fanuc报警中文显示

- 格式:docx

- 大小:80.41 KB

- 文档页数:1

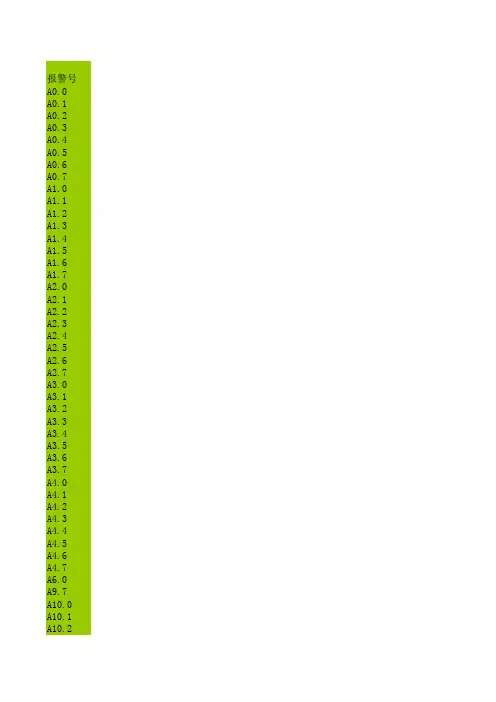

报警号A0.0 A0.1 A0.2 A0.3 A0.4 A0.5 A0.6 A0.7 A1.0 A1.1 A1.2 A1.3 A1.4 A1.5 A1.6 A1.7 A2.0 A2.1 A2.2 A2.3 A2.4 A2.5 A2.6 A2.7 A3.0 A3.1 A3.2 A3.3 A3.4 A3.5 A3.6 A3.7 A4.0 A4.1 A4.2 A4.3 A4.4 A4.5 A4.6 A4.7 A6.0 A9.7 A10.0 A10.1 A10.2A10.3 A10.4 A10.5 A10.6 A11.0 A11.1 A11.2 A11.3 A11.4 A20.1 A20.2 A20.3 A21.1 A21.2 A21.3 A22.0 A22.1英文报警信息1000 EMERGENCY STOP(A0.0)1001 SPINDLE ALARM(A0.1)1002 RINSE SCRAPS PUMP OFF(A0.2 X5.5)1003 COOLANT PUMP OFF(A0.3 X5.4)2004 AIR PRESSURE LOW(A0.4 X6.1)2005 LUBRICAT LOW POS.(A0.5 X9.7)2006 LUBRICATE NOT ON(A0.6 X5.3)1007 HYDRAULIC PUMP ALARM(A0.7 X6.0)2010 CHIP CONVEYOR ALARM(A1.0 X3.1)1011 T-CODE ERROR(A1.1)1012 MAG COUNT ALARM(A1.2 X3.4)1013 TOOL CLAMP/UNCLAMP ERROR(A1.3 X8.2/X8.3)1014 ATC ALARM(A1.4)2015 TOOL LIFE WILL OVER(A1.5)1016 TOOL LIFE ALARM(A1.6)1017 MAG-ROT OVERTIME(A1.7)1020 ARM-ROT OVERTIME(A2.0)1021 Z AXIS NO HOME ZERO(A2.1)1022 MAG POSITION ERRROR(A2.2 X3.3)1023 M06 OVERTIME(A2.3)1024 TOOL CUP UP ERROR(A2.4 X8.1)1025 TOOL CUP DOWN ERROR(A2.5 X8.0)2026 LUB.RPESSURE LOW ALA.(A2.6 X4.2)2027 SP NOT ST.(A2.7)2030 LOW-PRESSURE COOLING FLUID LOW POS(A3.0 X6.5)2031 NC BATTERY VOLTAGE LOW(A3.1)1032 SP FAN NOT ON(A3.2 X4.6)2033 AIR-CONDITION NOT ON(A3.3 X5.3)2034 WATER TANK LEVEL LOW POS(A3.4 X4.3)1035 SP CHANGE GEAR ALARM(X4.0 X4.1)1036 ZF COOLANT LEVEL ERROR(A3.6 X9.0 X9.1)1037 OIL MIST CLEANER NOT ON(A3.7 X9.2)1040 COOLANT FROM SP PUMP OFF(A4.0 X5.7)1041 UPGRADE PUMP OFF(A4.1 X5.6)2042 FILTER BAG ALARM(A4.2 X6.2)1043 OILCOOLANT ALARM(A4.3 X5.0/6.0)1044 TURN PLATE ERROR(A4.4 X5.1 5.2)1045 CHUCK CLAMP/UNCLAMP ALARM(A4.5)1046 CLOSE THE DOOR(A4.6 X8.5)1047 THE DOOR OPEN(A4.7 X8.5)2060 CTS PRESSURE ALM.(X6.5 A6.0)1097 SPINDLE NO ROTATIONED2000 1.PRESS <RESET> 2.CHANGE WOKE MODE TO EDIT 3.PRESS <F4> 2001 4.TAKE DOWN THE TOOL FROM ATC ARM2002 DEBUG CL/UNCL TOOL AT JOG MODE2003 IF ATC NOT RUN SMOOTH ,INFORM NEWAY2044 5.PRESS +4/-4 AT THE SAME TIME.2045 6.PRESS <F4>.2041 MACHINE IS REPAIRING2008 TOOL POT NOT DOWN(A11.0)2046 AXIS IS LOCKED(A11.1)2047 FEED OVERRIDE IS 0(A11.2)2048 MAG IN DEBUG STATE(A11.3)2049 Z NOT GO HOME(A11.4)1081 MACHINE IS LOCKED ENTER 1ST PASSWORD1082 MACHINE IS LOCKED ENTER 2ND PASSWORD1083 MACHINE IS LOCKED ENTER 3RD PASSWORD2011 MACHINE CAN WORK LESS THAN 8H ,TO OBTAIN THE 1ST PASSWORD FROM SUPPLIER 2012 MACHINE CAN WORK LESS THAN 8H ,TO OBTAIN THE 2ND PASSWORD FROM SUPPLIER 2013 MACHINE CAN WORK LESS THAN 8H ,TO OBTAIN THE 3RD PASSWORD FROM SUPPLIER 2020 ZF COOLANT LEVEL LOW(A22.0 X9.0)2021 ZF COOLANT LEVEL HIGH(A22.1 X9.1)中文报警信息(PMC)1000 @04BDF4BCB1CDA3D6B901@-X8.41001 @04D6F7D6E1B1A8BEAF01@-F45.01002 @04B3E5D0BCB5E7BBFACEB4CDA8B5E701@-QF4/KM61003 @04C0E4C8B4B5E7BBFACEB4CDA8B5E701@-QF3/KM52004 @04C6F8D4B4D1B9C1A6B5CD01@-X5.42005 @04C8F3BBACD2BACEBBB5CD01@-X9.72006 @04C8F3BBACB5E7BBFACEB4CDA8B5E701@-QF131007 @04D2BAD1B9D5BECEB4CDA8B5E701@-QF8/KM112010 @04C5C5D0BCB5E7BBFAB6C2C8FBB1A8BEAF01@-X3.41011 T@04B4FAC2EBB4EDCEF301@1012 @04B5B6BFE2BCC6CAFDB4EDCEF301@-X3.41013 @04D6F7D6E1CBC9C0ADB5B6B1A8BEAF01@-X8.2/X8.31014 @04BBFAD0B5CAD6B2BBD4DAD4ADB5E3CEBBD6C301@-A1.42015 @04B5B6BEDFCAD9C3FCBCB4BDABB5BDB4EF01@-A1.51016 @04B5B6BEDFCAD9C3FCBDE1CAF801@-A1.61017 @04B5B6BFE2D0FDD7AAB3ACCAB101@-A1.71020 @04BBFAD0B5CAD6D0FDD7AAB3ACCAB101@-A2.01021 Z@04D6E1CEB4BBD8B5DAB6FEB2CEBFBCB5E301@1022 @04B5B6BFE2B6A8CEBBB4EDCEF301@-X3.31023 @04BBBBB5B6B3ACCAB101@-A2.31024 @04BBD8B5B6B4EDCEF301@-X8.11025 @04B5B9B5B6B4EDCEF301@-X8.02026 @04C8F3BBACD1B9C1A6B5CD01@-X4.22027 @04D6F7D6E1CEB4C6F4B6AF01@2030 @04B8B1CBAECFE4D2BACEBBB5CD01@-X6.52031 @04B5E7B3D8B5E7D1B9B5CD01@1032 @04D6F7D6E1B7E7C9C8CEBBCDA8B5E701@-QF102033 @04BFD5B5F7CEB4CDA8B5E701@-QF141034 @04D6F7CBAECFE4D2BACEBBB5CD01@-X4.31035 @04D6F7D6E1BBBBB5B5B4EDCEF301@-X4.0/X4.11036 @045A46C1F7C1BFB9CAD5CF01@-X9.0/X9.11037 @04D3CDCEEDB7D6C0EBC6F7CEB4CDA8B5E701@-QF15/KM171040 @04D6D0D0C4B3F6CBAEB5E7BBFACEB4CDA8B5E701@-QF6/KM91041 @04CCE1C9FDB1C3B5E7BBFACEB4CDA8B5E701@-QF7/KM102042 @04B9FDC2CBD6BDB4FCB6C2C8FB01@-X6.21043 @04D3CDC0E4BBFAB9CAD5CF01@-QF9/X5.01044 @0441D6E1BCD0BDF4B7C5CBC9B4EDCEF301@-X5.1/X5.21045 @04BFA8C5CCBCD0BDF4B7C5CBC9B4EDCEF301@-A4.51046 @04C7EBB9D8C3C501@-X8.51047 @04C3C5B4F2BFAA01@-X8.52060 @04D6D0D0C4B3F6CBAED1B9C1A6B5CD01@-X6.51097 @04D6F7D6E1C3BBD3D0D0FDD7AA01@-A9.72000 1、@04B0B4CFC2B8B4CEBBB0B4BCFC01@2、@04C7D0BBBBB5BDB1E0BCADB7BDCABD01@3、@04B0B4CFC20 2001 4、@04B4D3BBFAD0B5CAD6C9CFC8A1CFC2B5B6BEDF01@2002 4、@04B4D3BBFAD0B5CAD6C9CFC8A1CFC2B5B6BEDF01@2003 ATC@04C6B5B7B1B1A8BEAFA3ACC7EBCDA8D6AAB9ABCBBE01@2044 @04CDACCAB1B0B4CFC201@+4/-4@04B0B4BCFC01@2045 @04B0B4CFC201@F4@04B0B4BCFC01@2041 @04BBFAB4B2D5FDD4DACEACD0DED6D001@2008 @04B5B6CCD7CEB4B5B9CFC201@-A11.02046 @04D6E1BBA5CBF8BDD3CDA801@-A11.1@04BDF8B8F8B1B6C2CACEAA01@%0-A11.22048 @04B5B6BFE2B5F7CAD4D7B4CCAC01@-A11.32049 Z@04D6E1CEB4B7B5BBD8D4ADB5E301@-A11.41081 @04BBFAB4B2CBF8D4DAA3ACCAE4C8EBB5DAD2BBB8F6D4C2C3DCC2EB01@ 1082 @04BBFAB4B2CBF8D4DAA3ACCAE4C8EBB5DAB6FEB8F6D4C2C3DCC2EB01@ 1083 @04BBFAB4B2CBF8D4DAA3ACCAE4C8EBB5DAC8FDB8F6D4C2C3DCC2EB01@ 2020 @045A46C1F7C1BFB5CD01@-X9.02021 @045A46C1F7C1BFB8DF01@-X9.1中文汉字紧急停止-X8.4主轴报警-F45.0冲屑电机未通电-QF4冷却电机未通电-QF3气源压力低-X5.4润滑液位低-X9.7润滑电机未通电-QF13液压站未通电-QF8排屑电机堵塞报警-X3.4T 代码错误刀库计数错误-X3.4主轴松拉刀报警-X8.2/X8.3机械手不在原点位置-A1.4刀具寿命即将到达-A1.5刀具寿命结束-A1.6刀库旋转超时-A1.7机械手旋转超时-A2.0Z轴未回第二参考点刀库定位错误-X3.3换刀超时-A2.3回刀错误-X8.1倒刀错误-X8.0润滑压力低-X4.2主轴未启动副水箱液位低-X6.5电池电压低主轴风扇位通电-QF10空调未通电-QF14主水箱液位低-X4.3主轴换档错误-X4.0/X4.1ZF流量故障-X9.0//X9.1油雾分离器未通电-QF15中心出水电机未通电-QF6提升泵电机未通电-QF7过滤纸袋堵塞-X6.2油冷机故障-QF9/X5.0A轴夹紧放松错误-X5.1/X5.2卡盘夹紧放松错误-A4.5请关门-X8.5门打开-X8.5中心出水压力低-X6.5主轴没有旋转1、按下复位按键2、切换到编辑方式3、按下F4按键4、从机械手上取下刀具手动方式下调试松拉刀动作ATC频繁报警,请通知公司同时按下+4/-4按键按下F4按键机床正在维修中刀套未倒下轴互锁接通进给倍率为0%刀库调试状态Z轴未返回原点机床锁在,输入第一个月密码机床锁在,输入第二个月密码机床锁在,输入第三个月密码机床工作少于8小时,从供应商获取第一个月密码机床工作少于8小时,从供应商获取第二个月密码机床工作少于8小时,从供应商获取第三个月密码ZF流量低-X9.0ZF流量高-X9.1。

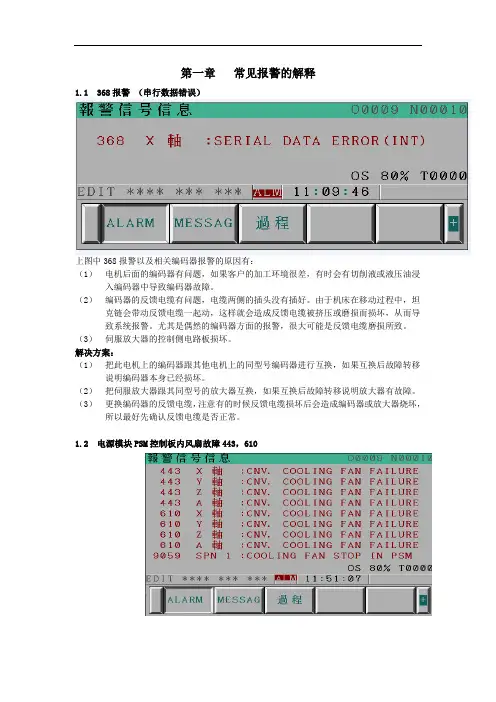

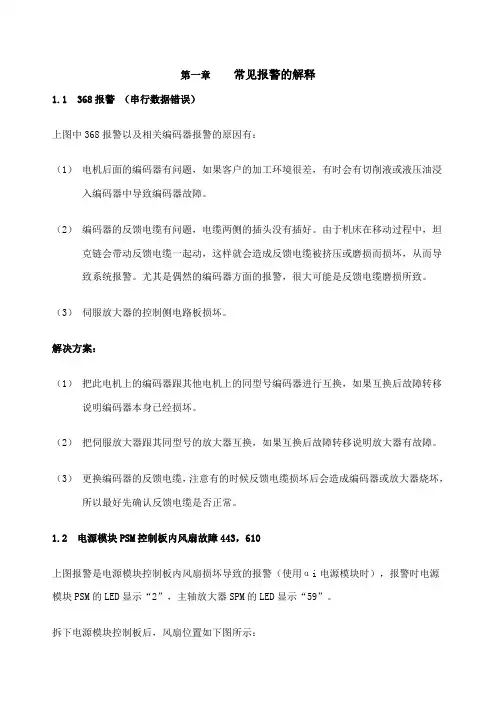

第一章常见报警的解释1.1 368报警(串行数据错误)上图中368报警以及相关编码器报警的原因有:(1)电机后面的编码器有问题,如果客户的加工环境很差,有时会有切削液或液压油浸入编码器中导致编码器故障。

(2)编码器的反馈电缆有问题,电缆两侧的插头没有插好。

由于机床在移动过程中,坦克链会带动反馈电缆一起动,这样就会造成反馈电缆被挤压或磨损而损坏,从而导致系统报警。

尤其是偶然的编码器方面的报警,很大可能是反馈电缆磨损所致。

(3)伺服放大器的控制侧电路板损坏。

解决方案:(1)把此电机上的编码器跟其他电机上的同型号编码器进行互换,如果互换后故障转移说明编码器本身已经损坏。

(2)把伺服放大器跟其同型号的放大器互换,如果互换后故障转移说明放大器有故障。

(3)更换编码器的反馈电缆,注意有的时候反馈电缆损坏后会造成编码器或放大器烧坏,所以最好先确认反馈电缆是否正常。

1.2 电源模块PSM控制板内风扇故障443,610上图报警是电源模块控制板内风扇损坏导致的报警(使用αi电源模块时),报警时电源模块PSM的LED显示“2”,主轴放大器SPM的LED显示“59”。

拆下电源模块控制板后,风扇位置如下图所示:1.3 主轴放大器SPM内冷风扇故障此故障没有画面报警信息,但是有上图的“FAN”在闪烁,此现象表明主轴放大器SPM的内冷风扇出现了故障。

1.4 伺服放大器SVM内冷风扇报警 608,444上图中的报警表示伺服放大器SVM的内冷风扇出现了故障(Z轴和A轴同时出现报警是因为Z轴和A轴是同一个放大器控制的)。

上图中的报警出现时对应的伺服放大器上的LED显示“1”。

1.5 主轴放大器和伺服放大器的内冷风扇位置上图中:(1)主轴放大器内冷风扇的安装位置(2)伺服放大器内冷风扇的安装位置(3)主轴放大器的型号A06B-6111-H XXX#H550(后面带#H***的都是主轴放大器)(4)伺服放大器的型号A06-6114-HXXX注:(1)不同型号的主轴放大器和伺服放大器对应的风扇的型号也不一样,请参考附录。

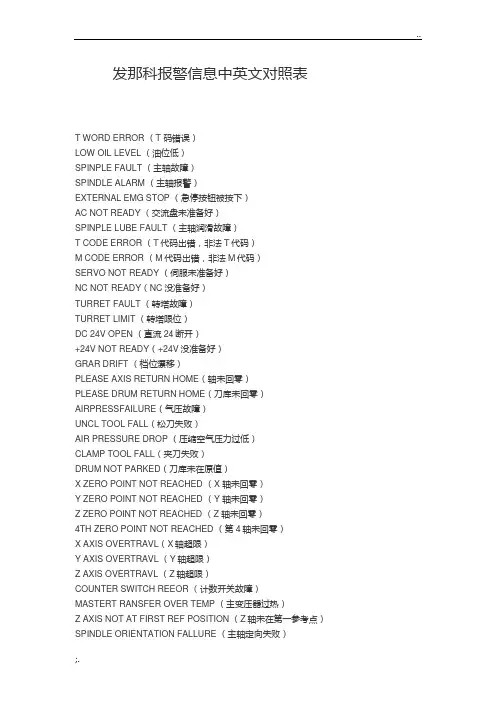

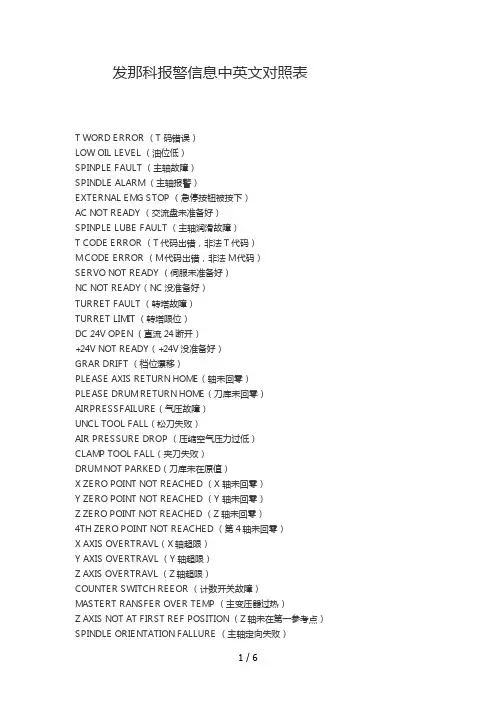

发那科报警信息中英文对照表T WORD ERROR (T 码错误)LOW OIL LEVEL (油位低)SPINPLE FAULT (主轴故障)SPINDLE ALARM (主轴报警)EXTERNAL EMG STOP (急停按钮被按下)AC NOT READY (交流盘未准备好)SPINPLE LUBE FAULT (主轴润滑故障)T CODE ERROR (T代码出错,非法T代码)M CODE ERROR (M代码出错,非法M代码)SERVO NOT READY (伺服未准备好)NC NOT READY(NC没准备好)TURRET FAULT (转塔故障)TURRET LIMIT (转塔限位)DC 24V OPEN (直流24断开)+24V NOT READY(+24V没准备好)GRAR DRIFT (档位漂移)PLEASE AXIS RETURN HOME(轴未回零)PLEASE DRUM RETURN HOME(刀库未回零)AIRPRESSFAILURE(气压故障)UNCL TOOL FALL(松刀失败)AIR PRESSURE DROP (压缩空气压力过低)CLAMP TOOL FALL(夹刀失败)DRUM NOT PARKED(刀库未在原值)X ZERO POINT NOT REACHED (X 轴未回零)Y ZERO POINT NOT REACHED (Y 轴未回零)Z ZERO POINT NOT REACHED (Z 轴未回零)4TH ZERO POINT NOT REACHED (第4轴未回零)X AXIS OVERTRAVL(X轴超限)Y AXIS OVERTRAVL (Y轴超限)Z AXIS OVERTRAVL (Z轴超限)COUNTER SWITCH REEOR (计数开关故障)MASTERT RANSFER OVER TEMP (主变压器过热)Z AXIS NOT AT FIRST REF POSITION (Z轴未在第一参考点)SPINDLE ORIENTATION FALLURE (主轴定向失败)TOOL DESENT OR TOOL DATA REEOR (刀具数据错误)PLEASE UNLOAD THE TOOL ON SPRINELK (请卸下主轴上的刀)PLEASE LOAD TOOL ON APINDLE (请装上主轴上的刀)A AXIS UNCLAMP FAIL (A 轴松开失败)A AXIS CLAMP FAIL (A 轴夹紧失败)DRUM OUT TO APRONDLEIS FALL (刀库摆向换刀位失败)MG SWING OVERLOAD(刀库摆动过载)DRUM BACK PARK IS FALL (刀库摆回原始位失败)TURRENT MOTOR1 OVERLOAD (刀库移动电机过载)COOLANT MOTOR OVERLOAD (冷却泵过载)DRUM ATC FAULT (自动换刀失败)TOOLS UNLOCKED (刀具未锁紧)BATTERY ALARM (电池报警)DRUM POSITION SWITCH ERROR (刀库位置检测开关故障)DRUM NOW NOT AT PARK (刀库未在原始位置)IT DANGOU TO MOVE DRUM (刀库禁动)POT UO FAILOR POT NOT AT UP POSITION (刀套未在水平位)POT DOWN FAIL (刀套翻下动作失败)IT IS DANGOUR TO MOVE ARM (机械手禁动)THE SPINDLE STATU IS ERROR (主轴状态错误)ARM MOTOR OR ARM SWITCH FALL (机械手或机械手开关故障)CENTRE LUBRICATION FALL (中心润滑故障)THE WORK NOT CLAMPED (工件未夹紧)AUTO TOOL CHANGE FAULT (自动换刀失败)TOOL DATA OUT OF RANGE (指令刀具号超出范围)THE ORDER TOOL NOW IN SPINDLE (目标刀具在主轴上)THE THREE SPINDLE SWITCH FAULT (主轴上的接近开关)THE CENTRE COOLANT IS LOWER (刀具内冷泵液位过低)DRUM RETURN 1# POSITION FAULT (刀库自动回零失败)SPINDLE OVERLOAD (主轴过载)TURRENT MOTOR OVERLOAD (刀盘转动电机过载)CHIP CONVEYER OVERLOAD (拉屑器过载)HARD LIMIT OR SERVO ALARM (硬限位或伺服报警)NO LUB OIL (无润滑油)INDEX HEAD UNLOCKED (分度头未锁紧)MT NOT READY(机床没准备好)MG OVERLOAD (刀库过载)LUB EMPTY(润滑无油)AIR PRESSURE(气压不足)COOLANT NOT READY(冷却没准备好)LUBE EMPTY(油雾油位低,润滑油位低)LUB PRESSURE LOW(润滑压力低)CONVEY VERLOAD(排屑过载)LUB OVERLOAD(润滑过载)LUBE PRESSURE LOW(油雾压力低)SERIAL SPINDLE ALARM (串行主轴报警)NC BATTERY LOW ALARM(NC电池低报警)MAGAZINE MOVE LIMIT SWITCH ERROR(刀库移动限位开关故障)SPINDLE TOOL UNLAMP POSITION LIMIT SWITCH ERROR(主轴刀具UNLAMP位置限位开关故障)MAGAZINE NOT IN POSITION OR SENSOR ERROR(刀库不在位或传感器错误)AIR PRESSURE LOW ALARM(气压低报警)MOTOR OVERLOAD(电机过载)T CODE > MAGAZINE TOOLST CODE < 1 ERROR5TH AXIS HARDWARE OVERTRAVER LIMIT ERRORDOOR IS OPENED(开门)LUB PRESSURE SWITCH ERROR(油压开关错误)SPINDLE OIL COOLANT UNIT ERRORSPINDLE LOAD ABNORMAL(主轴负荷异常)TRANSDUCER ALARM(传感器报警)BED-HEAD LUBRICATE OFF(床头润滑关闭)EMG OFFHYDRAULIC CHUCK PRESS LOW(液压夹头压力低)HYDRAULIC TAIL PRESS LOW(液压尾座压力低)LUB 0IL LOW(油压低)TURRET CODE ERROR(转塔码错误)TURRET RUN OVERTIME(转塔运行超时)MANUAL HANDLE INTERRUPTTRY TO RUN SPINDLE WHILE CHUCK NOT LOCKTRY TO RUN SPINDLE WHILE TAIL NOT LOCKSPINDLE NEUTRAL GEARMAGAZINE ADJUSTHYDRAULIC NOT RUNSAFETY DOOR BE OPENEDSAFETY DOOR NOT CLOSENOT ALL AXIS HAVE GONE BACK REFIN ADJUST,IGNORE GOING BACK REFAFTER EXCHANGE TOOL,CYCLE STARTATC MOTOR QF16 OFFX AXIS IS LOCKED(X 轴被锁定)Y AXIS IS LOCKED(Y 轴被锁定)Z AXIS IS LOCKED(Z 轴被锁定)A AXIS IS LOCKED(A 轴被锁定)SPINDLE MOTOR FAN QF26 OFF(主轴电机风扇QF26关闭) SPINDLE ORIENTATION INCOMPLETE(主轴定位不完全)M FUNCTION NOT COMPLETE(M 功能无法完成)SPINDLE NOT IN GEAR POSITION(齿轮不在主轴位置)SPINDLE NOT CHANGED TO LOW GEAR(主轴没有变为低档)SPINDLE NOT CHANGED TO HIGH GRAR(主轴没有变为高档)MAG NOT BACKWARDSPINDLE TOOL NOT CLAMPSPINDLE TOOL NOT UNCLAMPMAG NOT IN POSITIONMAG DOES NOT ROTATEMAG DOES NOT STOP RUNNINGA AXIS HAVE NOT CLAMPEDA AXIS HAVE NOT UNCLAMPEDSET D499=1,"MAG.JOG" SWITCH ONHYDRAULIC MOTOR QF7 OFF(液压马达QF7关闭)HYDRAULIC TEMPRETURE HIGH(液压使用温度高)HYDRAULIC FILTER BLOCKED(液压过滤器阻止)HYDRAULIC OIL LEVEL LOW(液压油位低)HYDRAULIC FAN QF8 OFF(液压风扇QF8关闭)HELIX CONYER QF9 OR QF10 OFFCHAIN CONYER QF11 OFFCOOLANT MOTOR QF12 OFF(冷却液电机QF12关闭)COOLNT LEVEL LOW,CYCLE STOP AFTER 20 MINUTESINNER COOLANT BLOCK(内冷却堵塞)SPINDLE COOLANT MOTOR QF14 OFF(主轴冷却液电机QF14关闭)INNER COOLANT QF13 OFF(内冷却液QF13关闭)MAG MOTOR QF15 OFFCABINET COOLANT EQUIP QF20 OFFOIL GATHER QF24 OFFAIR PRESSURE LOW(低气压)SPINDLE COOLANT MOTOR FAULT(主轴冷却液电机故障)LUB.OIL IS LOW(润滑油低)DOOR OPEN(门打开)FRONT DOOR(R) OPEN(前门打开)LEFT DOOR OPEN(左门打开)LUBRICATION OIL QF23 OFF(润滑油QF23关闭)LUBRICATION PRESS LOW(润滑油位低)IN ADJUST,MAG CAN'T EXCHANGE T(在调整,刀库不能交换T)NOT ALL DOOR CLOSED(门没有全部关闭)IN M06,MAG NOT READY(在M06,刀库未准备好)MAGAZINE NOT READY(刀库未准备好)POCKET NOT HORIZANTALIN M06,Z NOT BACK TO 2ND REFIN M06,Z AXIS NOT IN PSW1ATC NOT IN ZERO POSITIONSPINDLE ORIENTATION UNCOMPLETEPOCKET NOT HOR./MAG NOT BCKWRDPOCKET NOT VER./MAG NOT FORWRDUNCLAMP TOOL HAS NOT COMPLETEDCLAMP TOOL HAS NOT COMPLETEDAIM TOOL NO. IS WRONGMAG NOT BACKWARDAFTER RETRACT,SET R.T.BACK OFFZ NOT IN PSW2,FORBID ATC RUNNINGD499 EQUAL 1MAG.JOG SOFT SWITCH IS ONZ NOT IN PSW2,FORBID MAG FORWARDCHEKE SPINDLE MODULE ALARMOIL WATER SEPARATOR QF24 OFFSET THE SOFT SWITCH MAG.JOG OFFSET D499 TO 0 设定D499为0K PARAM ABOUT MAG SET IS WRONG 关于MAG的K参数设定错误MECHANICAL BRAKE NOT RELEASED机床抱闸没有松开MECHANICAL BRAKE IS WRONG 机床抱闸错误PLEASE ADD LUB.OIL 请加润滑油PROBE BATTERY VOLTAGE IS LOW 探头电池电压低PROBE IS ERR 探头错误PARAMETER WRITE ENABLE(参数写使能)PMC EDIT ENABLE(PMC编辑使能)CHECK LUB ROUTINSPINDLE GEAR SIGNAL MISS 主轴档位信号消失T_CLAMPED_SIGNAL MISS T夹紧信号消失SP OVERRIDE SWITCH DISCONNECTION 主轴倍率开关断路FEED OVERRIDE SWITCH DISCONNECTION 进给倍率开关断路THE TOTAL NUMBER OF POCKETS SET ERRCHANGE T STOPED BECAUSE NO AIR 因为缺少压空交换停止THE COOLANT WATER TOO LOW,ADD COOLANT WATER AT ONCE 冷却水少立即加水COOLANT LEVEL LOW,ADD COOLANT WATER 冷却水液位低PLEASE REPLACE CNC BATTERY QUICKLY 请立即更换CNC电池。

第一章常见报警的解释1.1 368报警(串行数据错误)上图中368报警以及相关编码器报警的原因有:(1)电机后面的编码器有问题,如果客户的加工环境很差,有时会有切削液或液压油浸入编码器中导致编码器故障。

(2)编码器的反馈电缆有问题,电缆两侧的插头没有插好。

由于机床在移动过程中,坦克链会带动反馈电缆一起动,这样就会造成反馈电缆被挤压或磨损而损坏,从而导致系统报警。

尤其是偶然的编码器方面的报警,很大可能是反馈电缆磨损所致。

(3)伺服放大器的控制侧电路板损坏。

解决方案:(1)把此电机上的编码器跟其他电机上的同型号编码器进行互换,如果互换后故障转移说明编码器本身已经损坏。

(2)把伺服放大器跟其同型号的放大器互换,如果互换后故障转移说明放大器有故障。

(3)更换编码器的反馈电缆,注意有的时候反馈电缆损坏后会造成编码器或放大器烧坏,所以最好先确认反馈电缆是否正常。

1.2 电源模块PSM控制板内风扇故障443,610上图报警是电源模块控制板内风扇损坏导致的报警(使用αi电源模块时),报警时电源模块PSM的LED显示“2”,主轴放大器SPM的LED显示“59”。

拆下电源模块控制板后,风扇位置如下图所示:1.3 主轴放大器SPM内冷风扇故障此故障没有画面报警信息,但是有上图的“FAN”在闪烁,此现象表明主轴放大器SPM的内冷风扇出现了故障。

1.4 伺服放大器SVM内冷风扇报警 608,444上图中的报警表示伺服放大器SVM的内冷风扇出现了故障(Z轴和A轴同时出现报警是因为Z轴和A轴是同一个放大器控制的)。

上图中的报警出现时对应的伺服放大器上的LED 显示“1”。

1.5 主轴放大器和伺服放大器的内冷风扇位置上图中:(1)主轴放大器内冷风扇的安装位置(2)伺服放大器内冷风扇的安装位置(3)主轴放大器的型号A06B-6111-H XXX#H550(后面带#H***的都是主轴放大器)(4)伺服放大器的型号A06-6114-HXXX注:(1)不同型号的主轴放大器和伺服放大器对应的风扇的型号也不一样,请参考附录。

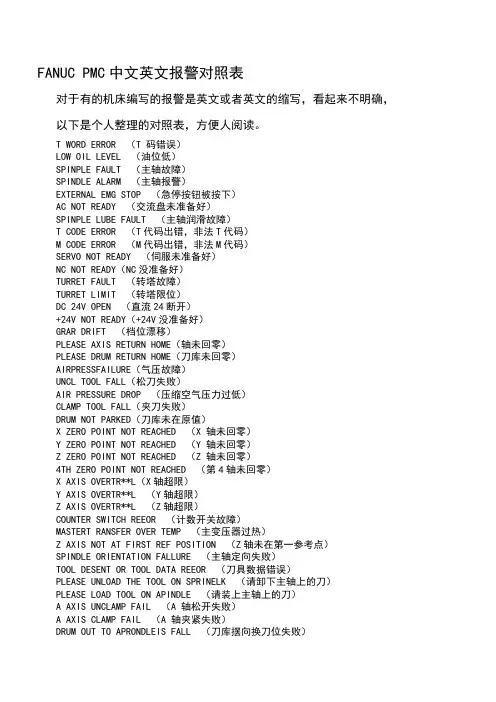

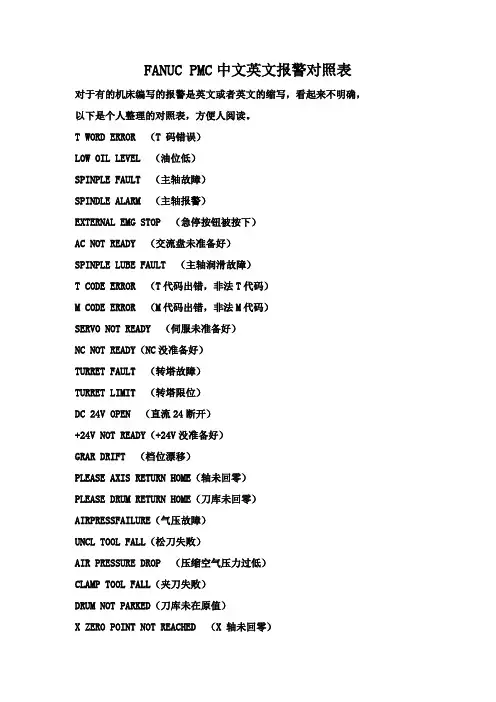

FANUC PMC中文英文报警对照表对于有的机床编写的报警是英文或者英文的缩写,看起来不明确,以下是个人整理的对照表,方便人阅读。

T WORD ERROR (T 码错误)LOW OIL LEVEL (油位低)SPINPLE FAULT (主轴故障)SPINDLE ALARM (主轴报警)EXTERNAL EMG STOP (急停按钮被按下)AC NOT READY (交流盘未准备好)SPINPLE LUBE FAULT (主轴润滑故障)T CODE ERROR (T代码出错,非法T代码)M CODE ERROR (M代码出错,非法M代码)SERVO NOT READY (伺服未准备好)NC NOT READY(NC没准备好)TURRET FAULT (转塔故障)TURRET LIMIT (转塔限位)DC 24V OPEN (直流24断开)+24V NOT READY(+24V没准备好)GRAR DRIFT (档位漂移)PLEASE AXIS RETURN HOME(轴未回零)PLEASE DRUM RETURN HOME(刀库未回零)AIRPRESSFAILURE(气压故障)UNCL TOOL FALL(松刀失败)AIR PRESSURE DROP (压缩空气压力过低)CLAMP TOOL FALL(夹刀失败)DRUM NOT PARKED(刀库未在原值)X ZERO POINT NOT REACHED (X 轴未回零)Y ZERO POINT NOT REACHED (Y 轴未回零)Z ZERO POINT NOT REACHED (Z 轴未回零)4TH ZERO POINT NOT REACHED (第4轴未回零)X AXIS OVERTR**L(X轴超限)Y AXIS OVERTR**L (Y轴超限)Z AXIS OVERTR**L (Z轴超限)COUNTER SWITCH REEOR (计数开关故障)MASTERT RANSFER OVER TEMP (主变压器过热)Z AXIS NOT AT FIRST REF POSITION (Z轴未在第一参考点)SPINDLE ORIENTATION FALLURE (主轴定向失败)TOOL DESENT OR TOOL DATA REEOR (刀具数据错误)PLEASE UNLOAD THE TOOL ON SPRINELK (请卸下主轴上的刀)PLEASE LOAD TOOL ON APINDLE (请装上主轴上的刀)A AXIS UNCLAMP FAIL (A 轴松开失败)A AXIS CLAMP FAIL (A 轴夹紧失败)DRUM OUT TO APRONDLEIS FALL (刀库摆向换刀位失败)MG SWING OVERLOAD(刀库摆动过载)DRUM BACK PARK IS FALL (刀库摆回原始位失败)TURRENT MOTOR1 OVERLOAD (刀库移动电机过载)COOLANT MOTOR OVERLOAD (冷却泵过载)DRUM ATC FAULT (自动换刀失败)TOOLS UNLOCKED (刀具未锁紧)BATTERY ALARM (电池报警)DRUM POSITION SWITCH ERROR (刀库位置检测开关故障)DRUM NOW NOT AT PARK (刀库未在原始位置)IT DANGOU TO MOVE DRUM (刀库禁动)POT UO FAILOR POT NOT AT UP POSITION (刀套未在水平位)POT DOWN FAIL (刀套翻下动作失败)IT IS DANGOUR TO MOVE ARM (机械手禁动)THE SPINDLE STATU IS ERROR (主轴状态错误)ARM MOTOR OR ARM SWITCH FALL (机械手或机械手开关故障)CENTRE LUBRICATION FALL (中心润滑故障)THE WORK NOT CLAMPED (工件未夹紧)AUTO TOOL CHANGE FAULT (自动换刀失败)TOOL DATA OUT OF RANGE (指令刀具号超出范围)THE ORDER TOOL NOW IN SPINDLE (目标刀具在主轴上)THE THREE SPINDLE SWITCH FAULT (主轴上的接近开关)THE CENTRE COOLANT IS LOWER (刀具内冷泵液位过低)DRUM RETURN 1# POSITION FAULT (刀库自动回零失败)SPINDLE OVERLOAD (主轴过载)TURRENT MOTOR OVERLOAD (刀盘转动电机过载)CHIP CONVEYER OVERLOAD (拉屑器过载)HARD LIMIT OR SERVO ALARM (硬限位或伺服报警)NO LUB OIL (无润滑油)INDEX HEAD UNLOCKED (分度头未锁紧)MT NOT READY(机床没准备好)MG OVERLOAD (刀库过载)LUB EMPTY(润滑无油)AIR PRESSURE(气压不足)COOLANT NOT READY(冷却没准备好)LUBE EMPTY(油雾油位低,润滑油位低)LUB PRESSURE LOW(润滑压力低)CONVEY VERLOAD(排屑过载)LUB OVERLOAD(润滑过载)LUBE PRESSURE LOW(油雾压力低)SERIAL SPINDLE ALARM (串行主轴报警)NC BATTERY LOW ALARM(NC电池低报警)MAGAZINE MOVE LIMIT SWITCH ERRORSPINDLE TOOL UNLAMP POSITION LIMIT SWITCH ERROR MAGAZINE NOT IN POSITION OR SENSOR ERRORAIR PRESSURE LOW ALARM(气压低报警)MOTOR OVERLOAD(电机过载)T CODE > MAGAZINE TOOLST CODE < 1 ERROR5TH AXIS HARDWARE OVERTR**ER LIMIT ERRORDOOR IS OPENED(开门)LUB PRESSURE SWITCH ERROR(油压开关错误)SPINDLE OIL COOLANT UNIT ERRORSPINDLE LOAD ABNORMAL(主轴负荷异常)TRANSDUCER ALARM(传感器报警)BED-HEAD LUBRICATE OFF(床头润滑关闭)EMG OFFHYDRAULIC CHUCK PRESS LOW(液压夹头压力低)HYDRAULIC TAIL PRESS LOW(液压尾座压力低)LUB 0IL LOW(油压低)TURRET CODE ERROR(转塔码错误)TURRET RUN OVERTIME(转塔运行超时)MANUAL HANDLE INTERRUPTTRY TO RUN SPINDLE WHILE CHUCK NOT LOCKTRY TO RUN SPINDLE WHILE TAIL NOT LOCKSPINDLE NEUTRAL GEARMAGAZINE ADJUSTHYDRAULIC NOT RUNSAFETY DOOR BE OPENEDSAFETY DOOR NOT CLOSENOT ALL AXIS H**E GONE BACK REFIN ADJUST,IGNORE GOING BACK REFAFTER EXCHANGE TOOL,CYCLE STARTATC MOTOR QF16 OFFX AXIS IS LOCKED(X 轴被锁定)Y AXIS IS LOCKED(Y 轴被锁定)Z AXIS IS LOCKED(Z 轴被锁定)A AXIS IS LOCKED(A 轴被锁定)SPINDLE MOTOR FAN QF26 OFF(主轴电机风扇QF26关闭)关注我们的微信公众号shukongzhpngguo,获取更多数控技术文章。

发那科报警信息中英文对照表T WORD ERROR (T 码错误)LOW OIL LEVEL (油位低)SPINPLE FAULT (主轴故障)SPINDLE ALARM (主轴报警)EXTERNAL EMG STOP (急停按钮被按下)AC NOT READY (交流盘未准备好)SPINPLE LUBE FAULT (主轴润滑故障)T CODE ERROR (T代码出错,非法T代码)M CODE ERROR (M代码出错,非法M代码)SERVO NOT READY (伺服未准备好)NC NOT READY(NC没准备好)TURRET FAULT (转塔故障)TURRET LIMIT (转塔限位)DC 24V OPEN (直流24断开)+24V NOT READY(+24V没准备好)GRAR DRIFT (档位漂移)PLEASE AXIS RETURN HOME(轴未回零)PLEASE DRUM RETURN HOME(刀库未回零)AIRPRESSFAILURE(气压故障)UNCL TOOL FALL(松刀失败)AIR PRESSURE DROP (压缩空气压力过低)CLAMP TOOL FALL(夹刀失败)DRUM NOT PARKED(刀库未在原值)X ZERO POINT NOT REACHED (X 轴未回零)Y ZERO POINT NOT REACHED (Y 轴未回零)Z ZERO POINT NOT REACHED (Z 轴未回零)4TH ZERO POINT NOT REACHED (第4轴未回零)X AXIS OVERTRAVL(X轴超限)Y AXIS OVERTRAVL (Y轴超限)Z AXIS OVERTRAVL (Z轴超限)COUNTER SWITCH REEOR (计数开关故障)MASTERT RANSFER OVER TEMP (主变压器过热)Z AXIS NOT AT FIRST REF POSITION (Z轴未在第一参考点)SPINDLE ORIENTATION FALLURE (主轴定向失败)TOOL DESENT OR TOOL DATA REEOR (刀具数据错误)PLEASE UNLOAD THE TOOL ON SPRINELK (请卸下主轴上的刀)PLEASE LOAD TOOL ON APINDLE (请装上主轴上的刀)A AXIS UNCLAMP FAIL (A 轴松开失败)A AXIS CLAMP FAIL (A 轴夹紧失败)DRUM OUT TO APRONDLEIS FALL (刀库摆向换刀位失败)MG SWING OVERLOAD(刀库摆动过载)DRUM BACK PARK IS FALL (刀库摆回原始位失败)TURRENT MOTOR1 OVERLOAD (刀库移动电机过载)COOLANT MOTOR OVERLOAD (冷却泵过载)DRUM ATC FAULT (自动换刀失败)TOOLS UNLOCKED (刀具未锁紧)BATTERY ALARM (电池报警)DRUM POSITION SWITCH ERROR (刀库位置检测开关故障)DRUM NOW NOT AT PARK (刀库未在原始位置)IT DANGOU TO MOVE DRUM (刀库禁动)POT UO FAILOR POT NOT AT UP POSITION (刀套未在水平位)POT DOWN FAIL (刀套翻下动作失败)IT IS DANGOUR TO MOVE ARM (机械手禁动)THE SPINDLE STATU IS ERROR (主轴状态错误)ARM MOTOR OR ARM SWITCH FALL (机械手或机械手开关故障)CENTRE LUBRICATION FALL (中心润滑故障)THE WORK NOT CLAMPED (工件未夹紧)AUTO TOOL CHANGE FAULT (自动换刀失败)TOOL DATA OUT OF RANGE (指令刀具号超出范围)THE ORDER TOOL NOW IN SPINDLE (目标刀具在主轴上)THE THREE SPINDLE SWITCH FAULT (主轴上的接近开关)THE CENTRE COOLANT IS LOWER (刀具内冷泵液位过低)DRUM RETURN 1# POSITION FAULT (刀库自动回零失败)SPINDLE OVERLOAD (主轴过载)TURRENT MOTOR OVERLOAD (刀盘转动电机过载)CHIP CONVEYER OVERLOAD (拉屑器过载)HARD LIMIT OR SERVO ALARM (硬限位或伺服报警)NO LUB OIL (无润滑油)INDEX HEAD UNLOCKED (分度头未锁紧)MT NOT READY(机床没准备好)MG OVERLOAD (刀库过载)LUB EMPTY(润滑无油)AIR PRESSURE(气压不足)COOLANT NOT READY(冷却没准备好)LUBE EMPTY(油雾油位低,润滑油位低)LUB PRESSURE LOW(润滑压力低)CONVEY VERLOAD(排屑过载)LUB OVERLOAD(润滑过载)LUBE PRESSURE LOW(油雾压力低)SERIAL SPINDLE ALARM (串行主轴报警)NC BATTERY LOW ALARM(NC电池低报警)MAGAZINE MOVE LIMIT SWITCH ERROR(刀库移动限位开关故障)SPINDLE TOOL UNLAMP POSITION LIMIT SWITCH ERROR(主轴刀具UNLAMP位置限位开关故障)MAGAZINE NOT IN POSITION OR SENSOR ERROR(刀库不在位或传感器错误)AIR PRESSURE LOW ALARM(气压低报警)MOTOR OVERLOAD(电机过载)T CODE > MAGAZINE TOOLST CODE < 1 ERROR5TH AXIS HARDWARE OVERTRAVER LIMIT ERRORDOOR IS OPENED(开门)LUB PRESSURE SWITCH ERROR(油压开关错误)SPINDLE OIL COOLANT UNIT ERRORSPINDLE LOAD ABNORMAL(主轴负荷异常)TRANSDUCER ALARM(传感器报警)BED-HEAD LUBRICATE OFF(床头润滑关闭)EMG OFFHYDRAULIC CHUCK PRESS LOW(液压夹头压力低)HYDRAULIC TAIL PRESS LOW(液压尾座压力低)LUB 0IL LOW(油压低)TURRET CODE ERROR(转塔码错误)TURRET RUN OVERTIME(转塔运行超时)MANUAL HANDLE INTERRUPTTRY TO RUN SPINDLE WHILE CHUCK NOT LOCKTRY TO RUN SPINDLE WHILE TAIL NOT LOCKSPINDLE NEUTRAL GEARMAGAZINE ADJUSTHYDRAULIC NOT RUNSAFETY DOOR BE OPENEDSAFETY DOOR NOT CLOSENOT ALL AXIS HAVE GONE BACK REFIN ADJUST,IGNORE GOING BACK REFAFTER EXCHANGE TOOL,CYCLE STARTATC MOTOR QF16 OFFX AXIS IS LOCKED(X 轴被锁定)Y AXIS IS LOCKED(Y 轴被锁定)Z AXIS IS LOCKED(Z 轴被锁定)A AXIS IS LOCKED(A 轴被锁定)SPINDLE MOTOR FAN QF26 OFF(主轴电机风扇QF26关闭) SPINDLE ORIENTATION INCOMPLETE(主轴定位不完全)M FUNCTION NOT COMPLETE(M 功能无法完成)SPINDLE NOT IN GEAR POSITION(齿轮不在主轴位置)SPINDLE NOT CHANGED TO LOW GEAR(主轴没有变为低档)SPINDLE NOT CHANGED TO HIGH GRAR(主轴没有变为高档)MAG NOT BACKWARDSPINDLE TOOL NOT CLAMPSPINDLE TOOL NOT UNCLAMPMAG NOT IN POSITIONMAG DOES NOT ROTATEMAG DOES NOT STOP RUNNINGA AXIS HAVE NOT CLAMPEDA AXIS HAVE NOT UNCLAMPEDSET D499=1,"MAG.JOG" SWITCH ONHYDRAULIC MOTOR QF7 OFF(液压马达QF7关闭)HYDRAULIC TEMPRETURE HIGH(液压使用温度高)HYDRAULIC FILTER BLOCKED(液压过滤器阻止)HYDRAULIC OIL LEVEL LOW(液压油位低)HYDRAULIC FAN QF8 OFF(液压风扇QF8关闭)HELIX CONYER QF9 OR QF10 OFFCHAIN CONYER QF11 OFFCOOLANT MOTOR QF12 OFF(冷却液电机QF12关闭)COOLNT LEVEL LOW,CYCLE STOP AFTER 20 MINUTESINNER COOLANT BLOCK(内冷却堵塞)SPINDLE COOLANT MOTOR QF14 OFF(主轴冷却液电机QF14关闭)INNER COOLANT QF13 OFF(内冷却液QF13关闭)MAG MOTOR QF15 OFFCABINET COOLANT EQUIP QF20 OFFOIL GATHER QF24 OFFAIR PRESSURE LOW(低气压)SPINDLE COOLANT MOTOR FAULT(主轴冷却液电机故障)LUB.OIL IS LOW(润滑油低)DOOR OPEN(门打开)FRONT DOOR(R) OPEN(前门打开)LEFT DOOR OPEN(左门打开)LUBRICATION OIL QF23 OFF(润滑油QF23关闭)LUBRICATION PRESS LOW(润滑油位低)IN ADJUST,MAG CAN'T EXCHANGE T(在调整,刀库不能交换T)NOT ALL DOOR CLOSED(门没有全部关闭)IN M06,MAG NOT READY(在M06,刀库未准备好)MAGAZINE NOT READY(刀库未准备好)POCKET NOT HORIZANTALIN M06,Z NOT BACK TO 2ND REFIN M06,Z AXIS NOT IN PSW1ATC NOT IN ZERO POSITIONSPINDLE ORIENTATION UNCOMPLETEPOCKET NOT HOR./MAG NOT BCKWRDPOCKET NOT VER./MAG NOT FORWRDUNCLAMP TOOL HAS NOT COMPLETEDCLAMP TOOL HAS NOT COMPLETEDAIM TOOL NO. IS WRONGMAG NOT BACKWARDAFTER RETRACT,SET R.T.BACK OFFZ NOT IN PSW2,FORBID ATC RUNNINGD499 EQUAL 1MAG.JOG SOFT SWITCH IS ONZ NOT IN PSW2,FORBID MAG FORWARDCHEKE SPINDLE MODULE ALARMOIL WATER SEPARATOR QF24 OFFSET THE SOFT SWITCH MAG.JOG OFFSET D499 TO 0 设定D499为0K PARAM ABOUT MAG SET IS WRONG 关于MAG的K参数设定错误MECHANICAL BRAKE NOT RELEASED机床抱闸没有松开MECHANICAL BRAKE IS WRONG 机床抱闸错误PLEASE ADD LUB.OIL 请加润滑油PROBE BATTERY VOLTAGE IS LOW 探头电池电压低PROBE IS ERR 探头错误PARAMETER WRITE ENABLE(参数写使能)PMC EDIT ENABLE(PMC编辑使能)CHECK LUB ROUTINSPINDLE GEAR SIGNAL MISS 主轴档位信号消失T_CLAMPED_SIGNAL MISS T夹紧信号消失SP OVERRIDE SWITCH DISCONNECTION 主轴倍率开关断路FEED OVERRIDE SWITCH DISCONNECTION 进给倍率开关断路THE TOTAL NUMBER OF POCKETS SET ERRCHANGE T STOPED BECAUSE NO AIR 因为缺少压空交换停止THE COOLANT WATER TOO LOW,ADD COOLANT WATER AT ONCE 冷却水少立即加水COOLANT LEVEL LOW,ADD COOLANT WATER 冷却水液位低PLEASE REPLACE CNC BATTERY QUICKLY 请立即更换CNC电池(注:范文素材和资料部分来自网络,供参考。

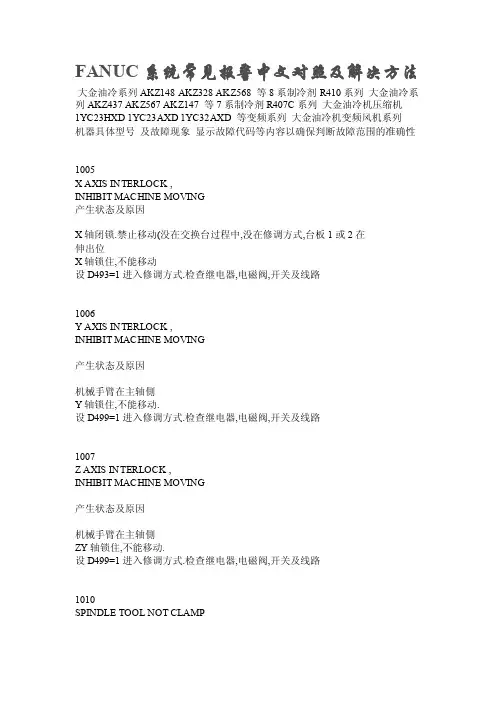

FANUC系统常见报警中文对照及解决方法大金油冷系列AKZ148 AKZ328 AKZ568 等8系制冷剂R410系列大金油冷系列AKZ437 AKZ567 AKZ147 等7系制冷剂R407C系列大金油冷机压缩机1YC23HXD 1YC23AXD 1YC32AXD 等变频系列大金油冷机变频风机系列机器具体型号及故障现象显示故障代码等内容以确保判断故障范围的准确性1005X AXIS INTERLOCK ,INHIBIT MACHINE MOVING产生状态及原因X轴闭锁.禁止移动(没在交换台过程中,没在修调方式,台板1或2在伸出位X轴锁住,不能移动设D493=1进入修调方式.检查继电器,电磁阀,开关及线路1006Y AXIS INTERLOCK ,INHIBIT MACHINE MOVING产生状态及原因机械手臂在主轴側Y轴锁住,不能移动.设D499=1进入修调方式.检查继电器,电磁阀,开关及线路1007Z AXIS INTERLOCK ,INHIBIT MACHINE MOVING产生状态及原因机械手臂在主轴側ZY轴锁住,不能移动.设D499=1进入修调方式.检查继电器,电磁阀,开关及线路1010SPINDLE TOOL NOT CLAMP产生状态及原因主轴刀具未夹紧。

主轴不能旋转。

检查主轴刀具夹紧开关,确认动作正常后,同时按下键和键,清除报警。

1011SPINDLE TOOL NOT UNCLAMP产生状态及原因主轴刀具未松开。

主轴不能旋转。

检查主轴刀具松开开关,确认动作正常后,同时按下键和键,清除报警。

1012SPINDLE ORIENTAL NOT COMPLETE产生状态及原因主轴定向未完成(F45.7没输出)。

不能进行刀具交换。

检查主轴定向开关是否工作正常。

1013M FUNCTION DID NOT COMPLETE产生状态及原因在执行M功能时,可能是某个M代码未执行完.程序加工不能正常进行.检查是哪一个M功能未执行。

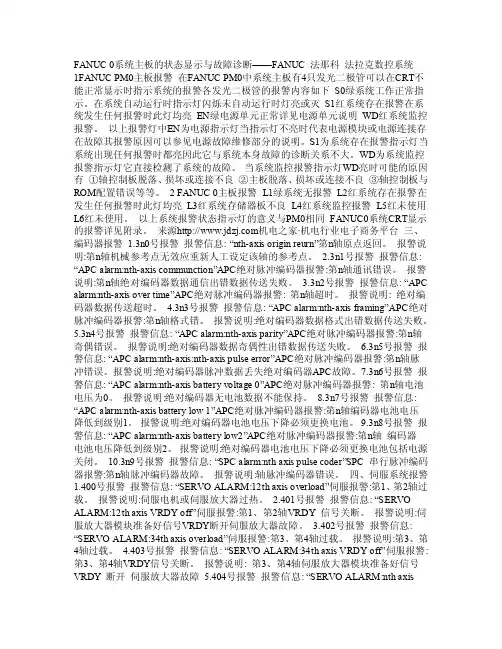

FANUC 0系统主板的状态显示与故障诊断——FANUC 法那科法拉克数控系统1FANUC PM0主板报警在FANUC PM0中系统主板有4只发光二极管可以在CRT不能正常显示时指示系统的报警各发光二极管的报警内容如下S0绿系统工作正常指示。

在系统自动运行时指示灯闪烁未自动运行时灯亮或灭S1红系统存在报警在系统发生任何报警时此灯均亮EN绿电源单元正常详见电源单元说明WD红系统监控报警。

以上报警灯中EN为电源指示灯当指示灯不亮时代表电源模块或电源连接存在故障其报警原因可以参见电源故障维修部分的说明。

S1为系统存在报警指示灯当系统出现任何报警时都亮因此它与系统本身故障的诊断关系不大。

WD为系统监控报警指示灯它直接检测了系统的故障。

当系统监控报警指示灯WD亮时可能的原因有①轴控制板脱落、损坏或连接不良②主板脱落、损坏或连接不良③轴控制板与ROM配置错误等等。

2 FANUC 0主板报警L1绿系统无报警L2红系统存在报警在发生任何报警时此灯均亮L3红系统存储器板不良L4红系统监控报警L5红未使用L6红未使用。

以上系统报警状态指示灯的意义与PM0相同FANUC0系统CRT显示的报警详见附录。

来源机电之家·机电行业电子商务平台三、编码器报警 1.3n0号报警报警信息: “nth-axis origin reurn”第n轴原点返回。

报警说明:第n轴机械参考点无效应重新人工设定该轴的参考点。

2.3n1号报警报警信息: “APC alarm:nth-axis communction”APC绝对脉冲编码器报警:第n轴通讯错误。

报警说明:第n轴绝对编码器数据通信出错数据传送失败。

3.3n2号报警报警信息: “APC alarm:nth-axis over time”APC绝对脉冲编码器报警: 第n轴超时。

报警说明: 绝对编码器数据传送超时。

4.3n3号报警报警信息: “APC alarm:nth-axis framing”APC绝对脉冲编码器报警:第n轴格式错。

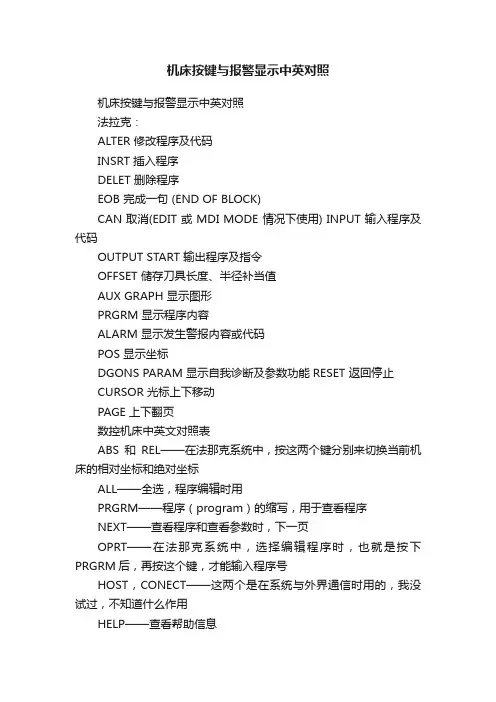

机床按键与报警显示中英对照机床按键与报警显示中英对照法拉克:ALTER 修改程序及代码INSRT 插入程序DELET 删除程序EOB 完成一句 (END OF BLOCK)CAN 取消(EDIT 或 MDI MODE 情况下使用) INPUT 输入程序及代码OUTPUT START 输出程序及指令OFFSET 储存刀具长度、半径补当值AUX GRAPH 显示图形PRGRM 显示程序内容ALARM 显示发生警报内容或代码POS 显示坐标DGONS PARAM 显示自我诊断及参数功能RESET 返回停止CURSOR 光标上下移动PAGE 上下翻页数控机床中英文对照表ABS和REL——在法那克系统中,按这两个键分别来切换当前机床的相对坐标和绝对坐标ALL——全选,程序编辑时用PRGRM——程序(program)的缩写,用于查看程序NEXT——查看程序和查看参数时,下一页OPRT——在法那克系统中,选择编辑程序时,也就是按下PRGRM后,再按这个键,才能输入程序号HOST,CONECT——这两个是在系统与外界通信时用的,我没试过,不知道什么作用HELP——查看帮助信息SHIFT——换档键,有些键有两个字符,按下这个键,用来输入顶部那个字符ALTER——程序修改键,编辑程序时用INSERT——程序插入键,编辑程序时用EOB——程序结束符,在编辑程序时,没段程序结束时,要加这个符号CAN——取消键,用来取消输入INPUT——输入键,用来输入程序或参数POS——按此键显示当前机床位置画面PROS——按此键显示当前程序画面OFFSET——按此键显示刀具偏置画面SETTING——按此键显示刀具偏置设定画面SYSTEM——按此键显示系统信息及系统状态画面GRAPH——按此键显示加工时刀具轨迹的图形画面CUSTOM——按此键显示用户宏程序画面手动数据输入 (MDI)直接数字控制方法 (DNC)控制器单元或机控制器单元(MCU常见机床报警信息中英文对照T WORD ERROR (T 码错误)LOW OIL LEVEL (油位低)SPINPLE FAULT (主轴故障)SPINDLE ALARM (主轴报警)EXTERNAL EMG STOP (急停按钮被按下)AC NOT READY (交流盘未准备好)SPINPLE LUBE FAULT (主轴润滑故障)T CODE ERROR (T代码出错,非法T代码)M CODE ERROR (M代码出错,非法M代码)SERVO NOT READY (伺服未准备好)NC NOT READY(NC没准备好)TURRET FAULT (转塔故障)TURRET LIMIT (转塔限位)DC 24V OPEN (直流24断开)+24V NOT READY(+24V没准备好)GRAR DRIFT (档位漂移)PLEASE AXIS RETURN HOME(轴未回零)PLEASE DRUM RETURN HOME(刀库未回零)AIRPRESSFAILURE(气压故障)UNCL TOOL FALL(松刀失败)AIR PRESSURE DROP (压缩空气压力过低)CLAMP TOOL FALL(夹刀失败)DRUM NOT PARKED(刀库未在原值)X ZERO POINT NOT REACHED (X 轴未回零)Y ZERO POINT NOT REACHED (Y 轴未回零)Z ZERO POINT NOT REACHED (Z轴未回零)4TH ZERO POINT NOT REACHED (第4轴未回零)X AXIS OVERTRAVL(X轴超限)Y AXIS OVERTRAVL (Y轴超限)Z AXIS OVERTRAVL (Z轴超限)COUNTER SWITCH REEOR (计数开关故障)MASTERT RANSFER OVER TEMP (主变压器过热)Z AXIS NOT AT FIRST REF POSITION (Z轴未在第一参考点)SPINDLE ORIENTATION FALLURE (主轴定向失败)TOOL DESENT OR TOOL DATA REEOR (刀具数据错误)PLEASE UNLOAD THE TOOL ON SPRINELK (请卸下主轴上的刀)PLEASE LOAD TOOL ON APINDLE (请装上主轴上的刀)A AXIS UNCLAMP FAIL (A 轴松开失败)A AXIS CLAMP FAIL (A 轴夹紧失败)DRUM OUT TO APRONDLEIS FALL (刀库摆向换刀位失败)MG SWING OVERLOAD(刀库摆动过载)DRUM BACK PARK IS FALL (刀库摆回原始位失败)TURRENT MOTOR1 OVERLOAD (刀库移动电机过载)COOLANT MOTOR OVERLOAD (冷却泵过载)DRUM ATC FAULT (自动换刀失败)TOOLS UNLOCKED (刀具未锁紧)BATTERY ALARM (电池报警)DRUM POSITION SWITCH ERROR (刀库位置检测开关故障)DRUM NOW NOT AT PARK (刀库未在原始位置)IT DANGOU TO MOVE DRUM (刀库禁动)POT UO FAILOR POT NOT AT UP POSITION (刀套未在水平位)POT DOWN FAIL (刀套翻下动作失败)IT IS DANGOUR TO MOVE ARM (机械手禁动)THE SPINDLE STATU IS ERROR (主轴状态错误)ARM MOTOR OR ARM SWITCH FALL (机械手或机械手开关故障)CENTRE LUBRICATION FALL (中心润滑故障)THE WORK NOT CLAMPED (工件未夹紧)AUTO TOOL CHANGE FAULT (自动换刀失败)TOOL DATA OUT OF RANGE (指令刀具号超出范围)THE ORDER TOOL NOW IN SPINDLE (目标刀具在主轴上)THE THREE SPINDLE SWITCH FAULT (主轴上的接近开关)THE CENTRE COOLANT IS LOWER (刀具内冷泵液位过低)DRUM RETURN 1# POSITION FAULT (刀库自动回零失败)SPINDLE OVERLOAD (主轴过载)TURRENT MOTOR OVERLOAD (刀盘转动电机过载)CHIP CONVEYER OVERLOAD (拉屑器过载)HARD LIMIT OR SERVO ALARM (硬限位或伺服报警)NO LUB OIL (无润滑油)INDEX HEAD UNLOCKED (分度头未锁紧)MT NOT READY(机床没准备好)MG OVERLOAD (刀库过载)LUB EMPTY(润滑无油)AIR PRESSURE(气压不足)COOLANT NOT READY(冷却没准备好)LUBE EMPTY(油雾油位低,润滑油位低)LUB PRESSURE LOW(润滑压力低)CONVEY VERLOAD(排屑过载)LUB OVERLOAD(润滑过载)LUBE PRESSURE LOW(油雾压力低)SERIAL SPINDLE ALARM (串行主轴报警)NC BATTERY LOW ALARM(NC电池低报警)MAGAZINE MOVE LIMIT SWITCH ERRORSPINDLE TOOL UNLAMP POSITION LIMIT SWITCH ERROR MAGAZINE NOT IN POSITION OR SENSOR ERRORAIR PRESSURE LOW ALARM(气压低报警)MOTOR OVERLOAD(电机过载)T CODE > MAGAZINE TOOLST CODE < 1 ERROR5TH AXIS HARDWARE OVERTRAVER LIMIT ERRORDOOR IS OPENED(开门)LUB PRESSURE SWITCH ERROR(油压开关错误) SPINDLE OIL COOLANT UNIT ERRORSPINDLE LOAD ABNORMAL(主轴负荷异常)TRANSDUCER ALARM(传感器报警)BED-HEAD LUBRICATE OFF(床头润滑关闭)EMG OFFHYDRAULIC CHUCK PRESS LOW(液压夹头压力低)HYDRAULIC TAIL PRESS LOW(液压尾座压力低)LUB 0IL LOW(油压低)TURRET CODE ERROR(转塔码错误)TURRET RUN OVERTIME(转塔运行超时)MANUAL HANDLE INTERRUPTTRY TO RUN SPINDLE WHILE CHUCK NOT LOCKTRY TO RUN SPINDLE WHILE TAIL NOT LOCKSPINDLE NEUTRAL GEARMAGAZINE ADJUSTHYDRAULIC NOT RUNSAFETY DOOR BE OPENEDSAFETY DOOR NOT CLOSENOT ALL AXIS HAVE GONE BACK REFIN ADJUST,IGNORE GOING BACK REFAFTER EXCHANGE TOOL,CYCLE STARTATC MOTOR QF16 OFFX AXIS IS LOCKED(X 轴被锁定)Y AXIS IS LOCKED(Y 轴被锁定)Z AXIS IS LOCKED(Z 轴被锁定)A AXIS IS LOCKED(A 轴被锁定)SPINDLE MOTOR FAN QF26 OFF(主轴电机风扇QF26关闭) SPINDLE ORIENTATION INCOMPLETE(主轴定位不完全)M FUNCTION NOT COMPLETE(M 功能无法完成)SPINDLE NOT IN GEAR POSITION(齿轮不在主轴位置)SPINDLE NOT CHANGED TO LOW GEAR(主轴没有变为低档)SPINDLE NOT CHANGED TO HIGH GRAR(主轴没有变为高档)MAG NOT BACKWARDSPINDLE TOOL NOT CLAMPSPINDLE TOOL NOT UNCLAMPMAG NOT IN POSITIONMAG DOES NOT ROTATEMAG DOES NOT STOP RUNNINGA AXIS HAVE NOT CLAMPEDA AXIS HAVE NOT UNCLAMPEDSET D499=1,"MAG.JOG" SWITCH ONHYDRAULIC MOTOR QF7 OFF(液压马达QF7关闭)HYDRAULIC TEMPRETURE HIGH(液压使用温度高)HYDRAULIC FILTER BLOCKED(液压过滤器阻止)HYDRAULIC OIL LEVEL LOW (液压油位低)HYDRAULIC FAN QF8 OFF(液压风扇QF8关闭)HELIX CONYER QF9 OR QF10 OFFCHAIN CONYER QF11 OFFCOOLANT MOTOR QF12 OFF(冷却液电机QF12关闭)COOLNT LEVEL LOW,CYCLE STOP AFTER 20 MINUTES INNER COOLANT BLOCK(内冷却堵塞)SPINDLE COOLANT MOTOR QF14 OFF(主轴冷却液电机QF14关闭)INNER COOLANT QF13 OFF(内冷却液QF13关闭)MAG MOTOR QF15 OFFCABINET COOLANT EQUIP QF20 OFFOIL GATHER QF24 OFFAIR PRESSURE LOW(低气压)SPINDLE COOLANT MOTOR FAULT(主轴冷却液电机故障)LUB.OIL IS LOW(润滑油低)DOOR OPEN(门打开)FRONT DOOR(R) OPEN(前门打开)LEFT DOOR OPEN(左门打开)LUBRICATION OIL QF23 OFF(润滑油QF23关闭)LUBRICATION PRESS LOW(润滑油位低)IN ADJUST,MAG CAN'T EXCHANGE T(在调整,刀库不能交换T)NOT ALL DOOR CLOSED(门没有全部关闭)IN M06,MAG NOT READY(在M06,刀库未准备好)MAGAZINE NOT READY(刀库未准备好)POCKET NOT HORIZANTALIN M06,Z NOT BACK TO 2ND REFIN M06,Z AXIS NOT IN PSW1ATC NOT IN ZERO POSITIONSPINDLE ORIENTATION UNCOMPLETEPOCKET NOT HOR./MAG NOT BCKWRDPOCKET NOT VER./MAG NOT FORWRDUNCLAMP TOOL HAS NOT COMPLETEDCLAMP TOOL HAS NOT COMPLETEDAIM TOOL NO. IS WRONGMAG NOT BACKWARDAFTER RETRACT,SET R.T.BACK OFFZNOT IN PSW2,FORBID ATC RUNNINGD499 EQUAL 1MAG.JOG SOFT SWITCH IS ONZ NOT IN PSW2,FORBID MAG FORWARDCHEKE SPINDLE MODULE ALARMOIL WATER SEPARATOR QF24 OFFSET THE SOFT SWITCH MAG.JOG OFFSET D499 TO 0 设定D499为0K PARAM ABOUT MAG SET IS WRONG 关于MAG的K参数设定错误MECHANICAL BRAKE NOT RELEASED机床抱闸没有松开MECHANICAL BRAKE IS WRONG 机床抱闸错误PLEASE ADD LUB.OIL 请加润滑油PROBE BATTERY VOLTAGE IS LOW 探头电池电压低PROBE IS ERR 探头错误PARAMETER WRITE ENABLE(参数写使能)PMC EDIT ENABLE(PMC编辑使能)CHECK LUB ROUTINSPINDLE GEAR SIGNAL MISS 主轴档位信号消失T_CLAMPED_SIGNAL MISS T夹紧信号消失SP OVERRIDE SWITCH DISCONNECTION 主轴倍率开关断路FEED OVERRIDE SWITCH DISCONNECTION 进给倍率开关断路THE TOTAL NUMBER OF POCKETS SET ERRCHANGE T STOPED BECAUSE NO AIR 因为缺少压空交换停止THE COOLANT WATER TOO LOW,ADD COOLANT WATER AT ONCE 冷却水少立即加水COOLANT LEVEL LOW,ADD COOLANT WATER 冷却水液位低PLEASE REPLACE CNC BATTERY QUICKLY 请立即更换CNC 电池SIEMENS常用缩略语A Output 输出ASCII American Standard Code for Information Interchange 美国信息交换标准代码AV Preparation for work 运行准备BA Operating mode 运行方式BAG Operating mode groups 运行方式组BB Ready for operation 准备好运行BCD Binary Coded Decimals 二-十进制BHG Hand-held terminal 手提终端BOF User interface 用户接口CNC Computerized Numerical Control 计算机化数字控制CP Communication Processor 通迅处理器CPU Central Processing Unit 计算机中央处理装置CR Carriage Return 托架折回CSB Central Service Board(PLC module) 中央维护板,PLC 模块CTS Clear To Send 发送使能DAU Digital-Analog Converter 数模转换器DB Data Block 数据块DIN German Industrial Standards 德国工业标准DIO Data Input/Output 数据输入/输出DRF Differential Resolver Function 差分功能DRY Dry Run 空运行DSB Decoding Single Block 译码单段DSR Data Send Ready 备用输入DW Data Word 数据字E Input 输入EIA-Code Special tape code,number of holes per characters always odd 特殊纸带码,每个字符的孔数为奇数EPROM Programm memory with fixed program 有固定程序的程序存储器E/R Controlled Supply and Energy Recovery Module 可控电源和能量恢复模块ETC ETC key:Extension of the softkey bar in the same menu ETC 键:同级菜单扩展键FDB Product designation database 产品指定数据库FIFO First in First Out 先进先出FRA Frame module 帧频模块FRAME Coordinate conversion with the components zerooffset,rotation,scaling,mirror-imaging 坐标换算,具有零点偏置,坐标旋转,标度功能和镜向功能FRK Cutter radius compensation 铣刀半径补偿FST Feed Stop 停止进给GUD Global User Data 全体用户数据HMS High-Resolution Measuring System 高分辨率测量系统HSA Main Spindle Drive 主轴驱动HW Hardware 硬件IM Interface Module 接口模块IM-S/R Interface Module(S=send/R=receive) 接口模块,S=发送/R=接收INC Increment 步进增量ISO-Code Special tape code,number of holes per character always even特殊纸带码,每个字符的孔数为偶数K1...k4 Channel 1 to Channel 4 通道1 到通道4KOP Ladder Diagram 梯形图KV Loop-Gain Factor 增益系数KUE Transformation Ratio 传动比LCD Liquid Crystal Display 液晶显示LED Light Emitting Diode 发光二极管显示LUD Local User Data 局部用户数据MB Megabyte 兆字节MD Machine Data 机床数据MK Measuring Circuit 测量回路MDA Manual Data Automatic 手动输入,自动执行MLFB Machine-readable product designation 机器可识别的产品代号MMC Man Machine Communication:User interface of the numerical controlsystem for operation,programming and simulation 人机通讯:系统操作界面,用操作,编程和模拟MPF Main Program File:NC part program(main program)NC 零件程序,主程序MPI Multi Point Interface 多点通讯接口MSTT Machine control panel 机床控制面板NC Numerical Control 数字控制NCK Numerical Control Kernel(numerical krnel with block preparation,traversing range etc.) 数字控制核心:具有程序段预处理,运行范围等等NCU Numerical Control Unit 数控单元NURBS Non Uniform Rational B Spline 非均值有理B样条NV Zero Offset 零点偏置OEM Original Equipment Manufacturer 原设备制造商OP Operator Panel 操作面板OPI Operator Panel Interface 操作面板接口PC Personal Comprter 个人计算机PCMCIA Personal Computer Menory Card International Association 接口协议PG Programming Device 编程器PLC Programmable Logic Control 可编程逻辑控制器PRT Program Test 程序测试RAM Random Access Memory 随机存取存储器RISC Reduced Instruction Set Computer 处理器,具有指令组小、通过能力强ROV Rapid Override 快速修调RPA R Parameters Active(NCK memoty area for R parameter numbers)R 参数有效,NCK 中用于R 参数号的存储器区RTS Request To Send(control signal from serial data interfaces)发送请求:来自串行接口的控制信号SBL Single Block 单段SBL2 Single Block Decoding 译码单段SEA Setting Data Active(memory area for setting data in NCK) 设定数据有效:用于NCK 中设定数据的存储区。

FANUC PMC中文英文报警对照表对于有的机床编写的报警是英文或者英文的缩写,看起来不明确,以下是个人整理的对照表,方便人阅读。

T WORD ERROR (T 码错误)LOW OIL LEVEL (油位低)SPINPLE FAULT (主轴故障)SPINDLE ALARM (主轴报警)EXTERNAL EMG STOP (急停按钮被按下)AC NOT READY (交流盘未准备好)SPINPLE LUBE FAULT (主轴润滑故障)T CODE ERROR (T代码出错,非法T代码)M CODE ERROR (M代码出错,非法M代码)SERVO NOT READY (伺服未准备好)NC NOT READY(NC没准备好)TURRET FAULT (转塔故障)TURRET LIMIT (转塔限位)DC 24V OPEN (直流24断开)+24V NOT READY(+24V没准备好)GRAR DRIFT (档位漂移)PLEASE AXIS RETURN HOME(轴未回零)PLEASE DRUM RETURN HOME(刀库未回零)AIRPRESSFAILURE(气压故障)UNCL TOOL FALL(松刀失败)AIR PRESSURE DROP (压缩空气压力过低)CLAMP TOOL FALL(夹刀失败)DRUM NOT PARKED(刀库未在原值)X ZERO POINT NOT REACHED (X 轴未回零)Y ZERO POINT NOT REACHED (Y 轴未回零)Z ZERO POINT NOT REACHED (Z 轴未回零)4TH ZERO POINT NOT REACHED (第4轴未回零)X AXIS OVERTR**L(X轴超限)Y AXIS OVERTR**L (Y轴超限)Z AXIS OVERTR**L (Z轴超限)COUNTER SWITCH REEOR (计数开关故障)MASTERT RANSFER OVER TEMP (主变压器过热)Z AXIS NOT AT FIRST REF POSITION (Z轴未在第一参考点)SPINDLE ORIENTATION FALLURE (主轴定向失败)TOOL DESENT OR TOOL DATA REEOR (刀具数据错误)PLEASE UNLOAD THE TOOL ON SPRINELK (请卸下主轴上的刀)PLEASE LOAD TOOL ON APINDLE (请装上主轴上的刀)A AXIS UNCLAMP FAIL (A 轴松开失败)A AXIS CLAMP FAIL (A 轴夹紧失败)DRUM OUT TO APRONDLEIS FALL (刀库摆向换刀位失败)MG SWING OVERLOAD(刀库摆动过载)DRUM BACK PARK IS FALL (刀库摆回原始位失败)TURRENT MOTOR1 OVERLOAD (刀库移动电机过载)COOLANT MOTOR OVERLOAD (冷却泵过载)DRUM ATC FAULT (自动换刀失败)TOOLS UNLOCKED (刀具未锁紧)BATTERY ALARM (电池报警)DRUM POSITION SWITCH ERROR (刀库位置检测开关故障)DRUM NOW NOT AT PARK (刀库未在原始位置)IT DANGOU TO MOVE DRUM (刀库禁动)POT UO FAILOR POT NOT AT UP POSITION (刀套未在水平位)POT DOWN FAIL (刀套翻下动作失败)IT IS DANGOUR TO MOVE ARM (机械手禁动)THE SPINDLE STATU IS ERROR (主轴状态错误)ARM MOTOR OR ARM SWITCH FALL (机械手或机械手开关故障)CENTRE LUBRICATION FALL (中心润滑故障)THE WORK NOT CLAMPED (工件未夹紧)AUTO TOOL CHANGE FAULT (自动换刀失败)TOOL DATA OUT OF RANGE (指令刀具号超出范围)THE ORDER TOOL NOW IN SPINDLE (目标刀具在主轴上)THE THREE SPINDLE SWITCH FAULT (主轴上的接近开关)THE CENTRE COOLANT IS LOWER (刀具内冷泵液位过低)DRUM RETURN 1# POSITION FAULT (刀库自动回零失败)SPINDLE OVERLOAD (主轴过载)TURRENT MOTOR OVERLOAD (刀盘转动电机过载)CHIP CONVEYER OVERLOAD (拉屑器过载)HARD LIMIT OR SERVO ALARM (硬限位或伺服报警)NO LUB OIL (无润滑油)INDEX HEAD UNLOCKED (分度头未锁紧)MT NOT READY(机床没准备好)MG OVERLOAD (刀库过载)LUB EMPTY(润滑无油)AIR PRESSURE(气压不足)COOLANT NOT READY(冷却没准备好)LUBE EMPTY(油雾油位低,润滑油位低)LUB PRESSURE LOW(润滑压力低)CONVEY VERLOAD(排屑过载)LUB OVERLOAD(润滑过载)LUBE PRESSURE LOW(油雾压力低)SERIAL SPINDLE ALARM (串行主轴报警)NC BATTERY LOW ALARM(NC电池低报警)MAGAZINE MOVE LIMIT SWITCH ERRORSPINDLE TOOL UNLAMP POSITION LIMIT SWITCH ERROR MAGAZINE NOT IN POSITION OR SENSOR ERRORAIR PRESSURE LOW ALARM(气压低报警)MOTOR OVERLOAD(电机过载)T CODE > MAGAZINE TOOLST CODE < 1 ERROR5TH AXIS HARDWARE OVERTR**ER LIMIT ERRORDOOR IS OPENED(开门)LUB PRESSURE SWITCH ERROR(油压开关错误) SPINDLE OIL COOLANT UNIT ERRORSPINDLE LOAD ABNORMAL(主轴负荷异常)TRANSDUCER ALARM(传感器报警)BED-HEAD LUBRICATE OFF(床头润滑关闭)EMG OFFHYDRAULIC CHUCK PRESS LOW(液压夹头压力低)HYDRAULIC TAIL PRESS LOW(液压尾座压力低)LUB 0IL LOW(油压低)TURRET CODE ERROR(转塔码错误)TURRET RUN OVERTIME(转塔运行超时)MANUAL HANDLE INTERRUPTTRY TO RUN SPINDLE WHILE CHUCK NOT LOCKTRY TO RUN SPINDLE WHILE TAIL NOT LOCK SPINDLE NEUTRAL GEARMAGAZINE ADJUSTHYDRAULIC NOT RUNSAFETY DOOR BE OPENEDSAFETY DOOR NOT CLOSENOT ALL AXIS H**E GONE BACK REFIN ADJUST,IGNORE GOING BACK REFAFTER EXCHANGE TOOL,CYCLE STARTATC MOTOR QF16 OFFX AXIS IS LOCKED(X 轴被锁定)Y AXIS IS LOCKED(Y 轴被锁定)Z AXIS IS LOCKED(Z 轴被锁定)A AXIS IS LOCKED(A 轴被锁定)SPINDLE MOTOR FAN QF26 OFF(主轴电机风扇QF26关闭)关注我们的微信公众号shukongzhpngguo,获取更多数控技术文章。

F A N U C常见报警的解释 Revised by Petrel at 2021常见报警的解释1.1368报警(串行数据错误)上图中368报警以及相关编码器报警的原因有:(1)电机后面的编码器有问题,如果客户的加工环境很差,有时会有切削液或液压油浸入编码器中导致编码器故障。

(2)编码器的反馈电缆有问题,电缆两侧的插头没有插好。

由于机床在移动过程中,坦克链会带动反馈电缆一起动,这样就会造成反馈电缆被挤压或磨损而损坏,从而导致系统报警。

尤其是偶然的编码器方面的报警,很大可能是反馈电缆磨损所致。

(3)伺服放大器的控制侧电路板损坏。

解决方案:(1)把此电机上的编码器跟其他电机上的同型号编码器进行互换,如果互换后故障转移说明编码器本身已经损坏。

(2)把伺服放大器跟其同型号的放大器互换,如果互换后故障转移说明放大器有故障。

(3)更换编码器的反馈电缆,注意有的时候反馈电缆损坏后会造成编码器或放大器烧坏,所以最好先确认反馈电缆是否正常。

1.2电源模块PSM控制板内风扇故障443,610上图报警是电源模块控制板内风扇损坏导致的报警(使用αi电源模块时),报警时电源模块PSM的LED显示“2”,主轴放大器SPM的LED显示“59”。

拆下电源模块控制板后,风扇位置如下图所示:1.3主轴放大器SPM内冷风扇故障此故障没有画面报警信息,但是有上图的“FAN”在闪烁,此现象表明主轴放大器SPM的内冷风扇出现了故障。

1.4伺服放大器SVM内冷风扇报警608,444上图中的报警表示伺服放大器SVM的内冷风扇出现了故障(Z轴和A轴同时出现报警是因为Z轴和A轴是同一个放大器控制的)。

上图中的报警出现时对应的伺服放大器上的LED显示“1”。

1.5主轴放大器和伺服放大器的内冷风扇位置上图中:(1)主轴放大器内冷风扇的安装位置(2)伺服放大器内冷风扇的安装位置(3)主轴放大器的型号A06B-6111-HXXX#H550(后面带#H***的都是主轴放大器)(4)伺服放大器的型号A06-6114-HXXX注:(1)不同型号的主轴放大器和伺服放大器对应的风扇的型号也不一样,请参考附录。

FANUC系统中文报警文本的开发数控机床发生故障时,绝大多数情况下数控系统能及时地显示报警号和报警信息,维修人员可依据系统画面的报警显示进行故障的维修分析及处理。

在FANUC系统中,由机床厂商设计的外部报警,常以英文字符串构成,给维修人员诊断故障带来了一定的困难,开发一套具有中文文本的报警信息,可方便机床操作人员与维修人员快速定位与解决机床所产生的故障。

1 FANUC数控系统报警的分类根据报警显示形式的不同,FS-0iD可分为内部报警和外部报警。

1.1 内部报警内部报警主要是由FANUC系统根据它所控制的对象,如系统本体、伺服放大器、主轴放大器、机床操作、编程循环等运行状态来产生对应的报警文本,系统上绝大部分的报警都属于此类情况。

报警)。

由于内部报警功能丰富,报警数量较大,报警文字描述不够详尽,平时在使用和维修机床时,无法依靠系统画面显示的报警来解决问题,这就需要FANUC自带的维修说明书(B-64305CM)供参考,通过查阅说明书中对应的解决办法,逐一排除机床上出现的故障。

1.2 外部报警外部报警主要由机床生产厂家所设计,只能够用于特定的机床。

由于机床报警无通用性,维修人员必须阅读机床生产厂家所提供的使用说明书来进行故障处理。

2 信息显示功能2.1 信息显示请求地址在FANUC PMC(Programmable Machine Controller)程序中,信息显示请求位共2000位(A0.0~A249.7),每一位都对应一条信息。

在PMC程序运行中,当信息请求位输出为1,系统画面即会显示对应的文本信息;当信息请求位输出为0,则会清除对应的显示信息。

2.2 信息数据表每一位信息请求地址都会有专门的信息数据表与之对应,信息数据表的内容包括信息号和信息数据两部分。

在FANUC系统中,信息号有特定的分类,见表1:当出现1000~1999信息时,会跳转至报警界面并显示报警信息,同时中断机床的工作;而出现2000号以后的信息时,只在操作界面中显示,并不会中断机床的工作状态。

报警号A0.0 A0.1 A0.2 A0.3 A0.4 A0.5 A0.6 A0.7 A1.0 A1.1 A1.2 A1.3 A1.4 A1.5 A1.6 A1.7 A2.0 A2.1 A2.2 A2.3 A2.4 A2.5 A2.6 A2.7 A3.0 A3.1 A3.2 A3.3 A3.4 A3.5 A3.6 A3.7 A4.0 A4.1 A4.2 A4.3 A4.4 A4.5 A4.6 A4.7 A6.0 A9.7 A10.0 A10.1 A10.2A10.3 A10.4 A10.5 A10.6 A11.0 A11.1 A11.2 A11.3 A11.4 A20.1 A20.2 A20.3 A21.1 A21.2 A21.3 A22.0 A22.1英文报警信息1000 EMERGENCY STOP(A0.0)1001 SPINDLE ALARM(A0.1)1002 RINSE SCRAPS PUMP OFF(A0.2 X5.5)1003 COOLANT PUMP OFF(A0.3 X5.4)2004 AIR PRESSURE LOW(A0.4 X6.1)2005 LUBRICAT LOW POS.(A0.5 X9.7)2006 LUBRICATE NOT ON(A0.6 X5.3)1007 HYDRAULIC PUMP ALARM(A0.7 X6.0)2010 CHIP CONVEYOR ALARM(A1.0 X3.1)1011 T-CODE ERROR(A1.1)1012 MAG COUNT ALARM(A1.2 X3.4)1013 TOOL CLAMP/UNCLAMP ERROR(A1.3 X8.2/X8.3)1014 ATC ALARM(A1.4)2015 TOOL LIFE WILL OVER(A1.5)1016 TOOL LIFE ALARM(A1.6)1017 MAG-ROT OVERTIME(A1.7)1020 ARM-ROT OVERTIME(A2.0)1021 Z AXIS NO HOME ZERO(A2.1)1022 MAG POSITION ERRROR(A2.2 X3.3)1023 M06 OVERTIME(A2.3)1024 TOOL CUP UP ERROR(A2.4 X8.1)1025 TOOL CUP DOWN ERROR(A2.5 X8.0)2026 LUB.RPESSURE LOW ALA.(A2.6 X4.2)2027 SP NOT ST.(A2.7)2030 LOW-PRESSURE COOLING FLUID LOW POS(A3.0 X6.5)2031 NC BATTERY VOLTAGE LOW(A3.1)1032 SP FAN NOT ON(A3.2 X4.6)2033 AIR-CONDITION NOT ON(A3.3 X5.3)2034 WATER TANK LEVEL LOW POS(A3.4 X4.3)1035 SP CHANGE GEAR ALARM(X4.0 X4.1)1036 ZF COOLANT LEVEL ERROR(A3.6 X9.0 X9.1)1037 OIL MIST CLEANER NOT ON(A3.7 X9.2)1040 COOLANT FROM SP PUMP OFF(A4.0 X5.7)1041 UPGRADE PUMP OFF(A4.1 X5.6)2042 FILTER BAG ALARM(A4.2 X6.2)1043 OILCOOLANT ALARM(A4.3 X5.0/6.0)1044 TURN PLATE ERROR(A4.4 X5.1 5.2)1045 CHUCK CLAMP/UNCLAMP ALARM(A4.5)1046 CLOSE THE DOOR(A4.6 X8.5)1047 THE DOOR OPEN(A4.7 X8.5)2060 CTS PRESSURE ALM.(X6.5 A6.0)1097 SPINDLE NO ROTATIONED2000 1.PRESS <RESET> 2.CHANGE WOKE MODE TO EDIT 3.PRESS <F4> 2001 4.TAKE DOWN THE TOOL FROM ATC ARM2002 DEBUG CL/UNCL TOOL AT JOG MODE2003 IF ATC NOT RUN SMOOTH ,INFORM NEWAY2044 5.PRESS +4/-4 AT THE SAME TIME.2045 6.PRESS <F4>.2041 MACHINE IS REPAIRING2008 TOOL POT NOT DOWN(A11.0)2046 AXIS IS LOCKED(A11.1)2047 FEED OVERRIDE IS 0(A11.2)2048 MAG IN DEBUG STATE(A11.3)2049 Z NOT GO HOME(A11.4)1081 MACHINE IS LOCKED ENTER 1ST PASSWORD1082 MACHINE IS LOCKED ENTER 2ND PASSWORD1083 MACHINE IS LOCKED ENTER 3RD PASSWORD2011 MACHINE CAN WORK LESS THAN 8H ,TO OBTAIN THE 1ST PASSWORD FROM SUPPLIER 2012 MACHINE CAN WORK LESS THAN 8H ,TO OBTAIN THE 2ND PASSWORD FROM SUPPLIER 2013 MACHINE CAN WORK LESS THAN 8H ,TO OBTAIN THE 3RD PASSWORD FROM SUPPLIER 2020 ZF COOLANT LEVEL LOW(A22.0 X9.0)2021 ZF COOLANT LEVEL HIGH(A22.1 X9.1)中文报警信息(PMC)1000 @04BDF4BCB1CDA3D6B901@-X8.41001 @04D6F7D6E1B1A8BEAF01@-F45.01002 @04B3E5D0BCB5E7BBFACEB4CDA8B5E701@-QF4/KM61003 @04C0E4C8B4B5E7BBFACEB4CDA8B5E701@-QF3/KM52004 @04C6F8D4B4D1B9C1A6B5CD01@-X5.42005 @04C8F3BBACD2BACEBBB5CD01@-X9.72006 @04C8F3BBACB5E7BBFACEB4CDA8B5E701@-QF131007 @04D2BAD1B9D5BECEB4CDA8B5E701@-QF8/KM112010 @04C5C5D0BCB5E7BBFAB6C2C8FBB1A8BEAF01@-X3.41011 T@04B4FAC2EBB4EDCEF301@1012 @04B5B6BFE2BCC6CAFDB4EDCEF301@-X3.41013 @04D6F7D6E1CBC9C0ADB5B6B1A8BEAF01@-X8.2/X8.31014 @04BBFAD0B5CAD6B2BBD4DAD4ADB5E3CEBBD6C301@-A1.42015 @04B5B6BEDFCAD9C3FCBCB4BDABB5BDB4EF01@-A1.51016 @04B5B6BEDFCAD9C3FCBDE1CAF801@-A1.61017 @04B5B6BFE2D0FDD7AAB3ACCAB101@-A1.71020 @04BBFAD0B5CAD6D0FDD7AAB3ACCAB101@-A2.01021 Z@04D6E1CEB4BBD8B5DAB6FEB2CEBFBCB5E301@1022 @04B5B6BFE2B6A8CEBBB4EDCEF301@-X3.31023 @04BBBBB5B6B3ACCAB101@-A2.31024 @04BBD8B5B6B4EDCEF301@-X8.11025 @04B5B9B5B6B4EDCEF301@-X8.02026 @04C8F3BBACD1B9C1A6B5CD01@-X4.22027 @04D6F7D6E1CEB4C6F4B6AF01@2030 @04B8B1CBAECFE4D2BACEBBB5CD01@-X6.52031 @04B5E7B3D8B5E7D1B9B5CD01@1032 @04D6F7D6E1B7E7C9C8CEBBCDA8B5E701@-QF102033 @04BFD5B5F7CEB4CDA8B5E701@-QF141034 @04D6F7CBAECFE4D2BACEBBB5CD01@-X4.31035 @04D6F7D6E1BBBBB5B5B4EDCEF301@-X4.0/X4.11036 @045A46C1F7C1BFB9CAD5CF01@-X9.0/X9.11037 @04D3CDCEEDB7D6C0EBC6F7CEB4CDA8B5E701@-QF15/KM171040 @04D6D0D0C4B3F6CBAEB5E7BBFACEB4CDA8B5E701@-QF6/KM91041 @04CCE1C9FDB1C3B5E7BBFACEB4CDA8B5E701@-QF7/KM102042 @04B9FDC2CBD6BDB4FCB6C2C8FB01@-X6.21043 @04D3CDC0E4BBFAB9CAD5CF01@-QF9/X5.01044 @0441D6E1BCD0BDF4B7C5CBC9B4EDCEF301@-X5.1/X5.21045 @04BFA8C5CCBCD0BDF4B7C5CBC9B4EDCEF301@-A4.51046 @04C7EBB9D8C3C501@-X8.51047 @04C3C5B4F2BFAA01@-X8.52060 @04D6D0D0C4B3F6CBAED1B9C1A6B5CD01@-X6.51097 @04D6F7D6E1C3BBD3D0D0FDD7AA01@-A9.72000 1、@04B0B4CFC2B8B4CEBBB0B4BCFC01@2、@04C7D0BBBBB5BDB1E0BCADB7BDCABD01@3、2001 4、@04B4D3BBFAD0B5CAD6C9CFC8A1CFC2B5B6BEDF01@2002 4、@04B4D3BBFAD0B5CAD6C9CFC8A1CFC2B5B6BEDF01@2003 ATC@04C6B5B7B1B1A8BEAFA3ACC7EBCDA8D6AAB9ABCBBE01@2044 @04CDACCAB1B0B4CFC201@+4/-4@04B0B4BCFC01@2045 @04B0B4CFC201@F4@04B0B4BCFC01@2041 @04BBFAB4B2D5FDD4DACEACD0DED6D001@2008 @04B5B6CCD7CEB4B5B9CFC201@-A11.02046 @04D6E1BBA5CBF8BDD3CDA801@-A11.1@04BDF8B8F8B1B6C2CACEAA01@%0-A11.22048 @04B5B6BFE2B5F7CAD4D7B4CCAC01@-A11.32049 Z@04D6E1CEB4B7B5BBD8D4ADB5E301@-A11.41081 @04BBFAB4B2CBF8D4DAA3ACCAE4C8EBB5DAD2BBB8F6D4C2C3DCC2EB01@ 1082 @04BBFAB4B2CBF8D4DAA3ACCAE4C8EBB5DAB6FEB8F6D4C2C3DCC2EB01@ 1083 @04BBFAB4B2CBF8D4DAA3ACCAE4C8EBB5DAC8FDB8F6D4C2C3DCC2EB01@ 2020 @045A46C1F7C1BFB5CD01@-X9.02021 @045A46C1F7C1BFB8DF01@-X9.1中文汉字紧急停止-X8.4主轴报警-F45.0冲屑电机未通电-QF4冷却电机未通电-QF3气源压力低-X5.4润滑液位低-X9.7润滑电机未通电-QF13液压站未通电-QF8排屑电机堵塞报警-X3.4T 代码错误刀库计数错误-X3.4主轴松拉刀报警-X8.2/X8.3机械手不在原点位置-A1.4刀具寿命即将到达-A1.5刀具寿命结束-A1.6刀库旋转超时-A1.7机械手旋转超时-A2.0Z轴未回第二参考点刀库定位错误-X3.3换刀超时-A2.3回刀错误-X8.1倒刀错误-X8.0润滑压力低-X4.2主轴未启动副水箱液位低-X6.5电池电压低主轴风扇位通电-QF10空调未通电-QF14主水箱液位低-X4.3主轴换档错误-X4.0/X4.1ZF流量故障-X9.0//X9.1油雾分离器未通电-QF15中心出水电机未通电-QF6提升泵电机未通电-QF7过滤纸袋堵塞-X6.2油冷机故障-QF9/X5.0A轴夹紧放松错误-X5.1/X5.2卡盘夹紧放松错误-A4.5请关门-X8.5门打开-X8.5中心出水压力低-X6.5主轴没有旋转1、按下复位按键2、切换到编辑方式3、按下F4按键4、从机械手上取下刀具手动方式下调试松拉刀动作ATC频繁报警,请通知公司同时按下+4/-4按键按下F4按键机床正在维修中刀套未倒下轴互锁接通进给倍率为0%刀库调试状态Z轴未返回原点机床锁在,输入第一个月密码机床锁在,输入第二个月密码机床锁在,输入第三个月密码机床工作少于8小时,从供应商获取第一个月密码机床工作少于8小时,从供应商获取第二个月密码机床工作少于8小时,从供应商获取第三个月密码ZF流量低-X9.0ZF流量高-X9.1。

发那科FANUC机器人报警处理(中文)3 按下F2[RELEASE(释放)]以释放超行程轴。

4 按住shift键,按下警告清除按钮。

5按住shift键,按下微动键把工具沿超行程轴线微动到可移动的有效范围内。

从损坏的腕部警告复原(SERVO-006)步骤: 1 按住SHIFT键,然后按下RESET键。

2 按住SHIFT键的同时,按下正确的微动键以把机器人移到其能被维修的位置。

从一个脉冲不匹配警告,BZAL警告,RCAL警告复原(SRVO-038,062,063)步骤:1 按下MENUS键,显示界面菜单。

2 按下“0--NEXT---”,然后在下个页面选择“ 6 SYSTEM”。

按下F1“[TYPE(类型)]”,然后选择“Variables”。

显示系统变量界面。

3 把系统变量$MCR.$SPC_RESET设为TRUE。

(这个系统变量很快会被自动设回FALSE)。

4 按下RESET键以释放警告。

提示:即使检测到一个脉冲计数不匹配警告,该控制数据可能会被纠正。

如果该控制数据被纠正,控制不需要被执行。

只要把$DMR_GRP.$MASTER_DONE设为真,然后在位置界面上选择 6 MASTER/CAL。

从其他警告复原步骤:1 清除该警告的引发源。

例如,纠正程序。

2 按下RESET键来重置该警告。

然后,教导盒界面上的警告信息消失。

ALARM LED (发光二极管)灯灭。

C.2 警告代码SRVO 错误代码(ID=11)SRVO-001SERVO Operator panel E--stop可能原因:操作面板上的紧急停止按钮被按下。

解决方法:顺时针拧动紧急停止按钮以松开此按钮,并按下RESET(重启)。

SRVO-002 SERVO T each pendant E--stop 可能原因:教导盒上的紧急停止按钮被按下。

c-671解决方法:松开教导盒上的紧急停止按钮。

SRVO-003 SERVO Deadman switch released可能原因:当开启教导盒时没有按下特殊手持式开关按钮。