轮胎异常磨损(卡客车轮胎)

- 格式:pptx

- 大小:2.30 MB

- 文档页数:42

简述汽车轮胎异常磨损的现象及可能产生的原因。

1 非正常磨损现象

汽车轮胎的异常磨损主要表现为轮胎局部或者全部磨耗加速,可能导致剧烈摩擦、破裂等危险。

下面是一些典型的异常磨损现象:

穿刺:轮胎表面遭受尖锐物体刺穿,造成气压损失。

偏磨:轮胎一边磨耗过快,磨损出现失衡。

斑驳磨:形状不规则,大小不一的磨损。

横向裂纹:轮胎肩部,橡胶外露的地方出现裂纹。

线性裂纹:轮胎侧壁或接口出现裂纹。

2 异常磨损可能的原因

对于这些异常磨损现象,原因也是多种多样的。

一般可能涉及驾驶习惯、路况、气候和轮胎质量等因素。

驾驶习惯:突然加速、刹车,以及长期在糟糕的路面条件下行驶等,会对轮胎产生过大的磨擦力,增加其磨损程度。

路况:长期在破损的路面上行驶,或是经常磕碰路边的台阶和石头,都会导致轮胎磨损、损坏或者因撞击而导致裂纹。

气候:气候变化对轮胎有一定的影响,特别是在温度变化剧烈的季节,橡胶材料会因此变干,导致其更易于裂纹。

轮胎质量:如果轮胎质量差,或者不是原装配件,也可能因此而容易产生异常磨损。

汽车维护:汽车未定期进行维护,如调整轮胎的气压或不做四轮定位,也可能导致轮胎偏磨。

以上就是关于汽车轮胎异常磨损的一些现象和可能产生的原因。

建议汽车主人定期对汽车进行保养和检查,保证轮胎处于良好状态,保障行车安全。

导致汽车轮胎异常磨损的原因有哪些汽车轮胎是汽车行驶机构中的重要组成部分,它们支持着整车的重量,提供汽车正常行驶所需要的驱动力,及时检查轮胎磨损情况,可以排除车辆隐患,避免造成意外,那么导致汽车轮胎异常磨损的原因有哪些呢?小编给大家一一解答!1、轮胎的中央部分早期磨损。

主要原因:轮胎充气量过大,这样不但影响轮胎的减震性能,还会使轮胎的变形量过大。

处理方法:可测量和调整轮胎的气压,并且让轮胎按期换位。

通常子午轮胎与普通斜交轮胎的换位方法不同。

2、轮胎的两边磨损过大。

主要原因:轮胎充气量不足或长期超负荷行驶,使轮胎与地面接触面大,造成轮胎两边与地面接触而形成早期磨损。

处理方法:可测量轮胎的气压,并调整到规定值,汽车使用时限制负荷,防止超载。

3、轮胎的一边磨损量过大。

主要原因:是由于车轮外倾角不对引起。

处理方法:可修理或更换车桥和悬架上的零件,并调整车轮外倾角来解决。

4、轮胎胎面出现锯齿状磨损。

主要原因:前轮定位调整不当或前悬架系统位置失常、球头松旷等,使正常滚动的车轮发生支承架滑动或行驶中车轮定位不断变化而造成轮胎锯齿状磨损。

处理办法:调整前轮定位,检查前悬架系统和球头销,必要时进行调整或更换。

5、个别轮胎磨损量过大。

主要原因:是由于个别车轮悬架系统失常、支承架弯曲或个别车轮不平衡所致。

处理办法:检查磨损严重的车轮定位情况、独立悬架弹簧和减震器的工作情况,同时应缩短车轮的换位周期。

6、轮胎出现斑秃形磨损。

主要原因:轮胎的个别部位出现斑秃性严重磨损,是轮胎的平衡性差,当不平衡的车轮高速转动时,个别部位受力很大,磨损相应加快,伴随转向发抖,使操纵性变差。

处理办法:如果在汽车行驶中发现某一特定速度车辆有轻微抖动时,就应立即对车轮进行平衡,这样可防止轮胎出现斑秃性磨损。

轮胎异常磨损故障分析导致轮胎异常磨损的原因是多样的,有轮胎本身的质量问题、有用户的使用保养及特殊的道路使用条件问题、有设计问题,也有底盘制造、装配调整的问题。

10m以下车型有前轮摆振的倾向,在四轮定位稍不良时就会诱发前轮摆振,导致前轮轮胎波浪状磨损的反馈比较多。

对于轮胎本身的质量问题,要完善质量保证协议并加强监控力度。

用户使用保养的问题,可通过完善使用说明书及售后提示用户来解决。

特殊道路使用条件应在销售订单中作为一项控制点。

设计要严格控制轮胎负荷率和前轮定位参数合理,增加10米以下车型前轮回正能力和阻尼力。

轴距是车辆最基本的参数,要通过轴距工装严格保证制造精度。

空气悬架车要通过推进线进行四轮定位,推进线的检测精度是非常重要的。

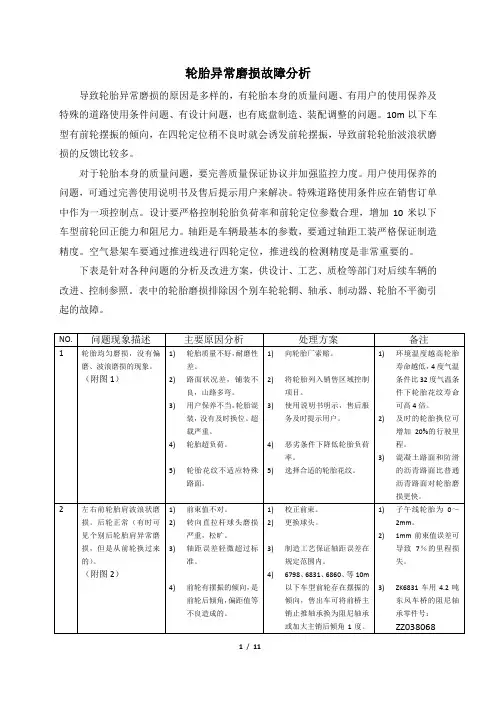

下表是针对各种问题的分析及改进方案,供设计、工艺、质检等部门对后续车辆的改进、控制参照。

表中的轮胎磨损排除因个别车轮轮辋、轴承、制动器、轮胎不平衡引起的故障。

附图1附图2附图3(图中为了表示轴距误差,后桥与底盘中心线偏转一个角度,实际上有些车是前轮偏转一个角度而后桥与底盘中心垂直,在此没有图形表示。

)附图4(图中为了表示轴距误差,后桥与底盘中心线偏转一个角度,实际上有些车是前轮偏转一个角度而后桥与底盘中心垂直,在此没有图形表示。

)附图5底盘中心线后桥中心线第二部分轮胎异常磨损的处理方法一、轮胎异常磨损的分类不同形态的异常磨损,其形成的机理不同,因而处理的方法也就不同。

工作中经常见到一些人,只要听到轮胎异常磨损,马上就去做车轮动平衡或者前轮定位,这种不分青红皂白,千篇一律的处理问题的方法是错误的。

在此我们将工作中经常见到的轮胎异常磨损形态做一大致分类:1、磨损均匀但寿命很短。

最常见的是旅游车上,真空轮胎行驶里程只有4~5 万公里,公交车使用的斜交胎,行驶的里程只有2 万公里左右,轮胎花纹已全部磨光。

2、波浪形磨损。

轮胎胎面呈波浪状,或者个别轮胎胎面在圆周上出现半边的花纹深度比另外半边的花纹深度有明显的差别。

轮胎异常磨损名词解释轮胎异常磨损是指轮胎表面出现不均匀的磨损现象,其中部分区域磨损更严重或更快。

这种异常磨损可能会导致轮胎性能下降,甚至影响行车安全。

常见的轮胎异常磨损包括以下几种类型:1. 前后中央磨损:轮胎中央部分的磨损比两侧严重。

这种磨损通常是由于过度充气或胎压不均匀造成的。

过高的胎压会使轮胎中央部分与地面接触过多,导致磨损加剧。

而胎压不均匀则会使轮胎在接地时产生侧向力,导致中央磨损。

2. 两侧磨损:轮胎两侧的磨损比中央部分严重。

这种磨损通常是由于胎压过低或过度载重造成的。

过低的胎压会使轮胎两侧的肩部与地面接触过多,导致磨损加剧。

而过度载重则会使轮胎承受超过设计负荷,同样导致两侧磨损。

3. 肩部异状磨损:轮胎肩部出现不规则的磨损现象。

这种磨损通常是由于车辆过度转弯或行驶过于激烈造成的。

在转弯时,轮胎肩部承受较大的侧向力,如果频繁转弯或驾驶方式过于激烈,会导致肩部磨损。

4. 斜肩磨损:轮胎肩部磨损呈斜线形状。

这种磨损通常是由于轮胎对称性问题或转弯时的横向滑移造成的。

当轮胎的内外侧面摩擦力不均衡时,会导致磨损呈斜线分布。

而转弯时的横向滑移则会加剧该磨损。

轮胎异常磨损对行车安全和轮胎寿命都有着负面影响。

适时检查轮胎磨损情况并采取相应的调整措施是非常重要的。

保持适当的胎压、避免过度载重、平稳驾驶、定期进行轮胎轮位调整和定期轮胎旋转,都可以帮助延长轮胎使用寿命并减少异常磨损的发生。

此外,定期检查轮胎磨损情况也是及时发现并解决问题的关键。

如果发现轮胎异常磨损,应及时更换或修复轮胎,以确保行车安全。

轮胎异常磨损名词解释

轮胎异常磨损是指轮胎表面在使用过程中出现的非正常磨损情况。

以下是几种常见的轮胎异常磨损形式及其解释:

1.前后不均匀磨损(Uneven Wear Front-to-Rear):指轮胎前后两

侧的磨损程度不一致。

可能是由于行驶时悬挂系统不平衡、车

轮定位不正确或胎压不均匀等原因造成。

2.内侧或外侧磨损(Inner or Outer Edge Wear):指轮胎内侧或外

侧的磨损更为明显。

常见原因包括前后悬挂系统不平衡、轮胎

对准度不准确、过度或不足的胎压、过度转向等。

3.中央部位磨损(Center Wear):指轮胎中央部位的磨损程度更

高。

可能是由于胎压过高、过度载荷、长时间的高速行驶以及

过多的紧急制动等因素导致。

4.斜坡式磨损(Scalloping):指轮胎表面出现连续的凹凸形状,

形似楔形或弧形槽状。

斜坡式磨损通常与轮胎失衡、悬挂系统

故障或轮轴问题有关。

5.脱新磨损(Feathering):指轮胎表面出现逐渐变化的倾斜边缘。

通常是由于前轮对向不准确或轮胎夹角不正确造成的。

轮胎异常磨损不仅会缩短轮胎的使用寿命,还可能导致行车安全问题。

因此,定期检查轮胎磨损情况并采取相应的调整措施非常重要,例如定期调整胎压、检查和修正车轮对准度、平衡轮胎等。

及时解决轮胎异常磨损问题可以提高行车安全性和轮胎的使用寿命。

目录一、轮胎异常磨损原因分析1、磨损故障模式2、磨损原因分析二、轮胎异常磨损维修方法1、前桥轮胎磨损维修2、双前桥轮胎磨损维修3、中后桥轮胎磨损维修三、车轮使用保养规范轮胎的作用是承受汽车的负荷,保证车轮与地面的抓着力,并将汽车的动力传递给路面,减轻和吸收汽车在行驶时的震动和冲击力,保证行驶的安全与舒适。

轮胎在使用过程中,由于路况、使用条件以及保养不当等原因,常会造成轮胎的异常磨损(吃胎),给用户带来安全行车隐患和经济损失,因此,当轮胎出现异常磨损迹象时,需认真查明故障原因并排除。

轮胎异常磨损原因分析一、轮胎异常磨损原因分析1、轮胎异常磨损故障模式维修中较为常见的磨损故障模式有:偏磨(内侧或外侧磨损)、胎冠两肩磨损、胎冠中央磨损、胎冠局部磨损、胎冠锯齿状磨损或波浪状磨损等。

根据不同的磨损模式,初步判断轮胎异常磨损的原因和需要采取的简要措施。

1.1轮胎内侧磨损轮胎内侧磨损是偏磨的一种形式。

主要原因多为车轮定位参数不准确、频繁的急转弯、轮胎长时间不换位等。

1.2轮胎外侧磨损1.3内外侧磨损1.4胎冠中央磨损1.5胎冠凹陷或局部光秃1.6胎冠锯齿状(侧齿)磨损(胎面呈斜坡形)前桥变形或定位不良,使轮胎行驶中左右摇摆,使用两胎肩受到过大“吃角磨损”,花纹被磨成锯齿状。

1.7胎冠呈波浪形或碟形磨损半轴套管变形后,使半轴与轮毂不能在同一水平线上转动,产生不平衡性转动,或是后桥壳变形负荷集中到内档轮胎内侧胎肩上,同时轮胎呈失重转动,造成胎面成凹凸状磨损。

1.8轮胎间隔均匀吃胎,可能间隔数个花纹1.9中后桥轮胎磨损一轴(桥)的单边轮胎异常磨损,且装于同一轮毂的双胎磨损存在差异性,一般伴随着车辆自动跑偏。

由于公差的累积,造成车架两侧的轴距不等。

2、轮胎异常磨损原因分析通过轮胎异常磨损的故障模式分析,可以发现无论哪种形式的磨损,都是由于车轮的定位参数发生了变化。

能引起定位参数变化的因素主要有连接车轮的零部件变形或损坏和紧固件以及气压失调。

汽车轮胎异常磨损的原因与对策摘要:介绍汽车轮胎异常磨损的几种情况,从物力角度详细分析了轮胎异常磨损的原因,并结合图示进行了对比研究,具体研究了汽车轮胎的保养和维护措施,对于现代交通运输业的发展和国民经济的良性运行具有重要的现实意义。

关键词:轮胎磨损维护汽车轮胎是车辆的重要组成部分,关系到汽车的使用性能和行驶安全。

在汽车的运行过程中要特别注意预防轮胎的早期磨损,防止轮胎的不正常损坏。

正确合理地使用汽车轮胎,不但可以有效地延长轮胎的使用寿命,而且对于现代交通运输业的发展和国民经济的良性运行具有重要的现实意义。

1 轮胎异常磨损的物理分析轮胎内胎故障多数属于偶然原因(撞击、扎漏、暴裂)所致,一旦故障发生,胎压顿减,外胎凹瘪,症状明显,易于对症排除。

[1]而外胎若使用不当就会发生异常磨损,其主要有以下六种情况。

1.1 胎冠两肩磨耗造成胎冠两肩磨耗的原因一是胎压经常不足造成的外胎胎冠及两肩严重磨损;二是在标准胎压下使用的外胎,胎冠磨损均匀、轻微,胎面保持了原来的基本形状。

而轮胎胎压不足和汽车超载是造成胎冠两肩磨耗的主要原因。

当轮胎胎压不足时,充气轮胎的刚度也要因之下降,行驶时胎侧发生强烈弯曲,使胎体产生很大的应力,帘布层要受到损害,在弯曲变形的同时,还提高了胎温。

由于温度和应力的提高,导致外胎脱层,因脱层间产生摩擦,又使胎温更进一步增高,其恶果可造成轮胎暴裂故障[2]。

此外,胎压严重不足时,外胎能在轮辋上窜动,内胎气门嘴受剪切,易于损坏。

特别是在使用双胎并装的场合,由于胎压不足或轮胎超载,胎侧变形严重,还会产生两胎胎壁的磨损(擦伤)。

1.2 胎冠中部磨损当轮胎气压过高时,轮胎接地的单位面积上压力增高,致使胎冠中部很快磨损,同时,帘布层中的帘线将承受极大的拉伸应力,也会引起早期损坏。

如果胎压超过标准20%,轮胎应力就超过30%以上[2]。

在充气过量的情况下,汽车如果行驶在不平坦的路面上或遇到路面上的障碍物,那么,它行驶的平稳性就会下降,甚至还可能导致轮胎冠部暴裂。

轮胎不正常磨损原因及解决办法轮胎磨损主要是轮胎与地面间滑动产生的摩擦力造成的。

汽车起步、转弯及制动等行驶条件的不断变化,转弯速度过快、起步过急、制动过猛,轮胎的磨损就快。

另外,轮胎的磨损还与汽车的行驶速度有关,行驶速度愈快,轮胎磨损愈严重,路面的质量也直接影响到轮胎与地面的摩擦力,路面较差时,轮胎与地面滑动加剧,轮胎的磨损加快。

以上情况产生的轮胎磨损,基本上是均匀的,属正常磨损。

若轮胎使用不当或前轮定位不准,将产生故障性不正常磨损,常见的不正常磨损有以下几种:1、轮胎的中央部分(胎冠)早期磨损:主要原因是充气量过大。

适当提高轮胎的充气量,可以减少轮胎的滚动阻力,节约燃油。

但充气量过大时,不但影响轮胎的减振性能,还会使轮胎变形量过大,与地面的接触面积减小,正常磨损只能由胎面中央部分承担,形成早期磨损。

2、轮胎两边(胎肩)磨损过大:主要原因是充气量不足,或长期超负荷行驶。

充气量小或负荷重时,轮胎与地面的接触面大,使轮胎的两边与地面接触参加工作而形成早期磨损。

轮胎气压高于或低于额定值20%,里程损失20%~25%。

3、轮胎的一边磨损量过大:主要原因是前轮定位失准。

当前轮的外倾角过大时,轮胎的外边形成早期磨损,外倾角过小或没有时,轮胎的内边形成早期磨损。

4、左右前轮胎肩波浪状磨损,左后轮内侧,右后轮外侧异常磨损严重。

主要原因是前后轴不平行,轴距右侧比左侧大,超过标准。

轴距标准(前后桥板簧座处测量)左右最大差值4mm。

解决办法为:板簧车可通过筛选、调整板簧长度解决。

空气悬架车调整推力杆长度。

5、左右前轮胎肩波浪状磨损,右后轮内侧,左后轮外侧异常磨损严重。

原因是前后轴不平行,轴距左侧比右侧大,超过标准。

6、左右前轮胎肩波浪状磨损,后轮正常(有时可见个别后轮胎肩异常磨损,但是从前轮换过来的)。

主要原因是前束值不对、转向直拉杆球头磨损严重,松旷、轴距误差轻微超过标准、前轮有摆振的倾向。

子午线轮胎为0~2mm,1mm前束值误差可导致 7%的里程损失。

轮胎的磨损有自然磨损和异常磨损。

自然磨损是轮胎使用过程中的正常现象,轮胎在出厂前在胎侧都标注有磨损极限记号,有的为三角形符号,表明当轮胎花纹磨损到此标记,应更换新胎,因为此时轮胎的排水性能和抗扎性能都会大幅下降。

轮胎异常磨损是指正常轮胎在行驶过程中所发生的磨损速度加快,胎面形状出现异常的状态。

汽车在正常使用过程中,轮胎损坏的形式很多,但常见的损坏形式是轮胎的异常磨损。

它大大缩短了轮胎的正常使用寿命,说明车辆使用中存在隐患,应该根据轮胎的磨损特征找出原因,采取有效措施及时排除,延长轮胎的使肘寿命。

1.轮胎异常磨损的原因(1)轮胎胎冠的内侧偏磨,呈现内锥体。

主要原因有:汽车长期在拱形路面上行驶,不及时换位,车轴两端向上弯曲变形,使轮胎内侧承载过大;前轮外倾角不正确等。

(2)轮胎胎冠外侧磨损严重,呈现外锥体,则为角失准或长期未换位所致。

在轮胎定期换位的情况下,当胎面外侧肩部磨损严重时,则为外倾角过大;当胎面内侧磨损严重时,则为外倾角过小。

(3)轮胎的胎冠中部磨损严重,即胎面中部磨损。

主要原因为轮胎长期在过高胎压下工作,这样容易造成轮胎胎冠中部磨损增加,花纹底部开裂。

另外,车辆过载,在行驶中随着轮胎内部温度升高,同样也会加剧轮胎气压的升高。

(4)轮胎胎冠的两边磨损严重。

主要原因是轮胎气压长期不足,或轮胎胎面过窄、轮辆过宽,轮胎的磨损主要由胎面两侧承担。

(5)轮胎局部磨损严重。

主要原因为汽车使用中紧急制动较多,制动鼓失圆,轮胎不平衡;轮胎变形等。

(6)前轮胎单侧胎肩磨成椭圆形。

主要原因是前束值不正确且气压不足所致。

(7)轮胎花纹斑状磨损。

车轮总成动平衡不好或车辆减振性能差,使车辆行驶中车轮跳动过大,造成轮胎花纹出现斑状磨损;也可能是由于汽车长期在棱角石块路面上行驶所致。

(8)胎面两边小花纹或大花纹块磨成锯齿形。

一般是由于胎面接触坚硬路面的瞬时,花纹块的前端受挤压变形。

(9)胎面磨损痕迹从外向内横过胎面,外侧磨损较严重,内侧磨损较轻,则为前束过大;如磨损痕迹从内向外横过胎面,内侧磨损较严重,外侧磨损较轻,则为前束过小。

轮胎异常磨损(Abnormal wear of tyre)Summary of abnormal wear of tyreTire wear marks are the specific manifestation of automobile parts failure or four wheel alignment problems. Many of the car's problems with suspension and steering systems may be reflected by tire wear marks.(1) the tread inside and outside of the uniform wear, but wear too fast, because the tire pressure is insufficient.(2) the middle part of the tread is worn too fast because of excessive tire pressure.(3) the side wear and tread wear are too fast, the reason is that the camber of tyre is out of range (abrasion inside and outside).(4) feather edge wear (serrated) because the front of the wheel is not correct, including wear or damage to the steering components, leading to the front beam overrun.(5) bald spot, that is, the tread has grooves and concave wear. The reason is that the shock absorber is out of order or the tyre is unbalanced.(6) fan wear, reasons for the steering problem such as steering toe error.Causes and maintenance of abnormal wear of Santana's tireShanghai Fontana series cars fitted with parallel bars is Tubeless Radial tire, compressed air directly into the tire. This kind of tyre has the advantages of simple structure, light weight, and can be directly through the rim heat, low working temperature, long service life, named was broken, because the tire itself is compressed and the puncture object wrapped tight, so it can not maintain long-term chlorine leakage. But in use, it was found that some of the vehicle tire abnormal wear phenomenon, tire side wear, tire patterns appear rough edges, tire wear surface wave (also known as sawtooth) and so on.1, the cause of abnormal wear of tiresAccording to the structural features of Shanghai Santana and the repair of abnormal wear and tear of some tires, the main reason for abnormal wear is:(1) the unilateral wear of the tyre is mainly caused by the inaccurate camber of the wheel. Whether it is front wheel or rear wheel, if there is a large amount of internal wear, it is too small; the outside wear is large, but the outside angle is too large.(2) the tread on the tread pattern is usually not caused by the front beam. If the burrs appear on the inside of the pattern, the front beam is too large. If the burr appears on the outside, it is too small for the front beam.(3) the tyre surface is made of wave, which is caused by the left and right shimmy of the wheel during rolling. There are many factors, such as tire mass unbalance, wheel rimdeformation, deformation of front and rear axles and suspension, failure of steering system, birch or steering shock absorber, and reduction of damping.Abnormal wear of tires can not only shorten the life of tires, but also affect the ride comfort, economy and handling of automobiles. The reasons should be found out in time and repaired in time.2, the tire side wear or decorative edges of the overhaulWhen the tyre appears unilateral wear or the tread of the tyre appears rough, the location angle of each wheel should be checked whether or not it is inaccurate.The front axle suspension of Shanghai Santana car is a Mcpherson suspension. It is a kind of independent suspension wheel along the main pin axis (no kingpin entity). The camber angle and the rake angle of the kingpin are guaranteed by the structure without adjustment, but the front and toe angles of the front wheel must be adjusted. As the Shanghai Santana car wheel alignment angle requires accurate, so most of her inspection in the instrument, the edge adjustment is more accurate and reliable. In the condition of no detection equipment, the vehicle positioning parameter is confirmed to be inaccurate and inaccurate, and the gauge can be manually checked and adjusted.(1) inspection and adjustment of front wheel front beam. The car parked on the flat ground, the two front straight line position, in the steering system without looseness condition, with spacing between measurement points before and after thefront beam steel ruler or Zheng ruler to measure the two front axle and optional in the young level indicator at the inner tire wear, before and after each measurement time after reducing the number of operations of the front wheel value (should be negative). When the value is not in accordance with the standard, the adjusting screw sleeve on the two tie rod can be adjusted. First, the locking bolts at both ends of the adjusting screw sleeve are twisted and loosened; the wrench is rotated clockwise; the tie rod is shortened; the front beam value is increased; the counter clockwise rotating tie rod is extended, and the front beam value is reduced. Two tie rod should be adjusted at the same time, after adjustment, should the locking bolt.(2) adjustment of camber angle. Similarly, the car should be placed on a flat floor with the wheels in a straight position. The tread center is selected at the front of the tire, and the tangent line of the vertical line and the center line of the tread is respectively made. The angle of the two lines is the camber angle of the wheel. The angle is too big or too small to adjust the joint of the ball hinge arm and the swing arm. The two locking nuts are twisted, and there are two incurable 10MM long strip holes on the swing arm, and the ball hinge arm is moved inwards. The camber of the wheel becomes larger, and vice versa. Both sides should adjust, after adjustment of the lock nut tightening. It should be pointed out that the manual measuring tool adjustment, the value must be measured accurately, repeated proof 2-3 times, and pay attention to check the adjusted road test results.The front and outer angles of the rear wheel are also securedby the structure and do not need to be adjusted. But the car is running,Because of the wear and tear of each component, the rear wheel alignment angle will also be changed.Two after the front end of the cantilever and bear body hinged metal rubber bushing, such as aging, cracking, Songkuang, will not only affect the damping performance, but also damage the correct positioning of the two rear wheels, resulting in two after the tire abnormal wear.There was a Santana sedan because of a metal rubber bushing broken loose, two after the tire side of the interior wear without pattern, and the wear surface into a wave shape, replaced a metal rubber bushing, completely restored to normal.2, the tire wear into a wave shaped overhaulWhen it is found that the tread of the tyre is made into a wave (jagged edge), the following parts shall be carefully repaired.(1) check whether the steering system is loose or not. The moving parts of the steering system of Shanghai Santana car are all without clearance (the steering wheel is free of travel). If the steering wheel has a free stroke and rotates a larger angle, and the wheel does not deflect, the steering gear is wide. This can be a wheel, and a straight line position, loosen the lock nut steering device, rotating the adjusting bolt with six angle wrench, eliminate the meshing clearance between the gear and the rack, and then press the lock nut (do not allow theadjustment bolt to rotate together with the lock nut). If the transmission component Songkuang, such as ball pin, ball seat wear, spring break, should be replaced. If the steering shock absorber fails and does not act as a damping device, it shall be repaired or replaced.(2) check whether the tyre is balanced and whether the rim is deformed or not. The unbalance of the tyre and the deformation of the rim. It is the main factor that causes the shimmy of the front wheel in the vehicle running, which will directly cause the wave abnormal wear of the tyre, make the driving operation difficult, and influence the safe driving, and should be corrected or replaced in time. The replacement of new or refurbished tires should be balanced test, before loading, and to pair replacement, but refurbished tires can not be installed in the front wheel.(3) inspect the body, front and rear axles and suspension parts for deformation, looseness and damage. The above components such as deformation, Ying moving or damaged, not only will be caused by oscillation of the wheel, will cause the wheel alignment angle changes, increased tire abnormal wear, should be promptly corrected, tighten or replacement.Ways and measures to increase tire mileageA car, all tire costs, accounting for 10%-20% of the cost of motor transport. The fuel consumption can be changed by 105-15% under the influence of tire condition and tire pressure. Therefore, saving tires can not only significantly reduce transportation costs, but also save a lot of valuable rubber,cord and oil resources.But at present, China's average car tire mileage is very low, professional transport enterprises tire average mileage of only more than 90 thousand km, so to improve the tire technical level, prolong the service life of the tyre, the car is one of the important contents of technology management.In the deformation of the tire, it also produces shear stress between the plies. When the shear stress exceeds the adsorption force between the curtain and the rubber, there will be loose cord and ply delamination. In the deformation of the tire, due to internal friction heating, the tire temperature increases, speeding up the cord or cord damage.On the basis of the above damage, coupled with high speed or uneven road and dynamic load increase, the tire may burst.To sum up, due to the tire structure, stress and deformation of the special, the main forms of tire damage: tread wear, loose or broken curtain, ply delamination, or even flat tire.1, the use of factors affecting tire lifeTire pressure, load, vehicle speed, temperature, road and management, driving and maintenance technology have a great influence on the service life of automobile tires.The high speed of the vehicle will increase the tire load and cause a sharp decrease in tire properties.The car chassis, especially the technical condition of running system or bad driving method is improper, the tires have cut service force or tire rolling when shimmy, the tire circumferential direction or transverse uneven wear.In addition, the tire transportation, improper storage, disassembly and assembly, inconsistent with the operating procedures, maintenance is not timely, the operation is not perfect, will also lead to lower tire quality, accident damage, tire life shortened.2, improve the basic ways and measures of automobile tire mileage(1) correct shipment and proper management. A transport tire, and shall not, inflammable, chemical corrosion products mixed, and covered with a sheet, so as to avoid sunlight and rain. The long distance moving of the tyre must be put upright. If the inner tube is not packed, the temperature in the warehouse should be between -15-30 and 50%-80%, and the relative humidity is. The warehouse should not be close to the power plant and where he may produce ozone. Tire or tires should be set vertically placed in wooden frame on non flat stacked or through suspension, at least every two months for a rotary fulcrum.(2) preventing overloading. The load of the tyre shall comply with the load stipulated in the current national tire standard, and the load shall be uniform.(3) mastering speed,Cooling explosion protection. The maximum allowable temperature of the carcass is 100 degrees, and the back of the hand feels hot on the tread, which means that the temperature in the fetal body is close to 100 degrees centigrade. If the carcass temperature is too high, slow down or cool down in the shade. Shall not use gas and water pouring method to reduce the tire temperature, otherwise it will aggravate the damage to the tire.Change the way of simple disassembly methodThe driver on the way to repair the inner tyre, was bonded tire and rim is difficult to split. In this case we can use a small stone tire way. With a crowbar rim edge. When the wheel rim and the tyre gap, and the gap will fit the size of the stones into the gap, and then move along the slit crowbar a little, then pry the rim edge. So repeatedly, the stone is gradually inserted into the rim and the rim of the tire, and the tyre and the rim are separated naturally.Tyres with more tread wear should not inflate too muchIf the tread is spinning more worn tyres, if it is still inflated by standard air pressure, it will do more harm to the safety of driving. This is because the coefficient of adhesion decreases significantly with the tread pattern worn (the ability to grip decreases). At this time, if the tire pressure is high, the contact area of the tire and the ground is reduced, a result of the ground pressure increases, the central tread wear, tire burst may increase two; adhere to the performance becomes poor, a little careless, prone to slip.Of course, the internal gas should not fall too low, otherwise, rolling resistance increases during driving. At the same time, because of lower tire pressure, the tire deformation increases, and aggravate the aging and wear of tire rubber. Therefore, it is advisable to reduce the tire pressure when tires inflated by wearing more tires, which is generally lower than the standard 0.03-0.05MPA (0.3-0.5KGF/CM2).。

AUTO TIME37THEORETICAL INVESTIGATION | 理论探讨时代汽车 肇世华辽宁工程职业学院 辽宁省铁岭市 112000摘 要: 轮胎磨损主要是轮胎与地面间滑动产生的摩擦力造成的。

若轮胎使用不当、前轮定位不准、维护不及时势必会对轮胎造成故障性异常磨损,甚至会造成严重事故。

因此,掌握其现象、原因并及时预防是非常必要的。

关键词:汽车轮胎;磨损;分析;预防1 轮胎异常磨损种类及原因分析1.1 胎冠中部严重磨损、胎纹磨光轮胎充气量如果过大会使得轮胎与地面的接触面积减小,造成胎冠中部严重磨损。

1.2 轮胎两边(胎肩)磨损过大轮胎充气量如果不足或者超负荷行驶,会造成轮胎与地面的接触面积加大,导致轮胎两边(胎肩)早期磨损。

1.3 轮胎单边磨损过大当车轮外倾角过大时,轮胎的外侧容易形成严重磨损;反之车轮外倾角过小时,磨损常常发生在轮胎的内边,见图1所示。

图1 轮胎单边磨损1.4 胎冠锯齿状磨损轮胎胎冠磨损呈锯齿状,均与汽车前束有关。

定位调整不当或悬挂系统位置失常、球头松旷等,会形成轮胎锯齿状磨损。

如果胎冠由外侧向里侧呈锯齿状,说明汽车前束过大;反之,汽车前束过小会形成胎冠由里侧向外侧呈锯齿状磨损,见图2所示。

1.5 斑秃形磨损当车轮处于高速转动时发生不平衡,个别部位受力加大,磨损加快,个别部位出现斑秃性严重磨损,见图3所示。

2 预防措施与对策2.1 及时检查和保持轮胎气压如果胎压过低,轮胎的刚性变小,使得胎面、胎肩的磨损加剧;轮胎如果在外力作用下使得胎体变形大,滚动阻力会变大,发动机的动力和燃油消耗会加大。

反之,如果轮胎气压过高,这样长期下去会使得轮胎磨损加剧,容易发生爆胎现象。

因此应及时检查轮胎气压并保持在正常范围之内。

2.2 合理操作,正确选择路面汽车驾驶时应选择相对平坦良好的路面,避免较差路况,行车时应做到平稳起步,转弯减速、尽可能减少紧急制动,以减少汽车轮胎磨损。

2.3 尽量避免轮胎处于超负荷运行轮胎运行时,由于负荷是有限的,所以应尽量避免超负荷,尤其是在差路况时,车辆的颠簸甚至会使货物偏到车箱一侧,使车辆和轮胎的冲击负荷加大,严重加剧轮胎的磨损。

轮胎异常磨损原因分析及预防措施作者:蔡丽华郭延霞来源:《农机使用与维修》2014年第08期轮胎的磨损有自然磨损和异常磨损。

自然磨损是轮胎使用过程中的正常现象,轮胎在出厂前在胎侧都标注有磨损极限记号,有的为三角形符号,表明当轮胎花纹磨损到此标记,应更换新胎,因为此时轮胎的排水性能和抗扎性能都会大幅下降。

轮胎异常磨损是指正常轮胎在行驶过程中所发生的磨损速度加快,胎面形状出现异常的状态。

汽车在正常使用过程中,轮胎损坏的形式很多,但常见的损坏形式是轮胎的异常磨损。

它大大缩短了轮胎的正常使用寿命,说明车辆使用中存在隐患,应该根据轮胎的磨损特征找出原因,采取有效措施及时排除,延长轮胎的使肘寿命。

1.轮胎异常磨损的原因(1)轮胎胎冠的内侧偏磨,呈现内锥体。

主要原因有:汽车长期在拱形路面上行驶,不及时换位,车轴两端向上弯曲变形,使轮胎内侧承载过大;前轮外倾角不正确等。

(2)轮胎胎冠外侧磨损严重,呈现外锥体,则为车轮外倾角失准或长期未换位所致。

在轮胎定期换位的情况下,当胎面外侧肩部磨损严重时,则为外倾角过大;当胎面内侧磨损严重时,则为外倾角过小。

(3)轮胎的胎冠中部磨损严重,即胎面中部磨损。

主要原因为轮胎长期在过高胎压下工作,这样容易造成轮胎胎冠中部磨损增加,花纹底部开裂。

另外,车辆过载,在行驶中随着轮胎内部温度升高,同样也会加剧轮胎气压的升高。

(4)轮胎胎冠的两边磨损严重。

主要原因是轮胎气压长期不足,或轮胎胎面过窄、轮辋过宽,轮胎的磨损主要由胎面两侧承担。

(5)轮胎局部磨损严重。

主要原因为汽车使用中紧急制动较多,制动鼓失圆,轮胎不平衡;轮胎变形等。

(6)前轮胎单侧胎肩磨成椭圆形。

主要原因是前束值不正确且气压不足所致。

(7)轮胎花纹斑状磨损。

车轮总成动平衡不好或车辆减振性能差,使车辆行驶中车轮跳动过大,造成轮胎花纹出现斑状磨损;也可能是由于汽车长期在棱角石块路面上行驶所致。

(8)胎面两边小花纹或大花纹块磨成锯齿形。