齿轮泵样本

- 格式:pdf

- 大小:43.08 MB

- 文档页数:38

NP- FluidTechnologysolution-微型磁力齿轮泵Specialist索 富您忠实的伙伴您忠实的伙伴上海索富实业有限公司成立于2010,是一家以市场需求为先导、技术创新为核心、坚持为客户提供优质产品和服务的微型磁力齿轮泵公司。

我们的目标是成为世界领先的微型泵设计和生产者。

公司目前在上海拥有研发和销售中心,在福建三明市拥有生产基地。

公司人员来自外企管理和技术团队以及国内技师团队,具有微型特种泵15年以上的技术和市场经验以及40年的产品生产和管理经验。

公司拥有特种材料应用、专业型线设计、高精度加工、一次注塑成型、精密装配到检测的全套自主技术,已经获得12项专利,包含4项发明专利。

公司适应市场需求,每年都有新产品推向市场,都有新技术得到开发和应用。

项目进入中国创新创业大赛全国总决赛并获得省级二等奖。

全系列产品获得欧盟CE认证。

多年来我们的产品行销国内外,在医疗设备、化工装置、工程机械、商用机械、实验室分析、柴油机尾气后处理(SCR)、润滑系统、植保无人机、工业雾化系统、冷却系统、燃料电池、锂电池生产等领域得到广泛应用。

产品的稳定、长寿命、高压性能达到甚至超过欧美同类进口产品,获得国内外客户的好评。

我们一直致力于以高度的专业性和贴近客户的服务为您提供最适合需求的完整解决方案。

您的需求就是我们的使命。

企业简介Company pro le 上海索富实业有限公司成立于2010,是一家以市场需求为先导、技术创新为核心、坚持为客户提供优质产品和服务的微型磁力齿轮泵公司。

我们的目标是成为世界领先的微型泵设计和生产者。

公司目前在上海拥有研发和销售中心,在福建三明市拥有生产基地。

公司人员来自外企管理和技术团队以及国内技师团队,具有微型特种泵15年以上的技术和市场经验以及40年的产品生产和管理经验。

公司拥有特种材料应用、专业型线设计、高精度加工、一次注塑成型、精密装配到检测的全套自主技术,已经获得12项专利,包含4项发明专利。

海特克齿轮泵样本(实用版)目录1.海特克齿轮泵样本概述2.海特克齿轮泵的特点3.海特克齿轮泵的应用领域4.海特克齿轮泵的维护与保养正文一、海特克齿轮泵样本概述海特克齿轮泵样本是一款详细介绍海特克齿轮泵的产品样本,其中包含了齿轮泵的结构、原理、性能参数、使用说明等方面的详细信息。

通过阅读这份样本,用户可以全面了解海特克齿轮泵的特点和优势,以便在实际应用中做出正确的选择。

二、海特克齿轮泵的特点1.高效节能:海特克齿轮泵采用高效率电机,降低了能耗,同时提高了工作效率。

2.结构紧凑:齿轮泵结构紧凑,体积小,便于安装和维护。

3.可靠性高:齿轮泵采用优质材料和精湛工艺制造,保证了产品的可靠性和长久使用寿命。

4.噪音低:齿轮泵在运行过程中噪音低,有利于改善工作环境。

5.适用范围广:齿轮泵可广泛应用于各种工业领域,如石油化工、冶金、船舶等。

三、海特克齿轮泵的应用领域1.石油化工:用于输送石油、润滑油等高粘度介质。

2.冶金:用于输送熔融金属及高温介质。

3.船舶:用于输送燃油、滑油等船舶专用介质。

4.机械制造:用于机床、液压设备等机械设备的润滑系统。

5.医药、食品行业:用于输送卫生要求较高的介质。

四、海特克齿轮泵的维护与保养1.定期检查:定期检查齿轮泵的运行状况,发现异常及时处理。

2.清洁保养:定期清理齿轮泵内部杂质,保证泵的正常运行。

3.润滑保养:定期给齿轮泵的轴承、齿轮等部件润滑,降低磨损。

4.存储:在停用期间,应将齿轮泵存放在干燥、通风的地方,避免受潮、腐蚀。

通过以上介绍,相信大家对海特克齿轮泵样本已经有了全面的了解。

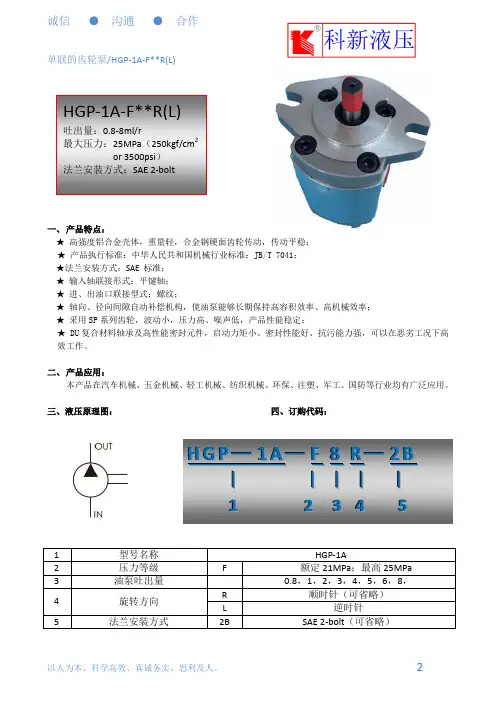

一、 产品特点:

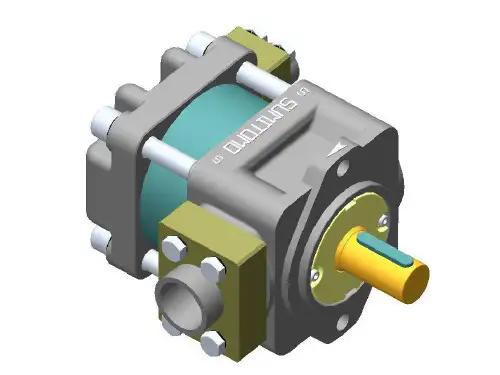

★ 高强度铝合金壳体,重量轻,合金钢硬面齿轮传动,传动平稳; ★ 产品执行标准:中华人民共和国机械行业标准:JB/T 7041; ★法兰安装方式:SAE 标准; ★ 输入轴联接形式:平键轴; ★ 进、出油口联接型式:螺纹;

★ 轴向、径向间隙自动补偿机构,使油泵能够长期保持高容积效率、高机械效率; ★ 采用SP 系列齿轮,波动小,压力高、噪声低,产品性能稳定;

★ DU 复合材料轴承及高性能密封元件,启动力矩小、密封性能好、抗污能力强,可以在恶劣工况下高效工作。

二、 产品应用:

本产品在汽车机械、五金机械、轻工机械、纺织机械、环保、注塑、军工、国防等行业均有广泛应用。

三、液压原理图: 四、订购代码:

五、规格参数:

六、尺寸参数(单位:mm)。

海特克齿轮泵样本1. 介绍海特克齿轮泵是一种常用的工业泵,被广泛应用于各个领域,如石油、化工、冶金等。

它以其高效、可靠的性能而闻名,是许多工业流体输送系统中不可或缺的一部分。

本文将深入探讨海特克齿轮泵样本的特点、应用领域以及使用注意事项。

2. 海特克齿轮泵样本的特点海特克齿轮泵样本具有以下几个显著特点:2.1 高效能海特克齿轮泵样本采用先进的设计和制造技术,具有高效的能量转换效率。

其优化的齿轮结构和精确的加工工艺确保了泵的高效运行,最大限度地减少了能量损失。

2.2 可靠性海特克齿轮泵样本采用高品质的材料和严格的质量控制标准,确保了泵的可靠性和长寿命。

其结构简单、零部件少,减少了故障的可能性,提高了泵的运行稳定性。

2.3 多样化的型号和规格海特克齿轮泵样本提供多种型号和规格,以满足不同用户的需求。

无论是小型的工业设备还是大型的工程项目,都可以找到适合的海特克齿轮泵样本。

3. 海特克齿轮泵样本的应用领域海特克齿轮泵样本广泛应用于以下几个领域:3.1 石油工业海特克齿轮泵样本在石油开采、输送和加工过程中发挥着重要作用。

它可以用于原油、石油产品和液化天然气的输送,确保石油工业的正常运行。

3.2 化工工业海特克齿轮泵样本在化工工业中被广泛使用,用于各种液体的输送和循环。

它可以处理各种腐蚀性、高温、高压的介质,确保化工工业的安全生产。

3.3 冶金工业海特克齿轮泵样本在冶金工业中的应用也非常广泛。

它可以用于铁矿石、煤炭等矿石的输送,以及冶炼过程中的循环和冷却。

3.4 其他领域海特克齿轮泵样本还可以在许多其他领域中发挥作用,如能源、水处理、建筑等。

它可以处理各种液体和介质,满足不同领域的需求。

4. 海特克齿轮泵样本的使用注意事项在使用海特克齿轮泵样本时,需要注意以下几点:4.1 泵的安装在安装海特克齿轮泵样本时,需要确保泵的基础稳固、水平。

泵的进出口管道应与泵的连接部位密封可靠,避免泄漏和松动。

4.2 泵的维护保养定期对海特克齿轮泵样本进行维护保养是确保其正常运行的关键。

海特克齿轮泵样本摘要:一、海特克齿轮泵样本简介1.海特克齿轮泵样本的背景2.海特克齿轮泵样本的内容和特点二、海特克齿轮泵的工作原理1.齿轮泵的基本结构2.齿轮泵的工作原理和性能参数三、海特克齿轮泵样本的主要性能参数1.流量2.压力3.功率4.效率四、海特克齿轮泵样本的应用领域1.工业领域2.汽车领域3.能源领域4.其他领域五、海特克齿轮泵样本的优缺点分析1.优点a.高效率b.高压力c.低噪音d.长寿命2.缺点a.结构复杂b.制造成本较高六、结论1.海特克齿轮泵样本的价值和意义2.对未来海特克齿轮泵发展的展望正文:海特克齿轮泵样本是一款具有代表性的齿轮泵产品,展示了海特克在齿轮泵领域的技术实力。

本文将简要介绍海特克齿轮泵样本的背景和内容特点,并重点阐述其工作原理、主要性能参数、应用领域以及优缺点分析。

首先,海特克齿轮泵样本的背景。

随着工业技术的发展,齿轮泵在各个领域中的应用越来越广泛。

海特克作为齿轮泵行业的佼佼者,一直致力于齿轮泵的研发和生产。

海特克齿轮泵样本不仅展示了该公司的产品实力,还为广大用户提供了参考和选择。

其次,海特克齿轮泵样本的内容和特点。

海特克齿轮泵样本详细介绍了齿轮泵的结构、工作原理、性能参数以及应用领域等方面的内容,具有很高的实用价值。

此外,样本还突出了齿轮泵的高效率、高压力、低噪音和长寿命等优点,充分展示了海特克齿轮泵的优势。

接下来,我们来了解海特克齿轮泵的工作原理。

齿轮泵是一种正向位移泵,通过两个相互啮合的齿轮产生压力差,实现液体的输送。

齿轮泵的结构主要由主动齿轮、从动齿轮、泵体和轴承等组成。

性能参数方面,齿轮泵的关键参数包括流量、压力、功率和效率等。

然后,我们来看海特克齿轮泵样本的主要性能参数。

流量是齿轮泵的基本性能参数,表示单位时间内泵的液体输送量。

压力是齿轮泵的工作性能参数,表示泵能产生的压力差。

功率是齿轮泵的动力性能参数,表示驱动泵所需的功率。

效率是齿轮泵的能量性能参数,表示泵的液体输送效率。

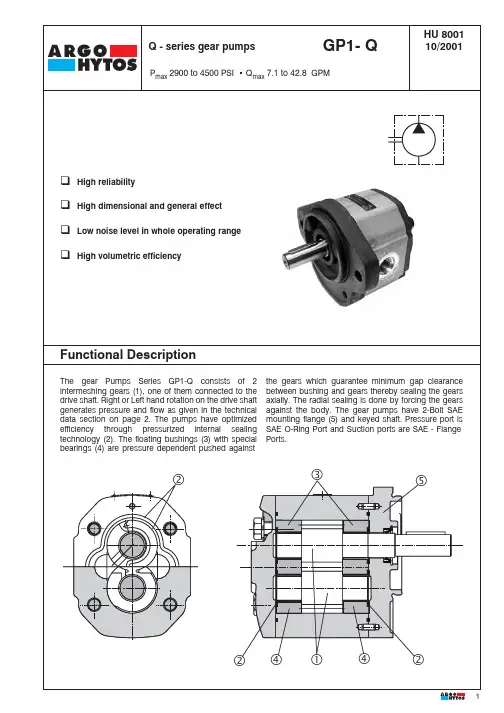

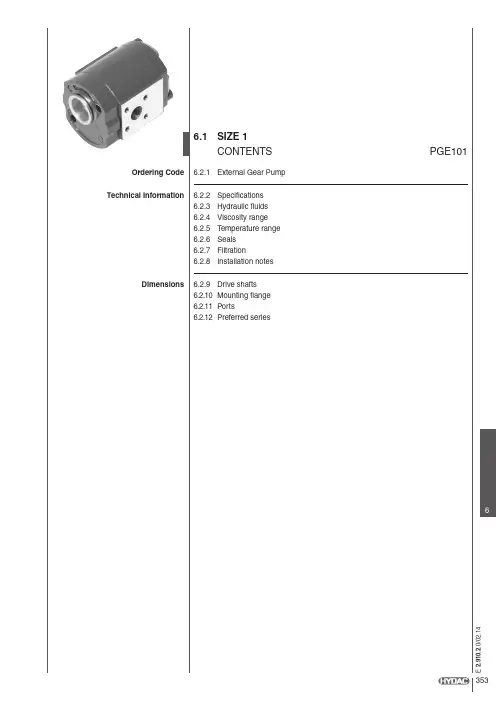

E 2.910.2.0/02.1466.1 SIZE 1CO N TE N TSPGE1016.2.1 External Gear Pump6.2.2 Specifications 6.2.3 Hydraulic fluids 6.2.4 Viscosity range 6.2.5 Temperature range 6.2.6 Seals 6.2.7 Filtration6.2.8 Installation notes 6.2.9 Drive shafts 6.2.10 Mounting flange 6.2.11 Ports6.2.12 Preferred series354ORDERING CODE6.2.1 External Gear PumpE 2.910.2.0/02.146TECHNICAL INFORMATION6.2.2 Specifications the performance will be reduced. T o find out whether a pump with threaded ports can be used in a high pressure application, please consult HYDAC.6.2.3 Hydraulic fluidsThe pump series is designed for use withHL Hydraulic oil (normal mineral oil) andHLP Hydraulic oils of the R&O type (Rust and Oxidation inhibitor) 6.2.4 Viscosity rangeNormal operating viscosity: 16 - 200 cSt (mm²/s)For other viscosity ranges, please contact HYDAC.6.2.5 Temperature range Ambient temperature range -22 to 55 °CFluid temperature range NBR-25 up to 85 °C Viton-15 up to 90 °C3566.2.6 SealsThe pump series is equipped with NBR seals.If special hydraulic fluids are used, the seal material must be changed if required. Please contact HYDAC.6.2.7 FiltrationFor maximum service life of the pump and system components, the system should be protected from contamination by effective filtration. Cleanliness class:21/18/15 to ISO 4406:1999orClass 9 to NAS 1638 or cleaner.At system pressures above 160 bar cleanliness class:19/17/14 to ISO 4406:1999orClass 8 to NAS 1638 is required.6.2.8 Installation notesA. MountingThe pump can be installedhorizontally or vertically with the shaft at the top. If the pump is installed on the tank or above the oil level, the distance between the pump inlet and the oil level should not exceed 1 metre.When installing a HYDAC pump always ensure that the fluid remains in the pump during stoppages. B. Suction pipeIf the pump is installed above the oil level, particular attention must be paid to the suction pressure. The cross-section of the suction pipe must be equal to or larger than the cross-section of the pump port. The suction pressure must be kept within the values specified.Minimum suction pressure: 0.8 bar abs.Maximum suction pressure: 2.2 bar abs.C. DriveUse a flexible coupling whenever possible. There must not be any radial or axial forces on the pump shaft. The maximum misalignment of the shafts is 0.2 mm and the angular deviation must be less than 0.2°.Drive shafts with tang are for direct mounting onto an electric motor or a gearbox. The driver for the tang is not included.For indirect drives (with gear, chain or belt drives) please consult Hydac.E 2.910.2.0/02.146DIMENSIONS6.2.9 Drive shafts6.2.10 Mounting flange358E 2.910.2.0/02.1466.2.12 Preferred series360E 2.910.2.0/02.14E 2.910.2.0/02.146362E 2.910.2.0/02.14E 2.910.2.0/02.146364E 2.910.2.0/02.14。

、、CB-B系列齿轮泵BB-B系列摆线油泵BB-B#Y摆线油泵HY01(CBJ)型齿轮油泵DCB-B160~500低噪音大流量泵DCB-B600~1000低噪音大流量泵(圆形)DCB-B600~1000低噪音大流量泵(椭圆形)CB-B双联齿轮泵CB-0.8油泵电机装置CB-BJZ齿轮泵电机组(卧式)BB-BJZ摆线齿轮泵电机组(立卧式)LBZ立式齿轮泵电机装置SNBY双向润滑油泵CB-FA(Fc)型高压齿轮泵KCB-5-32300510~1.510m /s OUTLINEKCB type gear oil transferring pumps are applicable to transfer various kind of oil like crude oil, diesel, lubricating oil. If equipped with copper gears they can transfer low flash point liquid like gasoline and benzene and soon on. Temperature of medium is not over 70. If for high temperature resistant pump, only change material to high temperature resistant typematerial.for this kind of pump, the temperature can`t be over-5-32300, viscosity should be 510~1.510m /s. L ubricatingoil, heavy oil, light oil for industry purpose, edible oil whichare free of solid and fibre, no corrosion. They are applicablein bulk plants, wharf, water crafts, factories, farmers and minesand so on.01WORKING PRINCIPLE() A B (A)(B)3Rated flow is 12m /h (200L/min)pump with relief valve (200L/min)MODEL MEANINGA pair of reverse gears are fitted in this type of pump,one is drive, the other is passive, depend on mesh between thetwo gears, the whole operating chamber is divided into twoindependent parts.As right drawing,A is suction chamber, Bis discharge chamber.When pump runs, drive gear lead thepassive gear rotate, when gear work from mesh to depart, apartial vacuum will occure at suction side (A), the liquid issucked in the sucked liquid is fill each gear valley and lead tooutlet side (B), when gear mesh, the liquid is squeezed out andbecome high pressure liquid, then drained from exhaust port.STRUCTURAL AND FEATURES(1)(2)(3)KCB-300~960KCB-18.3~83.3(4)(5)(1)(2)(3)(4)021. Structure(1)This type of pumps are horizontal reverse pump, whichis composed of casing, gear, bearing seat, relief valve,bearingand sealing device and so on.(2) Casing and bearing seat are made of cast iron gearis made of superior carbon steel, if customers require, it canalso be made of copper and stainless steel.(3)There is a packing gland in the bearing seat,for axialseal purpose. KCB-300~960 type pumps adopt mechanical sealdevice, bearing is single row radial ball bearing. KCB-18.3~83.3type of pumps are composed of three oil-proof rubber seals andmiddlelined retainer, adjust two nuts in the gland to control seal.Copper beryllium powder with oil bearing.Additionally,thisseries of pumps can be fitted with packing gland, features ofgood sealing, high & low temperature resistant, steady chemicalnature and the packing is supple graphite with self lubricatingproperty.(4) In the pump there is a relief valve,when failures occurto the pump or exhaust pipeline, or completely close the dis-charge valve by mistake to produce high pressure or high pr-essure impact, relief valve will be opened automatically,tospoil partial or all high pressure liquid return to low pressurechamber, thus it keeps safety and protect pumps and pipelines.(5) Directly connect with drive motor with flexible coupler,and installed on a public cast iron base2. Features(1) This type of pump is in smart and impact structure,convenient operation and maintenance.(2) This series of pump features of good self-priming,soit is not necessary to pour lubricant for ordinary work.(3) The lubrication of this type of pumps are automaticallycompleted by transferring liquid, so no lubricant will be pouredfor ordinary work.(4) Transmit power with flexible coupler can compensatelittle deviation from installation. The coupler can be in bufferaction when pump is impacted by inevitable pressure surge.KCB(2CY) TYPE PUMP PERFORMANCE TABLE2CY TYPE PUMP PERFORMANCE TABLE032CY TYPE PUMP INSTALLATION DIMENSION DARWING T ABLE040506EASY-WORN P ARTS LISTITEMS SHOULD BE NOTED1 234()56()7 1.Check whether the pumps were damaged during tran-sportation, such as whether the motor was dam ped, anti-d ustcover of inlet and outlet damaged or not, so that the dirty enterthe pump chamber and so on.2.Clean inner wall of pipes with pure water or steambefore installation. When install the pipelines try to avoid weightbearing by pump in ca se of influence of precision of pumps.There should be no air or liquid leakage occur at the joints,or otherwise, there will be no liquid sucked.3. To avoid impurities like particles entering, a metal st-rainer should be fitted at the inlet.4.Check bolts and nuts of pump whether firm or not ,driving shaft whether sensitive or not, the valve of inlet and outlet pipeline open or not, the direction of rotation whether meet requirements or not (view motor from pump end, rotating direction is anti-clockwise)5.Note that pressure of pump and read of vacuum gauge should within specification of pump.6.Pay attention to operation of gland box,if leakage occur, tighten gland according to the condition.(can`t tighten too much to avoid fast wearing of seal ring and acute heat)7.If there is abnormal noise or too high temperature riseduring operation of pump, stop pump, dismantleand check.FAILURES CAUSES AND TROUBLESHOOTING8KCB-18.3KCB-33.31.7MPa KCB-55KCB-83.3KCB-300KCB-483.30.45MPa 9078.Generally, relief valve should not be adjusted freely, if do, alignments should be made. Pressure of valve-close should be 1.7MPa for KCB-18.3 type. KCB-33.3 type, 0.45 Mpa for KCB-55 type, KCB-83.3 type, KCB-300 type. For KCB-200 and three type of pumps, the pressure should be 0.45MPa, 0.8MPa, 1.4MPa separately.9.When stop,the power should be cut off,then close valve at inlet and outlet of pipeline.08•••••••••••••19。

齿轮泵零件图发展的思路和开发重点。

三是提出东北地区能源结构调整方案、筹划东北地区“十一五”实施的重大能源项目布局,并研究东北地区能源发展相关政策和配套措施。

东北电网有限公司副总经理王广辉说,目前东北电网覆盖面积124万平方公里,供电服务人口1.15亿,从本网看,一次能源主要分布在东北部和西部,负荷主要分布在中部和南部。

因此,从“一盘棋”的角度规划东北地区的能源发展方向尤为重要。

节能:重中之重的主题东北地区能源资源丰富,同时能源消耗也非常大。

辽宁省发展改革委副主任李国运说,辽宁“十一五”期间将实施“节能优先”战略,走新型工业化道路。

到2010年,全省万元生产总值综合能耗将由目前的1.83吨标准煤下降到1.46吨。

鉴于东北地区特殊的气候条件,辽宁省鼓励发展热电联产项目,提高资源利用效率,改善城市的生态环境。

“十一五”期间,全省计划新增集中供热面积一亿平方米。

2CY系列齿轮润滑油泵产品概述:适用于输送不含固体颗粒和纤维,无腐蚀性,温度不高于80℃,粘度为5×10-6~1.5×10-3m2/s(5-1500cSt)的润滑油或性质类似润滑油的其他液体以及用于液压转动系统。

2CY齿轮泵作为另一个主要用途:在沥青搅拌厂用于重油喷射泵,已配置了大批的沥青搅拌厂,得到用户普遍好评。

应用范围:在输油系统中可用作传输,增压泵;在燃油系统中可用作输送、加压、喷射的燃油泵;在液压传动系统中可用作提供液压动力的液压泵;在一切工业领域中,均可作润滑油泵用;结构特点此系列齿轮泵主要有齿轮、轴、泵体、泵盖、轴承套、轴端密封等组成。

齿轮经氮化处理有较高的硬度和耐磨性。

与轴一同安装在可更换的轴套内运转。

泵内全部零件的润滑均在泵工作时利用输送介质而自动达到。

泵内四个轴承套在泵内浮动安装,随工作压力大小自动调整端面间隙,因此泵的压力稳定,输出流量脉动小,溶积效率高。

从主轴外伸端向泵看,为顺时针旋转。

高压齿轮泵,2CY齿轮泵,缷油泵,输油泵,原油泵,船用齿轮泵等。

、、CB-B系列齿轮泵BB-B系列摆线油泵BB-B#Y摆线油泵HY01(CBJ)型齿轮油泵DCB-B160~500低噪音大流量泵DCB-B600~1000低噪音大流量泵(圆形)DCB-B600~1000低噪音大流量泵(椭圆形)CB-B双联齿轮泵CB-0.8油泵电机装置CB-BJZ齿轮泵电机组(卧式)BB-BJZ摆线齿轮泵电机组(立卧式)LBZ立式齿轮泵电机装置SNBY双向润滑油泵CB-FA(Fc)型高压齿轮泵KCB-5-32300510~1.510m /s OUTLINEKCB type gear oil transferring pumps are applicable to transfer various kind of oil like crude oil, diesel, lubricating oil. If equipped with copper gears they can transfer low flash point liquid like gasoline and benzene and soon on. Temperature of medium is not over 70. If for high temperature resistant pump, only change material to high temperature resistant typematerial.for this kind of pump, the temperature can`t be over-5-32300, viscosity should be 510~1.510m /s. L ubricatingoil, heavy oil, light oil for industry purpose, edible oil whichare free of solid and fibre, no corrosion. They are applicablein bulk plants, wharf, water crafts, factories, farmers and minesand so on.01WORKING PRINCIPLE() A B (A)(B)3Rated flow is 12m /h (200L/min)pump with relief valve (200L/min)MODEL MEANINGA pair of reverse gears are fitted in this type of pump,one is drive, the other is passive, depend on mesh between thetwo gears, the whole operating chamber is divided into twoindependent parts.As right drawing,A is suction chamber, Bis discharge chamber.When pump runs, drive gear lead thepassive gear rotate, when gear work from mesh to depart, apartial vacuum will occure at suction side (A), the liquid issucked in the sucked liquid is fill each gear valley and lead tooutlet side (B), when gear mesh, the liquid is squeezed out andbecome high pressure liquid, then drained from exhaust port.STRUCTURAL AND FEATURES(1)(2)(3)KCB-300~960KCB-18.3~83.3(4)(5)(1)(2)(3)(4)021. Structure(1)This type of pumps are horizontal reverse pump, whichis composed of casing, gear, bearing seat, relief valve,bearingand sealing device and so on.(2) Casing and bearing seat are made of cast iron gearis made of superior carbon steel, if customers require, it canalso be made of copper and stainless steel.(3)There is a packing gland in the bearing seat,for axialseal purpose. KCB-300~960 type pumps adopt mechanical sealdevice, bearing is single row radial ball bearing. KCB-18.3~83.3type of pumps are composed of three oil-proof rubber seals andmiddlelined retainer, adjust two nuts in the gland to control seal.Copper beryllium powder with oil bearing.Additionally,thisseries of pumps can be fitted with packing gland, features ofgood sealing, high & low temperature resistant, steady chemicalnature and the packing is supple graphite with self lubricatingproperty.(4) In the pump there is a relief valve,when failures occurto the pump or exhaust pipeline, or completely close the dis-charge valve by mistake to produce high pressure or high pr-essure impact, relief valve will be opened automatically,tospoil partial or all high pressure liquid return to low pressurechamber, thus it keeps safety and protect pumps and pipelines.(5) Directly connect with drive motor with flexible coupler,and installed on a public cast iron base2. Features(1) This type of pump is in smart and impact structure,convenient operation and maintenance.(2) This series of pump features of good self-priming,soit is not necessary to pour lubricant for ordinary work.(3) The lubrication of this type of pumps are automaticallycompleted by transferring liquid, so no lubricant will be pouredfor ordinary work.(4) Transmit power with flexible coupler can compensatelittle deviation from installation. The coupler can be in bufferaction when pump is impacted by inevitable pressure surge.KCB(2CY) TYPE PUMP PERFORMANCE TABLE2CY TYPE PUMP PERFORMANCE TABLE032CY TYPE PUMP INSTALLATION DIMENSION DARWING T ABLE040506EASY-WORN P ARTS LISTITEMS SHOULD BE NOTED1 234()56()7 1.Check whether the pumps were damaged during tran-sportation, such as whether the motor was dam ped, anti-d ustcover of inlet and outlet damaged or not, so that the dirty enterthe pump chamber and so on.2.Clean inner wall of pipes with pure water or steambefore installation. When install the pipelines try to avoid weightbearing by pump in ca se of influence of precision of pumps.There should be no air or liquid leakage occur at the joints,or otherwise, there will be no liquid sucked.3. To avoid impurities like particles entering, a metal st-rainer should be fitted at the inlet.4.Check bolts and nuts of pump whether firm or not ,driving shaft whether sensitive or not, the valve of inlet and outlet pipeline open or not, the direction of rotation whether meet requirements or not (view motor from pump end, rotating direction is anti-clockwise)5.Note that pressure of pump and read of vacuum gauge should within specification of pump.6.Pay attention to operation of gland box,if leakage occur, tighten gland according to the condition.(can`t tighten too much to avoid fast wearing of seal ring and acute heat)7.If there is abnormal noise or too high temperature riseduring operation of pump, stop pump, dismantleand check.FAILURES CAUSES AND TROUBLESHOOTING8KCB-18.3KCB-33.31.7MPa KCB-55KCB-83.3KCB-300KCB-483.30.45MPa 9078.Generally, relief valve should not be adjusted freely, if do, alignments should be made. Pressure of valve-close should be 1.7MPa for KCB-18.3 type. KCB-33.3 type, 0.45 Mpa for KCB-55 type, KCB-83.3 type, KCB-300 type. For KCB-200 and three type of pumps, the pressure should be 0.45MPa, 0.8MPa, 1.4MPa separately.9.When stop,the power should be cut off,then close valve at inlet and outlet of pipeline.08•••••••••••••19。