08070620吴汉钊-外文翻译

- 格式:doc

- 大小:31.00 KB

- 文档页数:5

DANGDAIJIAOYANLUNCONG2019年06月探究能力是学生利用已掌握的知识,通过观察、对比、猜测、验算、归纳和总结等方法,对艰难的问题进行研究与探索的能力。

帮助高中生掌握良好的自主探究能力,教师需要改变传统教学思路,让学生形成提出问题、思考问题和解决问题的能力。

长此以往,有助于学生数学核心素养的全面提升。

在培养方法上,教师可以从情境的塑造、探究的展开、能力的锤炼入手,目的是为了让学生在循序渐进中逐渐形成探究能力。

一、营造趣味情境,激发学生问题意识提高学生学习兴趣是落实探究能力培养的第一步,而趣味情境的打造则是增强学生学习兴趣的关键。

教师要改变传统课堂枯燥乏味的局面,选择具有诱发性、启发性和激趣性特征的问题情境调动学生的好奇心。

教师在日常教学中可围绕现代热点新闻、案例等落实数学知识,给学生提供一个真实体验的平台,由此供学生在已掌握知识和新的问题之间形成冲突,刺激学生思考,强化学生的探究欲望与学习积极性。

生活既是课堂,任何知识都可以在生活中寻到其影子,数学亦是如此。

教师要善于捕捉数学中的生活元素,及时为学生反馈数学的生活特征,以此诱导学生的问题意识。

如在教学“统计与概率”的时候,教师就曾给学生出示情境“学生喜欢学习数学的概率是否和性别有关系?”这个问题瞬间激发学生的好奇心,他们开始交头接耳地询问对方是否真的喜欢学习数学。

这时,教师可以鼓励他们课后进行探究,然后利用统计和概率的知识总结数据。

由此可见,围绕学生的生活布置探究情境,可以立即增强知识的代入感。

在这期间,学生会一改以往“谈数色变”的情况,而是积极自主地使用知识满足个人的探究欲望,从而达到深度探究知识,获得对数学的新认知和理解。

二、探究活动并行,引导学生课堂实践克罗齐曾说过:“用认识的活动去了解事物,用实践的活动去改变事物;用前者去掌握宇宙,用后者去制造宇宙”,学习的道路亦是如此,学生只能在探究中了解知识,在实践中缔造真理。

因此,在点燃学生探究欲望的基础上,教师也要给学生提供合理的实践平台,让学生的知识和技能有所施展。

大连交通大学信息工程学院毕业设计(论文)外文翻译学生姓名陈辉专业班级机械073班指导教师王凤彪职称讲师所在单位机械工程系教学部主任吕海霆完成日期 2011年4月15日Numerical Control SystemThe numerical control system is the digital control system abbreviation. By early is composed of hardware circuit is called hardware numerical control (Hard NC), after 1970, hardware circuit components gradually instead by the computer called for computer numerical control system.Computerized numerical control system is a system that is use computer control processing function to achieve numerical control system. CNC system according to the computer memory stored in the control program execution part or all, numerical control function, and is equipped with interface circuit and servo drive the special computer system.CNC system consists of NC program, input devices; output devices, computer numerical control equipment (CNC equipment), programmable logic controllers (PLC), the spindle and feed drive (servo) drive (including detection devices) and so on.The core of CNC system is equipment. By using the computer system with the function of software and PLC instead of the traditional machine electric device to make the system logic control more compact, its flexibility and versatility, reliability become more better, easy to implement complex numerical control function, use and maintenance can be more convenient, and it also has connected and super ordination machine and the remote communication function.At present, the numerical control system has variety of different forms; composition structure has its own characteristics. These structural features from the basic requirements of the initial system design and engineering design ideas. For example, the control system of point and continuous path control systems have different requirements. For the T system and the M system, there are also very different, the former applies to rotary part processing, the latter suitable for special-shaped the axially symmetrical parts processing. For different manufacturers, based on historical development factors and vary their complex factors, may also be thinking in the design is different. For example, the United States Dynapath system uses a small plate for easy replacement and flexible combination of the board; while Japan FANUC system is a large plate structure tends to make the system work in favor of reliability, make the system MTBF rate continues to increase. However, no matter what kind of system, their basic principle and structure are very similar.The numerical control system generally consists of three major components, namely the control system, servo system and position measuring system. Control procedures by interpolation operation work piece, issue control instructions to the servo drive system; servo drive system control instructions amplified by the servo motor-driven mechanical movement required; measurement system detects the movement of mechanical position or speed, and feedback to the control system, to modify the control instructions. These three parts combine to form a complete closed-loop control of the CNC system.Control system mainly consists of bus, CPU, power supply, memory, operating panel and display, position control unit, programmable logic controller control unit and datainput / output interface and so on. The latest generation of CNC system also includes a communication unit; it can complete the CNC, PLC's internal data communications and external high-order networks. Servo drive system including servo drives and motors. Position measuring system is mainly used grating, or circular grating incremental displacement encoder.CNC system hardware from the NC device, input / output devices, drives and machine logic control devices, electrical components, between the four parts through the I / O interface to interconnect.Numerical control device is the core of CNC system, its software and hardware to control the implementation of various CNC functions.The hardware structure of no device by CNC installations in the printed circuit board with infixing pattern can be divided into the big board structure and function module (small board) structure; Press CNC apparatus hardware manufacturing mode, can be divided into special structure and personal computer type structure; Press CNC apparatus in the number of microprocessor can be divided into single microprocessor structure and many microprocessor structure.(1)Large panel structure and function templates structure1) Large panel structurePanel structures CNC system CNC equipment from the main circuit board, position control panels, PC boards, graphics control panel, additional I / O board and power supply unit and other components. The main circuit board printed circuit board is big; the other circuit board is a small plate, inserted in the large printed circuit board slot. This structure is similar to the structure of micro-computer.2) Function templates structure(2)Single-microprocessor structure and mulct-microprocessor structure1) Single-microprocessor structureIn a single-microprocessor structure, only a microprocessor to focus on control, time-sharing deals with the various tasks of CNC equipment.2) melt-microprocessor structureWith the increase in numerical control system functions, CNC machine tools to improve the processing speed of a single microprocessor CNC system can not meet the requirement; therefore, many CNC systems uses a multi-microprocessor structure. If a numerical control system has two or more microprocessors, each microprocessor via the data bus or communication to connect, share system memory and common I / O interfaces, each processor sharing system Part of the work, which is multi-processor systems.CNC software is divided into application software and system software. CNC system software for the realization of various functions of the CNC system, the preparation of special software, also known as control software, stored in the computer EPROM memory. CNC Systems feature a variety of settings and different control schemes, and their system software in the structure and size vary widely, but generally include input data processing procedures, computing interpolation procedures, speed control procedures, management procedures and diagnostic procedures.(1)Input data processing proceduresIt receives input part program, the standard code, said processing instructions and datadecoding, data processing, according to the prescribed format for storage. Some systems also calculated to compensate, or interpolation operation and speed control for pre-computation. Typically, the input data processing program, including input, decoding and data processing three elements.(2)Computing interpolation proceduresCNC work piece processing system according to the data provided, such as curve type, start, end, etc. operations. According to the results of operations were sent to each axis feed pulse. This process is called interpolation operation. Feed drive servo system Impulsive table or by a corresponding movement of the tool to complete the procedural requirements of the processing tasks.Interpolation for CNC system is the side of the operation, while processing, is a typical real-time control, so the interpolation directly affects the speed of operation the machine feed rate, and should therefore be possible to shorten computation time, which is the preparation of interpolation Complements the key to the program.(3)Speed control proceduresSpeed control program according to the given value control the speed of operation of the frequency interpolation, in order to maintain a predetermined feed rate. Changes in speed is large, the need for automatic control of acceleration and deceleration to avoid speed drive system caused by mutations in step.(4)Management proceduresManagement procedures responsible for data input, data processing, interpolation processing services operations as the various procedures for regulation and management. Management process but also on the panel command, the clock signal, the interrupt caused by fault signals for processing.(5)Diagnostic proceduresDiagnostic features are found in the running system failure in a timely manner, and that the type of failure. Y ou can also run before or after the failure, check the system main components (CPU, memory, interfaces, switches, servo systems, etc.) function is normal, and that the site of failure.MachiningAny machining must have three basic conditions: machining tools, work piece and machining sports. Machining tool edge should be, the material must be rigid than the work piece. Different forms of tool structure and cutting movements constitute different cutting methods. Blade with a blade-shaped and have a fixed number of methods for cutting tools for turning, drilling, boring, milling, planning, broaching, and sawing, etc.; edge shape and edge with no fixed number of abrasive or abrasive Cutting methods are grinding, grinding, honing and polishing.Machining is the most important machinery manufacturing processing methods. Although the rough improve manufacturing precision, casting, forging, extrusion, powder metallurgy processing applications on widely, but to adapt to a wide range of machining,and can achieve high accuracy and low surface roughness, in Manufacturing still plays an important role in the process. Cutting metal materials have many classifications. Common are the following three kinds.By cutting process feature distinguishing characteristics of the decision process on the structure of cutting tools and cutting tools and work piece relative motion form. According to the technical characteristics of cutting can be divided into: turning, milling, drilling, boring, reaming, planning, shaping, slotting, broaching, sawing, grinding, grinding, honing, super finishing, polishing, gear Processing, the worm process, thread processing, ultra-precision machining, bench and scrapers and so on. By material removal rate and machining accuracy distinction can be divided into: ① rough: with large depth of cut, one or a few times by the knife away from the work cut out most or all allowances, such as rough turning, rough planning, Rough milling, drilling and sawing, etc., rough machining precision high efficiency low, generally used as a pre-processing, and sometimes also for final processing. ② Semi-finishing: General roughing and finishing as the middle between the process, but the work piece accuracy and surface roughness on the less demanding position, but also can be used as the final processing. ③ finishing: cutting with a fine way to achieve higher machining surface accuracy and surface quality, such as fine cars, fine planning, precision hinges, grinding and so on. General is the final finishing process. ④Finishing process: after the finish, the aim is to obtain a smaller surface roughness and to slightly improve the accuracy. Finishing processing allowance is small, such as honing, grinding, ultra-precision grinding and super finishing and so on. ⑤Modification process: the aim is to reduce the surface roughness, to improve the corrosion, dust properties and improve appearance, but does not require higher precision, such as polishing, sanding, etc. ⑥ultra-precision machining: aerospace, lasers, electronics, nuclear energy and other cutting-edge technologies that need some special precision parts, high accuracy over IT4, surface roughness less than Ra 0.01 microns. This need to take special measures to ultra-precision machining, such as turning mirror, mirror grinding, chemical mechanical polishing of soft abrasive.Distinguished by method of surface machining, the work piece is to rely on the machined surface for cutting tool and the work piece to obtain the relative motion. By surface methods, cutting can be divided into three categories. ①tip trajectory method: relying on the tip relative to the trajectory of the surface to obtain the required work piece surface geometry, such as cylindrical turning, planning surface, cylindrical grinding, with the forming surface, such as by turning mode. The trajectory depends on the tool tip provided by the cutting tool and work piece relative motion. ② forming tool method: short forming method, with the final work piece surface profile that matches the shape forming cutter or grinding wheel, such as processing a shaped surface. At this time forming part of the machine movement was replaced by the blade geometry, such as the shape of turning, milling and forming grinding forming and so on. The more difficult the manufacture of forming cutter, machine - clamp - work piece - tool formed by the process system can withstand the cutting force is limited, forming method is generally used for processing short shaped surface. ③generating method: also known as rotary cutting method, cutting tool and work piece during processing as a relatively developed into a campaign tool (or wheel) and the work piece instantaneous center line of pure rolling interaction between thetwo maintain a certain ratio between Is obtained by processing the surface of the blade in this movement in the envelope. Gear machining hobbling, gear shaping, shaving, honing, and grinding teeth (not including form grinding teeth), etc. are generating method processing.PLCEarly called the programmable logic controller PLC (Programmable Logic Controller, PLC), which is mainly used to replace the logic control relays. With the technology, which uses micro-computer technology, industrial control device function has been greatly exceeded the scope of logic control, therefore, such a device today called programmable logic controller, referred to as the PC. However, in order to avoid personal computer (Personal Computer) in the short confusion, it will be referred to as programmable logic controller PLC, plc since 1966, the U.S. Digital Equipment Corporation (DEC) developed there, the current United States, Japan, Germany, PLC Good quality and powerful.The basic structure of Programmable Logic ControllerA. PowerPLC's power in the whole system plays a very important role. If you do not have a good, reliable power system is not working, so the PLC manufacturers design and manufacture of power very seriously. General AC voltage fluctuations of +10% (+15%) range, you can not take other measures to PLC to connect directly to the AC line.B.Central processing unit (CPU)Central processing unit (CPU) is the central PLC control. It is given by the function of PLC system program from the programmer receives and stores the user program and data type; check the power supply, memory, I / O and timer alert status, and to diagnose syntax errors in the user program. When the PLC into run-time, first it scans the scene to receive the status of various input devices and data, respectively, into I / O image area, and then one by one from the user program reads the user program memory, after a shell and press Provisions of the Directive the result of logic or arithmetic operations into the I / O image area or data register. And the entire user program is finished, and finally I / O image area of the state or the output of the output register data to the appropriate output device, and so on to run until stopped.To further improve the reliability of PLC, PLC is also large in recent years constitutes a redundant dual-CPU system, or by three voting systems CPU. Thus, even if a CPU fails, the whole system can still work properly.C.MemoryStorage system software of memory called system program memory. Storage application software of memory called the user program memory.D.Input and output interface circuit1, the live input interface circuit by the optical coupling circuit and the computer input interface circuit, the role of PLC and field control of an interface for input channels.2, Field output interface circuit by the output data registers, interrupt request strobe circuit and integrated circuit, the role of PLC output interface circuit through the on-siteimplementation of parts of the output to the field corresponding control signal.E.Function moduleSuch as counting, positioning modules.munication moduleSuch as Ethernet, RS485, Prefab’s-DP communication module.数控系统数控系统是数字控制系统简称,英文名称为Numerical Control System,早期是由硬件电路构成的称为硬件数控(Hard NC),1970年代以后,硬件电路元件逐步由专用的计算机代替称为计算机数控系统。

毕业论文(设计)外文译文题目广安渠江大学学生公寓设计系部建筑与土木工程专业土木工程年级 2008级学生姓名唐志华学号 080812025指导教师李静Tall Building BehaviorAbstract: This paper first pair of high-rise building construction history of thedevelopment of a brief introduction. Subsequent adoption of high-rise building in Kennedy to load and wind load and seismic load, The complex structure of the stress analysis after each draw : the major component between the vertical shear vertical structure of the resistance level of load which is in the importance of the vertical component's Intergovernmental have another form of interaction, the level of interaction is also increasedstructural rigidity to the important role.Key words:Tall tower and buildings shear rigidityTall tower and buildings have fascinated mankind from the beginning of civilization, their construction being initially for defense and subsequently for ecclesiastical purposes. The growth in modem tall building construction ,however, which began in the 1880s, has been largely for commercial purpose.Tall commercial buildings are primarily a purpose to the demand by business activities to be as close to each other, and to the city center, as possible, thereby putting intense pressure on the available land space. Also because they form distinctive landmarks, tall commercial buildings are frequently developed in city centers as prestige symbols for corporate organizations. Further, the business and tourist community, with its increasing mobility, has fuelled a need for more, frequently high-rise, city center hotel accommodations.The rapid growth of the urban population and the consequent pressure on limited space have considerably influenced city residential development. The high cost of land, the desire to avoid a continuous urban sprawl, and the need to preserve important agricultural production have all contributed to drive residential buildings upward. In some cities, for example, Hong Kong and Rio de Janeiro, local topographical restrictions make tall buildings the only feasible solution for housing needs.Ideally, in the early stages of planning a buildings, the entire design team, including the architect, structural engineer, and services engineer, should collaborate to agree on a form of structure to satisfy their respective requirements of function, safety and serviceability, and servicing. A compromise between conflicting demands will be almost inevitable. In all but the very tallest structures, however, the structural arrangement will be subservient to the architectural requirements of space arrangement and that will tax the ingenuity; and probably the patience, of the structural engineer.The two primary types of vertical load-resisting elements of tall buildings are columns and walls, the latter acting either independently as shear walls or in assemblies as shear wall cores. The building function will lead naturally to the provision of walls to divide and enclose space, and of cores to contain and convey services such as elevators. Columns will be provided, in otherwise unsupported regions. To transmit gravity loads and, in some types of structure, horizontal loads also.The inevitable primary function of the structural elements is to resist the gravity loading from the weight of the building and its contents. Since the loading on different floors tends to be similar the weight of the floor system per unit floor area is approximately constant, regardless of the building height of a building, the weight of columns per unit area increases approximately linearly with the building height.The highly probable second function of the vertical structural elements is to resist also the parasitic load caused by wind and possibly earthquakes, whose magnitudes will be obtained from National Building Codes or wind tunnel studies. The bending moments on the building caused by these lateral forces increase with at least the square of the height, and their effects will become progressively more important as the building height, and their will become progressively more important as the building height increase.Once the functional layout of the structure has been decided, the design process generally follows a well-defined iterative procedure. Preliminary calculations for member sizes are usually based on gravity loading augmented by an arbitrary increment to account for wind forces. The cross-sectional areas of the vertical members will be based on the accumulated loading from their associated areas, with reductions to account for the probability that not all floors will be subjected simultaneously to their maximum live loading. The initial sizes of beams and slabs method of gravity load analysis, such as two-cycle moment distribution, or from codified mid-and end-span values.A check is then made on the maximum horizontal, and the forces in the major structural members, using some rapid approximate analysis technique. If the deflection is excessive, or some of the members are inadequate, adjustments are made to the members sizes or the structural arrangement. If certain members attract excessive loads, the engineer may reduce their stiffness to redistribute the load to less heavily stressed components. The procedure of preliminary analysis, checking, and adjustment is repeated until a satisfactory solution is obtained.Invariably, alterations to the initial layout of the building will be required as theclient’s and architect’s ideas of the building evolve. This w ill call for structural modifications, or perhaps a racial rearrangement, which necessitates a complete review of the structural design. The various preliminary stages may therefore have to be repeated a mumber of times before a final solution is reached.Speed of erection is a vital factor in obtaining a return on the investment involved in such large-scale projects. Most tall buildings are constructed in congested city sites, with difficult access; therefore careful planning and organization of the construction sequence become essential. The story-to-story uniformity of most multistory building encourages construction through repetitive operations prefabrication techniques. Progress in the ability to build tall has gone hand in hard with the development of more efficient equipment and improved methods of construction, such as slip-and flying-formwork, concrete pumping, and the use of tower, climbing, and large mobile cranes.A reasonably accurate assessment of a proposed high-rise structure’s behavior is necessary to form a properly representative model for analysis. A high-rise structure is essentially a vertical cantilever that is subjected to axial loading by gravity and to transverse loading by wind to earthquake.Cravity live loading acts on the slabs, which transfer it horizontally to the vertical walls and columns through which it passes to the foundation. The magnitude of axial loading in the vertical components is estimated from the slab tributary areas, and its calculation is not usually considered to be a difficult problem. Horizontal loading at each level of a building a shear ,a moment ,and some times, a torque, which have maximum values at the base of that structure that increase ra paidly with the building’s height. The response of a structure to horizontal loading, in having to carry the external shear, moment, and torque, is more complex than its first-order response to gravity loading. The recognition of the structure’s behavior under horizontal loading and the formation of the corresponding model are usually the dominant problems of analysis. The principal criterion of a satisfactory model is that under horizontal loading it should deflect similarly to the prototype structure.The resistance of the structure to the external moment is provided by flexure of the vertical components, and by their axial action acting as the chords of the vertical truss. The allocation of the external moment between the flexural truss. The allocation of the external moment , between the flexural and axial actions of the vertical component depends on the vertical shearing stiffness of the “web” system connecting the vertical components, that is ,the girders, slabs, and bracing. The stiffer the shear connection, the larger the proportion of the external moment that is carried by axialforces in the vertical members, and the stirrer and more efficiently the structure behaves.The described flexural and axial actions of the vertical components and the shear action of the connecting members are interrelated, and their relative contribution define the fundamental characteristics of the structure. It is necessary in forming a model to components so that the resulting flexural and axially generated moments will be apportioned properly.The horizontal shear at any level in a high-rise structure is resisted by shear in the vertical members and by the horizontal component of the axial force in any diagonal bracing at that level. If the external shear will automatically be properly apportioned between the components.Torsion on a building is resisted mainly by shear in the vertical components, by the horizontal components, by the horizontal components of axial warping torque resistance of elevator, stair, and service shafts. If the individual bents, and vertical components with assigned torque constants, are correctly simulated and located, their contribution to the torsional resistance of the structure will be correctly represented also.A structure’s resistance to bending and torsion can be significantly influenced also by the vertical shearing action between connected orthogonal bents or walls. It is important therefore that this is properly included in the model by ensuring the vertical connections between orthogonal components.The preceding discussion of a high-rise structure’s behavior has emphasized the importance of the role of the vertical shear interaction between the main vertical components in developing the structure’s lateral load resistance .An additional mode of interaction between the vertical components, a horizontal force interaction, can also play a significant role in stiffening the structure, and this also should be recognized when forming the model. Horizontally force interaction, occurs when a horizontally deflected system of vertical components with dissimilar lateral deflection characteristics,for example, a wall and a frame, is connected horizontally. In constraining the different vertical components to deflect similarly, the connecting links or slabs are subjected to horizontal interactive forces that redistribution the horizontal loading between the vertical components. For this reason, in a tall wall-frame structure the wall tends to restrain the frame near the base while the frame restrains the wall near the top. Simi-larly, horizontal components twists. In constraining the different vertical components to displace about a center of rotation and to twist identically at each level, the torque between the vertical components andincrease the torque resistance of the structure.高层建筑结构及性能摘要:本文首先对高层建筑的建设的历史发展简要介绍。

毕业设计外文资料翻译题目POLISHING OF CERAMIC TILES抛光瓷砖学院材料科学与工程专业复合材料与工程班级学生学号指导教师二〇一二年三月二十八日MATERIALS AND MANUFACTURING PROCESSES, 17(3), 401–413 (2002) POLISHING OF CERAMIC TILESC. Y. Wang,* X. Wei, and H. YuanInstitute of Manufacturing Technology, Guangdong University ofTechnology,Guangzhou 510090, P.R. ChinaABSTRACTGrinding and polishing are important steps in the production of decorative vitreous ceramic tiles. Different combinations of finishing wheels and polishing wheels are tested to optimize their selection. The results show that the surface glossiness depends not only on the surface quality before machining, but also on the characteristics of the ceramic tiles as well as the performance of grinding and polishing wheels. The performance of the polishing wheel is the key for a good final surface quality. The surface glossiness after finishing must be above 208 in order to get higher polishing quality because finishing will limit the maximum surface glossiness by polishing. The optimized combination of grinding and polishing wheels for all the steps will achieve shorter machining times and better surface quality. No obvious relationships are found between the hardness of ceramic tiles and surface quality or the wear of grinding wheels; therefore, the hardness of the ceramic tile cannot be used for evaluating its machinability.Key Words: Ceramic tiles; Grinding wheel; Polishing wheelINTRODUCTIONCeramic tiles are the common decoration material for floors and walls of hotel, office, and family buildings. Nowadays, polished vitreous ceramic tiles are more popular as decoration material than general vitreous ceramic tiles as they can *Corresponding author. E-mail: cywang@401Copyright q 2002 by Marcel Dekker, Inc. have a beautiful gloss on different colors. Grinding and polishing of ceramic tiles play an important role in the surface quality, cost, and productivity of ceramic tiles manufactured for decoration. The grinding and polishing of ceramic tiles are carried out in one pass through polishing production line with many different grinding wheels or by multi passes on a polishing machine, where d ifferent grinding wheels are used.Most factories utilize the grinding methods similar to those used for stone machining although the machining of stone is different from that of ceramic tiles. Vitreous ceramic tiles are thin, usually 5–8mm in thickness, and are a sintered material,which possess high hardness, wear resistance, and brittleness. In general, the sintering process causes surface deformation in the tiles. In themachining process, the ceramic tiles are unfixed and put on tables. These characteristics will cause easy breakage and lower surface quality if grinding wheel or grinding parameters are unsuitable. To meet the needs of ceramic tiles machining, the machinery, grinding parameters (pressure, feed speed, etc.), and grinding wheels (type and mesh size of abrasive, bond, structure of grinding wheel, etc.) must be optimized. Previous works have been reported in the field of grinding ceramic and stone[1 –4]. Only a few reports have mentioned ceramic tile machining[5 –8], where the grinding mechanism of ceramic tiles by scratching and grinding was studied. It was pointed out that the grinding mechanism of ceramic tiles is similar to that of other brittle materials. For vitreous ceramic tiles, removing the plastic deformation grooves, craters (pores), and cracks are of major concern, which depends on the micro-structure of the ceramic tile, the choice of grinding wheel and processing parameters, etc. The residual cracks generated during sintering and rough grinding processes, as well as thermal impact cracks caused by the transformation of quartz crystalline phases are the main reasons of tile breakage during processing. Surface roughness Ra and glossiness are different measurements of the surface quality. It is suggested that the surface roughness can be used to control the surface quality of rough grinding and semi-finish grinding processes, and the surface glossiness to assess the quality of finishing and polishing processes. The characteristics of thegrinding wheels, abrasive mesh size for the different machining steps, machining time, pressure, feed, and removing traces of grinding wheels will affect the processing of ceramic tiles[9].In this paper, based on the study of grinding mechanisms of ceramic tiles, the manufacturing of grinding wheels is discussed. The actions and optimization of grinding and polishing wheels for each step are studied in particular for manualpolishing machines.GRINDING AND POLISHING WHEELS FOR CERAMIC TILEMACHININGT he mac hi ni ng of cer ami c t i l e s i s a vol ume-pr oduc t i on pr oc e s s t hat uses significant numbers of grinding wheels. The grinding and polishing wheels forceramic tile machining are different from those for metals or structural ceramics. In this part, some results about grinding and polishing wheels are intro duced for better understanding of the processing of ceramic tiles.Grinding and Polishing WheelsCeramic tiles machining in a manual-polishing machine can be divided into four steps—each using different grinding wheels. Grinding wheels are marked as 2#, 3#, and 4# grinding wheels, and 0# polishing wheel; in practice, 2# and 3# grinding wheels are used for flattening uneven surfaces. Basic requirements of rough grinding wheels are long life, high removal rate, and lower price. For 2# and 3# gr inding wheel s, Si C a brasi ve s wi th me s h #180 (#320)a r e bonde d by m a g n e s i u m o x yc h l o r i d e c e m e n t(M O C)t o g e t h e r w i t h s o m e p o r o u s f i l l s, waterproof additive, etc. The MOC is used as a bond because of its low price, simple manufacturing process, and proper performance.T he 4# grinding wheel will refine the surface to show the brightness of ceramic tile. The GC#600 abrasives and some special polishingmaterials, etc., are bonded by MOC. In order to increase the performance such as elasticity, etc., of the grinding wheel, the bakelite is always added. The 4# grinding wheels must be able to rapidly eliminate all cutting grooves and increase the surface glossiness of the ceramic tiles. The 0# polishing wheel is used for obtaining final surface glossiness, whichis made of fine Al2O3 abrasives and fill. It is bonded by unsaturated resin. The polishing wheels must be able to increase surface glossiness quickly and make the glossy ceramic tile surface permanent.Manufacturing of Magnesium Oxychloride Cement Grinding WheelsAfter the abrasives, the fills and the bond MOC are mixed and poured into the models for grinding wheels, where the chemical reaction of MOC will solidify the shape of the grinding wheels. The reaction will stop after 30 days but the hardness of grinding wheel is essentially constant after 15 days. During the initial 15-day period, the grinding wheels must be maintained at a suitable humidity and temperature.For MOC grinding wheels, the structure of grinding wheel, the quality of abrasives, and the composition of fill will affect their grinding ability. All the factors related to the chemical reaction of MOC, such as the mole ratio of MgO/MgCl2, the specific gravity of MgCl2, the temperature and humidity to care the cement will also affect the performance of the MOC grinding wheels.Mole Ratio of MgO/MgCl2When MOC is used as the bond for the grinding wheels, hydration reaction takes place between active MgO and MgCl2, which generates a hard XMg e OH T2·Y e MgCl2T·ZH2O phase. Through proper control of the mole ratio of MgO/MgCl2, a reaction product with stable performance is formed. The bond is composed of 5Mg e OH T2·e MgCl2T·8H2O and 3Mg e OH T2·e MgCl2T·8H2O: As the former is more stable, optimization of the mole ratio of MgO/MgCl2 to produce more 5Mg e OH T2·e MgCl2T·8H2O is required. In general, the ideal range for the mole ratio of MgO/MgCl2 is 4–6. When the contents of the active MgO and MgCl2 are known, the quantified MgO and MgCl2 can be calculated.Active MgOThe content of active MgO must be controlled carefully so that hydration reaction can be successfully completed with more 5Mg e OH T2·e MgCl2T·8H2O: If the content of active MgO is too high, the hydration reaction time will be too short with a large reaction heat, which increases too quickly. The concentrations of the thermal stress can cause generation of cracks in the grinding wheel. On thecontrary, if the content of active MgO is too low, the reaction does not go to completion and the strength of the grinding wheel is decreased.Fills and AdditivesThe fills and additives play an important role in grinding wheels. Some porous fills must be added to 2# and 3# grinding wheels in order to improve the capacity to contain the grinding chips, and hold sufficient cutting grit. Waterproof additives such as sulfates can ensure the strength of grinding wheels in processing under water condition. Some fills are very effective in increasing the surface quality of ceramic tile, but the principle is not clear.Manufacturing of Polishing WheelsFine Al2O3 and some soft polishing materials, such as Fe2O3, Cr2O3, etc., are mixed together with fills. Unsaturated resin is used to bond these powders, where a chemical reaction takes place between the resin and the hardener by means of an activator. The performance of polishing wheels depends on the properties of resin and the composition of the polishing wheel. In order to contain the fine chips, which are generated by micro-cutting, some cheap soluble salt can be fed into the coolant. On the surface of the polishing wheel, the salt will leave uniform pores, which not only increase the capacity to contain chips and self-sharpening of the polishing wheel, but also improves the contact situation between polishing wheel and ceramic tiles.Experimental ProcedureTests were carried out in a special manual grinding machine for ceramictiles. Two grinding wheels were fixed in the grinding disc that was equipped to the grinding machine. The diameter of grinding disc was 255 mm. The rotating speed of the grinding disc was 580 rpm. The grinding and polishing wheels are isosceles trapezoid with surface area 31.5 cm2 (the upper edge: 2 cm, base edge: 5 cm, height: 9 cm). The pressure was adjusted by means of the load on the handle for different grinding procedures. A zigzag path was used as t he moving trace for the grinding disc. To maintain flatness and edge of the ceramic tiles, at least one third of the tile must be under the grinding disc. During the grinding process, sufficient water was poured to both cool and wash the grinding wheels an d the tiles. Four kinds of vitreous ceramic tiles were examined, as shown in Table 1.Two different sizes of ceramic A, A400 (size: 400 £400 £5mm3T and A500(size: 500 £500 £5mm3T were tested to understand the effect of the tile size. Forceramic tile B or C, the size was 500 £500 £5mm3: The phase composition of thetiles was determined by x-ray diffraction technique. Surface reflection glossiness and surface roughness of the ceramic tiles and the wear of grinding wheels were measured.The grinding and polishing wheels were made in-house. The 2# grindingwheels with abrasives of mesh #150 and 3# grinding wheels with mesh #320 were used during rough grinding. Using the ceramic tiles with different surface toughness ground by the 2# grinding wheel for 180 sec, the action of the 3# grinding wheels were tested. The ceramic tile was marked as A500-1 (or B500-1, C500-1, A400-1) with higher initial surface toughness or A500-2 (or B500-2, C500-2, A400-2) with lower initial surface toughness.Two kinds of finishing wheels, 4#A and 4#B were made with the same structure, abrasivity, and process, but different composition of fills and additives. Only in 4#B, a few Al2O3, barium sulfate, and magnesium stearate were added for higher surface glossiness. The composition of the polishing wheels 0#A and 0#B were different as well. In 0#B, a few white alundum (average diameter 1mm), barium sulfate, and chrome oxide were used as polishing additives, specially. After ground by 4#A (or 4#B) grinding wheel, the ceramic tiles were polished with 0#A (or 0#B). The processing combinations with 4# grinding wheels and 0#RESULTS AND DISCUSSIONSEffects of 2# and 3# Grinding WheelsSurface QualityIn rough grinding with a 2# grinding wheel, the surface roughness for all the tiles asymptotically decreases as the grinding time increases, see Fig. 1. The initial asymptote point of this curve represents the optimized rough grinding time, as continued grinding essentially has no effect on the surface roughness. In these tests, the surface roughness curves decrease with grindingtime and become smooth at ,120 sec. The final surface quality for different kinds of ceramic tiles is slightly different. In terms of the initial size of the tile, the surface roughness of ceramic tile A400 e £400 £5mm3T is lower than that of A500 e500 £500 £5mm3T: The surface roughness ofc e r a m i c t i l e B500r a p id l y d r o p s a s t he g r i n d i n g t i m e i n c r e a s e s.Thus, it is easier to remove surface material from the hardest of thethree kinds of the ceramic tiles (Table 1). However, as the final surface roughness of ceramic tile A500 is the same as that of ceramic tile C500, the hardness of theceramic tile does not have a direct relationship with the final surface quality.In the 3# grinding wheel step, all craters and cracks on the surface of ceramic tiles caused by the 2# grinding wheel must be removed. If residual cracks and craters exist, it will be impossible to get a high surface quality in the next step. The surface roughness obtained by the 2# grinding wheel willalso affect the surfaceFigure 1. Surface roughness of several ceramic tiles as a function of grinding time for 2# grindingwheel.quality of next grinding step by the 3# grinding wheel. In Fig. 2, the actions of the 3# grinding wheels are given using the ceramic tiles with different initial R a, which were ground by the 2# grinding wheel for 180 sec. The curves of surface vs. grinding time rapidly decrease in 60 sec. Asymptotic behavior essentially becomes constant after 60 sec. In general, the larger the initial surface roughness, the worse the final surface roughness. For example, for ceramic tile B500-1, the initial R a was 1.53mm, the finial R a was 0.59mm after being ground by the 3# grinding wheel. When the initial R a was 2.06mm for ceramic tile B500-2, the finial R a was 0.67mm. In Ref. [8], we studied the relations between abrasive mesh size and evaluation indices of surface quality, such as surface roughness and surface glossiness. In rough grinding, the ground surface of ceramic tile shows fracture craters. These craters scatter the light, so that the surface glossiness values are almost constant at a low level. It is difficult to improve the surface glossiness after these steps. Figure 3 shows the slow increase in surface glossiness with time by means of the 3# grinding wheel. It can be seen that the glossiness of ceramic tile B500-1 is the highest. The surface glossiness of ceramic tile A400-1 is better than that of A500-1 because the effective grinding times per unit area for former is longer than for latter. These trends are similar to those for surface r o u g h n e s s i nFig. 2.Wear of Grinding WheelsThe wear of grinding wheels is one of the factors controlling the machining cost. As shown in Fig.4, the wear of grinding wheels is proportional to grindingFigure 2. Surface roughness of several ceramic tiles as a function of grinding time for 3# grindingwheel.Figure 3. Surface glossiness of several ceramic tiles as a function of grinding time by 3# grindingwheel.time for both the grinding wheels and the three types of ceramic tiles. The wear rate of the 3# grinding wheel is larger than the 2# grinding wheel. It implies that the wear resistance of the 3# grinding wheel is not as good as 2# for constant grinding time of 180 sec. When the slope of thecurve is smaller, life of thegrinding wheels will be longer. Comparison of the ceramic tiles hardness (Table 1) with the wear resistance behavior in Fig. 4 does not reveal a strong dependency. Therefore, the hardness of the ceramic tile cannot be used to distinguish the machinability. The difference ofFigure 4. Wear of grinding wheels of several ceramic tiles as a function of grinding time for 2# and3# grinding wheels.initial surface roughness of ceramic tile will affect the wear of grinding wheel. In Fig. 4, the wear of the 3# grinding wheel for ceramic tile B500-1 is smaller than that for ceramic tile B500-2. The initial surface roughness of the latter is higher than that of the former so that additional grinding time is required to remove the deeper residual craters on the surface. Improvement of the initial surface roughness can be the principal method for obtaining better grinding quality and grinding wheel life during rough grinding.Effects of 4# Grinding Wheels and 0# Polishing WheelsSurface QualityThe combination and the performance of 4# grinding and 0# polishingwheels show different results for each ceramic tile. The grinding quality vs. grinding (polishing) time curves are presented in Fig. 5, where all the ceramic tiles were previously ground by 2# and 3# grinding wheels to the same surface quality.The surface glossiness is used to assess surface quality because the surface roughness is nearly constant as finishing or polishing time increases[8]. In this test, the ceramic tile A400 were fast ground by 4#A and 4#B grinding wheels [Fig. 5(a)]. The surface glossiness increased rapidly during the initial 90 sec and then slowly increased. The surface glossiness by grinding wheel 4#B is higher than by 4#A. Afterwards, polishing was done by four different combinations of finishing wheel and polishing wheel. By means of polishing wheels 0#A and 0#B, we processed the surface finished by 4#A grinding wheel (described as 4#A–0#A and 4#A–0#B in Fig. 5), and the surfacef i n i s h e d b y4#Bg r i n d i n g wh e e l (described as 4#B–0#A and 4#B–0#B in Fig. 5). The curves of surface glossiness vs. polishing timeshow parabolic behavior. After 60 sec of polishing, the surface glossiness reaches to ,508, then slowly increases. The polishing wheel 0#B gives a better surface quality than 0#A.In Fig. 5(a), the maximum surface glossiness of ceramic tile A400 is about ,75 by 4#B–0#B.The relation between initial surface glossiness and the final surface quality is not strong. The effect of pre-polishing surface glossiness can be observed by 0#B polishing wheel as polishing ceramictile A500 [Fig. 5(b)]. The maximum surface glossiness that can be achieved is 748 in 240 sec by4#A–0#B or 4#B–0#B. This value is lower than that of ceramic tile A400 [Fig. 5(a)].The final surface glossiness by 4#A grinding wheel is highly different from that by 4#B grinding wheel for ceramic tile B500, as shown in Fig. 5(c), but the final polishing roughness is the same when 0#A polishing wheel is used. The better performance of 0#B polishing wheel is shown because the surface glossiness canincrease from 17 to 228 in 30 sec. The maximum surface glossiness is 658 by 4#B–0#B. Thecurves of polishing time vs. surface glossiness in Fig. 5(d) present the same results as polishing of ceramic tile B500 [Fig. 5(c)]. With 0#A polishingFigure 5. Surface glossiness for ceramic tiles (a) A400, (b) A500, (c) B500, and (d) C500 as afunction of grinding (polishing) time for 4# grinding wheels and 0# polishing wheels.wheel, the action of pre-polishing surface glossiness is significant. The best value of surface glossiness in 240 sec is 708 by 4#B–0#B as polishing ceramic tile C500. The results discussed earlier describe that the surface glossiness by 0# polishing wheel will depend not only on the pre-polishing surface glossiness formed by 4# grinding wheel, but also on the characteristics of the ceramic tiles and the performance of 0# polishing wheel. The differences of initial surface glossiness and final surface glossiness are larger for 4#A and 4#B. If the prepolishing surfaceroughness is lower, the final surface glossiness will be higher.Figure 5. Continued.The polishing time taken to achieve the maximum surface glossiness will be also shorter. The initial surface quality will limit the maximum value of polishing surface glossiness that can be obtained. To reach a final surface glossiness of above 608, the minimum pre-polishing surface glossiness must be above 208.The performance of the polishing wheel is the key to good surface quality. The polishing ability of the polishing wheels depends on the properties of the ceramic tiles as well. Even if the same grinding and polishing wheels are used, on all four ceramic tiles, the maximum surface glossiness values of ceramic tiles are different. The ceramic tile A500 shows the best surface glossiness, and ceramictile B500 shows the worst, although it is easier to roughly grind ceramic tile B500. The peak valueof the surface glossiness is also limited by the properties ofWear of Grinding and Polishing WheelsThe life of 4# grinding wheels and 0# polishing wheels (Fig. 6) are longer than those of the rough grinding wheels (Fig. 4). For finer grinding (Fig. 6), it is impossible to distinguish the relation between grinding wheels and ceramic tiles. Polishing wheels have longer life because they produce more plastic deformation than removal.SUMMARY OF RESULTS(1) The performance of grinding and polishing wheels will affect its life and the surface quality of ceramic tiles.(2) In ceramic tile machining, the surface quality gained in the previous step will limit the final surface quality in the next step. The surface glossiness of pre-polishing must be higher than 208 inorder to get the highest polishing quality. The optimization of the combination of grinding wheels and polishing wheels for all the steps will shorten machining time and improve surface quality. Optimization must be determined for each ceramics tiles.Figure 6. Wear of grinding wheels 4# and polishing wheels 0# for several ceramic tiles as afunction of grinding time.(3) The effect of hardness of ceramic tiles is not direct, thus the hardness of ceramic tiles cannot be used for evaluating the machinability ofACKNOWLEDGMENTThe authors thank Nature Science Foundation of Guangdong Province and Science Foundation of Guangdong High Education for their financial support.REFERENCES1. Wang, C.Y.; Liu, P.D.; Chen, P.Y. Grinding Mechanism of Marble. AbrasivesGrinding 1987, 2 (38), 6–10, (in Chinese).2. Inasaki, I. Grinding of Hard and Brittle Materials. Annals of the CIRP 1987, 36 (2),463–471.3. Zhang, B.; Howes, D. Material Removal Mechanisms in Grinding Ceramics. Annalsof the CIRP 1994, 45 (1), 263–266.4. Malkin, S.; Hwang, T.W. Grinding Mechanism for Ceramics. Annals of the CIRP1996, 46 (2), 569–580.5. Black, I. Laser Cutting Decorative Glass, Ceramic Tile. Am. Ceram. Soc. Bull. 1998,77 (9), 53–57.6. Black, I.; Livingstone, S.A.J.; Chua, K.L. A Laser Beam Machining (LBM) Database for the Cutting of Ceramic Tile. J. Mater. Process. Technol. 1998, 84 (1–3), 47–55.7. Jiang, D.F. Mirror Surface Polishing of Ceramic Tile. New Building Mater. 1994, 20(11), 27–30, (in Chinese).8. Ma, J.F. Analysis on Man-Made Floor Brick and Manufacture of Grinding SegmentUsed for Floor Brick. Diamond Abrasive Eng. 1996, 6 (95), 35–46, (in Chinese). 9. Wang, C.Y.; Wei, X.; Yuan, H. Grinding Mechanism of Vitreous Ceramic Tile. Chin.J. Mech. Eng. 1998, 9 (8), 9–11, 46 (in Chinese).材料与制造工艺17(3), 401–413 (2002)抛光瓷砖王CY,* 魏X, 袁H制造技术研究所,广东工业大学科技,广州510090,中国P.R.摘要研磨和抛光,是装饰玻璃陶瓷砖的生产中的重要步骤。

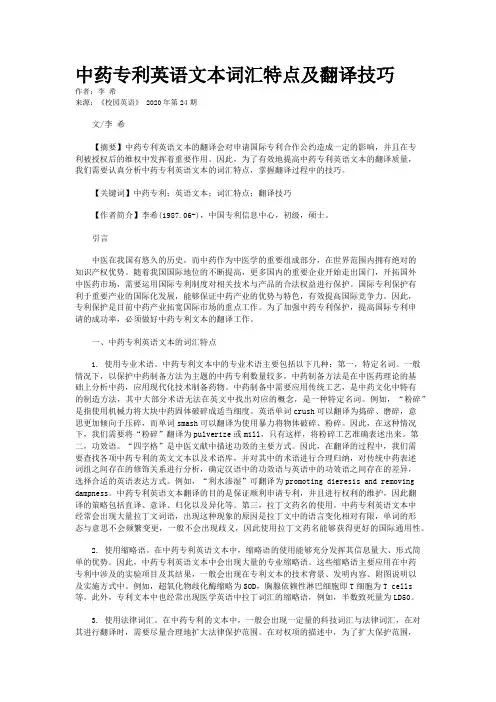

中药专利英语文本词汇特点及翻译技巧作者:李希来源:《校园英语》 2020年第24期文/李希【摘要】中药专利英语文本的翻译会对申请国际专利合作公约造成一定的影响,并且在专利被授权后的维权中发挥着重要作用。

因此,为了有效地提高中药专利英语文本的翻译质量,我们需要认真分析中药专利英语文本的词汇特点,掌握翻译过程中的技巧。

【关键词】中药专利;英语文本;词汇特点;翻译技巧【作者简介】李希(1987.06-),中国专利信息中心,初级,硕士。

引言中医在我国有悠久的历史,而中药作为中医学的重要组成部分,在世界范围内拥有绝对的知识产权优势。

随着我国国际地位的不断提高,更多国内的重要企业开始走出国门,开拓国外中医药市场,需要运用国际专利制度对相关技术与产品的合法权益进行保护。

国际专利保护有利于重要产业的国际化发展,能够保证中药产业的优势与特色,有效提高国际竞争力。

因此,专利保护是目前中药产业拓宽国际市场的重点工作。

为了加强中药专利保护,提高国际专利申请的成功率,必须做好中药专利文本的翻译工作。

一、中药专利英语文本的词汇特点1. 使用专业术语。

中药专利文本中的专业术语主要包括以下几种:第一,特定名词。

一般情况下,以保护中药制备方法为主题的中药专利数量较多,中药制备方法是在中医药理论的基础上分析中药,应用现代化技术制备药物。

中药制备中需要应用传统工艺,是中药文化中特有的制造方法,其中大部分术语无法在英文中找出对应的概念,是一种特定名词。

例如,“粉碎”是指使用机械力将大块中药固体破碎成适当细度。

英语单词crush可以翻译为捣碎、磨碎,意思更加倾向于压碎,而单词smash可以翻译为使用暴力将物体破碎、粉碎。

因此,在这种情况下,我们需要将“粉碎”翻译为pulverize或mill,只有这样,将粉碎工艺准确表述出来。

第二,功效语。

“四字格”是中医文献中描述功效的主要方式。

因此,在翻译的过程中,我们需要查找各项中药专利的英文文本以及术语库,并对其中的术语进行合理归纳,对传统中药表述词组之间存在的修饰关系进行分析,确定汉语中的功效语与英语中的功效语之间存在的差异,选择合适的英语表达方式。

建筑学毕业设计的外文文献及译文文献、资料题目:《Advanced Encryption Standard》文献、资料发表(出版)日期:2004.10.25系(部):建筑工程系生:陆总LYY外文文献:Modern ArchitectureModern architecture, not to be confused with Contemporary architecture1, is a term given to a number of building styles with similar characteristics, primarily the simplification of form and the elimination of ornament. While the style was conceived early in the 20th century and heavily promoted by a few architects, architectural educators and exhibits, very few Modern buildings were built in the first half of the century. For three decades after the Second World War, however, it became the dominant architectural style for institutional and corporate building.1. OriginsSome historians see the evolution of Modern architecture as a social matter, closely tied to the project of Modernity and hence to the Enlightenment, a result of social and political revolutions.Others see Modern architecture as primarily driven by technological and engineering developments, and it is true that the availability of new building materials such as iron, steel, concrete and glass drove the invention of new building techniques as part of the Industrial Revolution. In 1796, Shrewsbury mill owner Charles Bage first used his "fireproof design, which relied on cast iron and brick with flag stone floors. Such construction greatly strengthened the structure of mills, which enabled them to accommodate much bigger machines. Due to poor knowledge of iron's properties as a construction material, a number of early mills collapsed. It was not until the early 1830s that Eaton Hodgkinson introduced the section beam, leading to widespread use of iron construction, this kind of austere industrial architecture utterly transformed the landscape of northern Britain, leading to the description, πDark satanic millsπof places like Manchester and parts of West Yorkshire. The Crystal Palace by Joseph Paxton at the Great Exhibition of 1851 was an early example of iron and glass construction; possibly the best example is the development of the tall steel skyscraper in Chicago around 1890 by William Le Baron Jenney and Louis Sullivan∙ Early structures to employ concrete as the chief means of architectural expression (rather than for purely utilitarian structure) include Frank Lloyd Wright,s Unity Temple, built in 1906 near Chicago, and Rudolf Steiner,s Second Goetheanum, built from1926 near Basel, Switzerland.Other historians regard Modernism as a matter of taste, a reaction against eclecticism and the lavish stylistic excesses of Victorian Era and Edwardian Art Nouveau.Whatever the cause, around 1900 a number of architects around the world began developing new architectural solutions to integrate traditional precedents (Gothic, for instance) with new technological possibilities- The work of Louis Sullivan and Frank Lloyd Wright in Chicago, Victor Horta in Brussels, Antoni Gaudi in Barcelona, Otto Wagner in Vienna and Charles Rennie Mackintosh in Glasgow, among many others, can be seen as a common struggle between old and new.2. Modernism as Dominant StyleBy the 1920s the most important figures in Modern architecture had established their reputations. The big three are commonly recognized as Le Corbusier in France, and Ludwig Mies van der Rohe and Walter Gropius in Germany. Mies van der Rohe and Gropius were both directors of the Bauhaus, one of a number of European schools and associations concerned with reconciling craft tradition and industrial technology.Frank Lloyd Wright r s career parallels and influences the work of the European modernists, particularly via the Wasmuth Portfolio, but he refused to be categorized with them. Wright was a major influence on both Gropius and van der Rohe, however, as well as on the whole of organic architecture.In 1932 came the important MOMA exhibition, the International Exhibition of Modem Architecture, curated by Philip Johnson. Johnson and collaborator Henry-Russell Hitchcock drew together many distinct threads and trends, identified them as stylistically similar and having a common purpose, and consolidated them into the International Style.This was an important turning point. With World War II the important figures of the Bauhaus fled to the United States, to Chicago, to the Harvard Graduate School of Design, and to Black Mountain College. While Modern architectural design never became a dominant style in single-dwelling residential buildings, in institutional and commercial architecture Modernism became the pre-eminent, and in the schools (for leaders of the profession) the only acceptable, design solution from about 1932 to about 1984.Architects who worked in the international style wanted to break with architectural tradition and design simple, unornamented buildings. The most commonly used materials are glass for the facade, steel for exterior support, and concrete for the floors and interior supports; floor plans were functional and logical. The style became most evident in the design of skyscrapers. Perhaps its most famous manifestations include the United Nations headquarters (Le Corbusier, Oscar Niemeyer, Sir Howard Robertson), the Seagram Building (Ludwig Mies van der Rohe), and Lever House (Skidmore, Owings, and Merrill), all in New York. A prominent residential example is the Lovell House (Richard Neutra) in Los Angeles.Detractors of the international style claim that its stark, uncompromisingly rectangular geometry is dehumanising. Le Corbusier once described buildings as πmachines for living,∖but people are not machines and it was suggested that they do not want to live in machines- Even Philip Johnson admitted he was πbored with the box∕,Since the early 1980s many architects have deliberately sought to move away from rectilinear designs, towards more eclectic styles. During the middle of the century, some architects began experimenting in organic forms that they felt were more human and accessible. Mid-century modernism, or organic modernism, was very popular, due to its democratic and playful nature. Alvar Aalto and Eero Saarinen were two of the most prolific architects and designers in this movement, which has influenced contemporary modernism.Although there is debate as to when and why the decline of the modern movement occurred, criticism of Modern architecture began in the 1960s on the grounds that it was universal, sterile, elitist and lacked meaning. Its approach had become ossified in a πstyleπthat threatened to degenerate into a set of mannerisms. Siegfried Giedion in the 1961 introduction to his evolving text, Space, Time and Architecture (first written in 1941), could begin ,,At the moment a certain confusion exists in contemporary architecture, as in painting; a kind of pause, even a kind of exhaustion/1At the Metropolitan Museum of Art, a 1961 symposium discussed the question πModern Architecture: Death or Metamorphosis?11In New York, the coup d r etat appeared to materialize in controversy around the Pan Am Building that loomed over Grand Central Station, taking advantage of the modernist real estate concept of πair rights,∖[l] In criticism by Ada Louise Huxtable and Douglas Haskell it was seen to ,,severπthe Park Avenue streetscape and πtarnishπthe reputations of its consortium of architects: Walter Gropius, Pietro Belluschi and thebuilders Emery Roth & Sons. The rise of postmodernism was attributed to disenchantment with Modern architecture. By the 1980s, postmodern architecture appeared triumphant over modernism, including the temple of the Light of the World, a futuristic design for its time Guadalajara Jalisco La Luz del Mundo Sede International; however, postmodern aesthetics lacked traction and by the mid-1990s, a neo-modern (or hypermodern) architecture had once again established international pre-eminence. As part of this revival, much of the criticism of the modernists has been revisited, refuted, and re-evaluated; and a modernistic idiom once again dominates in institutional and commercial contemporary practice, but must now compete with the revival of traditional architectural design in commercial and institutional architecture; residential design continues to be dominated by a traditional aesthetic.中文译文:现代建筑现代建筑,不被混淆与‘当代建筑’,是一个词给了一些建筑风格有类似的特点,主要的简化形式,消除装饰等.虽然风格的设想早在20世纪,并大量造就了一些建筑师、建筑教育家和展品,很少有现代的建筑物,建于20世纪上半叶.第二次大战后的三十年,但最终却成为主导建筑风格的机构和公司建设.1起源一些历史学家认为进化的现代建筑作为一个社会问题,息息相关的工程中的现代性, 从而影响了启蒙运动,导致社会和政治革命.另一些人认为现代建筑主要是靠技术和工程学的发展,那就是获得新的建筑材料,如钢铁,混凝土和玻璃驱车发明新的建筑技术,它作为工业革命的一部分.1796年,Shrewsbury查尔斯bage首先用他的‘火’的设计,后者则依靠铸铁及砖与石材地板.这些建设大大加强了结构,使它们能够容纳更大的机器.由于作为建筑材料特性知识缺乏,一些早期建筑失败.直到1830年初,伊顿Hodgkinson预计推出了型钢梁,导致广泛使用钢架建设,工业结构完全改变了这种窘迫的面貌,英国北部领导的描述,〃黑暗魔鬼作坊〃的地方如曼彻斯特和西约克郡.水晶宫由约瑟夫paxton的重大展览,1851年,是一个早期的例子, 钢铁及玻璃施工;可能是一个最好的例子,就是1890年由William乐男爵延长和路易沙利文在芝加哥附近发展的高层钢结构摩天楼.早期结构采用混凝土作为行政手段的建筑表达(而非纯粹功利结构),包括建于1906年在芝加哥附近,劳埃德赖特的统一宫,建于1926 年瑞士巴塞尔附近的鲁道夫斯坦纳的第二哥特堂,.但无论原因为何,约有1900多位建筑师,在世界各地开始制定新的建筑方法,将传统的先例(比如哥特式)与新的技术相结合的可能性.路易沙利文和赖特在芝加哥工作,维克多奥尔塔在布鲁塞尔,安东尼高迪在巴塞罗那,奥托瓦格纳和查尔斯景mackintosh格拉斯哥在维也纳,其中之一可以看作是一个新与旧的共同斗争.2现代主义风格由1920年代的最重要人物,在现代建筑里确立了自己的名声.三个是公认的柯布西耶在法国,密斯范德尔德罗和瓦尔特格罗皮乌斯在德国.密斯范德尔德罗和格罗皮乌斯为董事的包豪斯,其中欧洲有不少学校和有关团体学习调和工艺和传统工业技术.赖特的建筑生涯中,也影响了欧洲建筑的现代艺术,特别是通过瓦斯穆特组合但他拒绝被归类与他们.赖特与格罗皮乌斯和Van der德罗对整个有机体系有重大的影响.在1932年来到的重要moma展览,是现代建筑艺术的国际展览,艺术家菲利普约翰逊. 约翰逊和合作者亨利-罗素阁纠集许多鲜明的线索和趋势,内容相似,有一个共同的目的, 巩固了他们融入国际化风格这是一个重要的转折点.在二战的时间包豪斯的代表人物逃到美国,芝加哥,到哈佛大学设计黑山书院.当现代建筑设计从未成为主导风格单一的住宅楼,在成为现代卓越的体制和商业建筑,是学校(专业领导)的唯一可接受的,设计解决方案,从约1932年至约1984 年.那些从事国际风格的建筑师想要打破传统建筑和简单的没有装饰的建筑物。