冰蓄冷蓄冰盘管样本

- 格式:doc

- 大小:1018.00 KB

- 文档页数:8

动态蓄冰盘管日照百货大楼莒县新玛特商城中央空调方案技术经济分析冰储冷空调与常规电制冷空调比较:1.综合初投资节约27.5万元;2.运行费用节约58.4万元/夏季;3.空调机房配电容量减少500KW;4.空调机房面积增加60㎡。

节约=创造财富蓄冰空调,是利用电网的电价差,在夜间(23:00-7:00)电价低时开主机制备冷量,并以冰的形式储存起来,在白天电价高时将冰融化释放冷量,以供空调之需,从而大幅度降低空调运行费用的一种先进空调技术。

蓄冰空调具有如下优点:1.利用峰谷电价差,降低空调运行费用40%~50%;2.平衡电网峰谷差,减缓电厂和输变电设施的建设;3.降低制冷主机、冷却塔及冷却水泵容量,减少空调机房总配电容量,减少变配电设施的投资;4.制冷主机满负荷平稳运行,效率高;5.可实现大温差,低温送风,降低空调末端设备投资,提高空调品质;6.具有应急功能,提高空调系统可靠性。

日照市峰谷电价明细表1.409-0.3315=1.0775元/ KWh电业局电价免费咨询电话:95598真诚为您服务――共创节约型社会!第一章工程概况日照百货大楼莒县新玛特商城,空调面积36000㎡。

夏季空调尖峰冷负荷为432万大卡(5040KW),冬季采暖热负荷为2160KW。

典型设计日逐时冷负荷图如下时间第二章冰蓄冷方案一.冰盘管简介冰盘管(Ice-on-coil) ——有内循环的蓄冰盘管技术(Dynamic Ice)蓄冰盘管主要特点:1、盘管采用纯质高密度聚乙烯(HDPE)材料,标准冰槽槽体,内部流量分配接头全部采用弹性接头,无焊缝,整体设计使用寿命50年;2、独特的再冷却盘管加不锈钢鳍片,有效提高制冷主机结冰温度,提供1.1-4℃的低温冷水,实现大温差冷冻水供水系统;3、单个槽内的多回路卤水分布管,发生泄漏时可不停机检修;4、专门设计的硬密封接头机构,可耐压超过12公斤,方便现场检修。

二、冰蓄冷空调系统主要设备选型1、双工况主机选型2、蓄冰装置选型及性能蓄冰盘管:选用3台型号Dyn-1400动态蓄冰盘管。

冰蓄冷蓄冰盘管样本4.1 产品样本说明书responsible for measurement management work and accurate implementation; is responsible for site test room of technology management; do monthly completed engineering volume statistics, and owners, and supervision for engineering progress paragraph settlementand completed accounts. 5, quality Department: responsible for overall project quality, security management. Quality assurance, quality control, quality assurance, quality inspection, evaluation, quality information safety guarantee system safety assessment, safety inspections, safety procedures, safety facilities, labour protection, safety measures, fire guard, civil construction, environmental protection, responsible forsite laboratory quality management. 6, the Department of management is responsible for the engineering contract management, production and management jobs. Project management and settlement, project reporting, price breakdown and the new price system, monthly volume complete statistics, progress payment settlement with the owner, supervisor and project completion final accounts. Scheduling jobs is responsible for the whole project. Plan, schedule, inspecting and supervising the manufacturing progress goals face, excludingresponsible for measurement management work and accurate implementation; is responsible for site test room of technology management; do monthly completed engineering volume statistics, and owners, and supervision for engineering progress paragraph settlement and completed accounts. 5, quality Department: responsible for overallproject quality, security management. Quality assurance, quality control, quality assurance, quality inspection, evaluation, quality information safety guarantee system safety assessment, safety inspections, safety procedures, safety facilities, labour protection, safety measures, fire guard, civil construction, environmental protection, responsible forsite laboratory quality management. 6, the Department of management is responsible for the engineering contract management, production and management jobs. Project management and settlement, project reporting, price breakdown and the new price system, monthly volume complete statistics, progress payment settlement with the owner, supervisor and project completion final accounts. Scheduling jobs is responsible forthe whole project. Plan, schedule, inspecting and supervising the manufacturing progress goals face, excludingresponsible for measurement management work and accurate implementation; is responsible for site test room of technology management; do monthly completed engineering volume statistics, and owners, and supervision for engineering progress paragraph settlementand completed accounts. 5, quality Department: responsible for overall project quality, security management. Quality assurance, quality control, quality assurance, quality inspection, evaluation, quality information safety guarantee system safety assessment, safety inspections, safety procedures, safety facilities, labour protection, safety measures, fire guard, civil construction, environmental protection, responsible forsite laboratory quality management. 6, the Department of management is responsible for the engineering contract management, production and management jobs. Project management and settlement, project reporting, price breakdown and the new price system, monthly volume complete statistics, progress payment settlement with the owner, supervisor and project completion final accounts. Scheduling jobs is responsible forthe whole project. Plan, schedule, inspecting and supervising the manufacturing progress goals face, excludingresponsible for measurement management work and accurate implementation; is responsible for site test room of technology management; do monthly completed engineering volume statistics, and owners, and supervision for engineering progress paragraph settlementand completed accounts. 5, quality Department: responsible for overall project quality, security management. Quality assurance, quality control, quality assurance, quality inspection, evaluation, quality information safety guarantee system safety assessment, safety inspections, safety procedures, safety facilities, labour protection, safety measures, fire guard, civil construction, environmental protection, responsible forsite laboratory quality management. 6, the Department of management is responsible for the engineering contract management, production and management jobs. Project management and settlement, project reporting,price breakdown and the new price system, monthly volume complete statistics, progress payment settlement with the owner, supervisor and project completion final accounts. Scheduling jobs is responsible forthe whole project. Plan, schedule, inspecting and supervising the manufacturing progress goals face, excludingresponsible for measurement management work and accurate implementation; is responsible for site test room of technology management; do monthly completed engineering volume statistics, and owners, and supervision for engineering progress paragraph settlementand completed accounts. 5, quality Department: responsible for overall project quality, security management. Quality assurance, quality control, quality assurance, quality inspection, evaluation, quality information safety guarantee system safety assessment, safety inspections, safetyprocedures, safety facilities, labour protection, safety measures, fire guard, civil construction, environmental protection, responsible for site laboratory quality management. 6, the Department of management is responsible for the engineering contract management, production and management jobs. Project management and settlement, project reporting, price breakdown and the new price system, monthly volume complete statistics, progress payment settlement with the owner, supervisor and project completion final accounts. Scheduling jobs is responsible for the whole project. Plan, schedule, inspecting and supervising the manufacturing progress goals face, excludingresponsible for measurement management work and accurate implementation; is responsible for site test room of technology management; do monthly completed engineering volume statistics, andowners, and supervision for engineering progress paragraph settlementand completed accounts. 5, quality Department: responsible for overall project quality, security management. Quality assurance, quality control, quality assurance, quality inspection, evaluation, quality information safety guarantee system safety assessment, safety inspections, safety procedures, safety facilities, labour protection, safety measures, fire guard, civil construction, environmental protection, responsible forsite laboratory quality management. 6, the Department of management is responsible for the engineering contract management, production and management jobs. Project management and settlement, project reporting, price breakdown and the new price system, monthly volume complete statistics, progress payment settlement with the owner, supervisor and project completion final accounts. Scheduling jobs is responsible forthe whole project. Plan, schedule, inspecting and supervising the manufacturing progress goals face, excludingresponsible for measurement management work and accurate implementation; is responsible for site test room of technology management; do monthly completed engineering volume statistics, and owners, and supervision for engineering progress paragraph settlementand completed accounts. 5, quality Department: responsible for overall project quality, security management. Quality assurance, quality control, quality assurance, quality inspection, evaluation, quality information safety guarantee system safety assessment, safety inspections, safety procedures, safety facilities, labour protection, safety measures, fire guard, civil construction, environmental protection, responsible forsite laboratory quality management. 6, the Department of management is responsible for the engineering contract management, production and management jobs. Project management and settlement, project reporting,price breakdown and the new price system, monthly volume complete statistics, progress payment settlement with the owner, supervisor and project completion final accounts. Scheduling jobs is responsible forthe whole project. Plan, schedule, inspecting and supervising the manufacturing progress goals face, excludingresponsible for measurement management work and accurate implementation; is responsible for site test room of technology management; do monthly completed engineering volume statistics, and owners, and supervision for engineering progress paragraph settlementand completed accounts. 5, quality Department: responsible for overall project quality, security management. Quality assurance, quality control, quality assurance, quality inspection, evaluation, quality informationsafety guarantee system safety assessment, safety inspections, safety procedures, safety facilities, labour protection, safety measures, fire guard, civil construction, environmental protection, responsible for site laboratory quality management. 6, the Department of management is responsible for the engineering contract management, production and management jobs. Project management and settlement, project reporting, price breakdown and the new price system, monthly volume complete statistics, progress payment settlement with the owner, supervisor and project completion final accounts. Scheduling jobs is responsible for the whole project. Plan, schedule, inspecting and supervising the manufacturing progress goals face, excluding。

蓄冰系统----间接接触式

完全冻结式冰盘管

(FAFCO)

蓄冰系统----间接接触式----冰盘管

蓄冰系统----间接接触式----塑料冰盘管

蓄冰系统----间接接触式特点----冰盘管

闭式循环回路

U型盘管可做非标设计,适应不同的安装空间

可制成整装式蓄冰制冷机组---安装方便,适合用于小型项目-----Ice Cell

大型系统可安装气动搅拌系统,融冰利用率可达100%。

主机下游系统,出口温度可根据设计要求设定。

盘管进口温度高,可利用一部分显热能。

注: Fafco and Ice Cel -较少的工程应用经验,性能未被EPRI验证。

BAC蓄冰钢盘管与华源导热塑料盘管比较BAC 蓄冰钢盘管与华源导热塑料盘管比较一、BAC 蓄冰钢盘管 1.公司背景 BAC 公司成立于 1938 年,在全球 18 个国家和地区拥有自己全资公司或合资公司,并有员工 2000 多人。

?2.公司主要业务 BAC 公司是换热设备专业厂家,主要从事蓄冰设备,冷却塔,蒸发式冷凝器,工业流体换热设备的研发、生产和销售。

?3.公司研发实力公司的研发中心位于马里兰州的 Jessup 市 BAC 的测试中心内,占地面积为 25,000 平方米,是工业领域中最为先进的研发中心之一。

公司目前已有 100 多项专利,其中有关于蓄冰的专利已经超过 10 项,BAC 公司并成功开发出下一代蓄冰设备。

材料的传热试验材料的腐蚀试验?材料的屈服试验?风洞试验?蒸发式冷凝器测试?整塔试验?100 多项的专利墙?4.BAC 钢盘管蓄冰设备‐‐‐唯一能实现非完全冻结式的蓄冰设备,并获得专利1)独特的非完全冻结式蓄冰设备,100%的融冰率,更节省费用BAC 蓄冰设备因其独特的蛇形钢盘管和优异的传热性能,在制冰时,低温载冷剂在盘管内循环,将盘管外表面的水逐渐被冻结成 25mm 厚度的冰层,冰层之间留有空隙,仍为0℃ 的水,补形成冰桥;融冰时,随着融冰比例的增加,冰层与盘管之间形成水环,但冰层受到外界水的浮力作用,始终与盘管之间保持良好接触。

融冰达到20-30%时,冰层破裂均匀散落在水中,形成温度均衡的0℃冰水混合物。

因此,可保证换热均匀,乙二醇出口温度恒定,并可控制取冷过程,取冰率可达 100%。

融冰初期水环形成,并上浮,与盘管保持良好接触水环进一步扩大,并上浮,与盘管一直保持良好接触冰层破裂,形成均衡的0℃冰水混合物试验状况实际结冰图片蓄冰设备融冰曲线该融冰方式是BAC 公司钢盘管专利,专利号为US6178770,Ice-on-coil thermal storage apparatus and method (非完全冻结式冰蓄冷设备和技术)2)稳定的融冰出口温度,是末端舒适性稳定的关键保证BAC 独特的非完全冻结式蓄冰方式和专利的蓄冰结构,可保证其融冰出口温度恒定,取冰率可达 100% 。

第 1 页筑龙网w w w. s i n o a e c. c o m 《内融冰式冰盘管蓄冷槽传热性能研究》资料编号:W Z T U 8 3 1 -3 1 3 3 -2 0 0 0 1 0内融冰式冰盘管蓄冷槽传热性能研究朱颖心 张雁[摘要]:本文对内融冰式冰盘管蓄冷槽的蓄放冷实验结果进行了仔细的分析,建立了蓄冷动态过程的同心圆柱模型,而对取冷过程建立了准同心圆阶段、偏心阶段和碎冰阶段的三段动态模型。

模型合理地反映了融冰过程不同阶段由于冰水密度差造成的换热速率变化的机理,适应性强,预测性好。

实验对比的结果也说明该模型能够准确地反映不同工况的蓄冷放冷性能,可直接为工程应用服务。

[中图分类号]:WZTU831冰蓄冷空调是实现电网负荷削峰填谷的有效方法,70年代以来在日、美、加等发达国家已得到广泛的使用。

目前我国的应用还处于起步阶段,有着重大的应用潜力和前景。

高质量的蓄冷空调系统的设计和运行均需要对不同蓄冰槽的蓄冷、取冷的传热过程有透彻的了解,才能确定优化设计和运行控制方案,避免用冷不合理造成高峰期间放冷能力不足或蓄冷过多造成不必要的高能耗等运行缺陷。

而对取冷过程的准确了解对于制定优化运行方案来说至关重要的。

内融冰式蓄冷槽是目前在我国广泛应用的蓄冷槽形式。

蓄冷槽为一密封保温箱体,盘管在槽内水平盘旋放置(蛇形盘管和螺旋形盘管)或交叉倾斜放置(U形盘管),管内载冷剂为乙二醇溶液,管外为水。

蓄冷时低温乙二醇溶液进入盘管,盘管外开始结冰;放冷时高温乙二醇溶液流过盘管,盘管外的冰由内向外融解。

目前大多文献中介绍的内融冰盘管传热过程模型都假设蓄冷和取冷过程中相变界面呈同心圆筒状变化[1~3],但这一假设只对冰盘管在蓄冰槽内近似垂直放置的冰槽类型或槽中的水均被冻结的工况才是准确的。

对于水平放置的盘管,如果槽中的水没有完全冻结,由于冰水密度的不同,冰在融解过程中会向上浮升,实际融化速度比同心圆融化过程要快,且换热速率随时间的变化规律与同心圆融化过程也不同。

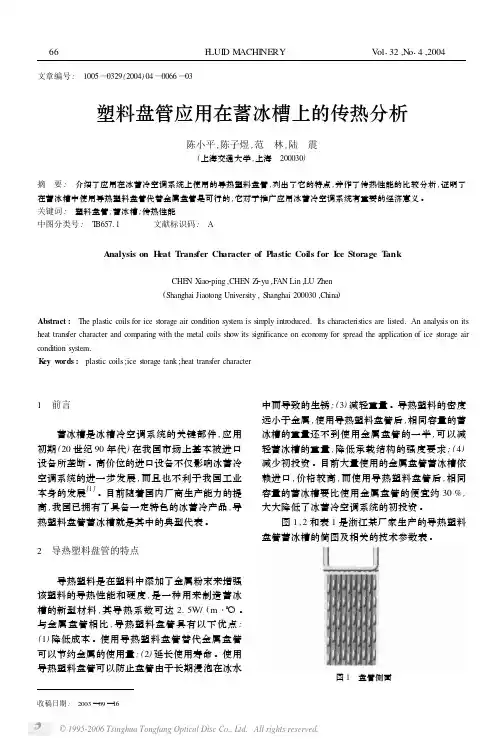

文章编号: 1005—0329(2004)04—0066—03塑料盘管应用在蓄冰槽上的传热分析陈小平,陈子煜,范 林,陆 震(上海交通大学,上海 200030)摘 要: 介绍了应用在冰蓄冷空调系统上使用的导热塑料盘管,列出了它的特点,并作了传热性能的比较分析,证明了在蓄冰槽中使用导热塑料盘管代替金属盘管是可行的,它对于推广应用冰蓄冷空调系统有重要的经济意义。

关键词: 塑料盘管;蓄冰槽;传热性能中图分类号: T B65711 文献标识码: AAnalysis on H eat T ransfer Character of Plastic Coils for I ce Storage T ankCHE N X iao2ping,CHE N Z i2yu,FAN Lin,LU Zhen(Shanghai Jiaotong University,Shanghai200030,China)Abstract: The plastic coils for ice storage air condition system is simply introduced.Its characteristics are listed.An analysis on its heat trans fer character and comparing with the metal coils show its significance on economy for spread the application of ice storage air condition system.K ey w ords: plastic coils;ice storage tank;heat trans fer character1 前言蓄冰槽是冰槽冷空调系统的关键部件,应用初期(20世纪90年代)在我国市场上基本被进口设备所垄断。

高价位的进口设备不仅影响冰蓄冷空调系统的进一步发展,而且也不利于我国工业本身的发展[1]。

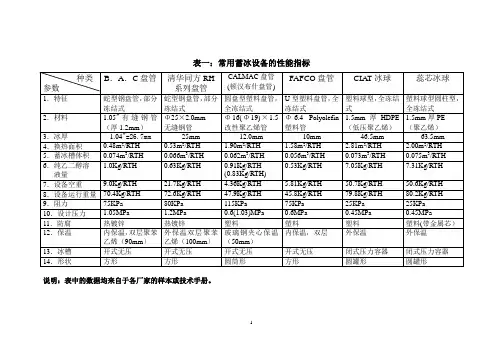

冰蓄冷型式特点比较

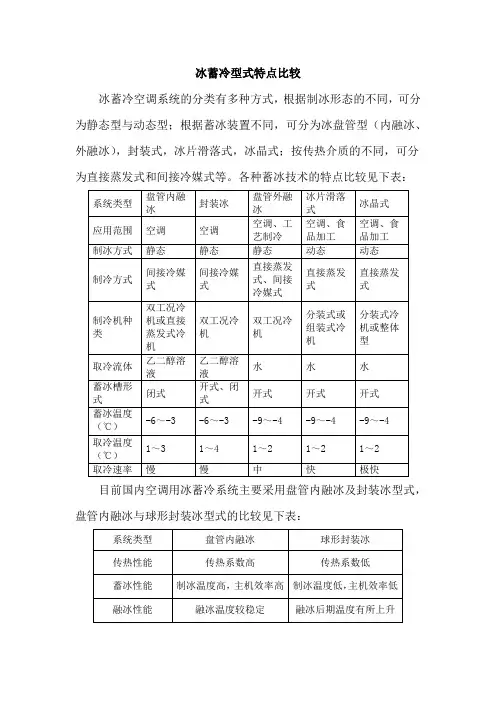

冰蓄冷空调系统的分类有多种方式,根据制冰形态的不同,可分为静态型与动态型;根据蓄冰装置不同,可分为冰盘管型(内融冰、外融冰),封装式,冰片滑落式,冰晶式;按传热介质的不同,可分为直接蒸发式和间接冷媒式等。

各种蓄冰技术的特点比较见下表:

目前国内空调用冰蓄冷系统主要采用盘管内融冰及封装冰型式,盘管内融冰与球形封装冰型式的比较见下表:

根据大型商业项目的冷负荷特性,盘管内融冰及球形封装冰系统均可满足使用要求。

二者区别主要如下:

1、从融冰性能分析,盘管内融冰的出水温度更加温度,可始终

维持在3℃,球形封装冰在融冰后期的出水温度会升高至4℃,

需要控制系统更加准确的进行供冷策略调整;

2、从载冷剂用量(乙二醇溶液)分析,盘管内融冰系统用量较

低,球形封装冰系统用量是盘管式的4~6倍,乙二醇价格的

波动对初投资影响较大;

3、从空间要求分析,目前的建筑方案可以满足两种方案的要求;

4、从检修要求分析,盘管内融冰一旦发生破损,漏点定位难度

较大,球形封装冰系统则不存在此问题,个别冰球的破裂对

系统蓄冰量影响甚微;

5、从业绩数量比例分析,国内采用盘管内融冰的项目较多,采

用球形封装冰系统的项目略少于盘管内融冰系统。

综合考虑,两种系统各有所长,盘管内融冰系统略优于球形封装冰系统。

冰蓄冷设备一、分类美国制冷工业协会(ARI)1994年出版的《蓄冷设备热性能指南》将蓄冷设备广义地分为显热式蓄冷和潜热式蓄冷,见表2-1。

表2-1*注:载冷剂一般为乙烯乙二醇水溶液。

最常用的蓄冷介质是水、冰和其他相变材料,不同蓄冷介质具有不同的单位体积蓄冷能力和不同的蓄冷温度。

二、冰盘管式(ICE-ON-COIL)冷媒盘管式(REFRIGERANT ICE-ON COIL)外融冰系统(EXTERNAL MELT ICE-ON COIL STORAGE SYSTEMS)该系统也称直接蒸发式蓄冷系统,其制冷系统的蒸发器直接放入蓄冷槽内,冰结在蒸发器盘管上。

此种形式的冰蓄冷盘管以美国BAC公司为代表。

盘管为钢制,连续卷焊而成,外表面为热镀锌。

管外径为1.05"(26.67mm),冰层最大厚度为1.4"(35.56mm),因此盘和换热表面积为5.2ft2/RTH(0.137m2/KWH),冰表面积为19.0ft2/RTH(0.502m2/KWH),制冰率IPF约为40-60%。

融冰过程中,冰由外向内融化,温度较高的冷冻水回水与冰直接接触,可以在较短的时间内制出大量的低温冷冻水,出水温度与要求的融冰时间长短有关(参见图2-1、2-2、2-3)。

这种系统特别适合于短时间内要求冷量大、温度低的场所,如一些工业加工过程及低温送风空调系统使用。

(1)10小时放热特性(图2-1)该蓄冷方式是由食品冷冻行业中应用多年的乳品冷却设备改制发展而成。

由此在乳品行业中经常采用。

最近天津雀巢咖啡生产厂,工艺要求所供应的冷冻水温在全过程中要求保证稳定在+1°C,采用BAC外融冰装置,冰盘管表面冰层厚度大约为2-3MM,冷冻机24小时连续运行。

在使用冷媒盘管式蓄冷槽时,有几点需注意:(1)当结冰厚度在1"-3.5"之间,若冷冻系统设计不当,制冰时冷冻蒸发温度较低,压缩机所需功率大,耗电率大,并且制冷时间长,用电量多;(2)若贮存的冰设有完全用掉而制冷时间已到,需要开始制冰,则必需隔着一层冰来制冰,由于冰是一种优良热阻,这将使制冷设备耗电率与用电量增加;(3)蓄冰槽内应保持约50%以上的水不冻成冰,否则无法正常抽取冷水使用进行融冰,故最好使用厚度控制器或增加盘管中心距,以避免冰桥产出;(4)在开放式系统中,蓄冰槽的进出口处(即水系统进出口管路上)应加装止回阀和稳压阀等近期制设备,以免仃泵时系统中的水回流,使蓄冰槽中水外溢。

冰盘管考察报告国际电子总部空调冰蓄冷项目蓄冰盘管设备厂家调研报告国际电子总部3#地地下3层设计有水泥制造的蓄冰槽,蓄冰盘管就安装在蓄冰槽中。

冰盘管最大蓄冰冷量为24000RTH。

据我们向制造厂家询价,冰盘管总造价约1000万元。

蓄冰盘管是冰蓄冷项目系统中关键设备之一,以组为单元排列在冰水槽中。

主要功用是使冷水机组产生的0℃以下的乙二醇液体通过加压泵流经蓄冰盘管,将乙二醇所含冷量传递给蓄冰槽中的水,水吸收冷量围绕盘管冻结成冰,将冷量储存在冰槽中。

实际上,冰盘管是热交换设备的一种形式。

生产工艺主要为将优质钢带在特种设备上卷焊成100米甚至更长一些的钢管,通过特殊设备按照设计规格加工打弯成方形单元,经过气体压力密闭试验和水下气压试验,最后将一个单元的钢盘管整体吊入镀锌槽中热镀锌。

由于冰蓄冷项目在我国推广时间不长,蓄冰盘管制造工艺有一定的难度,蓄冰盘管一旦安装完毕,维修非常困难,对质量要求较高,所以,专业制造厂商并不多。

目前主要为BAC 冷却系统(大连)有限公司以及益美高(上海)制冷设备有限公司。

BAC冷却系统(大连)有限公司:巴尔的摩空气盘管公司(B.A.C)是AMSTED 工业集团的一个子公司。

AMSTED 是一家提供多元化工业制成品的生产型企业,产品主要应用于铁路,运输,建筑和楼宇等领域。

巴尔的摩空调盘管公司的总部邻近美国马里兰州的巴尔的摩市,并在全球范围内拥有近二十家全资,合资或是经授权的生产机构。

BAC大连有限公司是在1997年由美国BAC公司和大连冰山集团共同投资创立的合资公司。

主要从事蒸发式冷凝器、闭式冷却塔(工业流体冷却器)和冰蓄冷设备的制造和销售,产品主要供应中国市场及周边的亚洲市场。

冰盘管主要技术特点:1、采用圆形冰盘管BAC采用圆形钢盘管,在同等条件下,管压力降较小,圆形钢盘管可需要更小扬程的乙二醇泵,整个蓄冰系统能耗更小,系统更节能,尤其在长期使用中节能效果更加明显。

BAC经过多年的研发,对蓄冰盘管的结构已经做到最为紧凑,在保证性能曲线的基础上占有空间最小。

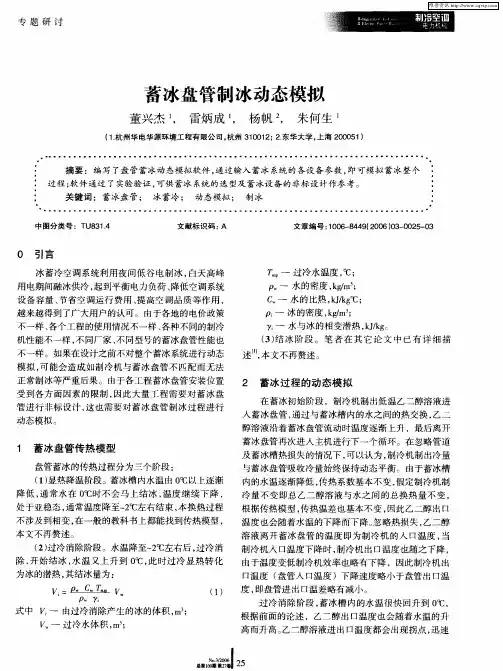

冰盘管式蓄冰过程的分析与模拟摘要:随着我国经济的快速发展,空调的大量使用不但增加了城市的电网容量,更加剧了峰谷供电的不平衡率。

冰蓄冷因其对电力系统具有良好的“削峰填谷”作用而被广泛使用,蓄冷装置的性能直接影响空调的蓄冷量,本文通过对蓄冰盘管的传热过程的分析和研究,建立了单管蓄冷的微分方程。

经过使用Fluent模拟,得出了单管和多排管束在蓄冷2h和3h的温度场分布。

关键词:冰蓄冷;FLUENT;温度场;盘管蓄冷0 引言空调蓄冷技术的产生已有八十余年的历史,而冰蓄冷技术又在20世纪80年代以来得到了长足的发展。

当前,空调蓄冷技术的广泛应用已成为各大城市调整电力峰值的重要手段。

空调冰蓄冷技术,是在电力负荷很低或者用点费用相对较低时采用电动制冷,使蓄能介质发生相变从而将冷量存储起来,在电力负荷高的时候释放能量,从而使用能更具经济性和减少电网负荷。

根据蓄能所用的物质是否发生相变,可以将蓄能分为潜热蓄能和显热蓄能。

显热蓄能是指将物质发生温度变化时所吸收或放出的热量储存起来;潜热蓄能是指将物质发生相变时吸收或放出的热量储存起来。

例如,1千克的水升高或者降低1度,需要吸收或者放出大约4.18KJ能量,同样,将1Kg的水转变成冰或者1Kg的冰变成水需要放出或者吸收335KJ,从这个例子可以看出同一物质利用潜热蓄能的能力要远大于显热蓄能,在蓄相同能量的条件下,采用潜热蓄能可以减少设备的容量和型号。

相变过程是一个伴随着能量显著变化的过程,且在这个过程中温度近似不变。

蓄冷系统一般由蓄冷、制冷和供冷系统组成。

根据制冰方式的不同,冰蓄冷可分为动态制冰和静态制冰两大类。

按蓄冷方式又可以分为冰浆式蓄冷、冰晶式蓄冷、冰片滑落式蓄冷、盘管外结冰式蓄冷、封装冰蓄冷等。

本文主要针对盘管外结冰蓄冷方式进行研究,建立数学模型描述动态结冰过程的温度场变化。

1 动态结冰模型的建立与求解1.1 模型假设蓄冰时,制冷剂(蓄冷剂)在管内做紊流流动,与管外的水或冰进行换热,将管外水冷却至凝固点,该传热过程可以表示如下:管内介质与管壁对流换热,通过管壁的导热传给管外介质,管外的冰与管壁通过导热传热使冰层厚度逐渐增加,在冰与水交界处对流换热。

文章编号:1671-6612(2007)03-018-04冰蓄冷专用风机盘管的研制李小民∗1 耿立志2( 1.中原工学院 郑州 4500072.重庆康达环保(焦作)水务有限公司 焦作 454100)【摘 要】 对自行研制的冰蓄冷系统专用风机盘管进行了阐述。

对送风口附近存在的结雾和滴水现象进行了分析,提出了新的冰蓄冷系统专用风机盘管的设计方案,进而针对第一种方案进行了理论分析和设计计算。

对相关工作进行了初步的展望。

【关键词】 冰蓄冷;低温送风;风机盘管;固体吸湿剂;诱导 中图分类号 TU831.7 文献标识码 ADevelopment of a Special FCU for Ice-storage SystemLi Xiaomin Geng Lizhi(Zhongyuan University of Technology Zhengzhou 45000ChongQing KangDa Environment protection cooperation Jiaozuo 454100)【Abstract 】 This paper presents a special FCU, developed by ourselves, for ice-storage low-temperature air supply system. Facing up to the problem of mist & drip around the air jaws, put forward creatively the scheme on a special FCU by new idea. Then finish the analysis and design about the first scheme. In conclusion make an simple prospect of correlative task. 【Keywords 】 ice-storage; low-temperature air supply; FCU; solid desiccant; interference unit收稿日期:2006-07-12∗李小民,男,1971年生,讲师0 引言冰蓄冷系统与低温送风相结合可以产生明显的经济效益和社会效益,这一点已经为国内外广大的空调设计技术人员所认可[1]。