球阀安装使用说明书

- 格式:pdf

- 大小:422.93 KB

- 文档页数:12

DFH-20/10矿用本安型电动球阀使用说明书1警告:1)安装、使用前应阅读使用说明书,严格按说明书中方法进行安装和操作2)检修时不得修改本安电路及关联电路中元器件的型号、规格及电气参数3)本安产品不得随意与其它未经联检的设备连接1.概述DFH-20/10矿用本安型电动球阀(以下简称电动球阀)为矿用本质安全型产品,主要用于煤矿井下进回风大巷、采掘工作面进回风巷道、上下山、车场、煤仓及其它需要控制液体或气路开闭的场合。

具有适应压力范围广、不受泥沙和污水影响、通径大、工作稳定可靠、使用寿命长、抗干扰能力强等特点,而且电动球阀具备数据采集、控制输出、数据传输、故障自诊断等功能,联网后能与各种煤矿安全及生产监测监控系统或自动喷雾降尘装置配套使用。

1.1.防爆型式:Ex ib I Mb。

1.2.型号意义(此处阀径尺寸和水压为最大值,实际根据定货要求定制)最高工作压力:10MPa阀径:20mm本质安全型电动阀1.3.防护等级:IP65。

2.使用环境a)环境温度:5℃~40℃;b)环境湿度:≤95%;c)环境大气压:80kPa~106kPa;d)无显著振动和冲击的场合;e)煤矿井下有甲烷、煤尘爆炸性混合物,但无破坏绝缘的腐蚀性气体、无直接滴水和淋水的场所。

3.主要技术参数①额定工作电压:18.0V DC;②工作电流:≤200mA。

③输入信号:a)2路电平型开关量信号输入(与频率量信号输入共用):高电平不小于3.0V且不大于18V,低电平不大于0.5V;b)2路电平型频率量信号输入(与开关量信号输入共用):频率范围200Hz~1000Hz,高电平应不小于3.0V且不大于18V,低电平时不大于0.5V,正负脉冲宽度不得小于0.3ms,误差:±2Hz。

④输出信号:a)电平型开关量信号输出,负载电阻大于1.5kΩ时,输出高电平大于3V。

红色发光二极管H3为电平输出指示,发光二极管亮时,有信号输出,反之则无输出。

偏心半球阀使用说明书Q340F-16.C产品使用说明尊敬的用户:非常感谢你选择使用本公司钢制球阀系列产品。

本公司集阀门产品的设计、开发、制造、安装和销售服务于一体,对所有阀门产品的质量、售后服务有了全面保障。

现对阀门产品的结构特点、工作原理、设计制造标准、技术性能参数等做出详细的说明。

请你务必在安装使用本公司产品前详细阅读《使用说明书》,确保你在安装使用时更加便利。

如果你在阀门使用过程中有何疑难问题,请致电本公司售后服务部。

1,用途和性能规范1.1用途a、本产品主要用于气体、液体介质管路上作启闭器,接通或截断介质,具有流阻小,启闭较省力等优点。

b、适用范围:化工、石油、冶金、造纸等行业。

11.3阀门最大工作压力额定值(压力-温度基准)表中温度是指工作状态下管路介质的温度,表中压力是持续无冲击压力2 采用标准2.1设计制造按GB/T 12237的规定;2.2检验和试验按GB/T 13927的规定;2.3法兰尺寸按GB/T 9113或JB/T 79的规定,焊接尺寸按GB/T 122242.4结构长度按GB/T 12221的规定或企业标准;3 结构特点和使用原理3.1结构及主要外形尺寸参见简图3.2本阀靠蜗轮使阀杆转动而带动球转动来达到启闭目的。

3.3本阀门采用增强四氟/碳纤维封圈,工艺简单、密封更换方便。

3.4采用可换式密封结构,维修方便。

-1-1,阀盖;2,底盖;3,球体;4,阀座;5,阀杆;6,压盖;7,支架;8,螺柱、螺母;9,蜗轮。

4零件名称阀体阀盖阀杆阀座球体填料螺栓螺母平键所用材料WCB 2Cr13A105+RPTFEWCB+ENP石墨35CrMoA 45 455 保管、安装、使用、检查5.1保管a.本阀须保管存放在干燥、通风的室内,放置整齐,阀杆不得着力。

b.本阀保管存放期间,球处于全开状态,两端法兰应封闭。

c.本阀存放期间,阀杆及机加工表面应用容易清除的防锈剂涂覆。

d.长期存放的阀门应定期检查,清除污垢,涂防锈剂。

DFH-20/10 矿用本安型电动球阀使用说明书1警告:1)安装、使用前应阅读使用说明书,严格按说明书中方法进行安装和操作2)检修时不得修改本安电路及关联电路中元器件的型号、规格及电气参数3)本安产品不得随意与其它未经联检的设备连接1.概述DFH-20/10 矿用本安型电动球阀(以下简称电动球阀)为矿用本质安全型产品,主要用于煤矿井下进回风大巷、采掘工作面进回风巷道、上下山、车场、煤仓及其它需要控制液体或气路开闭的场合。

具有适应压力范围广、不受泥沙和污水影响、通径大、工作稳定可靠、使用寿命长、抗干扰能力强等特点,而且电动球阀具备数据采集、控制输出、数据传输、故障自诊断等功能,联网后能与各种煤矿安全及生产监测监控系统或自动喷雾降尘装置配套使用。

1.1.防爆型式: Ex ib I Mb。

1.2.型号意义(此处阀径尺寸和水压为最大值,实际根据定货要求定制)DFH20/10最高工作压力:10MPa阀径: 20mm本质安全型电动阀1.3.防护等级:IP65。

2.使用环境a)环境温度 :5 ℃~ 40℃;b)环境湿度 : ≤ 95%;c)环境大气压 :80kPa ~ 106kPa;d)无显著振动和冲击的场合;e)煤矿井下有甲烷、煤尘爆炸性混合物,但无破坏绝缘的腐蚀性气体、无直接滴水和淋水的场所。

3.主要技术参数①额定工作电压: 18.0V DC ;②工作电流:≤ 200mA。

③输入信号:a) 2路电平型开关量信号输入(与频率量信号输入共用):高电平不小于 3.0V 且不大于18V,低电平不大于 0.5V ;b) 2路电平型频率量信号输入(与开关量信号输入共用):频率范围200Hz~ 1000Hz,高电平应不小于 3.0V 且不大于 18V,低电平时不大于0.5V ,正负脉冲宽度不得小于0.3ms,误差:±2Hz。

④输出信号:a)电平型开关量信号输出,负载电阻大于 1.5kΩ时,输出高电平大于3V。

球阀—产品使用说明书(总8页) -CAL-FENGHAI.-(YICAI)-Company One1-CAL-本页仅作为文档封面,使用请直接删除Ball valves球阀使用说明书Ball Valve Operating Manual浙江石化阀门有限公司Zhejiang Petrochemical Valve Co., Ltd.二O一一年 Year 2011一用途Application球阀是一种管线阀门产品,用于接通或截断管路中的介质。

一般是处于全开或全关状态,在微开状态下可作流量的调节使用。

广泛适用于工况条件下水、气、油品等介质的各种管路中。

Ball valve is pipeline valve, used for connecting or cutting off medium in the pipelines.Normally it is at the state of opening or closing. And it could function as regulating the flow when it is at the state of slightly open. It is used on the pipeline such as water, gas, oil etc.二性能规范 Performance Specification压力等级: Class150; Class300; Class600;Pressure: Class150; Class300; Class600;公称尺寸:NPS 2 ~NPS24;Nominal Size: NPS 2 ~NPS24阀体材料: ASTM A216 WCB; ASTM A351 CF8;Body Material:ASTM A216 WCB;ASTM A351 CF8;产品的设计、制造按API6D的规定;检查试验按API6D的规定;法兰连接尺寸按ASME 的规定;结构长度按API6D的规定;Designed and manufactured according to API6D; Inspected and tested according to API6D;Flange ends according to ASME ; Face to face according to API 6D适用介质:水、蒸汽、油品等。

老式水管球阀安装方法1. 背景介绍老式水管球阀是一种常见的阀门类型,安装在供水管道上起到截止水流的作用。

由于其安装相对简单,使用方便,成本较低等优点,被广泛应用于家庭供水系统和工业管道中。

在本文中,我们将介绍老式水管球阀的安装方法,以便您正确安装和使用。

2. 安装材料及准备工作在安装老式水管球阀之前,您需要准备以下材料和完成一些准备工作:- 老式水管球阀- 符合管道尺寸的管道接头- 扳手- 管道胶带在准备工作中,您需要先关闭供水管道,并排空管道中的水流,以免安装过程中发生意外。

3. 安装步骤以下是老式水管球阀的安装步骤:步骤1:清洁管道口使用一块布或纸巾清洁所需安装球阀的管道口。

确保管道口光滑、干净以便于安装。

步骤2:包裹管道接头在管道接头上使用管道胶带,将其包裹几圈。

这有助于提供更好的密封效果。

步骤3:安装球阀将球阀的接口与包裹管道胶带的管道接头对齐,然后用手将其旋紧。

一般来说,您不需要使用扳手,因为手动旋紧即可达到阀门与管道接头的紧密连接。

步骤4:检查安装是否牢固轻轻拧动球阀,检查其是否与管道接头紧密连接。

确保没有松动或滴漏的迹象。

步骤5:试运行阀门缓慢打开管道的供水阀门,然后观察球阀的运作情况。

确保球阀能够完全打开和关闭,并且没有任何渗漏。

步骤6:正式使用如果球阀在试运行过程中没有出现问题,您可以将供水阀门完全打开,并开始正式使用老式水管球阀。

4. 注意事项在安装老式水管球阀时,需要注意以下事项:4.1. 安装时机选择选择合适的安装时机,例如在水流较小或者停水时进行安装,以免造成不必要的浪费或水压问题。

4.2. 接口紧密连接确保球阀与管道接头紧密连接,以免出现漏水或松动的情况。

4.3. 阀门位置在选择球阀位置时,应考虑方便操作和维修。

确保球阀处于易于达到的位置,并能够正常操作。

4.4. 规范使用在使用老式水管球阀时,应按照操作说明书的规范使用,避免使用过大的力量或在不适当的情况下操作。

5. 结论老式水管球阀的安装十分简单,只需按照上述步骤正确安装即可。

上装式固定球阀的使用说明上装式固定球阀是一种常用的阀门,主要用于控制管道中介质的流动。

以下是上装式固定球阀的使用说明:

1.安装前准备:检查球阀的规格、型号是否符合使用要求,并确认阀门

质量合格。

同时,需要清理管道内的杂物,保证球阀的顺利安装和运行。

2.安装:根据球阀的结构和管道系统的要求,确定球阀的安装位置和方

向。

然后,按照球阀的安装说明进行安装。

一般来说,需要将球阀放入预留的管道口中,调整球阀的位置和方向,保证其符合要求。

3.使用操作:在操作球阀时,需要先确认管道内的介质流向,避免出现

倒流现象。

然后,按照球阀的操作方式进行操作,保证其开关灵活、密封良好。

4.维护保养:定期对球阀进行检查和保养,包括清理阀体、检查密封件

是否完好、检查阀门开关是否灵活等。

如果发现球阀有损坏或磨损,需要及时进行更换或修复。

5.注意事项:在使用球阀时,需要注意避免超压使用,以免造成阀门损

坏或泄漏。

同时,需要定期检查管道系统是否正常,避免出现管道系统故障导致球阀无法正常工作。

总之,上装式固定球阀在使用过程中需要注意安全、正确、合理等原则,确保其正常运转并延长使用寿命。

Brief IntroductionSplit body (2-piece) valve allows easy replacement of gasket, seal, and seats without special tools. Series 90 ball valves use “floating ball” design. Induced by the line pressure the ball is free to move horizontally inside the valve body. The valve is capable of tight shutoff with flow in either direction or dead-end, regardless of the position of the valve in the line. The downstream seat, opposite the pressurized side of a closed valve, carries the load exerted by the line pressure on the ball, while the upstream seat is subject to little load or wear. For this reason, it is sometimes possible to increase seat life by turning the valve end-for-end in the pipeline.1. USE:1.1 Life of valve can be maximized if the valve is used within the rated range, in accordance with pressure, temperature,and corrosion data.2. MANUAL OPERATION:2.1 To open or close the valve, turn the handle ¼ turn (90 degrees).A. Valve in Open Position – the handle is in parallel (in-line) with the valve or pipeline.B. Valve in Closed Position – the handle is perpendicular (crossed) with the valve or pipeline.3. AUTOMATED OPERATION:3.1 Valves with actuators should be checked for valve stem alignment. Angular or linear misalignment will result in highoperational torque and unnecessary wear on the stem seal.4. GENERAL INFORMATION FOR ON-SITE INSTALLATION:4.1 The valve may be fitted in any position on the pipeline.4.2 To prevent damage to the seats and ball surface, the pipeline must be flushed, free of dirt, burrs, and weldingresidues before installing the valve.5. DISASSEMBLING & CLEANING THE VALVE:5.1 If the valve has been used in hazardous media, it must be decontaminated before disassembly.5.2 As shipped from the factory, valves contain silicon-free lubricant. If Lubricant is unacceptable for your particularapplication, you may disassemble the valve and wash the parts in solvent.6. REPLACING THE THRUST WASHER AND PACKING6.1 Before replacing the thrust washer and the packing, the pipeline must be de-pressurized.Note: Stem seal leakage may be corrected without replacing the seal and/or packing. Tighten the packing nut toflatten the belleville washers. If leakage continues or valve’s operating torque becomes excessive, the seals are worn and must be replaced.A. Remove flange bolts and nuts and lift the valve from the line. Care should be taken to avoid scratching ordamaging serrated gasket. The valves are heavy, and they should be adequately supported before removing it from the line.B. Loosen the stem nut and remove handle and stop plate. Next, remove lock saddle, packing nuts, bellevillewashers and gland.C. Remove body bolt nuts, using proper wrench. Lift off body end. One seat should come out with the body end.D. Remove body seal.E. To take out the ball, rotate stem so ball is in fully closed position. Lift ball from the body, using a strap and liftdevice, if necessary. Extreme caution should be taken to avoid damage to the ball. F. Take out the other seat.G. Stem must be removed from inside the body. A tap to the top of the stem should loosen it. The thrust washershould come out with the stem. Then, remove the stem packing.7. VISUAL INSPECTION:7.1 Clean and inspect metal parts. It is not necessary to replace neither ball nor stem unless the surface has signs ofabrasion or corrosion. We strongly recommend replacement of all soft parts whenever the valve is disassembled for reconditioning. We provide replacement kits that contain all the replaceable parts.Note: The valve may be assembled and operated dry with any lubricant. However, a light lubrication will aid inassembly and reduce initial operating torque. Lubricant used must be acceptable with the intended line fluid.8. ASSEMBLYInstall one seat in the body cavity with the spherical curvature facing the ball.8.1 Install the thrust washer on stem and slide the stem up through the body. Install packing, gland, belleville washers,locking saddle. Screw the packing nut into the stem. Lock the saddle in place.8.3 Install stop plate, handle and washer. Screw the stem nut into the stem until the handle is secure.8.4 Turn handle to the closed position. Line up the ball slot with the stem end and slide the ball into position. Turn thehandle to the open position to hold the ball in place. 8.5 Install the remaining seat into body side.8.6 Put body seal gasket into body and line up end flange. Because the body flange bolt pattern is different from the lineflange bolt pattern, it is possible to assemble the valve such that the line flanges bolt pattern don’t line up. Be certain to align end flanges bolt holes to straddle valve center lines. Be careful not to damage body seal when putting cap end into body.8.8 Install cap end nuts and tighten in the “star” pattern to the proper torque. Extreme care must be exercised duringadjustment of cap end nuts to make sure that complete engagement of the studs with body flange is maintained. There should be at least one stud thread exposed on each side.8.9 Cycle the valve slowly, with a gentle back and forth motion, to build gradually to the full quarter turn. By cyclingslowly, the seat lips will assume a permanent seal shape against the ball. A fast turning motion, at this point, may cut the seats before they have a chance to form the proper seal.8.10 Test valve, if possible, prior to placing valve back into line position. If not properly secured, the valve can separatefrom the pressure source, resulting in possible injury. Always join the valve to companion flanges of same pressure rating as valve and secure with a full set of flange bolts.TEST AS FOLLOWS:A. Secure valve to a test fixture by means of a mating flange with full bolting and a suitable gasket. Orient valve soseat to be tested is facing up.B. Introduce 50 to 100 psig air. Partially cycle the valve, under pressure, then slowly close to make sure the cavity ispressurized (use hearing protection). Pour water into the upper port to cover the ball and visually check for bubbles. If bubbles appear, pour the water out, cycle the valve several times and recheck. To check for leakage in the other port, reverse the valve and introduce air pressure to the port just checked.C. Check stem seal at this time by coating the stem top area with a water/soap solution. If leakage occurs, tighten stemseal just until leakage stops.Valve SizeBreak Away Torque(In-lbs.)Torque of Body Bolts(In-lbs.)Torque of Stem Nut(In-lbs.)½” 92 95 ~ 130 87 ¾” 115 122 ~ 156 87 1” 150 365 ~ 399 130 1-1/2” 320 365 ~ 399 208 2” 415 365 ~ 399 208 2-1/2” 675 365 ~ 399 208 3” 1000 477 ~ 521 304 4”1800477 ~ 521304A-T Controls product, when properly selected, is designed to perform its intended function safely during its useful life. However, the purchaser or user of A-T Controls products should be aware that A-T Controls products might be used in numerous applications under a wide variety of industrial service conditions. Although A-T Controls can provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser / user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of A-T Controls products. The user should read and understand the installation operation maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of A-T Controls products in connection with the specific application.While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only. Because A-T Controls is continually improving and upgrading its product design, the specifications, dimensions and information contained in this literature are subject to change without notice. Should any question arise concerning these specifications, the purchaser/user should contact A-T Controls.For product specifications go to /A-T Controls, Inc. • 9955 International Boulevard, Cincinnati, OH 45246 • Phone: (513) 530-5175 • Fax: (513) 247-5462 • 。

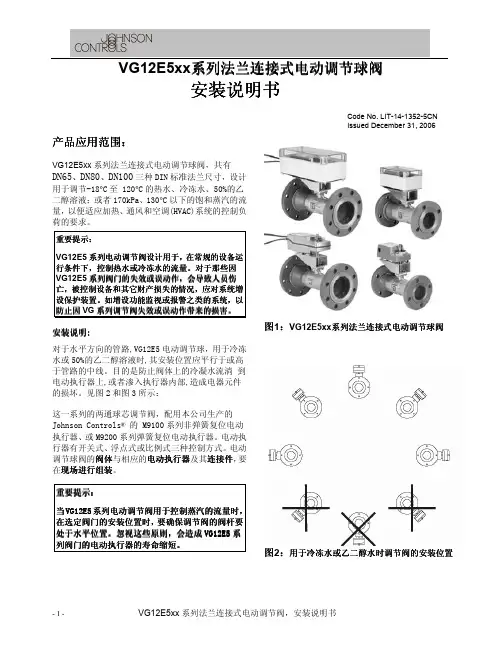

VG12E5xx 系列法兰连接式电动调节球阀安装安装说明书说明书Code No. LIT-14-1352-5CNIssued December 31, 2006产品应用范围产品应用范围::VG12E5xx 系列法兰连接式电动调节球阀,共有DN65、DN80、DN100三种DIN 标准法兰尺寸,设计用于调节-18°C 至 120°C 的热水、冷冻水、50%的乙二醇溶液;或者170kPa、130°C 以下的饱和蒸汽的流量,以便适应加热、通风和空调(HVAC)系统的控制负荷的要求。

重要提示重要提示::VG12E5系列电动调节阀设计用于系列电动调节阀设计用于,,在常规在常规的的设备运行条件下行条件下,,控制热水或冷冻水的流量控制热水或冷冻水的流量。

对于对于那些因那些因VG12E5系列阀门的失效或误动系列阀门的失效或误动作作,会导致人员伤亡,被控制设备和其它财产损失的被控制设备和其它财产损失的情况情况情况,,应对系统应对系统增增设保护装置设保护装置。

如增设功能监视或报警之类的系统如增设功能监视或报警之类的系统,,以防止因VG 系列调节阀失效或误动作带来的损害系列调节阀失效或误动作带来的损害。

安装说明安装说明::对于水平方向的管路,VG12E5电动调节球,用于冷冻水或50%的乙二醇溶液时,其安装位置应平行于或高于管路的中线。

目的是防止阀体上的冷凝水流淌 到电动执行器上,或者渗入执行器内部,造成电器元件的损坏。

见图2和图3所示:这一系列的两通球芯调节阀,配用本公司生产的Johnson Controls® 的 M9100系列非弹簧复位电动执行器、或M9200系列弹簧复位电动执行器。

电动执行器有开关式、浮点式或比例式三种控制方式。

电动调节球阀的阀体阀体阀体与相应的电动执行器电动执行器电动执行器及其连接件连接件连接件,要在现场进行组装现场进行组装现场进行组装。

重要提示重要提示::当VG12E5系列电动系列电动调节阀用于调节阀用于调节阀用于控制控制控制蒸汽蒸汽蒸汽的流量的流量的流量时时,在选定阀门的安装位置时在选定阀门的安装位置时,,要确保调节阀的阀杆要确保调节阀的阀杆要要处于水平位置处于水平位置。

球阀使用说明书球阀使用说明书1.简介1.1 球阀定义1.2 球阀的工作原理1.3 球阀的主要组成部分2.产品特点2.1 阀体材质2.2 阀门类型2.3 连接方式2.4 使用环境要求2.5 阀门的优点3.安装3.1 环境准备3.2 安装步骤3.2.1 阀门准备3.2.2 连接管道3.2.3 固定阀门3.2.4 测试阀门3.3 定位装置的安装(适用于自动球阀)3.4 电动装置的安装(适用于电动球阀)4.使用4.1 操作步骤4.1.1 手动球阀的操作4.1.2 自动球阀的操作4.2 注意事项4.2.1 使用前的检查4.2.2 阀门的开启和关闭4.2.3 阀门的维护保养5.故障排除5.1 无法开启或关闭阀门5.2 阀门漏气5.3 阀门卡住或堵塞5.4 其他常见故障6.附件6.1 阀门相关配件6.2 阀门示意图7.法律名词及注释7.1 根据本文档中所述,球阀指的是一种用于控制流体流动的阀门装置。

7.2 阀体材质是指球阀所使用的主要材料,常见的材质包括不锈钢、铸铁和铜合金等。

7.3 连接方式是指球阀与管道之间的连接方式,包括螺纹连接、焊接连接和法兰连接等。

7.4 环境要求是指球阀在使用时所需的温度、压力和介质等条件。

7.5 自动球阀是指通过电动装置、气动装置或液动装置等可以实现自动开闭的球阀。

附件:1.阀门示意图2.安装准备检查表3.球阀维护保养手册4.球阀使用常见问题解答指南法律名词及注释:1.球阀:根据本文档中所述,球阀指的是一种用于控制流体流动的阀门装置。

2.阀体材质:阀体材质是指球阀所使用的主要材料,常见的材质包括不锈钢、铸铁和铜合金等。

3.连接方式:连接方式是指球阀与管道之间的连接方式,包括螺纹连接、焊接连接和法兰连接等。

4.环境要求:环境要求是指球阀在使用时所需的温度、压力和介质等条件。

5.自动球阀:自动球阀是指通过电动装置、气动装置或液动装置等可以实现自动开闭的球阀。

SERIES TS2, TS3, TM3TRUNNION MOUNTED BALL VALVES INSTALLATION, OPERATION & MAINTENANCE MANUALContents1SCOPE (3)2DESIGN (3)3INSTALLATION (4)4TESTING (4)5VALVE OPERATION (5)6DRAINING, VENTING THE VALVE (5)7REMOVING AND REPLACING THE VENT/DRAIN PLUGS (6)8DISASSEMBLY (6)9STORAGE (6)10MATERIAL DESCRIPTION (7)10.1MATERIAL DESCRIPTION – SERIES TS2 (7)10.2MATERIAL DESCRIPTION – SERIES TS3 (8)10.3MATERIAL DESCRIPTION –SERIES TM3 (2”-14”) (9)10.4MATERIAL DESCRIPTION –SERIES TM3 (16”-24) (10)11NAME PLATE (11)12SPARE PARTS AND REPAIR KITS (11)1 SCOPEThis IOM provides a general guideline in installing and operating Series TS2/TS3/TM3 Trunnion Mounted Ball Valves with standard features. It is responsibility of the end user to determine that the valve is appropriate for the intended service and proper Personal Protective Equipment (PPE) are used when installing or operating the valves. Contact factory for any specific technical details.2 DESIGNDepending on the specific valve configurations, Trunnion Mounted Ball Valves may have the following features: Double Block and Bleed (DBB)This feature is based on Double Block and Bleed feature as defined in API 6D standard where the line pressure can be applied simultaneously to one single valve from both valve ends in closed position. The pressure inside the body cavity can be released thru a vent valve.Note that the DBB concept as defined in API 6D standard is different from OSHA standards, which carry different meanings. OSHA describes DBB as two in-line valves with a method or device to bleed the pressure between two valves.Emergency sealant injection fittingsStandard soft seated trunnion ball valves (TS2/TS3) include emergency sealant injection fittings for the valve stem and seat sealing area. Due to the flange thickness, some of the smaller valves may not have an emergency sealant injection fitting for the seats.WARNING: Fittings must be replaced if there are any signs of damage or corrosion. Some sealant injection fittings for the seat sealing area may have another internal check valve installed below the injection fitting. DO NOT remove the fittings or the internal check valves when the valve is under pressure.Body Vent and Drain plugTypical construction includes a vent plug at the upper body and a drain plug at the lower valve body.Single Piston Effect Seats (SPE) or Self-Relieving SeatsSPE seats or Self-relieving seats are standard design features. The SPE seats are designed to prevent any excess pressure build-up inside the body cavity.Double Piston Effect (DPE) Seats and Double Isolation and Bleed (DIB)DPE seats are optional features. Usually a pressure relief valve is installed on the body to provide overpressure protection inside the body cavity. If equipped, check the operating conditions and make sure that the pressure relief valve is installed properly.Valves equipped with DPE seats are also referred to as Double Isolation and Bleed (DIB) valves per API 6D standard.* Some smaller valves may not have an emergency sealant injection fitting for the seats.The valve may be supplied with different configurations. Contact factory if there are any questions regarding the specific valve design features.3 INSTALLATIONExcept for the fail-safe closed configuration, the valves should be installed in open position. Prior to installation, check the valve for any sign of damage. The valve must be properly cleaned as any foreign material, weld slag or construction debris may damage the sealing surfaces during operation.Verify that proper studs and nuts are being used and check flange surfaces for correct finishes, blemishes, etc.CAUTION: Lifting and handling of the valve assembly should be done by qualified personnel and in compliance with the applicable law and safety regulations. Lifting equipment must be rated and suitable for lifting the entire valve and actuator assembly.Lifting lugs on the actuators or gear operators are not designed to support the weight of the valve and actuator assembly. Never lift the valve assembly by handle, hand wheel, gear operator or actuator.Valves should be lifted by using lifting lugs on the valve body or using a strap to lift the valve assembly. Do not stand near and under the valve assembly during lifting operation.4 TESTINGMost piping system requires a pressure test that includes a hydrostatic shell test and a seat (closure) test. Hydrostatic shell test must be performed with the valve in partially open position. Seat test can be performed in closed position.Test fluid must be fresh water mixed with a corrosion inhibitor or liquid that is compatible with the metal and soft seal components. Valves should be pressure tested at ambient temperature and the maximum test pressure is listed as follows:The pressure rating of the valve is listed on the nameplate.Due to the danger of testing with air or gas, test pressure for a pneumatic shell test may be lower. Check the design specifications or standard for the correct test pressure for air or gas.After testing, valve should be drained, cleaned and kept dry.5 VALVE OPERATIONThe ball valve is designed for on-off service. In other words, the valve should be operated either in fully open or fully closed position. Do not operate the valve in partially open position.Wrench Operated Valves:To open the valve, rotate the handle until it is parallel to the flow direction. To close the valve, rotate the handle until the orientation of the handle is perpendicular to the flow direction.Gear Operated Valves:A position locator on top of the gear operator shows the valve position. Turn the hand wheel clockwise to close the valve and counter clockwise to open the valve. The valve is open when the position indicator is parallel to the flow direction. The valve is closed when the position indicator is perpendicular to the flow direction.Valves with Actuators:Contact factory or suppliers of the actuators for the specific operating procedures for actuators.6 DRAINING, VENTING THE VALVEWARNING: Allow the surface temperature of the valve and flow media to cool down until it is safe for handling before attempting to drain the valve or remove the plugs.Check with local regulations regarding the proper procedures of disposing off the drain fluid.The vent valve assembly consists of a vent valve body and a bleed screw. The vent valve can be open by loosening the bleed screw in counter-clockwise direction.CAUTION: To open the vent valve, unscrew the bleed screw slowly until the pressure starts to vent. Once the bleed valve is fully open, do not unscrew the bleed screw any further as the bleed screw could disengage from the bleed valve assembly.Exercise caution and make sure that the vent pressure or the discharge is directed away from the operator and other people.7 REMOVING AND REPLACING THE VENT/DRAIN PLUGSVent and drain plugs must be replaced if there are any signs of damage or corrosion.WARNING: DO NOT remove or loosen the vent plugs or drain plug when the valve is under pressure.Check and make sure that the valve is not under pressure before removing or replacing the vent plugs or drain plugs. Under certain circumstances, the bleed valve may be clogged due to debris, overspray paint, etc., and this may give the false impression that the valve is depressurized. Cycle the valve a few times and make sure that there is no pressure trapped inside the body cavity before removing the plugs.Contact factory for the correct type of vent and drain plugs. Before installing the plugs, wrap the thread of the plug with PTFE/Teflon tape or coat with anti-seize compound. When installing the plug assembly, make sure to tighten it properly but do not over-tighten. Ensure the bleed valve is closed before operating the valve.8 DISASSEMBLYPrior to removing the valve from the line, it is recommended to keep the valve in open position.Ensure that the valve is completely depressurized before removing the valve from the line. Do not attempt to remove or work on any valve under pressure. For valves intended for high temperature service, wait until the temperature cools down first before handling the valves.For valves actuators that are equipped with electric or pneumatic actuators, disconnect electrical supplies, shut off pneumatic supply and vent the actuator.9 STORAGEValves should be stored indoor in open position and kept dry. Unpainted surface areas must be coated with oil that is compatible with metal and soft seal components.Original port protectors should be kept in the ports during storage.Valves must be cycled at least once every 90 days in storage or in operation.Consult factory for proper storage procedures if valves are required to be stored for longer than 6 months.10 MATERIAL DESCRIPTION10.1 MATERIAL DESCRIPTION – SERIES TS210.2 MATERIAL DESCRIPTION – SERIES TS310.3 MATERIAL DESCRIPTION –SERIES TM3 (2”-14”)10.4 MATERIAL DESCRIPTION –SERIES TM3 (16”-24)SERIES TS2, TS3 & TM3TRUNNION MOUNTED BALL VALVESInstallation & Maintenance ManualValves11 NAME PLATEThe information on the nameplate includes the following:•P/N: Part number •SIZE: Nominal pipe size •CL: Pressure class • S/N: Serial Number•BODY: Body material •BALL: Ball material •SEAT: Seat material •STEM: Stem material •SEAL: Seal material •F/F: Face-to-face dimension •MFG: Manufacture date •P/T: Pressure temperature rating of the valves (Imperial and Metric)12 SPARE PARTS AND REPAIR KITSTo order replacement seal kits or spare parts please provide the following information:• Part number of the valve• Serial Number• Type of spare part kitA-T Controls product, when properly selected, is designed to perform its intended function safely during its useful life. However, the purchaser or user of A-T Controls products should be aware that A-T Controls products might be used in numerous applications under a wide variety of industrial service conditions. Although A-T Controls can provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser / user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of A-T Controls products. The user should read and understand the installation operation maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of A-T Controls products in connection with the specific application.While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only. Because A-T Controls is continually improving and upgrading its product design, the specifications, dimensions and information contained in this literature are subject to change without notice. Should any question arise concerning these specifications, the purchaser/user should contact A-T Controls.For product specifications go to /A-T Controls, Inc. • 9955 International Boulevard, Cincinnati, OH 45246 • Phone: (513) 530-5175 • Fax: (513) 247-5462 • 。

VYH 气动 V 型球阀使用说明书上海屹沪阀门有限公司Shanghai Yi Hu Control Valve CO., LTD.地址:上海市奉贤区金汇工业园工业路 1390 号 电话:021-******** E-mail:sales@ 邮编:201315 传真:021-******** 网址:一、概述VYH 气动 V 型调节球阀是一种直角回转式调节阀,它由 GT 系列 气动活塞式执行机构(单、双作用) 和 V 形球阀二部分组成。

与电磁阀和电气阀门定位器配套使用,输入 4~20ma DC 信号及 0.5~0.7Mpa 气源即 可控制运转,实现对压力、流量、温度、液位等参数的调节。

它是以压缩空气为动力,阀杆带动阀芯在阀体 内转动 90°,可以实现全开-全闭的动作。

该产品按其密封性能分为金属密封与软密封。

由于气动 V 型调节 球阀为直角回转结构,当阀芯相对于阀座旋转时具有较强的剪切作用,尤其适用于带有纤维和微小颗粒介质 的调节控制。

同时还具有结构紧凑、体积精小、运行可靠、密封性好、维修容易、安装方便、适应性强等特 点。

可广泛应用于石油,化工、轻工、电力、制药、造纸、冶金等工业自动控制系统中,作远距离集中控制 或就地控制。

二、特点1、由于 V 型球阀流路简单、流阻较小,因而流通能力较大。

2、V 型球阀阀芯上具有近似等百分比流量特性的 V 型和具有近似线性流量特性的 U 型两种缺口形式,因 而无须通过定位器调整,即能实现不同流量特性的流量控制。

3、可调比可达到 300∶1 远大于直通单、双座调节阀。

4、 具有较高的密封等级: 软密封结构的泄漏等级为 GB/T4213 VI 级;硬密封结构的泄漏等级为 GB/T4213 IV 级。

O 5、正、反作用方式变换较为方便,只需将阀芯初始位置旋转 90 ,即能实现作用方式的转换。

6、结构简单、维护方便。

体积较小、易于安装。

三、型号编制说明V YH 6 41 F——16CG 温度类型(表 1) 阀体材质(表 2) 公称压力(表 3) 密封面材料(表 4) 连接方式(表 5) 执行机构类型(表 6) 屹沪公司标志 阀门代号:V 型球阀表1工作温度℃ 代号 中温 G 常温 无表2阀体材质 代号 碳钢 C 不锈钢 P 铸铁 省略表3公称压力 Mpa 代号 1.6 16 2.5 25 4.0 40 6.4 64表4密封面材料 代号 四氟乙烯 F 金属密封 H表5连接形式 代号 法兰 41 丝扣 11 对夹式 71表6执行机构 代号 电动 9 气动 6四、工作原理和结构VYH 气动 V 型调节球阀由气动活塞式执行机构和 V 形球阀二部分组成。

球阀使用及维护1.前言感谢您选择我公司阀门产品。

作为一种承压设备,当阀门用于输送流体及易燃易爆气体时,由于泄露或使用不当而存在一些安全隐患,为了安全考虑,用户使用时应阅读本说明书,以了解阀门在运输、放置、安装、维护及安全方面应该注意的事项和必须遵守的原则。

2.范围本使用说明书包括了公称通径NPS 2~48、压力等级Class150~2500法兰端连接、承插焊端连接的两片式、三片式硬密封、软密封锻钢固定球阀;适用介质水、油、汽等介质;操作方式包括齿轮、手柄、电动执行机构、液动、气动和气液联动执行机构。

3.产品描述和用户须知3.1技术要求—球阀作为一种标准产品来设计,由于它的适用工况范围较广所以并不考虑每一个细节的工作条件。

—美标球阀设计参照API 6D,阀门材料的选择符合ASME B16.34 压力—温度额定值的要求;国标球阀的设计参照GB/T 12237或GB/T 19672,阀门的材料选择符合GB/T 12224压力—温度额定值的要求。

—阀门密封材料应根据介质对材料的腐蚀性和工况耐磨损的要求而选择,参照API 6D、GB/T 12237或GB/T 19672的规定。

—阀门设计时应有防静电装置及防火结构,放火实验设备符合API 607及API 6FA 规范,并已通过英国的劳氏船级社认证。

—阀门不含轻金属(例如镁),各零部件通过相互接触形成导电通路,通过管道流向大地,以防止静电积累。

—阀门根据它的型号、扭矩、及操作要求配以手轮、齿轮、或电动头。

3.2 用户须知3.2.1 概述3.2.1.1 任何场合,应首先保证人身安全。

3.2.1.2 使用阀门时允许工作压力应符合 ASME B16.34 或GB/T12224压力—温度额定值的规定。

3.2.1.3 选择阀门材料时应考虑工作介质对材料的腐蚀性和工况对耐磨损的要求。

3.2.1.4 工作介质是易燃/易爆的,要限制工作温度。

3.2.1.5 当维修/维护时,应先打开泄放阀或泄放螺塞,以泄掉中腔压力。

南京苯邦阀门公司球阀使用说明书Ball valve operating instruction1.一般预防General prevention2.产品介绍Product Introduction3.压力温度等级Pressure-temperature rating4.交货条件和存放Delivery terms and storage5.安装和操作Installation and operation6.使用前安装检查Inspection installation before use7.不适当的危险使用Inappropriate use of danger8.维护Maintenance南京苯邦阀门公司1.一般预防General preventiona.材料选择: Material selection材料在使用中有失效的可能性,需根据阀门内的流体进行定期检查。

碳化物在低温下(甚至在高于-29℃时)可能转化为石墨、氧化铁素体,塑性减小等变化。

后面均加以了说明。

使用者需依据说明慎重选择适合自己要求的材质(阀门)。

Material have the possibility of failure in use, and should be checked on a regular basisdepending on fluid within the valve. Carbide at low temperature (or even above - 29 ℃)may be converted to graphite, iron oxide ferrite, reducing the plasticity. The behind aredescribed. According to the instructions,the user need to carefully chose the material that fits their requirements (valve).b.压力温度等级: Pressure-temperature rating压力温度等级额定值是在静态压力下的温度额定值。

请参考第3页工作预防方法部分的P&T额定值。

阀门允许使用温度在-20℃~200℃之间,不允许超过此温度范围,以免发生危险。

Pressure-temperature rating is the temperature rating in the static pressure. Please referto page 3 work prevention part of P&T rating. In order to avoid danger, Valve allows theuse temperature between-20℃to 200℃, and doesn't allow more than this temperaturerange.c.流动性热的扩充: Liquidity thermal expansion当球阀在封闭的条件下工作,阀体内的封闭腔体可能封有流体。

若流体不能被及时释放出来,将会升温膨胀,导致压力边缘失效。

而我们的产品具有球垫压力自动调节功能,能够预防压力增强。

建议用户通过管道系统设计、安装或操作程序等方法来进行预防,以避免阀体内压力超过额定压力值。

When ball valve working in the closed conditions, the valve body of closed cavity couldseal a fluid. If the fluid can not be released in time, it will be heating expansion, leading to the failure of pressure edges. However, our products have the cushion pressureautoregulation, preventing pressure increase. To avoid the valve body pressure exceed the rated value, we recommend that users through the piping system design, installation oroperation procedure and methods for prevention.d.静电影响:Electrostatic effect南京苯邦阀门公司球阀具有抗静电能力,当使用环境连续用电需要预防静电时,阀门应有接地,以使静电能够即时得以释放。

Ball valves have the antistatic ability. When the using environment continuous electricity needs to prevent static electricity, the valve should be grounded, so that static electricity can be released immediately.e.意外火灾预防:Accidental fire prevention通常,球阀的使用应遵守压力温度要求。

如果发生意外火灾时造成的危险较大,建议您选择我们的防火型产品。

此产品已通过API-607认证。

具体请与阀门销售商联系或直接联系我们。

Usually, ball valve should be used in compliance with the pressure and temperaturerequirements. If causing greater risk in the event of accidental fires, it is recommended that you choose our fire protection products. The product has passed the API - 607certification. For details, please contact with the valve sales or contact with us directly.f.液体流速:Liquid velocity当球阀必须经常在高速流体条件下频繁开关时,销售商或制造商应适当建议最小化密封垫变形的可能性,尤其是在高温线上进行高温密封的球阀,并进行检查。

When the ball valve must always frequently switch in high speed fluid condition, vendors or manufacturers should suggest to minimize the possibility of Gasket deformationappropriately, especially the ball valves in the high- temperature line for high-temperature sealing, and check.g.节流装置:Throttling device当用阀门做为节流装置时,流体和钢球的前边缘能损坏密封垫的回弹力,导致泄露。

因此建议球阀一般不要用做节流。

用做节流时产生的高流体流速及悬浮固体颗粒将进一步缩短密封垫的使用寿命。

When the valves used as the throttle device, fluid and the front edge of the ball candamage the resiliency of the gasket, causing leakage. So, we suggest that ball valvegenerally don't used as throttle. High fluid velocity used for throttling and suspended solids will further shorten the service life of the seal.h.当打开阀门困难时,(阀体内正承受压力时)不要拧开螺帽检查。

用户可以通过管道系统用其它方法检查。

球阀不配备增压装置。

When you have difficulty opening the valve, (the body is under pressure) don't twist off the nut for inspection. Users can check in other ways through the piping system. Ball valve is not equipped with a supercharger device.南京苯邦阀门公司i.阀门处于高温时不要用手触摸其外表面。

Don't touch the outside surface when the valve is in high temperature.j.不允许应用于不稳定流体,除非在说明及使用手册中提及。

Unless mentioned in the description and user manual, applied to unstable fluid is notallowed.k.阀门手柄挂锁,是为了防止对阀门的误操作。

The valve handle hanging lock is to prevent wrong operation of the valve.2.产品介绍Product Introductiona. 标准类型,三片式全流量球阀.a. The standard type, three-pieces full-flow ball valve.b. 中轴倒装防脱出;防爆设计b. Axial inversion can prevent emerging; Explosion-proof design.c. 通过钢球、中轴和阀体建立防静电功能(可选)c. Anti-static function can be established through the ball, axial and body (optional).d. 阀体、阀盖标记有可追溯的炉号、流水序号,以便责任认定d. For responsibility identification, the valve body and valve cover mark traceable heatnumber and flowing number.e. 钢球上设有压力平衡孔(可选)e. The ball is equipped with pressure balance hole (optional).f. 球垫具有压力自我调节功能f. The ball pad has pressure autoregulation.g. 手柄可以锁定(可选)g. Handle can be locked (optional).3.压力温度等级Pressure-temperature rating球阀压力温度额定值不仅被阀体材料,而且也被球垫、中口组与大薄片的材料限制。