因果图、5WHY、8D报告标准模板

- 格式:xls

- 大小:5.15 MB

- 文档页数:4

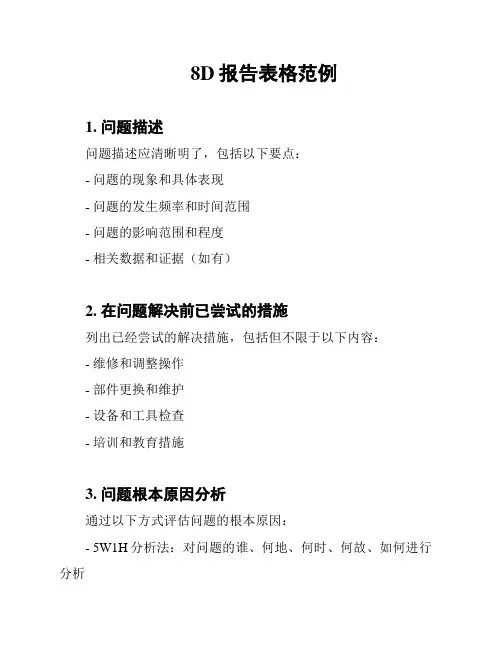

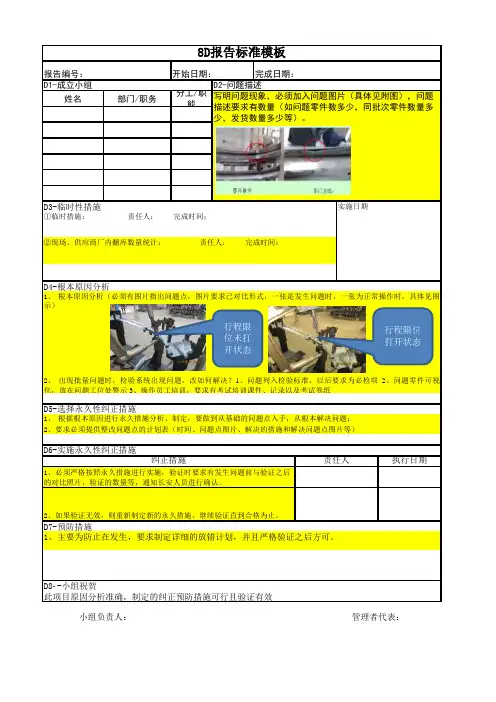

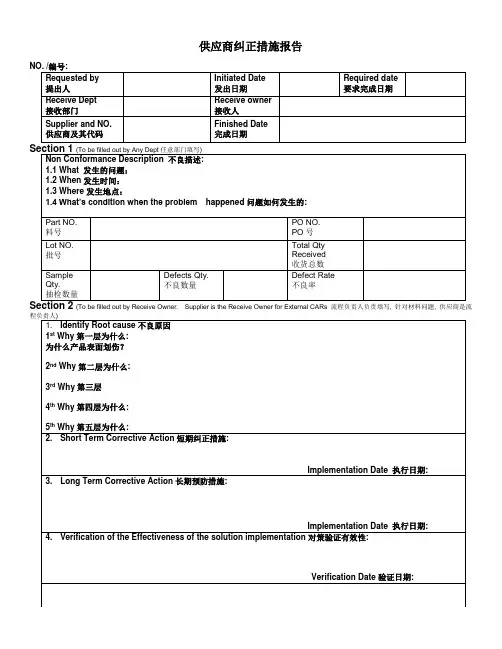

8D报告表格范例1. 问题描述问题描述应清晰明了,包括以下要点:- 问题的现象和具体表现- 问题的发生频率和时间范围- 问题的影响范围和程度- 相关数据和证据(如有)2. 在问题解决前已尝试的措施列出已经尝试的解决措施,包括但不限于以下内容:- 维修和调整操作- 部件更换和维护- 设备和工具检查- 培训和教育措施3. 问题根本原因分析通过以下方式评估问题的根本原因:- 5W1H分析法:对问题的谁、何地、何时、何故、如何进行分析- 鱼骨图:将问题分为人员、方法、机器、材料、测量和环境等方面进行分类分析- 逻辑树:通过逻辑关系确定问题根本原因4. 实施的纠正措施详细描述已经实施的纠正措施,包括以下要点:- 执行的具体步骤和操作- 使用的工具和设备- 参与的人员和责任分工- 预计的实施时间和进度安排5. 纠正措施的效果验证验证所采取纠正措施的效果,包括以下内容:- 确认问题是否被解决- 检查是否出现其他问题- 对纠正措施效果进行评估和记录6. 预防措施的制定根据问题的原因和纠正措施,制定预防措施以防止问题再次发生,包括以下要点:- 针对问题根本原因的改进措施- 强化操作规范和流程控制- 培训和技能提升计划7. 实施预防措施的计划制定实施预防措施的计划,包括以下要点:- 执行的具体步骤和操作- 使用的工具和设备- 参与的人员和责任分工- 预计的实施时间和进度安排8. 结论和总结总结报告的主要内容和结果,包括以下要点:- 问题的原因和解决过程- 实施的纠正和预防措施- 问题解决的效果和预防措施的计划以上是一份典型的8D报告表格范例,可以根据具体情况进行调整和修改。

该报告用于对问题进行系统化的分析和解决,并制定预防措施以避免问题再次发生。

在编写报告时,应确保信息准确、简明扼要,以便他人能够清晰理解问题及其解决过程。

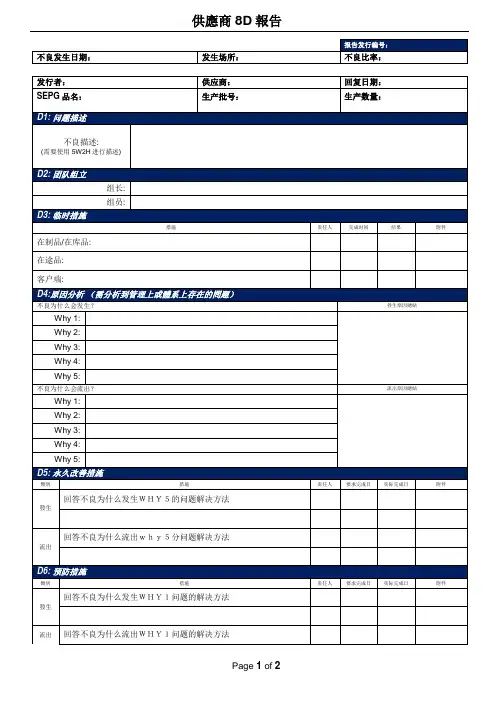

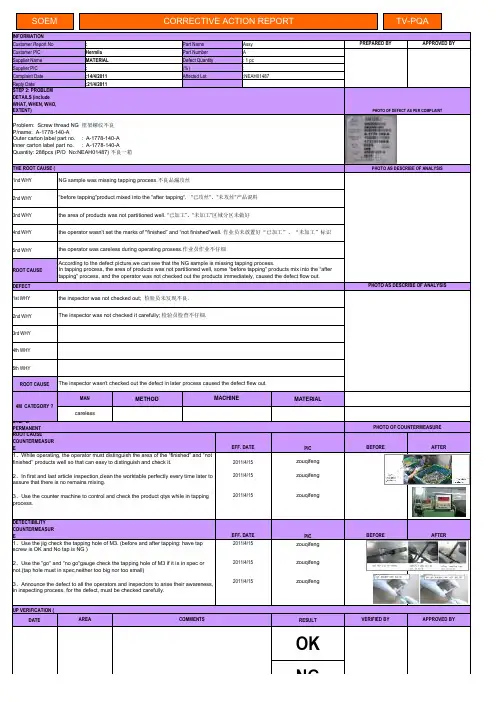

STEP 1: GENERAL INFORMATION Customer Report No :Part Name : Pre Case Assy Customer PIC : Ms Hermila Part Number : A-1778-140-A Supplier Name : NEW MATERIAL Defect Quantity : 1 pc Supplier PIC :Defect Ratio (%):Complaint Date :14/4/2011Affected Lot:NEAH01487Reply Date:21/4/2011STEP 2: PROBLEM DETAILS (include WHAT, WHEN, WHO,EXTENT)STEP 3: DESCRIBE THE ROOT CAUSE (1nd WHY 2nd WHY 3nd WHY 4nd WHY 5nd WHYROOT CAUSE STEP 4: WHY DEFECT 1st WHY 2nd WHY 3rd WHY 4th WHY 5th WHY ROOT CAUSEMETHODMATERIALSTEP 6:PERMANENT ROOT CAUSECOUNTERMEASUR EPIC zouqifeng zouqifengzouqifengDETECTIBILITY COUNTERMEASUR EPIC zouqifeng zouqifeng zouqifengSTEP 7: FOLLOW UP VERIFICATION (DATERESULTPREPARED BYAPPROVED BYPHOTO OF DEFECT AS PER COMPLAINTPHOTO AS DESCRIBE OF ANALYSISNG sample was missing tapping process.不良品漏攻丝"before tapping"product mixed into the "after tapping". "已攻丝"、"未攻丝"产品混料the area of products was not partitioned well. “已加工”、“未加工”区域分区未做好the operator wasn't set the marks of "finished” and “not finished”well. 作业员未放置好“已加工”、“未加工”标识the operator was careless during operating prosess.作业员作业不仔细According to the defect picture,we can see that the NG sample is missing tapping process.In tapping process, the area of products was not partitioned well, some “before tapping” products mix into the “after tapping” process, and the operator was not checked out the products immediately, caused the defect flow out.PHOTO AS DESCRIBE OF ANALYSISthe inspector was not checked out; 检验员未发现不良.The inspector was not checked it carefully; 检验员检查不仔细.The inspector wasn't checked out the defect in later process caused the defect flew out.MANMACHINEcarelessPHOTO OF COUNTERMEASUREEFF. DATE BEFORE AFTER2011/4/152011/4/152011/4/15EFF. DATE BEFORE AFTER2011/4/152011/4/152011/4/15AREACOMMENTSVERIFIED BYAPPROVED BY4M CATEGORY ?OK NGProblem: Screw thread NG 框架螺纹不良P/name: A-1778-140-AOuter carton label part no. : A-1778-140-A Inner carton label part no. : A-1778-140-AQuantity: 288pcs (P/O No:NEAH01487) 不良一箱1、While operating, the operator must distinguish the area of the “finished” and “not finished” products well so that can easy to distinguish and check it.2、In first and last article inspection,clean the worktable perfectly every time later to assure that there is no remains mixing.3、Use the counter machine to control and check the product qtys while in tapping process.1、Use the jig check the tapping hole of M3. (before and after tapping: have tap screw is OK and No tap is NG )2、Use the "go" and "no go"gauge check the tapping hole of M3 if it is in spec or not.(tap hole must in spec,neither too big nor too small)3、Announce the defect to all the operators and inspectors to arise their awareness,in inspecting process, for the defect, must be checked -PQASOEMCORRECTIVE ACTION REPORT。

8d报告国际标准格式(体现制造不良、流出不良等项目)下载提示:该文档是本店铺精心编制而成的,希望大家下载后,能够帮助大家解决实际问题。

文档下载后可定制修改,请根据实际需要进行调整和使用,谢谢!本店铺为大家提供各种类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by this editor. I hope that after you download it, it can help you solve practical problems. The document can be customized and modified after downloading, please adjust and use it according to actual needs, thank you! In addition, this shop provides you with various types of practical materials, such as educational essays, diary appreciation, sentence excerpts, ancient poems, classic articles, topic composition, work summary, word parsing, copy excerpts, other materials and so on, want to know different data formats and writing methods, please pay attention!8D报告国际标准格式(体现制造不良、流出不良等项目)摘要在现代制造业中,遇到质量问题是不可避免的。

质量8D报告模板示例一、问题描述(1)问题描述:请详细描述出现的问题,包括产品名称、型号、质量主题、发现时间、发现地点等。

(2)临时措施:在问题发生后,为防止问题继续扩大或影响客户,采取的临时措施。

(3)问题描述示例:产品名称:XXX手机型号:XXX质量主题:屏幕亮度不均发现时间:XXXX年XX月XX日发现地点:生产线二、组建小组与问题描述(1)组建小组:成立一个跨部门的8D小组,包括质量、研发、生产、采购等相关部门成员。

(2)问题描述:使用5W1H方法对问题进行详细描述,明确问题的现象、影响及严重程度。

三、实施临时措施与验证效果(1)实施临时措施:针对问题描述中提到的问题,采取紧急措施,如暂停生产、隔离不良品等。

(2)验证效果:通过收集数据、测试等方法验证临时措施的有效性,确保问题不再继续扩大。

四、分析原因与确定根本原因(1)分析原因:运用鱼骨图、5Why等工具对问题产生的原因进行深入分析,列出可能的原因。

(2)确定根本原因:通过对可能原因进行逐一排查,结合数据和事实,确定问题的根本原因。

五、制定永久措施与验证效果(1)制定永久措施:根据问题的根本原因,制定相应的改进措施,如修改工艺、更换材料等。

(2)验证效果:通过实施永久措施,收集数据、测试等方法验证措施的有效性,确保问题得到彻底解决。

六、实施永久措施与跟踪效果(1)实施永久措施:将制定的永久措施落实到具体的操作流程中,确保措施得以有效执行。

(2)跟踪效果:定期对实施永久措施后的产品进行抽查和测试,确保问题不再发生。

七、总结经验教训与预防措施(1)总结经验教训:对整个8D过程进行总结,提炼经验教训,以便后续遇到类似问题时能够迅速应对。

(2)预防措施:针对类似问题可能出现的环节,制定预防措施,如加强员工培训、完善检测手段等。

八、感谢与致辞感谢参与此次8D活动的所有成员和相关部门的支持与配合,使得问题得以顺利解决。

未来我们将继续努力,为提升产品质量和客户满意度而不懈奋斗。