冲孔落料连续模设计

- 格式:doc

- 大小:827.00 KB

- 文档页数:48

冲压工艺学学习报告题目:落料冲孔连续模报告学院:机械工程学院专业年级:工业工程12级姓名:谢兵班级学号:工程12-01-08指导教师:伦凤艳二O一五年十月九日目录模具设计说明 (2)1.冲压件工艺性分析 (2)2.冲压工艺方案的确定 (3)3.主要设计计算 (3)4. 模具总体设计 (6)5. 主要零部件设计 (6)6.模具总装图 (10)7.冲压设备的选定 (10)8、模具的装配 (11)主要参考文献: (13)学习小结 (14)模具设计说明题目:落料冲孔连续模报告任务描述:工件名称:冲孔落料件工件简图:如下图生产批量:中批量生产材料:Q235A材料厚度:2mm零件公差:IT13展开板金件,设计一副冲孔、落料连续模。

为弯曲模准备毛坯。

图1 工件图1.冲压件工艺性分析(1)冲裁件结构形状分析该冲裁件结构简单,从图中不难看出,此工件只有冲孔和落料两个工序。

其外形为规则形,内部有两个小孔和一个方孔,结构较为简单适合冲裁。

(2)尺寸制件图给出的外形为规则形,其尺寸为50*70,两个内孔直径为8mm和一个10*15mm的方孔,其尺寸如图1所示,制件厚度为2mm。

属于中等尺寸的冲裁件。

(3)尺寸精度从图1可知,该制件的公差等级为IT13级,用冲裁加工可以达到该精度要求。

其余尺寸为自由公差,精度要求不高,所以均按IT14级确定制件公差。

(4)表面粗糙度该制件的厚度为2,查表可知表面表面粗糙度Ra为6.3μm。

冲裁件内、外形可到达的经济精度为0.16mm和0.23mm,两孔中心距公差为±0.12mm,孔中心与边缘距离尺寸公差为±0.6mm。

2.冲压工艺方案的确定该工件包括落料、冲孔两个基本工序,可有以下三种工艺方案:方案一:先落料,后冲孔。

采用单工序模生产。

方案二:落料和冲孔复合冲压。

采用复合模生产。

方案三:冲孔——落料级进冲压。

采用级进模生产。

方案一模具结构简单,但需要两道工序两套模具,成本高而生产效率低,难以满足大批量生产要求。

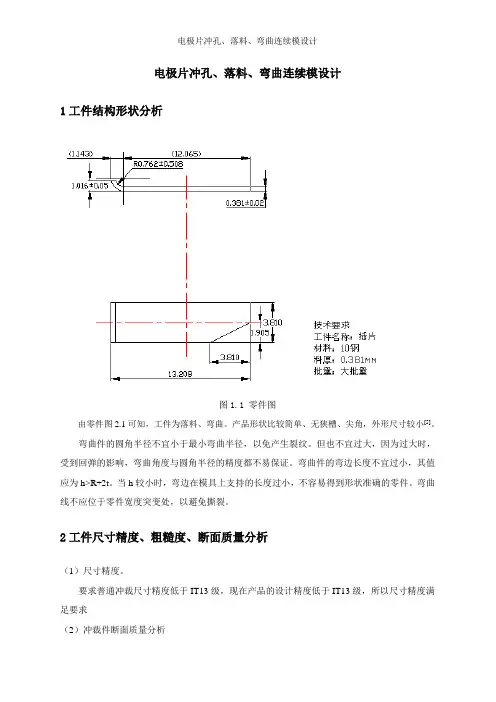

电极片冲孔、落料、弯曲连续模设计1工件结构形状分析图1.1 零件图由零件图2.1可知,工件为落料、弯曲。

产品形状比较简单、无狭槽、尖角,外形尺寸较小[5]。

弯曲件的圆角半径不宜小于最小弯曲半径,以免产生裂纹。

但也不宜过大,因为过大时,受到回弹的影响,弯曲角度与圆角半径的精度都不易保证。

弯曲件的弯边长度不宜过小,其值应为h>R+2t。

当h较小时,弯边在模具上支持的长度过小,不容易得到形状准确的零件。

弯曲线不应位于零件宽度突变处,以避免撕裂。

2工件尺寸精度、粗糙度、断面质量分析(1)尺寸精度。

要求普通冲裁尺寸精度低于IT13级,现在产品的设计精度低于IT13级,所以尺寸精度满足要求(2)冲裁件断面质量分析因为一般用普通冲裁方式冲2mm以下的金属板料时,其断面粗糙度Ra可达12.5~3.2 ,毛刺允许高度为0.01~0.05mm;本产品在断面粗糙度和毛刺高度上没有太严格的要求,所以只要模具精度达到一定要求,冲裁件的断面质量可以保证。

(3)产品材料分析对于冲压件材料一般要求得力学性能是强度低,塑性高,表面质量和厚度公差符合国家标准。

本设计的工件材料是10钢,属于优质碳素结构钢,其力学性能是强度、硬度和塑性指标适中,经退火后,用冲裁的加工方法是完全可以成形的。

另外产品对于厚度和表面质量没有严格要求,所以尽量采用国家标准的板材,其冲裁出的产品的表面质量和厚度公差就可以保证[6]。

经上述分析,产品的材料性能符合冷冲压加工要求。

3 插片冲模结构的确定级进模的排样是指制件(一个或多个)在条料上分几个工位冲刺的布置方法。

3.1排样论证的基本思路排样论证的目的是为了画出正确的模具排样图。

一个较佳的排样方案必须兼顾冲压件的公差等级、冲压件的生产批量、模具结构和材料利用率等方面的因素。

(1)冲压件的尺寸精度图2.1所示冲压件,材料为10钢板,料厚0.381mm,其未注公差尺寸精度等级为IT13,属一般冲裁模能达到的公差等级,不需采用精冲或整修等特殊冲裁方式。

院(系)、部:机电工程学院题目:带槽三角形固定板冲圆孔、冲槽、落料连续模设计3 设计(论文)所用资源和参考资料:《冷冲压工艺及模具设计》,《冲模设计应用实例》,《冲压工艺学》,《冲模设计手册》,《冷冲压技术问答》,《冲压工艺与模具设计》,《模具设计与制造简明手册》,《冲压工艺及模具设计》等等。

4 设计(论文)完成的主要内容:5 提交设计(论文)形式(设计说明与图纸或论文等)及要求:1根据总体设计方案,绘制出落料模具总图一张;2绘制模具零件图若干张;4科技译文;7编写毕业设计说明书一套。

指导教师:(签名)学生:(签名)注:此表一式两份:一份存学院,一份发给学生。

指导人:(签名)年月日指导人评定成绩:评阅人:(签名)年月日评阅人评定成绩:毕业设计(论文)答辩委员会主任:(签名)委员:(签名)(签名)(签名)(签名)答辩成绩:总评成绩:目录湖南科技大学.................................................................................................... 错误!未定义书签。

湖南科技大学.................................................................................................... 错误!未定义书签。

湖南科技大学毕业设计(论文)评阅人评语 .............................................. 错误!未定义书签。

湖南科技大学.................................................................................................... 错误!未定义书签。

1 前言 (7)1.1 冷冲压术的发展趋势 (7)1.1.1 冷冲压设备自动化 (7)1.1.2 高速化复合化相结合,提高加工效率 (7)1.2 模具技术发展的几个特点 (8)1.2.1 充分运用IT技术发展 (8)1.2.2 缩短金属成型模具的试模时间 (8)1.2.3 车身制造中的级进冲模发展迅速 (8)1.3 我国锻压工业的现状及发展对策 (9)2 零件工艺性分析 (9)2.1 冲裁工艺性 (9)2.1.1 结构与尺寸 (9)2.1.2 精度 (10)2.1.3 材料 (10)3 确定冲裁工艺方案 (10)3.1 工序性质与数量的确定 (11)3.2 工序顺序的确定 (11)3.3 工序组合方式的确定 (11)4 确定模具总体结构方案 (11)4.1 模具类型 (11)4.2 操作与定位方式 (11)4.3 卸料方式与出件方式 (11)4.4 模架类型及精度 (11)5 工艺与设计计算 (12)5.1 排样设计与计算......................................................................................... 错误!未定义书签。

湖南农业大学东方科技学院课程设计说明书需图纸,联系QQ153893706课程名称:冷冲压模具设计与制造题目名称:冲孔落料连续模班级:2008级机制专业机制三班姓名:学号:指导教师:评定成绩:教师评语:指导老师签名:年月目录冷冲压的概述 (2)冲压工艺的特点及其应用 (2)模具设计的主要内容 (3)一、零件设计总图 (3)二、冲压件的工艺分析 (4)四、冲裁工艺方案 (5)五、排样 (8)六、计算冲压力 (10)七、确定模具压力中心 (10)八、计算凸凹模刃口尺寸 (12)九,凸模和凹模工作部分尺寸的设计计算 (13)十、磨具其他装置的设计 (15)十一、模架的选择 (16)十二、压力机相关参数的计算 (17)十三、装配图 (17)十四、结论 (17)十五、参考文献 (18)1。

冷冲压的概述:冷冲压是在常温下利用冲模在压力机上对材料施加压力,使其产生分离或变形,从而获得一定形状,尺寸和性能的零件加工方法。

它是压力加工方法的一种,是机械制造中先进的加工方法之一。

在冷冲压加工中,冷冲模就是冲压加工所用的工艺设备,没有先进的冷冲模,先进的冲压工艺就无法实现。

冷冲压工序的分类:由于冷冲压加工的零件形状、尺寸、精度要求、批量大小、原材料性能等不同,其冲压方法可分为分离工序和变形工序两大类。

冷冲压可分为5个基本工序:冲裁使板料实现分离的冲压工序。

弯曲将金属材料沿弯曲线弯成一定的角度和形状的冲压工序。

拉伸将平面板料变成各种开口空心件,或者把空心件的尺寸作进一步改变的冲压工序。

成形用各种步同性质的局部变形来改变毛坯或冲压件形状的冲压工序。

立体压制将金属材料体积重新分布的冲压工序。

冲压工艺的特点及应用冷冲压工艺与其他加工方法相比,有以下特点:用冷冲压加工方法可以得到形状复杂,用其他加工方法难以加工的工件。

冷冲压的尺寸精度是由模具保证的,因此,尺寸稳定,互换性好。

材料利用率高,工件质量轻,刚性好,强度高,冲压过程耗能少,因此工件成本较低。

冲压模具设计说明书一、课题名称:垫片冲孔落料连续模二、设计要求:1.主要内容(1)编制冲压工艺(2)设计模具(分析、计算、装配图、非标零件图)(3)编制模具主要零件制造工艺(4)分析估算工时,确定完成工期(5)核算成本,报价(6)编写全套设计制造说明书2.基本要求:(1)分析计算全面,图纸表达准确;(2)工艺水平规程制定,力求符合实际;(3)必要的数据须进行市场调查;(4)分析核算工期、成本,着重于过程。

第2章工艺分析及模具结构设计2.1 制件的工艺性分析及工艺计算2.1.1 工艺分析,方形垫片,结构如图所示,材料08,t=1.2mm。

精度要求为IT14。

三、主要内容1、制件的工艺性分析1.1、可行性分析1.1.1、形状、尺寸:制件形状规则、简单、对称。

1.1.2、精度:该制件尺寸精度为IT14,用一般精度制造模具即可满足。

1.1.3、材料:08是冲压用钢板中沸腾钢的一种牌号(中国称08,日本称S9CK,德国用C10,前苏联用08)08指的是含碳量万分之八;特性:强度低和硬度、塑性、韧性好,易于深冲、拉延、弯曲和焊接。

用途:钢板用作深冲压和深拉延的容器,如搪瓷制品、仪表板、汽车驾驶室盖板等。

圆钢用作心部强度要求不高的渗碳或氰化零件。

力学性能:抗拉强度σb (MPa):≥295(30)屈服强度σs (MPa):≥175(18)伸长率δ5 (%):≥35断面收缩率ψ (%):≥60硬度:未热处理,≤131HB推荐热处理/℃:正火930正火推荐保温保温时间≤30min,空冷;淬火推荐保温时间≤30min,70.80和85钢油冷,其余钢水冷;回火推荐保温时间≤1h。

2、总体工艺方案的确定2.1、冲压工序性质的确定:先进行冲孔再进行落料。

2.2、冲压方案的确定:方案一:采用单工序模生产。

方案二:采用复合模生产。

因为方案二的工件精度和生产效率较高,属于大批量生产,所以选用方案二最为合适。

3、主要工艺计算3.1、排样设计3.1.1、排样方式:查《冷冲压工艺及模具设计》P53,表2-7,确定排样方式为单行直排。

垫片冲孔落料连续模具设计1.设计的主要任务及目标(1)任务:1)模具装配图及零件图2)设计说明书一本3)电子资料一份(2)目标:以所学专业知识为基础,以实用为目的,通过对垫片冲压工艺的分析及相关参数的计算,进一步进行模具的总装图及零件的设计,总结出并熟练掌握模具设计的规律和方法。

2.设计的基本要求和内容(1)基本要求1)认真学习相关书籍,查阅中外文资料,制定出合理的设计方案;2)认真做好各环节计算与分析,使零件的工艺分析正确,模具设计合理;3)勤于思考,应用所学的专业知识来解决设计中遇到的问题;4)翻译一篇与本课题相关的英文文献;(2)主要内容1)对垫片的工艺性进行科学的分析;对相关参数进行准确的计算。

2)通过查阅相关的模具图册,设计出合理的模具装配图及主要零部件图(不少于5张)。

3)探索总结出一套相关的模具设计规律和方法。

3.主要参考文献[1]《冲模设计手册》,《冲模设计手册》编写组编注机械工业出版社 1999.06[2]《冲压工艺与模具设计》,姜奎华主编机械工业出版社1999.1[3]《互换性与技术测量》,廖念创等计量出版社 1998.02[4]《冲压工艺与模具设计》,姜奎华主编机械工业出版社1999.14.进度安排设计各阶段名称起止日期1 资料查阅,完成开题报告2013.12.17—2014.03.172 制定工艺方案,制定模具大体结构2014.03.18—2014.03.253 完成模具的设计与计算2014.03.25—2014.05.154 绘制图纸及编写设计说明书2014.03.25—2014.05.155 撰写毕业设计2014.06.02—2014.06.126 制作答辩PPT,准备毕业设计答辩2014.06.13—2014.06.205.附图厚度为1mm的黄铜板注:一式4份,系部、指导教师各1份、学生2份:[毕业设计(论文)]及答辩评分表各一份垫片冲孔落料连续模具设计摘要:本设计是垫片冲裁模,利用的是级进模生产的。

xxxxxxxxxxxxxxxxxxxxxxxxxx学院课程设计说明书课程名称:冷冲压模具设计与制造题目名称:冲孔落料连续模班级:20 级专业班姓名: xxxxx学号: xxxxxxxx指导教师: xxx评定成绩:教师评语:指导老师签名:20 年月日成绩评阅教师日期目录摘要 1关键词 1一、前言 11.1冲压工艺的介绍 11.2冲压工艺的种类 11.3冲压技术的现状及发展方向 2二、设计任务书 5三、工艺方案分析及确定53.1冲压件工艺分析 53.2冲裁零件方案及模具结构类型确定 6四、模具设计计算 64.1排样设计 64.2冲压力的计算 74.3确定模具压力中心 84.4计算凸、凹模刃口尺寸 94.5定位方式 12五、确定各主要零件的结构尺寸 135.1凹模的外形尺寸 135.2凸模的设计 145.3模座 145.4模柄 155.5模具总体设计 155.6其它模具零件结构尺寸 15六、冲压设备的选定 15七、绘图 16八、总结 16九、参考文献 16摘要:在指导教师周密安排和精心指导下,这次冷冲压设计从确定课程设计任务书、拟定设计方案、设计过程到课程设计都按照严格的课程设计工作计划进行。

冷冲压模具是现代工业生产的重要工艺装备,模具工业是国民经济的基础工业。

在课程设计中能主动请教指导老师,培养综合运用机械制图、工程材料与热处理、公差配合、计算机绘图、机械制造工艺等专业知识的能力,培养查阅技术资料和其它专业文献的能力。

我虚心求教,仔细认真地进行毕业设计。

关键词:模具冲压冲裁模一、前言1.1冲压工艺介绍冲压是靠压力机和模具对板材、带材、管材和型材等施加外力,使之产生塑性变形或分离,从而获得所需形状和尺寸的工件(冲压件的成形加工方法。

冲压和锻造同属塑性加工(或称压力加工,合称锻压。

冲压的坯料主要是热轧和冷轧的钢板和钢带。

全世界的钢材中,有60~70%是板材,其中大部分是经过冲压制成成品。

汽车的车身、底盘、油箱、散热器片,锅炉的汽包、容器的壳体、电机、电器的铁芯硅钢片等都是冲压加工的。

毕业论文开题报告机械设计制造及其自动化落料、冲孔连续模具的设计一、选题的背景和意义模具是工业产品生产用的重要工艺装备,在现代工业生产中,60%-90%的工业产品需要使用模具,模具工业已经成为工业发展的基础,许多新产品的开发和研制在很大程度上都依赖于模具生产,它在汽车、拖拉机、飞机、家用电器、工业机械、动力机械、机床、兵器,仪器仪表、轻工、日用五金等制造业中起着极为重要的作用。

而作为制造业基础的机械行业,根据国际生产技术协会的预测,21世纪机械制造工业的零件,其粗加工的75%和精加工的50%都将依靠模具完成,模具工业发展的关键是模具技术的进步。

作为重要的生产装备行业在为各行各业服务的同时,也直接为高技术产业服务。

由于模具生产要采用一系列高新技术,如CAD/CAE/CAM/CAPP等技术、计算机网络技术、激光技术、逆向工程技术和并行工程技术、快速成型技术及敏捷制造技术、高速加工及超精密加工技术等等。

模具工业已然成为高新技术产业的一个重要组成部分。

因此,模具工业已经成为国民经济的重要基础工业。

几年前,全球近60%的模具由欧美等国家生产,但是近几年,随着亚洲模具市场的发展,亚洲生产模具的比例正在不断上升。

我国模具,尤其是中低档模具在国际市场上存在着较大的价格优势,部分模具价格只有国际市场的几分之一,再加之我国低廉的优质劳动力资源、较好的技术基础和基础配套设施,到中国来采购模具的跨国公司越来越多,“中国模具”也正走向世界舞台。

随着外资对我国模具行业投入量增大,工业发达国家将模具向我国转移的趋势进一步明朗化,中国正成为世界模具大国。

同时中国经济的高速发展,也对模具工业提出了越来越高的要求,为其发展提供了巨大的动力,我国模具发展驶入了快车道。

但是就我国模具行业的现状来看,产品结构不尽合理,大多数产品多是低值产品,而技术含量高的模具需要进口,主要缺口在精密,大型,复杂,长寿命模具方面,我国未来模具的发展方向只要有一下几方面:模具结构日趋大型、精密、复杂及寿命日益提高。

垫片冲孔落料连续模具设计1.设计的主要任务及目标(1)任务:1)模具装配图及零件图2)设计说明书一本3)电子资料一份(2)目标:以所学专业知识为基础,以实用为目的,通过对垫片冲压工艺的分析及相关参数的计算,进一步进行模具的总装图及零件的设计,总结出并熟练掌握模具设计的规律和方法。

2.设计的基本要求和内容(1)基本要求1)认真学习相关书籍,查阅中外文资料,制定出合理的设计方案;2)认真做好各环节计算与分析,使零件的工艺分析正确,模具设计合理;3)勤于思考,应用所学的专业知识来解决设计中遇到的问题;4)翻译一篇与本课题相关的英文文献;(2)主要内容1)对垫片的工艺性进行科学的分析;对相关参数进行准确的计算。

2)通过查阅相关的模具图册,设计出合理的模具装配图及主要零部件图(不少于5张)。

3)探索总结出一套相关的模具设计规律和方法。

3.主要参考文献[1]《冲模设计手册》,《冲模设计手册》编写组编注机械工业出版社 1999.06[2]《冲压工艺与模具设计》,姜奎华主编机械工业出版社1999.1[3]《互换性与技术测量》,廖念创等计量出版社 1998.02[4]《冲压工艺与模具设计》,姜奎华主编机械工业出版社1999.14.进度安排设计各阶段名称起止日期1 资料查阅,完成开题报告2013.12.17—2014.03.172 制定工艺方案,制定模具大体结构2014.03.18—2014.03.253 完成模具的设计与计算2014.03.25—2014.05.154 绘制图纸及编写设计说明书2014.03.25—2014.05.155 撰写毕业设计2014.06.02—2014.06.126 制作答辩PPT,准备毕业设计答辩2014.06.13—2014.06.205.附图厚度为1mm的黄铜板注:一式4份,系部、指导教师各1份、学生2份:[毕业设计(论文)]及答辩评分表各一份垫片冲孔落料连续模具设计摘要:本设计是垫片冲裁模,利用的是级进模生产的。

冲孔落料连续模设计冲孔落料连续模设计是一种常见的金属加工工艺,它可以高效地进行金属件的穿孔或切割。

在连续模设计中,工件被连续输送到模具上,然后通过冲压或剪切操作进行加工,最后将加工后的工件连续地排出。

本文将对冲孔落料连续模设计进行详细的介绍。

首先,冲孔落料连续模设计的目的是提高生产效率,减少人工操作。

在传统的冲孔落料过程中,工人需要将每个工件手工放置在模具上,并进行冲压或剪切操作。

这种手工操作需要耗费大量的时间和人力资源,并且容易出现操作不准确或者工件出现偏差的情况。

而在连续模设计中,工件可以通过输送设备在模具上连续地传送,工作人员只需要负责设备的操作和监控即可,大大提高了生产效率。

其次,冲孔落料连续模设计需要考虑的几个关键因素是输送设备的设计、模具的设计和加工参数的选择。

首先,输送设备需要保证工件的稳定输送,避免出现工件堆积或者偏移的情况。

同时,输送设备还需要能够适应不同尺寸和形状的工件。

其次,模具的设计需要考虑到工件的尺寸和形状,确保模具能够准确地对工件进行冲压或剪切操作。

模具的设计还需要考虑到模具的耐用性和易于更换的性质。

最后,冲孔落料的加工参数选择也是非常关键的。

不同的金属材料和工件厚度需要选择不同的冲压力和冲压速度,以保证加工质量和效率。

冲孔落料连续模设计的优点是显而易见的。

首先,它可以大大提高生产效率,减少人工成本。

其次,由于模具的准确定位和工艺参数的控制,冲孔落料的质量和精度得到了大幅提高。

同时,冲孔落料连续模设计还可以减少误操作和工件浪费,提高了生产线的整体效率和产能。

然而,冲孔落料连续模设计也存在一些挑战和限制。

首先,连续模设计需要先进的自动化设备和控制系统,这需要投入大量的资金。

其次,连续模设计对模具和设备的要求较高,需要进行定期的维护和保养。

此外,冲孔落料的工艺参数选择也需要经验和专业知识,并且不同材料和工件厚度可能需要不同的加工工艺。

总的来说,冲孔落料连续模设计是一种高效、精确的金属加工工艺。

落料连续模设计实例之薄弱部分先冲孔冲压模具设计有一个很基本的原则,那就是弱区先变形。

我们很多时候会遇到一些需要下料的产品,而这样的产品,是不规则的,特别是一些地方会出现薄弱部分,比如细长的腰形部分,如果整体冲出来,会很大程度上降低下料冲头的强度,这时我们可以对薄弱部分先冲孔,来看一个落料连续模设计薄弱部分先冲孔的实例。

首先我们看下产品图,如下:看到这个产品图,你会想到什么?如果对轮廓形状中的薄弱部分进行外形落料冲裁,则会导致薄弱部分的凹模或凸模损坏,无法维持模具的可靠性。

连续加工时,易于对这种问题采取应对措施。

如【图2】的卸料板布局所示,对薄弱部分进行冲孔,然后进行外形冲裁。

由于连续加工时采取冲孔与外形冲裁的模式,因此即使将外形的部分加工改为冲孔,也没什么大问题。

但采取这种布局时,外形形状冲孔加工部分与落料冲裁部分的毛刺方向相反,这是在落料型加工方法中无法回避的问题,要使毛刺方向一致时,采用外形冲切型加工方法。

当然,我们可以在模具中进行压毛边的步骤。

这也存在问题,这就是【图2】中示为搭接头的部分,在冲孔与落料交叉的部分,与1次加工的形状相比并不光洁,在产品的显著部分或重要部分放上搭接头是避免上述问题的一种方法,但也易于出现毛刺。

可制作搭接头的代表性形状为【图3】的倒角形状与【图4】的R形状。

倒角形状时,可采取通过延长倒角线来制作冲裁形状的措施,R形状时,如【图4】(b)所示,如果完全按形状制作搭接头部分,则会失败。

如【图4】(a)所示,从R形状划30度左右的切线,然后按倒角形状制作冲裁形状。

虽然不是完全的R形状,但可减少毛刺的发生。

小结:对于这个产品来说,算是非常简单了,但这里我们需要注意的一点,就是要对薄弱部分先冲孔,对此来保证模具质量和寿命。

至于连接搭边的话,还有很多种其他的方法。

盘形零件冲孔落料连续模设计目录引言 (1)1 冲裁件的工艺分析 (2)1.1冲裁件的结构与尺寸 (2)1.2冲裁件的材料 (3)2 冲裁间隙 (4)2.1间隙对冲压力的影响 (4)2.2间隙对模具寿命的影响 (4)2.3冲裁间隙值的确定 (5)3 凸、凹模刃口尺寸的公差 (6)3.1凸、凹模刃口尺寸计算的原则 (6)3.2凸、凹模刃口尺寸的计算方法 (6)3.3计算凸、凹模刃口及公差 (8)4 排样 (9)4.1材料的合理利用 (9)4.2搭边与条料宽度的确定 (9)4.3排样图 (11)5 冲压力与压力中心的计算 (12)5.1冲压力的计算 (12)5.2压力机规格参数 (13)5.3压力机的选用要点 (13)5.4压力中心确定 (14)6 模具零部件的设计与选用 (15)6.1凹模设计 (16)6.2凸模设计 (17)6.3凸模固定板设计 (19)6.4卸料板的设计 (20)6.5定位零件选用 (20)6.6模架及其零件的选用 (20)6.7模柄设计 (22)6.8导套和导柱选择 (23)6.9挡料销、限位柱、压柱的设计………………………………………………256.10紧固零件选择 (25)6.11接触环级进模结构总图 (26)致谢…………………………………………………………………………………28参考文献 (29)盘形零件冲孔落料连续模设计机电技术教育专业学生周广威指导教师:高迟摘要: 本文主要介绍连续冲裁模的设计方法。

在模具的设计中,对冲裁件的零件结构与尺寸进行了工艺分析;对连续冲裁级进模中的冲裁间隙、凸模、凹模的刃口尺寸进行精确计算;对条料进行排样,计算冲裁所需要的冲压力,及压力中心;对凸、凹模及固定板、卸料板进行尺寸计算与机构的设计,并根据计算所得数据选择模架和紧固零件。

从而使模具达到了冲裁精确、使用寿命延长、制造成本降低的良好效果。

关键词: 凸模;凹模;级进模引言模具是机械工业的重要工艺装备。

连续板冲孔落料板课程设计班级:材控0902班姓名:周荻翔学号:U200911110目录一、零件概况 (2)二、冲裁件工艺性分析 (3)三、确定工艺方案 (4)四、选定冲模类型及结构形式 (5)五、工艺计算 (5)(一)排样设计 (5)(二)计算冲压力 (7)(三)确定压力中心 (8)(四)计算凸凹模刃口尺寸 (9)六、选择压力机型号 (13)七、绘制模具总装图和非标零件图 (14)八、校核冲压设备基本参数 (21)一、零件概况零件名称:钢板生产批量:大批量材料:45钢,t=2mm设计加工该工件的冲裁模二、冲裁件工艺性分析1、材料:45钢是优质碳素结构钢,具有良好的冲压工艺性能;2、工件结构:该零件结构简单厚度为2mm,所冲孔径为φ2mm,最小孔边距为2mm,均满足冲裁工艺要求;3、尺寸精度:所有尺寸均为未注公差,可按国标IT14级处理,普通冲压即可满足精度要求;4、结论:可以冲裁。

三、确定工艺方案该零件包括落料、冲孔两个基本工序,可有以下3种工艺方案。

方案一:先落料,后冲孔,采用单工序模生产。

方案二:落料—冲孔复合冲压,采用复合模生产。

方案三:冲孔—落料复合冲压,采用级进模生产。

方案分析方案一:模具结构简单,但需两道工序两副模具,每副模具的结构简单,易于操作。

但是工序较多,要经过两次定位,易产生积累误差,需要设备多,时间消耗多,生产效率低,难以满足该零件大批量的生产。

方案二:只需一副模具,生产效率高,冲压件的尺寸精度容易保证,但该零件厚度为2mm,查P76-表2.27,得倒装复合膜的凸凹模所需最小壁厚为4.9mm,而该零件最小孔边距为2mm,这样做出的凸凹模,易被内孔积存的废料涨裂,故不能采用。

方案三:只需一副模具,生产效率很高,但模具结构较为复杂,定位精度较低。

综上分析,冲裁件尺寸精度要求不高,尺寸不大,形式较为简单,但产量较大,根据材料料厚(2mm)的特点,为保证孔位精度,冲模有较高的生产率,实行工序集中的工艺方案,采用导正销进行精定位,固定卸料装置、自然漏料方式的级进模,即选择方案三。

冲孔落料连续模设计及三维CAD实体动画仿真摘要连续模,又称为多工位连续模、级进模、跳步模,它是在一副模具内,按所加工的工件分为若干等距离的工位,在每个工位上设置一个或几个基本冲压工序,来完成冲压工件某部分的加工。

被加工材料,事先加工成一定宽度的条料,采用某种送进方法,每次送进一个步距。

经逐个工位冲制后,便得到一个完整的冲压工件。

在一副级进模中,可以连续完成冲裁、弯曲、拉深、成形等工序。

一般来说,无论冲压零件形状怎样复杂,冲压工序怎样多,均可用一副级进模冲制完成。

本设计为冲孔、落料两工位级进冲裁模。

首先,分析工件的尺寸及精度要求等个方面的信息和要求,确定排样图和模具型式及总体结构方案。

然后根据工件分别计算和设计各2D零件草图及修改、检验、校核。

接着,设计挡料装置及定位装置,由于本设计工件的精度要求不高且生产为中、大批量故采用自动挡料装置和定位销装置即可满足要求。

最后,检验无误后,用Pro/E软件生成3D实体进行动画仿真,以校验该设计的合理性及正确性。

关键词连续模具;冲裁模;模具设计;仿真动画;Pro/EPunching cut Multi-position progressive mold Design And 3D-CAD Animation SimulationAbstractConsecutive modules, also known as the multi-national industrial spaces in a row, the class into modules, jump-state, it is in a warning, according to the final processing is divided into equidistance of the spaces in each of the spaces on one or several basic stamping processes, to complete the processing of certain ram her. Were processed materialsprior to the processing of materials into a certain width, using a hospital means a step away from each hospital. After-work spaces salt system, the ram will be a complete piece. In a class into modules that can be completed for arbitration, bending, pulling deep and formative processes. Generally, whether ram parts shape how complex, how much ram processes may use a salt-class system into modules completed.The design of accessible, public spaces class into two or expected arbitration modules. First, the size and accuracy of her analysis of the information and requirements for establishing emission maps and layout patterns and overall structure. According to her calculation and design, respectively, and then the 2D parts and the draft revision, testing, verification. Then, the design and positioning devices turned Liu devices, because the final design and production of precision do not ask for, the use of large quantities Zidongdang expected to be installed and positioning devices to meet local requirements. Finally, testing accuracy, the software used Pro/E generated 3D animation simulation entities to examine the reasonableness of the design and accuracyKeywords Multi-position progressive mold; Punching cut mold; Mold design; Animation simulation; Pro/E不要删除行尾的分节符,此行不会被打印目录摘要Abstract第1章绪论 11.1 课题背景 11.1.1 现状与差距 11.1.2 冲模设计技术的发展方向 11.1.3 冲模加工技术的发展方向 21.1.4 设计内容 3第2章模具结构总体设计 42.1 级进模简介 42.1.1 级进模的特点 42.2 排样及裁板方案设计 52.2.1 工艺分析 52.2.2 工艺方案的确定 52.2.3 排样图的设计 62.2.4 裁板方案设计 62.2.5 计算工艺力及确定模具压力中心 7 2.3 模具结构设计 82.3.1 模具型式的选择 82.3.2 模具工作部分尺寸计算: 82.3.3 模具其他主要零部件的设计及选取: 10 2.4 模具闭合高度及压力机的选取: 102.5 本章小结 10第3章 Pro-E三维实体造型及仿真 113.1 Pro/E发展状况简介 113.2 Pro/Engineer的CAD/CAM/CAE功能介绍` 12 3.3 Pro/E的三维造型功能及意义 123.4 底座部分的三维造型制作 123.4.1 建立新文件 133.4.2 创建拉伸特征 133.4.3 创建孔特征 153.4.4 创建阵列特征 173.4.5 创建圆角特征 173.4.6 着色 183.5 实体仿真 203.6 本章小结 20结论 21致谢 22参考文献 23附录 24千万不要删除行尾的分节符,此行不会被打印。

在目录上点右键“更新域”,然后“更新整个目录”。

打印前,不要忘记把上面“Abstract”这一行后加一空行第1章绪论1.1 课题背景冲压是一项量大而广、应用广泛的金属压力加工工艺,是机电制造行业中普遍使用的少切削或无切削的加工方法之一,其优点是操作简单、生产效率高、材料利用率高、生产成本低、易于事先自动化生产,特别是适用于定型产品的中大批量生产。

冲压要发展,模具是关键,提高模具的效率,需从冲模设计和制造开始。

从瑞士Feintool AG Lyss精密机械制造公司、美国Moore公司及德国、日本等发达国家购进了一批NC及CNC冲模制造设备,对国内的模具设计制造产生了巨大的促进和推动作用。

1.1.1 现状与差距从技术角度来看,模具制造(包括设计和加工)技术大致可分为五个发展阶段:手工操作阶段、手工操作加机械化(普通通用机床与工具)阶段、数字控制阶段、计算机化阶段和CAD/CAR/CAM信息网络技术一体化阶段,我国目前主要以数字控制阶段为主。

就冲模的类型与结构而言,目前国内在定型的机电产品生产中,至今仍然是单工序冲模多,多工位连续模与复合模、复合模占的比例很小,多工位连续模则更少见。

近年来在仪表行业的调研通缉表明:在较先进、经营形势良好的企业中,按冲模分类具有套数比,只能达到:单工序模:复合模:多工位连续模=5.5:3:1.5,沿海乡镇企业仅为:7.2:2:0.8。

内地的绝大多数企业只用单工序模,多数为没有模架的敞开模。

冲模设计方面的另一个重大问题是标准化问题。

国内1984年实施有史以来第一个<<冷冲模>>国家标准----GB2851-2875-81。

这个标准的局限性很大,除开关电器、骑车拖拉机行业外,对诸如电子、精密机械、仪表、兵器、航空等行业适用性较差,且错误较多。

虽然在1990年修订过一次,仍然存在问题。

因而,我们应当努力去推动模具行业的标准化,为模具的行业的标准化进一步推广做出更大的贡献。

1.1.2 冲模设计技术的发展方向自从20世纪80年代我国发展模具CAD以来,这项技术已在设计中显示出了巨大的优越性,改变了模具设计长期以来靠人的经验和机械制图来完成的历史。

一些发达国家的模具CAD技术已从二维发展到三维设计,且三维设计已达70% 以上。

我国大部分企业还不到20%。

CAE软件的应用国外已较普遍,国内应用还比较少,而且在用于预测零件成形过程中可能发生的缺陷方面,水平还比较低。

所以,要充分发挥CAD/CAE在模具设计中的作用,应从以下几点去进行考虑:1. 大力推进模具设计和适用的标准化,健全模具设计资料库和知识库系统,加强模具刚性、强度设计。

我们应该加强对模具设计资料的收集健全模具知识库,为模具的设计和模具CAD/CAPP/CAM积累更多的有价值的资料,为模具标准化的推广和适用做出努力。

2. 加强冲压模金属成形过程的模拟起皱及破裂分析、应力应变回弹分析等。

同时提高涉及和分析软件的快速性、智能化和集成化水平,并强化它们的功能,以适应模具的不断发展。

为了提高模具设计效率和可靠性,除了大力应用模具CAD/CAE之外,计算机辅助工艺设计技术在我国模具企业中也开始应用,为了较好的应用CAPP 技术,模具企业自身必须搞好开发和研究。

虽然CAPP技术的应用和推广要比CAD和CAE难的多,但这也是一个发展方向,应予以重视。

基于知识工程技术近年来已越来越受重视。

它是面向现代设计决策自动化的重要工具,已成为促进工程设计字能化的重要途径,KBE技术作为一种新兴的智能设计思想,将对模具的智能、优化设计产生重要的影响。

3. 专家系统在模具设计中的大力应用。

专家系统是一种通过模拟人类专家求解问题的过程来求解特定领域类的某些问题的一种软件系统。

人类专家在解决问题时是一个有机的整体过程,是在常识知识的约束下,利用专业知识和经验及从各种渠道得到的信息,综合运用理解、识别、规划、类比、推理等各种智能行为,最后得出问题的解决方案,这一点在目前的专家系统中没有得到良好的体现。