3D_Flexible_Roll_Forming(柔性辊弯成型)

- 格式:pdf

- 大小:3.82 MB

- 文档页数:45

材料成型工艺基础部分(中英文词汇对照)材料成型工艺基础部分0 绪论金属材料:metal material (MR)高分子材料:high-molecular material陶瓷材料:ceramic material复合材料:composition material成形工艺:formation technology1 铸造铸造工艺:casting technique铸件:foundry goods (casting)机器零件:machine part毛坯:blank力学性能:mechanical property砂型铸造:sand casting process型砂:foundry sand1.1 铸件成形理论基础合金:alloy铸造性能:casting property工艺性能:processing property收缩性:constringency偏析性:aliquation氧化性:oxidizability吸气性:inspiratory铸件结构:casting structure使用性能:service performance浇不足:misrun冷隔:cold shut夹渣:cinder inclusion粘砂:sand fusion缺陷:flaw, defect, falling流动性:flowing power铸型:cast (foundry mold)蓄热系数:thermal storage capacity 浇注:pouring凝固:freezing收缩性:constringency逐层凝固:layer-by-layer freezing 糊状凝固:mushy freezing结晶:crystal缩孔:shrinkage void缩松:shrinkage porosity顺序凝固:progressive solidification 冷铁:iron chill补缩:feeding等温线法:constant temperature line method 内接圆法:inscribed circle method铸造应力:casting stress变形:deforming裂纹:crack机械应力:mechanical stress热应力:heat stress相变应力:transformation stress气孔:blow hole铸铁:ingot铸钢:cast steel非铁合金:nonferrous alloy灰铸铁:gray cast-iorn孕育处理:inoculation球墨铸铁:spheroidal球化处理:sheroidisation可锻铸铁:ductile cast iron石墨:graphite蠕墨铸铁:vermicular cast iron热处理:heat processing铝合金:Al-alloy熔炼:fusion metallurgy铜合金:copper alloy氢脆:hydrogen brittleness1.2 铸造方法(casting method)手工造型:hand moulding机器造型:machine moulding金属型:metal mold casting金属模:permanent mould压力铸造:press casting熔模铸造:investment moulding蜡膜:cere离心铸造:centrifugal casting低压铸造:casting under low pressure 差压铸造:counter-pressure casting 陶瓷型铸造:shaw process1.3 铸造工艺设计浇注位置:pouring position分型面:mould joint活块:loose piece起模:patter drawing型芯:core型芯撑:chaplet工艺参数:processing parameter下芯:core setting合型:mould assembly冒口:casting head尺寸公差:dimensional tolerance尺寸公差带:tolerance zone机械加工余量:machining allowance 铸孔:core hole非标准:nonstandard label收缩率:rate of contraction线收缩:linear contraction体收缩:volume contraction起模斜度:pattern draft铸造圆角:curving of castings芯头:core register芯头间隙:clearance芯座:core print seat分型线:joint line分模线:die parting line1.4 铸造结构工艺性加强筋:rib reinforcement撒砂:stuccoing内腔:entocoele2 金属塑性加工塑性加工:plastic working塑性:plastic property锻造:forge work冲压:punching轧制:rolling拉拔:drawing挤压:extruding细化晶粒:grain refinement热锻:hit-forging温锻:warm forging2.1 金属塑性加工理论基础塑性变形:plastic yield加工硬化:work-hardening韧性:ductility回复温度:return temperature 再结晶:recrystallize再结晶退火:full annealing冷变形:cold deformation热变性:heat denaturation锻造比:forging ratio镦粗:upset拔长:pull out纤维组织:fibrous tissue锻造性能:forging property可锻性:forgeability变形抗力:resistance of deformation化学成分:chemical constitution热脆性:hot brittleness冷脆性:cold-shortness变形速度:deformation velocity应力状态:stress condition变形温度:deformation temperature过热:overheating过烧:burning脱碳:carbon elimination始锻温度:initiation forging temperature 终锻温度:final forging temperature2.2 金属塑性加工方法自由锻:flat-die hammer冲孔:jetting弯曲:bend弯曲半径:bending radius切割:cut扭转:twist rotation错移:offsetting锻接:percussion基本工序:basic process辅助工序:auxiliary process精整工序:finishing process模锻:contour forging锻模:forging die胎膜锻:fetal membrane forging剪床:shearing machine冲床:backing-out punch冲裁:blanking弹性变形:elastic distortion塑性变形:plastic yield剪切变形:shearing deformation最小弯曲半径:minimum bending radius 曲率:angularity弯裂:rupture回弹:rebound辊轧:roll forming辊锻:roll forging斜轧:oblique rolling横轧:transverse rolling辗压:tamping drum挤压:extruding拉拔:draft2.3 塑性加工工艺设计工艺规程:process specification锻件图:forging drawing敷料:dressing锻件余量:forging allowance锻件公差:forging tolerance工夹具:clamping apparatus加热设备:firing equipment加热规范:heating schedule冷却规范:cooling schedule后续处理:after treatment分模面:die parting face冲孔连皮:punching the wad模锻斜度:draft angle圆角半径:radius of corner圆饼类锻件:circumcresent cake-like forging 长轴类锻件:long axis-like forging2.4 锻件结构工艺性锥体:cone斜面:cant空间曲线:curve in space粗糙度:degree of roughness2.5 冲压件结构工艺性3 焊接焊接:welding铆接:riverting熔焊:fusion welding压焊:press welding钎焊:braze welding3.1 焊接理论基础冶金:metallurgy电弧焊:arc welding气焊:acetylene welding电渣焊:electro-slag welding高能束焊:high energy welding 电子焊:electronic welding激光焊:laser welding等离子焊:plasma welding电弧:electric arc阳极区:anode region阴极区:negative polarity弧柱区:arc stream正接法:electrode negative method反接法:opposition method脱氧剂:deoxidizing agent焊缝:welded seam焊缝区:weld zone熔合区:fusion area热影响区:heat-affected zone脆性断裂:brittle fracture过热区:overheated zone正火区:normalized zone相变区:phase change zone焊接应力:welding stress收缩变形:contraction distortion角变形:angular deformation弯曲变形:bend deformation扭曲变形:warping deformation波浪变形:wave transformation反变形法:reversible deformation method 刚性固定法:rigid fixing method预热:warming-up缓冷:slow cool焊后热处理:postweld heat treatment矫形处理:shape-righting3.2 焊接方法埋弧焊:hidden arc welding气体保护焊:gas shielded arc welding氩弧焊:argon welding熔化极氩弧焊:consumable electrode argon welding 钨极氩弧焊:argon tungsten-arc welding二氧化碳气体保护焊:CO2 gas shielded arc welding 碳弧焊:carbon arc welding碳弧气刨:carbon arc air gouging电渣焊:electro-slag welding高能焊:high grade energy welding等离子弧切割:plasma arc cutting (PAC)堆焊:bead weld电阻焊:resistance welding电焊:electric welding缝焊:seam welding压焊:press welding多点凸焊:multiple projection welding对焊:welding neck摩擦焊:friction welding扩散焊:diffusion welding硬钎料:brazing alloy软钎料:soft solder3.3 常用金属材料的焊接焊接性:weldability焊接方法:welding method 焊接材料:welding material 焊条:electrode焊剂:flux material碳素钢:carbon steel低碳钢:low carbon steel中碳钢:medium carbon steel 高碳钢:high carbon steel低合金钢:lean alloy steel不锈钢:non-corrosive steel 有色金属:nonferrous metal 3.4 焊接工艺设计型材:sectional bar药皮:coating焊丝:soldering wire连续焊缝:continuous weld断续焊缝:intermittent weld应力集中:stress concentration焊接接头:soldered joint坡口:groove对接:abutting joint搭接:lap joint角接:corner joint4 粉末冶金(power metallurgy)粉末冶金成品:finished power metallurgical product 铁氧体:ferrite硬质合金:sintered-carbide高熔点金属:high-melting metal陶瓷:ceramic4.1 粉末冶金工艺理论基础压坯:pressed compact扩散:diffusion烧结:agglomeration固溶:solid solubility化合:combination4.2 粉末冶金的工艺流程制备:preparation预处理:anticipation还原法:reduction method电解法:electrolytic method雾化法:atomization粒度:grain size松装密度:loose density流动性:flowing power压缩性:compressibility筛分:screen separation混合:compounding制粒:pelletization过烧:superburning欠烧:underburnt5 金属复合成型技术自蔓延焊接:SHS welding热等静压:HIP准热等静压:PHIP5.1 液态成型技术与固态成型技术的复合高压铸造:high-pressure casting电磁泵:magnetic-pump压射成型:injection molding柱塞:plunger piston冲头:drift pin凝固法:freezing method挤压法:extrusion method转向节:knuckle pivot制动器:arresting gear5.2 金属半凝固、半熔融成型技术凝固:freezing半熔融:semi-vitreous触变铸造:thixotropy casting触变锻造:thixotropy forging注射成型:injection molding5.3 其他金属成型新技术快速凝固:flash set非晶态:amorphous溢流法:press over system喷射沉积:ejecting deposit爆炸复合法:explosion cladding method 扩散焊接:diffusion welding挤压:extruding轧制:roll down6 非金属材料成型技术6.1 高分子材料成型技术高分子材料:non-metal material耐腐蚀:resistant material绝缘:insulation老化:ageing耐热性:heat-durability粘弹性:viscoelasticity塑料:plastic material橡胶:rubber合成纤维:synthetic fibre涂料:covering material粘结剂:agglomerant粘度:viscosity热塑性塑料:thermoplastic plastics 热固性塑料:thermosetting plastic 通用塑料:general-purpose plastics 工程塑料:engineering plastic薄膜:thin film增强塑料:reinforced plastics浇注塑料:pouring plastics注射塑料:injiection plastics挤出塑料:extrusion plastics吹塑塑料:blowing plastics模压塑料:die pressing plastics聚合物:ploymer semiconductor吸湿性:hygroscopic cargo定向作用:directional action生胶:green glue stock填料:carrier丁苯橡胶:SBR顺丁橡胶:BR氯丁橡胶:CR丁腈橡胶:NBR硅橡胶:Q聚氨酯橡胶:U压延:calender硫化:sulfuration胶粘剂:adhesive胶接:glue joint刹车片:brake block零件修复:parts renewal蜂窝夹层:honeycomb core material 6.2 工业陶瓷制品的成型技术干燥:drying坯料:blank润滑剂:anti-friction结合剂:binder热压铸:hot injiection moulding 6.3 非金属材料成型技术的新进展热压烧结:hot pressed sintering7 复合材料的成型技术复合材料:composite material树脂:resin7.1 金属复合材料的成型技术硼纤维:boron fiber钛合金:titanium alloy碳纤维:carbon filter等离子喷涂:plasma spraying浸渍法:immersion method锭坯:ingot blank7.2 聚合物基复合材料的成型技术晶须:whisker缠绕成形:enwind forming湿法缠绕:wet method enwind 7.3 陶瓷复合材料成型技术料浆:slurry溶胶-凝胶法:sol-gel method化学气相沉积:chemical vapor deposition (CVD) 原位:in situ8 材料成型方法的选择粉末冶金:powder metallurgy工程塑料:engineering plastics工程陶瓷:engineering ceramics。

辊轧成型(roll forming)是一种通过辊轧机将金属板材或带钢等长条材料连续弯曲成所需横截面形状的成型工艺。

这种工艺通常用于大批量生产金属制品,如建筑材料、车辆零部件、家具和电器等。

辊轧成型的工艺过程一般包括以下几个步骤:

1.设计模具:首先需要根据最终产品的要求设计好成型模具。

模具的设计需要考虑到产品

的尺寸、横截面形状以及材料性能等因素。

2.预处理:在进行辊轧成型之前,通常需要对原材料进行预处理,包括清洁、切割和对边

等工序,以确保材料的质量和尺寸符合要求。

3.辊轧成型:将经过预处理的金属板材或带钢送入辊轧机中,通过一系列辊轧的作用,使

材料连续地进行弯曲和塑性变形,最终得到所需的横截面形状。

4.切割和整形:在完成辊轧成型后,需要根据产品的长度要求对其进行切割,同时可能还

需要进行整形和修整,以确保产品的尺寸和外观符合要求。

5.其它加工:根据产品要求,还可能需要进行其它加工工序,如冲孔、打孔、焊接等,最

终得到成品。

辊轧成型工艺具有高效、自动化程度高、生产周期短等优点,适合于大规模生产相对简单形状的金属制品。

随着工艺技术的不断进步,辊轧成型在各个领域得到了广泛的应用。

中文译文:利用辊型的改变来改善冷轧厂的带钢平直度1 介绍在冷轧和退火过程后,变形减少的最低限度(0.5%~3%)应用在了带钢的生产中,这个变形过程的目标是达到优选机械性能,同时消除在钢的应力曲线上静止区域的冷轧,冷轧常常可以获得一个清晰地被设定的板料表面结构,达到更进一步的处理和改正可能的扁平瑕疵,从那个过程开始,冷轧是保证产品的完成的质量,同时也是最后的重要过程,增加对板带形状控制的能力对冷轧厂来说是头等重要的。

2 冶炼厂特殊形状控制冶炼厂有和其他一般冷轧厂同样的框架和几何结构,它前面的板带控制设备是常规控制器:合适的工作辊和支承辊顶端,工作辊的正反弯曲的灵巧像液压压下螺丝系统一样,但是,由于微量的减少和柔软的特殊性质的材料,作为轧辊,那必须是形状控制上的一些轧制和冷轧之间的区别,当前问题是冷轧厂的带材的质量能不能维持在一个稳定的水平上,哪个导致的废品率较高或较多的可修复的产品(必须再轧制的带材)归结于轧辊的扁平度,这样的系统研究由理论分析和实验性调查来完成,但是为了找到形状控制的特点除了在冷轧厂还要在独立的轧制车间。

2.1工作辊的安装和修整根据形状理论,影响辊形的主要因素是辊形的控制和辊系统在轧辊轧制时的弹性变形,辊轻微变形是由于小的轧制力,因此,改变辊缝的形状主要依靠工作辊外形,辊的作用与三个方面因素的关系:(1)计算出最合适的辊的中间部位,辊的最初的中间部位和磨辊的实际操作是依靠许多因素,包括工厂的位置环境,合适的材料和工厂技术条件等。

(2)辊的挠度研磨的精度,一般地,在新的轧制周期开始时,当支承辊的10~14d 时为轧制作准备不超出2~3h(或5~10卷),,因而,要求工作辊修整是紧配合。

(3)轧辊外形形状的改变,在轧制过程中,最终的辊外形是反弯曲辊、轧机机座和安装的部分的组合,所以,辊的安装热散失在为辊的形状做准备时通过一个滚动周期必须考虑在内,工作辊的弯曲是正值20微米并且和支承辊平行的抛物面,这就是早先辊形的改变情况,它的好处是促进研磨的支承辊是平的,尽管如此,二次方和四次方板带缺陷经常发生在轧制期间内。

辊弯成型工艺研究辊弯成型工艺研究是金属材料加工中,一种常见的成形工艺。

它利用辊弯机将金属材料进行弯曲,从而得到所需要的外形尺寸、曲率半径及几何精度的带弯部件。

辊弯成型工艺是一种比较古老的工艺,早在20世纪50年代就开始使用。

在辊弯成型工艺中,金属材料通过两个相对运动的辊子,实现弯曲加工。

根据不同的材料及加工要求,可选择不同类型的辊弯机,如气动式辊弯机、液压式辊弯机、数控辊弯机等。

辊弯机可分为卧式及立式两种,其中立式辊弯机又可分为3轴辊弯机、4轴辊弯机及5轴辊弯机。

辊弯成型工艺具有加工精度高、效率高、成本低等优点,在航空航天、汽车、冶金、电子、机械等行业被广泛应用。

但是,辊弯成型工艺也存在一些缺点,如加工尺寸受到加工参数的限制,加工厚度范围狭窄,加工能力受到材料性能限制等。

因此,在辊弯成型工艺研究中,需要考虑许多因素,如设计理念、选择辊弯机型号、选择加工参数、选择工具材料等。

首先,要确定好设计理念,以便正确的选择辊弯机型号及加工参数。

其次,应仔细研究辊弯机的结构特点,确定合适的机型,以保证加工效率及加工精度。

在选择加工参数方面,要根据材料的性能及加工精度,选择合理的加工参数,以保证加工效果。

另外,在选择工具材料方面,也要考虑到工具使用寿命、曲率半径及弯曲精度等因素。

总之,辊弯成型工艺研究是一项比较复杂的工作,需要考虑许多因素,以保证加工效果及成型精度。

此外,要根据实际情况,不断优化辊弯成型工艺,以提高加工效率及精度,满足不断发展的加工要求。

Roll bending forming technology research is a common forming process in metal material processing. It uses roll bending machine to bend the metal material, so as to obtain the bent parts with required shape size, curvature radius and geometric precision. Roll bending forming technology is a relatively old technology, which has been used since the 1950s.In roll bending forming process, the metal material is bent by two relative moving rolls. According to different materials and processing requirements, different types of roll bending machines can be selected, such as pneumatic rollbending machine, hydraulic roll bending machine, CNC roll bending machine, etc. Roll bending machines can be divided into horizontal andvertical types, among which vertical roll bending machines can be further divided into 3-axis, 4-axis and 5-axis roll bending machines.Roll bending forming technology has advantages of high processing accuracy, high efficiency and low cost. It is widely used in aerospace, automobile, metallurgy, electronics, machinery and other industries. However, roll bending forming technology also has some disadvantages, such as the processing size is limited by processing parameters, the processing thickness range is narrow, and the processing capacity is limited by material properties.Therefore, in the research of roll bending forming technology, many factors need to be considered, such as design concept, selection of roll bending machine model, selection of processing parameters, selection of tool materials, etc. First of all, it is necessary to determine the designconcept in order to select the right roll bending machine model and processing parameters. Secondly, the structure characteristics of the roll bending machine should be studied carefully to determinethe appropriate model in order to ensure the processing efficiency and accuracy. In terms of selecting processing parameters, reasonable processing parameters should be selected according to the material properties and processing accuracy to ensure the processing effect. In addition, when selecting the tool materials, the service life of the tools, curvature radius and bending accuracy should also be taken into account.In a word, the research of roll bending forming technology is a complicated work, which needs to consider many factors to ensure the processing effect and forming accuracy. In addition, according to the actual situation, the roll bending forming technology should be optimized continuously to improve the processing efficiency and accuracy, so as to meet the constantly developing processing requirements.。

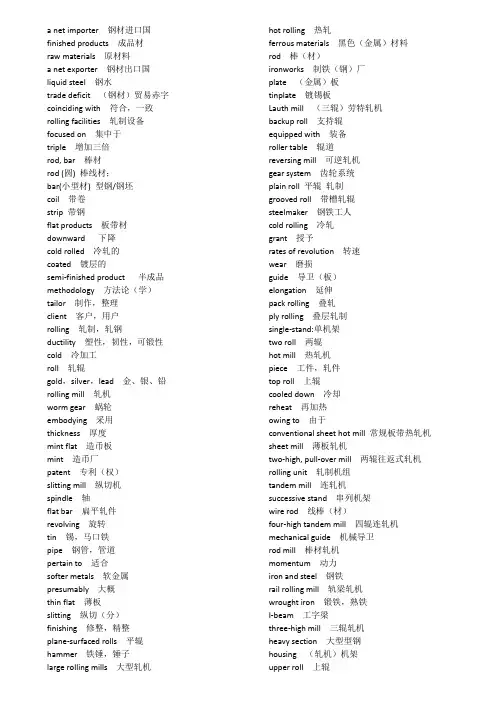

a net importer 钢材进口国finished products 成品材raw materials 原材料a net exporter 钢材出口国liquid steel 钢水trade deficit (钢材)贸易赤字coinciding with 符合,一致rolling facilities 轧制设备focused on 集中于triple 增加三倍rod, bar 棒材rod (圆) 棒线材;bar(小型材) 型钢/钢坯coil 带卷strip 带钢flat products 板带材downward 下降cold rolled 冷轧的coated 镀层的semi-finished product 半成品methodology 方法论(学)tailor 制作,整理client 客户,用户rolling 轧制,轧钢ductility 塑性,韧性,可锻性cold 冷加工roll 轧辊gold,silver,lead 金、银、铅rolling mill 轧机worm gear 蜗轮embodying 采用thickness 厚度mint flat 造币板mint 造币厂patent 专利(权)slitting mill 纵切机spindle 轴flat bar 扁平轧件revolving 旋转tin 锡,马口铁pipe 钢管,管道pertain to 适合softer metals 软金属presumably 大概thin flat 薄板slitting 纵切(分)finishing 修整,精整plane-surfaced rolls 平辊hammer 铁锤,锤子large rolling mills 大型轧机hot rolling 热轧ferrous materials 黑色(金属)材料rod 棒(材)ironworks 制铁(钢)厂plate (金属)板tinplate 镀锡板Lauth mill (三辊)劳特轧机backup roll 支持辊equipped with 装备roller table 辊道reversing mill 可逆轧机gear system 齿轮系统plain roll 平辊轧制grooved roll 带槽轧辊steelmaker 钢铁工人cold rolling 冷轧grant 授予rates of revolution 转速wear 磨损guide 导卫(板)elongation 延伸pack rolling 叠轧ply rolling 叠层轧制single-stand:单机架two roll 两辊hot mill 热轧机piece 工件,轧件top roll 上辊cooled down 冷却reheat 再加热owing to 由于conventional sheet hot mill 常规板带热轧机sheet mill 薄板轧机two-high, pull-over mill 两辊往返式轧机rolling unit 轧制机组tandem mill 连轧机successive stand 串列机架wire rod 线棒(材)four-high tandem mill 四辊连轧机mechanical guide 机械导卫rod mill 棒材轧机momentum 动力iron and steel 钢铁rail rolling mill 轨梁轧机wrought iron 锻铁,熟铁I-beam 工字梁three-high mill 三辊轧机heavy section 大型型钢housing (轧机)机架upper roll 上辊lower roll 下辊lifting table 升降辊道middle roll 中间轧辊reversing plate mill 可逆中板轧机universal mill 万能轧机continuous hot mill 连续式热轧机rod rolling mill 棒材轧机billet 小方坯horizontal 水平的vertical 垂直的cluster mill 多辊轧机work roll 工作辊Z-bars Z型轧件beam 钢梁H-beam H型钢梁semi-continuous hot strip mill 半连续热带轧机two-high tandem finishing train 两辊连轧精轧机组width 宽度length 长度roughing train 粗轧机two three-high stands 两架三辊轧机finishing train 精轧机组five-stand 五机架pig iron 生铁hammered bar 锻件forge 铸造pass 道次roll neck 辊颈boiler plate 锅炉板steel corporation 钢铁公司angle iron 角钢inventiveness 独创性mill housing 轧机机架stimulus 刺激,促进因素iron and steel industry 钢铁工业blooming mill 初轧机,方坯初轧机reversing blooming mill 可逆初轧机two-high reversing blooming mill 两辊可逆初轧机three-high roughing mill 三辊粗轧机three-high finishing mill 三辊精轧机horsepower 马力shaft 轴flywheel 飞轮reversal 可逆的electric generator 发电机direct current motor 直流电机main drive 主传动(系统)cold reduction facilities (金属)冷加工设备reduction 压下steel band 钢带high-carbon 高碳Lauth 3-high cold mill 三辊劳特冷轧机cold rolled strip 冷轧带钢2-high mill 两辊轧机roll neck bearing 辊颈轴承reversing cold mill 可逆冷轧机tandem cold rolling 冷连轧机2-high 4-stand tandem mill 两辊四机架连轧机tension 张力tension reel 张力卷取(机)cold strip reel 冷轧带钢卷取机hot strip reel 热轧带钢卷取机high-tension 大张力constant tension 恒张力current control 电流控制concurrent 同时发生的,一致的strip tension control 带钢张力控制interstand tension 机架间张力ingot 钢锭the order of …数量级flat-rolled 扁平轧制的five-stand tandem mill 五机架连轧机stainless sheet 不锈钢板fully continuous 全连续pay-off reel 开卷机welder 焊接机intermediate stand 中间机架Sendzimir mill 森吉米尔轧机shear 剪切机strip accumulator 带钢收集器flying shear 飞剪tension reel 张力卷取机silicon steel 硅钢special alloy 特殊钢single-stand reversing mill 单机架可逆轧机rolling lubricant 轧制润滑roll bite 轧制变形区foil Mill 箔材轧机temper or skin pass mill 平整机annealed strip 退火带钢flatness 平直度(板形)uncontaminated 无污染的tinning 镀锡friction 摩擦corrosion-resistant 抗腐蚀closer dimensional tolerance 更精确的尺寸公差mill components 轧机部件instrumentation 仪表control system 控制系统engineering science 工程科学rolling technology 轧制技术shaping 成型metallurgical properties 冶金性能in the case of …..情况下with respect of 关于conventional four-high mill stand 常规四辊轧机planetary mill 行星轧机six-high mill 六辊轧机screw 压下(螺丝)hydraulic roll-positioning system 液压轧辊定位系统(液压APC)automatic-gage-control (AGC) 厚度自动控制系统mathematical model 数学模型stiffness 刚度roll-bending 轧辊弯曲roll-bending jacks 弯辊装置pacing 节奏控制cross-sectional profile 横断面形状shape 板形slab 板坯in-line 在线continuously cast billet 连铸小方坯slab strand (连铸)扁坯billet casting machine 小方坯连铸机bar mill 小型轧机furnace 加热炉scale-breaker 除磷机roughing stand 粗轧机座six-stand finishing train 六机架精轧机组coiler 卷取机run-out table 输出辊道vertical edger 立辊轧机two-stand tandem-roughing mill 两机座粗轧连轧机finishing stand 精轧机座main drive 主传动auxiliary drive 辅助传动charged and discharged 装钢、出钢cooling system 冷却系统cast-iron and steel work roll 铸铁/铸钢工作辊rolling force 轧制压力back-roll-bending system 支持辊弯辊系统laminar-flow 层流冷却coil box 卷取箱microstructure 微观组织yield strength 屈服强度toughness 韧性structure steel 结构钢cooling bed 冷床measuring device 测量装置large reduction 大压下量single pass 单道次seamless tube 无缝钢管mill stand 轧钢机座component 部件deflection 变形,压扁roll gap adjustment mechanism 轧辊调整装置pass 1ine 轧制线housing / mill housing 机架main drive train 主传动机组rolling torque 轧制力矩roll arrangement 轧辊布置two-high mill stand 两辊轧机机座top,bottom and middle roll 上、下、中辊cluster type mill stand 多辊轧机机座intermediate roll 中间辊asymmetrical 非对称的,非均匀的symmetrical 对称的,均匀的roll axes 轧辊轴向horizontal mill stand 水平轧机机座vertical mill stand 垂直轧机机座non-reversing mill stand 不可逆轧机机座reversing mill stand 可逆轧机机座back-pass mill stand 返回式轧机机座direct drive 电机直接传动gear drive 齿轮传动A3 critical temperature A3临界温度austenitic phase 奥氏体相区slabbing mill 板坯轧机p1ate mill 中厚板轧机strip mill 带钢轧机universal rolling mill 万能轧机tandem roiling mill 连轧机reheat furnace 再加热炉roughing mill 粗轧机transfer bar 中间坯transfer table / delay table 中间辊道finishing mill 精轧机tandem finishing train 精轧连轧机组looper 活套interstand strip tension 机架间带钢张力runout table 输出辊道cooling header 冷却喷嘴desealing system 除鳞系统scale breaker 破鳞机roll coolant system 轧辊冷却系统interstand cooling system 机架间冷却系统semi-continuous 半连续twin reversing roughing train 两机架可逆粗轧机组three-quarter continuous 3/4连续式universal roughing mill stand 万能粗轧机座fully continuous. 全连续single-pass stand 单道次机座coilbox 卷取箱Steckel mill 斯泰克尔轧机tandem cold mill 冷连轧机strip tension 带钢张力pickling 酸洗annealing 退火residual stress 残余应力slitting and cutting 纵切rigidity 刚度inspection 表面检查marking 打印quenching 淬火two-high pull-over mills 两辊往复式轧机three-high and reversing mills 三辊轧机和可逆轧机two-high nonreversing mill 两辊不可逆轧机in tandem with 与……连轧multipass 多道次single-pass 单道次edgers 立辊轧机conditioned slab 精整板坯mechanical properties 机械性能walking beam furnaces 步进梁式加热炉scalebreaking stand 除鳞机架primary and secondary scale 初生和二次氧化铁皮modulus 系数,模数specific rolling force 单位轧制压力roll-positioning system 轧辊定位系统high-speed screwdown system 高速压下系统roll gap 辊缝blooming mill 方坯初轧机plate profile and flatness 中厚板断面和板形work-roll and backup-roll bending system 工作辊和支持辊弯辊系统tandem roughing stands 粗轧连轧机组7-stand finifhing train 七机架精轧机组laminar-flow cooling 层流冷却hot-rolling lubricant 热轧润滑zooming 加速轧制profile (带钢)横断面shape and flatness sensing 板形和平直度传感器delay table 中间辊道specialty steel 特殊钢passline 轧制线tunnel-type furnace 隧道式加热炉two-high roughing stand 两辊粗轧机座cooling table 冷却辊道roll wear 轧辊磨损alleviate 缓解,减轻reduction ratio 压下比soaking 均热slab reheat furnaces 板坯再加热炉two-high scalebreaker 两辊破鳞机hydraulic descaling unit 液压除鳞装置reversing roughing stand 可逆粗轧机座finishing train with four or more 4-high stands 由四个或四个以上四辊轧机组成的精轧机组steel grade 钢种hydraulic roll-balance system 液压轧辊平衡系统roll bearing 轧辊轴承crown 凸度screwdown systems 压下系统continuous 5-zone slab-heating furnace 五段连续式板坯再加热炉laminar-spray cooling system 层流冷却系统bite angle 咬入角interstand looper 机架间活套hydraulic cylinder 液压缸work-roll chock 工作辊轴承座screw 压下螺丝ipm(inch per minute)英寸/分钟automatic roll-changing equipment 自动换辊装置。

先进高强度钢辊弯成型有限元仿真研究摘要:本文通过有限元仿真方法,研究了先进高强度钢辊弯成型的工艺性能。

利用ABAQUS软件建立了辊弯成型的有限元模型,并通过调整辊弯成型过程中的力和速度参数,分析了辊弯成型过程中的应力分布、变形特征和成型质量。

研究结果表明,通过合理的辊弯成型参数可以获得较好的成型效果,提高先进高强度钢辊弯成型的质量和效率。

关键词:先进高强度钢;辊弯成型;有限元仿真;工艺性能1. 引言先进高强度钢材具有良好的力学性能和耐腐蚀性能,广泛应用于航空航天、汽车制造和建筑等领域。

辊弯成型作为一种常用的金属成形工艺,可以有效地将钢材弯曲成所需的形状。

为了提高辊弯成型的质量和效率,有限元仿真方法成为研究的重要手段。

2. 方法本研究选择了一种先进高强度钢材作为研究对象,利用ABAQUS软件建立了辊弯成型的有限元模型。

在模型中,考虑了材料的非线性特性和辊弯成型过程中的摩擦力。

通过调整辊弯成型过程中的力和速度参数,进行了多次有限元仿真计算。

3. 结果与讨论通过有限元仿真,得到了辊弯成型过程中的应力分布、变形特征和成型质量。

研究结果表明,合理的辊弯成型参数可以使得钢材在成型过程中受力均匀,避免出现应力集中和变形不均匀的问题。

同时,适当调整成型速度可以减小辊弯成型过程中的应力和变形,提高成型质量。

4. 结论通过有限元仿真研究,本文分析了先进高强度钢辊弯成型的工艺性能。

研究结果表明,通过合理的辊弯成型参数可以获得较好的成型效果,提高先进高强度钢辊弯成型的质量和效率。

本研究为进一步优化先进高强度钢辊弯成型工艺提供了一定的理论依据和技术支持。

5. 。

北方工业大学机电工程研究所辊压成型工艺与技术1辊压成型技术在汽车部件制造中的应用2国内外下一代辊压成型技术研究与发展3北方工业大学的研发目标4北方工业大学的辊压成型关键技术研发及应用5辊压成型产品应用汽车零部件钢结构及住宅输电铁塔建筑模板、脚手架集装箱焊管钢板桩铁道车辆公路护栏板保险杠结构构成安装板吸能盒横梁E/ABS蒙皮开卷Uncoil预冲孔Pre-punching辊压成型Roll forming 切断Cutting 焊接吸能盒Welding检测Inspection在线弯圆Sweeping 在线焊接Welding in line焊接拖钩套Welding辊压成型关键技术及应用理论研究与工程实际紧密结合为企业提供系统的理论指导理论与实践相结合达到世界先进水平)(15.05.113121fi r r r r r r f i i i •+•−=道次编号DP800所需总变形能(J)Q235所需总变形能(J)DP800比Q235所需总变形能之增量百分比%1 1.55757E+03 1.24244E+0325.4%2 3.65488E+03 2.61192E+0339.9%3 5.29967E+03 3.75306E+0341.2%4 6.99302E+03 4.84281E+0344.4%58.81970E+03 5.98377E+0347.4%6 1.02700E+04 6.85692E+0349.8%71.18738E+047.75561E+0353.1%类型Sorts成型方式Forming styles车型/名称Vehicles汽车厂OEM's钢制保险杠Steel bumpers 辊压成型Roll formingSGM12、SGM200SGM18、SGM201上海通用/ SGMW161,W261,S161,S261上海汽车/ SAICNew Bora, Jetta一汽大众/ FAW-VWM3, Focus,Mondeo长安福特/ Changan FordB51, B53, T63, X7神龙汽车/ DPCAH13, M14, B22奇瑞汽车/ Chery AutoA0, BSUV江淮汽车/ JACTF, ROVER南京名爵M11,S08, Y08, V08长城汽车/ Great Wall31个车型,27个断面断面A将高精度复杂截面的辊压成型科研成果应用于T11、B11车型车门框的开发,并一次调试成功。

课程名称:辊弯成形技术与装备课程编码:M683011课程学分:2学分适用学科:机械工程领域辊弯成形技术与装备Roll Forming Technology and Equipment教学大纲一、课程性质《辊弯成形技术与装备》是针对机械工程领域专业所开设的一门专业选修课。

二、课程教学目的其主要目的是使学生理解和掌握辊弯成形技术基本理论及装备的一般知识,通过本课程的学习,应掌握辊弯成形轧辊设计理论,金属板带的辊弯成形特性基本原理;培养具有初步辊弯成形产品设计以及轧机设计的能力;了解辊弯成形生产线上辅助加工,特种与未来的辊弯成形技术等;通过实验加深学生对所学理论基础知识的理解和认识,培养学生具备一定的辊弯成形工艺综合分析和处理成形实际问题的能力。

三、教学基本内容及基本要求1、教学基本内容(1)绪论本课程研究的对象及内容,本课程的性质及要求,学习本课程的方法,辊弯成形工艺及应用概述。

(2)辊弯成形轧机轧机概述,轧机的类型:悬臂式轧机、双端式轧机、标准轧机、双层轧机、成组快换式轧机、并列轧机、拉料成形轧机、螺旋管轧机、车载轧机、特种轧机,轧机的构成:床身、机架、轴、驱动、辅辊和插入式立辊道次、道次间导引、矫直头、润滑系统、轴肩定位、在轧机中安装其他装置。

(3)辊弯成形轧辊设计理论轧辊设计过程,断面,产品成形方位和其他在线操作,材料,辊弯成形轧机,模具设计的其他考虑,定位套和垫片,计算板带宽度,弯曲方法,道次数,辊花图,轧辊设计,人工设计轧辊尺寸,计算机辅助轧辊设计,轧辊标记系统,轧辊方向,安装图。

(4)辊弯成形产品设计薄壁产品的开发,设计中要考虑的因素,辅助加工,制造不同尺寸的断面,特殊产品的设计,尺寸与公差。

(5)金属板带的辊弯成形特性成形过程中的变形类型,冗余变形的原因及对产品缺陷的影响,金属板带变形的数学仿真,轧辊轮廓的计算机设计系统。

(6)辊弯成形生产线上辅助加工辅助加工主要工作原理及功用,矫直,张紧或松弛的生产线:在成形前、中、后的切断,辅助加工的位置,固定冲模和飞冲模,冲孔、冲多孔、切口和斜切,穿孔和局部冲切,翻边、冲百叶孔和切缝,压纹和冲压,弯曲,弯圆,标记,搭扣,旋转冲模,不同板带和零件间的机械连接,胶接,锡焊和铜焊,电阻焊,喷漆,发泡,打包。

加热辊弯成型技术加热辊弯成型技术是一种常用的金属加工方法,它通过使用热辊对金属材料进行加热,然后利用辊轮的弯曲作用使金属材料产生形变,从而达到制造所需产品的目的。

该技术广泛应用于航空、汽车、建筑等领域,具有成本低、效率高、制造精度高等优点。

一、加热辊弯成型技术的原理加热辊弯成型技术主要是通过对金属材料进行加热,使其变得柔软,然后利用辊轮的弯曲作用将其弯曲成所需的形状。

具体来说,该技术包括以下几个步骤:1. 加热:首先需要将金属材料放置在加热设备中进行加热,使其达到一定的温度。

加热温度的选择要根据金属材料的种类和厚度来确定,一般在材料的熔点以上。

2. 弯曲:加热后的金属材料变得柔软,此时需要将其放置在辊轮上,通过调节辊轮的位置和角度,使其对金属材料产生弯曲作用。

为了获得所需的弯曲角度和曲线形状,可能需要多次进行弯曲操作。

3. 冷却:完成弯曲后,金属材料需要进行冷却,以保持其形状。

冷却方法可以是自然冷却或者通过外部冷却设备进行加速冷却。

1. 航空领域:加热辊弯成型技术在航空领域被广泛应用于制造飞机机身、机翼等部件。

由于航空器对材料的轻量化要求较高,加热辊弯成型技术可以使得金属材料在保持强度的同时实现复杂曲线的成型,从而满足航空器的设计要求。

2. 汽车领域:汽车制造中需要大量的金属部件,如车身、车门等。

加热辊弯成型技术可以使得金属材料在不断变化的曲率下保持较高的强度和韧性,从而实现汽车部件的精确成型。

3. 建筑领域:加热辊弯成型技术在建筑领域被广泛应用于制造钢结构建筑中的梁柱、屋面等部件。

通过加热辊弯成型技术,可以使得钢材在保持强度的同时实现各种复杂的形状,满足建筑设计的要求。

三、加热辊弯成型技术的优势1. 成本低:相比传统的加工方法,加热辊弯成型技术无需复杂的模具和设备,可以大大降低制造成本。

2. 效率高:加热辊弯成型技术可以在较短的时间内完成金属材料的成型,提高生产效率。

3. 制造精度高:加热辊弯成型技术可以实现金属材料的精确成型,形状和尺寸的控制精度高,可以满足复杂产品的制造要求。