艾里逊自动变速箱安装手册_MD

- 格式:pdf

- 大小:2.41 MB

- 文档页数:77

概述:品牌公司深知质量的重要性,正因为如此,艾里逊(Allison)公司才会选中 Chelsea 加入其工程师团队,专门为 Allison World 变速箱研发取力器。

灵活通用的 859 系列是一种可换档式取力器,比 10 螺栓取力器的密封更严,比 8 螺栓取力器的最大扭矩更大。

对于消防和救援、垃圾和油田勘探等需要更大扭矩的应用,859 系列是理想的选择。

该系列提供五种速比、多种输出类型,并配备旋转式换档油阀选件,包括 Chelsea 有名的 360° 旋转法兰。

• 垃圾• 石油勘探• 消防与救援Chelsea ®859 系列适合艾里逊(Allison)3000/4000 变速箱联系信息:产品特性和优势:• 七 (7) 种速比和 六 (6) 种输出 选择• 可配备电子超速控制装置, 防止从动设备超速• 无需设置间隙• 两年保修Parker Hannifin Corporation Chelsea Products Division Hong Kong Ltd 8/F, Kin Yip Plaza 9 Cheung Yee StreetCheung Sha Wan, Hong Kong 电话:852-2428-8008 传真:852-2480-4256**************************www.parker/© 2010年Parker Hannifin Corporation版权所有型号编码规则基本型号859 (重型液压换档)安装类型X = 标准安装(10 螺栓)速比G = 24/43 J = 26/41 M = 28/39 R = 31/36 S = 32/34 T = 34/36 W = 37/30输入齿轮代码FJ = 艾里逊(Allison)KV = 卡特彼勒(Caterpillar)润滑P = 压力润滑R = 阀盖旋转 120°输出代码XS = “C”类 2 和 4 螺栓带泵 XV = 1410 系列法兰 XY = 泵 Mt. Meiller 泵 AB = Din 120 法兰 AC = Din 100 法兰AZ = S.A.E. “B”类 2 和 4 螺栓 BA = “XV”带制动器 BB = “AB”带制动器BC = “AC”带制动器装配方式5 = 齿轮在前、轴在后、凸部位于右上侧、 凸部位于左下侧换档机构类型B = 12 V 液压阀 D = 24 V 液压阀 G = 12 V 远置阀 H = 24 V 远置阀K = 12 V 液压式带电子超速控制 L = 24 V 液压式带电子超速控制M = 12 伏无安装工具包 329024-12X(仅限欧洲) N = 24 伏无安装工具包 329024-24X(仅限欧洲)859X G FJ P-B5 XV859*G 859*J 859*M 859*R 859*S859*T 859*W 标准输出轴规格1-1/2” 花键配 1410 法兰 间歇额定扭矩(磅英尺) 575 525 490 415 385 350 285 间歇额定扭矩(牛顿米) 780 712 664 563 522 475 386 间歇运转的额定马力输出轴转速为 500 R.P.M. 时(马力) 55 50 47 40 37 33 27 输出轴转速为 1000 R.P.M. 时(马力) 109 100 93 79 73 67 54 输出轴转速为 500 R.P.M. 时(千瓦) 41 37 35 30 27 25 20 输出轴转速为 1000 R.P.M. 时(千瓦) 82 75 70 59555041近似重量:66 磅 [30千克]手册 HY25-0094-B1/US 2010年5月 HY25-0094-B1/CN 2010年9月。

关于艾里逊变速箱关于艾里逊变速箱艾里逊变速箱(Allison Transmission)是世界上最大的商用车辆自动变速器制造商之一。

它的历史可以追溯到1915年,当时詹姆斯·艾里逊(James Allison)和史密斯·考沃斯基(Smith Covington)合作创建了艾里逊工程公司(Allison Engineering Company)。

艾里逊变速箱以其卓越的性能和可靠性闻名于世,被广泛应用于卡车、公共汽车、军用车辆等各类商用车辆中。

一、艾里逊变速箱的原理和特点1. 原理:艾里逊变速箱采用了液力传动原理,主要由液力变矩器和一系列行星齿轮机构组成。

液力变矩器是艾里逊变速箱的核心部件,它通过调整液力传动的效率来实现变速。

行星齿轮机构则负责将动力从输入轴传递到输出轴,使车辆能够平稳、高效地行驶。

2. 特点:(1)平顺的换挡:艾里逊变速箱采用了液力传动原理,能够实现平顺的换挡,减少了车辆在换挡过程中的震动和冲击,提升了乘坐舒适性。

(2)高效能的传动:艾里逊变速箱的液力变矩器可以根据车辆的需求自动调整传动比例,以实现最佳的动力输出。

这种自动调整的特性使得艾里逊变速箱具有较高的传动效率,能够提升车辆的燃油经济性和性能。

(3)可靠性强:艾里逊变速箱采用了高品质的材料和严格的制造工艺,确保了其在各种严苛工况下的可靠性。

艾里逊变速箱还具有自动保护功能,可以监测车辆的工作状态并自动调整传动模式,以防止过载和损坏。

二、艾里逊变速箱的应用领域艾里逊变速箱广泛应用于各类商用车辆中,包括卡车、公共汽车、军用车辆等。

其应用领域包括但不限于以下几个方面: 1. 物流运输:在物流运输行业中,艾里逊变速箱被广泛应用于重型卡车上。

它的平顺换挡和高效能的传动特性,使得卡车能够在长途运输中保持稳定和高效的运行,提升了物流运输的效率。

2. 公共交通:在公共汽车领域,艾里逊变速箱也是首选。

它的平顺换挡和大扭矩输出能力,使公共汽车能够在城市道路上平稳运行,减少乘客的不适感,提高了公共交通的质量和可靠性。

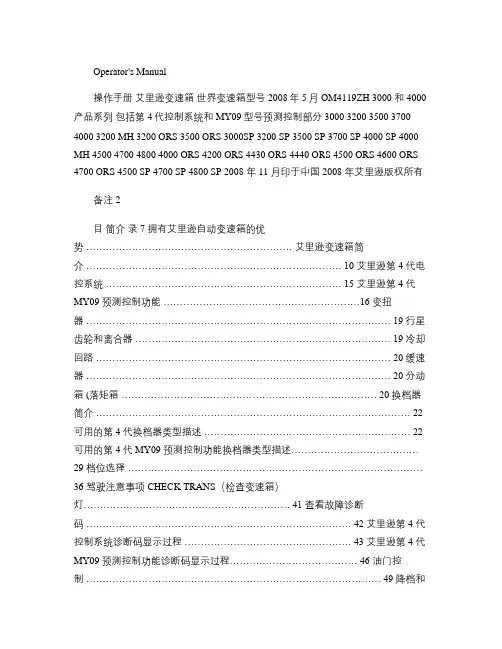

Operator's Manual操作手册艾里逊变速箱世界变速箱型号 2008年5月 OM4119ZH 3000 和 4000产品系列包括第4代控制系统和 MY09型号预测控制部分 3000 3200 3500 3700 4000 3200 MH 3200 ORS 3500 ORS 3000SP 3200 SP 3500 SP 3700 SP 4000 SP 4000 MH 4500 4700 4800 4000 ORS 4200 ORS 4430 ORS 4440 ORS 4500 ORS 4600 ORS 4700 ORS 4500 SP 4700 SP 4800 SP 2008 年 11 月印于中国 2008 年艾里逊版权所有备注 2目简介录 7 拥有艾里逊自动变速箱的优势............................................................... 艾里逊变速箱简介.............................................................................. 10 艾里逊第 4 代电控系统........................................................................ 15 艾里逊第 4 代MY09 预测控制功能............................................................16 变扭器............................................................................................. 19 行星齿轮和离合器.............................................................................. 19 冷却回路.......................................................................................... 20 缓速器............................................................................................. 20 分动箱 (落矩箱.............................................................................. 20 换档器简介 (22)可用的第 4 代换档器类型描述 (22)可用的第 4 代 MY09 预测控制功能换档器类型描述…………………………………29 档位选择………………………………………………………………………………36 驾驶注意事项 CHECK TRANS(检查变速箱)灯……………………………………………………… 41 查看故障诊断码……………………………………………………………………… 42 艾里逊第 4 代控制系统诊断码显示过程…………………………………………… 43 艾里逊第 4 代MY09 预测控制功能诊断码显示过程………………………………… 46 油门控制……………………………………………………………………………… 49 降档和换档操作的抑制功能………………………………………………………… 49 利用发动机降低车速………………………………………………………………… 50 使用液力缓速器……………………………………………………………………… 51 档位预选择…………………………………………………………………………… 55 冷天启动……………………………………………………………………………… 55 冰雪路面行驶………………………………………………………………………… 56 陷在泥泞、沙地或雪地中如何驶出………………………………………………… 56 变速箱油温过高的情况处理………………………………………………………… 57 驻车制动……………………………………………………………………………… 58 拖车或推车注意事项………………………………………………………………… 58 3关闭发动机的注意事项……………………………………………………………… 59 优先换档/辅助换挡模式…………………………………………………………… 59 巡航控制操作………………………………………………………………………… 59 陡峭下坡操作(后部卸货的搅拌车………………………………………………… 60 动力输出操作由发动机驱动的取力器(PTO ………………………………………………………61 保养与维护定期检查.......................................................................................... 62 应预防的主要问题.............................................................................. 62 保持正确油液液位的重要性.................................................................. 62 用换挡器检查艾里逊第 4 代停用 MY09 预测控制功能的和七速变速箱的油位 (63)MY09 预测控制功能……………………………………………………………………67 用换挡器检查艾里逊第 4 代 MY09 启用预测控制功能的变速箱油位……………… 70 用诊断工具检查变速箱油位………………………………………………………… 76 人工检查变速箱油位的步骤………………………………………………………… 76 冷态检查……………………………………………………………………………… 78 热态检查……………………………………………………………………………… 79 推荐使用的自动变速箱油液及其粘度等级................................................ 80 保持油液清洁.................................................................................... 81 推荐的艾里逊第 4 代及停用 MY09 预测控制功能的变速箱油及内部滤芯更换周期 81 推荐的艾里逊第 4 代带 MY09 预测控制功能的变速箱油及内部滤芯更换周期...... 88 油液分析.......................................................................................... 90 重新加注变速箱油液........................................................................... 90 故障诊断故障诊断码....................................................................................... 91 客户服务车主支持 (93)维修资料 (95)艾里逊变速箱在世界各地的办事处 (96)4商标使用以下商标归所列公司所有:· Allison DOC™ 是 General Motors Corporation 的商标。

Fluid and FilteR Change ReCommendationsuse of the proper fluid and filters is the simplest thing that an owner can do to ensure the ongoing performance and reliability of allison automatic transmissions. allison transmission has designed extensive specification and testing programs to verify the quality of fluids. as a result, the specificfluid and filter change interval recommendations closely match today’s operating environments.local conditions, severity of operation or duty cycle may require more or less frequent fluid change intervals that differ from the information contained in the following charts. allison transmission recommends that customers use fluid analysis as the primary method for determining fluid change intervals. in the absence of a fluid analysis program, the fluid change intervals listed in the following charts should be used.if you have questions regarding fluid or filter change intervals, or models not listed in this brochure, additional information can be found at ; click service, then Fluids orFluid/Filter Change intervals. or, contact the allison technical assistance Center at 1-800-252-5283. Fluidsallison transmission recommends that customers use an allison approved tes 295 automatic transmission fluid to extend drain intervals and to enhance transmission performance and durability in all operating environments. Customers may continue to choose from a wide variety of allison approved fluids. effective January 1, 2007, general motors no longer licenses deXRon®-iii fluids. deXRon®-Vi fluids may be used in the 1000 and 2000 Product Families transmissions beginning with s/n 6310670488and 6320784373; and in the 3000 and 4000 Product Families transmissions beginning withs/n 6510717281 and 6610220990. deXRon®-Vi shall not be used in allison 500, 600 or 700series transmissions (at, mt, ht, ht/V/Clt products).schedule one tes 389 and deXRon®-Vi fluids will have the same fluid change intervals as thecurrent allison approved non-tes 295 fluid intervals.C4 fluids are no longer recommended in any commercial on-highway transmissions. a complete list of approved fluids can be found at ; click service, then Fluids.Fluid loss with FilteR Change onlywhen performing initial main Filter change or changing main and lube Filters at recommended intervals, approximate fluid loss for each filter is as follows:• 1000 and 2000 Product Families transmissionsControl main Filter = 1 pint (0.47 liters)• 3000 and 4000 Product Families transmissionsmain Filter = 2 quarts (1.9 liters)lube Filter = 8 quarts (7.6 liters)model yeaR ’09 PRognostiCsPrognostics make it even easier to control your maintenance costs while ensuring maximum performance of your allison transmission. starting with model year ‘09 production (serial numbers 6510822005, 6520099957, 6610257671, 6620007438), allison transmission has released fluid and filter Prognostics for 1000/2000/3000/4000 Product Families transmissions using allison approved tes 295 fluids. this new feature allows customers to maximize the life of the transmission fluid and filters. allison Prognostics must only be used with allison approved tes 295 fluids.the 1000/2000 Product Families transmissions require allison P/n 29539579 spin-on Control main Filter, and the 3000/4000 Product Families transmissions require allison high Capacity Filters to be used with Prognostics. 1000/2000/3000/4000 Product Families Prognostics may or may not be turned on in vehicles (oem/Customer option). this option requires the oem to wire/install the system and the customer to request this option to be turned on in their vehicle. Refer to the appropriate operator’s manual for methods of identifying if Prognostics are turned on.high CaPaCity FilteRshigh Capacity Filters for allison 3000/4000 Product Families transmissions were released into allison production July 2006, beginning with the following transmission serial numbers: 6510670912 (3000 series) 6610205144 (4000 series)high Capacity Filters allow extended filter change intervals when used with an allison approved tes 295 automatic transmission fluid.high Capacity Filters can be identified by P/n 29545777 or P/n 29545780 stamped into the filter end cap. Prior filters (non-high Capacity) for allison 3000/4000 Product Families transmissions can be identified by P/n 29538231 or P/n 29538232 stamped into the filter end cap.Beginning with s/n 6510670912 and s/n 6610205144, transmissions equipped with allison high Capacity Filters do not require an initial main Filter change at 5000 miles/8000 km/200 hours.extended fluid and filter change intervals are only allowed with an allison approved tes 295 automatic transmission fluid and allison high Capacity Filters. Filters must be changed at or before recommended intervals.when replacing gold series Filters with high Capacity Filters in transmissions containing 100% allison approved tes 295 automatic transmission fluid, high Capacity fluid and filter change intervals may be followed.For a list of current allison approved tes 295 automatic transmission fluids, go to ; click on service, then Fluids.3000/4000 Product Familieshigh Capacity Filter Kit2 inch Filter Kit P/n 295489874 inch Filter Kit P/n 29548988*deXRon®-Vi may only be used in units beginning with s/n 6310670488 and 6320784373.** l ess than 100% concentration of an allison approved tes 295 automatic transmission fluid is considered a mixture and should utilize non-tes 295 filter change intervals.***general Vocation: all vocations not classified as severe.****severe Vocation: 2000 mh, on/off highway, Refuse, City transit, shuttle transit.note: Change fluid and filters at or before the recommended mileage, months or hours have*deXRon®-Vi may only be used in units beginning with s/n 6510717281.** l ess than 100% concentration of an allison approved tes 295 automatic transmission fluid is considered a mixture and should utilize non-tes 295 filter change intervals.***general Vocation: all vocations not classified as severe and intercity Coach with duty cycle of less than or equal to one stop per mile.****severe Vocation: all Retarders, on/off highway, Refuse, transit and intercity Coach with duty cycle greater than one stop per mile.note: Change fluid and filters at or before the recommended mileage, months or hours have*deXRon®-Vi may only be used in units beginning with s/n 6610220990.** l ess than 100% concentration of an allison approved tes 295 automatic transmission fluid is considered a mixture and should utilize non-tes 295 filter change intervals.***general Vocation: all vocations not classified as severe and intercity Coach with duty cycle of less than or equal to one stop per mile. ****severe Vocation: all Retarders, on/off highway, Refuse, transit and intercity Coach with duty cycle greater than one stop per mile.note: Change fluid and filters at or before the recommended mileage, months or hours haveFilteRs and gasKet Kits with PaRts numBeRsFluid CaPaCity (aPPRoXimate)*add 2.8 liters (3 quarts) for transmissions with Pto.。

Operator's Manual操作手册艾里逊变速箱世界变速箱型号 2008年5月 OM4119ZH 3000 和 4000产品系列包括第4代控制系统和 MY09型号预测控制部分 3000 3200 3500 3700 4000 3200 MH 3200 ORS 3500 ORS 3000SP 3200 SP 3500 SP 3700 SP 4000 SP 4000 MH 4500 4700 4800 4000 ORS 4200 ORS 4430 ORS 4440 ORS 4500 ORS 4600 ORS 4700 ORS 4500 SP 4700 SP 4800 SP 2008 年 11 月印于中国 2008 年艾里逊版权所有备注 2目简介录 7 拥有艾里逊自动变速箱的优势............................................................... 艾里逊变速箱简介.............................................................................. 10 艾里逊第 4 代电控系统........................................................................ 15 艾里逊第 4 代MY09 预测控制功能............................................................16 变扭器............................................................................................. 19 行星齿轮和离合器.............................................................................. 19 冷却回路.......................................................................................... 20 缓速器............................................................................................. 20 分动箱 (落矩箱.............................................................................. 20 换档器简介 (22)可用的第 4 代换档器类型描述 (22)可用的第 4 代 MY09 预测控制功能换档器类型描述…………………………………29 档位选择………………………………………………………………………………36 驾驶注意事项 CHECK TRANS(检查变速箱)灯……………………………………………………… 41 查看故障诊断码……………………………………………………………………… 42 艾里逊第 4 代控制系统诊断码显示过程…………………………………………… 43 艾里逊第 4 代MY09 预测控制功能诊断码显示过程………………………………… 46 油门控制……………………………………………………………………………… 49 降档和换档操作的抑制功能………………………………………………………… 49 利用发动机降低车速………………………………………………………………… 50 使用液力缓速器……………………………………………………………………… 51 档位预选择…………………………………………………………………………… 55 冷天启动……………………………………………………………………………… 55 冰雪路面行驶………………………………………………………………………… 56 陷在泥泞、沙地或雪地中如何驶出………………………………………………… 56 变速箱油温过高的情况处理………………………………………………………… 57 驻车制动……………………………………………………………………………… 58 拖车或推车注意事项………………………………………………………………… 58 3关闭发动机的注意事项……………………………………………………………… 59 优先换档/辅助换挡模式…………………………………………………………… 59 巡航控制操作………………………………………………………………………… 59 陡峭下坡操作(后部卸货的搅拌车………………………………………………… 60 动力输出操作由发动机驱动的取力器(PTO ………………………………………………………61 保养与维护定期检查.......................................................................................... 62 应预防的主要问题.............................................................................. 62 保持正确油液液位的重要性.................................................................. 62 用换挡器检查艾里逊第 4 代停用 MY09 预测控制功能的和七速变速箱的油位 (63)MY09 预测控制功能……………………………………………………………………67 用换挡器检查艾里逊第 4 代 MY09 启用预测控制功能的变速箱油位……………… 70 用诊断工具检查变速箱油位………………………………………………………… 76 人工检查变速箱油位的步骤………………………………………………………… 76 冷态检查……………………………………………………………………………… 78 热态检查……………………………………………………………………………… 79 推荐使用的自动变速箱油液及其粘度等级................................................ 80 保持油液清洁.................................................................................... 81 推荐的艾里逊第 4 代及停用 MY09 预测控制功能的变速箱油及内部滤芯更换周期 81 推荐的艾里逊第 4 代带 MY09 预测控制功能的变速箱油及内部滤芯更换周期...... 88 油液分析.......................................................................................... 90 重新加注变速箱油液........................................................................... 90 故障诊断故障诊断码....................................................................................... 91 客户服务车主支持 (93)维修资料 (95)艾里逊变速箱在世界各地的办事处 (96)4商标使用以下商标归所列公司所有:· Allison DOC™ 是 General Motors Corporation 的商标。

I-Sync automated transmissionI-Sync is an automated gearbox offering the possibility of manualgearchanges, featuring 6 forward ratios with overdrive top. Using the lever behind the steering wheel, the driver chooses whether the gearchanges are to be automatic or manual. Manual changes up and down are also selected with this lever. There is no clutch pedal.This gearbox is designed for a maximum torque of 850 Nm. It is dimensioned for rigids in distribution operations and for gross combination weights of up to 24 tonnes.All the gears feature synchromesh and the gears are changed electro‑hydraulically.ATO8006140 kg9.8 litres850 Nm24 tonnesAutomated all-synchro gearbox616.583.602.121.391.000.786.06 SPECIFICATIONType designationWeight without oilOil-change volume oilMax. torqueMax. gross combination weightTypeNo. of forward ratiosNo. of reverse ratiosGear/ratio123456ReverseFEATURES AND BENEFITSAutomated gearchanging provides comfortable, safe and smooth operation.Choice - automatic or manual gearchanges.Robustly dimensioned design offering quiet operation and longservice life.Compact and lightweight design.FACT SHEETGearbox ATO8006ENG1(2) 2013-06-17 Version 01Smooth gearbox operationOperation of the gearbox takes place with the help of electro-hydraulics and requires very little force.All gearchange selection takes place with the lever to the rightbehind the steering wheel. By moving the lever towards the driver, it is possible to select automatic or manual gearchanges. In Manual mode,the driver changes up and down by moving the lever up or downrespectively. With the outer rotating ring, it is possible to lock first gear or to reverse. With the inner rotating ring, it is possible to choose between neutral and drive. A kickdown function is fitted as standard.Sturdily dimensioned design offering quiet operation and long service lifeAll the cogs in the gearbox are made of special case-hardened steel.All the gears apart from reverse are helical. This means that several teeth are in mesh with each other at any given time, resulting in quiet operation and high operating reliability.The gearbox’s service interval is every 360,000 km or once everythird year.Compact and lightweight designThe gearbox consists of a gearbox housing and a clutch housing made of aluminium. It weighs a total of just 140 kg. The compactgearbox housing is cast in two parts, which makes things easier in the event of major repairs.The gearbox’s design and its low total weight help give the truck its high productivity and low repair costs.Factory-prepared for installation of power take-offs.The gearbox is prepared for two different rear mounted power take-offs with pump and/or flange connection. Note! To eliminate possible gear shifting failures, rear engine power take-off usage is strictly limited to stand still operations only.FACT SHEETGearbox ATO8006Volvo Truck CorporationENG 2(2)2013-06-17 Version 01。