工业冷水机说明书精编

- 格式:docx

- 大小:191.95 KB

- 文档页数:10

文件制修订记录1.0目的/Aim:1.1为操作者提供使用说明,确保使用者及设备的安全。

2.0参考文件/Reference Instruction:2.1 相关设备的操作说明书3.0设备/材料/ Equipment/Material:3.1 工业冷水机机LT-5A4.0准备/要求/Prepare/Requirement:4.1确保输入电压为三相380V,功率4KW以上。

5.0安全/维护/Safety/Maintenance:5.1 日常维护5.2.1 设备故障时,请立即关闭设备电源,通知专职维修人员到现场检查。

5.2.2 未经培训且未经设备管理部门允许,请不要打开设备外壳触摸内部电路。

5.2.3 遇危险或紧急情况时,按下设备的压缩机按钮和水泵按钮,并把总电源开关关闭,将设备停止下来,故障排除后方可将重新开机。

5.2.4设备在冻水管装置中已安装旁通阀,当冻水流量减少时,可利用调节旁通阀达到舒缓水泵压力及防止蒸发器结冰目的。

5.2.5如设备停用一段时间,水泵泵叶可能被污积物凝固,再开机时必须先用螺丝刀拨动马达后盖风叶,以避免泵泵叶卡死而将马达烧毁。

6.0操作程序/Operation Process:6.1 开机操作程序6.1.1 首先打开冷却水阀门,检查设备水箱及冷凝器是否加满水。

6.1.2 合上电箱的总电源开关。

当把电源开关合上时,设备的电源指示灯将点亮,表示电已送到控制箱里。

6.1.3 检查设备周围有无影响设备的运行物件。

(如机顶不能放置任何物件,保证散热正常)6.1.4 将温度控制器设定于使用温度(勿低于5°C,冻水温度调得太低会降低设备的制冷效率,甚至使蒸发器铜管表面结冰而爆裂)。

6.1.5 打开水泵运行按钮。

6.1.6 打开压缩机按钮(注意压缩机运行是在打开水泵按钮3分钟才开始,以免压缩机过载)当冻水温度至温控表所设定之温度时,压缩机会自动停止,冻水温度升高时,压缩机会自动启动。

6.2 关机操作程序6.2.1 关闭压缩机按钮。

深圳市凯德利冷机设备有限公司机组安装、操作及维护说明书二零壹肆年肆月版本:A1.00目录一、机组的适用范围 (1)二、规格 (1)三、安装说明 (1)四、操作说明 (1)1、使用操作…………………………………………………………………………………… .. 12、面板操作简介 (2)3、用户操作 (2)4、故障显示及排除 (2)五、故障排除 (3)六、保养 (4)七、注意事项 (4)八、电路图……………………………………………………………………(见附页)风冷式冷水机组操作手册一﹑机组适用范围在工业上广泛用于塑料﹑电子﹑化工﹑冶金﹑食品﹑制药﹑电镀﹑皮革﹑工艺和科研等﹔在商业上广泛用于酒店﹑宾馆﹑超级市场和影剧院等。

二﹑规格三﹑安装说明1﹑机器安装﹐要求平放﹐不可倾斜﹔2﹑机器两侧应有一米左右保养空间﹔3﹑冰水管管路务必接成回路﹐使冰水得以循环﹔4﹑冰水管路必须保温﹔5﹑接电源时请确定电源足以承担冷水机组最大负荷﹔6﹑机组电源﹐必须单独控制﹔7﹑必须接地线﹐以确保安全。

四﹑操作說明启动机组前﹐应检查冰水管路阀门是否打开(注﹕长期停机后﹐再次开机前﹐应打开电源24小时后再开启机组)﹔机组控制﹕1、使用操作(面板图)本公司使用微电脑控制器,显示屏为模块式屏幕,。

显示界面的设计充分运用人类工程学原理,使用操作简便直观,操作人员只需稍阅说明书就可上岗操作,其操作面板如图示。

1.1>按键指示灯*COMP1* 压缩机1控制指示灯,灯亮允许启动否则不允许启动,由*COMP1*按键控制.*COMP2* 压缩机2控制指示灯,灯亮允许启动否则不允许启动,由*COMP2*按键控制.*RESET* 有故障时的指示灯(闪烁显示),无故障时按下<RESET>可关闭.*PUMP* 机组运行指示灯,机组运行时此灯亮,否则灭.*0FF* 延时停机指示灯,延时停机时闪烁点亮.*SET* 参数设置指示灯,处于参数设置界面时此灯亮.1.2>面板指示灯*POWER* 电源指示灯,通电后灯亮.*RUN* 机组运行指示器,非待机状态亮.*ERROR* 故障指示灯,有故障时亮.*COMP1* 压缩机1运行指示灯.*COMP2* 压缩机2运行指示灯2、面板操作键简介2.1>面板中间为两个模块显示屏,PV屏显示实际温度,SV屏显示设定温度。

.目录中文一、安装要求 (1)二、开机准备 (1)三、操作顺序 (2)四、面板示意图及操作说明 (2)五、修改参数操作说明 (3)六、参数设置表 (5)七、故障代码说明 (6)八、操作注意事项 (6)九、维护与保养 (8)十、故障排除方法 (9)十一、电器连接示意图 (10)十二、风冷式冷冻机内部结构示图 (11)十三、水冷式冷冻机内部结构示意图 (12)十四、风冷式冷水机安装示意图 (13)十五、水冷式冷水机安装示意图 (14)感谢您选用“亨瑞达”冷冻机,为了您能正确高效的使用,请详细阅读说明'..。

书。

注意:温度过低时,防止冷冻介质在设备中结冰损坏冷冻机一、安装要求:1、冷冻机安装前请选择地基平稳,四周空旷,畅通及避免腐蚀、污染、日晒、雨淋,方便安装维修之场所;2、水冷式冷冻机,根据冷冻机制冷量选用匹配的冷却水塔。

冷水机管路配管,请根据机身管路尺寸进行安装,切勿将冷却水管尺寸缩小,这样会引起高压超载,影响制冷效果及增加耗电量;3、风冷式冷冻机,请必须安装在距离墙壁一米以上空间位置,以免造成散热不良引起高压过载影响制冷效果及增加耗电量。

注:(1)电源负载及接地部分,请依照相关法规施工!(2)新安装的冷冻机冷冻水管必须包保温层!二、开机准备首次运转冷冻机必须先检查下列事项是否正确:1、电源电压及相数是否符合型号规格,请对照铭牌所示。

[注:三相电源相位线分别为R、S、T,中性线(零线)N,接地导线为双色线用E表示;机内设有错、缺相保护器,当在第一次开机时出现电源故障报警时,可能出现错相保护,可将相线任意两相对换接妥后合上开关即可;单相电源相线为L,中线为N,地线为E。

]2、检查冷冻水管及冷却循环水管是否接通管路,并保持阀门打开;(请参考安装示意图)3、先将冷冻水箱加满水或其它冷冻介质后方可启动水泵;(注:请根据要求来配用冷冻介质)4、水冷式检查冷却水泵运行方向及水塔风机是否逆转(如水泵是三相,逆转须将电源相位线中任意二相对换,接妥后再把开关合上即可)。

名称:工业冷(热)水机型号:HY – 05AC - R规格:风冷式冷(热)机******************************************************************* 机器电热管由发泡机控制,参照发泡机说明。

*******************************************************************一、概述理. 加水清洗方便. IC控制故障原因一目了然.具有功能先进.可靠性高,抗干扰能力强,用户安装设置简单灵活等优点二、主要配置1、机台配置◇外箱尺寸:长600mm * 宽1060mm * 高960mm◇不锈钢水箱:长460mm * 宽400mm * 高320mm◇水泵: 550W/380~400V/50Hz◇压缩机: 3.7KW/380~400V/50Hz◇散热风机: 2 * 165W/380V/50HZ◇使用制冷剂: R-22◇电热管: 9KW / 380V2、温度控制精度:1℃三、特点1、控制面板嵌入式设计,安装极为方便2、原装日本大金涡旋式压缩机,安静、体积小、效率高。

3、三相电源缺相及逆相保护功能4、电流检测,超限报警5、温度超限保护6、高压、低压保护、水箱水位保护四、控制器功能1、单压缩机运行系统2、可显示冷水温度3、掉电自动记忆各种参数。

4、压缩机启停保护5、高压;低压保护6、水流或水位保护7、压缩机过流保护及相序保护五、制冷功能说明:以下说明中符号意义:Ts:冷水设定温度(本温度点可调,详见下面显示板操作说明)Tw:冷水实际温度1.单冷运行:当Tw≥Ts时,启动压缩机1.2、压缩机关闭条件:当Tw≤Ts-回差温度(回差温度可调,详见后面说明)时,关闭压缩机1.3、开机流程开机 10秒水泵运行 30秒风机/压缩机运行1.4、关机流程手动关机按开关键水泵/压缩机/风机关闭自动关机到达关机条件压缩机/风机关闭水泵运转1.6水循环泵运行:开机时水循环泵运行,手动关机后立即关,开机过程中,水泵一直运行1.7风机启停与压缩机同步1.8故障输出系统正常运行时无输出,当发生故障时输出报警信号同时面板显示故障代码六、保护功能:1.压缩机启停保护压缩机关闭90秒后才能再次开启,压缩机最少运行60秒后才能停止运行,但关机和有故障时除外2.高压压力保护压缩机开启后检测高压开关,若高压开关持续断开1秒后进入报警状态;一旦确认高压保护即锁住该故障并停止一切输出,而不管其是否复位,并显示故障代码3.低压压力保护压缩机开启后延时1分钟检测,若低压开关持续断开1秒后进入报警状态;一旦确认低压保护即锁住该故障并停止一切输出,而不管其是否复位,并显示故障代码4.水流或水位保护水泵运行30秒后才对水流或水箱水位开关进行检测,当水流开关持续断开或水位低于开关水位5秒后进入报警状态;一旦确认水流保护即锁住该故障并停止一切输出,而不管其是否复位,并显示故障代码5.压缩机过流保护压缩机启动6秒后检测电流,当电流大于设定值且持续5秒时停止所有输出6.电源三相缺相及逆相保护当三相电源B相;C相掉相或A;B;C;三相错相时,停止所有输出。

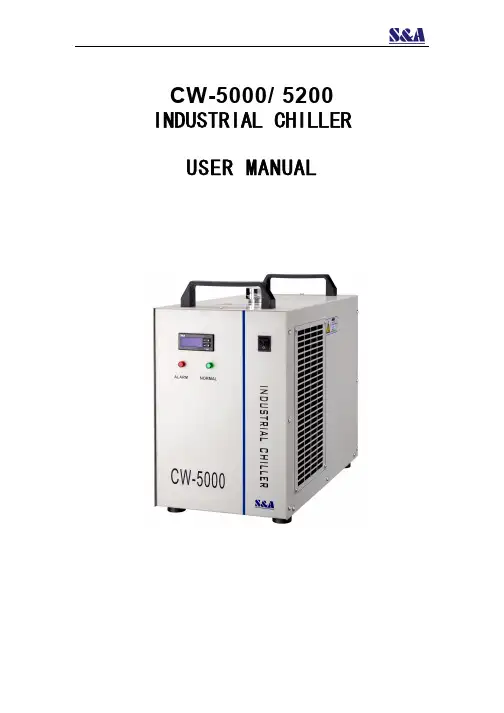

工业冷水机CW-5000/CW-5200 CW-5000/ 5200工业冷水机使用安装说明书目录一.使用注意事项-------------------------------------------------------------- 16二.部件介绍-------------------------------------------------------------------- 17三.安装说明-------------------------------------------------------------------- 18四.运行状况与参数调整----------------------------------------------------- 19五.流量报警与输出端口----------------------------------------------------- 23六.技术参数-------------------------------------------------------------------- 24七.简单故障处理-------------------------------------------------------------- 26感谢您购买广州特域机电有限公司的产品,请在使用前仔细阅读使用安装说明书,并妥善保管。

本使用安装说明书并非质量保证书,对印刷错误的更正, 所述信息谬误的勘误,以及产品的改进,均由广州特域机电有限公司随时做出解释,恕不预先通知,修正内容将编入再版使用安装说明书中。

一、使用注意事项1、请确保电源插座接触良好并且地线可靠接地!虽然冷水机的平均工作电流不大,但是其瞬时工作电流有时高达6~10安培(AC110V电源机型瞬时工作电流有时高达10~15安培)。

2、请确保冷水机的工作电压稳定、正常!由于制冷压缩机对电源电压比较敏感,我公司标准产品的正常工作电压为200~250V(110V机型为100~130V)。

CW-5000/ 5200 INDUSTRIAL CHILLER USER MANUALContents<1> Cautions---------------------------------------------------------------- 3<2> Parts introduction --------------------------------------------------- 4<3> Installation ------------------------------------------------------------ 5<4> Operation and parameters adjustment ---------------------- 6<5> Flow alarm and output ports ----------------------------------- 10<6> Specifications -------------------------------------------------------11<7> Simple troubleshooting ------------------------------------------13Thank you for using the machine from GUANGZHOU TEYU ELECTROMECHANICAL CO., LTD. Please read the installation instructions carefully before installing and operating and keep it properly.This installation instructions is not a quality assurance. GUANGZHOU TEYU ELECTROMECHANICAL CO., LTD. reserves the right to the interpretation of correction of typographical errors, improper mentioned information and product improvement. The amended content will be reprinted in installation instructions without notice in advance.<1> Cautions1. Please ensure that the power supply and electrical outlet are in good contactand the earth wire must be firmly grounded!Although the average operating current of the chiller is small, but the instantaneous operating current could be up to 6 ~ 10amps sometimes (The instantaneous operating current of models of AC110V power supply are possible to be up to 10 ~ 15amps).2. Please make sure there is stable and normal voltage for the working chiller!As the refrigeration compressor is more sensitive to the power supply and voltage, so the operating voltage of our standard product is of 200 ~ 250V (110V model is of 100 ~130V). If you do need a wider operating voltage range, customization is available for us.3. Unmatched power frequency can cause the chiller damage!Please choose model of 50Hz or 60Hz according to actual circumstance.4. To protect the pump, it’s strictly forbidden to run the chiller without water in thestorage water tank!The new machine is packed after draining whole water in the tank, so please make sure the tank has water inside before machine starting, otherwise it’s easily to have the pump damaged. When the water level is below the green (NORMAL) range of the water level gauge, the cooling capacity of our chiller will go down slightly. Hence please ensure the water level is within the green (NORMAL) range. To drain through circulating pump is strictly prohibited!5. Please be sure that the air inlet and air outlet are in good ventilation!There must be at least 30cm from obstructions to the air outlet which is in the back of the cooler, and should leave at least 8cm between obstructions and the side air inlet.6. The filter screen must be regularly cleaned!It’s essential to unpick and wash the dust gauze, or the serious blockage will cause breakdown to the chiller.7. Please pay attention to the effect of the condensate water!With greater ambient humidity, when the water temperature is lower than the ambient temperature, the condensate water will generate on the surface of water circular pipes and the cooled components. If above circumstance appears, it is recommended to set a higher water temperature or keep pipes and cooled parts warm.8. Professional use only!The appliance is not to be used by children or persons with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction, children being supervised not to play with the appliance!<2> Parts introductionPOWER SWITCHTEMPERATURE CONTROLLER NORMAL FLOW (GREEN)FLOW ALAMR (RED) AIR INLET(FILTER GAUZE)ALARM OUTPUT TERMINAL COOLING WATER OUTLET COOLING WATER INLET OUTFALLWATER LEVEL GAUGEWATER INJECTION PORTAIR OUTLETPOWER SOCKET (WITH FUSE)<3> InstallationIt is very simple to install this industrial cooling machine. The installation for the first time of the new machine can be carried out by following steps:1. Open the package to check if the machine is intact and all the necessaryaccessories are completed.2. Open the injection port to feed cooling water. (Do not let the water spill over!)Observing the water level gauge and adding water slowly, be careful not to have the water overflowed! For the cooling of carbon steel equipment, the water should be added an appropriate amount of cooling water additive (anti-corrosion water aqua). Working in cold north area, it’s better to use noncorrosive antifreeze fluid.3. According to system conditions, please connect the water inlet and outlet pipewell.4. Plug in power, turn on the power switch. (Do not start up without water in thewater tank!)(1) Power switch turned on, the circulation pump of the chiller starts working. Thefirst time of operating may cause more bubbles in the pipe leading to a flow alarming occasionally, but running for a few minutes later, it will go back to normal.(2) After the first boot, you must immediately check whether the water pipe leaks.(3) Power switched on, if the water temperature is below the set value, it is normalthat fans and other components of the machine do not work. The temperature controller will automatically control the working conditions of the compressor, magnetic valve, fans and other parts based on the set controlling parameters. (4) As it takes a longer time to start over the compressor and other components,according to different conditions, the time is range from seconds to minutes, so do not turn off the power and again on frequently.5. Check the water level in the water tank.The first startup of the new chiller empties the air in the water pipe, leading a slight water level decline, but in order to keep the water level in the green area, it’s allowed to add adequate water again. Please observe and record the current water level, and inspect it again after the chiller running for a period of time, if the water level drops obviously, please re-inspect the water pipeline leakage. 6. Adjust parameters of temperature controller.CW-5000/5200 series use an intelligent thermostat. Normally users do not need to adjust it. If it is really necessary, please refer to page 6, “Operating status and parameters adjustment.”<4> Operation status and parametersadjustmentThe new T503 intelligent temperature controller does not need to adjust the controlling parameters under normal circumstance. It will self-adjust controlling parameters according to room temperature for meeting equipment cooling requirements.The new T504 intelligent temperature controller is selected constant temperature control mode as factory setting with water temperature at 25℃.User can adjust it as needed.T503 and T504 controllers are of same functions and structure except factory parameters setting.1. Temperature controller panel description(1). Indicators D1, D2 (as shown) of thermostat working stateD1 ON: thermostat works in intelligent control mode;D1 OFF: thermostat works in temperature control mode;D1 FLASHES: thermostat works in parameters setting mode or displaysvalue of room temperature;D2 ON: chiller works in refrigerating state;D2 OFF: chiller works in the insulation working state;D2 FLASHES: chiller works in the energy-saving state;(2). Press ▼button will show the room temperature, 6 seconds later to displaythe restore defaults. (Meanwhile, D1 is flashing, displaying room temperature.)(3). ▲▼keys are for adjusting the display status of the controller, parametersselection and adjustment.(4). RST key: enter key.(5). SET key: function setting key.2. Restore to factory settingsBefore machine startup, please press and hold ▲▼button until the controller displays rE, 6 seconds later after releasing the button, the controller works in normal order. Then all parameters settings of the controller have been restored to factory settings.3. Alarm function(1) Alarm Display:E1 E2 E3 E4 E5Over highroom temperatureOver highwatertemperatureOver lowwatertemperatureRoomtemperaturesensor failureWatertemperaturesensor failureWhen alarm occurs, the error code and the temperature will be alternately displayed.(2) To suspend the alarm:In alarming state, the alarm sound could be suspended by pressing any button, but the alarm display remains until the alarm condition is eliminated.4. Thermostat parameters listOrder Code Item RangeT-503TemperatureControllerFactory SettingT-504TemperatureControllerFactory SettingNote1 F0 TemperaturesettingF9~F8 25 25Constanttemperaturecontroleffecting2 F1TemperatureDifference values-15~+5 -2 -2Intelligentcontroleffecting3 F2Coolinghysteresis0.1~3.0 0.8 0.14 F3 Way of control 0~1 1 0 1: intelligent 0: constant temperature5 F4 Alarm for over highwater temperature1~20 10 106 F5 Alarm for over lowwater temperature1~20 15 157 F6 Alarm for over highroom temperature40~50 45 458 F7 Password 00~99 8 89 F8 The allowed highestwater temperatureF0~40 30 3010 F9 The allowed lowestwater temperature1~F0 20 205. General settings adjustmentPress SET button(SET)to enter into the user-defined state. Meanwhile, D1 flashes to indicate that the controller is in parameters setup status.(1) Under intelligent mode, the control panel displays the temperature differencevalue between water and air (F1).(2) Under constant temperature mode,the control panel displays the settemperature value (F0).At this moment, press ▲▼key to change settings. After modifying the value, press the ENTER button (RST) to save and exit, then new parameters take effect, or press SET key (SET) to exit without saving parameters. If there is no more action within 20 seconds, it will automatically exit modifying status without saving parameters.6. Advanced settings adjustment(1) Press and hold the ▲key while press SET button (SET) for 5 seconds until 0displayed. Then press ▲button to select the password have been set, and then click the SET button (SET) again, if the password is correct, F0 would be shown, entering the set status, D1 flashing to indicate that the controller is under parameters setup status. What if the password is incorrect, then the panel returns to temperature display.(2) Enter setup state, press ▲key to enter and select set items circularly, or press▼to go in contrary direction circulation. Select an item, click SET button (SET) to proceed next parameters modifying, original settings being displayed, then press ▲▼key to modify parameter values, and press SET button (SET) to return to the previous setup menu. Press ENTER button (RST) at any time to exit parameters setup with saving modified parameters and return to temperature display, then the chiller runs under the new parameters. If no button is pressed within 20 seconds, the controller will automatically exit parameters setup without saving the modified parameters.Note:1. During parameters setting condition, system still runs under originalparameters.2. Under temperature control mode, the water temperature is controlled by(F0) parameters;3. Under Intelligent control mode, the water temperature will beautomatically adjusted according to temperature changes. Thetemperature difference is commanded by (F1) parameter.7. Advanced parameters adjustment case:(1) Case 1: cooling water temperature is controlled by intelligent mode. Requiringwater temperature to be between 25℃to 31℃. Ambient temperature keeping constant, when the set water temperature is 3℃lower than the ambient, the fluctuation will not exceed ±0.5℃. There will be an alert when water temperature is 10℃lower or higher than target. (e.g. when ambient temperature is 30.0℃, cooling water temperature is between 27.5℃to 26.5℃, if ambient temperature is up to 30.5℃, water temperature will be between 28.0℃to 27.0℃.)(2) Case 2: cooling water temperature is controlled by constant mode. Requiringwater temperature is constant in 28℃, and the fluctuate does not exceed ±2℃.The alarm of over high water temperature will be on when water temperature is 5℃higher than normal, and the alarm of over low water temperature will be on when water temperature is 10℃lower than normal.(3) Case 3: cooling water temperature is controlled by constant mode. Requiringwater temperature is constant in 25℃, and the fluctuate does not exceed ±1℃.The over high water temperature will be on then water temperature is higher than 30℃, and the alarm of over low water temperature will be on when water temperature is lower than 10℃. (No matter what is the ambient temperature, the cooling water temperature is constant in 24.0℃to 26.0℃)<5> Flow alarm and output portsIn order to guarantee the equipment will not be damaged while cooling water circulation is out of control, CW-5000/5200series chillers possesses an unique low flow alarm protection.(1) Flow alarm output ports and the wiring diagram(2) Flow alarm causes of circulating cooling water and working stateNote: The flow alarm is connected to the normally open relay and normally closed relay contacts, requiring operating current less than 5A, working voltage less than 300V.<6> Specifications1. CW-5000Model CW-5000AG CW-5000BG CW-5000DG CW-5000AI CW-5000BI CW-5000DI CW-5000AK CW-5000BK CW-5000DK Voltage AC220~240V AC208~230V AC100~110V AC220~240V AC208~230V AC100~110V AC220~240V AC208~230V AC100~110V Frequency50Hz 60Hz 60Hz 50Hz 60Hz 60Hz 50Hz 60Hz 60Hz Current 1.4~2.1A 3.5~5.6A 1.4~2.1A 3.5~5.6A 1.4~2.1A 3.5~5.6A Compressor0.295KW 0.38KW0.305KW0.295KW 0.38KW0.305KW0.295KW 0.38KW0.305KWpower0.40HP 0.52HP 0.41HP 0.40HP 0.52HP 0.41HP 0.40HP 0.52HP 0.41HP2361Btu/h 2999Btu/h 2866Btu/h 2361Btu/h 2999Btu/h 2866Btu/h 2361Btu/h 2999Btu/h 2866Btu/h Refrigeration0.692KW 0.879KW0.84KW0.692KW 0.879KW0.84KW0.692KW 0.879KW0.84KWcapacity595Kcal/h 756Kcal/h722Kcal/h595Kcal/h 756Kcal/h722Kcal/h595Kcal/h 756Kcal/h722Kcal/h Refrigerant R-134aRefrigerant300g 320g 280g 300g 320g 280g 300g 320g 280g chargePrecision±0.3℃Reducer CapillaryProtection Overcurrent protection for compressor, flow alarm, over temperature alarmPump power0.03KW0.1KW0.05KWTank capacity 6 LInlet andExternal Ø10mm brass connector Internal Ø8mm speedy connector outletMax. lift10M 25M 70MMax. flow10L/min 16L/min 2L/min N.W26Kgs 29KgsG.W31Kgs 34KgsDimension55X28X43 cm (L X W X H)Package72X44X62 cm (L X W X H)dimension*With heating function is optional.2. CW-5200Model CW-5200AG CW-5200BG CW-5200DG CW-5200AI CW-5200BI CW-5200DI CW-5200AK CW-5200BK CW-5200DK Voltage AC220~240V AC208~230V AC100~110V AC220~240V AC208~230V AC100~110V AC220~240V AC208~230V AC100~110V Frequency50Hz 60Hz 60Hz 50Hz 60Hz 60Hz 50Hz 60Hz 60Hz Current 2.4~3.1A 2.6~3.3A 4.5~6.5A 2.4~3.1A 2.6~3.3A 4.5~6.5A 2.4~3.1A 2.6~3.3A 4.5~6.5A Compressor0.52KW 0.5KW0.68KW0.52KW 0.5KW0.68KW0.52KW 0.5KW0.68KWpower0.71HP 0.68HP 0.93HP 0.71HP 0.68HP 0.93HP 0.71HP 0.68HP 0.93HP5084Btu/h 4982Btu/h 5186Btu/h 5084Btu/h 4982Btu/h 5186Btu/h 5084Btu/h 4982Btu/h 5186Btu/h Refrigeration1.49KW 1.46KW 1.52KW 1.49KW 1.46KW 1.52KW 1.49KW 1.46KW 1.52KWcapacity1281Kcal/h 1256Kcal/h1307Kcal/h1281Kcal/h 1256Kcal/h1307Kcal/h1281Kcal/h 1256Kcal/h1307Kcal/h Refrigerant R-22/R-134a/R-410aRefrigerant360g 380g 350g 360g 380g 350g 360g 380g 350g chargePrecision±0.3℃Reducer CapillaryProtection Overcurrent protection for compressor, flow alarm, over temperature alarmPump power0.03KW0.1KW0.05KWTank capacity 6 LInlet andExternal Ø10mm brass connector Internal Ø8mm speedy connector outletMax. lift10M 25M 70MMax. flow10L/min 16L/min 2L/min N.W30Kgs 33KgsG.W35Kgs 38KgsDimension55X28X43 cm (L X W X H)Package72X44X62 cm (L X W X H)dimension*With heating function is optional.<7> Simple troubleshootingFailure Failure Cause ApproachPower cord is not plugged in placeCheck and ensure the power interface and the power plug is plugged in place and in goodcontact.Machine turned onbut unelectrifiedFuse burnt-outPull out the fuse box from the power supply interface of the chiller, check the fuse, replace with spare fuse if necessary and check whether the power supply voltage is stable; Check and ensure the power interface and the power plug is plugged inplace and in good contact.Water level in the storage water tank istoo lowCheck the water level gauge display, add water until the level shown in the green area; And check whether water circulationpipe leaks.Flow Alarm (panel red light is on)use a water pipe directly connect to the water outlet andinlet but still without water flowing Water circulation pipes are blocked or apipe bending deformation.Check water circulation pipe Blocked dust gauze, bad thermolysisUnpick and wash the dust gauzeregularlyPoor ventilation for air outlet and inletTo ensure a smooth ventilationfor air outlet and inlet Voltage is extremely low or astableTo improve the power supplycircuit or use a voltage regulator Improper parameter settings onthermostatTo reset controlling parametersorrestore factory settings Switch the power frequentlyTo ensure there is sufficient timefor refrigeration(more than 5 minuets)Ultra-high temperature alarmExcessive heat loadReduce the heat load or use other model with larger coolingcapacityAlarm for ultra-high room temperatureThe working ambienttemperature is too high for the chillerTo improve the ventilation toguarantee that the machine isrunning under 40℃.Serious problem of condensate waterWater temperature is much lower thanambient temperature, with high humidityIncrease water temperature orto preserve heat for pipelineWater drains slowlyfrom outfall duringwater changingInjection port is not open Open the injection portCW-5000/ 5200 工业循环冷水机 使用安装说明书目录一.使用注意事项-------------------------------------------------------------- 16二.部件介绍-------------------------------------------------------------------- 17三.安装说明-------------------------------------------------------------------- 18四.运行状况与参数调整----------------------------------------------------- 19五.流量报警与输出端口----------------------------------------------------- 23六.技术参数-------------------------------------------------------------------- 24七.简单故障处理-------------------------------------------------------------- 26感谢您购买广州特域机电有限公司的产品,请在使用前仔细阅读使用安装说明书,并妥善保管。

工业风冷冷水机使用说明书一、产品概述• 1.1 基本介绍• 1.2 技术参数• 1.3 产品特点二、安装准备• 2.1 设备选址• 2.2 设备安装要求• 2.3 设备连接• 2.4 电源接入三、操作步骤• 3.1 开机操作• 3.2 设定温度• 3.3 设定冷却模式• 3.4 设定流量四、故障排除• 4.1 常见故障及解决办法• 4.2 定期维护五、安全注意事项• 5.1 设备安全操作• 5.2 电源供应• 5.3 清洁和维护• 5.4 防火措施一、产品概述1.1 基本介绍工业风冷冷水机是一种利用风冷方式对水进行降温的设备。

它广泛应用于各类工业场所,为生产过程中的设备和机器提供冷却水源。

该冷水机采用高效降温技术,具有节能环保、稳定性高、操作简便等特点。

1.2 技术参数•制冷量:XXX kW•制冷剂种类:XXX•额定功率:XXX kW•进出水口直径:XXX mm•外形尺寸:XXX mm1.3 产品特点•高效降温:采用先进的制冷技术,能够快速、高效地降低水的温度。

•节能环保:采用先进的节能技术,减少能耗,降低对环境的影响。

•稳定性高:设备运行稳定可靠,能够长时间持续运行。

•操作简便:设备配备直观的操作界面,操作简单方便,适用于各类操作人员。

二、安装准备2.1 设备选址安装工业风冷冷水机时,应选择通风良好、无明火、无腐蚀性气体和快速流动空气的场所。

同时,要确保设备周围没有遮挡物,以免影响设备的散热效果。

2.2 设备安装要求•设备铺设平稳的地面,确保运行时不会震动。

•设备周围需保持一定的空间,以便散热。

•设备的进出水口需与管道连接,保持密封。

2.3 设备连接在连接设备之前,需要确认进水管道和出水管道的位置和尺寸,以确保与设备的进出水口匹配。

将管道与设备的进出水口连接,并确保连接处密封可靠,无漏水情况。

2.4 电源接入将冷水机的电源线与电源插座相连接,确保电源稳定。

同时,应注意电压和电流的符合设备的要求,以避免设备损坏。

感謝您選用了“安格斯”冷凍機,為了您能正確高效的使用,請詳細閱讀說明書。

一、安裝要求:1、冷凍機安裝前請選擇地基平穩,四周空曠,暢通及避免腐蝕、污染、日曬、雨淋,方便安裝維修之場所;2、根據冷凍機製冷量選用匹配的冷卻水塔。

冷水機管路配管,請根據機身喉尺寸進行安裝,切勿將冷卻水管尺寸縮小,這樣會引起高壓超載,影響製冷效果及增加耗電量;3、風冷式冷凍機請必須安裝在距離牆壁一米以上空間位置,以免造成散熱不良引起高壓過載影響製冷效果及增加耗電量。

注:(1)電源負載及接地部分,請依照相關法規施工!(2)新安裝的冷凍機冷凍水管必須包保溫層!二、開機準備首次運轉冷凍機必須先檢查下列事項是否正確:1、電源電壓及相數是否符合型號規格,請對照銘牌所示。

[注3HP以上冷凍機電源是採用三相五線,電壓380~415V/50HZ電源相位線分另為R、S、T,中性線(零線)N,接地導線為雙色線用E表示;機內設有錯缺相保護器,當在第一次開機時出現不亮燈或亮紅燈並顯示故障代碼及警號時,可將相線任意兩相對換接妥後合上開關即可;3HP以下冷凍機採用單相電源,電壓220-240V/50HZ電源相位線為L,中線為N,地線為E。

]2、冷凍水喉及冷卻循環水喉是否接通管路,並保持閥門打開;(請參考安裝示意圖)3、先將冷凍水箱加滿水或其他冷凍介質後方可啟動水泵;(注:請根據要求來配用冷凍介質)4、請留意冷卻水泵運行方向及水塔風機是否逆轉(如水泵是三相,逆轉須將電源相位線中任意二相對換,接妥後再把開關合上即可)。

三、操作順序1、首先將總電源開關開啟ON位置;2、開啟冷卻水塔和冷卻水泵開關,此時注意冷卻水出入口閥門必須打開(注:風冷式冷凍機無須配備冷卻水塔)。

3、再開啟冷凍機運行開關,此時冷凍水泵開始運行,請注意冷凍水出入口閥門必須打開,經延時開關延時後壓縮機會自動運行,請查視及調節所需溫度。

4、關機時,請依相反的順序操作關機即可。

四、面板示意圖及操作說明1、開機:①打開冷凍機電箱內的空氣開關;②按“PUN”啟動鍵,開啟冷凍機,此時冷凍水泵啟動;③按“COMP1”壓縮機1鍵、“COMP2” 壓縮機2鍵開啟壓縮機(如:只有一台壓縮機時,按“COMP2” 壓縮機2鍵無效。

HACLW-06工业冷水机使用说明书宁波惠康实业有限公司为了保证机组能正常长久的使用,要求用户:在冬季断电时,但必须把机组内水箱的水水全部放掉。

一、概述本装置是以冷却水为主要目的的液体冷却机,使用于需要降低并保持水温的各类设备和装置。

本机由制冷系统,水循环系统和自动控制系统三部分组成,并自带不锈钢水箱。

制冷系统由进口的全封闭制冷压缩机,高效的冷凝、蒸发系统及进口阀件组成;水循环系统由水泵及安全旁通阀组成;自动控制系统由智能温控仪及继电控制系统组成。

整机具有操作方便,运转安全可靠的优点,性能达到国外同类产品的水平,是理想的液体冷却机。

二、主要技术参数型号HACLW-06制冷量(kW) 6.0电源主回路三相380V,50Hz控制回路单相220V,50Hz 整机功率(W)3300外循环水泵流量(L/min)≥17L/min温度调节根据用户需要,在10~25℃中选择适用液体清水外形尺寸(长×宽×高)900×690×1120接管螺纹尺寸吸入DN25 排出DN25水箱有效容积50L制冷剂用充灌量R22,1500g 三、安装注意事项⑴地面应平坦坚固。

⑵避免直接日晒并远离热源。

⑶低湿度、通风良好的环境。

环境温度低于45℃。

⑷安放位置应便于连接电源及水管。

⑸少粉尘、油雾的环境。

⑹在进、出水管0.5米范围内不应堆放其他物品。

⑺连接水管应尽量避免增加不必要的阀件,避免加大管阻。

四、操作注意事项1、日常点检与维护⑴定期清洗过滤网;使用1~2年后,用高压气枪清洗冷凝器。

⑵开机前,检查高压表与低压表,两表压力不得低于0.4Mpa。

低于0.4Mpa,检漏,充氟。

⑶制冷运转,高压不得高于2.8Mpa;低压不得低于0.2Mpa。

高压过高,清洗过滤网;检查制冷温度是否过高;检查风机是否正常。

低压过低,检查系统是否泄漏;检查制冷温度设置是否过低。

⑷表示被冷却液体出口压力。

当压力异常,检查管路是否异常或用手阀调节。

目录中文一、安装要求 (1)二、开机准备 (1)三、操作顺序 (2)四、面板示意图及操作说明 (2)五、修改参数操作说明 (3)六、参数设置表 (5)七、故障代码说明 (6)八、操作注意事项 (6)九、维护与保养 (8)十、故障排除方法 (9)十一、电器连接示意图 (10)十二、风冷式冷冻机内部结构示图.......................................... . (11)十三、水冷式冷冻机内部结构示意图....................................... .. (12)十四、风冷式冷水机安装示意图 (13)十五、水冷式冷水机安装示意图 (14)感谢您选用“亨瑞达”冷冻机,为了您能正确高效的使用,请详细阅读说明书。

注意:温度过低时,防止冷冻介质在设备中结冰损坏冷冻机。

一、安装要求:1、冷冻机安装前请选择地基平稳,四周空旷,畅通及避免腐蚀、污染、日晒、雨淋,方便安装维修之场所;2、水冷式冷冻机,根据冷冻机制冷量选用匹配的冷却水塔。

冷水机管路配管,请根据机身管路尺寸进行安装,切勿将冷却水管尺寸缩小,这样会引起高压超载,影响制冷效果及增加耗电量;3、风冷式冷冻机,请必须安装在距离墙壁一米以上空间位置,以免造成散热不良引起高压过载影响制冷效果及增加耗电量。

注:(1)电源负载及接地部分,请依照相关法规施工!(2)新安装的冷冻机冷冻水管必须包保温层!二、开机准备首次运转冷冻机必须先检查下列事项是否正确:1、电源电压及相数是否符合型号规格,请对照铭牌所示。

[注:三相电源相位线分别为R、S、T,中性线(零线)N,接地导线为双色线用E表示;机内设有错、缺相保护器,当在第一次开机时出现电源故障报警时,可能出现错相保护,可将相线任意两相对换接妥后合上开关即可;单相电源相线为L,中线为N,地线为E。

]2、检查冷冻水管及冷却循环水管是否接通管路,并保持阀门打开;(请参考安装示意图)3、先将冷冻水箱加满水或其它冷冻介质后方可启动水泵;(注:请根据要求来配用冷冻介质)4、水冷式检查冷却水泵运行方向及水塔风机是否逆转(如水泵是三相,逆转须将电源相位线中任意二相对换,接妥后再把开关合上即可)。

世一工业冷水机世一工业冷水机Schien lndustrial Chiller安装使用说明书安装使用说明书APPLICATION MANUAL广州世一工业设备有限公司广州世一工业设备有限公司Guangzhou Schien Industrial Equipment Co.,Ltd.目录一、概述 (2)二、机组特点 (2)三、型号说明 (2)四、安装要求 (3)五、开机准备 (3)六、控制器示意图及操作说明 (4)七、用户设置 (8)八、机组保护 (10)九、故障诊断 (11)十、维修与保养 (15)①② 一、概述SCH 系列工业冷水机广泛用于塑胶、电子制造、电镀、医药化工、超声波冷却、印刷等工业生产,它精确控制现代工业机械化生产所要求温度,从而大大提高了生产效率及产品质量。

世一工业冷水机操作简便、设计合理、品质卓越,其规格有上百种,是现代化工业生产不可缺少的良伴。

二、机组特点1、 机组精选进口名牌压缩机,内置安全保护,噪音低,省电耐用。

2、 进口水泵,流量大,效率高,恒久耐用。

3、 配备进口精密式数显温度控制器,能精确控制水温±1℃,设定温度范围5℃-50℃。

4、 全不锈钢厚质水箱,盘管蒸发器,内置补水等装置,清洗维护方便快捷。

5、 水冷机组冷凝器为壳管式,管内螺纹铜管,设计合理,换热效果良好。

6、 机组外形美观大方,外表板采用快速拆装形式,方便使用和维护。

三、型号说明-①产品代码SCH(世一工业):工业冷水机 ②制冷量:40匹③型式:W:水冷式;C:风冷式;L:激光冷水机4机头形式:无:涡旋机头 S:螺杆机头(30HP 以上才有螺杆机型)③ ④四、安装要求1、冻水机安装前请选择地基平稳,四周空旷,通畅及避免腐蚀、污染、日晒、雨淋、方便安装维修之场所;2、根据冷水机制冷量选用匹配的冷却水塔(风冷式不需要水塔),冷水机管路配管,请根据机身喉尺寸进行安装,切勿将冷却管尺寸缩小,这样会引起高压超载,影响制冷效果及增加耗电量;3、风冷式冻水机请必须 安装在距离墙壁一米以上空间位置,以免造成散热不良引起高压过载影响制冷效果及增加耗电量。

瀚艺水冷箱型工业冷水机组说明书一、瀚艺水冷箱型工业冷水机组简介瀚艺水冷箱型工业冷水机组是一款高性能、节能环保的制冷设备,广泛应用于化工、医药、电子、食品等行业。

本机组采用先进的水冷式制冷技术,具有高效、稳定、安全等特点,为用户提供优质的冷水供应。

二、产品特点与优势1.高效节能瀚艺水冷箱型工业冷水机组采用国际知名品牌压缩机,具备高能效比,降低了能耗,降低了运行成本。

2.稳定可靠本机组采用封闭式设计,有效减少了外界环境对制冷系统的影响,确保了运行稳定可靠。

3.防腐蚀性能机组内外壳采用优质不锈钢材料,具有良好的抗腐蚀性能,适用于各种恶劣环境。

4.易于维护机组设计紧凑,便于检修和维护。

内置自动保护装置,确保设备安全运行。

5.广泛应用领域瀚艺水冷箱型工业冷水机组可满足各种工业生产领域的制冷需求,如化工、医药、电子、食品等行业。

三、产品技术参数与选型指南为确保选购到合适的机组,请根据实际需求选择型号。

瀚艺水冷箱型工业冷水机组有以下几种规格:1.冷水量:500kg/h、1000kg/h、1500kg/h、2000kg/h等;2.制冷量:120kw、180kw、240kw、300kw等;3.压缩机:国际知名品牌;4.冷却方式:水冷;5.电源:380V/50HZ。

四、安装与使用说明1.安装要求在安装瀚艺水冷箱型工业冷水机组前,请确保选址合理,满足以下条件:(1)地面平整,无积水;(2)周围环境通风良好,无遮挡;(3)水源充足,水质符合标准;(4)电源供应稳定。

2.开机启动步骤(1)检查机组内外壳是否完好,连接管道是否紧固;(2)开启水源阀门,检查水流量是否正常;(3)开启电源,启动压缩机;(4)观察机组运行参数,如正常,即可投入生产使用。

3.操作与维护注意事项(1)定期检查机组运行参数,如发现异常,及时处理;(2)保持机组清洁,定期清理灰尘和污垢;(3)定期更换冷却水,确保水质清洁;(4)禁止机组在高温、湿度大、通风差的环境下运行。

雷德工业冷水机说明书摘要:1.雷德工业冷水机的概述2.雷德工业冷水机的主要特点3.雷德工业冷水机的安装与使用4.雷德工业冷水机的维护与保养5.雷德工业冷水机的安全注意事项正文:【雷德工业冷水机的概述】雷德工业冷水机是一款专为工业生产过程中提供恒定温度控制而设计的冷水设备。

它可以有效地控制生产过程中的温度,确保生产设备和产品的稳定性和可靠性,提高生产效率。

【雷德工业冷水机的主要特点】雷德工业冷水机具有以下几个主要特点:1.高效节能:采用高品质压缩机,确保在低温环境下仍能保持高效运行,降低能耗。

2.稳定可靠:采用智能控制系统,对冷水机的运行进行精确控制,保证设备运行的稳定性。

3.智能控制:配备人性化的触摸屏操作界面,方便用户实时监控和调整设备运行状态。

4.环保安全:采用环保冷媒,确保在运行过程中对环境无害。

【雷德工业冷水机的安装与使用】1.安装:在安装雷德工业冷水机时,应选择通风良好、散热条件良好的地方,确保设备周围有足够的空间以方便维护。

2.使用:在使用冷水机时,应先开启水源,然后开启设备电源,通过触摸屏操作界面设置所需的温度和运行模式。

【雷德工业冷水机的维护与保养】1.定期检查:应定期检查冷水机的运行状态,如发现异常声音、温度不稳定等情况,应及时停机检查。

2.清洁保养:定期清理冷水机的冷凝器、蒸发器等部件,确保设备运行畅通无阻。

3.润滑保养:定期对冷水机的运动部件进行润滑,延长设备使用寿命。

【雷德工业冷水机的安全注意事项】1.设备运行时,请勿触摸运行中的设备,以免发生意外。

2.请勿让非专业人员进行设备维修,以免造成设备损坏或人身伤害。

3.在设备附近工作时,请注意防止漏水、触电等事故的发生。

工业冷水机CW-5000/CW-5200 CW-5000/ 5200工业冷水机使用安装说明书目录一.使用注意事项-------------------------------------------------------------- 16二.部件介绍-------------------------------------------------------------------- 17三.安装说明-------------------------------------------------------------------- 18四.运行状况与参数调整----------------------------------------------------- 19五.流量报警与输出端口----------------------------------------------------- 23六.技术参数-------------------------------------------------------------------- 24七.简单故障处理-------------------------------------------------------------- 26感谢您购买广州特域机电有限公司的产品,请在使用前仔细阅读使用安装说明书,并妥善保管。

本使用安装说明书并非质量保证书,对印刷错误的更正, 所述信息谬误的勘误,以及产品的改进,均由广州特域机电有限公司随时做出解释,恕不预先通知,修正内容将编入再版使用安装说明书中。

一、使用注意事项1、请确保电源插座接触良好并且地线可靠接地!虽然冷水机的平均工作电流不大,但是其瞬时工作电流有时高达6~10安培(AC110V电源机型瞬时工作电流有时高达10~15安培)。

2、请确保冷水机的工作电压稳定、正常!由于制冷压缩机对电源电压比较敏感,我公司标准产品的正常工作电压为200~250V(110V机型为100~130V)。

工业冷水机使用说明书一、机组1、水冷开放式工业冷水机组2、风冷工业冷水机组3、水冷箱式工业冷水机组二、水管安装流程图三、冷水机安装说明1)、冷水机搬运:冷水机搬运前应做好必要的防护措施,搬运过程中注意不要损坏机组。

(2)、机组安装:2-1、安装冷水机时,注意不要损坏机组,合理布局冷水机周围空间,以方便维修保养冷水机。

2-2、按照公认的配管系统设计及施工安装标准,合理设计和安装冻水及冷却水系统,以充分发挥冷水机性能。

2-3、冷水机组应水平放置,及安装在通风干燥的位置,风冷机组安装时须注意排气口保留足够的空间,并且四周保持必须的距离以利于热交换。

2-4、水源及散热水塔周围环境恶劣时,冷冻水和冷却水回路必须安装Y型过滤器及定时清理,封闭冷冻水系统最高处必须安装自动排气阀、系统最低处安装排水接头,以系统排水用。

2-5、根据机组制冷能力选用匹配的冷却塔(风冷机组不需配置冷却塔)。

2-6、冷冻水喉通过试漏后,包保温层,避免冷量散失及管路滴水。

(3)、电源连接:3-1、冷水机电源采用三相四线、电源线(R、S、T)接电源火线。

(N)接零线(G)接地线※切勿将零线(N)接于电源火线。

3-2、机组用主电源线经电控箱上的穿孔连接在箱内接柱上,保证连接紧固。

3-3、机组配电要求:主电源电压:额定电压±10%以内主电源频率:额定频率±2%以内3-4、主电源电压波动超过规定范围时,不准起动冷水机、否则视作操作不当,由此引起的损坏不在本公司保养范围之内。

3-5、水系统之水流开关、水泵、冷却水塔电机等联锁电路必要时可正确连接在机组控制电路中(风冷机组不需配置冷却塔)。

3-6、冷水机组设有电流过载保护、压缩机排气端之高低压保护,马达线圈过热保护、防冰保护,冷却水之水流连锁保护等多种保护措施,控制电路先进。

本公司冰水机组的控制电路已在工厂里安装调试完成。

切勿擅自改动、如需改动请与本公司联络。

四、开机运行(1)、开机前的准备:1-1、检查机组周围有否异状。

工业冷水机说明书精编 Document number:WTT-LKK-GBB-08921-EIGG-22986

东莞市纳金机械有限公司

工业冷水机

使

用

说

明

书

TEL:3

FAX:6

售后专线:

地址:东莞市横沥镇横沥村综合开发区

1.首先开启电源开关;

2. 开启冷却水塔和冷却水泵开关,此时注意冷却水出入口阀门必须

打开(注:风冷式无冷却水塔,故无此操作)。

3.再开启冷冻机运行开关,此时冷冻水泵开始运行,请注意冷冻水出入口阀门必须打开,经延时开关延时后压缩机会自动运行,请查视及调节所需温度。

4.关机时,请依相反的顺序操作关机即可。

四、面板示意图及操作说明

(1)开机:

①打开冷水机电源;

②按“RUN”启动键,开启冷水机,此时冷冻水泵启动。

③按“COMP1”压缩机1键、“COMP2”压缩机2键开启压缩机

(如:只有一台压缩机时,按“COMP2”压缩机2键无效)。

延时后起动压缩机,左上角压缩机运行指示灯绿灯亮起。

同时冷却风机运转,(水冷式冷冻机的冷却水塔和冷却水泵在外部控制需预先起动。

)冷水机进入运行状态。

(2)关机:按<STOP>键停机机器:

关闭所有压缩机 ?延时(时间可设)?关冷却泵(冷却风机) ?延时(时间可设)?关冷冻泵

如长时间不使用时,请关闭冷水机电源并排掉水箱内或壳管式蒸

发器内的冷冻介质。

注:能量调节:

a) 只有1个压缩机:在升温过程中,当T>=Ts+ΔT 时启动压缩机;在降

温过程中,当T<ΔT时停止压缩机

b) 有两个压缩机:

在升温过程中:

当T>=Ts+ΔT/2 时启动1台压缩机;当T>=Ts+ΔT 时启动2台压缩机;

在降温过程中:

当T<Ts+ΔT/2 时启动1台压缩机;当T<ΔT/2 时压缩机全停。

二、修改参数操作说明

(1)上电,系统开始10秒倒计时,面板上PV区显示版本,SV区显示倒计时间。

等倒计时间完毕之后主程序开始工作。

(2)主程序开始后PV区显示实际温度,SV显示设定温度,,此时,按<SET可以修改当前设定温度,若设定温度没有被锁定,利用

<UP><DOWN>可以修改后按<SET>键退出,若设定温度被锁定,SV区

显示”LOCK”,

(3)若有故障,PV区显示”Err”,SV区显示故障代码,请按故障代码在表2查找相应的故障,按<RESET>键可以消音,排除故障后,按

<RESET>键复位故障.

(4)7<COMP1>和<COMP2>分别允许压机1,压机2开启的按键,压机若被允许开启,则相应按键上LED指示灯被点亮;若不允许开启,则

相应的压机不会开启,按键上的LED灯也不亮,只有在机组运行

的时候, <COMP1>和<COMP2>按键才有效,当<COMP1>和<COMP2>有效时,按下该键对应的LED灯亮,再按下LED灭.

(5)8指示灯:POWER电源指示灯,RUN机组运行状态, COMP1压缩机1运行状态,COMP2压缩机2运行状态,Error表示有故障.

三、故障代码说明

.冷冻水泵不可在

.操作开关请尽量

.冷冻水温度达到

.温度开关应避免

5℃以下,

防止蒸发器结冰;5.为确保制冷效果,保持最佳状态,请定期清洗冷凝器、蒸发器及水过滤器。

注:如出现故障报警请立即关机,按第七项和第十项所列方法排出故障后方可开机。

或及时通知维修人员处理。

附注(一):

散热不良及处理方法

当冷凝器散热不良时,压缩机效率低,运转电流提高,当风冷式高压压力升至24kgf/cm2 ,水冷式高压压力升至20kgf/cm2,压缩机受高压开关保护跳脱,压缩机停止运转,散热不良高压过载并显示故障代码或故障指示,此时请检视冷却塔循环水是否正常,冷却水温是否过高,冷却塔风扇水泵是否运转,冷却水阀门是否完全打开(风冷式请检查散热器是否脏堵),以上正常后再按复位按扭(REST)或关机重启即可正常运转。

如经常出现高压过载情况,请尽快安排清洗冷凝器。

附注(二)

冷媒不足低压处理方法:

1.当水温在5℃以上时,低压表压力显示低于2kgf/cm2时,即表示冷媒不足,先将漏冷媒的地方进行补漏处理再更换干燥过滤器重新抽真空,充适当冷媒。

2.当发现漏冷媒部分浸于水中,请立即停止冷冻机运行,速将水箱内水排除掉,尽快通知公司派人员处理维修,以免压缩机将水吸入系统中造成更严重损坏。

附注(三)

高低压是否正常

水冷式压缩机正常运行时高压压力显示~15kgf/cm2为最佳,(风冷式14~17kgf/cm2为最佳)但不得高于cm2,当水冷式压力高于cm2,风冷式压力高于24kgf/cm2时,高压开关跳脱请依附注

(一)处理,低压以~cm2为最佳,但不得低于2kgf/cm2,低于

2kgf/cm2低压跳脱请依附注(二)处理。

当压缩机运行时高压和低压两者压差极少或相等时,即表示压缩机本身阀片破损和断裂,请立即停止运转并通知公司派人处理。

请注意以上状况是当压缩机运行时,如没有运行高低压平衡仍属正常状况。

附注(四):

当故障指示灯及保护开关全部正常时,压缩机不能启动,请检查:1.温度开关是否调得太高,或损坏;

2.切换开关是否损坏;

3.防冻开关是否损坏;

4.压力开关是否跳脱或损坏;

5.压缩机过载保护器是否损坏或跳脱;

6.电磁继电器线圈是否损坏及过载保护器是否损坏;

7.水箱内是否液位过低;

8.请检查冷冻水水流量开关是否损坏;

注:以上控制开关或线路有故障即压缩机就不能运转。

五、维护与保养

1.定期清洗冷凝器、蒸发器,使整机保持良好运转;

2.保持冷却塔清洁干净,定期清洗,冷却塔内不得有杂物及其它障碍物;

3.风冷式冷冻机请保持散热器表面清洁干净,并定期清洗,使机器保持良好的性能。

六、故障排除方法:

七、电器连接示意图。