Integrated Circuits集成电路(英汉翻译)

- 格式:docx

- 大小:18.63 KB

- 文档页数:4

什么叫集成电路集成电路介绍集成电路(integrated circuit)是一种微型电子器件或部件。

采用一定的工艺,把一个电路中所需的晶体管、电阻、电容和电感等元件及布线互连一起,制作在一小块或几小块半导体晶片或介质基片上,然后封装在一个管壳内,成为具有所需电路功能的微型结构;其中所有元件在结构上已组成一个整体,使电子元件向着微小型化、低功耗、智能化和高可靠性方面迈进了一大步。

它在电路中用字母“IC”表示。

集成电路发明者为杰克·基尔比(基于锗(Ge)的集成电路)和罗伯特·诺伊思(基于硅(Si)的集成电路)。

当今半导体工业大多数应用的是基于硅的集成电路。

集成电路结构电路形成于硅基板上,电路具有至少一输出/输入垫。

固定封环形成于硅基板上,并围绕电路及输出/输入垫。

接地环形成于硅基板及输出/输入垫之间,并与固定封环电连接。

防护环设置于硅基板之上,并围绕输出/输入垫,用以与固定封环电连接。

集成电路特点集成电路具有体积小,重量轻,引出线和焊接点少,寿命长,可靠性高,性能好等优点,同时成本低,便于大规模生产。

它不仅在工、民用电子设备如收录机、电视机、计算机等方面得到广泛的应用,同时在军事、通讯、遥控等方面也得到广泛的应用。

用集成电路来装配电子设备,其装配密度比晶体管可提高几十倍至几千倍,设备的稳定工作时间也可大大提高。

集成电路芯片种类介绍1.按功能结构分集成电路,又称为IC,按其功能、结构的不同,可以分为模拟集成电路、数字集成电路和数/模混合集成电路三大类。

模拟集成电路又称线性电路,用来产生、放大和处理各种模拟信号(指幅度随时间变化的信号。

例如半导体收音机的音频信号、录放机的磁带信号等),其输入信号和输出信号成比例关系。

而数字集成电路用来产生、放大和处理各种数字信号(指在时间上和幅度上离散取值的信号。

例如3G手机、数码相机、电脑CPU、数字电视的逻辑控制和重放的音频信号和视频信号)。

2.按制作工艺分集成电路按制作工艺可分为半导体集成电路和膜集成电路。

元器件英语阅读涉及到阅读关于元器件的英语资料时,以下是一些常见的词汇和短语,以及它们的解释:1. Component(元器件): 用于构建电子产品的基本部件或部分。

2. Resistor(电阻器): 控制电流流动的元器件,通常用于限制电流或调整电路中的电压。

3. Capacitor(电容器): 存储电荷的元器件,常用于滤波、耦合和蓄电等应用。

4. Inductor(电感器): 存储能量的元器件,常用于滤波、辐射抑制和变压器等应用。

5. Diode(二极管): 具有单向导电性的元器件,通常用于电源保护、整流和信号调节等应用。

6. Transistor(晶体管): 控制电流流动的半导体设备,常用于放大信号和开关电路等应用。

7. Integrated circuit (IC)(集成电路): 在单个芯片上集成多个元器件,可实现复杂的功能。

8. Printed Circuit Board (PCB)(印刷电路板): 用于支持和连接元器件的基板,通常由导电轨道和焊盘组成。

9. Schematic diagram(原理图): 用符号和线路表示元器件之间的连接关系和电气特性。

10. Datasheet(数据手册): 包含有关元器件的详细规格、性能和应用信息的文件。

阅读英语资料时,可以注意以下几点:1. 熟悉常见的元器件名称和功能,以便理解文章中的描述。

2. 查看上下文以获取更多信息。

在阅读过程中,可能会遇到不熟悉的词汇或缩写,尝试从上下文推断其含义。

3. 注意关键词和技术术语。

了解相关的专业术语和表达方式,可帮助你更好地理解文章内容。

4. 参考数据手册。

如果遇到不熟悉的元器件或术语,查阅相关的数据手册可以提供更详细的信息。

希望这些提示对你在阅读元器件英语资料时有所帮助!。

关于集成电路的英语作文英文回答:Integrated circuits (ICs), also known as microchips, are small electronic devices that contain a large number of transistors and other electronic components packed into a small space. They are used in a wide range of electronic devices, from computers and smartphones to cars and medical devices.The main components of an IC are transistors, which act as switches or amplifiers, and resistors and capacitors, which control the flow of electricity. ICs are manufactured using a process called photolithography, in which a pattern is created on a silicon wafer using ultraviolet light. The pattern is then etched into the silicon wafer to create the transistors and other components.The first IC was developed in 1958 by Jack Kilby of Texas Instruments. It contained only a few transistors, butit was the foundation for the development of more complex ICs. In the 1970s, the development of large-scale integration (LSI) technology allowed for the creation of ICs with thousands of transistors. This led to the development of microprocessors, which are the central processing units (CPUs) of computers.Today, ICs are used in a wide range of applications, including:Computers.Smartphones.Cars.Medical devices.Industrial automation.Military equipment.ICs have revolutionized the electronics industry and made it possible to create devices that are smaller, faster, and more efficient. They are essential for the developmentof new technologies and will continue to play a vital rolein the future of electronics.中文回答:什么是集成电路。

Integrated circuitsIntegrated circuits are a tiny electronic devices or components. By a certain technology, a circuit for the transistor, the diode, resistance, capacitance and inductance and components and wiring interconnection together, make on a small piece of or a few small piece of semiconductor wafer or medium substrate, and then encapsulated in a tube and shell inside, as has the required the miniature circuit function structure; Among them all components in the structure of a whole has, make the electronic components to micro miniaturization, low power consumption and high reliability take a big step. It in a circuit with the letter "IC" said. Integrated circuit for the inventor jack kilby (based on the silicon integrated circuits) and Robert noe of thought (based on the ge integrated circuit). The semiconductor industry is based on the most applications silicon integrated circuits.1.characteristicsIntegrated circuit has small volume, light weight, lead wire and welding points less, long service life, high reliability, good performance advantages, at the same time, low cost, easy to mass production. It not only in the work, civil electronic equipments such as radio, television, computers and other aspects of the widely application, and in the military, communication, remote control, etc also widely used. With integrated circuit to assembly electronic equipment, its density than transistor can improve assembly several times to thousands of times, the stability of the equipment can greatly improve the work time.2. classificationAccording to their function, integrated circuit of the different structure, can be divided into analog integrated circuit, digital integrated circuit and hybrid integrated circuit model/three categoriesNO.1 According to the function structure classificationAnalog integrated circuit also called linear circuits, used to produce, amplification and dealing with various kinds of analog signals (refers to the signal amplitude change over time. Such as semiconductor radio's audio signal, the tape recorders signal), the input signal and the output signal proportional relations. While digital integrated circuit used to generate, amplification and dealing with various kinds of digital signal (point to in time and range of values in discrete signal. For example 3 G mobile phones, digital cameras, computer CPU, digital TV logic control and replay the audio and video letter.NO.2 According to production processes classificationAccording to the production of integrated circuit technology can be divided into semiconductor integrated circuit and membrane integrated circuit. Film integrated circuit and classification thick film integrated circuit and film integrated circuit.NO.3 According to the classification of high and low level of integrationSSI (Small Scale Integrated circuits)MSI (Medium Scale Integrated circuits)LSI (Large Scale Integrated circuits)VLSI (Very Large Scale Integrated circuits)ULSI (Ultra Large Scale Integrated circuits)GSI (Giga Scale Integration)。

汉译英1. 集成电路 integrated circuit2. 轴向载荷 thrust load3. 柔性制造 flexible manufacture4. 瞬态电流 transient current5. 滑动接触 sliding contact6. 压敏电阻 pizeo-resistive7. 光敏开关 light-activated switch8. 刚性自动化 hard automation9. 圆锥齿轮 bevel gear10.模拟信号 analogue signal11.发光二极管 light-emitting diodes12.耐磨擦轴承 antifriction bearing13.声学传感器 acoustics transducer14.实时控制 real-time control15.随机存储器 random access memory英译汉1.friction clutch 摩擦离合器2. feed rod 进刀杆3. be confronted with 面临着4.angular-contact bearing 角接触轴承5. herringbone 人字齿轮6.lead angle 导角7.internal thread 内螺纹8.robotics 机器人技术9. pressure transducer 压力传感器10.programmable Controllers 可编程调节器11.self-aligning bearing 自动调心轴承12.machining tolerance 机械加工公差13.sliding velocity 滑动速度14.screws and fasteners螺钉和紧固件15.reliability 可靠性16.multipoint tool 多刃刀具17.boring machine 镗床18.rpm 每分钟转速19.work piece 工件20.viscosity 粘性句子翻译(英译汉)1.The life of an individual bearing is defined as the total number of revolutions,or the number of hours at a given constant speed, of bearing operation before the first evidence of fatigue develops.译文:在疲劳损伤首次单个发生之前,单个轴定义的寿命是轴承运转的总转数或以轴承在给定恒速下运转的小时数来定义的。

集成电路专业英语一、单词1. Integrated Circuit (IC)- 英语释义:A set of electronic circuits on one small flat piece (chip) of semiconductor material, typically silicon.- 用法:常作为名词短语使用,可在句中作主语、宾语等。

例如:The development of integrated circuits has revolutionized the electronics industry.(集成电路的发展使电子工业发生了革命性的变化。

)2. Semiconductor- 英语释义:A material which has a conductivity between that of an insulator and that of most metals, either due to the addition of an impurity or because of temperature effects.- 用法:作名词,例如:Silicon is a widely used semiconductor in integrated circuit manufacturing.(硅是集成电路制造中广泛使用的半导体。

)3. Transistor- 英语释义:A semiconductor device used to amplify or switch electronic signals and electrical power.- 用法:作名词,如:The transistor is a keyponent in integrated circuits.(晶体管是集成电路中的一个关键元件。

)4. Chip- 英语释义:A small piece of semiconducting material (usually silicon) on which an integrated circuit is fabricated.- 用法:作名词,可指集成电路芯片。

Integrated Circuits(集成电路)英文原稿:The Integrated CircuitDigital logic and electronic circuits derive their functionality from electronic switches called transistor. Roughly speaking, the transistor can be likened to an electronically controlled valve whereby energy applied to one connection of the valve enables energy to flow between two other connections.By combining multiple transistors, digital logic building blocks such as AND gates and flip-flops are formed. Transistors, in turn, are made from semiconductors. Consult a periodic table of elements in a college chemistry textbook, and you will locate semiconductors as a group of elements separating the metals and nonmetals.They are called semiconductors because of their ability to behave as both metals and nonmetals. A semiconductor can be made to conduct electricity like a metal or to insulate as a nonmetal does. These differing electrical properties can be accurately controlled by mixing the semiconductor with small amounts of other elements. This mixing is called doping. A semiconductor can be doped to contain more electrons (N-type) or fewer electrons (P-type). Examples of commonly used semiconductors are silicon and germanium. Phosphorous and boron are two elements that are used to dope N-type and P-type silicon, respectively.A transistor is constructed by creating a sandwich of differently doped semiconductor layers. The two most common types of transistors, the bipolar-junction transistor (BJT) and the field-effect transistor (FET) are schematically illustrated in Figure 2.1.This figure shows both the silicon structures of these elements and their graphical symbolic representation as would be seen in a circuit diagram. The BJT shown is an NPN transistor, because it is composed of a sandwich of N-P-N doped silicon. When a small current is injected into the base terminal, a larger current is enabled to flow from the collector to the emitter.The FET shown is an N-channel FET, which is composed of two N-type regions separated by a P-type substrate. When a voltage is applied to the insulated gate terminal, a current is enabled to flow from the drain to the source. It is called N-channel, because the gate voltage induces an N-channel within the substrate, enabling current to flow between the N-regions.Another basic semiconductor structure is a diode, which is formed simply by a junction of N-type and P-type silicon. Diodes act like one-way valves by conducting current only from P to N. Special diodes can be created that emit light when a voltage is applied. Appropriately enough, these components are called light emitting diodes, or LEDs. These small lights are manufactured by the millions and are found in diverse applications from telephones to traffic lights.The resulting small chip of semiconductor material on which a transistor or diode is fabricated can be encased in a small plastic package for protection against damage and contamination from the outside world.Small wires are connected within this package between the semiconductor sandwich and pins that protrude from the package to make electrical contact with other parts of the intended circuit. Once you have several discrete transistors, digital logic can be built by directly wiring these components together. The circuit will function, but any substantial amount of digital logic will be very bulky, because several transistors are required to implement each of the various types of logic gates.At the time of the invention of the transistor in 1947 by John Bardeen, Walter Brattain, and William Shockley, the only way to assemble multiple transistors into a single circuit was to buy separate discrete transistors and wire them together. In 1959, Jack Kilby and Robert Noyce independently invented a means of fabricating multiple transistors on a single slab of semiconductor material. Their invention would come to be known as the integrated circuit, or IC, which is the foundation of our modern computerized world. An IC is so called because it integrates multiple transistors and diodes onto the same small semiconductor chip. Instead of having to solder individual wires between discrete components, an IC contains many small components that are already wired together in the desired topology to form a circuit.A typical IC, without its plastic or ceramic package, is a square or rectangular silicon die measuring from 2 to 15 mm on an edge. Depending on the level of technology used to manufacture the IC, there may be anywhere from a dozen to tens of millions of individual transistors on this small chip. This amazing density of electronic components indicates that the transistors and the wires that connect them are extremely small in size. Dimensions on an IC are measured in units of micrometers, with one micrometer (1mm) being one millionth of a meter. To serve as a reference point, a human hair is roughly 100mm in diameter. Some modern ICs contain components and wires that are measured in increments as small as 0.1mm! Each year, researchers and engineers have been finding new ways to steadily reduce these feature sizes to pack more transistors into the same silicon area, as indicated in Figure 2.2.When an IC is designed and fabricated, it generally follows one of two main transistor technologies: bipolar or metal-oxide semiconductor (MOS). Bipolar processes create BJTs, whereas MOS processes create FETs. Bipolar logic was more common before the 1980s, but MOS technologies have since accounted the great majority of digital logic ICs. N-channel FETs are fabricated in an NMOS process, and P-channel FETs are fabricated in a PMOS process. In the 1980s, complementary-MOS, or CMOS, became the dominant process technology and remains so to this day. CMOS ICsincorporate both NMOS and PMOS transistors.Application Specific Integrated CircuitAn application-specific integrated circuit (ASIC) is an integrated circuit (IC) customized for a particular use, rather than intended for general-purpose use. For example, a chip designed solely to run a cell phone is an ASIC. In contrast, the 7400 series and 4000 series integrated circuits are logic building blocks that can be wired together for use in many different applications.As feature sizes have shrunk and design tools improved over the years, the maximum complexity (and hence functionality) possible in an ASIC has grown from 5,000 gates to over 100 million.Modern ASICs often include entire 32-bit processors, memory blocks including ROM, RAM, EEPROM, Flash and other large building blocks. Such an ASIC is often termed a SoC (System-on-Chip). Designers of digital ASICs use a hardware description language (HDL), such as Verilog or VHDL, to describe the functionality of ASICs.Field-programmable gate arrays (FPGA) are the modern day equivalent of 7400 series logic and a breadboard, containing programmable logic blocks and programmable interconnects that allow the same FPGA to be used in many different applications. For smaller designs and/or lower production volumes, FPGAs may be more cost effective than an ASIC design. The non-recurring engineering cost (the cost to setup the factory to produce a particular ASIC) can run into hundreds of thousands of dollars.The general term application specific integrated circuit includes FPGAs, but most designers use ASIC only for non-field programmable devices and make a distinction between ASIC and FPGAs.HistoryThe initial ASICs used gate array technology. Ferranti produced perhaps the first gate-array, the ULA (Uncommitted Logic Array), around 1980. Customization occurred by varying the metal interconnect mask. ULAs had complexities of up to a few thousand gates. Later versions became more generalized, with different base dies customized by both metal and polysilicon layers. Some base dies include RAM elements.Standard cell designIn the mid 1980s a designer would choose an ASIC manufacturer and implement their design using the design tools available from the manufacturer. While third party design tools were available, there was not an effective link from the third party design tools to the layout and actual semiconductor process performance characteristics of the various ASIC manufacturers.Most designers ended up using factory specific tools to complete the implementation of their designs. A solution to thisproblem that also yielded a much higher density device was the implementation of Standard Cells. Every ASIC manufacturer could create functional blocks with known electrical characteristics, such as propagation delay, capacitance and inductance; that could also be represented in third party tools.Standard cell design is the utilization of these functional blocks to achieve very high gate density and good electrical performance. Standard cell design fits between Gate Array and Full Custom design in terms of both its NRE (Non-Recurring Engineering) and recurring component cost.By the late 1980s, logic synthesis tools, such as Design Compiler, became available. Such tools could compile HDL descriptions into a gate-level netlist. This enabled a style of design called standard-cell design. Standard-cell Integrated Circuits (ICs) are designed in the following conceptual stages, although these stages overlap significantly in practice.These steps, implemented with a level of skill common in the industry, almost always produce a final device that correctly implements the original design, unless flaws are later introduced by the physical fabrication process.A team of design engineers starts with a non-formal understanding of the required functions for a new ASIC, usually derived from requirements analysis.*The design team constructs a description of an ASIC to achieve these goals using an HDL. This process is analogous to writing a computer program in a high-level language. This is usually called the RTL (register transfer level) design.*Suitability for purpose is verified by simulation. A virtual system created in software, using a tool such as Virtutech’s Simics, can simulate the performance of ASICs at speeds up to billions of simulated instructions per second.*A logic synthesis tool, such as Design Compiler, transforms the RTL design into a large collection of lower-level constructs called standard cells. These constructs are taken from a standard-cell library consisting of pre-characterized collections of gates such as 2 input nor, 2 input nand, inverters, etc.The standard cells are typically specific to the planned manufacturer of the ASIC. The resulting collection of standard cells, plus the needed electrical connections between them, is called a gate-level netlist.*The gate-level netlist is next processed by a placement tool which places the standard cells onto a region representing the final ASIC. It attempts to find a placement of the standard cells, subject to a variety of specified constraints. Sometimes advanced techniques such as simulated annealing are used to optimize placement.*The routing tool takes the physical placement of the standard cells and uses the netlist to create the electrical connections between them. Since the search space is large, this process will produce a “sufficient” rather than “globally-optimal” solution. The output is a set of photomasks enabling semiconductor fabrication to produce physical ICs.*Close estimates of final delays, parasitic resistances and capacitances, and power consumptions can then be made. In the case of a digital circuit, this will be further mapped into delay information. These estimates are used in a final round of testing. This testing demonstrates that the device will function correctly over all extremes of the process, voltage and temperature. When this testing is complete the photomask information is released for chip fabrication.These design steps (or flow) are also common to standard product design. The significant difference is that Standard Cell design uses the manufacturer’s cell libraries tha t have been used in hundreds of other design implementations and therefore are of much lower risk than full custom design.Gate array designGate array design is a manufacturing method in which the diffused layers, i.e. transistors and other active devices, are predefined and wafers containing such devices are held in stock prior to metallization, in other words, unconnected.The physical design process then defines the interconnections of the final device. It is important to the designer that minimal propagation delays can be achieved in ASICs versus the FPGA solutions available in the marketplace. Gate array ASIC is a compromise as mapping a given design onto what a manufacturer held as a stock wafer never gives 100% utilization.Pure, logic-only gate array design is rarely implemented by circuit designers today, replaced almost entirely by field programmable devices such as FPGAs, which can be programmed by the user and thus offer minimal tooling charges, marginally increased piece part cost and comparable performance.Today gate arrays are evolving into structured ASICs that consist of a large IP core like a processor, DSP unit, peripherals, standard interfaces, integrated memories SRAM, and a block of reconfigurable uncommitted logic.This shift is largely because ASIC devices are capable of integrating such large blocks of system functionality and “system on a chip” requires far more than just logic blocks.Full-custom designThe benefits of full-custom design usually include reduced area, performance improvements and also the ability to integrate analogcomponents and other pre-designed components such as microprocessor cores that form a System-on-Chip. The disadvantages can include increased manufacturing and design time, increased non-recurring engineering costs, more complexity in the CAD system and a much higher skill requirement on the part of the design team.However for digital only designs, “standard-cell” libraries together with modern CAD systems can offer considerable performance/cost benefits with low risk. Automated layout tools are quick and easy to use and also offer the possibility to manually optimize any performance limiting aspect of the design.Structured designStructured ASIC design is an ambiguous expression, with different meanings in different contexts. This is a relatively new term in the industry, which is why there is some variation in its definition. However, the basic premise of a structured ASIC is that both manufacturing cycle time and design cycle time are reduced compared to cell-based ASIC by virtue of there being pre-defined metal layers and pre-characterization of what is on the silicon.One definition states that, in a structured ASIC design, the logic mask-layers of a device are predefined by the ASIC vendor (or in some cases by a third party). Structured ASIC technology is seen as bridging the gap between field-programmable gate arrays and “standard-cell” ASIC designs.What makes a structured ASIC different from a gate array is that in a gate array the predefined metal layers serve to make manufacturing turnaround faster. In a structured ASIC the predefined metallization is primarily to reduce cost of the mask sets and is also used to make the design cycle time significantly shorter as well.Likewise, the design tools used for structured ASIC can substantially lower cost, and are easier to use than cell-based tools, because the tools do not have to perform all the functions that cell-based tools do.One other important aspect about structured ASIC is that it allows IP that i s common to certain applications to be “built in”, rather than “designed in”. By building the IP directly into the architecture the designer can again save both time and money compared to designing IP into a cell-based ASIC.中文翻译:集成电路集成电路数字逻辑和电子电路由称为晶体管的电子开关得到它们的(各种)功能。

积体电路的英语原文和大陆的通用译名English:Integrated circuit, also known as IC, is a small electronic device made out of a semiconductor material. It can contain a few to millions of transistors, resistors, and capacitors, all working together to perform a particular function. Integrated circuits are widely used in almost all electronic equipment, from simple calculators to advanced computer systems. They are also found in telecommunication devices, medical equipment, and automotive systems. The development of integrated circuits has greatly contributed to the miniaturization, cost reduction, and performance improvement of electronic devices.Chinese:集成电路,也称为IC,是由半导体材料制成的小型电子器件。

它可以包含几个到数百万个晶体管,电阻器,和电容器,所有的元件一起工作,执行特定的功能。

集成电路广泛应用于几乎所有的电子设备,从简单的计算器到先进的计算机系统。

它们也出现在通信设备,医疗设备和汽车系统中。

集成电路的发展极大地促进了电子设备的小型化,降低成本,和性能的改善。

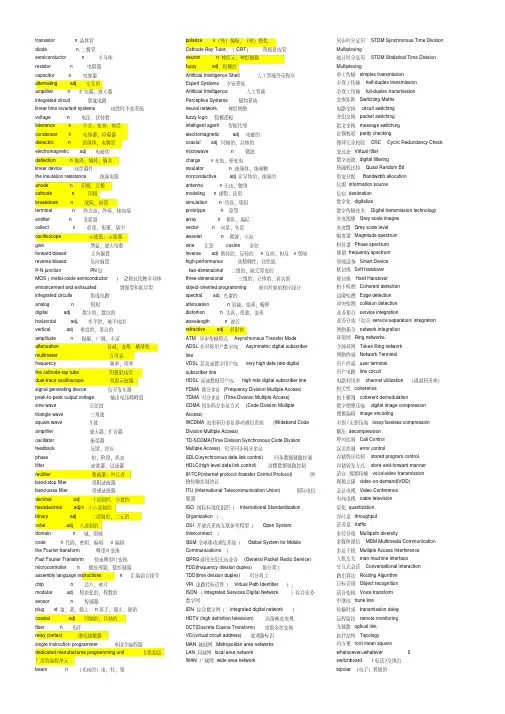

电子行业英语词汇大全预览说明:预览图片所展示的格式为文档的源格式展示,下载源文件没有水印,内容可编辑和复制品质专业英语大全从事品质工作以来积累的常用英语,希望对有需要的朋友有所帮品质专业英语大全零件材料类的专有名词CPU:central processing unit(中央处理器)IC:Integrated circuit(集成电路)Memory IC:Memory Integrated circuit(记忆集成电路)RAM:Random Access Memory(随机存取存储器)DRAM:Dynamic Random Access Memory(动态随机存取存储器)SRAM:Staic Random Access Memory(静态随机存储器)ROM:Read-only Memory(只读存储器)EPROM:Electrical Programmable Read-only Memory(电可抹只读存诸器)EEPROM:Electrical Erasbale Programmable Read-only Memory(电可抹可编程只读存储器)CMOS:Complementary Metal-Oxide-Semiconductor(互补金属氧化物半导体)BIOS:Basic Input Output System(基本输入输出系统)Transistor:电晶体LED:发光二极体Resistor:电阻Variator:可变电阻Capacitor:电容Capacitor array:排容Diode:二极体Transistor:三极体Transformer:变压器(ADP)Oscillator:频率振荡器(0sc)Crystal:石英振荡器XTAL/OSC:振荡产生器(X)Relay:延时器Sensor:感应器Bead core:磁珠Filter:滤波器Flat Cable:排线Inductor:电感Buzzer:蜂鸣器Socket:插座Slot:插槽Fuse:熔断器Current:电流表Solder iron:电烙铁Magnifying glass:放大镜Caliper:游标卡尺Driver:螺丝起子TFT:液晶显示器Oscilloscope:示波器Connector:连接器PCB:printed circuit board(印刷电路板)PCBA:printed circuit board assembly(电路板成品)PP:并行接口HDD:硬盘FDD:软盘PSU:power supply unit(电源供应器)SPEC:规格Attach:附件Case:机箱,盖子Cover:上盖Base:下盖Bazel:面板(panel)Bracket:支架,铁片Lable:贴纸Guide:手册Manual:手册,指南Card:网卡Switch:交换机Hub:集线器Router:路由器Sample:样品Gap:间隙Sponge:海绵Pallet:栈板Foam:保利龙Fiber:光纤Disk:磁盘片PROG:程序Barcode:条码System:系统System Barcode:系统条码M/B:mother board:主板CD-ROM:光驱FAN:风扇Cable:线材Audio:音效K/B:Keyboard(键盘)Mouse:鼠标Riser card:转接卡Card reader:读卡器Thermal pad:散热垫Heat sink:散热片Rubber:橡胶垫Rubber foot:脚垫Bag:袋子Washer:垫圈Sleeve:袖套Config:机构Label hi-pot:高压标签Firmware label:烧录标签Metal cover:金属盖子Plastic cover:塑胶盖子Tape for packing:包装带Bar code:条码Tray:托盘Collecto:集线夹Holder:固定器,L铁Connecter:连接器IDE:集成电路设备,智能磁盘设备SCSI:小型计算机系统接口Gasket:导电泡棉AGP:加速图形接口PCI:周边组件扩展接口LAN:局域网USB:通用串形总线架构Slim:小型化COM:串型通讯端口LPT:打印口,并行口Power cord:电源线I/O:输入,输出Speaker:扬声器EPE:泡棉Carton:纸箱Button:按键,按钮Foot stand:脚架部门名称的专有名词QS:Quality system品质系统CS:Coutomer Sevice客户服务QC:Quality control品质管理IQC:Incoming quality control进料检验LQC:Line Quality Control生产线品质控制IPQC:In process quality control制程检验FQC:Final quality control最终检验OQC:Outgoing quality control出货检验QA:Quality assurance品质保证SQA:Source(supplier)Quality Assurance供应商品质保证(VQA) CQA:Customer Quality Assurance客户质量保证PQA rocess Quality Assurance制程品质保证QE:Quality engineer品质工程CE:component engineering零件工程EE:equipment engineering设备工程ME:manufacturing engineering制造工程TE:testing engineering测试工程PPE roduct Engineer产品工程IE:Industrial engineer工业工程ADM:Administration Department行政部RMA:客户退回维修CSDI:检修PC:producing control生管MC:mater control物管GAD:General Affairs Dept总务部A/D:Accountant/Finance Dept会计LAB:Laboratory实验室DOE:实验设计HR:人资PMC:企划RD:研发W/H:仓库SI:客验PD:Product Department生产部PA:采购(PUR:Purchaing Dept)SMT:Surface mount technology表面粘着技术MFG:Manufacturing制造MIS:Management information system资迅管理系统DCC:document control center文件管制中心厂内作业中的专有名词QT:Quality target品质目标QP:Quality policy目标方针QI:Quality improvement品质改善CRITICAL DEFECT:严重缺点(CR)MAJOR DEFECT:主要缺点(MA)MINOR DEFECT:次要缺点(MI)MAX:Maximum最大值MIN:Minimum最小值DIA iameter直径DIM imension尺寸LCL:Lower control limit管制下限UCL:Upper control limit管制上限EMI:电磁干扰ESD:静电防护EPA:静电保护区域ECN:工程变更ECO:Engineering change order工程改动要求(客户)ECR:工程变更需求单CPI:Continuous Process Improvement连续工序改善Compatibility:兼容性Marking:标记DWG rawing图面Standardization:标准化Consensus:一致Code:代码ZD:Zero defect零缺点Tolerance:公差Subject matter:主要事项Auditor:审核员BOM:Bill of material物料清单Rework:重工ID:identification识别,鉴别,证明PILOT RUN:(试投产)FAI:首件检查FPIR:First Piece Inspection Report首件检查报告FAA:首件确认SPC:统计制程管制CP:capability index(准确度)CPK:capability index of process(制程能力)PMP:制程管理计划(生产管制计划)MPI:制程分析DAS efects Analysis System缺陷分析系统PPB:十亿分之一Flux:助焊剂P/N:料号L/N:Lot Number批号Version:版本Quantity:数量Valid date:有效日期MIL-STD:Military-Standard军用标准ICT:In Circuit Test(线路测试)ATE:Automatic Test Equipment自动测试设备MO:Manafacture Order生产单T/U:Touch Up(锡面修补)I/N:手插件P/T:初测F/T:Function Test(功能测试-终测)AS组立P/K:包装TQM:T otal quality control全面品质管理MDA:manufacturing defect analysis制程不良分析(ICT) RUN-IN:老化实验HI-pot:高压测试FMI:Frequency Modulation Inspect高频测试DPPM:Defect Part Per Million(不良率的一种表达方式:百万分之一)1000PPM即为0.1% Corrective Action:(CAR改善对策)ACC:允收REJ:拒收S/S:Sample size抽样检验样本大小SI-SIV:Special I-Special IV特殊抽样水平等级CON:Concession/Waive特采ISO:国际标准化组织ISA:Industry Standard Architecture工业标准体制结构OBA:开箱稽核FIFO:先进先出PDCA:管理循环Plan do check action计划,执行,检查,总结WIP:在制品(半成品)S/O:Sales Order(业务订单)P/O:Purchase Order(采购订单)P/R:Purchase Request(请购单)AQL:acceptable quality level允收品质水准LQL;Limiting quality level最低品质水准QVL:qualified vendor list合格供应商名册AVL:认可的供货商清单(Approved Vendor List)QCD:Quality cost delivery(品质,交期,成本)MPM:Manufacturing project management制造专案管理KPI:Key performance indicate重要绩效指标MVT:Manufacturing Verification Test制造验证试产Q/R/S:Quality/Reliability/Service质量/可靠度/服务STL:ship to line(料到上线)NTF:No trouble found误判CIP:capacity improvement plan(产能改善计划)MRB:material review board(物料审核小组)MRB:Material reject bill退货单JIT:just in time(即时管理)5S:seiri seiton seiso seiketsu shitsuke(整理,整顿,清扫,清洁,修养)SOP:standard operation process(标准作业程序)SIP:Specification inspection process制程检验规范TOP:T est Operation Process(测试作业流程)WI:working instruction(作业指导书)SMD:surface mounting device(表面粘着原件)FAR:failure aualysis report故障分析报告CAR:Corrective action report改善报告BPR:企业流程再造(Business Process Reengineering)ISAR:首批样品认可(Initial Sample Approval Request)-JIT:实时管理(Just In Time)QCC:品管圈(Quality Control Circle)Engineering Department(工程部)TQEM:T otal Quality Environment Management(全面品质环境管理)PD:Production Department(制造)LOG:Logistics(后勤支持)Shipping:(进出口)AOQ:Average Output Quality平均出货质量AOQL:Average Output Quality Level平均出货质量水平FMEA:failure model effectiveness analysis失效模式分析CRB:Change Review Board(工程变更会议)CSA:Customer Simulate Analysis客户模拟分析SQMS:Supplier Quality Management System供应商品质管理系统QIT:Quality Improvement Team品质改善小组QIP:Quality Improvement Plan品质改善计划CIP:Continual Improvement Plan持续改善计划M.Q.F.S:Material Quality Feedback Sheet(来料品质回馈单) SCAR:Supplier Corrective Action Report(供货商改善对策报告) 8D Sheet:8Disciplines sheet(8D单)PDCA:PDCA(Plan-Do-Check-Action)(管理循环)MPQ:Material Packing Quantity(物料最小包装量) DSCN:Delivery Schedule Change Notice(交期变更通知) QAPS:Quality Assurance Process Sheet(品质工程表) DRP:运销资源计划(Distribution Resource Planning) DSS:决策支持系统(Decision Support System)EC:电子商务(Electronic Commerce)EDI:电子资料交换(Electronic Data Interchange)EIS:主管决策系统(Excutive Information System)ERP:企业资源规划(Enterprise Resource Planning) FMS:弹性制造系统(Flexible Manufacture System) KM:知识管理(Knowledge Management)4L:逐批订购法(Lot-for-Lot)LTC:最小总成本法(Least Total Cost)LUC:最小单位成本(Least Unit Cost)MES:制造执行系统(Manufacturing Execution System) MPS:主生产排程(Master Production Schedule)MRP:物料需求规划(Material Requirement Planning) MRPⅡ:制造资源计划(Manufacturing Resource Planning) OEM:委托代工(Original Equipment Manufacture) ODM:委托设计与制造(Original Design&Manufacture) OLAP:线上分析处理(On-Line Analytical Processing) OLTP:线上交易处理(On-Line Transaction Processing) OPT:最佳生产技术(Optimized Production Technology) PDCA:PDCA管理循环(Plan-Do-Check-Action)PDM:产品数据管理系统(Product Data Management)) RCCP:粗略产能规划(Rough Cut Capacity Planning) SCM:供应链管理(Supply Chain Management)SFC:现场控制(Shop Floor Control)TOC:限制理论(Theory of Constraints)TQC:全面品质管制(Total Quality Control)FYI/R:for your information/reference仅供参考ASAP:尽快S/T:Standard time标准时间TPM:total production maintenance:全面生产保养ESD Wrist strap:静电环IT:information technology信息技术,资讯科学CEO:Chief Executive Officer执行总裁COO:Chief Operaring Officer首席业务总裁SWOT:Strength,Weakness,Opportunity,Threat优势﹐弱点﹐机会﹐威胁Competence:专业能力Communication:有效沟通Cooperation:统御融合Vibration Testing:振动测试IDP:Individual Development Plan个人发展计划MRP:Material Requirement Planning物料需求计划MAT'S:Material材料LRR:Lot Rejeet Rate批退率ATIN:Attention知会3C:Computer,Communication,Consumer electronic消费性电子5W1H:When,Where,Who,What,Why,How5M:Man,Machine,Material,Method,Measurement人,机器,材料,方法,测量4MIE:Man,Material,Machine,Method,Environment人力,物力,财务,技术,时间(资源)7M1I:Manpower,Machine,Material,Method,Market,Manage ment,Money,Information 人力,机器,材料,方法,市场,管理,资金,资讯1Accuracy准确度2Action行动3Activity活动4Analysis Covariance协方差分析5Analysis of Variance方差分析6Approved承认7Attribute计数值8Average平均数9Balance sheet资产负债对照表10Binomial二项分配11Brainstorming T echniques脑力风暴法12Cause and Effect Matrix因果图(鱼骨图)13CL:Center Line中心线14Check Sheets检查表15Complaint投诉16Conformity合格(符合)17Control控制18Control chart控制(管制)图19Correction纠正20Correlation Methods相关分析法21CPI:continuouse Process Improvement连续工序改善22Cross Tabulation Tables交叉表23CS:Customer Sevice客(户)服(务)中心24DSA:Defects Analysis System缺陷分析系统25Data数据Description:品名26DCC:Document Control Center文控中心27Decision决策、判定28Defects per unit单位缺点数29Description描述30Device装置31Do执行32DOE:Design of Experiments实验设计33Element元素34Engineering recbnology工程技35Environmental环境36Equipment设备37Estimated accumulative frequency计算估计累计数38E Equipment Variation设备变异39External Failure外部失效,外部缺陷40FA:Failure Analysis失效分析41Fact control事实管理42Fatigue疲劳43FMEA:Failure Mode and Effect Analysis失效模式与效果分析44FP First-Pass Yield(第一次通过)合格率45FQA:Final Quality Assurance最终品质保证46FQC:Final Quality control最终品质控制47Gauge system测量系统48Grade等级49Histogram直方图50Improvement改善51Initial review先期审查52Inspection检验53Internal Failure内部失效、内部缺陷54IPQC:In Process Quality Control制程品质控制55IQC:Incomming Quality Control来料品质控制56IS International Organization for Standardization国际标准化组织57LCL:Lower Control limit管制下限58LQC:Line Quality Control生产线品质控制59LSL:Lower Size Limit规格下限60Machine机械61Manage管理62Materials物料63Measurement测量64Median中位数65MSA:Measurement System Analysis测量系统分析66Occurrence发生率67Operation Instruction作业指导书68Organization组织69Parto柏拉图70PPM arts per Million(百万分之)不良率71Plan计划72Policy方针73Population群体74PQA:Process Quality Assurance制程品质保证75Practice实务(践)76Prevention预防77Probability机率78Probability density function机率密度函数79Procedure流程80Process过程81Process capability analysis制程能力分析(图)82Process control and Process capability制程管制与制程能力83Product产品84Production生产85Projects项目86QA:Quality Assurance品质保证87QC:Quality Control品质控制88QE:Quality Engineering品质工程89QFD:Quality Function Desgin品质机能展开(法)90Quality质量91Quality manual品质手册92Quality policy品质政策(质量方针)93Random experiment随机试验94Random numbers随机数95R:Range全距(极差)96Reject拒收97Repair返修98Repeatusility再现性99Reproducibility再生性100Requirement要求101Responsibilities职责102Review评审103Reword返工104Rolled yield直通率105RPN:Risk Priority Number风险系数106Sample抽样,样本107Sample space样本空间108Sampling with replacement放回抽样109Sampling without replacement不放回抽样110Scatter diagram散布图分析111Scrap报废112Simple random sampling简单随机取样113Size规格114SL:Size Line规格中心线115Stratified random sampling分层随机抽样116SOP:Standard Operation Procedure标准作业书117SPC:Statistical Process Control统计制程管制118Specification规范119SQA:Source(Supplier)Quality Assurance供货商品质保证120Stage sampling分段随机抽样121Standard Deviation标准差122Sum of squares平方和123Taguchi-method田口(试验)方法124Theory原理125TQC:Total Quality Control全面品质控制126TQM:T otal Quality Management全面品质管理127Traceablity追溯128Training培训129UCL:Upper Control Limit管制(控制)上限130USL:Upper Size Limit规格上限131Validation确认132Variable计量值133Verification验证134Version版本135VOC:Voice of Customer客户需求136VOE:Voice of Engineer工程需求137Inventory stock report:庫存清单报告138Sales order report:出货报告质量人员名称类QC quality control品质管理人员FQC final quality control终点质量管理人员IPQC in process quality control制程中的质量管理人员OQC output quality control最终出货质量管理人员IQC incoming quality control进料质量管理人员TQC total quality control全面质量管理POC passage quality control段检人员QA quality assurance质量保证人员OQA output quality assurance出货质量保证人员QE quality engineering质量工程人员质量保证类FAI first article inspection新品首件检查FAA first article assurance首件确认CP capability index能力指数CPK capability process index模具制程能力参数SSQA standardized supplier quality audit合格供货商质量评估FMEA failure model effectiveness analysis失效模式分析FQC运作类AQL Acceptable Quality Level运作类允收质量水平S/S Sample size抽样检验样本大小ACC Accept允收REE Reject拒收CR Critical极严重的MAJ Major主要的MIN Minor轻微的Q/R/S Quality/Reliability/Service质量/可靠度/服务P/N Part Number料号L/N Lot Number批号AOD Accept On Deviation特采UAI Use As It特采FPIR First Piece Inspection Report首件检查报告PPM Percent Per Million百万分之一制程统计品管专类SPC Statistical Process Control统计制程管制SQC Statistical Quality Control统计质量管理GRR Gauge Reproductiveness&Repeatability量具之再制性及重测性判断量可靠与否DIM Dimension尺寸DIA Diameter直径N Number样品数其它质量术语类QIT Quality Improvement Team质量改善小组ZD Zero Defect零缺点QI Quality Improvement质量改善QP Quality Policy目标方针TQM T otal Quality Management全面质量管理RMA Return Material Audit退料认可7QCT ools7Quality Control Tools品管七大手法通用之件类ECN Engineering Change Notice工程变更通知(供货商) ECO Engineering Change Order工程改动要求(客户) PCN Process Change Notice工序改动通知PMP Product Management Plan生产管制计划SIP Standard Inspection Procedure制程检验标准程序SOP Standard Operation Procedure制造作业规范IS Inspection Specification成品检验规范BOM Bill Of Material物料清单PS Package Specification包装规范SPEC Specification规格DWG Drawing图面系统文件类ES Engineering Standard工程标准CGOO China General PCE龙华厂文件IWS International Workman Standard工艺标准ISO International Standard Organization国际标准化组织GS General Specification一般规格部类PMC Production&Material Control生产和物料控制PCC Product control center生产管制中心PPC Production Plan Control生产计划控制MC Material Control物料控制DC Document Center资料中心QE Quality Engineering质量工程(部)QA Quality Assurance质量保证(处)QC Quality Control质量管理(课)PD Product Department生产部LAB Laboratory实验室IE Industrial Engineering工业工程R&D Research&Design设计开发部生产类PCs Pieces个(根,块等)PRS Pairs双(对等)CTN Carton卡通箱PAL Pallet/skid栈板PO Purchasing Order采购订单MO Manufacture Order生产单D/C Date Code生产日期码ID/C Identification Code(供货商)识别码SWR Special Work Request特殊工作需求L/N Lot Number批号P/N Part Number料号OEM Original Equipment Manufacture原设备制造PC Personal Computer个人计算机CPU Central Processing Unit中央处理器A.S.A.P As Soon As Possible尽可能快的E-MAIL Electrical-Mail电子邮件N/A Not Applicable不适用QTY Quantity数量I/O input/output输入/输出NG Not Good不行,不合格C=0Critical=0极严重不允许APP Approve核准,认可,承认CHK Check确认ASS'Y Assembly装配,组装T/P True Position真位度5WIH When,Where,Who,What,Why,How to6M Man,Machine,Material,Method,Measurement,Message 4MTH Man,Material,Money,Method,Time,How人力,物力,财务,技术,时间(资源) SQA Strategy Quality Assurance策略质量保证DQA Design Quality Assurance设计质量保证MQA Manufacture Quality Assurance制造质量保证SSQA Sales and service Quality Assurance销售及服务质量保证LRR Lot Reject Rate批退率SPS Switching power supply电源箱DT Desk Top卧式(机箱)MT Mini-Tower立式(机箱)DVD Digital Video DiskVCD Video Compact DiskLCD Liquid Crystal DisplayCAD Computer Aided DesignCAM Computer Aided ManufacturingCAE Computer Aided EngineeringPCB Printed Circuit Board印刷电路板CAR Correction Action Report改善报告NG Not Good不良WDR Weekly Delivery Requirement周出货要求PPM Percent Per Million百万分之一TPM Total Production Maintenance全面生产保养MRP Material Requirement Planning物料需计划OS Operation System 操作系统TBA To Be Assured待定,定缺D/C Drawing ChangeP/P Plans&ProcedureEMI Electrical-Music Industry电子音乐工业Electrical Magnetic Interference电子干扰RFI Read Frequency Input读频输入MMC Maximum Material ConditionMMS Maximum Material SizeLMC Least Material ConditionLMS Least Material SizeLED lighting-emitting diode发光二极管QBR Quarter Business RecordCIP Continuous improvement processFGI Forecasted Goal InventoryCNC Computerized numeral controllerB2C Business to customerB2B Business to businessAVL Approved vendor listPOP Procedure of packagingEOL End of lifeVDCS Vender defect correcting sheetPDCS Process defect correcting sheetGRN Goods receiving noteA/R Accounting receivableA/P Accounting payable专业词汇通用类president董事长operator作业员general manager总经理special assistant特助deputy manager|'depjuti|=vice manager副理deputy supervisor=vice supervisor副课长group leader组长line leader线长supervisor课长responsible department负责单位Human Resources Department人力资源部Head count人数production department生产部门planning department企划部QC Section品管课stamping factory冲压厂painting factory烤漆厂molding factory成型厂administration/general affairs dept./总务部production unit生产单位meeting minutes会议记录distribution department分发单位subject主题conclusion结论decision items决议事项pre-fixed finishing date预定完成日Color management颜色管理Visual management目视管理production capacity生产力first count初盘first check初盘复棹second count复盘second check复盘复核quantity of physical inventory second count复盘点数量physical inventory盘点数量physical count quantity账面数量difference quantity差异量spare parts physical inventory list备品盘点清单cause analysis原因分析waste materials废料description品名specification规格work order工令revision版次remark备注registration登记registration card登记卡to control管制application form for purchase请购单consume,consumption消耗to notify通知to fill in填写to collect,to gather收集statistics统计cosmetic inspection standard外观检验规范computer case计算机外壳(组件)personal computer enclosure计算机机箱产品front plate前板rear plate后板chassis|'∫?si|基座bezel panel面板Hood上盖base pan基座bezel面板riser card扩充卡flat cable排线TOP driver cage上磁架bottom driver cage下磁架resin film树脂膜raw materials原料materials物料steel plate钢板roll/coil material卷料spare parts=buffer备品plastic parts塑料件sheet metal parts/stamping parts冲件material check list物料检查表finished product成品semi-finished product半成品good product/accepted goods/accepted parts/good parts良品defective product/non-good parts不良品disposed goods处理品warehouse/hub仓库packing material包材basket蝴蝶竺plastic basket胶筐flow chart流程窗体production tempo生产进度现状lots of production生产批量manufacture procedure制程to revise,modify修订to switch over to,switch—to,switching over切换engineering bottleneck,project difficulty工程瓶颈glove(s)手套glove(s)with exposed fingers割手套Band-Aid创可贴Industrial alcohol工业酒精broom扫把mop拖把vacuum cleaner吸尘器rag抹布garbage container灰箕garbage can垃圾箱garbage bag垃圾袋liaison联络单rags抹布lamp holder灯架to mop the floor拖地to clean a table擦桌子air pipe气管delivery deadline交货期die worker模工production,to produce生产equipment设备resistance电阻beacon警示灯coolant冷却液crusher破碎机club car高尔夫球车plate电镀power button电源按键reset button重置键forklift叉车Workshop traveler天车trailer=long vehicle拖板车Hydraulic trolley手压车hydraulic hand jack油压板车casing=containerization装箱velocity速度patent专利coordinate坐标supply and demand供求career card履历卡barricade隔板carton box纸箱to pull and stretch拉深work cell/work shop工作间sub-line支线bottleneck瓶颈模具工程类plain die简易模pierce die冲孔模forming die成型模progressive die连续模stage die工程模compound die复合模shearing die剪边模riveting die铆合模feature die公母模male die公模female die母模cavity型控母模core模心公模die change换模to fix a die装模to repair a die修模punch set上模座punch pad上垫板punch holder上夹板stripper pad脱料背板up stripper上脱料板upper plate上模板lower plate下模板die pad下垫板die holder下夹板die set下模座bottom block下垫脚bottom plate下托板(底板)upper supporting blank上承板upper padding plate blank上垫板top plate上托板(顶板)top block上垫脚。

ic行业英语词汇IC 行业英语词汇IC (Integrated Circuit) 集成电路ASIC (Application-Specific Integrated Circuit)专用集成电路FPGA (Field Programmable Gate Array)现场可编程门阵列SoC (System-on-Chip)片上系统CPU (Central Processing Unit)中央处理器GPU (Graphics Processing Unit)图形处理器RAM (Random Access Memory)随机存取存储器ROM (Read-Only Memory)只读存储器SRAM (Static Random Access Memory) 静态随机存储器DRAM (Dynamic Random Access Memory)动态随机访问存储器Flash Memory闪存EEPROM (Electrically Erasable Programmable Read-Only Memory)电可擦可编程只读存储器NAND Flash Memory NAND 闪存NOR Flash Memory NOR 闪存SRAM-based FPGA基于SRAM的FPGAAntifuse-based FPGA基于断丝器的FPGAPLD (Programmable Logic Device)可编程逻辑器件CPLD (Complex Programmable Logic Device)复杂可编程逻辑器件PAL (Programmable Array Logic)可编程阵列逻辑GAL (Generic Array Logic)通用阵列逻辑PCB (Printed Circuit Board)印制电路板BGA (Ball Grid Array)球栅阵列QFN (Quad Flat No-Lead)无引脚扁平封装QFP (Quad Flat Package)无引脚扁平封装TQFP (Thin Quad Flat Package)超薄无引脚扁平封装LQFP (Low Profile Quad Flat Package)低轮廓无引脚扁平封装 SMT (Surface Mount Technology)表面贴装技术Through-hole Technology插孔技术Die Dice芯片Wafer晶圆Lithography光刻术Etching蚀刻Deposition沉积CMP (Chemical Mechanical Polishing)化学机械抛光Patterning图案制作Doping掺杂Front-End Processing前端工艺Back-End Processing后端工艺BEOL (Back-End Of Line)线路尾端工艺FEOL (Front-End Of Line)线路前端工艺EDA (Electronic Design Automation)电子设计自动化RTL (Register Transfer Level)寄存器传输级别HDL (Hardware Description Language)硬件描述语言VerilogVHDL (VHSIC Hardware Description Language)高速集成电路硬件描述语言SPICE (Simulation Program with Integrated Circuit Emphasis)电路模拟器CAD (Computer-Aided Design)计算机辅助设计CAM (Computer-Aided Manufacturing)计算机辅助制造PDK (Process Design Kit)工艺设计套件LVS (Layout Versus Schematic)版图和原理图比较DRC (Design Rule Check)器件设计规则检查ERC (Electrical Rule Check)电路规则检查Netlist网络列表Place and Route布局布线STA (Static Timing Analysis)静态时间分析DFT (Design for Testability)可测试性设计ATE (Automatic Test Equipment)自动测试设备JTAG (Joint Test Action Group)联合测试行动小组Boundary Scan边界扫描BIST (Built-In Self-Test)自测A/D (Analog-to-Digital)模数转换D/A (Digital-to-Analog)数模转换ADC (Analog-to-Digital Converter)模数转换器DAC (Digital-to-Analog Converter)数模转换器PLL (Phase Locked Loop)锁相环SERDES (Serializer/Deserializer)串行器/解串器I/O (Input/Output)输入/输出GPIO (General Purpose Input/Output)通用输入输出LVDS (Low Voltage Differential Signaling)低压差分信号LVPECL (Low Voltage Positive Emitter Coupled Logic)低电平正发射极耦合逻辑HDMI (High-Definition Multimedia Interface)高清晰度多媒体接口USB (Universal Serial Bus)通用串行总线SPI (Serial Peripheral Interface)串行外设接口I2C (Inter-Integrated Circuit)互联集成电路UART (Universal Asynchronous Receiver/Transmitter)通用异步收发器CAN (Controller Area Network)控制器局域网LIN (Local Interconnect Network)局域互连网FlexRayEthernet以太网TCP/IP (Transmission Control Protocol/Internet Protocol)传输控制协议/网络协议WiFi无线局域网RF (Radio Frequency)射频Bluetooth蓝牙ZigBeeNFC (Near Field Communication)近距离无线通信RFID (Radio Frequency Identification)无线射频识别。

集成电路的英文单词Integrated Circuit1. 解答与解释- 中文翻译为“集成电路”。

英语解释:An integrated circuit is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, normally silicon. It is a tiny device that contains many components such as transistors, resistors, and capacitors, which are interconnected to perform a specific function, like processing data in a computer or amplifying a signal in an electronic device.2. 词干(词根)、前缀、后缀的使用情况- “integrate”是这个词组中的词干(词根),它的意思是“使一体化;使整合”,源于拉丁语“integratus”,表示“使完整”。

“ - ed”是过去分词的后缀,表示被动或者完成的动作,在这里“integrated”表示已经被整合的。

“circuit”本身是一个单词,词源上来自拉丁语“circuitus”,表示“环行;巡回”,没有典型的前缀或后缀在这个词组里对它进行变形。

整个词组“Integrated Circuit”是一个名词短语,是由一个形容词(integrated)+名词(circuit)组成,表示一种特殊的电路,即经过整合的电路。

3. 不同词式及造句- Integrate(动词原形)- 英文:We need to integrate all these different systems into one.- 中文:我们需要把所有这些不同的系统整合为一个。

Household appliances 家用电器External storage 外存Environmentally friendly 对环境不造成伤害Speech recognition 语音识别Intellectual capital 智力资本Information technology industry 信息技术产业Alternative energy sources 替代能源Artificial intelligence 人工智能Attached files 附加文档Broadband communication systems 宽带通讯系统Chip technology 芯片技术Cyberspace 网络空间Digital video 数字视频E-business 电子商务Electrical power systems 电力系统Electronic banking service 电子银行业务Genetic engineering 基因工程Global positioning systems(GPS)全球定位系统Green power technology 绿色能源技术Greenhouse gas 温室气体Information technology industry 信息技术产业Instantaneous translator 同声翻译器Integrated circuits 集成电路Internet-enabled smart phones 可上网的智能电话Liquid crystal display 液晶显示器Market-based economies 市场经济Nuclear power plants 核电站Storage capacity 存储容量Vending machine 投币式自动售货机Video display monitors 视频显示器Video telephone 可视电话Virtual reality 虚拟现实Broadband communication system 宽带通讯系统Complete genetic makeup 全套的基因组合computer vision 计算机视觉Immune system 免疫系统Transgenic organisms 转基因生物体word processor 文字处理器Translate the following technical terms into English or Chinese:1) genetic engineering2) hormone insulin3) interferon4) complete geneticblueprint 5) hereditary material6) biomedical research7) multi-cellular organisms8) double helix of DNA9) inherited traits10) base pairs11) 人体生长激素12) 抗病毒物质13) 基因剪接14) 活的人体细胞15) 医学治疗16) 基因作图工程17) DNA重组技术18) 遗传特征carbon footprint(碳足迹)Ecological footprint (生态足迹)1. 低碳产品2。

特殊效果项目 special items电枢(电) armatures [electricity]电缆接头套 cables (junction sleeves for electric) 集成电路块 chips [integrated circuits]电线连接物 connections for electric lines电器接插件 connections, electric电器联接器 connectors [electricity]电源插座罩 covers for electric outlets导管(电) ducts [electricity]石墨碳精块 graphite carbon loaf家用遥控器 home used remote controler电缆接头套 junction sleeves for electric cables 电涌保护器 protectors (voltage surge –)电子管阳极 radio tube anode硒堆和硒片 selenium pile and selenium slice半导体器件 semiconductor apparatus电热保护套 socks, electrically heated闸盒(电) switchboxes [electricity]可变电感器 variometers电视荧光屏 video screens电涌保护器 voltage surge protectors氟氏聚光灯 fresnel spotlights香菇效果灯 mushroom effect lights月花效果灯 promoon幽浮效果灯 u.f.o. lights碳素材料 carbon material主照明员 chief lighting technician电磁线圈 coils (electromagnetic –)显色系统 color appearance system混色系统 color mixture system电器插头 contacts, electric电耦合器 couplings, electric摄影指导 director of photography 电导线管 electricity conduits电磁线圈 electromagnetic coils电子束管 electron beam tube照明组长 gaffer石墨电刷 graphite brush石墨电极 graphite electrode置景部门 grip department无缘极板 insulate pole plank集成电路 integrated circuits低压电源 low voltage power supply 对立色说 opponent color theory陶滤波器 pottery filter印刷电路 printed circuits石英晶体 quartz crystal遥控仪器 remote control apparatus 电阻材料 resistance material剧本指导 script supervisor电缆铠表 sheaths for electric cables 硅外延片 silicon extending slice稳压电源 stable electrical source 三原色说 trichromatic theory超高频管 uhf tube摄影灯具 t.v. lights放大器 amplifiers放大管 amplifying tubes放大管 amplifying valves阳极糊 anode paste调压器 booster电容器 capacitors碳精棒 carbon碳电刷 carbon brush碳电极 carbon electrode碳精片 carbon plate碳精粉 carbon powder断路器 circuit breakers闭路管 circuit closers电线圈 coils, electric集电器 collectors, electric整流器 commutators电容器 condensers [capacitors]电导体 conductors, electric电线管 conduits (electricity –)变压器 converters, electric整流器 current rectifiers消磁器 demagnetize ware发射管 emission tube碳精块 extractive carbon loaf泛光灯 flood lights荧光屏 fluorescent screens熔断器 fuse ware灯光师 gaffer母线槽 generatrix groove碳精粒 granular carbon换片员 loader保险丝 metal alloys (wires of –) [fuse wire] 互感器 mutual inductance ware启辉器 open switch ware示波管 oscillotron光电管 photovoltaic cells多晶硅 polysilicon电位器 potentiometer电子管 radio tube电阻器 resistances, electric变阻器 rheostats起动器 self-starter单晶硅 single crystal silicon升降机 snorke lift/condor闪光灯 strobes配电盘 switchboards电开关 switches, electric传感器 transducer光束球 ball rays天幕灯 cyclorama lights蝴蝶灯 derby跟随灯 follow spotlights摇摆灯 moveing head置物箱 par 64 case聚光灯 profile spotlights烟雾机 smoke machines碳管 carbon tube电工 electricians熔丝 fuses磁铁 magnets四盏 par 64雨灯 pin spotspar灯光杆及灯箱 par bars & par banks par聚光灯 par can。

Integrated circuit (IC)IntroducionIntegrated circuit also called microelectronic circuit or chip an assembly of electronic components, fabricated as a single unit, in which miniaturized active devices (e.g., transistors and diodes) and passive devices (e.g., capacitors and resistors) and their interconnections are built up on a thin substrate of semiconductor material (typically silicon). The resulting circuit is thus a small monolithic “chip,” which may be as small as a few square centimetres or only a few square millimetres. The individual circuit components are generally microscopic in size.Integrated circuits have their origin in the invention of the transistor in 1947 by William B. Shockley and his team at the American Telephone and Telegraph Company's Bell Laboratories. Shockley's team (including John Bardeen and Walter H. Brattain) found that, under the right circumstances, electrons would form a barrier at the surface of certain crystals, and they learned to control the flow of electricity through the crystal by manipulating this barrier. Controlling electron flow through a crystal allowed the team to create a device that could perform certain electrical operations, such as signal amplification, that were previously done by vacuum tubes. They named this device a transistor, from a combination of the words transfer and resistor (see photograph). The study of methods of creating electronic devices using solid materials became known as solid-state electronics. Solid-state devices proved to bemuch sturdier, easier to work with, more reliable, much smaller, and less expensive than vacuum tubes.Using the same principles and materials, engineers soon learned to create other electrical components, such as resistors and capacitors. Now that electrical devices could be made so small, the largest part of a circuit was the awkward wiring between the devices.In 1958 Jack Kilby of Texas Instruments, Inc., and Robert Noyce of Fairchild Semiconductor Corporation independently thought of a way to reduce circuit size further. They laid very thin paths of metal (usually aluminum or copper) directly on the same piece of material as their devices. These small paths acted as wires. With this technique an entire circuit could be “integrated” on a single piece of sol id material and an integrated circuit (IC) thus created. ICs can contain hundreds of thousands of individual transistors on a single piece of material the size of a pea. Working with that many vacuum tubes would have been unrealistically awkward and expensive. The invention of the integrated circuit made technologies of the Information Age feasible. ICs are now used extensively in all walks of life, from cars to toasters to amusement park rides.Basic IC typesAnalog versus digital circuitsAnalog, or linear, circuits typically use only a few components and are thus some of the simplest types of ICs. Generally, analog circuits are connected to devices that collect signals from the environment or send signals back to theenvironment. For example, a microphone converts fluctuating vocal sounds into an electrical signal of varying voltage. An analog circuit then modifies the signal in some useful way—such as amplifying it or filtering it of undesirable noise. Such a signal might then be fed back to a loudspeaker, which would reproduce the tones originally picked up by the microphone.Another typical use for an analog circuit is to control some device in response to continual changes in the environment. For example, a temperature sensor sends a varying signal to a thermostat, which can be programmed to turn an air conditioner, heater, or oven on and off once the signal has reached a certain value.A digital circuit, on the other hand, is designed to accept only voltages of specific given values. A circuit that uses only two states is known as a binary circuit. Circuit design with binary quantities, “on” and “off” representing 1 and 0 (i.e., true and false), uses the logic of Boolean algebra. The three basic logic functions—NOT, AND, and OR—together with their truth tables are given in the figure. (Arithmetic is also performed in the binary number system employing Boolean algebra.) These basic elements are combined in the design of ICs for digital computers and associated devices to perform the desired functions.Microprocessor circuitsMicroprocessors are the most complicated ICs. They are composed of millions of transistors that have been configuredas thousands of individual digital circuits, each of which performs some specific logic function. A microprocessor is built entirely of these logic circuits synchronized to each other.Just like a marching band, the circuits perform their logic function only on direction by the bandmaster. The bandmaster in a microprocessor, so to speak, is called the clock. The clock is a signal that quickly alternates between two logic states. Every time the clock changes state, every logic circuit in the microprocessor does something. Calculations can be made very quickly, depending on the speed (“clock frequency”) of the microprocessor.Microprocessors contain some circuits, known as registers, that store information. Registers are predetermined memory locations. Each processor has many different types of registers. Permanent registers are used to store the preprogrammed instructions required for various operations (such as addition and multiplication). Temporary registers store numbers that are to be operated on and also the result. Other examples of registers include the “program counter,” the “stack pointer,” and the “address” register.Microprocessors can perform millions of operations per second on data. In addition to computers, microprocessors are common in video game systems, televisions, cameras, and automobiles.Memory circuitsMicroprocessors typically have to store more data than can be held in a few registers. This additional information isrelocated to special memory circuits. Memory is composed of dense arrays of parallel circuits that use their voltage states to store information. Memory also stores the temporary sequence of instructions, or program, for the microprocessor. Manufacturers continually strive to reduce the size of memory circuits—to increase capability without increasing space. In addition, smaller components typically use less power, operate more efficiently, and cost less to manufacture.Digital signal processorsA signal is an analog waveform—anything in the environment that can be captured electronically. A digital signal is an analog waveform that has been converted into a series of binary numbers for quick manipulation. As the name implies, a digital signal processor (DSP) processes signals digitally, as patterns of 1s and 0s. For instance, using an analog-to-digital converter, commonly called an A-to-D or A/D converter, a recording of someone's voice can be converted into digital 1s and 0s. The digital representation of the voice can then be modified by a DSP using complex mathematical formulas. For example, the DSP algorithm in the circuit may be configured to recognize gaps between spoken words as background noise and digitally remove ambient noise from the waveform. Finally, the processed signal can be converted back (by a D/A converter) into an analog signal for listening. Digital processing can filter out background noise so fast that there is no discernible delay and the signal appears to be heard in “real time.” For instance, such processing enables “live” televisionbroadcasts to focus on a quarterback's signals in an American gridiron football game. DSPs are also used to produce digital effects on live television. For example, the yellow marker lines displayed during the football game are not really on the field; a DSP adds the lines after the cameras shoot the picture but before it is broadcast. Similarly, some of the advertisements seen on stadium fences and billboards during televised sporting events are not really there.Application-specific ICsAn application-specific IC (ASIC) can be either a digital or an analog circuit. As their name implies, ASICs are not reconfigurable; they perform only one specific function. For example, a speed controller IC for a remote control car is hard-wired to do one job and could never become a microprocessor. An ASIC does not contain any ability to follow alternate instructions.Radio-frequency ICsRadio-frequency ICs (RFICs) are rapidly gaining importance in cellular telephones and pagers. RFICs are analog circuits that usually run in the frequency range of 900 MHz to 2.4 GHz (900 million hertz to 2.4 billion hertz). They are usually thought of as ASICs even though some may be configurable for several similar applications. Most semiconductor circuits that operate above 500 MHz cause the electronic components and their connecting paths to interferewith each other in unusual ways. Engineers must use special design techniques to deal with the physics of high-frequency microelectronic interactions.Microwave monolithic ICsA special type of RFIC is known as a microwave monolithic IC (MMIC). These circuits run in the 2.4- to 20-GHz range, or microwave frequencies, and are used in radar systems, in satellite communications, and as power amplifiers for cellular telephones.Just as sound travels faster through water than through air, electron velocity is different through each type of semiconductor material. Silicon offers too much resistance for microwave-frequency circuits, and so the compound gallium arsenide (GaAs) is often used for MMICs. Unfortunately, GaAs is mechanically much less sound than silicon. It breaks easily, so GaAs wafers are usually much more expensive to build than silicon wafers.Basic semiconductor designAny material can be classified as one of three types: conductor, insulator, or semiconductor. A conductor (such as copper or salt water) can easily conduct electricity because it has an abundance of free electrons. An insulator (such as ceramic or dry air) conducts electricity very poorly because it has few or no free electrons. A semiconductor (such as silicon or gallium arsenide) is somewhere between a conductor and aninsulator. It is capable of conducting some electricity, but not much.Basic semiconductor designDoping siliconMost ICs are made of silicon, which is abundant in ordinary beach sand. Pure crystalline silicon, as with other semiconducting materials, has a very high resistance to electrical current at normal room temperature. However, with the addition of certain impurities, known as dopants, the silicon can be made to conduct usable currents. In particular, the doped silicon can be used as a switch, turning current off and on as desired.The process of introducing impurities is known as doping or implantation. Depending on a dopant's atomic structure, the result of implantation will be either an n-type (negative) or a p-type (positive) semiconductor. An n-type semiconductor results from implanting dopant atoms that have more electrons in their outer (bonding) shell than silicon, as shown in the figure. The resulting semiconductor crystal contains excess, or free, electrons that are available for conducting current. A p-type semiconductor results from implanting dopant atoms that have fewer electrons in their outer shell than silicon. The resulting crystal contains “holes” in its bonding structure where electrons would normally be located. In essence, such holes can move through the crystal conducting positive charges.Basic semiconductor designThe p-n junctionA p-type or an n-type semiconductor is not very useful on its own. However, joining these opposite materials creates what is called a p-n junction. A p-n junction forms a barrier to conduction between the materials. Although the electrons in the n-type material are attracted to the holes in the p-type material, the electrons are not normally energetic enough to overcome the intervening barrier. However, if additional energy is provided to the electrons in the n-type material, they will be capable of crossing the barrier into the p-type material—and current will flow. This additional energy can be supplied by applying a positive voltage to the p-type material,as shown in the figure. The negatively charged electrons will then be highly attracted to the positive voltage across the junction.A p-n junction that conducts electricity when energy is added to the n material is called forward-biased because the electrons move forward into the holes. If voltage is applied in the opposite direction—a positive voltage connected to the n side of the junction—no current will flow. The electrons in the n material will still be attracted to the positive voltage, but the voltage will now be on the same side of the barrier as the electrons. In this state a junction is said to be reverse-biased. Since p-n junctions conduct electricity in only one direction, they are a type of diode. Diodes are essential building blocks of semiconductor switches.Basic semiconductor designField-effect transistorsBringing a negative voltage close to the centre of a long strip of n-type material will repel nearby electrons in the material and thus form holes—that is, transform some of the strip in the middle to p-type material. This change in polarity utilizing an electric field gives the field-effect transistor its name. (See animation.) While the voltage is being applied, there will exist two p-n junctions along the strip, from n to p and then from p back to n. One of the two junctions will always be reverse-biased. Since reverse-biased junctions cannot conduct, current cannot flow through the strip. The field effect can be used to create a switch (transistor) to turn current off and on, simply by applying and removing a small voltage nearby in order to create or destroy reverse-biased diodes in the material.A transistor created by using the field effect is called a field-effect transistor (FET).The location where the voltage is applied is known as a gate. The gate is separated from the transistor strip by a thin layer of insulation to prevent it from short-circuiting the flow of electrons through the semiconductor from an input (source) electrode to an output (drain) electrode. Similarly, a switch can be made by placing a positive gate voltage near a strip of p-type material. A positive voltage attracts electrons and thus forms a region of n within a strip of p. This again creates two p-n junctions, or diodes. As before, one of the diodes will always be reverse-biased and will stop current from flowing. FETs are good for building logic circuits because they require only a small current during switching. No current is required for holding the transistor in an on or off state; a voltage willmaintain the state. This type of switching helps preserve battery life. A field-effect transistor is called unipolar (from “one polarity”) because the main conduction method is either holes or electrons, not both.Basic semiconductor designEnhancement mode FETsThere are two basic types of field-effect transistors. The type described previously is a depletion mode FET, since a region is depleted of its natural charge. The field effect can also be used to create what is called an enhancement mode FET by enhancing a region to appear similar to its surrounding regions.An n-type enhancement mode FET is made from two regions of n-type material separated by a small region of p. As this FET naturally contains two p-n junctions—two diodes—it is normally switched off. However, when a positive voltage is placed on the gate, the voltage attracts electrons and creates n-type material in the middle region, filling the gap that was previously p-type material, as shown in the animation. The gate voltage thus creates a continuous region of n across the entire strip, allowing current to flow from one side to the other. This turns the transistor on. Similarly, a p-type enhancement mode FET can be made from two regions of p-type material separated by a small region of n. The gate voltage required for turning on this transistor is negative. Enhancement mode FETs switch faster than depletion mode FETs because they require a change only near the surface under the gate, rather than all the way through the material, as shown in the figure.Basic semiconductor designComplementary metal-oxide semiconductorsRecall that placing a positive voltage at the gate of an n-type enhanced mode FET will turn the switch on. Placing the same voltage at the gate of a p-type enhanced mode FET will turn the switch off. Likewise, placing a negative voltage at the gate will turn the n-type off and the p-type on. These FETs always respond in opposite, or complementary, fashion to a given gate voltage. Thus, if the gates of an n-type and a p-type FET are connected, any voltage applied to the common gate will operate the complementary pair, turning one on and leaving the other off. A semiconductor that pairs n- and p-type transistors this way is called a complementary metal-oxide semiconductor (CMOS). Because complementary transistor pairs can quickly switch between two logic states, CMOSs are very useful in logic circuits. In particular, because only one circuit is on at any time, CMOSs require less power and are often used for battery-powered devices, such as in digital cameras, and for the special memory that holds the date, time, and system parameters in personal computers.Basic semiconductor designBipolar transistorsBipolar transistors simultaneously use holes and electrons to condu ct, hence their name (from “two polarities”). Like FETs, bipolar transistors contain p- and n-type materials configured ininput, middle, and output regions. In bipolar transistors, however, these regions are referred to as the emitter, the base, and the collector. Instead of relying, as FETs do, on a secondary voltage source to change the polarity beneath the gate (the field effect), bipolar transistors use a secondary voltage source to provide enough energy for electrons to punch through the reverse-biased base-collector junction (see figure). As the electrons are energized, they jump into the collector and complete the circuit. Note that even with highly energetic electrons, the middle section of p-type material must be extremely thin for the electrons to pass through both junctions.Designing ICsAll ICs use the same basic principles of voltage (V), current (I), and resistance (R). In particular, equations based on Ohm's law, V = IR, determine many circuit design choices. Design engineers must also be familiar with the properties of various electronic components needed for different applications.Designing ICsAnalog designAs mentioned earlier, an analog circuit takes an infinitely variable real-world voltage or current and modifies it in some useful way. The signal might be amplified, compared with another signal, mixed with other signals, separated from other signals, examined for value, or otherwise manipulated. For the design of this type of circuit, the choice of every individualcomponent, size, placement, and connection is crucial. Unique decisions abound—for instance, whether one connection should be slightly wider than another connection, whether one resistor should be oriented parallel or perpendicular to another, or whether one wire can lie over the top of another. Every small detail affects the final performance of the end product. When integrated circuits were much simpler, component values could be calculated by hand. For instance, a specific amplification value (gain) of an amplifier could typically be calculated from the ratio of two specific resistors. The current in the circuit could then be determined, using the resistor value required for the amplifier gain and the supply voltage used. As designs became more complex, laboratory measurements were used to characterize the devices. Engineers drew graphs of device characteristics across several variables and then referred to those graphs as they needed information for their calculations. As scientists improved their characterization of the intricate physics of each device, they developed complex equations that took into account subtle effects that were not apparent from coarse laboratory measurements. For example, a transistor works very differently at different frequencies, sizes, orientations, and placements. In particular, scientists found parasitic components (unwanted effects, usually resistance and capacitance) that are inherent in the way the devices are built.Designing ICsDigital designSince digital circuits involve millions of times as manycomponents as analog circuits, much of the design work is done by copying and reusing the same circuit functions, especially by using digital design software that contains libraries of prestructured circuit components. The components available in such a library are of similar height, contain contact points in predefined locations, and have other rigid conformities so that they fit together regardless of how the computer configures a layout. While SPICE is perfectly adequate for analyzing analog circuits, with equations that describe individual components, the complexity of digital circuits requires a less-detailed approach. Therefore, digital analysis software ignores individual components for mathematical models of entire preconfigured circuit blocks (or logic functions).Whether analog or digital circuitry is used depends on the function of a circuit. The design and layout of analog circuits are more demanding of teamwork, time, innovation, and experience, particularly as circuit frequencies get higher, though skilled digital designers and layout engineers can be of great benefit in overseeing an automated process as well. Digital design emphasizes different skills from analog design.集成电路(IC)引言集成电路也称为微电子电路或芯片的电子元件,作为一个单元,其中微型有源器件(如晶体管和二极管)和无源器件(例如,电容器和电阻器)和他们的互连是建立在制造薄基板的半导体材料(通常是硅)。

Integrated Circuits集成电路The Integrated CircuitDigital logic and electronic circuits derive their functionality from electronic switches called transistor. (数字逻辑和电子电路由称为晶体管的电子开关得到它们的(各种)功能。

)Roughly speaking, the transistor can be likened to an electronically controlled valve whereby ener gy applied to one connection of the valve enables energy to flow between two other connections .By combining multiple transistors, digital logic building blocks such as AND gates and flip-flops ar e formed. Transistors, in turn, are made from semiconductors. (粗略地说,晶体管好似一种电子控制阀,由此加在阀一端的能量可以使能量在另外两个连接端之间流动。

通过多个晶体管的组合就可以构成数字逻辑模块,如与门和触发电路等。

而晶体管是由半导体构成的。

)Consult a periodic table of elements in a college chemistry textbook, and you will locate semicon ductors as a group of elements separating the metals and nonmetals.They are called semiconduct ors because of their ability to behave as both metals and nonmetals.(查阅大学化学书中的元素周期表,你会查到半导体是介于金属与非金属之间的一类元素。

它们之所以被叫做半导体是由于它们表现出来的性质类似于金属和非金属。

)A semiconductor can be made to conduct electricity like a metal or to insulate as a nonmetal doe s. These differing electrical properties can be accurately controlled by mixing the semiconductor with small amounts of other elements. This mixing is called doping.(可使半导体像金属那样导电,或者像非金属那样绝缘。

通过半导体和少量其它元素的混合可以精确地控制这些不同的电特性。

这种混合技术称之为“半导体掺杂”。

)A semiconductor can be doped to contain more electrons (N-type) or fewer electrons (P-type). Ex amples of commonly used semiconductors are silicon and germanium. Phosphorous and boron ar e two elements that are used to dope N-type and P-type silicon, respectively. (半导体通过掺杂可以包含更多的电子(N型)或更少的电子(P型)。

常用的半导体是硅和锗,N型硅半导体掺入磷元素,而P型硅半导体掺入硼元素。

)A transistor is constructed by creating a sandwich of differently doped semiconductor layers. The two most common types of transistors, the bipolar-junction transistor (BJT) and the field-ef fect transistor (FET) are schematically illustrated.This figure shows both the silicon structures of th ese elements and their graphical symbolic representation as would be seen in a circuit diagram. The BJT shown is an NPN transistor, because it is composed of a sandwich of N-P-N doped silicon.(不同掺杂的半导体层形成的三明治状夹层结构可以构成一个晶体管,最常见的两类晶体管是双极型晶体管(BJT)和场效应晶体管(FET),这些晶体管的硅结构,以及它们用于电路图中的符号。

BJT是NPN型晶体管,因为由N—P—N掺杂硅三层构成。

)When a small current is injected into the base terminal, a larger current is enabled to flow from t he collector to the emitter.The FET shown is an N-channel FET, which is composed of two N-type r egions separated by a P-type substrate. When a voltage is applied to the insulated gate terminal, a current is enabled to flow from the drain to the source. It is called N-channel, because the gatevoltage induces an N-channel within the substrate, enabling current to flow between the N-regio ns. (当小电流注入基极时,可使较大的电流从集电极流向发射极。

)(图示的FET是N沟道的场效应型晶体管,它由两块被P型基底分离的N型组成。

)(将电压加在绝缘的栅极上时,可使电流由漏极流向源极。

)(它被叫做N沟道是因为栅极电压诱导基底上的N通道,使电流能在两个N区域之间流动。

)Another basic semiconductor structure is a diode, which is formed simply by a junction of N-type and P-type silicon.(另一个基本的半导体结构是二极管,由N型和P型硅连接而成的结组成。

)Diodes act like one-way valves by conducting current only from P to N.Special diodes can be creat ed that emit light when a voltage is applied. Appropriately enough, these components are called l ight emitting diodes, or LEDs. (二极管的作用就像一个单向阀门,由于电流只能从P流向N。

)(可以构建一些特殊二极管,加电压时可以发光,这些器件被叫做发光二极管或LED。

)These small lights are manufactured by the millions and are found in diverse applications from tel ephones to traffic lights. (这种小灯泡数以百万计地被制造出来,有各种各样的应用,从电话机到交通灯。

)The resulting small chip of semiconductor material on which a transistor or diode is fabricated ca n be encased in a small plastic package for protection against damage and contamination from th e out-side world.Small wires are connected within this package between thesemiconductor sandwich and pins that protrude from the package to make electrical contact with other parts of the intended circuit. Once you have several discrete transistors, digital logic can be built by directly wiring these components together. The circuit will function, but any substantial a mount of digital logic will be very bulky, because several transistors are required to implement ea chof the various types of logic gates.(半导体材料上制作晶体管或二极管所形成的小芯片用塑料封装以防损伤和被外界污染。

在这封装里一些短线连接半导体夹层和从封装内伸出的插脚以便与(使用该晶体管的)电路其余部分连接。

一旦你有了一些分立的晶体管,直接用电线将这些器件连线在一起就可以构建数字逻辑(电路)。

电路会工作,但任何实质性的数字逻辑(电路)都将十分庞大,因为要在各种逻辑门中每实现一种都需要多个晶体管。

)At the time of the invention of the transistor in 1947 by John Bardeen, Walter Brattain, and Willia m Shockley, the only way to assemble multiple transistors into a single circuit was to buy separate discrete transistors and wire them together. (1947年,John Bardeen、Walter Brattain 和and William Shockley发明晶体管的时候。