国际-538磷酸锌底漆-CPA537&CPA538

- 格式:pdf

- 大小:508.20 KB

- 文档页数:4

最初编制日期: 28-九月-2016修订日期 29-四月-2021SDS 编号: -产品名称: TRIM® SC538版本号: 03化学品安全技术说明书按照 GB/T 16483、GB/T 17519编制。

第1部分 化学品及企业标识TRIM® SC538产品名称生产商/供应商Master Fluid Solutions (Tianjin)马思特(天津)化学有限公司地址天津市经济技术开发区西区新业九街66号否。

66, No.9 Xin Ye Street Tianjin 300462P.R. China联系电话+86 21 6807-0101电子邮件网站 应急电话+86 21 4001-204937推荐用途及限制用途Metal Working Fluids.推荐用途28-九月-2016最初编制日期29-四月-2021修订日期27-一月-2021替代日期第2部分 危险性概述紧急情况概述吞咽可能有害。

造成皮肤刺激。

危险类别未被分类。

物理危险类别 5急性毒性-经口健康危害类别 2皮肤腐蚀/刺激未被分类。

环境危害标签要素象形图警示词警告危险性说明H303吞咽可能有害。

H315造成皮肤刺激。

防范说明预防措施P264作业后彻底洗手。

P280戴防护手套。

事故响应P302 + P350如皮肤沾染:用大量水清洗。

P332 + P313如发生皮肤刺激:求医/就诊。

P301 + P312如误吞咽:如感觉不适,呼叫解毒中心或医生。

P362 + P364脱去被污染的衣物,清洗后方可重新使用。

安全储存远离禁忌物保存。

废弃处置P501按照地方/区域/国家/国际规章处置内装物/容器。

补充信息无。

第3部分 成分/组成信息混合物物质/混合物浓度(%)CAS 号化学名称64742-53-6石油油品,经过严格地加氢处理和溶剂精制20 - < 30SEVERELY HYDROTREATED PETROLEUM OIL三乙醇胺102-71-65 - < 10TRIETHANOLAMINE1 - < 3貿易秘密所有者TRADE SECRET貿易秘密所有者1 - < 3TRADE SECRET貿易秘密1 - < 3所有者貿易秘密1 - < 3所有者低于报告水平的其它成分60 - < 70第4部分 急救措施移至空气新鲜处。

天津市朝晖化工有限公司永富牌特种油漆FXE-53851 水性无机富锌底漆(文字说明)一、产品说明:本品为双组分水性白固化涂料,漆膜坚硬耐磨,用于钢铁表面的防腐,具有优异的防腐性能,长期的耐候性,良好的导热性,耐水性和耐盐水性,耐各种油品长期浸泡,对各种有机溶剂,包括酮类、酯类、醚类、醇类、烃类等强溶剂都有极强的抵抗能力,同时具有优良的导静电性和长时间的阴极保护作用,且焊接性能优良,带漆焊接,不起泡、不脱落。

长期耐热达400℃,可抵抗PH值5.5-9.0范围的化学腐蚀。

二、产品用途:用于暴露在海洋大气、高温和各种环境的各种钢铁构件的长效防腐。

包括船舶、集装箱、各类码头设备、海洋平台、大型建筑的钢铁构件,特别适合于储油罐的罐底板从内壁防腐,油轮、溶剂舱内外防腐,热交换器内外壁的长效防腐。

同时叫用于各类水下、地下各类输油管线,化工管线等。

三、施工要求:1、表面处理:将准备喷漆和钢材表面先除去油污再以抛丸、喷沙(磨料推荐使用菱角状的粒度为18号钛砂,并且应是清洁干燥的)(相当于BG8923-88既Sa2.5级)等方法除去铁鳞、铁锈,并且表面粗糙度要求控制在25-60um范围内,经过处理之后,用压缩空气彻底除去沙砾、尘土等杂质后,再逆行喷(涂)漆。

注:打磨:所有气割、剪切、机加工后的自由锐角均应打磨至R2,磨土气割表面的割痕及火工矫正部位的硬化层,以使喷沙后在这些部位形成合适的粗糙度。

(1)除油:喷砂前,钢材表面先除去油污,且喷砂用压缩空气必须装有性能良好的油水分离器。

施工人员不可穿戴有油污的工作服。

(2)修补:局部修补时,要求刊磨不(GB8923-88)St3级。

2、混合条件;基料:粉料=1:2.5-2.8,应将粉料慢慢倒进基料同时不断搅拌,充分混合使锌粉处于悬浮状态,喷涂前应以40-80目筛网过滤。

3、熟化:应在充分搅拌混合20分钟后喷涂。

4、施工条件:(1)采用喷涂或刷涂,工具干净无油。

表面施工温度在5℃以上50℃以下。

液体。

产品类型应急咨询电话(带值班时间)::企业标识:化学品的推荐用途和限制用途产品代码:2920中国化学事故应急服务 Tel: +86 532 83889090佐敦涂料(张家港)有限公司中国江苏扬子江国际化学工业园南海路39号 215634电话: +86 512 58937988传真: +86 512 58937986Jotun Coatings (Zhangjiagang) Co. LtdNO.39 Nanhai Road Jiangsu Yangtze River International Chemical Industry Park,Jiangsu Province 215634 China Tel: +86 512 58937988Fax: +86 512 58937986中远佐敦船舶涂料(青岛)有限公司中国山东省青岛市高新区春阳路800号总机电话: +86-532-68689888总机传真: +86-532-66726750Jotun COSCO Marine Coatings (Qingdao) Co. Ltd.No. 800, Chunyang Road, High-tech Zone, Qingdao, P. R. China Tel: +86-532-68689888Fax: +86-532-66726750产品名称Penguard Express ZP Comp A :快干环氧磷酸锌漆 组份A产品描述:油漆。

皮肤腐蚀/刺激 - 类别 2严重眼损伤/眼刺激 - 类别 2A 皮肤致敏物 - 类别 1致癌性 - 类别 2危害水生环境一急性危险 - 类别 2危害水生环境一长期危险 - 类别 2警示词:警告.象形图:标签要素H315 - 造成皮肤刺激。

H317 - 可能造成皮肤过敏反应。

H319 - 造成严重眼刺激。

H351 - 怀疑致癌。

H411 - 对水生生物有毒并具有长期持续影响。

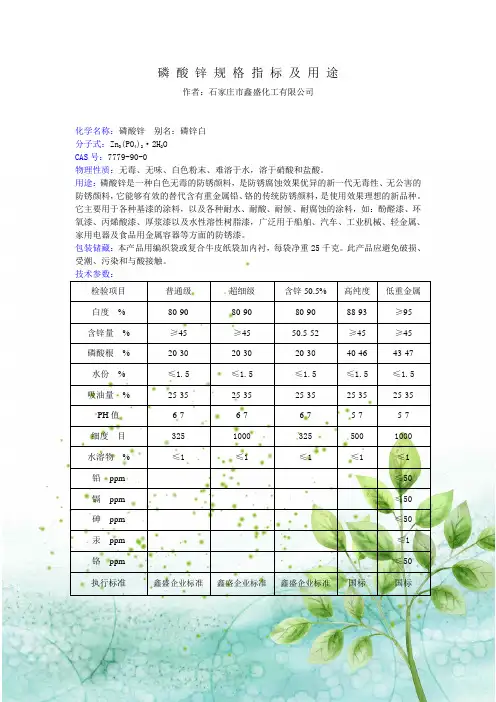

磷酸锌规格指标及用途作者:石家庄市鑫盛化工有限公司化学名称:磷酸锌别名:磷锌白分子式:Zn3(PO4)2·2H2OCAS号:7779-90-0物理性质:无毒、无味、白色粉末、难溶于水,溶于硝酸和盐酸。

用途:磷酸锌是一种白色无毒的防锈颜料,是防锈腐蚀效果优异的新一代无毒性、无公害的防锈颜料,它能够有效的替代含有重金属铅、铬的传统防锈颜料,是使用效果理想的新品种。

它主要用于各种基漆的涂料,以及各种耐水、耐酸、耐候、耐腐蚀的涂料,如:酚醛漆、环氧漆、丙烯酸漆、厚浆漆以及水性溶性树脂漆,广泛用于船舶、汽车、工业机械、轻金属、家用电器及食品用金属容器等方面的防锈漆。

包装储藏:本产品用编织袋或复合牛皮纸袋加内衬,每袋净重25千克。

此产品应避免破损、受潮、污染和与酸接触。

技术参数:检验项目普通级超细级含锌50.5% 高纯度低重金属白度% 80-90 80-90 80-90 88-93 ≥95 含锌量% ≥45 ≥45 50.5-52 ≥45 ≥45 磷酸根% 20-3020-3020-3040-46 43-47 水份% ≤1.5≤1.5≤1.5≤1.5≤1.5吸油量% 25-35 25-35 25-35 25-35 25-35 PH值6-7 6-7 6-7 5-7 5-7 细度目32510003255001000水溶物% ≤1≤1≤1≤1≤1铅ppm ≤50镉ppm ≤50砷ppm ≤50汞ppm ≤1铬ppm ≤50执行标准鑫盛企业标准鑫盛企业标准鑫盛企业标准国标国标三聚磷酸铝规格指标及用途化学名称:三聚磷酸铝改性三聚磷酸铝三聚磷酸二氢铝分子式:AlH2P3O10·2H2OCAS号:13939-25-8物理性质:无毒、无味、白色粉末、难溶于水,溶于硝酸和盐酸。

用途:三聚磷酸铝系列广泛用于各种底漆以及底面合一的涂料中,与清漆亲合性良好,可与各种颜料、填料配合使用,也可与各种防锈颜料合用,可制备各种高性能防腐蚀涂料。

分为四个等级分别为Sa1、Sa2、Sa2.5、Sa3,具体如下:Sa1级——相当于美国SSPC—SP7级。

采用一般简单的手工刷除、砂布打磨方法,这是四种清洁度中度最低的一级,对涂层的保护仅仅略好于未采用处理的工件。

Sa1级处理的技术标准:工件表面应不可见油污、油脂、残留氧化皮、锈斑、和残留油漆等污物。

Sa1级也叫做手工刷除清理级(或清扫级)。

Sa2级——相当于美国SSPC—SP6级。

采用喷砂清理方法,这是喷砂处理中最低的一级,即一般的要求,但对于涂层的保护要比手工刷除清理要提高许多。

Sa2级处理的技术标准:工件表面应不可见油腻、污垢、氧化皮、锈皮、油漆、氧化物、腐蚀物、和其它外来物质(疵点除外),但疵点限定为不超过每平方米表面的33%,可包括轻微阴影;少量因疵点、锈蚀引起的轻微脱色;氧化皮及油漆疵点。

如果工件原表面有凹痕,则轻微的锈蚀和油漆还会残留在凹痕底部。

Sa2级也叫商品清理级(或工业级)。

Sa2.5级——是工业上普遍使用的并可以作为验收技术要求及标准的级别。

Sa2.5级也叫近白清理级(近白级或出白级)。

Sa2.5级处理的技术标准:同Sa2要求前半部一样,但疵点限定为不超过每平方米表面的5%,可包括轻微暗影;少量因疵点、锈蚀引起的轻微脱色;氧化皮及油漆疵点。

Sa3级——级相当于美国SSPC—SP5级,是工业上的最高处理级别,也叫作白色清理级(或白色级)。

Sa3级处理的技术标准:与Sa2.5级一样,但5%的阴影、疵点、锈蚀等疵点不得存在了。

注意:保护层法在金属表面覆盖保护层,使金属制品与周围腐蚀介质隔离,从而防止腐蚀。

如:(1)在钢铁制件表面涂上机油、凡士林、油漆或覆盖搪瓷、塑料等耐腐蚀的非金属材料。

(2)用电镀、热镀、喷镀等方法,在钢铁表面镀上一层不易被腐蚀的金属,如锌、锡、铬、镍等。

这些金属常因氧化而形成一层致密的氧化物薄膜,从而阻挡水和空气等对钢铁的腐蚀。

(3)用化学方法使钢铁表面生成一层细密稳定的氧化膜。

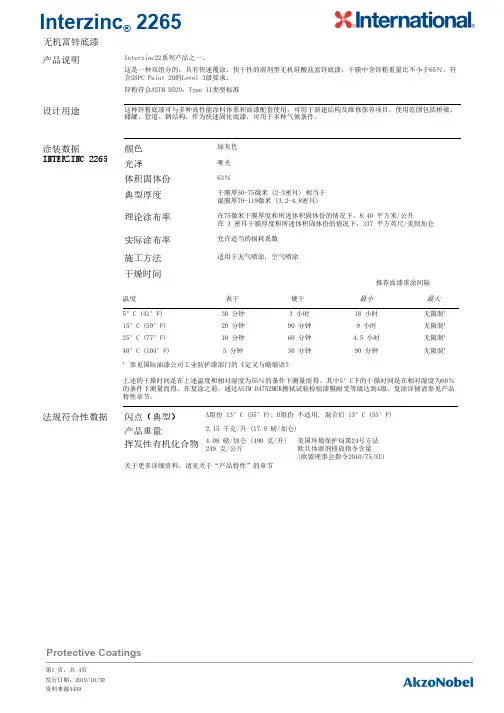

Interzinc22系列产品之一。

这是一种双组分的,具有快速覆涂,快干性的溶剂型无机硅酸盐富锌底漆,干膜中含锌粉重量比不小于65%,符合SSPC Paint 20的Level 3级要求。

锌粉符合ASTM D520,Type II类型标准产品说明这种锌粉底漆可与多种高性能涂料体系和面漆配套使用,可用于新建结构及维修保养项目,使用范围包括桥梁、储罐、管道、钢结构。

作为快速固化底漆,可用于多种气候条件。

设计用途绿灰色哑光63%干膜厚50-75微米 (2-3密耳) 相当于 湿膜厚79-119微米 (3.2-4.8密耳)在75微米干膜厚度和所述体积固体份的情况下,8.40 平方米/公升在 3 密耳干膜厚度和所述体积固体份的情况下,337 平方英尺/美制加仑允许适当的损耗系数适用于无气喷涂, 空气喷涂涂装数据INTERZINC 2265颜色光泽体积固体份典型厚度理论涂布率实际涂布率施工方法干燥时间温度表干硬干最小最大¹ 参见国际油漆公司工业防护漆部门的《定义与略缩语》上述的干燥时间是在上述温度和相对湿度为55%的条件下测量而得。

其中5°C下的干燥时间是在相对湿度为60%的条件下测量而得。

在复涂之前,通过ASTM D4752MEK擦拭试验检验漆膜耐受等级达到4级。

复涂详情请参见产品特性章节。

推荐面漆重涂间隔5°C (41°F) 30 分钟 3 小时18 小时 无限制¹15°C (59°F) 20 分钟90 分钟9 小时 无限制¹25°C (77°F) 10 分钟60 分钟 4.5 小时 无限制¹40°C (104°F)5 分钟30 分钟90 分钟无限制¹A组份 13°C (55°F); B组份 不适用, 混合后 13°C (55°F)2.15 千克/升 (17.9 磅/加仑)法规符合性数据闪点(典型)产品重量挥发性有机化合物关于更多详细资料,请见关于“产品特性”的章节4.08 磅/加仑 (490 克/升) 美国环境保护局第24号方法249 克/公斤欧共体溶剂排放指令含量(欧盟理事会指令2010/75/EU)第1 页,共 4页资料来源4459发行日期:2019/10/30Protective Coatings所有待涂漆表面均应清洁、干燥、没有污染物。

环氧磷酸锌底漆施工方法

以下就是环氧磷酸锌底漆施工方法,仅供参考:

1.基面处理:施工前需要将被施工的基面处理干净,如果使用在钢材基面,可以采取喷砂的方式处理达到Sa

2.5级别,有油污的部位使用专用试剂处理干净,清水冲洗掉杂质,干净干燥后即可上漆使用,避免有残渣影响油漆附着。

2.油漆混合:双组份的油漆在使用上漆前,需要将其两个组份进行混合,根据施工面积大小确定使用量,避免不必要的浪费,先将成分一加入到搅拌容器中,混合,颜色一致后在常温下熟化10-20min后即可上漆使用。

3.施工方式:施工上漆的方式有多种,可以选择喷涂,刷涂以及滚涂的施工方式,在上漆前,需要将油漆的粘度调节适宜,这样比较容易产生均匀平整的涂层,使用哪一种施工方式都要注意不要有漏涂现象,这样能够保障油漆的性能体现。

以上内容仅供参考。

SSPC-Paint 20November 1, 1982Editorial Changes August 1, 1991 SSPC: The Society for Protective CoatingsPAINT SPECIFICATION NO. 20Zinc-Rich Primers (Type I, "Inorganic," and Type II, "Organic")1. Scope1.1 This specification covers one group of highly pig-mented zinc-rich coatings that are uniquely defined by their capability of galvanically protecting steel exposed at discontinuities such as narrow scratches and holidays. While the major pigment component in this coating is zinc dust, the vehicle may be inorganic (Type I) or organic (Type II).1.2 This specification does not cover all types of zinc-rich coatings. For example, it is not a straight performance specification, nor does it pertain to extended zinc-rich coatings, nor to weldable pre-fabrication zinc-rich primers, which are applied at low thicknesses (approximately one mil [25 micrometers] or less). Further information regarding these and other zinc-rich coatings can be found in SSPC-PS Guide 12.00, "Guide to Zinc-Rich Painting Systems," and other SSPC specifications.1.3 This specification defines the minimum composi-tional and laboratory performance requirements for identi-fying a group of zinc-rich paints. It is to be used in conjunc-tion with SSPC-PS Guide 12.00, "Guide to Zinc-Rich Paint-ing Systems"; and with other SSPC specifications covering surface preparation, applications, thickness, inspection, and safety.1.4 This primer, when applied over properly prepared steel surfaces, is suitable for use on parts or structures exposed in Environmental Zones 1A (interior, normally dry), 1B (exterior, normally dry), 2A (frequently wet by fresh water), and 2C (fresh water immersion). They may be used in Environmental Zones 2B (frequently wet by salt water), 2D (salt water immersion), 3A (chemical, acidic), and 3C (chemical, alkaline) with proper topcoating.1.5 This primer is intended for application by spray and is to be applied in accordance with SSPC-PA 1, "Shop, Field, and Maintenance Painting of Steel."2. Description2.1 The zinc-rich coatings described in this specifica-tion consist of zinc dust, an organic or inorganic vehicle, and selected additives as required.2.2 PIGMENTATION:2.2.1 The major pigment component in these coatings is zinc dust of the type described in ASTM D 520, "Zinc Dust (Metallic Zinc Powder)."2.2.2 Other pigment components may include curing aids, tinting colors, suspension and pot life control agents, but should constitute only a minor part of the total pigment portion so as not to detract from the ability of these coatings to protect galvanically.2.3 VEHICLE TYPES:2.3.1 Type l-A, inorganic post-curing vehicles—water soluble, include alkali metal silicates, phosphates, and modifications thereof which must be subsequently cured by application of heat or a solution of a curing compound.2.3.2 Type l-B, inorganic self-curing vehicles—water reducible, include water soluble alkali metal silicates, quarternary ammonium silicates, phosphates, and modifi-cations thereof. These coatings cure by crystallization after evaporation of water from the coating.2.3.3 Type l-C, inorganic self-curing vehicles—solvent reducible, include titanates, organic silicates, and poly-meric modifications of these silicates. These systems are dependent upon moisture in the atmosphere to complete hydrolysis, forming the polysilicate.2.3.4Type II, organic vehicles—include phenoxies, catalyzed epoxies, urethanes, chlorinated rubbers, sty-renes, silicones, vinyls, and other suitable resinous bind-ers. The organic vehicles covered by this specification may be chemically cured or may dry by solvent evaporation. Under certain conditions heat may be used to facilitate or accelerate hardening.3. Reference Standards3.1 The standards referenced in this specification are listed in Sections 3.4 through 3.7 and form a part of this specification.3.2The latest issue, revision, or amendment of the referenced standards in effect on the date of invitation to bid shall govern unless otherwise specified.SSPC-Paint 20November 1, 1982Editorial Changes August 1, 19913.3 If there is a conflict between the requirements of any of the cited reference standards and this specification, the requirements of this specification shall prevail.3.4 SSPC STANDARDS AND JOINT STANDARDS:PA 1Shop, Field, and MaintenancePainting of SteelPA Guide 3 A Guide to Safety in Paint Appli-cationPS 12.01One-Coat Zinc-Rich PaintingSystemPS Guide 12.00Guide to Zinc-Rich Coating Sys-temsSP 5/NACE No. 1White Metal Blast Cleaning3.5 AMERICAN SOCIETY FOR TESTING AND MA-TERIALS (ASTM) STANDARDS:A 36Specification for Carbon Structural SteelB 117Practice for Operating Salt Spray (Fog)ApparatusD 56Test Method for Flash Point by Tag ClosedTesterD 185Test Methods for Coarse Particles in Pig-ments, Pastes, and PaintsD 521Test Methods for Chemical Analysis ofZinc Dust (Metallic Zinc Powder)D 562Test Method for Consistency of PaintsUsing the Stormer ViscometerD 1200Test Method for Viscosity by Ford Viscos-ity CupD 1308Test Method for Effect of HouseholdChemicals on Clear and Pigmented Or-ganic FinishesD 2369Test Method for Volatile Content of Coat-ingsD 2371Test Method for Pigment Content of Sol-vent-Reducible PaintsD 3359Test Methods for Measuring Adhesion byTape TestD 3925Practice for Sampling Liquid Paints andRelated Pigmented Coatings3.6 FEDERAL STANDARDS:PPP-P-1892Paint, Varnish, Lacquer, andRelated Materials; Packaging,Packing and Marking ofFED-STD-141 Paint, Varnish, Lacquer and Related Materials: Methods of Inspection, Sampling and TestingMethod 4331Spraying PropertiesMethod 4541Working Properties and Appear-ance of Dried Film3.7 AMERICAN NATIONAL STANDARDS INSTITUTE (ANSI) STANDARD:Z129.1Hazardous Industrial Chemicals—Precautionary Labeling4. Composition4.1 The paint shall conform to the composition (analy-sis) requirements of Table 1. This table defines the mini-mum compositional requirements of these zinc-rich paints without specifying the vehicle.5. Qualitative Requirements5.1 The paint shall meet the qualitative requirements Sections 5.2 through 5.10.TABLE 1REQUIREMENTSMINIMUM REQUIREMENTS STANDARDSCHARACTERISTISCS1 Inorganic Organic ASTMTotal Solids, % by weight of paint78 70 D 2369 Pigment, % by weight of total solids85 83 D 2371Total zinc dust2, % by weight of pigment87 93 D 521Total zinc dust2, % by weight of total solids74 77 —1The minimum composition requirements of a zinc-rich paint is controversial. It is recognized that zinc-rich primers containing extenders, although having less total zinc dust than specified, may be able to pass all other requirements of this specification. However, these compositional requirements arenecessary, as certain non-zinc containing coatings may also be able to pass all other requirements of this specification.2Zinc dust shall meet ASTM D 521.SSPC-Paint 20November 1, 1982 Editorial Changes August 1, 19915.2 MIXING: The raw materials of the liquid portion of either the inorganic or organic multi-component paints shall be mixed and dispersed as required to produce a product which is uniform, stable, free from grit, and conforms to the requirements of this specification.The pigment portion of multi-component paints, prior to mixing, shall be dry and loosely packed.The ready-mixed paint shall be capable of being bro-ken up with a paddle to a smooth, uniform consistency and shall not liver, thicken, curdle, gel, or hard settle, nor show any other objectionable properties in a mixed, freshly opened container.After mixing, all types of coarse particles and skins as residue retained on a standard 60 mesh screen shall be no more than 0.5% by weight of total paint, regardless of type, in accordance with ASTM D 185.5.3 POT LIFE: The pot life of the zinc-rich paint, when mixed and ready for application in accordance with manufacturer's instructions, shall be a minimum of four hours at 70°F (2°C) and 50% relative humidity. Although physical properties (viscosity, etc.) may not change, loss of pot life is indicated by lack of adhesion when tested in accordance with Section 5.8. Good practice has been that multicomponent zinc-rich paint be used within 12 hours after mixing.5.4 STORAGE LIFE: Neither the vehicle of the multi-component paint nor the ready-mixed paint shall show thickening, curdling, gelling, gassing, or hard caking after being stored unmixed for six months from date of delivery in a tightly covered unopened container at a temperature of 50-90°F (10-32°C).5.5 WORKING PROPERTIES: The mixed paint shall spray easily, and show no streaking, running, sagging, or other objectionable features when tested in accordance with FED-STD-141, Methods 4331 and 4541.5.6 TEST PANEL PREPARATION: Steel test panels (ASTM A 36 hot rolled steel or equivalent), measuring 4"x 6"x 1/16" (10 cm x 15 cm x 1.5 mm) or greater, shall be white metal blast cleaned (SSPC-SP 5) with a nominal anchor profile from 1.5-3.5 mils (38-88 micrometers) (Section 10.4) and coated with the zinc-rich paint. The panels shall be blast cleaned and coated on both sides and all edges. The paint shall be spray applied and hardened in accordance with manufacturer's recommendations. The dry film thick-ness shall be 2.5-3.5 mils (64-88 micrometers) unless otherwise designated. Prior to any exposure testing, all panels shall be aged for 14 days at 75-79°F (24-26°C) and 45-55% relative humidity.5.7 MUDCRACKING: The coating when applied in accordance with Section 5.6 to a five to six mil (125-150 micrometers) dry film thickness, shall show no mudcracking when viewed under 10X magnifications.5.8 ADHESION: The coating when applied and hard-ened in accordance with Section 5.6, shall adhere to the steel substrate when subjected to the "Cross-Cut/Tape Test" (ASTM D 3359, Method B).There shall be no separation of the paint film, or delamination of an entire square. Spalling loss of adhesion around the perimeter due to cutting of each square is acceptable.Adhesion rating should be no less than 4B grading when evaluated according to the procedure of ASTM D 3359, Method B.5.9 SALT FOG RESISTANCE:The coating, when applied and hardened in accordance with Section 5.6 and scribed as described below, shall pass 1,000 hours mini-mum exposure to salt fog (ASTM B 117) without any blistering or rusting of the coated portion, with no undercut-ting from the scribe. (Slight rusting in the scribe mark will be permissible and resulting staining should be ignored.) Strips 1/4" (6 mm) wide along the edges of the panel may be ignored. Testing shall be done in triplicate.The scribe mark shall be centrally positioned in the lower half of the panel and shall consist of an "X" comprising the diagonals of a 2" x 2" (5 x 5 cm) square. To insure proper positioning, cleanliness and depth of scribe mark, a tem-plate and scriber or cutting tool having a cutting edge at least 1 /32" (0.8 mm) wide shall be used. The operator shall bear down hard and go over each arm of the cut twice to insure a clean scribe of sufficient depth to remove any zinc particles from the scribe and to expose clean steel.5.10 ADDITIONAL RESISTANCE TESTS: Additional screening qualification tests may be required by the user (Section 10.8).6. Material Quality Assurance6.1 In order to determine the acceptability of a lot or batch of a qualified product, the paint shall meet the re-quirements of Sections 6.2 through 6.4.6.2 Viscosity of the mixed paint shall be determined in accordance with ASTM D 562. Variance shall be within ±5 Krebs Units or equivalent units of another viscometer of the viscosity of the previously qualified paint.For viscosities lower than 55 K.U., a 4 Ford Cup shall be used in accordance with ASTM D 1200. Variations shall be within ±5 seconds of the viscosity of the previously qualified paint.6.3Weight per gallon of the mixed paint shall be determined in accordance with ASTM D 1475. Variance shall be within ±0.4 pounds (180 g) of the nominal weight per gallon of the previously qualified paint.SSPC-Paint 20November 1, 1982Editorial Changes August 1, 19916.4 Solids percent by weight of the mixed paint shall be determined in accordance with ASTM D 2369. The percent solids by weight shall be no less than that specified in Table 1. Variance shall be within ±2% of the nominal percent solids by weight of the previously qualified paint.6.5 Other tests may be used to determine the accept-ability of a lot or batch of a qualified product at the discretion of the user.7. Labeling7.1 Refer to ANSI Standard Z129.1, "Industrial Hazard-ous Chemicals—Precautionary Labeling." Other guidelines can be found in the National Paint and Coating Association (NPCA) "Paint Industry Labeling Guide."7.2 MARKING OF CONTAINER: Each container shall be legibly marked with the following information:Name: Zinc-Rich PrimerSpecification: SSPC-Paint 20, TypeComponent:Color:Lot Number:Stock Number:Date of Manufacture:Quantity of Paint in Container:Information and Warnings as may be required byFederal and State Laws:Manufacturer's Name and Address:7.3 PACKAGING: The pigment portion of multicompo-nent zinc-rich paints shall be packaged separately to be mixed with the liquid portion shortly before use. Each container of liquid shall be packaged and labeled in accor-dance with the requirements of Federal Specification PPP-P-1892 and shall include directions showing correct propor-tions of liquid to pigment along with necessary mixing instructions. The packaging of single component zinc-rich paints, Types I and II, shall also comply with the above Federal Specification.7.4 DIRECTIONS FOR USE: The manufacturer shall supply complete instructions covering uses, surface prepa-ration, mixing, thinning, application method, application conditions, pot life, wet and dry film thicknesses, tempera-ture and humidity limitations, drying times, etc. with each container of paint.8. Inspection8.1 All materials (coatings) supplied under this specifi-cation are subject to timely inspection by the purchaser or his authorized representative. The purchaser shall have the right to reject any materials supplied which are found to be defective under this specification. (See Note 10.1.) In case of dispute, unless otherwise specified, the arbitration or settlement procedure established in the procurement docu-ments shall be followed. If no arbitration procedure is established, the procedure specified by the American Arbi-tration Association shall be used.8.2 Samples of paints may be requested by the pur-chaser and shall be supplied upon request along with the manufacturer’s name and identification for the materials. Samples may be requested at the time the purchase order is placed or may be taken from unopened containers at the job site.8.3 Unless otherwise specified, the sampling shall be in accordance with ASTM D 3925.9. Disclaimer9.1 While every precaution is taken to ensure that all information furnished in SSPC standards and specifica-tions is as accurate, complete, and useful as possible, SSPC cannot assume responsibility nor incur any obliga-tion resulting from the use of any materials, coatings, or methods specified herein, or of the specification or stan-dard itself.9.2This specification does not attempt to address problems concerning safety associated with its use. The user of this specification, as well as the user of all products or practices described herein, is responsible for instituting appropriate health and safety practices and for insuring compliance with all governmental regulations.10. NotesNotes are not requirements of this specification.10.1 The procurement documents should establish the responsibility for samples, testing, and any required affida-vit certifying full compliance with the specification.10.2 COVERAGE: Except for special cases, most zinc-rich primers are formulated to apply at nominal dry film thicknesses of 2.5-3.5 mils (64-88 micrometers). In actual practice a coverage of 150 to 300 square feet per gallon (3.7- 7.4 square meters per liter) will be expected over flat blast cleaned surfaces.10.3 FLASH POINT:The minimum flash point, as determined by the Tag closed cup (ASTM D 56) should be "none" for inorganic water base zinc-rich coatings, and a minimum of 55°F (13°C) for solvent base inorganic zincs (Type l-C) and 50°F (10°C) for organic zincs (Type II).SSPC-Paint 20November 1, 1982 Editorial Changes August 1, 1991Specific applications, such as the interior of tanks, holds, and other confined spaces normally require a minimum flash point of 100°F (38°C).10.4A Surface Profile Comparator is available from SSPC for sand, grit, and shot blast cleaned surfaces. Alternatively, replica tape, depth micrometer, stylus, micro-scopic measurement methods, or other suitable techniques may be used.10.5 Inorganic zinc-rich paints Types l-A and l-B should not be stored at temperatures below 40°F (4°C). Further-more, storage of all zinc-rich paints above 90°F (32°C) should be avoided.10.6Inorganic zinc-rich primers (Types l-A and l-B) should not be applied at surface temperatures below 40°F (4°C). Type l-C should not be applied at relative humidities below 50%, without specific instructions from the paint manufacturer.10.7Multiple component zinc-rich paints should be applied within four hours after mixing and should be con-tinuously agitated during application.10.8 ADDITIONAL RESISTANCE TESTS: Because of the diversity of potential service environments, this specifi-cation may require the zinc-rich primer be further exposed and qualified by at least one additional test relating to the intended exposure. For example, if the intended service is a petroleum tanker cargo hold which is ballasted with sea water, appropriate test requirements other than those al-ready specified might be:•Salt Water Immersion (1,000 hours) ASTM D 1308•Oil Immersion (1,000 hours) ASTM D 1308 or a cycling combination of bothComparative testing of all candidate zinc-rich primers will be more meaningful than individual testing of each primer.Standard tests which may be useful for further qualifi-cation are available from a number of organizations, includ-ing ASTM, U.S. Government Federal Specifications (TT-P; MIL-P, etc.), Federal Test Method Standards (141), and Canadian Government Specifications Board. A partial list-ing of public zinc-rich specifications requiring qualification testing is presented in the Notes of SSPC-PS Guide 12.00, "Guide for Selecting Zinc-Rich Painting Systems."However, it should be emphasized that a well designed non-standard test may often provide more meaningful infor-mation for a given service condition than one or more standard tests.SSPC规范-油漆20美国钢结构涂装协会标准1总则1.1技术规范涵盖的两个种类的富锌漆,只有一个定义:在露底和细小擦损部位涂层漆膜不连续的情况下也能保护裸露金属。

环氧磷酸锌防锈底漆组成科漆士环氧磷酸锌防锈底漆由改性环氧树脂、磷酸锌、改性胺固化剂、助剂、溶剂等组成的双组份快干防锈底漆。

主要特性漆膜具有良好的耐水性和耐盐水性能;漆膜坚韧具有优异的附着力和耐冲击性能;漆膜具有良好的耐油性和耐溶剂性能;漆膜具有良好的防锈性能和耐久性。

用途用于港口、码头、重型机械、矿山机械、电力机械、化工设备、水利工程等钢铁结构、以及船舶水线以上部位钢铁结构等处作防锈底漆之用;用于湿热及经常接触水的钢铁表面作防锈底漆使用。

基本参数颜色铁红色、灰色光泽无光固体份含量50~55%干膜厚度35μm理论用量100~115g/m2闪点25℃干燥时间(25℃)表干≤30min,实干≤24h,完全固化7d复涂间隔时间底材温度5℃25℃40℃最短20h 12h4h最长不限表面处理所有表面必须清洁、干燥且无污染。

应按照ISO8504进行评估和处理。

裸钢清洁度:喷砂处理至Sa2.5级(ISO8501-1:1998)。

根据暴露情况,亦可用动力工具清洁,最低St2级,无氧化皮(ISO8501-1:1988)。

涂有车间底漆的钢材清洁、干燥和完好的经认可的车间底漆。

涂有油漆的表面清洁、干燥和完好的配套底漆。

其它表面该产品用于其它底材。

前道配套用漆无。

后道配套用漆环氧涂料、氯化橡胶涂料、丙烯酸涂料、聚氨酯涂料、氯磺化聚高氯化聚乙烯涂料、互穿网络涂料、聚硅氧烷涂料、氟树脂涂料、漆酚涂料等中间漆或面漆。

施工条件底材温度不低于5℃,且至少高于空气露点温度3℃(温度和相对湿度应在底材附近测量)。

通常需要良好的通风,以确保油漆正常干燥。

施工方法喷涂:无气喷涂或有气喷涂。

推荐采用高压无气喷涂。

采用有气喷涂应注意调整涂料粘度和气压。

稀释剂不宜超过10%,否则影响涂层性能。

刷涂:建议在预涂和小面积涂装时采用,但必须达到规定的干膜厚度。

施工参数混合比(重量)见产品包装桶上标签,搅拌均匀混合后使用寿命(23℃)4小时(随温度升高而减少)稀释剂/清洗剂H系列专用稀释剂无气喷涂的指导性数据喷嘴压力150~200千克力/平方厘米喷嘴孔径0.4~0.5毫米喷涂幅度40~80度稀释量0~10%(以油漆重量计)包装及贮存按照国家规定包装、贮存。

环氧富锌底漆标准HG/T3668-2009备案号:27258-2010HG中华人民共和国化工行业标准富锌底漆Zinc rich primerHG/T 3668-2009代替 HG/T 3668-2000前言HG/T 3668-2009本标准代替HG/T 3668-2000《富锌底漆》。

本标准与HG/T 3668-2000的主要技术差异为:——增加了按不挥发分中金属锌含量的高低对产品进行分类;——增加了对“附着力”、“密度”的要求;——取消了对“耐候性”、无机富锌底漆“耐冲击性”和有机富锌底漆“环氧树脂的定性”的要求;——提高了对“耐盐雾性”和无机富锌底漆“干燥时间”的要求;——增加了仪器法测定“不挥发分中金属锌含量”的方法;——改变了漆膜厚度和养护时间的规定。

富锌底漆HG/T 3668-20091 范围本标准规定了富锌底漆的分类、要求、试验方法、检验规则、标志、包装和贮存等内容。

本标准适用于由锌粉(除鳞片状锌粉)、无机或有机漆基及固化剂、溶剂等组成的多组分涂料,该涂料主要用于钢铁底材的防锈。

本标准不适用于不挥发分中金属锌含量低于60%的非富锌类产品。

2规范性引用文件下列文件中的条款通过本标准的引用而成为本标准的条款。

凡是注日期的引用文件,其随后所有的修改单(不包括勘误的内容)或修订版均不适用于本标准,然而,鼓励根据本标准达成协议的各方研究是否可使用这些文件的最新版本。

凡是不注日期的引用文件,其最新版本适用于本标准。

GB/T 1725-2007 色漆、清漆和塑料不挥发物含量的测定(idt IS0 3251:2003)GB/T 1728-1979 (1989) 漆膜、腻子膜干燥时间测定法GB/T 1732-1993 漆膜耐冲击测定法GB/T 1771-2007 色漆和清漆耐中性盐雾性能的测定(idt IS0 7253:1996)GB/T 3186 色漆、清漆和色漆与清漆用原材料取样(GB/T 3186-2006,idt IS0 15528:2000)GB/T 5210-2006 色漆和浦漆拉开法附着力试验(idt IS0 4624:2002)GB/T 6750-2007色漆和清漆密度的测定比重瓶法(idt IS0 2811-1:1997,Paint andvarnishes-Determination of density-Part l:Pyknometer method)GB/T 8170数值修约规则与极限数值的表示和判定GB/T 9271 色漆和清漆标准试板(GB/T 9271-2008,mod IS0 1514:2004)GB/T 8923涂装前钢材表面锈蚀等级和除锈等级(GB/T 8923-1988,eqv IS0 8501-1:1988)GB/T 9278涂料试样状态调节和试验的温湿度(GB/T 9278-2008,idt IS0 3270:1984,Paintsand varnishes and their raw materials-Temperatures and humidities for conditioning and testing)GB/T 9750 涂料产品包装标志GB/T 13288.1涂覆涂料前钢材表面处理喷射清理后的钢材表面粗糙度特性第1部分:用于评定喷射清理后钢材表面粗糙度的ISO表面粗糙度比较样块的技木要求和定义(GB/T 13288-2008,idt IS0 8503-1:1998)GB/T 13452.2 色漆和清漆漆膜厚度的测定(GB/T 13452. 2-2008,idt IS0 2808:2007)GB/T 13491 涂料产品包装通则ASTMD 6580-2000(2005) 锌粉颜料和富锌涂料干漆膜中金属锌含量的测定3产品分类本标准按富锌底漆的漆基类型分为I型和Ⅱ型:-I型:无机富锌底漆,包括溶剂型无机富锌底漆和水性无机富锌底漆; ——Ⅱ型:有机富锌底漆。

中华人民共和国汽车行业标准QC/T 484—1999代替 JB/Z 111—86汽车油漆涂层本标准适用于汽车油漆涂层,不适用于汽车电器和仪表产品的油漆涂层。

1 油漆涂层代号的规定按汽车零部件的使用条件和涂漆质量要求的不同,油漆涂层分10个组和若干等级,按表1的规定。

2 技术要求2.1 油漆涂层的主要质量指标,按油漆涂层代号的组别和级别规定于表2。

(如有其他特殊要求,应在产品图纸或技术文件中注明)。

2.2 整车的漆膜应完整,不允许有露底(包括焊缝、封闭内腔)和碰伤的表面。

在总装的过程中,应加强对车身及覆盖件的油漆涂层的保护。

在总装后车架、底盘件等应补漆。

2.3 汽车零部件油漆涂层的颜色,本标准不作统—规定。

由各企业根据零部件的用途和用户的要求确定。

3 标注根据汽车各零部件的使用条件、涂层质量要求,选择油漆涂层的代号和等级。

例如:高级轿车车身装饰性涂层,在产品图纸上的标注如下:漆以TQ2甲QC/T 484—1999。

4 检验4.1 油漆涂层质量指标的检验方法,按下述规定:4.1.1 涂膜外观:与标准板目测比较。

4.1.2 漆膜光泽:按GB/T 1743—1979《漆膜光泽度测定法》测定。

4.1.3 漆膜厚度:按GB/T 1764—1979《漆膜厚度测定法》测定。

4.1.4 冲击强度:按GB/T 1732—1979《漆膜耐冲击测定法》测定。

4.1.5 弹性:按GB/T 1731—1979《漆膜柔韧性测定法》测定。

4.1.6 硬度:按GB/T 1730—1979《漆膜硬度测定法(摆杆法)》测定。

4.1.7 附着力:按GB/T 1720—1979《漆膜附着力测定法》测定。

4.1.8 耐碱性:采用以下两种检验方法测定:a)把涂漆的样板,浸入80±2℃2%的Na2CO3水溶液中,经10min后,检查漆膜被溶解的状况;b)把涂漆的样板,浸在55±l℃含0.1NaOH水溶液中,经4h后,检查漆膜变化情况。