parts more difficult. Typi-cally, some spare parts have long delivery times, especially motor parts.The contactors used to start the motors direct-on-line are also prone to failures, adding to the maintenance of the ship. If the winch is hauling in the rope and a contactor fails, it is possible for the rope to continue to spin around the winch’s drum, uncontrolled, until the main power is dis-connected.Cost efficient modernization with ABB drives After contacting ABB, Viking Line decided to eval-uate and test ABB’s proposed solution on one winch. Using the ship’s drawings from 1985, ABB specified the ACS800-01 marine certified indus-trial drive with the built-in winch control program. This allowed the m/s Mariella to keep the existing three-winding motor, motor cable, and operator control stands. “It was quite cheap to do it like this” says Jonas. “This is a big factor in deciding to do the rest.” The drive’s IP55 enclosure permit-ted it to be mounted directly to the wall of the ship.—“The best thing is that we don’t have to touch it anymore.” says Jo-nas Rautelius, the electrician from m/s Mariella. “It’s easier; winch op-erators can just put the auto-mooring control on and leave the winch. With the old system, they had to constantly see if the rope was tight.”Measuring torque allows auto-mooring without load cell sensorsBecause the drive uses ABB’s direct torque con-trol (DTC), it does not rely on external sensors such as a load cell sensor in the gearbox or en-coder on the motor. DTC allows open-loop control of the winch motor and this permitted the m/s Mariella to reuse the existing winch motor with-out having to install an encoder. The winch con-trol program in the drive uses DTC and patented winch application torque measuring logic to mea-sure the rope’s tension and to calculate the re-quired torque at every start without a load cell sensor.—Electrical winches offer signifi-cant savings over the conven-tional hydraulic winch configura-tion, as well as significant benefits in environmental issues. The vessel’s crew also benefits from considerably reduced noise levels on deck.Easier operationWith the ABB solution, as the ship arrives in har-bour, the winch operation starts with the drive in hand-mooring control to quickly and smoothly let out the rope at a high speed. When the rope is connected to the harbour, the winch hauls in the slack rope quickly. The winch control program’s peak torque protection function automatically stops the hand-mooring operation when the torque limits are reached. Winch operators then switch to auto-mooring mode. In auto-mooring mode, time control sequences are used to contin-ually monitor the rope’s tension, automatically making adjustments as needed to keep the ship secure.“The best thing is that we don’t have to touch it anymore.” says Jonas. “It’s easier; winch opera-tors can just put the auto-mooring control on and leave the winch. With the old system, they had to constantly see if the rope was tight.”Integrated mechanical brake controlBrake control is integrated into the winch’s brake circuit through a relay output on the drive. The drive ensures the disc brake is closed before stopping the drive’s torque control. When open-ing the brake, the sequence is reversed, the drive determines and brings the motor to the needed torque to hold the rope’s tension, and then re-leases the brake.Cost efficient retrofit• Improves reliability• Reduces maintenance• Reuses existing winch motor• Reuses existing motor cable• Reuses existing operator control stand• Replaces contactor control• Eliminates external load cell sensor• Eliminates auto-mooring unit• Integrated brake control• Soft starting eliminates start-up peaks• Smooth continuous speed and torque control • Improves operator experience• Marine certified hardware (ACS800-01)• Wall mounted drive• Adaptive programming in the drive is used to match existing signals to drive controls—Viking Line, MS Mariella—01—Figure 1: The existingwinch motor, motorcable, mechanical discbrake and operator con-trol stand were reused.—Figure 2: Rope tension ismaintained automati-cally using time controlsequences without aload cell sensor—Figure 3: Built-inauto-mooring withmechanical brakecontrol keep the shipsecurely docked—Figure 4: The wallmounted ACS800 indus-trial drive with built-inwinch control programreplaced contactors forsmooth, trouble freestarting.—02—03—04m/s Mariella• Built 1985• Length 176.9m• Width 28.4mWith room for 2,500 passengers and 450 cars, adisco, a casino, restaurants and shopping, VikingLine’s cruise ship the m/s Mariella is a floatingfamily entertainment experience providing ser-vice between Helsinki and Stockholm.Viking LineToday Viking Line has seven vessels which sail be-tween the Finnish mainland, Åland Islands andSweden as well as between Finland and the Balticstates. Operations include passenger services,recreation and cargo carrier services。