离散元课件

- 格式:ppt

- 大小:2.89 MB

- 文档页数:104

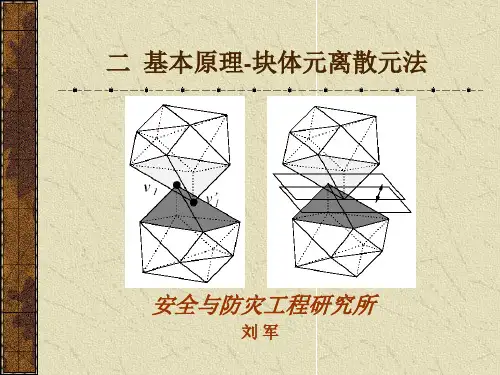

DEM course, July 2009Technical University of GrazDiscrete element modelling and simulation of rock cuttingJ. RojekInstitute of Fundamental Technological Research (IPPT PAN), Warsaw, Poland International Center for Numerical Methods in Engineering (CIMNE), Barcelona, SpainOutline of the presentationIntroduction–basic information of rock cuttingBasic assumptions of the numerical model of rock cuttingDiscrete element model of rock cuttingExperimental validation of the numerical modellaboratory testsnumerical simulationSensitivity studiesConcluding remarksIntroductionRock cutting−process or rock desintegration under the action ofthe cutting tool in different works of rock excavation in mining industry or civil engineeringRoadheader DredgeFrom Discovery channel: …Dirty Jobs: Road Headers”Excavation sequence with a roadheader: a) sumping, b) cutting of face, c)profilingDesign of a point attack pickBreakthrough of the tunnel with a TBMTBM cutterheadTBM disc cutters Cutting mechanismLaboratory test of rock cuttingPhysical phenomena in rock cuttingReproduced from P.N.W.Verhoef“Wear of Rock Cutting Tools)Rock cuttingReproduced from P.N.W.Verhoef“Wear of Rock Cutting Tools)Cutting forceCutting force in ductile and brittle cutting(P.N.W. Verhoef “Wear of Rock Cutting Tools”)Cutting force parametersMost important factors influencing rock cuttingRock properties/cuttability−mechanical properties (uniaxial compressive strength,tensilestrength, brittleness, fracture properties,hardness)−texture, discontinuities existing in the rock−abrasive capacity of rockTool characteristics−mechanical properties of the tool material (strength, stiffness,hardness)−tool design, geometryCutting process parameters−position of a tool with respect to rock (cutting depth, rake and cutting angles)−cutting velocity−heat generation and conduction, temperatureMain assumption:breakage is essentially tensile and occurs along failure surface, which approximates a circular arc .Evans’modelof cuttingwith drag picksMain assumption:failure is purely due to shear and occurs along a plane .Nishimatsumodel−angle of internal friction of intact plane −angle of sliding friction rock-tool−stress distribution factor obtained from the testsFinite element modelling of rock cuttingRemark:Difficulties in modelling of discontinuities using finite element method(special formulations must be used). Modelling of failure characterized with multiple fracturing and post-fracture behaviour is especially difficult.Discrete element model of rock cuttingModel of rockdiscretisation with spherical discreteelementsappropriate contact laws allow us to obtaindesired macroscopic material propertiescohesive bonds between particles takeninto accountfracture modelled by breakage of bondswhen cohesion strength exceededafter fracture frictional contact betweenparticlesModel of tooltool considered rigiddiscrete or finite element typediscretization ofthe tool or tool surfacetool surface interact with rock particles leadingto rock fracturenormal (pressure) and tangential (friction)interaction at the tool/rock interfaceProcess modellingrock cutting treated as dynamic processprescribed tool velocityadequate damping introducedFailure modeDiscrete element model of rock cuttingSimulation of rock cutting2D simulation of rock cuttingExperimental validation of discrete elementmodel of rock cuttingLaboratory tests−uniaxial compressive strength test−Brazilian test−rotating rock cutting testNumerical simulations−determination of the numerical model parameters(dimensionless relationships)−simulation of the uniaxial compressive test−simulation of the Brazilian test−simulation of the cutting test−sensitivity studiesUniaxial compression testRock sample: sandstone, d=h=50 mm(Sandvik Mining and Construction, Zeltweg, Austria)Brazilian testRock sample: sandstone, d=50 mm, h=25 mm (Sandvik Mining and Construction, Zeltweg, Austria)Laboratory test of rock cuttingRock type: sandstone Cutting tool: roadheader cutterhead bitLaboratory of Sandvik Mining and Construction, Zeltweg, AustriaTest parametersTestResults of laboratory testsDimensionless micro–macro relationshipsKt/Kn = 0.2v = 0.2Kt/Kn = 0.2Distribution of axial stresses Force−strain curveUniaxial compressive strength•in simulation: 116 MPa•average measured in laboratory: 127 MPat=0.0014 st=0.0018 st=0.0020 sStresses SyySimulationLaboratory testDiscrete element simulationSimulation Tensile strength:•calculated 05.0110319,12260=⋅⋅⋅⋅==ππLD P T t=0.0010 st=0.0016 st=0.0018 s2D Numerical simulation of the cutting testFailure mode Force vs. timeNumerical simulation of the cutting testComparison of averaged cutting force:experiment: ~ 6350 N2D simulation: ~ 4300 NStressvs. strain Simulation ofthe unconfinedcompressiontest3D simulation of Brazilian testForce vs. Time curveCalibrationNumerical modelExperimental and numerical cutting force componentsAverage experimental and numerical cutting force componentsComparisonof numericaland experimentalresults Chip sizes20-25 mm15-20 mmDistributionof chip sizes(experiment)Cutting with TBM disc cutters–linear cutting testLaboratory of Colorado School of MinesObjective:Numerical prediction of interactionforcesNumerical model of the linear cutting testNormal forceRolling forceFailure mode Equivalent Stress Numerical simulation of the linear cutting testInfluence of material propertiesMaterial1UCS = 147.3 MPaBTS = 10.2 MPaMaterial2UCS = 102.6 MPaBTS = 11.5 MPaDredging–underwater rock cuttingCourtesy of Boskalis bv, HollandModel of dredgingKinematics of a dredge cutterhead Model geometrySimulation of dredgingModel details:92 000 particles modelling a sample of a rock5400 elements modelling a toothswing velocity0.2 m/s, rotational velocity1.62 rad/sTool geometry and positionα–rake angleβ–clearance angleInfluence of the rake angleRemarks:smaller rake angle–bigger cutting forcesthe normal force in the plot above smallerthan the cutting force。