阿里斯顿 电热水器 说明书

- 格式:pdf

- 大小:7.18 MB

- 文档页数:2

4.3 向浴缸内注水4.3.1使用前准备¥ 关闭浴缸的放水栓;¥ 如果有浴缸盖请盖上。

(注水时请打开)4.3.2 通过面板操作器注水时请按照以下的方法进行A. 初次使用时,按下面板操作器的电源开关,面板显示器闪烁显示标准模式的水温"42℃",3秒钟后显示实际出水温度。

标准模式下的水温(例42℃)标准模式下的水温(例42℃)优先显示亮¥ 热水器的设定温度范围为35℃-70℃,在温度范围35℃-48℃区间内,按下温度设定按键以1℃为单位上升或下降,而 且设定完温度时,会闪烁显示3秒设定温度,随后显示实际水温;在温度范围50℃-70℃区间,按下温度设定按键是以 5℃为单位上升或下降,且设定温度完成后会闪烁10秒显示设定温度,随后显示实际水温。

¥ 为了使机器在进水温度较低的情况下,也能达到更好的恒温使用性能,在部分额定热负荷较小的机型上特设水量调节 旋钮。

当出现出水温度低于设定温度时,请将水量调节旋钮适当关小, 使得到最佳的恒温调节范围.”¥ 当超出机器使用范围而无法达到设定温度,不属于产品质量问题,可通过调节进水量达到设定温度.4.2 水温调节¥ (热水器同时连接面板操作器和浴室有线遥控器时)正在使用热水时¥ 无法从35~48℃的温度设定改变为高温(50℃,55℃,60℃,65℃,70℃)。

¥ 设定为高温(50℃,55℃,60℃,65℃,70℃)时,无法升高温度。

Hi7机型:Ei7+/Ei6+机型:¥ Hi7系列通过按auto 按键,使LCD 上的"浴缸模式"闪烁,同时显示屏会闪烁显示水量设定值,此时可通过上下键设定水 量。

¥ 对Ei7+和Ei6+系列按下水量设定开关,LCD 显示屏会闪烁显示水量设定值时,按触上下按键进行水量设定。

¥ 设定水量范围为10~990升(每10升为1单位),用户可根据自己需求任意设定。

目录功能与特点 (1)各部分零件名称 (2)使用前准备 (5)使用方法 (6)使用注意事项 (10)防冻注意事项 (12)安装 (13)试运行 (19)日常检查及保养 (19)故障、异常的判断及处理方法 (20)规格表 (21)配线图 (22)一.功能与特点一. 功能与特点采用静电喷涂处理,可搭配各款现代厨房设计,结构紧凑,机身小巧,大大节省了安装空间。

操作简单双低压启动缓点火设计操作面板显示水温调节方便可拆式过滤装置瞬间停电或降压的安全保护设计1外型美观12345678多重安全保护装置,使用更放心10● 自动熄火保护装置, 使用过程中发生意外熄火时,本机会自动关闭气源,防止燃气外泄,安全可靠。

● 超时使用安全装置,连续使用30分钟后,热水器自动停机,若要继续使用,只需关上热水阀,数秒后再开启即 可重新点火。

● 强制鼓风燃烧方式设计,采用高效能风机将烟气全部排放室外,确保使用安全。

●另配有过热保护装置,水过压泄压装置,风机停转安全保护装置,防止空烧安全保护装置,排烟管堵塞保护装 置,防冻保护装置(仅限防冻机型)等,确保热水器在正常状态下工作。

●Pa1/Pa2机型使用auto功能模式时有48°安全锁保护。

●Pb1机型提供使用48°安全锁保护的选项,使用此选项可确保热水器在出水温度不高于48°的火力分段下燃烧, 确保您的安全使用。

当供电网络电压瞬间跌落或停电时,仍能保持热水器正常工作或安全停机。

自动变升功能(Pa1/Pa2)9特设有自动变升功能,在自动变升模式下使用时,系统会根据用户的实际需求与季节不同,自动变升调节火力段进行燃烧,以最优化的状态工作,节能省气。

省电设计11本机处于待机并显示屏点亮的状态下,如2分钟内未做任何操作,则显示器背光源会关闭,如需查看只需按触电源开关按键则背光源点亮。

P1/Pa1/Pb1面板操作器可以自由调控升位大小,燃烧指示灯显示工作状态;Pa2 LED数码显示屏显示出水温度、升位大小及工作状态,一目了然 。

1.AR2700, AR2788, AR2788S, FA1000, FA1234Problem and SolutionUnit Will Not Power UpTurn the power switch on. The unit LCD will display revision program and filter life within 3 to 5 seconds after turning on unit.If this process does not happen then see the trouble shooting tips below.1.Check power cord is firmly plugged into unit all the way.2.Check Circuit breaker on unit. Check that it is not tripped.3.Check power source to unit. Check with voltage meter. (The fan will run as soon asyou plug it in on the following unit listed by serial number.)a.AR2700 Serial Numbers Beyond to 03/13 AR00764b.AR2788 Nonec.AR2788S Serial Numbers Beyond to 10/12 AR001844d.FA1000 Alle.FA1234 All4.Check for LED light on main PCB is powered up. Open top panel to see lights onMain PCB.5.Check power to the power supply PCB (120 volts AC in) and power from the (PCB12 volts DC out).6.Check Contrast on PCB for adjustment.7. Unit passes the above checklist. The LCD or Main PCB maybe bad.a.If the LCD is bad and main PCB is good. The unit will go through PT setup,but no display on screen.b.If the LCD is good even there is no display showing and Main PCB is bad. Theunit will not run through PT setup.Unit Stuck In PT Calibration ModeTurn the power switch on. The unit LCD will display revision program and filter life within 3 to 5 seconds after turning on unit. Then the Please wait PT CAL with display a second or two after filter life. During the PT CAL the recovery compressor will run first until PT is satisfied. After compressor turns then 40 seconds later the vacuum pump will run for 4 seconds and turn off. The unit will then look to see if air purge is needed. If noair purge is needed then the unit displays Main Menu. This process from turning unit onto main menu display is 90 seconds. Note: If the unit needs to purge then process willtake longer than the 90 seconds. Additional 5 minutes is possible depending on pressurein recovery tank being purged.If the above process does not happen then see trouble shooting tips below.1.Check oil injection bottle assembly.a.Oil Injection bottle is tight to the back of the unit.b.Check that the oil injection valve is closed. (Earlier unit had flip level.)2. Check that recovery compressor turns on and then off. Compressor will turn off once vacuum is satisfied on Pressure Transducer3. Check that vacuum pump on/off switch is in the on position. (I)4. Check that the vacuum pump power cord is plugged in firmly both ends.5. Check that vacuum pump is good.a.Plug vacuum pump directly into power source using main power cord.6.Vacuum Pump runs constantly. (Should run for 4 seconds during PT Cal)a.Check yellow batch cord on main PCB and Low side block.b.Check oil level on vacuum pump. (Vacuum pump over filled won’t pullvacuum.)7. Check tank pressure and manually purge tank if needed.a.Connect red service hose to filter block red cap on top of tank. Open red tankvalve, ball valve on hose from liquid tank valve to filter, and red service8. AR2788 units only manually re calibrate Pressure Transducer.Unit Stuck In Air Purge1.Air Purge has a five minute time limit.2.To reset unit press the bottom key button after 5 minutes.3.Check tank pressure and manually purge tank if needed.a.Connect red service hose to filter block red cap on top of tank. Open redtank valve, ball valve on hose from liquid tank valve to filter, and redservice coupler. Tank presser will display on red high side gauge.4. AR2788 units only manually re calibrate Pressure Transducer.Oil Drain Bottle Cap Blew Off (Prior to Serial No. Rev. 5.1.81.Check tank valve and tank hose are open.2.Check tank pressure and manually purge tank if needed.a.Connect red service hose to filter block red cap on top of tank. Open red tankvalve, ball valve on hose from liquid tank valve to filter, and red servicecoupler. Tank presser will display on red high side gauge.Unit Will Not Inject Oil1. Vacuum pump ran for 15 minutes on closed system, and 45 open system.2.Check service couplers are open.3.Unit gauges are showing a vacuum before open oil injection valve.4.Check that oil injection is tight on back of unit.5.Unit oil injection bottle has oil in it.6.Check valve at the end of the pick up tube in oil injection bottle is stuck.1.Check for pressure on gauges.2.Checks the service couplers are open.3.Check tank valve are open.4.Check that the compressor is running.5.Check tank pressure and manually purge tank if needed.a.Connect red service hose to filter block red cap on top of tank. Open redtank valve, ball valve on hose from liquid tank valve to filter, and redservice coupler. Tank presser will display on red high side gauge.6. Manually purge Compressor on suction and discharge port.1.Check for pressure on Red gauge.2.Checks the Red service coupler is open.3.Check tank valve are open.4.Check that the virgin tank bottle valve is open.5.Check that the compressor is running.6.Check tank pressure and manually purge tank if needed.a.Connect red service hose to filter block red cap on top of tank. Open redtank valve, ball valve on hose from liquid tank valve to filter, and redservice coupler. Tank presser will display on red high side gauge.7. Manually purge Compressor on suction and discharge port.Unit Will Not Pull Into Vacuum During Recovery1.Check the service couplers are tight to service hoses.2.Check that the compressor is running.3.Check that the oil injection bottle valve is closed and tight to unit.4.Check that gauges are calibrated.a. Remove couplers from service hoses. Gauges should read 0 PSI. If adjustmentis needed, then remove plastic plug from plastic lenses and adjust to 0 psi.5.Check that the o rings in service couplers are good. Remove couplers from carservice ports and recover hoses. If gauge pull down into vacuum o rings needreplaced.6.Check tank pressure and manually purge tank if needed.a. Connect red service hose to filter block red cap on top of tank. Open red tankvalve, ball valve on hose from liquid tank valve to filter, and red service coupler.Tank presser will display on red high side gauge.Unit Vacuum Pump Will Not Pull Deep Vacuum1.Check the service couplers are tight to service hoses.2.Check that vacuum pump is running.3.Check that oil level in sight glass is not over filled.4.Check that gauges are calibrated.a. Remove couplers from service hoses. Gauges should read 0 PSI. Ifadjustment is needed, then remove plastic plug from plastic lenses and adjust to 0 psi.5.Check that oil injection bottle valve is closed and tight to unit.6.Check o rings in service couplers are good. Remove couplers from car serviceports and recover hoses. If gauge pull down into vacuum o rings need replaced.Unit Will Not Charge1.Display stated unit charging, but weight showed the unit did not put anyrefrigerant in (Hose holds 2 oz). Then the check connection message came up on display after two minutes.2.Check that the Red gauge is reading pressure, if so then the Charge solenoid isworking. If the Red gauge is still in vacuum need to continue to next step.3. Check the valves on the recovery tank and tank hoses ball valves are open.4.Check that the service couplers are open.5.Check that there is refrigerant available for charging. (4 to 5 lbs in tank aftercharge selected).6.Check service couplers for flow restriction.7.Check that the solenoid Valve is clicking after starting charge mode. The lightnext to the LS1 orange connector on low side block PCB should be energizedwith red light.a. If red light is on, but solenoid not clicking. Remove connector if it is old styleconnector orange in color from low side block PCB and push both black wiresfurther down in connector.Unit Will Not Complete Charge1.Display stated unit charging with pressure on gauges, but did not complete the fullcharge. (Normally at least half the charge was dispensed). Then the checkconnection message came up on display after two minutes.2.Check that there is refrigerant available for charging. (4 to 5 lbs in tank aftercharge selected).3.Vacuum pump ran for 15 minutes on closed system, and 45 minutes on openedsystem for deep vacuum.e low side adaptor to complete charge AR2788, AR2788S. FA unit turn hi sideadaptor off, and start car.E5 Ball Valve Error Message1.E5 is motorized ball valve error.∙LV in the message indicates low side valve.∙HV in the message indicates hi side valve∙Number indicated which valve is having trouble.2.Check connector on PCB for motorized ball valve location.3.The old blue connector only. You can remove connector from PCB and pushwire further into connector for better connection.High Pressure Cut out 450psi1.Check tank and hose valves are open.2.Check tank pressure.3.Check orange high pressure switch wire for connection.LCD Display Is Dim or Read out1.Adjust contrast on main PCB2.Unit cannot be in the direct sun light.Changing Filter1. Remove filter from tank bracket and turn filter 90 degrees with black blockwith red and blue caps pointed downwards. It will cut 30 minutes off recovering filter.2. Close red tank valve off to prevent additional refrigerant into filter.3. Connect red and blue service hoses to black block on filter.Air Flow Switch E-15 Error1.Check wire connection on main PCB two purple wires. (FA1234 unit only)2.Check that the air flow switch assembly has two clear PVC tubes attachedproperly. (FA1234 unit only)3.Jump out two pins on main PCB where flow switch wire connect to confirm wiresor flow switch is bad.。

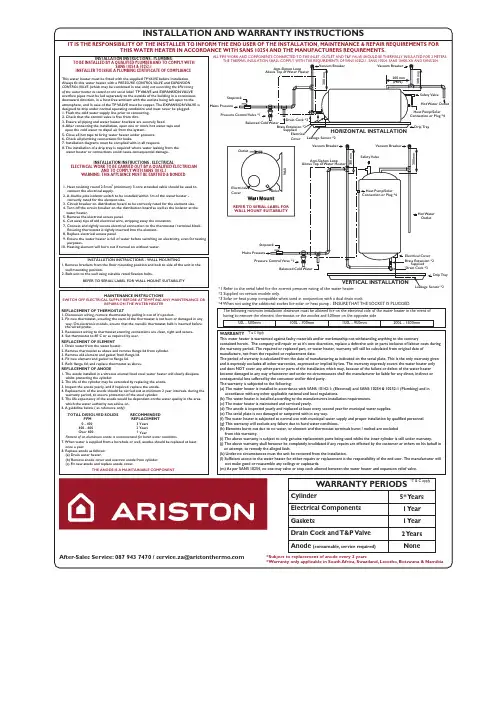

YearYears Years INSTALLATION INSTRUCTIONS - ELECTRICALELECTRICAL WORK TO BE CARRIED OUT BY A QUALIFIED ELECTRICIANAND TO COMPLY WITH SANS 10142-1WARNING: THIS APPLIANCE MUST BE EARTHED & BONDEDINSTALLATION INSTRUCTIONS - PLUMBINGTO BE INSTALLED BY A QUALIFIED PLUMBER AND TO COMPLY WITHSANS 10254 & 10252-1INSTALLER TO ISSUE A PLUMBING CERTIFICATE OF COMPLIANCETHIS WATER HEATER IN ACCORDANCE WITH SANS 10254 AND THE MANUFACTURERS REQUIREMENTS.IT IS THE RESPONSIBILITY OF THE INSTALLER TO INFORM THE END USER OF THE INSTALLATION, MAINTENANCE & REPAIR REQUIREMENTS FORINSTALLATION AND WARRANTY INSTRUCTIONSREFER TO SERIAL LABEL FOR OutletInletW a l lElectrical CoverBalanced Cold WaterPressure Control Valve *1Mains PressureStopcockHeat Pump/Solar Connection or Plug *4Heat Pump/SolarConnection or Plug *4Drain Cock *3Brass Extension *2Supplied Electrical Cover Drip TrayDrip TrayHot Water OutletHot Water OutletSafety ValveSafety ValveAnti-Siphon LoopAbove Top of Water HeaterVacuum BreakerVacuum BreakerVacuum Breaker Anti-Siphon LoopBalanced Cold WaterMains PressurePressure Control Valve *1Vacuum BreakerStopcock*Subject to replacement of anode every 2 years*Warranty only applicable in South Africa, Swaziland, Lesotho, Botswana & NamibiaALL PIPE WORK AND COMPONENTS CONNECTED TO THE INLET, OUTLET AND T&P VALVE SHOULD BE THERMALLY INSULATED FOR 2 METERS.THE THERMAL INSULATION SHALL COMPLY WITH THE REQUIREMENTS OF SANS 10252-1, SANS 10254, SANS 10400-XA AND SANS 204.1. Remove brackets from the floor mounting position and bolt to side of the unit in the wall mounting position.2. Bolt unit to the wall using suitable rated fixation bolts.REFER TO SERIAL LABEL FOR WALL MOUNT SUITABILITYINSTALLATION INSTRUCTIONS - WALL MOUNTING*1 Refer to the serial label for the correct pressure rating of the water heater.*2 Supplied on certain models only.*3 Solar or heat pump compatible when used in conjunction with a dual drain cock.*4 When not using the additional socket for solar or heat pump - ENSURE THAT THE SOCKET IS PLUGGED.300 m m300 m mWALL MOUNT SUITABILITYDrain Cock *3ElectricalCover200 mm 300 m m(MIN)300 m mHORIZONTAL INSTALLATION VERTICAL INSTALLATIONBrass Extension *2SuppliedThe following minimum installation clearance must be allowed for on the electrical side of the water heater in the event of having to remove the element, thermostat or the anodes and 500mm on the opposite side.WARRANTY This water heater is warrantied against faulty materials and/or workmanship not withstanding anything to the contrarycontained herein. The company will repair or at it’s own discretion, replace a defective unit or parts inclusive of labour costs during the warranty period. The repaired or replaced part, or water heater, warranty will still be calculated from original date of manufacture, not from the repaired or replacement date.The period of warranty is calculated from the date of manufacturing as indicated on the serial plate. This is the only warranty given and it expressly excludes all other warranties, expressed or implied by law. The warranty expressly covers the water heater only and does NOT cover any other part or parts of the installation which may, because of the failure or defect of the water heater become damaged in any way whatsoever and under no circumstances shall the manufacturer be liable for any direct, indirect or consequential loss suffered by the consumer and/or third party.The warranty is subjected to the following:(a) The water heater is installed in accordance with SANS 10142-1: (Electrical) and SANS 10254 & 10252-1 (Plumbing) and in accordance with any other applicable national and local regulations.(b) The water heater is installed according to the manufacturers installation requirements.(c) The water heater is maintained and serviced yearly.(d) The anode is inspected yearly and replaced at least every second year for municipal water supplies.(e) The serial plate is not damaged or tampered with in any way.(f) The water heater is subjected to normal use with municipal water supply and proper installation by qualified personnel.(g) This warranty will exclude any failure due to hard water conditions.(h) Elements burnt out due to no water, or element and thermostat terminals burnt / melted are excluded from this warranty.(i) The above warranty is subject to only genuine replacement parts being used whilst the inner cylinder is still under warranty.(j) The above warranty shall however be completely invalidated if any repairs are effected by the customer or others on his behalf in an attempt, to remedy the alleged fault.(k) Under no circumstances must the unit be removed from the installation.(l) Sufficient access to the water heater for either repairs or replacement is the responsibility of the end user. The manufacturer will not make good or reassemble any ceilings or cupboards.(m) As per SANS 10254, no one-way valve or stop cock allowed between the water heater and expansion relief valve.*T & C Apply1. The anode installed in a vitreous enamel lined steel water heater will slowly dissipate whilst protecting the cylinder.2. The life of the cylinder may be extended by replacing the anode.3. Inspect the anode yearly, and if required, replace the anode.4. Replacement of the anode should be carried out at minimum 2 year intervals, during the warranty period, to ensure protection of the steel cylinder.5. The life expectancy of the anode would be dependent on the water quality in the area, which the water authority can advise on.6. A guideline below ( as reference only):7. When water is supplied from a borehole or well, anodes should be replaced at least once a year.8. Replace anode as follows: (a) Drain water heater.(b) Remove anode cover and unscrew anode from cylinder. (c) Fit new anode and replace anode cover.MAINTENANCE INSTRUCTIONSSWITCH OFF ELECTRICAL SUPPLY BEFORE ATTEMPTING ANY MAINTENANCE ORREPAIRS ON THE WATER HEATER REPLACEMENT OF THERMOSTAT1. Disconnect wiring, remove thermostat by pulling it out of it’s pocket.2. Fit new thermostat, ensuring the stem of the thermostat is not bent or damaged in any way. On electronic models, ensure that the metallic thermostat bulb is inserted before3. Reconnect wiring to thermostat ensuring connections are clean, tight and secure.4. Set thermostat to 60˚C or as required by user.REPLACEMENT OF ELEMENT 1. Drain water from the water heater.2. Remove thermostat as above and remove flange lid from cylinder.3. Remove old element and gasket from flange lid.4. Fit new element and gasket to flange lid.5. Refit flange lid, and replace thermostat as above.REPLACEMENT OF ANODETOTAL DISSOLVED SOLIDS RECOMMENDEDPPM REPLACEMENT0 - 400 3 400 - 600 2 Over 600 1Fitment of an aluminium anode is recommended for harsh water conditions.THE ANODE IS A MAINTAINABLE COMPONENTThis water heater must be fitted with the supplied TP VALVE before installation.Always fit this water heater with a PRESSURE CONTROL VALVE and EXPANSION CONTROL VALVE (which may be combined in one unit) not exceeding the kPa rating of the water heater as stated on the serial label. TP VALVE and EXPANSION VALVE overflow pipes must be led separately to the outside of the building in a continuous downward direction, in a frost free ambient with the outlets being left open to the atmosphere, and in case of the TP VALVE must be copper. The EXPANSION VALVE is designed to drip under normal operating conditions and must never be plugged.1. Flush the cold water supply line prior to connecting.2. Check that the control valve is free from dirt.3. Ensure all piping and water heater brackets are securely fixed.4. After connecting the installation, open one or more hot water taps and open the cold water to dispel air from the system.5. Close all hot taps to bring water heater under pressure.6. Check all plumbing connections for leaks.7. Installation diagrams must be complied with in all respects.8. The installation of a drip tray is required where water leaking from the water heater or connections could cause consequential damage.WARRANTY PERIODS*T & C apply5* Y ears 1 Y ear 1 Y ear 2 Y ears NoneCylinderElectrical Components GasketsDrain Cock and T&P Valve Anode (consumable, service required)Above Top of Water Heaterthe wired probe.1. Heat resisting round2.5mm (minimum) 3 core stranded cable should be used to connect the electrical supply.2. A double pole isolator switch to be installed within 1m of the water heater - correctly rated for the element size.3. Circuit breaker on distribution board to be correctly rated for the element size.4. Turn off the circuit breaker on the distribution board as well as the isolator at the water heater.5. Remove the electrical access panel.6. Cut away tips of old electrical wire, stripping away the insulation.7. Connect and tightly secure electrical connection to the thermostat / terminal block. Ensuring thermostat is tightly inserted into the element. 8. Replace electrical access panel.9. Ensure the water heater is full of water before switching on electricity, even for testing purposes.10. Heating element will burn out if turned on without water.2After-Sales Service: 087 943 7470 / service.za@200L - 1500mm150L - 950mm100L - 700mm50L - 500mmLeakage Sensor *2Leakage Sensor *2。

4.3 向浴缸内注水4.3.1使用前准备¥ 关闭浴缸的放水栓;¥ 如果有浴缸盖请盖上。

(注水时请打开)4.3.2 通过面板操作器注水时请按照以下的方法进行A. 初次使用时,按下面板操作器的电源开关,面板显示器闪烁显示标准模式的水温"42℃",3秒钟后显示实际出水温度。

标准模式下的水温(例42℃)标准模式下的水温(例42℃)优先显示亮¥ 热水器的设定温度范围为35℃-70℃,在温度范围35℃-48℃区间内,按下温度设定按键以1℃为单位上升或下降,而 且设定完温度时,会闪烁显示3秒设定温度,随后显示实际水温;在温度范围50℃-70℃区间,按下温度设定按键是以 5℃为单位上升或下降,且设定温度完成后会闪烁10秒显示设定温度,随后显示实际水温。

¥ 为了使机器在进水温度较低的情况下,也能达到更好的恒温使用性能,在部分额定热负荷较小的机型上特设水量调节 旋钮。

当出现出水温度低于设定温度时,请将水量调节旋钮适当关小, 使得到最佳的恒温调节范围.”¥ 当超出机器使用范围而无法达到设定温度,不属于产品质量问题,可通过调节进水量达到设定温度.4.2 水温调节¥ (热水器同时连接面板操作器和浴室有线遥控器时)正在使用热水时¥ 无法从35~48℃的温度设定改变为高温(50℃,55℃,60℃,65℃,70℃)。

¥ 设定为高温(50℃,55℃,60℃,65℃,70℃)时,无法升高温度。

Hi7机型:Ei7+/Ei6+机型:¥ Hi7系列通过按auto 按键,使LCD 上的"浴缸模式"闪烁,同时显示屏会闪烁显示水量设定值,此时可通过上下键设定水 量。

¥ 对Ei7+和Ei6+系列按下水量设定开关,LCD 显示屏会闪烁显示水量设定值时,按触上下按键进行水量设定。

¥ 设定水量范围为10~990升(每10升为1单位),用户可根据自己需求任意设定。

**************************************Comfort Regulation:/ Set the desired performance with an easy to use power dialInstallation (wall mounted only)MULTI POINT can supply more water points at the same time (pressurised).Understanding PerformanceThe temperature and flow rate of the water entering the product determines how well it performs.Flow rate - For higher performance (temperature), reduce the flow rate (use the below chart for guidance).Ambient water temperature – The product can only heat the water by a certain amount of degrees (∆T). In winter when the incoming water temperature is colder, the output water temperature will be less. Please reduce the flow rate to compensate.****************************************************Aures Multi Point Features and BenefitsTechnical InformationThe warranty period is valid from your purchase date (please retain proof of purchase) and on condition that the unit was installed by a qualified electrician in accordance with theinstructions enclosed in the unit.AAures Multi 7kWAures Multi 9.5kW Aures Multi 12KW3 Phase Model Name Aures M 7 EU Aures M 9.5 EUAures M 12 TR EUProduct Code319521831952153195219ErP Class A A A Power (kW)79.512Type Multi point installation - HiddenVoltage (V)220 - 240220 - 240400 - 415PhaseSingle PhaseSingle PhaseThree PhaseAmpere (A)34,647,117,9Recommended fuse rating (Amps)4050 3 x 32Recommended Cable Size 6mm 210mm 2 3 x 6mm 2Frequency (Hz)50/6050/6050/60Heating ElementCopper Copper Copper Minimum Flow Rate (L/min)2,12,12,1Working Pressure (Min - Max)50kPa ~ 800kPa50kPa ~ 800kPa50kPa ~ 800kPaMax Working T emp (0C)555555IPX RatingIP25IP25IP25Dimension WxLxD (mm)304 x 180 x 110304 x 220 x 110304 x 220 x 110PERFORMANCEMODELDT (0C)FLOW RATE (L/MIN)AURES M 7 EU2005,0254,03003,3AURES M 9.5 EU EU 2006,82505,53004,5AURES M 12 TR EU208,62507,03005,7Unit must be installed with Pressure Relief Valve (supplied)Power knob Power LED Water inletPressure relief valve Filter* T erms and conditions applyWARRANTYOn tank and product WARRANTYOn heating element。

**************************************GAS INSTANTANEOUS WATER HEATERSFAST EVOIntroducing the new Gas Instantaneous Water heater range from Ariston , a global leader in comfort. FAST EVO c ombines easiness of installation and high comfort. Thanks to its technology it can work even with very low water flow rate and water pressure. Rest assured in the knowledge that your comfort is in the most trustworthy of hands.ITALIAN DESIGNCONSTANT TEMPERATURE BATTERY POWEREDIGNITION LOW PRESSURESTART 2 YEAR WARRANTY MAXIMUM SAFETYFor further information visit our website Ariston Service 010 745 9911DESCRIPTION16 LITRESDimension in mm (H x L x W)580 x 370 x 250Weight (net)11,1 [kg]Electricity supply 2x 1,5 V LR 20Ignition technology Direct mechanic Nominal heat input (min - max)10,5 - 27 [kW]Nominal heat output (min - max)9 - 23 [kW]Water pressure (min - max)0,1 - 10 [bar]Gas Consumption (max)2,45 [kg/h]FAST EVOFEATURES AND BENEFITS/ Continuous flame modulation via the NTC sensor located at the heater exchanger outlet (maximum temperature stability)/ Minimum operating pressure of 0.1 bar/ Also operates with a minimum water flow rate of 2 l/min / Up-to-date technology for complete safety / Electronic flame detectionOVERALL DIMENSIONSØab c def ghijk lm16L132580701172643704858,8131,52302502311,222,5TECHNICAL INFORMATIONB. Hot water outlet 1/2”C. Gas Inlet 1/2”D. Cold water inlet 1/2”FLUE DIMENSIONS (mm)Ø1a 1b 1c 1d Fast Evo 16L1325001000806001a1c1b1dIndoorWhen unit is installed indoors, the room must be ventilated as per SANS 10087-1OutdoorIf the unit is installed outside, it must be covered with aweather boxUNIT MUST BE INSTALLED WITH A FLUE。

用户手册尊敬的顾客:非常感谢您选购我们阿里斯顿的燃气采暖热水炉(以下简称热水炉)。

我们承诺已向您提供了一个技术合格的产品。

本手册用于告知您关于正确安装、使用和保养的方法和各种建议。

请您妥善保存本手册,以备以后查阅。

我们的地区技术服务中心将随时为您提供服务。

AUTO自动功能AUTO自动功能用来优化热水炉性能,同时保持最佳散热温度和最大用户舒适度。

在保证室内理想的温度环境下,同时节约能源。

其原理是根据室内环境温度自动调整热水炉出水口的温度。

保 修热水炉第一次点火应由制造商指定的工作人员实施。

包修期根据发票购机日期开始计算,具体包修政策请参考保修卡。

在核实了热水炉已正确安装并进行第一次点火之后,您的热水炉才能正式使用。

至于对燃气回路、水路以及电气回路的维修,请与当地指定的技术服务中心联系。

在中国市场销售的热水炉的数据和操作以中文技术说明书为准产品标准本产品执行以下中国产品标准:GB25034 燃气采暖热水炉GB20665 家用燃气快速热水器和燃气采暖热水炉能效限定值及能效等级产品寿命依据G B17905相关规定,采暖热水炉从出售之日起,使用天然气的采暖热水炉的使用年限为8年,为了保证您的舒适安全使用,请严格遵守。

处理和回收热水炉我们的热水炉设计制造成大部分组件为可回收材料热水炉和它的附件必须尽可能地充分处理、材料分类。

热水炉运输的包装必须有安装工或经销商处理。

注意!!热水炉和附件的回收和处理必须按照法规要求执行。

用户手册安全守则关键符号不遵守本警告会有损坏的风险,在某些情况对财产、动植物甚至很严重。

用户手册应当把热水炉连接到适合于其性能和功率的生活热水系统和供暖系统。

严禁使用与规定不同的场所。

制造商不对出自不恰当、错误和不合理使用引起的损坏负责。

应当遵照现行的行业及相关标准、制造商所提供的要求而实施安装、保养及其它任何操作。

制造商不对由于错误安装引起的人员、动物以及财产的损害负责。

任何对排烟管道或进气管道的维修和操作,必须通过断开外部开关而切断电源,同时关闭气阀。

5

23

7

阿里斯顿舒心系列电热水器是供家庭、企事业单位和服务业等用于淋浴、盥洗的电加热水装置,是现代生活必备品。

钛金搪瓷内胆,采用超厚钢板及钛金搪瓷粉,耐用、抗腐蚀超温超压保护特大阳极镁棒,防腐除垢产品系列齐全,适应用户不同需求12. 热水出水管 3. 冷水进水管 6.调温旋钮 7.温度计

国家标准中也许会对在浴室中安装电热水器提出某些限定条件。

默洛尼卫生洁具(中国)有限公司对用户不遵循本说明书的安装要求以及由于不正确的安装电热水器所引起的任何破损,不承担任何责任。

安装必须由我公司授权或认可的专尤其需十分注意下列所述内容:

必须按照相应章节中的要求联接导线。

随机的安全阀必须完好无损且是未被其他相似零件替换过的。

安装过程必须由我公司授权或认可的专业技术人员进行,膨胀螺钉必须固定牢靠。

检查供电电源的电压是否与铭牌上的指示值 一致,检查电表、电源插座和电线直径 是否符合热水器的额定电流。

根据国家标准检查接地情况,电源插座必须接有地线,且接地必须良好,地线和零线 应严格分开。

严禁在无可靠接地的情况下使用电热水器。

不要使用任何插座变换器、电缆延长线以适应电加热器的插头尺寸,也不要改用其他请不要使用接线板。

图7

图8

F

A

D

B

C

横式。

WARRANTY1.This warranty is only valid and applicable to ARISTON water heater products purchased from authorized dealers in Singapore. Warranty can also be registered online at 2.Ariston Pte Ltd warranty this product against all defects arising from faulty materials as follows:Instant water heater: All internal parts - One [1] year, heating element - Five [5] yearsStorage water heater: All internal parts - One [1] year, tank leakage - Five [5] yearsHeat pump: All internal parts - One [1] year, compressor - three [3] years, tank leakage - five [5] yearsWarranty valid from the date of purchase provided that it has been installed by a License Electric Worker/ Licensed Plumber in accordance with the manual instruction andconform to PUB (Water Supply) Regulations.3.Any parts found to be defective during the first year warranty period, we will undertake to repair or replace at our option without changes so long as it has been properly maintained andoperated in accordance with operating instructions, and has not been subject to misuse or damage4.This product must not be taken apart, modified or repaired, except by an authorized person.5.This warranty applies only within Singapore and does not apply to products used commercially.6.This warranty does not cover shower head, hose, fittings and accessories, piping & replacement of false ceiling.7.Warranty is not applicable to any damages to property caused by or in connections with leakage from the heater. Warranty is not applicable to any damages to property caused In theprocess of carrying out repair or servicing of appliances which are Installed in positions or locations which are deemed difficult or unreasonable for such damages to be avoided.8.Ariston shall only provide a one-time replacement if there is any tank leakage within the 5 years. In the event of tank leakage after the first year, labour and service charges apply. SERVICE POLICY1.In the event of a feedback, please call Ariston Pte Ltd, Customer Service Hotline 6305 0899 or E-MAIL:*******************, having available the mode! number,warranty card numberand the proof of purchase. “Alternatively, whatsapp to 8338 8189 the proof of purchase, leakage pictures and technical label. This number is strictly for documents submission and not for communication purposes.bour and service charges apply after the first year, Replacement of parts charged separately. Ariston shall retain all defective parts.3. A charge will be made in the event of an aborted service call or where a call under the terms of the warranty has been booked and the failure is not product related.4.If the product is no longer covered by the warranty, a charge will be made for the site visit and any parts supplied.5.All payments due must be paid to the serviceman upon completion of the service call by CASH. We reserve the right not to undertake work where payment cannot be made.6.It is the owner’s responsibility to provide our service technician direct access to the product.CAUTION: RISK OF ELECTRIC SHOCK!●To reduce risk of electric shock, do not attempt to repair this appliance by yourself.●No user-serviceable parts inside●Keep out of reach of childrenRefer servicing to qualified service center。