aspen换热器设计初步计算

- 格式:ppt

- 大小:2.58 MB

- 文档页数:56

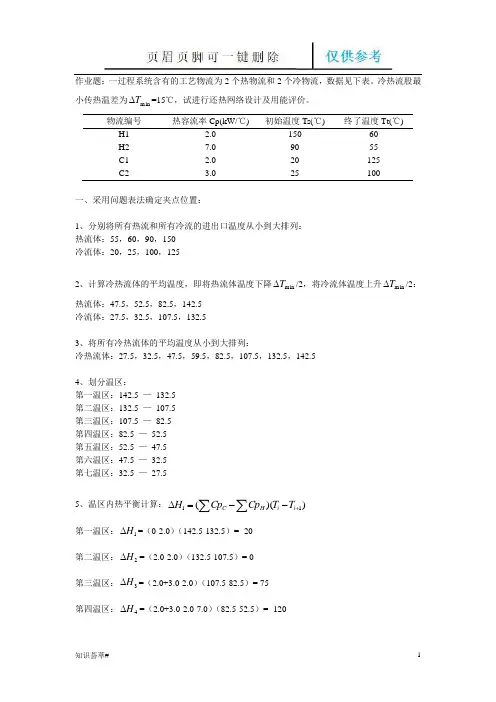

作业题:一过程系统含有的工艺物流为2个热物流和2个冷物流,数据见下表。

冷热流股最小传热温差为min T ∆=15℃,试进行还热网络设计及用能评价。

物流编号 热容流率Cp(kW/℃)初始温度Ts(℃)终了温度Tt(℃)H1 2.0 150 60 H2 7.0 90 55 C1 2.0 20 125 C23.025100一、采用问题表法确定夹点位置:1、分别将所有热流和所有冷流的进出口温度从小到大排列: 热流体:55,60,90,150 冷流体:20,25,100,1252、计算冷热流体的平均温度,即将热流体温度下降min T ∆/2,将冷流体温度上升min T ∆/2: 热流体:47.5,52.5,82.5,142.5 冷流体:27.5,32.5,107.5,132.53、将所有冷热流体的平均温度从小到大排列:冷热流体:27.5,32.5,47.5,59.5,82.5,107.5,132.5,142.54、划分温区:第一温区:142.5 — 132.5 第二温区:132.5 — 107.5 第三温区:107.5 — 82.5 第四温区:82.5 — 52.5 第五温区:52.5 — 47.5 第六温区:47.5 — 32.5 第七温区:32.5 — 27.55、温区内热平衡计算:))((1i +--=∆∑∑i i HCT T CpCp H第一温区:1H ∆=(0-2.0)(142.5-132.5)= -20 第二温区:2H ∆=(2.0-2.0)(132.5-107.5)= 0 第三温区:3H ∆=(2.0+3.0-2.0)(107.5-82.5)= 75 第四温区:4H ∆=(2.0+3.0-2.0-7.0)(82.5-52.5)= -120第五温区:5H ∆=(2.0+3.0-7.0)(52.5-47.5)= -10 第六温区:6H ∆=(2.0+3.0-0)(47.5-32.5)= 75 第七温区:7H ∆=(2.0-0)(32.5-27.5)= 106、计算外界无热量输入时各温区之间的热通量: 第一温区:输入热量=0,输出热量=20第二温区:输入热量=20,输出热量=20+0=20 第三温区:输入热量=20,输出热量=20-75=-55 第四温区:输入热量=-55,输出热量=-55+120=65 第五温区:输入热量=65,输出热量=65+10=75 第六温区:输入热量=75,输出热量=75-75=0 第七温区:输入热量=0,输出热量=0-10=107、计算外界输入最小公用工程时各温区之间的热通量: 第一温区:输入热量=55,输出热量=55+20=75 第二温区:输入热量=75,输出热量=75+0=75 第三温区:输入热量=75,输出热量=75-75=0 第四温区:输入热量=0,输出热量=0+120=120 第五温区:输入热量=120,输出热量=120+10=130 第六温区:输入热量=130,输出热量=130-75=55 第七温区:输入热量=55,输出热量=55-10=458、确定夹点位置第三、第四温区之间热通量为0,此处就是夹点,即夹点在平均温度82.5℃,热物流90℃,冷物流75℃处。

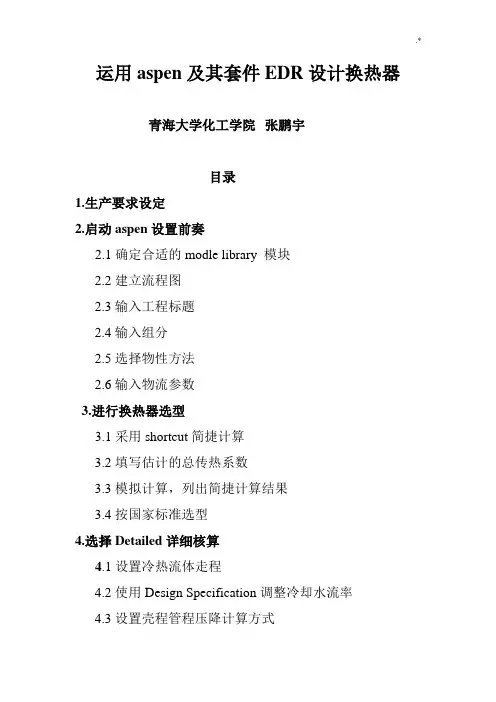

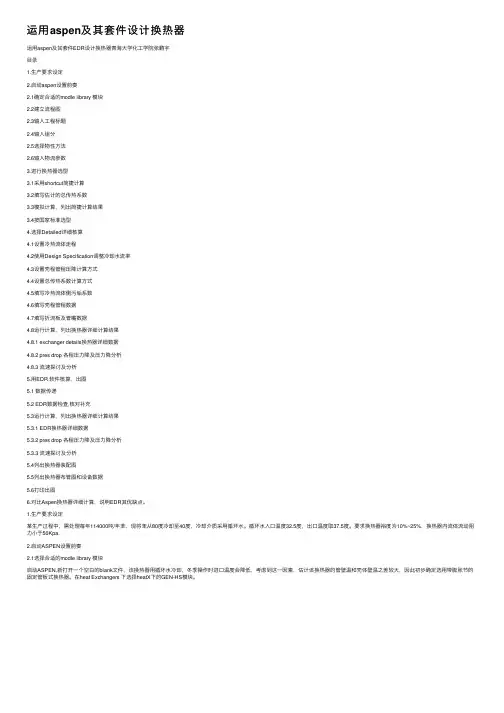

运用aspen及其套件EDR设计换热器青海大学化工学院张鹏宇目录1.生产要求设定2.启动aspen设置前奏2.1确定合适的modle library 模块2.2建立流程图2.3输入工程标题2.4输入组分2.5选择物性方法2.6输入物流参数3.进行换热器选型3.1采用shortcut简捷计算3.2填写估计的总传热系数3.3模拟计算,列出简捷计算结果3.4按国家标准选型4.选择Detailed详细核算4.1设置冷热流体走程4.2使用Design Specification调整冷却水流率4.3设置壳程管程压降计算方式4.4设置总传热系数计算方式4.5填写冷热流体侧污垢系数4.6填写壳程管程数据4.7填写折流板及管嘴数据4.8运行计算,列出换热器详细计算结果4.8.1 exchanger details换热器详细数据4.8.2 pres drop 各程压力降及压力降分析4.8.3 流速探讨及分析5.用EDR 软件核算,出图5.1 数据传递5.2 EDR数据检查,核对补充5.3运行计算,列出换热器详细计算结果5.3.1 EDR换热器详细数据5.3.2 pres drop 各程压力降及压力降分析5.3.3 流速探讨及分析5.4列出换热器装配图5.5列出换热器布管图和设备数据5.6打印出图6.对比Aspen换热器详细计算,说明EDR其优缺点。

1.生产要求设定某生产过程中,需处理每年114000吨/年苯,现将苯从80度冷却至40度,冷却介质采用循环水。

循环水入口温度32.5度,出口温度取37.5度。

要求换热器裕度为10%~25%,换热器内流体流动阻力小于50Kpa.2.启动ASPEN设置前奏2.1选择合适的modle library 模块启动ASPEN,新打开一个空白的blank文件,该换热器用循环水冷却,冬季操作时进口温度会降低,考虑到这一因素,估计该换热器的管壁温和壳体壁温之差较大,因此初步确定选用带膨胀节的固定管板式换热器。

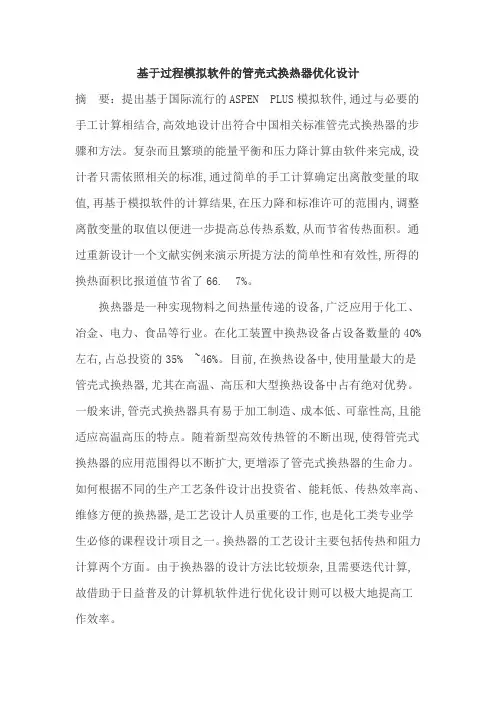

基于过程模拟软件的管壳式换热器优化设计摘要:提出基于国际流行的ASPEN PLUS模拟软件,通过与必要的手工计算相结合,高效地设计出符合中国相关标准管壳式换热器的步骤和方法。

复杂而且繁琐的能量平衡和压力降计算由软件来完成,设计者只需依照相关的标准,通过简单的手工计算确定出离散变量的取值,再基于模拟软件的计算结果,在压力降和标准许可的范围内,调整离散变量的取值以便进一步提高总传热系数,从而节省传热面积。

通过重新设计一个文献实例来演示所提方法的简单性和有效性,所得的换热面积比报道值节省了66. 7%。

换热器是一种实现物料之间热量传递的设备,广泛应用于化工、冶金、电力、食品等行业。

在化工装置中换热设备占设备数量的40%左右,占总投资的35% ~46%。

目前,在换热设备中,使用量最大的是管壳式换热器,尤其在高温、高压和大型换热设备中占有绝对优势。

一般来讲,管壳式换热器具有易于加工制造、成本低、可靠性高,且能适应高温高压的特点。

随着新型高效传热管的不断出现,使得管壳式换热器的应用范围得以不断扩大,更增添了管壳式换热器的生命力。

如何根据不同的生产工艺条件设计出投资省、能耗低、传热效率高、维修方便的换热器,是工艺设计人员重要的工作,也是化工类专业学生必修的课程设计项目之一。

换热器的工艺设计主要包括传热和阻力计算两个方面。

由于换热器的设计方法比较烦杂,且需要迭代计算,故借助于日益普及的计算机软件进行优化设计则可以极大地提高工作效率。

目前,工程上已大量使用商业软件进行换热器的计算。

最著名的专业换热器计算软件主要有成立于1962年的美国传热研究公司(HeatTrans-ferResearch Inc.,即HTRI)开发的XchangerSuite软件;成立于1967年的英国传热及流体服务中心(HeatTransferand Fluid Flow Service,即HTFS)开发的HTFS系列软件[1]和B-JAC软件。

完整版换热器计算步骤换热器是一种常见的热交换设备,常用于将热能从一个流体传递给另一个流体。

换热器的设计需要进行一系列的计算步骤,以确保其正常运行和高效工作。

下面是一个完整版的换热器计算步骤,包括设计要素、计算公式和实际操作。

设计要素:1.温度:确定进口和出口的流体温度2.流量:计算流体的质量流量,即单位时间内通过换热器的物质量3.效率:计算换热器的传热效率,即输入热量与输出热量之间的比值4.压降:计算流体在换热器中的压降,以确保流体能够正常流动计算步骤:1.确定换热器的类型:换热器可以分为三类,即管壳式换热器、管束式换热器和板式换热器。

选择适合的类型要考虑流体的性质、压力、温度和流量等因素。

2.确定流体的物性参数:包括热导率、比热容和密度等参数。

这些参数可以通过查阅资料或实验测量得到。

3.计算传热面积:传热面积是换热器的一个重要参数,可以通过传热率和传热温差来计算。

传热率可以通过查表或经验公式计算得到。

4.计算输出温度:根据换热器的效率和输入温度,可以计算出输出温度。

效率可以根据使用经验或理论估计。

5.计算流体的质量流量:通常需要根据应用的需求确定流体的质量流量。

质量流量可以通过测量或经验公式计算得到。

6.计算传热面积:传热面积决定了换热器的尺寸和成本,一般需要通过经验公式或计算得到。

7.计算压降:压降是换热器设计的一个关键参数,需要根据应用的压力要求和流体的性质计算得到。

压降过大会导致流体流速降低,影响传热效率。

8.确定流体流向:根据应用需求和设计要求选择流体的进出口方向。

实际操作:1.收集流体数据:收集流体的压力、温度和流量等数据。

2.计算换热面积:根据选择的换热器类型和待换热流体的数据,计算换热器的传热面积。

3.计算输出温度:根据输入温度、效率和换热器的传热特性,计算输出温度。

4.计算质量流量:根据应用需求和设计要求计算流体的质量流量。

5.计算压降:根据流体的性质和流动条件计算压降。

6.确定流体流向:根据应用需求和设计要求确定流体的进出口方向。

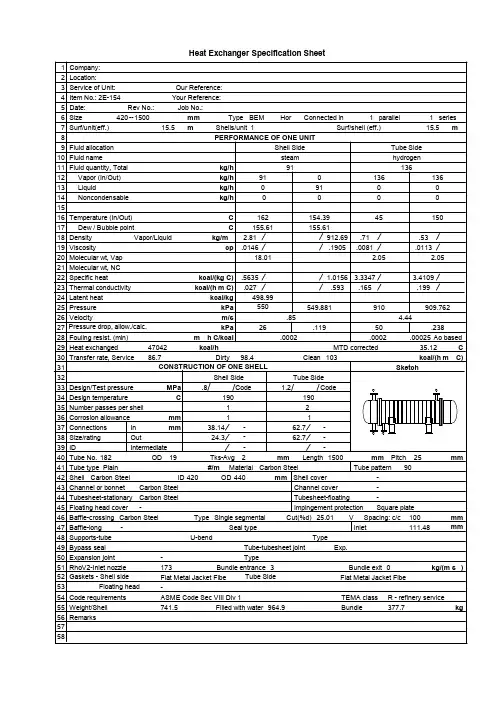

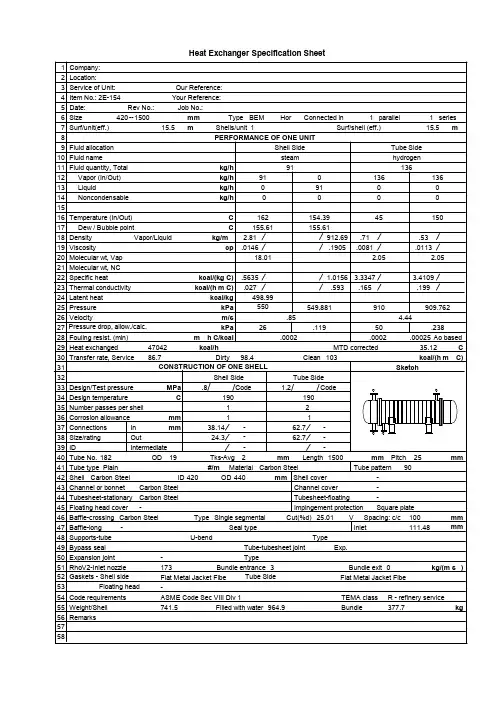

125211.48200R - refinery service Flat Metal Jacket Fibe ASME Code Sec VIII Div 1-Flat Metal Jacket FibeSingle segmental Carbon Steel -Exp.-mm Location:Service of Unit: Our Reference:Item No.: 2E-156 Your Reference:Date: Rev No.: Job No.:4501500BEM 1117.2m 117.2mH2EW21343930kg/h 134127kg/h 0007kg/h 39303930kg/h 04010.03 C51038.93 C .72.76kg/mcp2.14 2.04.99.99kcal/(kg C)kcal/(h m C)577.39kcal/kg 8.974.816kgf/cm 2.69.06m/s .102.002kgf/cm .51.008.0002.0002m h C/kcal kcal/h 17012 C 12.3880.1111.3kcal/(h m C)117.2MPa .57060 C 1211mm 62.7 -38.14 -62.7 -38.14 - - -mm 781.51032.8kg404.52004kg/(m s )323.9mm mm202251921500mm mm mmPlain Carbon Steel 90mm 470Carbon Steel Carbon Steel -Square plate ---Carbon Steel Hor V 593.53.99.99Avg 45012508.971.8081.2967.361032.881032.29.008.0068 1.1878 2.2275 1.91253.1984 3.324 1.0087.8656.8668.161.152.499.423.426.00025#/m ID Size/rating Ao based Vapor/Liquid --Code RemarksTEMA class Intermediate BundleFilled with water Weight/Shell Code requirements Floating headTube Side Gaskets - Shell sideBundle exit Bundle entrance Type Expansion joint Tube-tubesheet joint Bypass seal TypeU-bendSupports-tube Impingement protection Tubesheet-floating Channel cover Floating head cover Tubesheet-stationary Channel or bonnet Out In Surf/shell (eff.)Shells/unit Surf/unit(eff.)series parallel Connected in Type Size OD Sketch234567PERFORMANCE OF ONE UNIT8Fluid allocation 9Fluid name 10Fluid quantity, Total 11Vapor (In/Out)12Liquid 13Noncondensable 14Temperature (In/Out)15Dew / Bubble point 16171819202122232425262728Heat exchanged 29Transfer rate, Service 30CONSTRUCTION OF ONE SHELL 31Design/Test pressure 32Design temperature 33Number passes per shell 34Corrosion allowance 35Connections 363738Tube No.39Tks-4041Length 42Pitch 43Tube type 44Material 45Shell 46ID 47OD 48Shell Side 49Tube Side50Shell cover 51Tube pattern 52Baffle-crossing 53Type 54Cut(%d)55Spacing: c/c 56Baffle-long 57Seal type 58Inlet RhoV2-Inlet nozzle Shell Side Tube Side Fouling resist. (min)Pressure drop, allow./calc.VelocityPressure Latent heat Thermal conductivity Specific heatMolecular wt, NC Molecular wt, Vap ViscosityDensity MTD corrected Dirty Clean Code14261.48200R - refinery service Flat Metal Jacket Fibe ASME Code Sec VIII Div 1-Flat Metal Jacket FibeSingle segmental Carbon Steel -Exp.-mm Location:Service of Unit: Our Reference:Item No.: 2E-158 Your Reference:Date: Rev No.: Job No.:2191200BEM 112.2m1 2.2mH2water 172132kg/h 1716kg/h 0002kg/h 21322132kg/h 024045.33 C 323761.5 C .45.66kg/mcp2.44 2.21.97.97kcal/(kg C)kcal/(h m C)571.39kcal/kg .79.4MPa 1.92.2m/s .050MPa .10.0002.0006m h C/kcal kcal/h 10805 C 52.9592.3147.8kcal/(h m C)172.2kgf/cm 5.09925060 C 1211mm 52.5 -38.14 -52.5 -38.14 - - -mm 247.7293.2kg73.5110kg/(m s )24.91mm mm33251921200mm mm mmPlain Carbon Steel 90mm 239Carbon Steel Carbon Steel -Square plate ---Carbon Steel Hor V 587.8.97.97Avg 219140.79.412.237966.35996.88995.51.0135.0082.5458.7658.69162.93273.1055 1.0052 1.0007 1.0004.215.162.538.525.53.00076#/m ID Size/rating Ao based Vapor/Liquid --Code RemarksTEMA class Intermediate BundleFilled with water Weight/Shell Code requirements Floating headTube Side Gaskets - Shell sideBundle exit Bundle entrance Type Expansion joint Tube-tubesheet joint Bypass seal TypeU-bendSupports-tubeImpingement protection Tubesheet-floating Channel cover Floating head cover Tubesheet-stationary Channel or bonnet Out In Surf/shell (eff.)Shells/unit Surf/unit(eff.)series parallel Connected in Type Size OD Sketch234567PERFORMANCE OF ONE UNIT8Fluid allocation 9Fluid name 10Fluid quantity, Total 11Vapor (In/Out)12Liquid 13Noncondensable 14Temperature (In/Out)15Dew / Bubble point 16171819202122232425262728Heat exchanged 29Transfer rate, Service 30CONSTRUCTION OF ONE SHELL 31Design/Test pressure 32Design temperature 33Number passes per shell 34Corrosion allowance 35Connections 363738Tube No.39Tks-4041Length 42Pitch 43Tube type 44Material 45Shell 46ID 47OD 48Shell Side 49Tube Side50Shell cover 51Tube pattern 52Baffle-crossing 53Type 54Cut(%d)55Spacing: c/c 56Baffle-long 57Seal type 58Inlet RhoV2-Inlet nozzle Shell Side Tube Side Fouling resist. (min)Pressure drop, allow./calc.VelocityPressure Latent heat Thermal conductivity Specific heatMolecular wt, NC Molecular wt, Vap ViscosityDensity MTD corrected Dirty Clean Code0186.48150R - refinery service Flat Metal Jacket Fibe ASME Code Sec VIII Div 1-Flat Metal Jacket FibeSingle segmental Carbon Steel -Exp.-mm Location:Service of Unit: Our Reference:Item No.: 2E-159 Your Reference:Date: Rev No.: Job No.:2731500BEM 115.5m1 5.5mEW1EW275233930kg/h 00kg/h 0075237523kg/h 39303930kg/h 0-18-15C 105 C kg/mcpkcal/(kg C)kcal/(h m C)kcal/kg.13.3MPa .2.18m/s .05.004MPa .050.0002.0002m h C/kcal kcal/h 17218 C 23.88130.6174.1kcal/(h m C)189MPa .5-250 C 1211mm 38.14 -52.5 -38.14 -52.5 - - -mm 361.2450.6kg133.8316035kg/(m s )5539.03mm mm65251921500mm mm mmPlain Carbon Steel 90mm 293Carbon Steel Carbon Steel -Square plate ---Carbon Steel Hor H Avg 27300.126.3.51058.731058.731032.291032.886.1215.63161.91252.2275.7717.7717.8668.8656.374.374.426.423.00025#/m ID Size/rating Ao based Vapor/Liquid --Code RemarksTEMA class Intermediate BundleFilled with water Weight/Shell Code requirements Floating headTube Side Gaskets - Shell sideBundle exit Bundle entrance Type Expansion joint Tube-tubesheet joint Bypass seal TypeU-bendSupports-tubeImpingement protection Tubesheet-floating Channel cover Floating head cover Tubesheet-stationary Channel or bonnet Out In Surf/shell (eff.)Shells/unit Surf/unit(eff.)series parallel Connected in Type Size OD Sketch234567PERFORMANCE OF ONE UNIT8Fluid allocation 9Fluid name 10Fluid quantity, Total 11Vapor (In/Out)12Liquid 13Noncondensable 14Temperature (In/Out)15Dew / Bubble point 16171819202122232425262728Heat exchanged 29Transfer rate, Service 30CONSTRUCTION OF ONE SHELL 31Design/Test pressure 32Design temperature 33Number passes per shell 34Corrosion allowance 35Connections 363738Tube No.39Tks-4041Length 42Pitch 43Tube type 44Material 45Shell 46ID 47OD 48Shell Side 49Tube Side50Shell cover 51Tube pattern 52Baffle-crossing 53Type 54Cut(%d)55Spacing: c/c 56Baffle-long 57Seal type 58Inlet RhoV2-Inlet nozzle Shell Side Tube Side Fouling resist. (min)Pressure drop, allow./calc.VelocityPressure Latent heat Thermal conductivity Specific heatMolecular wt, NC Molecular wt, Vap ViscosityDensity MTD corrected Dirty Clean Code。

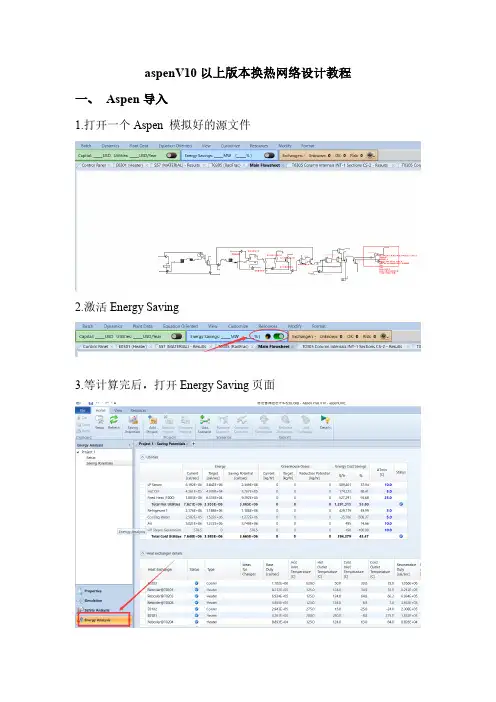

aspenV10以上版本换热网络设计教程一、Aspen导入1.打开一个Aspen 模拟好的源文件2.激活Energy Saving3.等计算完后,打开Energy Saving页面4.启动Aspen Energy Analyzer点击Yes:之后就进入Aspen Energy Analyzer软件页面:5.计算最小温差设置最小传热温差范围和步长,点击Calculate:通过成本和最低传热温差图得最低点,并将最低点输入左下角DTmin:6.目标查看窗口数字1:物流名称,不需要的可以删除,比如流量太小或能量太少数字2:冷热物流符号,蓝色代表冷物流,红色代表热物流,箭头弯的代表有相变,点击弯箭头可显示该物流的区间能量变化数据。

数字3和4:代表进出口温度数字5:热容流率数字6:该物流总的能量数字8:该物流质量流量数字9:该物流比热7.自动设计换热网络右击Scenario1选择Recommended Designs:8.Recommend Designs参数设置窗口9.自动设计方案无法正常运行如果出现温差太小的问题,如图:则双击对应的流股,点击“Delete All”:再次点击“Recommend Designs”,可以显示自动设计的三个方案如左上侧。

各方案比较:分析三个方案的数据——可比较总费用、换热器面积、换热单元数、设备投资费用、冷热公用工程费用、操作费用,还可查看各参数目标值。

一般以年度总费用最小为目标,则选择方案。

由于新版本推荐出来的方案都带有黄色换热器,说明该换热方案不可行,点击下方或在该方案名称上右键“Enter Retrofit mode”,黄色换热器就会消失。

点击下方或在该方案名称上右键“enter Retrofit mode”会跳出现“options”对话框,可以直接关掉,也可以点击“Enter Retrofit Environment”:如果点击“Enter Retrofit Environment”,则左上方显示该方案在新的Scenario1 1目录内,可以对其编辑,进一步优化。

运⽤aspen及其套件设计换热器运⽤aspen及其套件EDR设计换热器青海⼤学化⼯学院张鹏宇⽬录1.⽣产要求设定2.启动aspen设置前奏2.1确定合适的modle library 模块2.2建⽴流程图2.3输⼊⼯程标题2.4输⼊组分2.5选择物性⽅法2.6输⼊物流参数3.进⾏换热器选型3.1采⽤shortcut简捷计算3.2填写估计的总传热系数3.3模拟计算,列出简捷计算结果3.4按国家标准选型4.选择Detailed详细核算4.1设置冷热流体⾛程4.2使⽤Design Specification调整冷却⽔流率4.3设置壳程管程压降计算⽅式4.4设置总传热系数计算⽅式4.5填写冷热流体侧污垢系数4.6填写壳程管程数据4.7填写折流板及管嘴数据4.8运⾏计算,列出换热器详细计算结果4.8.1 exchanger details换热器详细数据4.8.2 pres drop 各程压⼒降及压⼒降分析4.8.3 流速探讨及分析5.⽤EDR 软件核算,出图5.1 数据传递5.2 EDR数据检查,核对补充5.3运⾏计算,列出换热器详细计算结果5.3.1 EDR换热器详细数据5.3.2 pres drop 各程压⼒降及压⼒降分析5.3.3 流速探讨及分析5.4列出换热器装配图5.5列出换热器布管图和设备数据5.6打印出图6.对⽐Aspen换热器详细计算,说明EDR其优缺点。

1.⽣产要求设定某⽣产过程中,需处理每年114000吨/年苯,现将苯从80度冷却⾄40度,冷却介质采⽤循环⽔。

循环⽔⼊⼝温度32.5度,出⼝温度取37.5度。

要求换热器裕度为10%~25%,换热器内流体流动阻⼒⼩于50Kpa.2.启动ASPEN设置前奏2.1选择合适的modle library 模块启动ASPEN,新打开⼀个空⽩的blank⽂件,该换热器⽤循环⽔冷却,冬季操作时进⼝温度会降低,考虑到这⼀因素,估计该换热器的管壁温和壳体壁温之差较⼤,因此初步确定选⽤带膨胀节的固定管板式换热器。

125211.48200R - refinery service Flat Metal Jacket Fibe ASME Code Sec VIII Div 1-Flat Metal Jacket FibeSingle segmental Carbon Steel -Exp.-mm Location:Service of Unit: Our Reference:Item No.: 2E-156 Your Reference:Date: Rev No.: Job No.:4501500BEM 1117.2m 117.2mH2EW21343930kg/h 134127kg/h 0007kg/h 39303930kg/h 04010.03 C51038.93 C .72.76kg/mcp2.14 2.04.99.99kcal/(kg C)kcal/(h m C)577.39kcal/kg 8.974.816kgf/cm 2.69.06m/s .102.002kgf/cm .51.008.0002.0002m h C/kcal kcal/h 17012 C 12.3880.1111.3kcal/(h m C)117.2MPa .57060 C 1211mm 62.7 -38.14 -62.7 -38.14 - - -mm 781.51032.8kg404.52004kg/(m s )323.9mm mm202251921500mm mm mmPlain Carbon Steel 90mm 470Carbon Steel Carbon Steel -Square plate ---Carbon Steel Hor V 593.53.99.99Avg 45012508.971.8081.2967.361032.881032.29.008.0068 1.1878 2.2275 1.91253.1984 3.324 1.0087.8656.8668.161.152.499.423.426.00025#/m ID Size/rating Ao based Vapor/Liquid --Code RemarksTEMA class Intermediate BundleFilled with water Weight/Shell Code requirements Floating headTube Side Gaskets - Shell sideBundle exit Bundle entrance Type Expansion joint Tube-tubesheet joint Bypass seal TypeU-bendSupports-tube Impingement protection Tubesheet-floating Channel cover Floating head cover Tubesheet-stationary Channel or bonnet Out In Surf/shell (eff.)Shells/unit Surf/unit(eff.)series parallel Connected in Type Size OD Sketch234567PERFORMANCE OF ONE UNIT8Fluid allocation 9Fluid name 10Fluid quantity, Total 11Vapor (In/Out)12Liquid 13Noncondensable 14Temperature (In/Out)15Dew / Bubble point 16171819202122232425262728Heat exchanged 29Transfer rate, Service 30CONSTRUCTION OF ONE SHELL 31Design/Test pressure 32Design temperature 33Number passes per shell 34Corrosion allowance 35Connections 363738Tube No.39Tks-4041Length 42Pitch 43Tube type 44Material 45Shell 46ID 47OD 48Shell Side 49Tube Side50Shell cover 51Tube pattern 52Baffle-crossing 53Type 54Cut(%d)55Spacing: c/c 56Baffle-long 57Seal type 58Inlet RhoV2-Inlet nozzle Shell Side Tube Side Fouling resist. (min)Pressure drop, allow./calc.VelocityPressure Latent heat Thermal conductivity Specific heatMolecular wt, NC Molecular wt, Vap ViscosityDensity MTD corrected Dirty Clean Code14261.48200R - refinery service Flat Metal Jacket Fibe ASME Code Sec VIII Div 1-Flat Metal Jacket FibeSingle segmental Carbon Steel -Exp.-mm Location:Service of Unit: Our Reference:Item No.: 2E-158 Your Reference:Date: Rev No.: Job No.:2191200BEM 112.2m1 2.2mH2water 172132kg/h 1716kg/h 0002kg/h 21322132kg/h 024045.33 C 323761.5 C .45.66kg/mcp2.44 2.21.97.97kcal/(kg C)kcal/(h m C)571.39kcal/kg .79.4MPa 1.92.2m/s .050MPa .10.0002.0006m h C/kcal kcal/h 10805 C 52.9592.3147.8kcal/(h m C)172.2kgf/cm 5.09925060 C 1211mm 52.5 -38.14 -52.5 -38.14 - - -mm 247.7293.2kg73.5110kg/(m s )24.91mm mm33251921200mm mm mmPlain Carbon Steel 90mm 239Carbon Steel Carbon Steel -Square plate ---Carbon Steel Hor V 587.8.97.97Avg 219140.79.412.237966.35996.88995.51.0135.0082.5458.7658.69162.93273.1055 1.0052 1.0007 1.0004.215.162.538.525.53.00076#/m ID Size/rating Ao based Vapor/Liquid --Code RemarksTEMA class Intermediate BundleFilled with water Weight/Shell Code requirements Floating headTube Side Gaskets - Shell sideBundle exit Bundle entrance Type Expansion joint Tube-tubesheet joint Bypass seal TypeU-bendSupports-tubeImpingement protection Tubesheet-floating Channel cover Floating head cover Tubesheet-stationary Channel or bonnet Out In Surf/shell (eff.)Shells/unit Surf/unit(eff.)series parallel Connected in Type Size OD Sketch234567PERFORMANCE OF ONE UNIT8Fluid allocation 9Fluid name 10Fluid quantity, Total 11Vapor (In/Out)12Liquid 13Noncondensable 14Temperature (In/Out)15Dew / Bubble point 16171819202122232425262728Heat exchanged 29Transfer rate, Service 30CONSTRUCTION OF ONE SHELL 31Design/Test pressure 32Design temperature 33Number passes per shell 34Corrosion allowance 35Connections 363738Tube No.39Tks-4041Length 42Pitch 43Tube type 44Material 45Shell 46ID 47OD 48Shell Side 49Tube Side50Shell cover 51Tube pattern 52Baffle-crossing 53Type 54Cut(%d)55Spacing: c/c 56Baffle-long 57Seal type 58Inlet RhoV2-Inlet nozzle Shell Side Tube Side Fouling resist. (min)Pressure drop, allow./calc.VelocityPressure Latent heat Thermal conductivity Specific heatMolecular wt, NC Molecular wt, Vap ViscosityDensity MTD corrected Dirty Clean Code0186.48150R - refinery service Flat Metal Jacket Fibe ASME Code Sec VIII Div 1-Flat Metal Jacket FibeSingle segmental Carbon Steel -Exp.-mm Location:Service of Unit: Our Reference:Item No.: 2E-159 Your Reference:Date: Rev No.: Job No.:2731500BEM 115.5m1 5.5mEW1EW275233930kg/h 00kg/h 0075237523kg/h 39303930kg/h 0-18-15C 105 C kg/mcpkcal/(kg C)kcal/(h m C)kcal/kg.13.3MPa .2.18m/s .05.004MPa .050.0002.0002m h C/kcal kcal/h 17218 C 23.88130.6174.1kcal/(h m C)189MPa .5-250 C 1211mm 38.14 -52.5 -38.14 -52.5 - - -mm 361.2450.6kg133.8316035kg/(m s )5539.03mm mm65251921500mm mm mmPlain Carbon Steel 90mm 293Carbon Steel Carbon Steel -Square plate ---Carbon Steel Hor H Avg 27300.126.3.51058.731058.731032.291032.886.1215.63161.91252.2275.7717.7717.8668.8656.374.374.426.423.00025#/m ID Size/rating Ao based Vapor/Liquid --Code RemarksTEMA class Intermediate BundleFilled with water Weight/Shell Code requirements Floating headTube Side Gaskets - Shell sideBundle exit Bundle entrance Type Expansion joint Tube-tubesheet joint Bypass seal TypeU-bendSupports-tubeImpingement protection Tubesheet-floating Channel cover Floating head cover Tubesheet-stationary Channel or bonnet Out In Surf/shell (eff.)Shells/unit Surf/unit(eff.)series parallel Connected in Type Size OD Sketch234567PERFORMANCE OF ONE UNIT8Fluid allocation 9Fluid name 10Fluid quantity, Total 11Vapor (In/Out)12Liquid 13Noncondensable 14Temperature (In/Out)15Dew / Bubble point 16171819202122232425262728Heat exchanged 29Transfer rate, Service 30CONSTRUCTION OF ONE SHELL 31Design/Test pressure 32Design temperature 33Number passes per shell 34Corrosion allowance 35Connections 363738Tube No.39Tks-4041Length 42Pitch 43Tube type 44Material 45Shell 46ID 47OD 48Shell Side 49Tube Side50Shell cover 51Tube pattern 52Baffle-crossing 53Type 54Cut(%d)55Spacing: c/c 56Baffle-long 57Seal type 58Inlet RhoV2-Inlet nozzle Shell Side Tube Side Fouling resist. (min)Pressure drop, allow./calc.VelocityPressure Latent heat Thermal conductivity Specific heatMolecular wt, NC Molecular wt, Vap ViscosityDensity MTD corrected Dirty Clean Code。

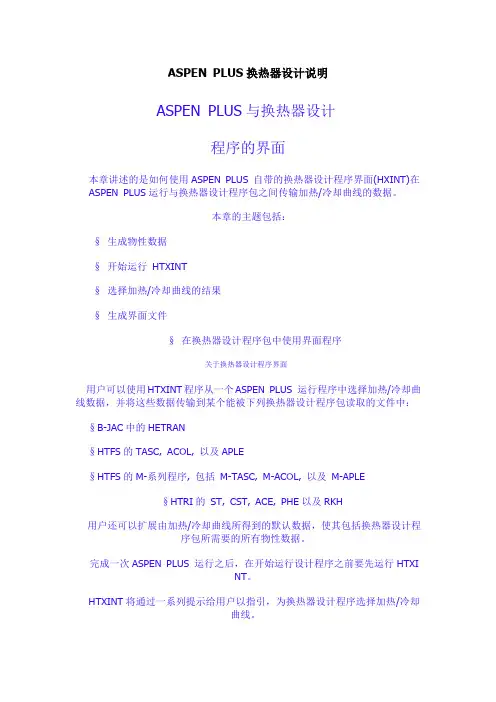

ASPEN PLUS换热器设计说明ASPEN PLUS与换热器设计程序的界面本章讲述的是如何使用ASPEN PLUS 自带的换热器设计程序界面(HXINT)在ASPEN PLUS运行与换热器设计程序包之间传输加热/冷却曲线的数据。

本章的主题包括:§生成物性数据§开始运行HTXINT§选择加热/冷却曲线的结果§生成界面文件§在换热器设计程序包中使用界面程序关于换热器设计程序界面用户可以使用HTXINT程序从一个ASPEN PLUS 运行程序中选择加热/冷却曲线数据,并将这些数据传输到某个能被下列换热器设计程序包读取的文件中:§B-JAC中的HETRAN§HTFS的TASC, ACOL, 以及APLE§HTFS的M-系列程序, 包括M-TASC, M-ACOL, 以及M-APLE§HTRI的ST, CST, ACE, PHE以及RKH用户还可以扩展由加热/冷却曲线所得到的默认数据,使其包括换热器设计程序包所需要的所有物性数据。

完成一次ASPEN PLUS 运行之后,在开始运行设计程序之前要先运行HTXINT。

HTXINT将通过一系列提示给用户以指引,为换热器设计程序选择加热/冷却曲线。

HTXINT是一个用于调用ASPEN PLUS 摘要文件工具的应用程序。

在模拟中生成物性数据HTXINT所使用的物性数据来自加热/冷却曲线,许多ASPEN PLUS单元操作模型都可以生成这种曲线。

在使用HTXINT时,用户必须先使用ASPEN PLUS 生成所需的加热/冷却曲线,对于每个想要的单元模块都要生成加热/冷却曲线(一条或多条)。

关于指定加热/冷却曲线的详细细节,请参见第10章“要求加热/冷却曲线计算”一节。

在模块的Hcurve上就可以:1.在“Property Sets”栏下选择“HXDESIGN”2.选择所需采样点的数目。

aspen导热油换热计算请看图⽚,导热油是Therminol你在ASPEN⾥⾯直接寻找物性输⼊TherminolMobiltherm600是美孚公司600系列的导热油,是导热油。

我觉得没必要重新去模拟导热油的,仅仅做换热计算的话是可以直接调⽤数据库的。

采⽤Aspen Properties的数据库搜索"Therm”关键字即可搜索到更多导热油组分,但是在版本中有个bug,就是⼀部分导热油组分是从B-JAC数据库转移过来的,⽐如Therminol-66计算出来的物性都是错误的,这个bug已经在中修好了。

另外注意:这些导热油组分都为专属设定,不必选择物性⽅法,⽐如⽆论你⽤NRTL或者是PR⽅程,计算出的物性都是⼀样的!导热油种类繁多,软件只能把⼀些最著名并且知名公司的部分代表产品列出来,⼤家在计算的时候可以根据后⾯的Tb沸点⾃⼰选择需要的导热油,在实际采购中,国内的⼤多数⼚商也都遵循这些典型产品的规律。

下⾯简单介绍下导热油的分类,这样⼤家就清楚aspen properties软件中各个导热油组分代表的含义,Aspen软件也没⽤包含下述所有的导热油,但下⾯的介绍⼀定会对⼤家选择那种导热油组分有帮助:导热油从结构上可分为合成型与矿油型两⼤类。

合成型导热油⼜称热传导液,是以⽯油化⼯或化⼯产品为原料经有机合成⼯艺制得,是纯的或⽐较纯的化学品,其特点是稳定性好,使⽤寿命长,可再⽣,但其价格也相对较⾼。

矿油型导热油⼜称热传导油,是以⽯油某线馏分为原料,经过加⼯调配制成,是多种烷烃组分的混合物。

矿油型导热油的原料来源较为⼴泛,⽣产⼯艺简单,价格低廉,但其热稳定性和抗氧化性受其多组分物质特性的影响相对较差。

⼀、合成型①联苯-联苯醚。

由%联苯醚和%联苯组成,是⼀种共沸体系,沸点257°,最⾼使⽤温度400°。

这是美国Dow公司30年代开发的⼀种产品,也是使⽤最早、使⽤时间最长的产品,优点是热稳定性好,积炭倾向⼩,缺点是渗透性强,⽓味难闻,有致癌作⽤。

运用aspen及其套件EDR设计换热器青海大学化工学院张鹏宇目录1.生产要求设定2.启动aspen设置前奏2.1确定合适的modle library 模块2.2建立流程图2.3输入工程标题2.4输入组分2.5选择物性方法2.6输入物流参数3.进行换热器选型3.1采用shortcut简捷计算3.2填写估计的总传热系数3.3模拟计算,列出简捷计算结果3.4按国家标准选型4.选择Detailed详细核算4.1设置冷热流体走程4.2使用Design Specification调整冷却水流率4.3设置壳程管程压降计算方式4.4设置总传热系数计算方式4.5填写冷热流体侧污垢系数4.6填写壳程管程数据4.7填写折流板及管嘴数据4.8运行计算,列出换热器详细计算结果4.8.1 exchanger details换热器详细数据4.8.2 pres drop 各程压力降及压力降分析4.8.3 流速探讨及分析5.用EDR 软件核算,出图5.1 数据传递5.2 EDR数据检查,核对补充5.3运行计算,列出换热器详细计算结果5.3.1 EDR换热器详细数据5.3.2 pres drop 各程压力降及压力降分析5.3.3 流速探讨及分析5.4列出换热器装配图5.5列出换热器布管图和设备数据5.6打印出图6.对比Aspen换热器详细计算,说明EDR其优缺点。

1.生产要求设定某生产过程中,需处理每年114000吨/年苯,现将苯从80度冷却至40度,冷却介质采用循环水。

循环水入口温度32.5度,出口温度取37.5度。

要求换热器裕度为10%~25%,换热器内流体流动阻力小于50Kpa.2.启动ASPEN设置前奏2.1选择合适的modle library 模块启动ASPEN,新打开一个空白的blank文件,该换热器用循环水冷却,冬季操作时进口温度会降低,考虑到这一因素,估计该换热器的管壁温和壳体壁温之差较大,因此初步确定选用带膨胀节的固定管板式换热器。