02-北美电池储能系统标准和法规简介-周飞

- 格式:pdf

- 大小:1.27 MB

- 文档页数:32

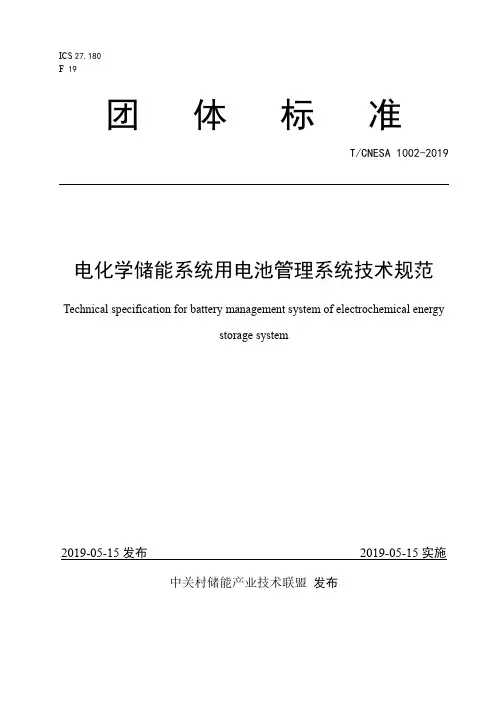

ICS 27.180F 19团体标准T/CNESA 1002-2019电化学储能系统用电池管理系统技术规范Technical specification for battery management system of electrochemical energystorage system2019-05-15发布2019-05-15实施中关村储能产业技术联盟发布T/CNESA 1002—2019目次前言 (II)1 范围 (1)2规范性引用文件 (1)3术语和定义 (1)4 符号和缩略语 (4)5 技术要求 (4)5.1 一般要求 (4)5.2 使用环境要求 (4)5.3 功能要求 (5)5.4 状态参数检测精度要求 (6)5.5 计算要求 (7)5.6 电池故障诊断 (7)5.7 绝缘性能要求 (7)5.8 电气性能要求 (8)5.9 环境适应性能 (8)5.10 电磁兼容性能 (9)6 试验方法 (10)6.1 试验条件 (10)6.2 状态参数检测精度 (10)6.3 计算精度 (11)6.4 均衡测试 (11)6.5 电池故障诊断 (11)6.6 绝缘性能 (11)6.7 电气适应性能 (12)6.8 环境适应性能 (12)6.9 电磁兼容性能 (13)7 检验规则 (14)7.1 检验分类 (14)7.2 出厂检验 (14)7.3 型式检验 (14)8 标志、包装、贮存和运输 (14)8.1 标志 (14)8.2 包装 (16)8.3 贮存 (16)8.4 运输 (16)附录A(规范性附录) SOC、SOE计算精度测试方法 (17)附录B(规范性附录)均衡测试方法 (19)附录C(资料性附录)电池系统典型充放电工况 (20)IT/CNESA 1002—2019II 前言本标准按照GB/T 1.1-2009给出的规则起草。

本标准由中关村储能产业技术联盟提出并归口。

本标准起草单位:杭州高特电子设备股份有限公司、广州智光储能科技有限公司、浙江正泰新能源开发有限公司、国网江苏电力设计咨询有限公司、国网江苏省电力有限公司经济技术研究院。

储能系统国标储能系统是能够将电能等形式的能量在一定时间内存储起来,并在需要时进行释放的设备。

随着新能源技术和智能电网的不断发展,储能系统在现代能源领域扮演着重要角色。

为了统一行业规范和提高储能系统的可靠性、安全性和效能,我国制定了储能系统的国家标准,下面将从几个方面进行介绍。

首先,储能系统国标规定了储能技术的分类和定义。

储能技术包括机械能储能、电化学储能、超级电容储能和储热技术等,每种技术都有其独特的特点和应用领域。

国标的明确分类有助于企业和研究机构在研发和生产中选择适合自身需求和市场需求的储能技术。

其次,储能系统国标对储能系统的安全性和可靠性进行了要求。

储能系统是一项涉及高压、高能量密度的技术,若不按规范进行设计、制造和运行,可能出现潜在的安全隐患和事故风险。

国标对储能系统的电气、机械和热管理等方面提出了严格要求,确保系统的安全性和可靠性,并为监测、检测和保护等环节提供了相关指导。

第三,储能系统国标规范了储能系统的性能评估和测试方法。

为了能够客观、准确地评估储能系统的性能和效果,国标制定了一系列的测试标准和方法。

这些标准和方法涵盖了储能系统的能量转换效率、储能容量、循环寿命、功率响应时间等多个方面,可供制造商、用户和第三方机构使用,提供数据支持和参考依据。

最后,储能系统国标对储能设备的设计、制造和运营管理提出了具体的技术要求和指导。

例如,国标规定了储能设备的外观尺寸、接口标识、安装要求等方面的内容,以保证不同厂家的产品在物理和电气接口上的兼容性。

此外,国标还对储能系统的容量配置、电网接入和储能调度等方面进行了要求,为运营商和用户提供了设计和管理储能系统的指南。

综上所述,储能系统国标是我国在储能技术领域标准化工作的重要成果,对于推动产业发展、促进技术创新和提高能源利用效率具有重要意义。

通过遵循国标的要求,储能系统从设计、制造到运营管理过程中能够更好地实现安全、可靠、高效运行,为新能源发展和能源转型提供强有力的支持。

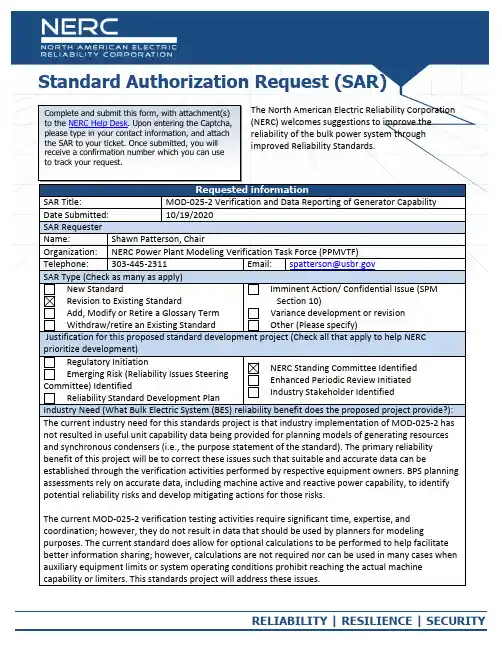

Standard Authorization Request (SAR)The North American Electric Reliability Corporation (NERC) welcomes suggestions to improve the reliability of the bulk power system through improved Reliability Standards.Complete and submit this form, with attachment(s) to the NERC Help Desk . Upon entering the Captcha, please type in your contact information, and attach the SAR to your ticket. Once submitted, you will receive a confirmation number which you can use to track your request.Requested informationOther benefits of this standards project to address issues with MOD-025-2 include, but are not limited to, the following:•Preventing over- or under-estimation of generating facility active and reactive power, which could lead to potential reliability risks or unnecessary and expensive solutions to mitigate •Identifying limitations within a generating facility that could constrain the resource from reaching the expected active/reactive capability at any given time•More clearly communicating the necessary data to be used for modeling the respective resources in steady-state power flow models•Ensure that the data users are part of the verification process to ensure that the necessary and usable data is provided and utilized appropriately•Ensure that raw test data alone is not used for resource modeling, but is analyzed, adjusted, and contextualized to account for measured system conditions•Coordinating with PRC-019 activities to develop a composite capability curve, inclusive of equipment capabilities, limiters, and other plant limitations to develop an appropriate capability curve•Ensuring that other means of verification (other than testing) can be more effectively leveraged to gather necessary and suitable data for verifying plant/machine capabilityPurpose or Goal (How does this proposed project provide the reliability-related benefit described above?):The intent of this standard revision project is to address the issues that exist with MOD-025-2 regarding verification and data reporting of generator active and reactive power capability (and any other relevant equipment capability). Currently, implementation of the standard rarely produces data that is suitable for planning models (i.e., the stated purpose of the standard). The vast majority of testing cases are limited by limits within the plant or system operating conditions that prohibit the generating resource from reaching its “composite capability curve” – the equipment capability or associated limiters. The goal of the proposed project is to:•Ensure that testing and other verification activities produce useful data for verification of plant active and reactive power capability•Ensure that the data is used by Transmission Planners and Planning Coordinators in an appropriate manner, with a sufficient degree of analysis prior to use•Ensure that the data is applicable and usable by the Transmission Planner and Planning Coordinator for reliability studies•Ensure Generator Owners appropriately identify limits within their generating resources (and synchronous condensers), and effectively communicate those limits to Transmission Plannersand Planning Coordinators for the purposes of modeling these resources in reliability studiesRequested informationProject Scope (Define the parameters of the proposed project):The scope of this project is to modify MOD-025-2 to ensure that data provided through verification activities performed by applicable Generator Owner or Transmission Owners produce suitable data for the purposes of developing accurate planning models in Transmission Planner and Planning Coordinator reliability studies. The project should consider, at a minimum, the following:1.Revisions to MOD-025-2 to ensure that verification activities produce data and information thatcan be used by Transmission Planners and Planning Coordinators for the purposes of developing accurate and reasonable plant active and reactive capability data (including possiblyrepresentation of the “composite capability curve” inclusive of capability and limiters, whereapplicable).2.Ensure that each Planning Coordinator and the area Transmission Planners developrequirements for the Planning Coordinator area real and reactive capability data verification3.Ensure that Generator Owners provide the data specified by the Planning Coordinator andTransmission Planners for the Planning Coordinator area4.Ensure that verification activities can apply other methods beyond only testing (or real-timedata) that allow plant capability information, protection settings, PRC-019 reports, and otherdocumentation to also complement the verification activities5.Ensure that data provided by the applicable Generator Owners and Transmission Owners isanalyzed and used appropriately by Transmission Planners and Planning Coordinators6.Ensure that the data provided by Generator Owners, if different from tested values, isacceptable to the Planning Coordinator and Transmission Planners with the standard providing guidance on acceptable reactive capability reporting if system conditions prevent reaching actual capability.7.Ensure alignment of the MOD-025 standard with MOD-032-1 regarding data submittals forannual case creation and PRC-019-2 regarding collection of information that can be effectivelyused for verification purposes. Ensure activities across standards can be applied to effectivelymeet the purpose of these standards, and avoid any potential overlap or duplication of activities.This is dependent on the success of bullet number 1.8.Ensure that equipment limitations are documented and classified as expected (e.g., systemvoltage limit reached) or unexpected (e.g., plant tripped or excitation limiter reachedunexpectedly). In cases of unexpected limitations reached, ensure that the equipment ownerdevelops and implements a corrective action plan to address this unexpected limitation.Requested informationDetailed Description (Describe the proposed deliverable(s) with sufficient detail for a drafting team to execute the project. If you propose a new or substantially revised Reliability Standard or definition, provide: (1) a technical justification1 which includes a discussion of the reliability-related benefits of developing a new or revised Reliability Standard or definition, and (2) a technical foundation document (e.g., research paper) to guide development of the Standard or definition):The NERC PPMVTF developed White Paper: Implementation of NERC Standard MOD-025-22 that recommends NERC initiate a standards project to address these issues with MOD-025-2. The white paper provides a detailed description and technical justification of the gaps that exist in MOD-025-2 and how the current standard may be leading to inaccurate data being used in BPS reliability studies. Further, the NERC PPMVTF Reliability Guideline: Power Plant Model Verification and Testing for Synchronous Machines3also describes in detail how testing activities per MOD-025-2 can lead to unusable data, and provides further guidance that a SDT could use to develop solutions to these issues.Cost Impact Assessment, if known (Provide a paragraph describing the potential cost impacts associated with the proposed project):The aforementioned NERC PPMVTF White Paper: Implementation of NERC Standard MOD-025-2 includes an example of one Registered Entity’s MOD-025 implementation costs (excluding cost of shifting the optimization of generation fleet assets due to minimum load testing requirements). The entity’s average test cost was $1,259 (897 tests) and $4,326 per generator (261 generators). The verification testing of units generally results in transferring energy to a higher cost resource during the test period. Further, the data produced is often NOT suitable for planning studies, which does not serve the intended purpose of the standard and makes the added cost unjustified.Please describe any unique characteristics of the BES facilities that may be impacted by this proposed standard development project (e.g., Dispersed Generation Resources):The current MOD-025-2 was written around synchronous generation, although it is not specifically applicable only to synchronous generators. Therefore, the project should ensure the language is clear and concise regarding how to handle BES dispersed generating resources (e.g., wind, solar photovoltaic, and battery energy storage systems).To assist the NERC Standards Committee in appointing a drafting team with the appropriate members, please indicate to which Functional Entities the proposed standard(s) should apply (e.g., Transmission Operator, Reliability Coordinator, etc. See the most recent version of the NERC Functional Model for definitions):•Generator Owner and Transmission Owner of synchronous condensers (asset owner that is in the best position to ascertain resource capability)1 The NERC Rules of Procedure require a technical justification for new or substantially revised Reliability Standards. Please attach pertinent information to this form before submittal to NERC.2https:///comm/PC/Power%20Plant%20Modeling%20and%20Verification%20Task%20Force/PPMVTF_White_Paper_MOD-025_Testing.pdf3https:///comm/PC_Reliability_Guidelines_DL/Reliability_Guideline_-_PPMV_for_Synchronous_Machines_-_2018-06-29.pdfRequested information•Transmission Planner and Planning Coordinator (user of the information provided by the Generator Owner; currently has no responsibility of ensuring accurate data per current MOD-025-2 standard)Do you know of any consensus building activities4 in connection with this SAR? If so, please provide any recommendations or findings resulting from the consensus building activity.The NERC PPMVTF White Paper, approved by NERC RSTC, details the challenges with MOD-025-2. The team deliberated this subject for a significant amount of time, and have identified major issues with the standard that need to be addressed by an SDT. The PPMVTF believes that a significant revision to MOD-025-2 is needed, that testing activities are useful and should be retained, but that the activities can focus on more effective means of collecting useful data for planning models. One dissenting opinion of PPMVTF membership believed the standard should be retired completely and not replaced with an alternative.Are there any related standards or SARs that should be assessed for impact as a result of this proposed project? If so, which standard(s) or project number(s)?The NERC standards development Project 2020-02 (Transmission-connected Dynamic Reactive Resources) SAR includes MOD-025-2, specifically addressing the applicability of transmission connected reactive devices in addition to generators and synchronous condensers.The SAR on PRC-019-2 submitted to NERC by the System Protection and Control Subcommittee is also related in that there is significant overlap of activities in PRC-019-2 and the development of planning models of machine capability.This SAR could be combined with those portions of those SARs to address this problem effectively. Are there alternatives (e.g., guidelines, white paper, alerts, etc.) that have been considered or could meet the objectives? If so, please list the alternatives.There are two key industry reference documents on this subject:1.NERC Reliability Guideline: Power Plant Model Verification and Testing for SynchronousMachines5 (July 2018) that provides recommended practices for synchronous machine capability testing. An appendix is devoted to MOD-025-2 testing, and highlights the challenges andinherent errors in MOD-025-2 to obtain useful data that can be applied for planning models.2.NATF Modeling Reference Document Reporting and Verification of Generating Unit ReactivePower Capability for Synchronous Machines6(April 2015) that describes testing activities perMOD-025-2 and means of ensuring data is sufficient for planning studies.4 Consensus building activities are occasionally conducted by NERC and/or project review teams. They typically are conducted to obtain industry inputs prior to proposing any standard development project to revise, or develop a standard or definition.5https:///comm/PC_Reliability_Guidelines_DL/Reliability_Guideline_-_PPMV_for_Synchronous_Machines_-_2018-06-29.pdf 6https:///docs/natf/documents/resources/planning-and-modeling/natf-reference-document-reporting-and-verification-of-generating-unit-reactive-power-capability-for-synchronous-machines.pdfRequested informationNeither industry reference document addresses the identified shortcomings of the standard described above and in NERC PPMVTF White Paper: Implementation of NERC Standard MOD-025-2.7 These reference materials help industry understand how to implement the standards using best practices, but do not address the reliability gaps created by the standard requirements themselves which is leading to inaccurate data being used in planning assessments.Market Interface PrinciplesDoes the proposed standard development project comply with all of the following Market Interface Principles?Enter (yes/no)1. A reliability standard shall not give any market participant an unfair competitiveadvantage. Yes2. A reliability standard shall neither mandate nor prohibit any specific marketstructure. Yes3. A reliability standard shall not preclude market solutions to achieving compliancewith that standard. Yes7https:///comm/PC/Power%20Plant%20Modeling%20and%20Verification%20Task%20Force/PPMVTF_White_Paper_MOD-025_Testing.pdfMarket Interface Principles 4. A reliability standard shall not require the public disclosure of commercially sensitive information. All market participants shall have equal opportunity to access commercially non-sensitive information that is required for compliance with reliability standards. Yes Identified Existing or Potential Regional or Interconnection Variances Region(s)/ Interconnection Explanation N/A None identified.For Use by NERC Only Version History Version Date Owner Change Tracking1June 3, 2013 Revised 1August 29, 2014 Standards Information Staff Updated template 2January 18, 2017 Standards Information Staff Revised 2June 28, 2017 Standards Information Staff Updated template 3February 22, 2019 Standards Information Staff Added instructions to submit via Help Desk 4February 25, 2020 Standards Information Staff Updated template footer。

储能行业相关标准

储能行业是近年来快速发展的领域,随着技术的不断进步和应用场景的不断扩展,储能行业的相关标准也在不断完善。

以下是一些储能行业相关的标准:

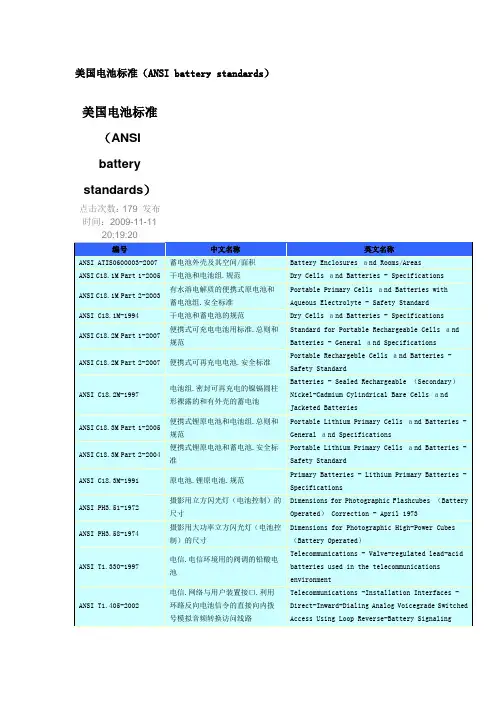

电池标准:电池是储能系统中的核心组件,因此电池的标准对于储能系统的性能和安全性至关重要。

目前,国际上通用的电池标准包括IEC 62133、IEC 62619等,这些标准规定了电池的尺寸、重量、容量、电压、电流等参数,以及电池的安全性、可靠性等方面的要求。

储能系统标准:储能系统是将电池与其他设备集成在一起的系统,因此储能系统的标准也是非常重要的。

目前,国际上通用的储能系统标准包括IEEE 1547、IEEE 1547.1等,这些标准规定了储能系统的设计、制造、安装、运行等方面的要求,以确保储能系统的安全性和可靠性。

储能电站标准:储能电站是储能系统的重要组成部分,因此储能电站的标准也是非常重要的。

目前,国际上通用的储能电站标准包括IEEE 1547.2、IEEE 1547.3等,这些标准规定了储能电站的设计、制造、安装、运行等方面的要求,以确保储能电站的安全性和可靠性。

充电设备标准:充电设备是储能系统中的重要组成部分,因此充电设备的标准也是非常重要的。

目前,国际上通用的充电设备标准包括IEC 62196等,这些标准规定了充电设备的尺寸、重量、功率等方面的要求,以及充电设备的安全性、可靠性等方面的要

求。

总之,储能行业的相关标准是保证储能系统安全性和可靠性的重要保障。

随着技术的不断进步和应用场景的不断扩展,这些标准也将不断完善和更新。

可充电储能系统功能安全国际标准在当今的社会中,可充电储能系统的应用范围越来越广泛,从家用电器到电动汽车再到可再生能源的储能系统,都需要可靠的储能系统来支撑其安全和高效运行。

而要保证这些储能系统的功能安全,国际标准扮演了至关重要的角色。

本文将对可充电储能系统功能安全国际标准进行深度和广度兼具的探讨,希望通过本文的阐述,我能更全面、深刻和灵活地理解这一重要主题。

1. 可充电储能系统功能安全的重要性可充电储能系统功能安全,是指在正常使用和预期失效条件下,系统不会对人、环境或财产造成不可接受的危害。

随着储能技术的不断发展和应用,功能安全成为了保障储能系统安全可靠运行的重要保障。

在实际应用中,如果储能系统出现功能安全问题,不仅会损害设备本身,还有可能引发火灾、爆炸等严重事故,造成不可估量的损失。

建立健全的可充电储能系统功能安全国际标准势在必行。

2. 相关的国际标准和组织目前,可充电储能系统功能安全的国际标准主要包括ISO 26262(汽车电子系统功能安全标准)、IEC 62109(可充电储能系统的安全标准)、IEC 61508(电气/电子/编程系统的功能安全标准)等。

这些国际标准覆盖了多个领域,涉及到汽车、航空航天、工业控制等多个方面。

在国际标准的制定和推广过程中,国际电工委员会(IEC)、国际标准化组织(ISO)等国际组织发挥着举足轻重的作用,不断推动着标准的更新和完善。

3. 可充电储能系统功能安全的评估和验证要保证可充电储能系统的功能安全,评估和验证是必不可少的环节。

评估和验证工作通常包括对硬件、软件、通信等多个方面的检测和测试,以确保系统在各种情况下均能保持安全可靠的运行状态。

评估和验证还需要考虑到系统的整体性能、可靠性以及与外部环境的互动等因素,这需要综合考虑多个因素并进行全面的分析。

4. 个人观点和理解作为文章写手,我认为可充电储能系统功能安全国际标准的制定和推广对于整个可充电储能行业都具有重要的意义。

液流电池储能技术国际标准1. 引言本标准为液流电池储能技术的国际标准,旨在规范液流电池储能技术的设计、制造和使用过程,提高能源存储系统的安全性、可靠性和性能。

本标准适用于液流电池储能技术的全球应用。

2. 术语和定义2.1 液流电池:一种以液态电解质为储能介质的电化学储能装置。

2.2 电池容量:电池储存和释放能量的最大能力。

2.3 电池效率:电池在储存和释放能量过程中的能量转化效率。

2.4 循环寿命:电池循环充放电次数达到指定容量损失的次数。

2.5 安全性:电池在正常使用和异常情况下的安全性能。

3. 设计要求3.1 液流电池应具备高能量密度、高功率性能和高效率。

3.2 液流电池应具备可扩展性和模块化设计,以便适应不同应用场景的需求。

3.3 电池设计应考虑充放电效率、循环寿命和安全性。

4. 制造要求4.1 电池制造过程应符合相关工艺规范,并且采用合适的质量管理体系。

4.2 电池的关键组件应具备稳定的性能和高质量制造。

4.3 电池的组装应符合相关安全和操作规程。

5. 使用要求5.1 液流电池储能系统应具备完善的监测和控制系统,以确保安全和正常运行。

5.2 液流电池储能系统应具备适应不同应用场景的灵活性和可靠性。

5.3 液流电池储能系统的维护保养应符合相关规定,并定期进行检测和维修。

6. 测试方法6.1 电池容量测试应采用标准充放电方式进行,以确保测试结果的可靠性和一致性。

6.2 电池效率测试应采用合适的测试方法,以评估电池在充放电过程中的能量转化效率。

6.3 循环寿命测试应模拟实际使用情况,进行充放电循环,并记录电池容量损失的次数。

6.4 安全性测试应包括电池的过充、过放、短路等异常情况下的安全性能评估。

7. 标识和文档要求7.1 液流电池应标识清晰可见的产品信息,包括生产厂商、型号、批次等。

7.2 液流电池应配备使用说明书和安全警示标识,以指导用户正确使用和维护电池。

7.3 生产厂商应提供相关的产品性能和安全性测试报告。

ERO ENTERPRISE-ENDORSED Standard ApplicationGuidePRC-002-2Clarification of Fault Recorder (FR) Trigger Setting RequirementsFebruary 20, 2020Table of ContentsPREFACE (3)DISCLAIMER (4)INTRODUCTION (5)Overview (5)Methodology (5)Common Terms and Definitions (5)EVALUATING PRC-002-2, SECTION 4 - APPLICABILITY (6)Analysis or Recommended Application Guidance: (6)EVALUATING PRC-002-2, REQUIREMENTS (6)Analysis or Recommended Application Guidance: (6)Recommendations (6)Standard Application Guide PrefacePREFACEMidwest Reliability Organization (MRO) is dedicated to its vision of a highly reliable and secure North American bulk power system. To ensure reliability of the bulk power system in the United States, Congress passed the Energy Policy Act of 2005, creating a new regulatory organization called the Electric Reliability Organization (ERO) to establish mandatory Reliability Standards and monitor and enforce compliance with those standards on those who own, operate or use the interconnected power grid.In 2006, the Federal Energy Regulatory Commission (FERC)approved the North American Electric Reliability Corporation(NERC) as the ERO under section 215(e)(4) of the FederalPower Act. NERC delegates its authority to monitor andenforce compliance to seven Regional Entitiesestablished across North America, of which MRO is one.Recognizing the international nature of the grid, NERC asthe ERO, along with MRO, established similararrangements with provincial authorities in Canada.The MRO region spans the provinces of Saskatchewan andManitoba, and all or parts of the states of Arkansas, Illinois,Iowa, Kansas, Louisiana, Michigan, Minnesota, Missouri,Montana, Nebraska, New Mexico, North Dakota, Oklahoma,South Dakota, Texas, and Wisconsin. The region includesapproximately 200 organizations that are involved in theproduction and delivery of electricity, including municipalutilities, cooperatives, investor-owned utilities, transmissionsystem operators, federal power marketing agencies,Canadian Crown Corporations, and independent powerproducers.MRO's primary responsibilities are to: ensure compliance withmandatory Reliability Standards by entities who own, operate, or use theNorth American bulk power system; conduct assessments of the grid's abilityto meet electricity demand in the region; and analyze regional system events.Additionally, MRO creates an open forum for stakeholder experts in the region to discuss importanttopics related to addressing risk and improving reliable operations of the bulk power system.Standard Application Guide DisclaimerDISCLAIMERThe Midwest Reliability Organization (MRO) Compliance Monitoring and Enforcement Advisory Council (CMEPAC) is committed to providing training and non-binding guidance to industry stakeholders regarding existing and emerging Reliability Standards. Any materials, including presentations, were developed through the MRO CMEPAC by Subject Matter Experts (SMEs) from member organizations within the MRO region.SMEs in the field of disturbance monitoring were brought together to prepare a guide for complying with North American Electric Reliability Corporation (NERC) Reliability Standard PRC-002-2 - Disturbance Monitoring and Reporting Requirements. Participants include representatives from Generator Owners (GOs) and Transmission Owners.PRC-002-2 Application Guide – Development Team Subject Matter ExpertsChris RoemmichBasin Electric Power Cooperative Dejan LeginovicGreat River EnergyKenneth KoelWestern Area Power AdministrationRandy PynenbergAmerican Transmission Company Stan ToewsManitoba HydroTodd LawsonAlliant EnergyThe materials have been reviewed by MRO staff and provide reasonable application guidance for the standard(s) addressed. Ultimately, demonstrating compliance depends on a number of factors including the precise language of the standard, the specific facts and circumstances, and quality of evidence.These documents may be reproduced or distributed to any person or entity only in its entirety.The MRO Subject Matter Expert Team is an industry stakeholder group which includes subject matter experts from MRO member organizations in various technical areas. Any materials, guidance, and views from stakeholder groups are meant to be helpful to industry participants; but should not be considered approved or endorsed by MRO staff or its board of directors unless specified.Standard Application Guide IntroductionINTRODUCTIONThe purpose of this Standard Application Guide (SAG) for NERC Reliability Standard PRC-002-2 - Disturbance Monitoring and Reporting Requirements is to provide additional guidance on the implementation of PRC-002-2 to Generator Owners (GOs) and Transmission Owners (TOs) when protective relays are used to meet PRC-002-2 requirements.OverviewThis SAG focuses on the trigger setting requirements of PRC-002-2 R4.3 when using protective relays to meet PRC-002-2 requirements. This SAG makes recommendations on FR triggers in the protective relay to comply with PRC-002-2 R4.3 but at the same time prevent excessive event triggering which could result in the loss of meaningful system event records due to exceeding the event logging capabilities of the relay. MethodologyThis SAG contains clarifications, techniques and recommendations, collectively the ‘suggested methodology’, to adhere to the requirements of the PRC-002-2 R4.3. These methods represent the intended best practices of members of the MRO PRC-002-2 Subject Matter Expert Team (SMET). Common Terms and DefinitionsThis SAG uses terms defined in the NERC Glossary of Terms used in NERC Reliability Standards, updated July 03, 20181. Where the MRO PRC-002-2 SMET introduced terms not defined by NERC, as necessary, inline definitions or narratives around the intent of those terms has been provided.1 NERC Glossary of Terms used in NERC Reliability Standards, updated July 03, 2018.https:///files/glossary_of_terms.pdfEVALUATING PRC-002-2, SECTION 4 - APPLICABILITYAnalysis or Recommended Application Guidance:As previously stated, the scope of this SAG is PRC-002-2 R4.3 when using protective relays. These recommendations are not intended for dedicated fault recorders (FR).EVALUATING PRC-002-2, REQUIREMENTSAnalysis or Recommended Application Guidance:As previously stated, the purpose of this SAG is to provide recommendations when using protective relays to comply with PRC-002-2 R4.3. The objective is to limit record triggers to only faults within the relay zone of protection to ensure that important FR data is not lost.RecommendationsGeneral1. Impedance elements (which utilize a combination of voltage and current quantities) alone do not meetthe requirement of the PRC-002-2 standard. R4.3 specifies FR data triggers for at least the following: Neutral (residual) overcurrent, and phase undervoltage or overcurrent.2. When there is a fault in a BES element connected to an identified BES bus, it is necessary to capturethe bus voltage and only the currents of the faulted BES element; it is not necessary to trigger the relays on the unfaulted BES elements to capture their currents.3. It is acceptable to use directional overcurrent elements (instead of non-directional) to limit recordtriggering to faults within the protective relay zone of protection.4. It is recommended to trigger a fault record whenever the protective relay issues a trip. In addition, asper R4.3, there is a requirement to set record triggers for neutral (residual) overcurrent, and phase undervoltage or overcurrent. These elements should be set to trigger a fault record for any fault in the zone of protection.5. The data requirements for PRC-002-2 are based on a system configuration assuming all normallyclosed circuit breakers on a bus are closed.6. The voltages of identified BES busses are required to be captured in fault records. This could beachieved with cross-triggering if the bus voltages are not connected to the protective relay.Transmission Lines1. The protective relay is required to be configured to trigger a fault record for all faults on the line usingneutral (residual) overcurrent, and phase undervoltage or overcurrent. Use directional ground and phase overcurrent elements as dedicated event recorder triggers.2. Trigger setting criteria:Set overcurrent triggers to trigger a recording for a remote bus fault at a minimum.3. Recommendation is to not use undervoltage elements for triggering for the following reasons:•The element is non-directional and more difficult to coordinate for out of zone faults.•PRC-002-2 requires either phase overcurrent or undervoltage triggers, not both.Transformers1. The protective relay is required to be set to trigger a recording for all faults in the zone of protectionusing neutral (residual) overcurrent, and phase undervoltage or overcurrent. Use directional ground and phase overcurrent elements as dedicated event recorder triggers.2. Trigger setting criteria:Set the overcurrent triggers to pick up for all faults within the zone of protection.3. Recommendation is to not use undervoltage elements for triggering for the following reasons:•The element is non-directional and more difficult to coordinate for out of zone faults.•PRC-002-2 requires either phase overcurrent or undervoltage triggers, not both.Standard Application Guide Revision TableDate Version Notes/ChangeFebruary 2020 1.0 Initial Document。

usabc标准

USABC标准涵盖了电动汽车电池的各个方面,包括材料选择、设计、制造、测试和性能评估等。

以下是一些重要内容:

1. 电池材料选择标准:为了确保电池的高能量密度和长寿命,USABC标准

明确了电池的正极、负极和电解液的材料选择要求。

这些材料需要具备良好的储能性能、长周期寿命和低成本等特点。

2. 电池设计标准:USABC标准规定了电池的结构和尺寸等设计要求,以确

保电池的安全性、可靠性和一致性。

3. 电池制造标准:USABC标准要求电池的制造过程需要符合严格的质量控

制和安全生产标准,以确保电池的质量和安全性。

4. 电池测试标准:USABC标准规定了电池的测试方法和测试要求,以确保

电池的性能和可靠性。

5. 电池性能评估标准:USABC标准规定了电池的性能评估方法,包括电池

的能量密度、充电次数、安全性、寿命等指标的评估方法。

总的来说,USABC标准是电动汽车电池行业的重要标准之一,旨在确保电

动汽车电池的质量、安全性和可靠性,推动电动汽车产业的健康发展。

全球储能电池安全标准

随着储能电池技术的不断发展,储能电池系统在能源领域得到了广泛应用。

然而,储能电池系统中的电池安全问题一直是制约其发展的瓶颈之一。

为了保障全球储能电池系统的安全运行,各国纷纷制定了相应的储能电池安全标准。

储能电池安全标准可以分为两类:一类是对电池自身安全进行的规定,包括电池的设计、制造、使用及回收等方面;另一类是对电池系统整体安全的规定,包括电池系统的设计、安装、运行及维护等方面。

目前,全球储能电池安全标准主要有以下几种:

1. UL9540储能电池系统标准,是美国UL公司发布的储能电池系统安全标准,涵盖了储能电池系统设计、制造、安装、运行及维护等方面。

2. GB/T 31485-2015储能电池安全技术规范,是中国国家标准化管理委员会发布的行业标准,规定了储能电池的基本要求、安全要求、环境要求、电池组设计及测试等内容。

3. IEC 62619储能电池系统安全标准,是国际电工委员会发布的储能电池系统安全标准,规定了储能电池系统的安全性能、电池组设计、安装及运行等方面的要求。

4. ISO 19880-1储能电池系统安全标准,是国际标准化组织发布的储能电池系统安全标准,规定了储能电池系统的基本要求、安全要求、环境要求及性能测试等方面。

总之,全球储能电池安全标准的制定和实施,有助于保障储能电池系统的安全运行,促进储能电池技术的发展和应用。

美国用能产品能效技术法规体系及其特点(中)张哲;张峰;王立舟【摘要】介绍美国用能产品能效技术法规体系的框架、脉络和特点,为我国用能产品的生产企业、贸易公司了解美国用能产品能效技术法规体系提供帮助和指南,同时对我国在用能产品能效法规和标准制定、市场监督管理等方面提供启示和借鉴.【期刊名称】《节能与环保》【年(卷),期】2010(000)009【总页数】4页(P27-30)【关键词】美国;用能产品;能效;技术法规【作者】张哲;张峰;王立舟【作者单位】河南出入境检验检疫局,河南,郑州,450000;国家质检总局标准法规中心,北京,100088【正文语种】中文【中图分类】D9(续上期)1.2.3.1 产品能效标准法规涉及产品能效标准的联邦法规有两个,分别为:10 CFR 430——民用产品能源节约计划;10 CFR 431——特定商用和工业用设备能效计划。

其中10 CFR 430和10 CFR 431分别为民用产品、商用和工业设备的能效限值标准和检测程序要求,由美国能源部制定。

这两个法规包括了25种民用产品、18种商用和工业设备的能效限值标准、能耗检测程序和方法,以及监督管理要求。

1.2.3.2 产品标识法规产品的能效标识是确保能源节约标准计划有效实施的重要组成部分,涉及到消费者市场购买行为,故“产品标识法规”(16 CFR 305)由美国联邦贸易委员会(FTC)负责制定和实施管理。

该法规全称为:16 CFR 305——美国能源政策和节约法案下的特定家用产品和其他产品的能源消耗和水消耗信息描述的法规,简称“产品标识法规”。

图1 2008年4月29日后的“EnergyGuide”图样该法规规定了19种产品的能效(包括水耗)标签要求,涉及11种民用产品的“EnergyGuide”标签(图1为2008年4月29日生效的标签,注意同图2的区别)和吊扇的专用标签、3种照明产品的“E”圈标志和4种水管产品的“水消耗参数和制造商信息”标识。

北美储能系统标准UL 9540第三版更新要求的解析朱海峰;孔庆刚;吴红浩;严燕萍【期刊名称】《电池工业》【年(卷),期】2024(28)1【摘要】北美储能系统标准UL 9540是ANSI(美国国家标准学会)和SCC(加拿大标准委员会)认可的国家安全标准,同时已经被众多国际规范所引用和要求,如ICC IFC(国际消防法规)、ICC IBC(国际建筑法规)、ICC IRC(国际住宅法规)、NFPA1(消防法规)、NFPA 70(国际电工法规)和NFPA 855(储能系统安装规范)。

某些州府,如加州也要求采用消防法规。

一旦该法规被当地政府、州府采用,对应的标准如UL 9540将变为强制性要求。

UL 9540标准是储能系统级别的安全标准,包含产品范围、结构检查、功能安全评估、电气测试(包括电磁兼容)、机械测试、环境测试、制造与生产线测试、标签和说明书等。

储能系统包括电池系统、功率转换系统、可能的智能控制系统和并机系统等,而单独的电池系统和功率转换系统不包含在UL 9540的产品范围内。

UL 9540标准已发布3个版本,从2016年11月26日发布的第一版到2023年6月28日发布的第三版。

本文阐述了UL 9540标准的应用背景和要求,重点介绍了第三版的重要技术变化及应对方案。

同时,还指出标准内容的不足,并提出建议,为相关行业的从业者提供指导和建议。

【总页数】6页(P40-45)【作者】朱海峰;孔庆刚;吴红浩;严燕萍【作者单位】施耐德电气(中国)有限公司【正文语种】中文【中图分类】TM911【相关文献】1.国家标准《快速公交(BRT)智能系统第2部分:调度中心系统技术要求》解析2.低压断路器国际标准IEC60947-22003年第三版系列报导(二)——附录L(标准的附录)无过电流保护要求的断路器3.浅析北美UL标准有关电线电缆火花试验电极要求的变化4.UL 1973储能电池系统标准(第三版)更新解析5.北美电池储能系统热失控评估方法的解析及对我国的参考因版权原因,仅展示原文概要,查看原文内容请购买。

美国电池储能安全协议书甲方(电池储能系统提供方):[全称]乙方(电池储能系统使用方):[全称]鉴于甲方为专业的电池储能系统提供商,乙方为电池储能系统的使用方,双方本着互惠互利的原则,就电池储能系统的安全使用达成如下协议:第一条定义1.1 “电池储能系统”指由甲方提供,用于储存和释放电能的设备及其配套系统。

1.2 “安全标准”指由美国国家消防协会(NFPA)或相关行业标准制定的,适用于电池储能系统的安全使用和维护的标准。

第二条系统提供与安装2.1 甲方负责提供符合安全标准的电池储能系统,并负责系统的安装、调试工作。

2.2 安装完成后,甲方应向乙方提供系统的详细操作手册和维护指南。

第三条安全使用3.1 乙方应按照甲方提供的手册和指南,合理使用电池储能系统。

3.2 乙方应确保使用环境符合安全标准,避免高温、潮湿等不利条件影响系统安全。

第四条维护与保养4.1 甲方负责电池储能系统的定期维护和保养工作,并保证系统的正常运行。

4.2 乙方应配合甲方的维护保养工作,并在必要时提供必要的协助。

第五条安全事故处理5.1 如电池储能系统发生安全事故,双方应立即启动应急预案,采取措施控制事故扩大。

5.2 事故原因调查由甲方负责,乙方应提供必要的协助。

5.3 根据事故调查结果,由责任方承担相应的责任。

第六条保密条款6.1 双方应对本协议内容及在合作过程中获知的对方商业秘密予以保密,未经对方书面同意,不得向第三方披露。

第七条违约责任7.1 如任何一方违反本协议条款,违约方应承担违约责任,并赔偿对方因此遭受的损失。

第八条争议解决8.1 本协议在履行过程中发生的任何争议,双方应首先通过友好协商解决;协商不成时,任何一方均可向甲方所在地的有管辖权的法院提起诉讼。

第九条协议的修改和终止9.1 本协议的任何修改和补充,必须经双方协商一致,并以书面形式确认。

9.2 如遇不可抗力或双方协商一致,本协议可提前终止。

第十条其他10.1 本协议未尽事宜,双方可另行协商解决。