电阻应变式测力仪 切削力

- 格式:doc

- 大小:397.50 KB

- 文档页数:15

车削切削刀的测定一、实验目的与要求:1、了解车削时切削用量(切削深度ap和进给量f)对切削刀的影响。

2、掌握实验数据处理方法,并推导出切削力与切削用理关系的经验公式。

3、了解八角环电阻式三项测力仪的工作原理及有关仪器的使用方法。

二、实验设备及仪器1、CA6140型普通车床;2、八角环电阻式车削三项测力仪;3、Y6D—3A型电阻应变仪及DY—3型电源供给器;4、SC—16型光线示波器;5、车刀、试件、卡尺等。

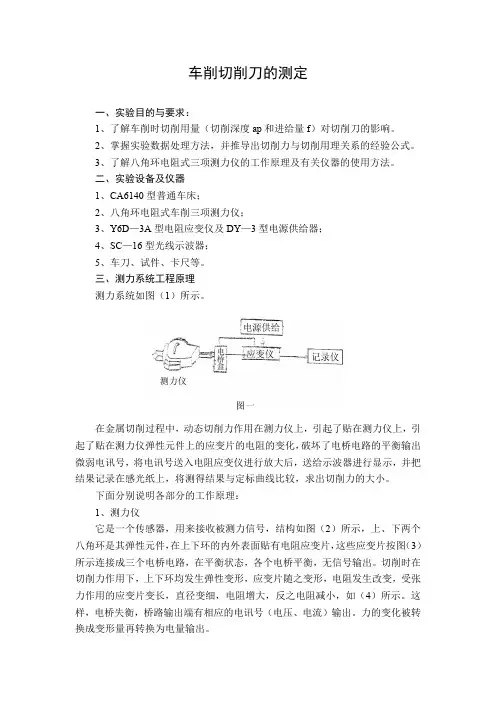

三、测力系统工程原理测力系统如图(1)所示。

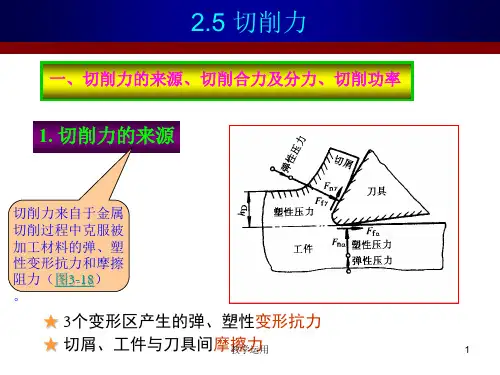

在金属切削过程中,动态切削力作用在测力仪上,引起了贴在测力仪上,引起了贴在测力仪弹性元件上的应变片的电阻的变化,破坏了电桥电路的平衡输出微弱电讯号,将电讯号送入电阻应变仪进行放大后,送给示波器进行显示,并把结果记录在感光纸上,将测得结果与定标曲线比较,求出切削力的大小。

下面分别说明各部分的工作原理:1、测力仪它是一个传感器,用来接收被测力信号,结构如图(2)所示,上、下两个八角环是其弹性元件,在上下环的内外表面贴有电阻应变片,这些应变片按图(3)所示连接成三个电桥电路,在平衡状态,各个电桥平衡,无信号输出。

切削时在切削力作用下,上下环均发生弹性变形,应变片随之变形,电阻发生改变,受张力作用的应变片变长,直径变细,电阻增大,反之电阻减小,如(4)所示。

这样,电桥失衡,桥路输出端有相应的电讯号(电压、电流)输出。

力的变化被转换成变形量再转换为电量输出。

2、电阻应变仪:它是测力系统的信号处理器,用来把电桥电路输出的曜号放大,检波、再输出给示波器记录。

电源供给器是应变仪的配套设备,用于向应变仪提供高压高频电源并通过应变仪向电桥电路的输入端提供低压高频电源。

3、光线示波器:其面板如图(5)所示它可以同时测量并记录16个被测信号,是本测量系统的记录仪。

四、测力系统的标定从示波器示出的光点的移动量与力的大小有一定的关系,通过对测力系统进行标定,就可得出这个函数关系。

实验二 切削力实验一、实验目的和要求1. 了解切削测力仪的工作原理和测力方法和实验系统;2. 掌握背吃刀量sp a 进给量f 和切削速度c v 对切削力的影响规律;3. 通过实验数据的处理,建立切削力的经验公式。

二、实验及标定原理三向切削力的检测原理,是使用三向车削测力传感器检测三向应变,三向应变作为模拟信号,输出到切削力实验仪器内进行高倍率放大,再经A/D 板又一次放大之后,转换为数字量送入计算机的。

测力系统首先应该通过三向电标定,以确定各通道的增益倍数。

然后,再通过机械标定,确定测力传感器某一方向加载力值与三个测力方向响应的线性关系。

经过这两次标定,形成一个稳定的检测系统之后,才能进行切削力实验。

测量切削力的主要工具是测力仪,测力仪的种类很多。

有机械测力仪、油压测力仪和电测力仪。

机械和油压测力仪比较稳定、耐用。

而电测力仪的测量精度和灵敏度较高。

电测力仪根据其使用的传感器不同,又可分为电容式、电感式、压电式、电阻式和电磁式等。

目前电阻式和压电式用得最多。

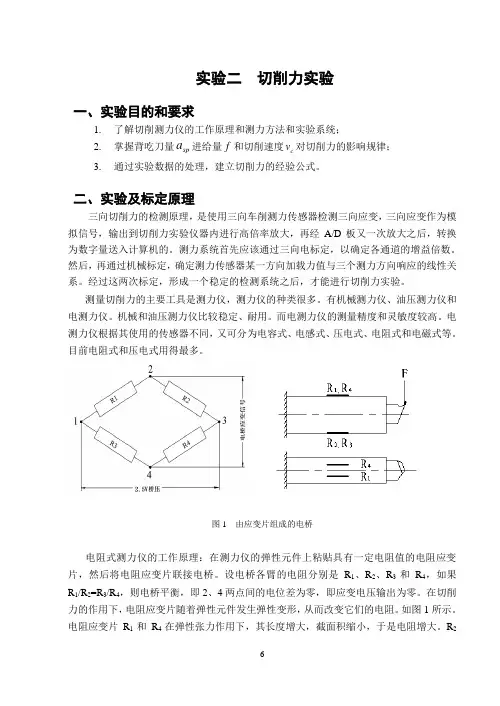

图1 由应变片组成的电桥电阻式测力仪的工作原理:在测力仪的弹性元件上粘贴具有一定电阻值的电阻应变片,然后将电阻应变片联接电桥。

设电桥各臂的电阻分别是R 1、R 2、R 3和R 4,如果R 1/R 2=R 3/R 4,则电桥平衡,即2、4两点间的电位差为零,即应变电压输出为零。

在切削力的作用下,电阻应变片随着弹性元件发生弹性变形,从而改变它们的电阻。

如图1所示。

电阻应变片R 1和R 4在弹性张力作用下,其长度增大,截面积缩小,于是电阻增大。

R 2和R 3在弹性压力作用下,其长度缩短,截面积加大,于是电阻减小,电桥的平衡条件受到破坏。

2、4两点间产生电位差,输出应变电压。

通过高精度线性放大区将输出电压放大,并显示和记录下来。

输出应变电压与切削力的大小成正比,经过标定,可以得到输出应变电压和切削力之间的线性关系曲线(即标定曲线)。

测力时,只要知道输出应变电压,便能从标定曲线上查出切削力的数值。

切削力测量技术现状及其发展趋势分析分析了目前切削力测量技术的现状及存在问题,根据现代切削加工高速、高精度和强力切削的特点,提出了切削力测量技术新的要求及发展趋势。

标签:切削力;测量技术;现状;发展趋势1 切削力测量技术现状分析切削力测量系统一般由三部分构成:由测力仪、数据采集系统和PC机三部分组成,如图1所示。

测力仪(测力传感器)通常安装在刀架(车削)或机床工作台上(铣削),负责拾取切削力信号,将力信号转换为弱电信号;数据采集系统对此弱电信号进行调理和采集,使其变为可用的数字信号;PC机通过一定的软件平台,将切削力信号显示出来,并对其进行数据处理和分析。

1.1 切削测力仪1.1.1 应变式测力仪应变式测力仪由弹性元件、电阻应变片及相应的测量转换电路组成,其工作原理如图2所示。

把电阻应变片贴在弹性元件表面,并连接成某种形式的电桥电路,当弹性元件受到力的作用而产生变形时,电阻应变片便随之产生变形,从而引起其电阻阻值的变化ΔR,即应变片电阻值的变化ΔR造成电桥不平衡,使电桥输出发生变化ΔU,通过标定建立输出电压与力之间的关系。

使用时根据输出电压反算切削力的大小。

应变式测力具有灵活性大、适应性广、性能稳定等优点,而且配套仪表(如静态应变仪、动态应变仪等已标准化,因而得到广泛应用。

但是其测量原理决定了测量精度和动态特性主要取决于弹性元件的结构,如何有效解决灵敏度和刚度之间的矛盾,是提高应变式测力仪测量精度和动态特性的关键。

1.1.2 压电式测力仪压电式测力仪是以压电晶体为力传感元件的切削测力仪,当石英晶体在外力作用下发生变形时,在它的某些表面上出现异号极化电荷。

这种没有电场的作用、只是由于应变或应力在晶体内产生电极化的现象称为压电效应。

通过测量产生电荷量即可以达到测量切削力的目的。

从动态测力的观点出发,压电式测力仪是一种比较理想的测力传感器,具有灵敏度高、受力变形小等优点。

然而压电式测力传感器仍然存在一系列缺点:如由于电荷泄漏而不能测试静态力、固有频率的提高受装配接触刚度的限制、维护极不方便、价格昂贵,因此在使用上受到很大的限制。

实验三车削力的测定1.实验目的(1)了解车削测力仪的工作原理;(2)掌握车削力的测定方法;(3)研究切削用量对车削力的影响规律。

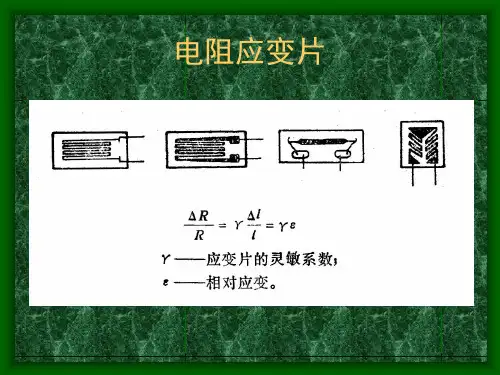

2.原理实验使用的测力仪为程控静态电阻应变仪,其工作原理是:在测力仪弹性元件的适当位置上粘贴着具有一定电阻R的电阻应变片,使其随着被测定对象的应变一起伸缩,这样应变片里面的金属箔材就随着应变伸长或缩短。

很多金属在机械性地伸长或缩短时其电阻会随之变化。

当应变片受拉伸变形时,电阻增大为R+ΔR,当应变片受压缩变形时,电阻减小为R-ΔR,应变片就是应用这个原理,通过测量电阻的变化而对应变进行测定。

一般应变片的敏感栅使用的是铜铬合金,其电阻变化率为常数,与应变成正比例关系。

即ΔR/R= K•ε在这里, R:应变片的原电阻值Ω;ΔR:伸长或压缩所引起的电阻变化Ω;K:比例常数(应变片常数)ε:应变不同的金属材料有不同的比例常数K。

铜铬合金的K值约为2。

这样,应变的测量就通过应变片转换为对电阻变化的测量。

应变片的电阻值一般来说是120 欧姆,即ΔR/120=2 .ε但是由于应变是相当微小的变化,所以产生的电阻变化也是极其微小的。

要精确地测量这么微小的电阻变化是非常困难的,一般的电阻计无法达到要求。

为了对这种微小电阻变化进行测量,我们使用带有韦斯通电桥回路的专用应变测量仪。

应变片本身的追随能力可以达到数百kHz,通过组合的测定装置可以对冲击现象进行测量。

行驶中的车辆,飞行中的飞机等各部位的变动应力可以通过应变片和测定装置进行初步的测量。

图1 半桥:(a)邻边和(b)对边图2 全桥接线(左一)、半桥接线(左二、左三)、1/4桥接线(左四、左五)实验利用韦斯通半桥回路测定车断刀的应变。

韦斯通电桥回路平衡时,输出端两端的电势差为零。

车削时,在车削力的作用下电阻应变片随着弹性元件发生了弹性变形,从而应变片的电阻R发生了变化。

因此输出端两端的电势差不为零,桥路有电信号输出,此电信号值的大小反映出车削力的相对大小。

传感器课程设计题目: 应变式测力仪指导教师:班级: 机检姓名:摘要随着切削加工向着高速、高精度、高度自动化方向发展,对切削过程的监控技术也提出了越来越高的要求,而各种自动化机械加工设备与制造系统绝大多数并不具备加工过程的监控功能。

为了使这些高度自动化加工设备充分发挥其优良性能,确保加工质量,提高生产效率,对刀具加工过程进行状态监测与控制就越来越重要。

大量的研究结果表明,切削状态的每个微小变化都能通过切削力的变化反映出来。

检测切削力是目前国内外研究与应用最多的监测方法之一,但这些方法在使用时或多或少地要改变机床的原有部件,影响机床的系统特性,并且在机械加工过程中,车削测力仪的应用最为广泛。

针对这些问题,需要设计出一种外型尺寸和使用状态都类似于普通外圆车刀的车削测力仪。

本文针对电阻应变式传感器对切削力的测量进行设计,应变式传感器具有灵敏度和精度高,性能稳定、可靠、尺寸小、重量轻、结构简单、使用方便、测量速度快等优点,且能在恶劣环境下工作,在力、压力和重要测试中有非常广泛的应用。

关键词:应变式测力仪;弹性元件;电阻应变;切削力应变式测力仪目录一概述·····················································································································- 2 -二应变式测力仪的工作原理及组成·····································································- 2 -2.1工作原理····································································································- 2 -2.2传感器的组成····························································································- 3 -2.2.1 敏感元件·······················································································- 3 -2.2.2转换元件························································································- 3 -2.2.3测量电路························································································- 3 -2.2.4辅助电源························································································- 3 -三切削测力传感器的主要性能及要求·································································- 4 -3.1金属切削测力仪主要性能指标的基本要求············································- 4 -3.2弹性体的设计过程必须满足的要求························································- 4 -3.3提高应力水平的应力集中原则································································- 5 -四应变式测力仪的结构设计·················································································- 6 -4.1应变式测力仪的测量原理········································································- 6 -4.2 弹性敏感元件的设计···············································································- 6 -4.2.1剪切梁式测力传感器的工作原理················································- 6 -4.2.2应变片的布局方位········································································- 7 -4.3 应变片的选择···························································································- 8 -4.3.1结构形式的选择············································································- 9 -4.3.2尺寸的选择····················································································- 9 -4.3.3 阻值的选择···················································································- 9 -4.3.4使用温度的选择············································································- 9 -4.4 电路的设计·······························································································- 9 -4.5 元件清单·································································································- 11 -小结·························································································································- 11 -参考文献·················································································································- 12 -- 1 -应变式测力仪- 2 -一 概述对于电阻应变片式测力传感器来说,弹性体的结构形状与相关尺寸对测力传感器性能的影响极大。