3m系列产品介绍

- 格式:ppt

- 大小:301.50 KB

- 文档页数:38

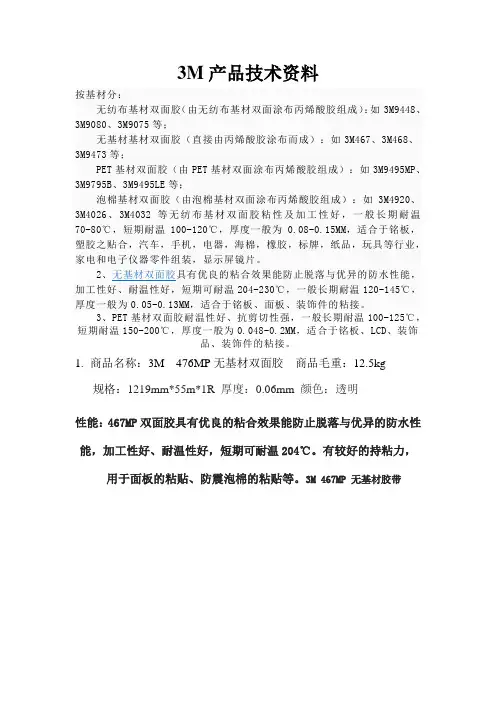

3M产品技术资料按基材分:无纺布基材双面胶(由无纺布基材双面涂布丙烯酸胶组成):如3M9448、3M9080、3M9075等;无基材基材双面胶(直接由丙烯酸胶涂布而成):如3M467、3M468、3M9473等;PET基材双面胶(由PET基材双面涂布丙烯酸胶组成):如3M9495MP、3M9795B、3M9495LE等;泡棉基材双面胶(由泡棉基材双面涂布丙烯酸胶组成):如3M4920、3M4026、3M4032等无纺布基材双面胶粘性及加工性好,一般长期耐温70-80℃,短期耐温100-120℃,厚度一般为0.08-0.15MM,适合于铭板,塑胶之贴合,汽车,手机,电器,海棉,橡胶,标牌,纸品,玩具等行业,家电和电子仪器零件组装,显示屏镜片。

2、无基材双面胶具有优良的粘合效果能防止脱落与优异的防水性能,加工性好、耐温性好,短期可耐温204-230℃,一般长期耐温120-145℃,厚度一般为0.05-0.13MM,适合于铭板、面板、装饰件的粘接。

3、PET基材双面胶耐温性好、抗剪切性强,一般长期耐温100-125℃,短期耐温150-200℃,厚度一般为0.048-0.2MM,适合于铭板、LCD、装饰品、装饰件的粘接。

1.商品名称:3M 476MP无基材双面胶商品毛重:12.5kg规格:1219mm*55m*1R 厚度:0.06mm 颜色:透明性能:467MP双面胶具有优良的粘合效果能防止脱落与优异的防水性能,加工性好、耐温性好,短期可耐温204℃。

有较好的持粘力,用于面板的粘贴、防震泡棉的粘贴等。

3M 467MP 无基材胶带参考价格:¥26.10/m22.商品名称:3M 476MP无基材双面胶商品毛重:12.5kg规格:1219mm*55m*1R 厚度:0.06mm 颜色:透明性能:467MP双面胶具有优良的粘合效果能防止脱落与优异的防水性能,加工性好、耐温性好,短期可耐温204℃。

有较好的持粘力,用于面板的粘贴、防震泡棉的粘贴等。

002623M™ Scotchcast™ Electrical Resin 262 One-Part, Class B, General PurposeEpoxy Powder ResinProduct Description3M™ Scotchcast™ Electrical Resin 262 is a widely used, well-known general purpose epoxy powder resin. A one-part, red pigmented, rapid heat-curing product, it is designed to provide a continuous, tough moisture and chemical resistant dielectric coating to a variety of substrates.• Fast curing• Excellent electrical properties• Excellent thermal shock and impact resistance• Excellent heat, chemical and moisture resistance• Good cut-through resistance• Excellent flow Scotchcast Electrical resin 262 is manufactured by a fusion blend process, insuring that each individual particle of powder contains all the components necessary to effect a complete cure and attain stated performance properties.Scotchcast electrical resin 262 is applied to an object that has been heated to a temperature above the melting point of the resin. On contact with the preheated application surface, the resin melts, flows to a controlled extent, then cures, bonding to the substrate and coalescing into a smooth, continuous, essentially uniform, thick coating. It effectively coats flat surfaces and corners, as well as, high points. Uses for Scotchcast 262 include moisture proofing and insulating armatures, stators, buss bars and toroid cores.Scotchcast™ Electrical Resin 262 – Typical PropertiesColor RedSpecific Gravity1 (cured) 1.34Dielectric Strength3 12 to 15 mil coating1000 v/milThermal Shock2 10 cycles-75°C to 155°C12 -15 mil coating 1/8’’ sandblasted steel PassesImpact Resistance212-15 mil coating 1/8’’ sandblasted steel panel Gardner 5/8’’ RadiusImpact Tester100 inch-lbsCut-Through Resistance2 – 1lb wt: 1/8 AWG wire130°C (266° F)Edge Coverage2 12-15 mil coating on flat38-48%Gel time2 @ 193°C hot plate12-16 seconds*Not recommended for specification purposes. Product specifications will be provided upon request.Test Methods1 ASTM D-7922 3M Test Method3 ASTM D-14933Corrosion Protection Products Division6801 River Place Blvd. Austin, TX 78726-9000 /corrosion Please recycle. Printed in USA.© 3M 2010. All rights reserved. 80-6111-0945-7 Rev AHandling and Safety PrecautionsRead all Health Hazard, Precautionary and First Aid,Material Safety Data Sheet, and/or product label prior to handling or use.Ordering Information/Customer ServiceFor ordering technical or product information, or a copy of the Material Safety Data Sheet, call:Phone: 800/722-6721 or 512/984-9393Fax: 877/601-1305 or 512/984-6296Important NoticeAll statements, technical information, and recommendations related to 3M’s prod-ucts are based on information believed to be reliable, but the accuracy or com-pleteness is not guaranteed. Before using this product, you must evaluate it and determine if it is suitable for your intended application. You assume all risks and liability associated with such use. Any statements related to the product which are not contained in 3M’s current publications, or any contrary statements contained on your purchase order shall have no force or effect unless expressly agreed upon, in writing, by an authorized officer of 3M.Warranty; Limited Remedy; Limited Liability. Because conditions of product use are outside of our control and vary widely, the following is made in lieu of all express or implied warranties: this product will conform to 3M’s published product specifications and be free from defects in material and manufacture on the date of your purchase. 3M MAKES NO OTHER WARRANTIES INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. If this product is defective upon your receipt, your exclusive remedy shall be, at 3M’s option, to replace the 3M product or refund the purchase price of the 3M product. Except where prohibited by law, 3M will not be liable for any indirect, special, incidental or consequential loss or damage arising from this 3M product, regardless of the legal theory asserted.Usage InformationMethod of ApplicationThe rapid cure of 3M™ Scotchcast™ Electrical Resin 262 permits the use of highspeed production methods. The powder can be readily applied by spraying techniques as well as through the use of fluid bed dipping of preheated parts. Automated and manual types of application equipment are both available. Equipment manufacturers’ names can be suggested upon request.CuringThe cure of Scotchcast 262 to a thermoset condition involves a time-temperature relationship. The retained heat in application units having high heat capacity is sufficient in many casesto effect a cure of the resin without the need for post-curing facilities. For example, if an application surface can retain a temperature of 204° C (400° F) for 60 seconds after coating, it will be fully cured. Small articles, or those with a large surface-to-mass ratio, lose heat rapidly and may require a higher preheat temperature and/or additional oven- curing.The figures below represent nominal guidelines for obtaining the resin’s adhesion, impact and chemical resistance characteristics.149° C (300° F)40 minutes177° C (350° F)20 minutes204° C (400° F)60 seconds232° C (450° F)30 secondsThe user must determine the time required for the coated substrate to reach listed temperatures.Preheat Temperature RangePrior to applying Scotchcast electrical resin 262, the part must be preheated to a temperature ranging from 150° C (302° F) to 260° C (500° F). The optimum preheat temperature depends upon the size, heat capacity and configuration of the object to be coated, as well as the method of application. The ideal coating temperature will vary for each application and is best determined by experimentation.StorageLaboratory evaluation indicates that the usable shelf life of the product is twenty four (24) months from the date of manufacture when stored at temperatures not exceeding 27° C (80° F), providing the material is stored in its original container. Care should be taken when removing the resin from the original container to prevent inclusion of foreign material. After the resin removal, the bag should be retied immediately. This will help to avoid agglomeration caused by excess moisture. For best results, store in a cool, dry place.00262。

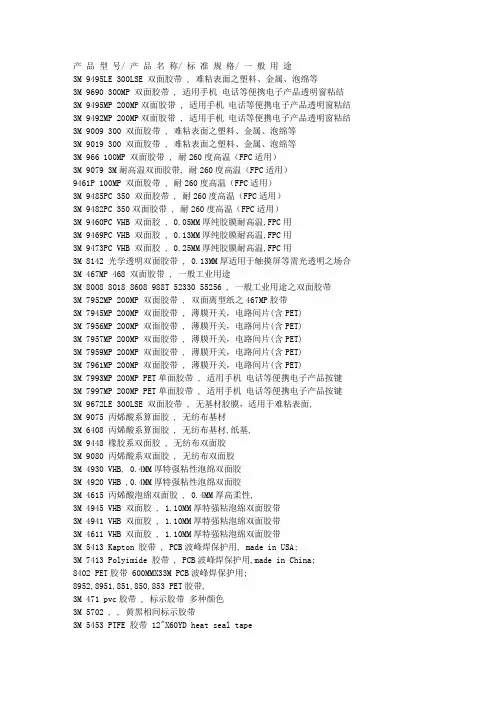

产品型号/ 产品名称/ 标准规格/ 一般用途3M 9495LE 300LSE 双面胶带 , 难粘表面之塑料、金属、泡绵等3M 9690 300MP 双面胶带 , 适用手机电话等便携电子产品透明窗粘结3M 9495MP 200MP双面胶带 , 适用手机电话等便携电子产品透明窗粘结3M 9492MP 200MP双面胶带 , 适用手机电话等便携电子产品透明窗粘结3M 9009 300 双面胶带 , 难粘表面之塑料、金属、泡绵等3M 9019 300 双面胶带 , 难粘表面之塑料、金属、泡绵等3M 966 100MP 双面胶带 , 耐260度高温(FPC适用)3M 9079 3M耐高温双面胶带, 耐260度高温(FPC适用)9461P 100MP 双面胶带 , 耐260度高温(FPC适用)3M 9485PC 350 双面胶带 , 耐260度高温(FPC适用)3M 9482PC 350双面胶带 , 耐260度高温(FPC适用)3M 9460PC VHB 双面胶 , 0.05MM厚纯胶膜耐高温,FPC用3M 9469PC VHB 双面胶 , 0.13MM厚纯胶膜耐高温,FPC用3M 9473PC VHB 双面胶 , 0.25MM厚纯胶膜耐高温,FPC用3M 8142 光学透明双面胶带 , 0.13MM厚适用于触摸屏等需光透明之场合3M 467MP 468 双面胶带 , 一般工业用途3M 8008 8018 8608 988T 52330 55256 , 一般工业用途之双面胶带3M 7952MP 200MP 双面胶带 , 双面离型纸之467MP胶带3M 7945MP 200MP 双面胶带 , 薄膜开关,电路间片(含PET)3M 7956MP 200MP 双面胶带 , 薄膜开关,电路间片(含PET)3M 7957MP 200MP 双面胶带 , 薄膜开关,电路间片(含PET)3M 7959MP 200MP 双面胶带 , 薄膜开关,电路间片(含PET)3M 7961MP 200MP 双面胶带 , 薄膜开关,电路间片(含PET)3M 7993MP 200MP PET单面胶带 , 适用手机电话等便携电子产品按键3M 7997MP 200MP PET单面胶带 , 适用手机电话等便携电子产品按键3M 9672LE 300LSE 双面胶带 , 无基材胶膜,适用于难粘表面,3M 9075 丙烯酸系算面胶 , 无纺布基材3M 6408 丙烯酸系算面胶 , 无纺布基材,纸基,3M 9448 橡胶系双面胶 , 无纺布双面胶3M 9080 丙烯酸系双面胶 , 无纺布双面胶3M 4930 VHB, 0.4MM厚特强粘性泡绵双面胶3M 4920 VHB ,0.4MM厚特强粘性泡绵双面胶3M 4615 丙烯酸泡绵双面胶 , 0.4MM厚高柔性,3M 4945 VHB 双面胶 , 1.10MM厚特强粘泡绵双面胶带3M 4941 VHB 双面胶 , 1.10MM厚特强粘泡绵双面胶带3M 4611 VHB 双面胶 , 1.10MM厚特强粘泡绵双面胶带3M 5413 Kapton 胶带 , PCB波峰焊保护用, made in USA;3M 7413 Polyimide 胶带 , PCB波峰焊保护用,made in China;8402 PET胶带 600MMX33M PCB波峰焊保护用;8952,8951,851,850,853 PET胶带,3M 471 pvc胶带 , 标示胶带多种颜色3M 5702 , , 黄黑相间标示胶带3M 5453 PTFE 胶带 12"X60YD heat seal tape3M 5421 5423 5425 UHMW-PE 1"X18YD 抗磨降低摩擦胶带3M 425 铝箔胶带 1"X60YD 一般性用途3M 9703 自粘导电双面胶带 12"X36YD EL片、薄膜开关FPC等用3M 9713 热压导电双面胶带 12"X36YD EL片、薄膜开关FPC等用3M 331T 蓝色保护胶带 1.2MX100M PCB电镀保护胶带,不锈钢表2K10,3K04,332,保护膜;3M 2142 美纹纸遮蔽胶带 400mmX 50m PCB过锡炉(波峰焊)等遮蔽场合使用3M 244 美纹纸遮蔽胶带 400mmX 50m PCB过锡炉(波峰焊)等遮蔽场合使用8152,8902, PCB电镀绿胶带 1000MMX50M PCB电镀等遮蔽场合使用610,600 测试胶带 1 "X36YD3M 616 遮光胶带 1"X36YD3M 810 隐形胶带 3/4"X36YD 一般性用途3M 811 半透明胶带 1/2"X36YD 一般性用途3M 665,666 双面胶带 1"X25YD 一面低粘性5952,5925,5962,465,ST-416,55256,55257,8018,8008,8004,4032,1600T,CIP-66,CIP-01; 4210,4214,5344,4229P,4211,CP5008,5012;7413T,7413D,5413,5419,7419;7816,7815, 57816,4950,4951,4609,4612,4611,4032,4008;5300,4799,471,5702,2328,2214,200,244,21 42,9996j,917,r3227,906b,900b,405,9022;9969b;1020,1015,1040,8592,8591,55230,8411, 5491;3M VHB胶带:4926, 4963,4941,4956,4919,4979,4991,5925,5952,5962,4943,4957,4604,4608,4612,4620,4630,4609,4615,4611,4646,4655,4920,4930,4950,4955,4945,4946,4905,4910,4951,4932。

3M胶带型号分类与用途3M是一个知名的多国企业,也是世界上最大的胶带制造商之一、3M 的胶带产品有许多不同的型号和用途,下面是一些常见的3M胶带型号分类与用途的介绍:1. 螺旋式胶带(Scotch Tape):最常见的一种胶带,用于文具、办公用品和一般家庭用途,如封口信封、粘贴文件和卡片等。

2. 包装胶带(Packaging Tape):用于包装、封箱和邮寄。

这种胶带通常有很强的粘性和耐用性,以确保包装箱的安全和完整性。

3. 双面胶带(Double-sided Tape):一面粘在物体上,另一面粘在其他物体上。

常用于家居装饰、工艺品制作和贴合材料等。

4. 聚酰胺胶带(Polyimide Tape):也称为Kapton胶带,具有高温耐受性和电绝缘性能,常用于电子器件的保护和固定。

5. 电子胶带(Electrical Tape):用于电气和电子设备的绝缘和保护,以防止电流泄露和损坏。

6. 室内装饰胶带(Decorative Tape):一种用于装饰和DIY项目的胶带,具有各种花纹和颜色可供选择。

7. 透明胶带(Clear Tape):透明的胶带,可在一些需要透明粘合的场合使用,如图纸、照片的修补和封口。

8. 防滑胶带(Anti-slip Tape):具有磨砂表面的胶带,用于防滑和增加地面摩擦力,在楼梯和斜坡等区域广泛使用。

9. 警示胶带(Warning Tape):通常具有醒目的颜色和印刷标识,用于警示危险区域、区分不同区域和标记管道等。

10. 重型粘贴胶带(Heavy-duty Mounting Tape):具有很高粘性的胶带,适用于固定和粘贴重型物品,如镜子、画框和装饰品等。

11. 剥离胶带(Removable Tape):具有可移除性的胶带,适用于不会损坏表面的临时粘贴,如海报和临时标记。

12. 钩子胶带(Hook and Loop Tape):也称为Velcro胶带,由一个钩和一个环组成,用于固定和连接物体,特别适用于布料和纺织品。

3M胶带型号及用途3M公司是全球知名的多元化技术公司,生产各种粘合剂、胶带和膜等产品,其中胶带是3M公司的主要产品之一、3M胶带以其高品质和多样化的型号而闻名于世,用途广泛,下面将介绍一些常见的3M胶带型号及其主要用途。

1. 透明胶带(Scotch Transparent Tape)透明胶带是3M最为常见的一款胶带产品,通常见于办公室和家庭使用。

它具有高透明度、强力粘性和拉伸性,可用于封口信封、包装礼物、固定纸张等。

2. 双面胶带(Scotch Mounting Tape)双面胶带是具有两面均涂有胶粘剂的胶带,适用于贴合两个物体的表面。

它通常用于固定海报、画框、家居装饰等场合,取代传统的钉子、螺丝等固定物品的方法,具有良好的贴合性和持久性。

3. 耐高温胶带(Scotch High Temperature Masking Tape)耐高温胶带是一种特殊的装饰、喷漆和包装胶带,具有良好的耐高温性能和防渗透性能。

它通常应用于汽车喷漆、电子产品组装、印刷等领域,能够承受高温和化学品的侵蚀。

4. 绝缘胶带(Scotch Electrical Tape)绝缘胶带是一种用于绝缘电线和电缆的胶带。

它通常用于电子产品的包装和维修,能够有效地隔离电流,避免电流泄漏和电击等电气危险。

5. 防水胶布(Scotch Waterproof Tape)防水胶布是一种具有防水特性的胶带,通常用于室外工程、灌装、船舶等场合。

它具有良好的粘接性能和防水性能,能够在潮湿和湿润的环境中保持稳定和可靠的粘接效果。

6. 抗紫外线胶带(Scotch UV Resistant Tape)抗紫外线胶带是一种具有抗紫外线特性的胶带,适用于户外应用,如阳光暴晒、长时间的户外装饰等。

它能够有效抵御紫外线的侵蚀,保证物体表面的颜色、质量和美观。

7. 拉伸片胶带(Scotch Stretchable Tape)拉伸片胶带是一种具有高弹性和可伸缩性能的胶带,用于固定弹性材料、包装等。

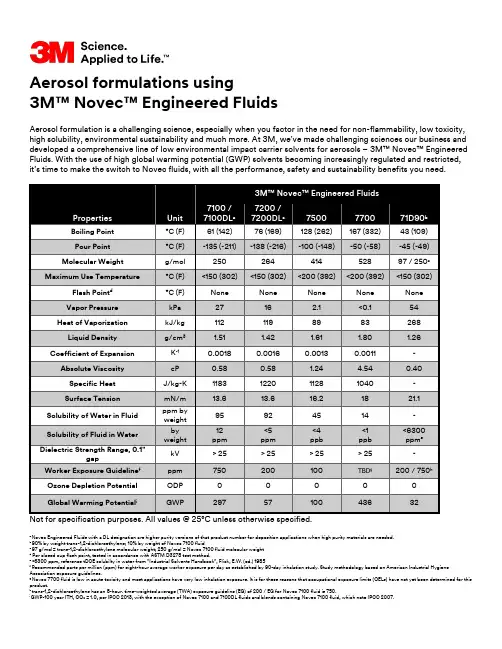

Aerosol formulations using3M™ Novec™ Engineered FluidsAerosol formulation is a challenging science, especially when you factor in the need for non-flammability, low toxicity, high solubility, environmental sustainability and much more. At 3M, we've made challenging sciences our business and developed a comprehensive line of low environmental impact carrier solvents for aerosols –3M™Novec™ Engineered Fluids. With the use of high global warming potential (GWP) solvents becoming increasingly regulated and restricted, it’s time to make the switch to Novec fluids, with all the performance, safety and sustainability benefits you need.Properties Unit3M™ Novec™ Engineered Fluids7100 /7100DL a7200 /7200DL a7500 7700 71D90bBoiling Point °C (F) 61 (142) 76 (169) 128 (262) 167 (332) 43 (109) Pour Point °C (F) -135 (-211) -138 (-216) -100 (-148) -50 (-58) -45 (-49) Molecular Weight g/mol 250 264 414 528 97 / 250c Maximum Use Temperature °C (F) <150 (302) <150 (302) <200 (392) <200 (392) <150 (302) Flash Point d°C (F) None None None None None Vapor Pressure kPa 27 16 2.1 <0.1 54 Heat of Vaporization kJ/kg 112 119 89 83 268 Liquid Density g/cm3 1.51 1.42 1.61 1.80 1.26 Coefficient of Expansion K-10.0018 0.0016 0.0013 0.0011 - Absolute Viscosity cP 0.58 0.58 1.24 4.54 0.40 Specific Heat J/kg-K 1183 1220 1128 1040 - Surface Tension mN/m 13.6 13.6 16.2 18 21.1Solubility of Water in Fluid ppm byweight95 92 45 14 -Solubility of Fluid in Waterbyweight12ppm<5ppm<4ppb<1ppb<6300ppm eDielectric Strength Range, 0.1"gapkV > 25 > 25 > 25 > 25 - Worker Exposure Guideline f ppm 750 200 100 TBD g200 / 750hOzone Depletion Potential ODP 0 0 0 0 0Global Warming Potential i GWP 297 57 100 436 32Not for specification purposes. All values @ 25°C unless otherwise specified.a Novec Engineered Fluids with a DL designation are higher purity versions of that product number for deposition applications when high purity materials are needed.b 90% by weight trans-1,2-dichloroethylene; 10% by weight of Novec 7100 fluidc 97 g/mol= trans-1,2-dichloroethylene molecular weight; 250 g/mol = Novec 7100 fluid molecular weightd Per closed cup flash point, tested in accordance with ASTM D3278 test method.e <6300 ppm, reference tDCE solubilty in water from "Industrial Solvents Handbook", Flick, E.W. (ed.) 1985f Recommended parts per million (ppm) for eight-hour average worker exposure per day as established by 90-day inhalation study. Study methodology based on American Industrial Hygiene Association exposure guidelines.g Novec 7700 fluid is low in acute toxicity and most applications have very low inhalation exposure. It is for these reasons that occupational exposure limits (OELs) have not yet been determined for this product.h trans-1,2-dichloroethylene has an 8-hour. time-weighted average (TWA) exposure guideline (EG) of 200 / EG for Novec 7100 fluid is 750.i GWP-100 year ITH, CO2 = 1.0, per IPCC 2013, with the exception of Novec 7100 and 7100DL fluids and blends containing Novec 7100 fluid, which note IPCC 2007.Aerosol formulations using3M™ Novec™ Engineered FluidsBelow are some recommendations to help with your formulations. 3M technical representatives are also available to help determine which 3M™ Novec™ Engineered Fluid is best for your specific needs and to help you with customizing your aerosol solution.Properties3M™ Novec™ Engineered Fluids7100 /7100DL7200 /7200DL 7500 7700 71D90Fluorocarbon solubility High High High High LowHydrocarbon solubility Medium Medium Low Low Very HighPlastic/elastomer compatibility High High Very High Very High LowApplicationsAerosol cleaners ●●●Aerosol coatings ●●●Dry lubricant aerosols /polytetrafluoroethylene (PTFE)●●●●Dissolving fluorochemicals ●●●●Dissolving hydrocarbons ●●●Reducing aerosol formulationflammability●Improving aerosol CARB VOCcompliance1●Extending dry time ●●Replacement forChlorofluorocarbons (CFCs) ●●●Hydrochlorofluorocarbons (HCFCs) ●●●Hydrofluorocarbons (HFCs) ●●Perfluorinated chemicals (PFCs) ●●●●Perfluoropolyethers (PFPEs) ●●n-propyl bromide (nPB)●1 Does not exceed the volatile organic compound (VOC) limits set by the California Environmental Protection Agency Air Resources Board for aerosol formulations. It is essential that the user evaluate the 3M product to determine whether it is fit for a particular purpose and that the end formulation meets the environmental and regulatory requirements of your area.Have questions? Need technical assistance? Contact your 3M technical service representative.We’re here to help.IMPORTANT NOTICE: The technical information, recommendations and other statements contained in this document are based upon tests or experience that 3M believes are reliable, but the accuracy or completeness of such information is not guaranteed. Contact your local 3M representative or visit /Novec for more information. Warranty and Limitation of Liability: if there is a defect in this product, your exclusive remedy shall be product replacement or refund of the purchase price. 3M MAKES NO OTHER WARRANTIES OR CONDITIONS, INCLUDING ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. 3M will not be liable for any direct, indirect, special, incidental or consequential damage related to the use of this product.Electronics Materials Solutions Division 3M Center, Building 224-3N-11St. Paul, MN 55144-10001-800-810-8513/novec©2016 3M. All rights reserved.3M and Novec are trademarks of 3M Company.60-5002-0824-89/2018 ●●。

3m劳动防护产品有哪些3M劳动防护产品是指由3M公司生产的各种劳动防护用品,旨在保护工人在工作过程中免受各种危害因素的影响。

以下是一些3M劳动防护产品的介绍:1. 呼吸防护产品:- 非医用口罩:包括N95、KN95等多种型号的口罩,能有效防护空气中的颗粒物、粉尘、烟雾等有害物质。

- 呼吸器:如半面罩呼吸器、全面罩呼吸器等,可提供更高级别的呼吸防护。

2. 眼部防护产品:- 护目镜:提供眼部的物理防护,防止飞溅物、颗粒物及化学品对眼睛的伤害。

- 护目镜防雾剂:能够防止护目镜上发生雾气,提高工作时的视野与安全性。

3. 耳部防护产品:- 耳塞:用于降低噪音对人耳的损害,可分为一次性耳塞和可重复使用耳塞两种类型。

- 耳罩耳塞一体式:结合了耳罩和耳塞的功能,提供更好的耳部防护效果。

4. 头部防护产品:- 安全帽:可提供保护头部的物理防护,防止坠落物、碰撞等对头部的伤害。

- 防护头盔:在安全帽基础上,增加了对侧面和后方的防护,提供更全面的头部安全保障。

5. 手部防护产品:- 防护手套:用于保护手部免受化学药品、溶剂、刺激物等因素的侵害。

- 绝缘手套:用于保护工人在电气作业时免受电流的伤害,能有效降低电击的危险。

6. 身体防护产品:- 防护服:包括一次性防护服和可重复使用的防护服,用于防护工人免受化学物质、细菌、病毒等的侵害。

- 防护背心:用于提醒周围人员注意工作人员的存在,减少在交通等场景中的意外伤害。

7. 足部防护产品:- 防护鞋:提供足部防护,同时防滑、防静电等特性,适用于各种工作环境。

- 防护靴:在防护鞋基础上,增加了对踝部及更高位置的防护,提供更全面的足部保护。

以上是一些3M劳动防护产品的介绍,3M公司还生产了更多种类的产品,以满足不同工作环境下的防护需求。

无论是在建筑、制造、化工等行业,还是在医疗、食品加工等场所,3M都提供了各种高质量的劳动防护产品,保护工人的安全与健康。

工业用3M百洁布是由美国3M公司发明制造的一种世界领先的手工操作的表面处理产品,今天主要是来给大家进行几款不同型号的百洁布介绍,方便以后选购。

(一)7447C百洁布栗红色

能彻底清除各种材料表面的污垢,锈斑和氧化皮等。

(二)8668C百洁布蓝色

在8698的基础上,是3M中国有限公司工厂新研制出来的换代产品,其提升了8698的性能,为顾客提供了另一种性价比更好的选择。

至于8698这款3m百洁布就不做型号介绍啦,感兴趣的话,大家可以自己百度搜索一下。

(三)7521C百洁布紫色

木器材料表面的涂层,如底气和中漆,经过处理后增强了各涂层之间的附着力,从而有效地延长了涂层的寿命。

(四)7448百洁布灰色

适合金属、木材,塑料和合成材料的精密抛光和清洁。

(五)7447B百洁布栗红色

能彻底清除各种材料表面的污垢,锈斑和氧化皮等。

(六)7445百洁布白色

通常同液体清洁剂配合使用。

主要用于不锈钢、上漆表面及玻璃处理。

(七)8698百洁布绿色

通用型产品,切削力强。

主要应用于不锈钢、铝合金,铜等各种金属材料表面的除锈,电镀产品的修饰线纹。

(八)7440B百洁布茶色

金钢砂含量高,能快速移除氧化层。

好啦,就先推荐给大家这么几款3m百洁布,其它的型号,下次再介绍啦。

武汉新诚信物业清洁管理有限公司秉承“信誉至上、承诺为本、客户是上帝,质量是生命,团结出业绩”的经营理念,致力于物业清洁用品、民用清洁技术、高空清洁工程以及日常保洁服务。

3m双面胶型号及特点介绍_图文3M 双面胶带胶带结构耐温型号推荐应用厚度基材颜色胶系短期长期 (mm)3M444 PET 0.10 白色 200丙烯酸 150? 80? 广泛地用在软性电路板散热片和塑胶中的粘接。

无基材纯胶高粘性耐高温,用于一般工业组装,面板冲型及其贴3M467MP 0.05 透明 200MP丙烯酸 204? 149? 膜合.无基材纯胶高粘性耐高温,用于一般工业组装,面板冲型及其贴3M468MP 0.13 透明 200MP丙烯酸 204? 149? 膜合.特点与应用:耐高温性能优良。

两面不同的粘性,一面高粘性,适合永久固定;另一面中粘性,适合重正面硅胶,背3M4377-50 PET 0.05 透明新定位的需求。

厚度是同类产品中最薄的一种,特149? 80? 面丙烯酸胶别符合薄型设计的要求。

主要用于元器件的粘接等。

正面硅胶,背4377-50的加厚版本,耐低温-40?,耐高温3M4377-85 PET0.085 透明 149? 80? 面丙烯酸胶 149?,耐高温性优良,主要用于元器件的粘接等。

闭孔结构的PE泡棉基材,高剪切力和及耐高温.主要3M4492 PE泡棉 0.8 白/黑 430胶型 82? 70? 应用于工业、汽车行业。

保护塑料和金属的滑槽.导轨和容器免受磨损. 无粘3M5423 聚乙烯 0.28 透明耐磨型 150? 107? 滞/防沾粘--能为许多涉及到油墨.胶水或密封剂的涂覆或胶粘类应用提供一个便于清洁的表面.初粘性和终粘性较强,广泛用于面板、电器、电3M55230H 无纺布 0.15 白色压敏胶 150? 70? 子、铭牌、冰箱、蒸发器等行业。

能耐温80度,有很强的粘接力持久性长用于广告及半透明3M55230 0.15 白色丙希酸工业的各种粘广泛适用于加工行业,包括橡塑行业120? 80? TISSUE 中橡胶条及塑料的黏结接.优良的耐热冲击及剥离强度,适合泡棉、元器件、3M55258 PET 0.125 透明丙希酸 120? 80? 电池绝缘体附件粘接。