冷凝器使用说明书

- 格式:doc

- 大小:68.00 KB

- 文档页数:5

目录一前言 (2)二安全注意事项.............. (2)三蒸发冷凝器的原理、构造及说明 (3)四搬运 (3)五安装注意事项. (3)六运转准备 (4)七运转方法 (5)八保养管理及注意事项.................................................................... . (5)九冬季运行时的注意事项 (6)十有关省能源运转 (7)十二长期停止运转时的注意事项 (7)十三特别注意事项 (7)十四关于补给水量 (7)十五故障原因及对策 (8)一前言本说明书是以一般食品加工、冷冻、啤酒、饮料、石油、化工、医药等行业用于SLC系列蒸发式冷凝器作为对象,是确保安全使用本产品的指南。

在本产品使用前,一定要先阅读本说明书,在充分了解了运行、检查、及修配方面的基础上使用。

由于产品的改良,本书的内容与机器的说明会出现异议的情况,请提前了解这种情况。

如果操作过程与本说明书不符,会造成重伤、死亡等重大事故。

在本说明书中,很多地方都提到如下所示的注意事项。

特别是确保安全的注意事项,应该在充分理解的基础上再进行操作。

在不注意的情况下使用本机器,会发生重伤、死亡等重大事故,造成严重伤害。

操作者及保养人员在操作和保养机器之前请认真阅读本说明书。

本说明书请保存在机器附近,以便随时查阅。

在没有完全理解本说明书之前,请不要对机器进行操作、保养。

本说明书在丢失或撕坏的情况下,请立即与本公司或本公司的代理处联系索取。

二安全注意事项(1)请委托专业销售厂家或专业公司进行安装。

自己安装有不完备之处,则会引起漏水、触电、火灾等运行故障。

(2)电加热器等另售商品请一定要使用本公司指定产品。

万一自己安装有不完备之处,则会造成漏水、触电、火灾等运行故障,请委托专业厂家进行安装。

(3)请接地线。

地线不能与燃气管、水道管、避雷针及电话地线等相连接。

地线不完备则会造成触电等运行事故。

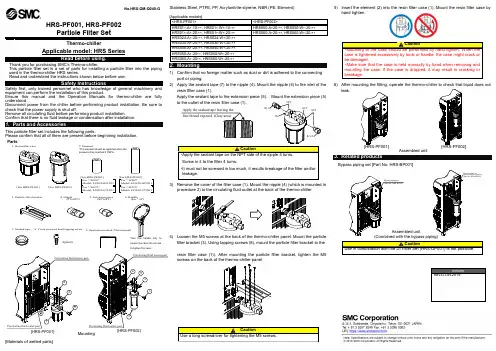

HRS-PF001, HRS-PF002Applicable model: HRS SeriesRead before using.Thank you for purchasing SMC’s Thermo -chiller.This particle filter set is a set of parts for installing a particle filter into the piping used in the thermo-chiller HRS series.Read and understand the instructions shown below before use.Safety InstructionsSafety first, only trained personnel who has knowledge of general machinery and equipment can perform the installation of this product.Ensure this manual and the Operation Manuals for thermo-chiller are fully understood.Disconnect power from the chiller before performing product installation. Be sure to check that the power supply is shut off.Remove all circulating fluid before performing product installation.Confirm that there is no fluid leakage or condensation after installation.1. Parts and AccessoriesThis particle filter set includes the following parts.Please confirm that all of them are present before beginning installation.Parts[Materials of wetted parts]Stainless Steel, PTFE, PP , Acrylonitrile-styrene, NBR (PE: Element)2. Mounting1) Confirm that no foreign matter such as dust or dirt is adhered to the connectingport or piping.2) Apply the sealant tape (7) to the nipple (4). Mount the nipple (4) to the inlet of theresin filter case (1).Apply the sealant tape to the extension piece (5). Mount the extension piece (5)to the outlet of the resin filter case (1).CautionApply the sealant tape on the NPT side of the nipple 4 turns.3) Remove the cover of the filter case (1). Mount the nipple (4) (which is mounted inprocedure 2) to the circulating fluid outlet at the back of the thermo-chiller4) Loosen the M5 screws at the back of the thermo-chiller panel. Mount the particlefilter bracket (3). Using tapping screws (8), mount the particle filter bracket to theresin filter case (1)). After mounting the particle filter bracket, tighten the M5 screws on the back of the thermo-chiller panel.Use a long screwdriver for tightening the M5 screws.5) Insert the element (2) into the resin filter case (1). Mount the resin filter case byhand tighten.Cautionshould be 6) After mounting the fitting, operate the thermo-chiller to check that liquid does notleak.3. Related productsBypass piping set [Part No: HRS-BP001]CautionUse in combination with the DI Filter Set (HRS-DP001) is not possible.(For "-H")(PTxNPT)(NPTxPT)7. Sealant tape 9. Operation munual (This manual)6. Handle8. Cross recessed head tapping screw 1. Resin filter case 2. Element 3. Particle filter bracket 4. Nipple 5. Extension piece [For HRS-PF001][For HRS-PF002][For HRS-PF001] For "-W005" Model: EJ202S-005X11 For "-W075" Model: EJ202S-075X11[For HRS-PF002] For "-W005" Model: EJ302S-005X11 For "-W075" Model: EJ302S-075X11No.HRX-OM-Q040-GMountingAssembled unit[HRS-PF001][HRS-PF002] [HRS-PF001][HRS-PF002]4 pieces *The element should be replaced when thepressure drop reaches 0.1MPa. *Use this handle only toloosen the case. Do not useto tighten the case.。

jct冷凝器说明书1. 产品概述JCT冷凝器是一种高效冷却设备,广泛应用于工业生产中的冷却与热回收过程。

本说明书将详细介绍JCT冷凝器的结构、工作原理、使用方法以及注意事项。

2. 结构与组成部分JCT冷凝器由以下几个主要部分组成:2.1 冷却管道:采用高品质铜材制成,具有良好的导热性能和耐腐蚀性。

2.2 高效散热器:采用先进的散热技术,能够有效地将废热散发出去,减少能量损耗。

2.3 控制系统:包括温度控制、压力控制和流量控制等多个模块,确保冷却过程的稳定性和自动化。

3. 工作原理JCT冷凝器通过传递冷却剂与待冷却物之间的热量,使待冷却物的温度迅速下降。

其工作原理如下:3.1 冷却剂的循环:冷却剂在冷却管道中进行循环,通过吸收待冷却物的热量后,被高效散热器冷却并重新循环。

3.2 热量传递:待冷却物通过接触冷却剂,传递热量至冷却剂中,使待冷却物的温度降低,从而实现冷却效果。

4. 使用方法4.1 安装:将JCT冷凝器放置在适当的位置,并确保其稳定性。

连接冷却管道与待冷却物,确保密封可靠。

4.2 开启电源:将冷凝器连接至电源,并打开电源开关。

验证控制系统是否正常启动,并进行必要的设置调整。

4.3 运行监控:监控冷凝器的运行状态,确保冷却效果和能量利用的最佳平衡。

定期清洗冷却管道,保证散热效果。

5. 注意事项5.1 安全操作:在使用JCT冷凝器时,操作人员应按照安全操作规程进行操作,避免发生人身伤害。

5.2 维护保养:定期检查冷凝器各部件的工作状态,及时清洁和更换故障部件,以确保其正常运行和延长使用寿命。

5.3 环境适应:在使用JCT冷凝器时,确保环境温度在适宜的范围内,避免过高或过低的温度对设备运行产生不利影响。

5.4 紧急处理:在出现故障或紧急情况时,应立即切断电源,并寻求专业人员的帮助进行检修和处理。

总结:本说明书对JCT冷凝器进行了全面的介绍,包括其结构、工作原理、使用方法和注意事项等。

通过正确使用和维护JCT冷凝器,可以提高工业生产中的冷却效率,达到节能的目的。

六、设备的清洗和维护 (4)七、注意事项 (5)八、售后服务承诺 (5)九、合格证 (7)十、配置表 (7)一、产品介绍采用不锈钢材质制造,特别适合于制药、化工、生化、农副产品、水产品深加工、食品等行业的稀料液的蒸发浓缩操作,根据工艺的不同,可用于对水蒸气、有机蒸汽的冷凝等等,冷却介质可以为冷却水和冷媒,可根据用户的工艺要求进行选择,本产品可广泛用于各种需加热或冷却操作工序中,具有结构紧凑简单,成本低,使用方便及性价比高等特点。

二、冷凝器的规格型号本公司生产的冷凝器的型号规格如下:依据换热面积分为:4㎡,6㎡,8㎡,10㎡,15㎡,20㎡,25㎡,30㎡,35㎡。

等。

还可根据客户所需实际换热面积定做。

三、基本技术数据本固定管板列管换热器的结构,主要部分是由不锈钢封头、不锈钢筒体、高效换热管、管板、管箱、管箱及筒体法兰、鞍座等部件构成。

筒体管板形成的内腔构成壳程,管箱换热管的空间构成管程。

经过管、壳程的不同的冷热流体通过对流、热传导及热辐射等方式进行换热,从而达到工艺所需冷却或加热的目的。

本产品可用于诸如蒸发器中的加热器、冷却器等。

因换热管不易清洗,所以换热管一般走清洁且不易结垢的流体以防止堵塞换热管。

五、设备的操作1、设备使用前应检查各法兰螺丝是否松动,密封垫圈是否良好。

2、使用前按倍的操作压力分到进行水压试验,保压二十分钟无泄漏方可投产。

3、本设备使用前用清自来水进行20分钟左右清洗循环即可了。

4、在管路系统中应设有放气阀开启后应排出设备中空气防止空气停留在设备中,降低传热效果。

5、冷热介质进出口接管之安装,应严格按出厂铭牌所规定方向连接。

否则,没能发挥设备最佳性能。

6、在冷凝器进出口应安装上压力表,确保不要超压使用。

六、设备的清洗和维护1、一般情况可不解体清洗,用水以与介质流动反方向冲洗,可冲出杂物,但压力不得高于工作压力,也可用对不锈钢无腐蚀性的化学清洗剂清洗。

2、如长时间使用,管壳程会有一定的沉积物结垢而影响换热效果,因此须定期拆洗。

DN-DZ-II 电子冷凝器使用说明书青岛源大环保科技有限公司Source big environmental protection technology Co., LTD1、概述电子冷凝器是用来对气体进行冷凝的装置,用在各种气体分析前的预处理过程中,起到提高分析测定精度的作用。

冷凝器的制冷部分采用半导体致冷器,故该装置具有体积小、重量轻等特点。

DN-DZ-II双路冷凝装置,相当于两台单路冷凝器,即有两组相对独立的气路,在环境温度2℃—40℃,进口气体露点温度2℃—40℃,气体流量1L/min—5L/min 时能将出口气体露点温度保持在 1℃—3℃以内。

当气体流量偏大或气体入口温度偏高时,该冷凝器可用于二级制冷。

冷凝器中气路部分的材质,采用不锈钢及聚四氟乙烯导管,故能使用在各种气体分析装置上,并且冷凝部件设计成可交换的组件,所以便于维修及保养,又因其露点控制精度高,且极其灵敏,从而得到广泛使用。

2、技术参数2.1 外形[参见后面示意图](1)外形尺寸:240(长)*210(宽)*160(高)mm3(2)安装尺寸:230 mm X 196 mm(3)重量:7kg2.2 性能:(1)正常使用条件下,出口气体露点温度在1—3℃之间(流量为5L/min)。

(2)环境温度超过40℃时,出口气体露点温度将成比例浮动上升,仪器在环境温度达到60℃时,连续使用也不会损坏,当环境温度恢复到40℃以下,又能恢复其性能。

(3)仪器预冷时间:仪器接通电源后,在环境温度40℃时,气体处于不流动状态的预冷时间不超过20分钟。

2.3 极限使用条件:(1)环境温度≥2℃、≤40℃(2)进口气体温度≤100℃[特殊要求可定制](3)进口气体露点温度≤40℃[当进口气体温度≥100℃时,须定制高温结构且建议流量控制在1~3L/min 左右。

我公司生产的DN-DZ-II双通道电子冷凝器,采用进口耐高温半导体致冷片和特制的冷却结露系统,主要用于气体流量较大或气体入口温度高时的二级制冷,完全可以代替压缩机冷凝器使用。

Z78802.80.05/01N-2400-18冷凝器说明书XX汽轮电机(集团)有限责任公司磁盘(带号)底图号旧底图号归档签名简要说明文件代号页次数量标记编制徐XX 2011.3.28校核王XX 2011.3.28审核王XX 2011.3.29会签刘XX 2011.3.29标准审查郝XX2011.3.29审定批准目次1.作用与工作原理3 2.技术规范3 3.冷凝器的构造3 4.冷凝器的运行与注意事项5 5.冷凝器的清洗6 6.严密性试验6⒈作用与工作原理1.1作用1.1.1冷凝器的作用是建立并维持汽轮机排汽口的高度真空,使蒸汽在汽轮机内膨胀到很低的压力,增大蒸汽的作功能力,从而使蒸汽在汽轮机中有更多的热能转变成机械能,提高循环效率。

1.1.2将排汽转变为凝结水收集起来,以便重新在循环中使用。

由于凝结水是品质最好的锅炉给水,所以收集凝结水对保证锅炉正常运行和提高电厂经济性有着重要的作用。

1.2工作原理本冷凝器为列管表面式热交换器,汽轮机排出的蒸汽进入冷凝器后,其热量被冷却水带走,蒸汽被冷却,凝结成凝结水。

由于在相同压力下蒸汽的体积比水的体积要大很多倍。

例如在0.005MPa(a)汽压的压力下,干饱和蒸汽比水的体积约大28720倍。

所以在排汽冷却的凝结过程中,体积急剧缩小,原来被蒸汽充满的空间就形成了高度真空,在此过程中,不凝结的气体系统中漏入的气体不断地被抽气器抽出,以维持冷凝器的这一高度真空。

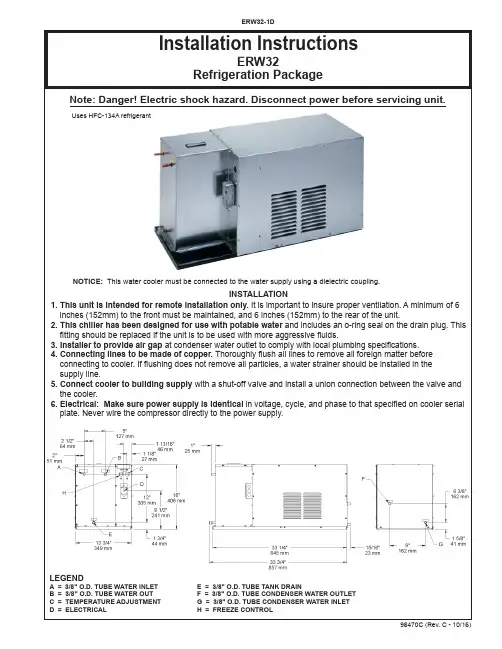

⒉技术规范型号N-2400-18型式分列二道制表面回热式(对分制双流程表面回热式)冷却面积2400m2汽轮机排汽量88.3t/h冷却循环水温度20℃冷凝器压力0.0049MPa(a)冷却循环水流量6500t/h(淡水)凝结水温度32.5℃冷却管材料316L不锈钢直管注:供货材质以合同或技术协议为准冷却管规格Φ25×0.7×7562(3920根)冷却水流速 2.1m/s水阻53kPa冷凝器净重39.3t冷凝器运行重量63t冷凝器灌水时重量98t强度设计压力壳侧:-0.1/0.1MPa管程:0.6MPa⒊冷凝器的构造冷凝器的结构简图如下:图1凝汽器结构简图1.——循环水出口2.——外壳3.——进汽室4.——减温减压器5.——管板6.——后水室7.——支座8.——抽气口9.——集水箱10.——前水室11.——循环水进口3.1壳体用12毫米钢板卷圆焊接成。

Installation and User InstructionsFor 12 / 24 Volt DC CompressorRefrigerators & Freezers fitted withSECOP / Nidec - BD35 & BD50Issue 21: 150618 MODEL: SERIAL No.:PLEASE READ CAREFULLYBEFORE INSTALLING•THIS APPLIANCE IS INTENDED FOR USE ON BOATS OR VEHICLES ONLY. IT IS NOT DESIGNED FOR HOUSEHOLDUSE.•THIS APPLIANCE MUST NEVER BE LAID DOWN ON ITS BACK OR SIDES, OR TURNED UPSIDE DOWN.•THIS APPLIANCE MUST BE ALLOWED TO RUN FOR ATLEAST 6 HOURS FROM STARING BEFORE LOADING WITHFOODS TO ENSURE CORRECT COOLING OPERATION. •IT IS RECOMMENDED THAT THIS APPLIANCE IS INSTALLED BY A COMPETANT MARINE OR AUTOMOTIVEELECTRICIAN.INTRODUCTION -Thank you for choosing SHORELINE for your mobile cooling needs. This appliance is manufactured using the very latest ‘low-energy’ compressor technology. To ensure that this appliance consumes the least amount of DC power, we ask you to read these instructions carefully before installing. •CLEANING YOUR APPLIANCE -Your appliance is easy to keep clean. Regular cleaning is important for health reasons.Exterior: Use a good wax polish, which will clean and polish the appliance in one easy application. Do not use an aerosol polish as the spray may damage or discolour plastic parts.Interior: Before using for the first time, and before reusing after a period on not being used, the interior of your appliance should be wiped with a cloth dampened with a solution of one teaspoon of Bicarbonate of Soda to one litre warm water and dried thoroughly.DO NOT use soaps, wire wool, scouring powders or disinfectants of any type.•POSITIONING -To operate correctly and efficiently, your appliance must have sufficient air ventilation around the rear; sides and top, to ensure the free flow of heat generated from the compressor and condenser during the cooling operation. This is most important on those models w ith ‘side skin’ condensers; i.e. if it has no black pipe-work on the rear exterior wall of the appliance.Position the appliance on a level floor using the adjustable front levelling foot where fitted, and allow at least 25 mm clearance above, to each side, and to the rear to provide sufficient air gap between the appliance and the adjacent galley walls. Re-position any interior shelves or storage trays correctly to ensure vibration free operation.Important - DO NOT OBSTRUCT the top or rear of the appliance or the condenser heat will not be able to escape and overheating could occur.This will result in excessive running periods of the compressor andreduce the life of your appliance.Remember - Better air flow means shorter running periodsand lower energy consumption.•CONNECTION -Your appliance can be powered from either a 12 or 24 Volt DC supply. Once connected to the power, the compressor electronic unit will automatically calibrate to the applied voltage.Warning - Connection direct to a 240-Volt AC mains power supply will result in irreparable damage to the compressor electronic control unit.Your DC power connection must be made to the terminals marked + and - at the top of the electronic control unit.Note - If the DC wires are reversed in their polarity then the appliance will not operate - refer to the Data Sheet at the rear of this booklet for correctpolarity.Only models fitted with an internal light are supplied with short RED and BLACK cable tails ready for connection to the battery supply cable. These are supplied with an LED interior lamp that works on both 12 & 24 Volt.Caution – The interior lamp is connected directly off the DC battery feed. If the light is allowed to be on for long periods, i.e. the door left open, this could cause overheating of the lamp and the surrounding lamphousing.A fuse rated for 15 Amp (Max) for 12-volt installations, or 7.5 Amp (Max) for 24-volt installations, must be fitted to the POSITIVE lead from the battery to protect the appliance. To allow power isolation of your appliance, a switch rated for 20 Amp (12 volt) switch, or 10 Amp (24 volt) should be fitted close to the appliance.•CABLE SIZES -Connection from the battery to your appliance should be made using a cable size selected from the chart below:A Copy of the Danfoss Compressor Motor Data Sheet can be found at the back of this booklet for your reference.•BATTERY PROTECTION –To protect your battery from any permanent damage, your appliance is fitted with an automatic low voltage cut-out protector. This will cut the power supply to the appliance if the battery voltage falls below the limit stated below:In addition, your appliance is fitted with a RED low-voltage LED alarm warning light. This is either mounted into the thermostat housing, the top facia, or behind the interior lower storage container. This indicator is continually OFF during normal operation. If the battery voltage falls below the limits stated above, this indicator will begin to flash once every 4 or 5 seconds to warn that the battery supply is low and that the appliance is no longer running.Warning - Low voltage limits are to be measured at the compressor electronic control unit. Beware of voltage drop over long cable lengths and through any cable connections and isolation switches of insufficient rating. Other electrical equipment, i.e. water pumps, should NOT be installed along the same cables supplying the appliance as low-voltage tripping can occur when these are switched on. •APPLIANCE OPERATION –The cold control or thermostat can be manually adjusted from position 1 (WARMEST / FULLY ANTI-CLOCKWISE) to position 5 or Higher (COLDEST / FULLY CLOCKWISE). It is recommended that a position somewhere between 1 and 3 is most suitable. Allow your fridge or freezer to operate for at least six hours from staring before loading with foods to ensure its correct operation. To achieve the optimum storage temperature for your food products, refrigerators should hold an average internal temperature of +5ºc, and freezers and freezer compartments below -12ºc. If your appliance is holding temperatures colder than these recommended settings, the appliance will be running unnecessarily. In ambient temperatures approaching +32ºc the motor compressor will be running for longer periods.Note - Correct storage temperatures inside the appliance cannot be ensured in ambient temperatures warmer than +32ºc.Note - These 12/24 Volt DC freezers are designed to store pre-frozen foods, not to freeze down large quantities of fresh foods. Expect the motor compressor to run for very long periods without cutting off if you attempt to freeze quantities of fresh foods.Caution: If the room temperature drops below +16ºc the freezer section in two-door fridge/freezers and refrigerators with freezer compartments may begin to defrost and may reduce the life of your frozen foodsCaution: If the room temperature starts to rise above +25ºc the motor compressor will begin to run for longer periods and consequently require more battery power. Room temperatures above +30ºc could result in correct storage temperatures not being maintained inside theappliance.If you intend to leave the appliance operating for longer periods in cold weather we suggest you remove the contents of the freezer compartment. The refrigerator section will continue to operate normally within correct storage temperatures.You may notice some unusual noises particularly if the fridge or freezer in placed in a quiet location. Most of these are perfectly normal, but you should be aware of them. Gurgling, Whooshing: these are the noises caused by the circulation of the liquid refrigerant in the cooling systems. These types of noises have become more pronounced since the introduction of CFC free gases. This is not a fault and will not affect the performance of your refrigerator or freezer. Humming, Purring or Pulsating: This is the compressor motor working as it pumps the refrigerant around the system.•DEFROSTING -It is necessary to regularly defrost your appliance in order to ensure efficient operation. The frost build up in the freezer compartments should not exceed 6 mm in thickness before defrosting. Use a PLASTIC scraper to keep the frost build up to a minimum. Freezers should be defrosted when the ice build-up becomes greater than 10mm.Before starting, ensure your food products are stored temporarily in an insulated container to minimise any temperature rise, particularly any frozen products. DO NOT re-freeze frozen foods if they have defrosted.To defrost your appliance, isolate the power to your appliance. Allow the defrost water to collect in plastic tray (where fitted) beneath the ice compartment. When defrosting is completed, remove the drip tray, empty theLarder refrigerator models and the refrigerator section in fridge/freezers will defrost automatically. You will notice frost or ice or water droplets down the inside back wall – this is normal. This moisture will drip out of the drain hole into the evaporation tray mounted above the motor/compressor unit at the rear. It is important to keep food stuffs and food containers clear of the rear wall and to keep the drain hole clear using a proprietary pipe cleaner, or the pipe stick if provided.Caution - Do not use sharp instruments to remove frost build-up as this could result in damage to the cooling plates or shelves. •AFTER SALES SERVICE –In the unlikely event of you experiencing problems with your appliance, please refer to the attached electrical fault analysis sheet. If you require any additional service information, contact your installer or you may contact Shoreline at the address below, quoting your appliance model number and serial number as displayed on the inside of your appliance.SHORELINE (UK) LTD16-17 Martello Enterprise Centre, Courtwick Lane,Littlehampton, West Sussex. BN17 7PA. England.Tel: + 44 (0)1903 733 877E-mail:*********************Web: NOTES -。

一、概述近年来根据市场需求,公司在燃天然气(油)的锅炉烟气余热冷凝回收利用方面进行了科研攻关。

在大量调研的基础上,总结了国内外几十家同类产品的优缺点,设计制造遵循《小型锅炉和常压热水锅炉技术条件》及专业标准,研制开发出了系列烟气冷凝器,并成功地投入了实际应用。

此装置为联接在锅炉尾部排烟处,吸收锅炉排烟的部分显热和潜热的节能装置。

也适用于旧锅炉的节能改造。

二、烟气冷凝器的原理国内使用的绝大部分燃气(油)热水锅炉的设计排烟温度都在160℃以上,而蒸汽锅炉则高达220℃。

这是为了避开燃料中含有硫及其在燃烧过程中产生的NOx化物等酸性物质在小于150℃时,其在受热面尾部产生酸凝结而腐蚀尾部受热面。

使尾部受热面强度降低,危害锅炉安全运行,使锅炉提前报废。

所以国内及国外的常规燃油气锅炉的设计排烟温度普遍大于160℃,热效率一般在86~90%。

造成了大量的排烟显热及潜热被浪费。

我国目前的热力计算标准中使用的燃料发热量都是指燃料的低位发热量,而低位发热量是不计潜热的。

但是当我们使用天然气作为燃料时,由于其含有大量的氢,其潜热和显热是相当可观的,所以使用烟气冷凝器可以把排烟中的大量热能回收,显著提高锅炉热效率,使锅炉热效率接近或超过100%。

为用户带来可观的经济效益。

使用本装置具有优秀的环保性能。

当烟气中的水蒸气冷凝时,排烟中的有害物质随冷凝水凝结下来,冷凝水呈弱酸性。

经中和处理后可作为中水使用。

经测定排烟中的有害物质减少量如下:二氧化硫:减少99% 水蒸汽:减少60%三氧化硫:减少99% 一氧化碳:减少60%烟尘:减少93% 氮氧化物:减少50%排热量:减少60% 二氧化碳:减少40%公司生产的烟气冷凝器设备,是采用间壁式换热原理,使被加热水从翅片管内部流过,烟气从翅片管外部流过,通过对流换热从而能够把烟气中的显热和潜热最大程度回收的一种专用于燃气(油)锅炉的节能装置。

此装置已通过国家专利局的认定,成为专利产品。

压缩机式冷凝干燥器CMS-3001.概述本装置是专门为工业过程控制、环保在线检测气体成分(CO、CO2、O2、SO2等)中使用的各种分析仪器(如:红外分析器)设计、生产的压缩机式冷凝干燥器。

其利用压缩机制冷的原理,通过一个专门设计的热交换器,将高温湿热的样品气体在热交换器内充分制冷,使其中湿热气体冷凝成液态,同时由蠕动泵(或其他方式)将冷凝液体排出,达到气液分离。

极大地降低了被测样品气体中的含水量,保证分析仪器的正常工作。

2.重要的安全性须知2.1 安全性提示:安装和初次开机之前,请务必仔细阅读本说明书,并请注意安全性提示。

本干燥器是以压缩机制冷的,搬运,安装时不能倒置。

压缩机具有热过载保护,停机后,重新启动必须等待五分钟,让压缩机复原后再启动。

本干燥器是一种电气设备,设备中某些部件在工作期间带有危险电压。

因此,在检修或维护时,要打开设备的外盖,必须断开电源!本干燥器适合安装在安全的无危险区域,不适用于可燃或有毒的样气。

2.2 功能提示:本干燥器用于降低潮温样气的露点,只允许使用经过过滤的气体。

另外,请注意气体进口处样气最大流率与露点不能超出本干燥器规定。

3.安装须知:3.1 安装环境:要保证前(后)、左右两端通风良好,要避免顶端不能有热源,至少要在顶端留有100mm 的空间高度(该干燥器是由顶端向外排出热气体)。

要注意+5℃~+45℃的环境温度的限制。

干燥器要尽可能靠近取样点。

冷凝水可能具有腐蚀性,要注意冷凝水的收集。

3.2安装:3.2.1本干燥器可以悬挂在墙壁上,安装尺寸为:360×210,也可安装在19″机柜内,安装尺寸为484×3123.2.2样气连接:3.2.3冷凝水连接●冷凝水通常是酸性的,在排放点应采取适当的安全措施,且遵守酸液排放的相关规程。

●水、气管连接接口必须无泄漏,可按下法检查:用一U形管压力计一端和样气出口管道连接,用一阀门关闭冷凝液出口,将压力为0.01MPa的空气(或N2)接到样气进口,待U形管压力计上有0.01MPa压差时关闭阀门。

Milk CoolersInstallation and Operation Manual Please read this manual completely before attempting to install or operate this equipmentTMKC-34STMKC-49STMKC-58STMKC-34DTMKC-49DTMKC-58D1. SPECIFICATIONS (2)2. SERIAL NUMBER (2)3. INSTALLATION (3)4. CLEANING & POWER CORD (4)5. BASIC OPERATION (5)6. TROUBLESHOOTING (6)7. WARRANTY ....................................................................................7~9MODEL COMP H.P V/HZ REFRIGERANT AMP TMKC-34S 1/3 115/60Hz R134a 5.50 TMKC-49S 1/2 115/60Hz R134a 7.00 TMKC-58S 1/2 115/60Hz R134a 7.00 TMKC-34D 1/3 115/60Hz R134a 5.50 TMKC-49D 1/2 115/60Hz R134a 7.00 TMKC-58D 1/2 115/60Hz R134a 7.00 SERIAL NUMBERThe serial number is located on the rating label which is on interior left side wall. Please retain the unit’s serial number for service purpose.1. GOOD AIR CIRCULATION- Please make sure to avoid any partition or objects that may stop the air flow- Please make sure there is enough space for air circulation to the rear of the unit. Recommended space between the rear of the unit to the wall is at least5 inches2. PLACE ABOVE STRONG FOUNDATION- Please make sure that the floor where the unit will be placed can supportthe total weight plus any other contents that it may hold3. DO NOT PLACE NEAR HEAT- Please make sure to avoid hot corners and locations near stoves- High ambient temperature will significantly reduce cooling efficiency4. INDOOR USAGE ONLY- This unit is designed and tested for indoor use only- Outdoor usage will void its warranty5. STABILIZATION- Turn leg levelers counter-clockwise in order to level the unit properly6. LEVELING- Please make sure that the unit levels from the front to the back and sideto side7. UNIT NEEDS TO BE PLUGGED TO A DEDICATED OUTLET8. PLACE BLACK CONDENSATE PAN FROM THE BACK OR FRONT. MAKE SURE PADS ARE INSTALLED UPWARDS AND A DRAIN HOSE IS IN PAN1. CLEANING STAINLESS STEEL INTERIOR AND EXTERIOR: Damage to stainless steel finish due to improper use of cleaning products or non- recommended products is NOT covered under this product's warranty.• Do- Use warm, soapy water and a soft, clean cloth or sponge- Rinse surfaces with clean, warm water and dry immediately to avoid water spots • DO NOT USE- Abrasive or harsh cleaners- Ammonia- Chlorine bleach- Concentrated detergents or solvents- Metal or plastic-textured scouring pads- Vinegar-based products- Citrus-based cleaners2. CLEANING THE CONDENSER FINS- To maintain proper refrigeration performance, the condenser coil must be free of dust, dirt, and greaseThis will require periodic cleaning. condenser fins should be cleaned at least every three months (90 days) or as needed3. CLEAN THE GASKET- The door gasket should be cleaned frequently to maintain proper sealing4. CHECK AFTER CLEANING- Check the unit again for safety- Check that the unit is operating properly1. POWER CORD- Please make sure that the power cord is connected to the proper voltage- The power cord must be connected to a protected circuit with the correct voltage and amperage- Turn ʻoffʼ the power switch before disconnecting the power cord, wheneverperforming maintenance functions or cleaning the refrigerated cabinet- Compressor warranties are void if compressor burns out due to improper voltage 2. RE-STARTING- If disconnected, wait for 5 minutes before re-starting1. The controller (thermostat) is located inside of the unit.2. The factory setting is at “4” and maintains about 38°F (3°C) inside the cabinet.3. Set toward ‘counter clockwise’ for warmer temperature and clockwise‘ forcolder temperature.4. The thermostat controls compressor’s on/off cycling by sensing insidetemperature.• If thermostat knob is pointing at OFF, compressor and condenser fan motor would not run• Unplug the unit, if not in use for long period of timeSYMPTOMS CAUSES SOLUTIONSThe unit is freezing or melting food productsThe unit does notrefrigerate at allThe unit does not refrigerate well There is a loud noise There are dew-dropson the unit exterior There are dew-drops on the unit interiorThe door does not close tightly • The temperature is set too highor low to maintain food fresh.• There is a power connectionfailure problem.• The unit is in sunlight or near aheating device.• The unit contains hot food or toomuch food.• The unit door is opened toofrequently or left open long.• The condenser is clogged.• The floor is too weak or theleveling feet are set incorrectly.• The back-side of the unit is tooclose to the wall.• The tray is not in the correctposition.• High-moisture air can producedewdrops during rainy season.• The door is opened toofrequently or left open long.• Damp food is stored.• The door is bent.• The unit has a leveling issue.• The door gasket has come out.• Turn the temperature dial to awarmer(or colder) setting.•Check the power cord to make surethe unit is pluged in it correctly.• Check the installation place• Move out of sunlight or awayfrom heater.• Check the condition of storedfood.• Check the temperature controlsetting.• Check the installation andadjust the tray position.• Wipe with a dry cloth.• Keep the door closed toremove dewdrops.• Level the unit again.• Reposition the gasket.The following points are not malfunctions:• A water-flowing sound can be heard when the compressor stops. This is the sound of REFRIGERANT flowing.• The compressor does not run against defrosting fuction.MANUFACTURING COMP ANYTurbo Air warrants to the original purchaser of every new Turbo Air refrigerated unit, the cabinet and all parts thereof, to be free from defects in material or workmanship, under normal use and service, for a period of three (3) year from the date of original installation or 39 months after shipment date from Turbo Air , whichever occurs first.Any parts covered by this warranty that are examined and determined by Turbo Air to have been defective within three (3) year o f original installation or thirty nine (39) months after shipment date from manufacturer, whichever occurs first, shall be repaired or replaced as stated below. Turbo Air shall be deemed to have fully complied with its obligation under the foregoing warranties b y electing either one of the following procedures, at the sole discretion of Turbo Air.1. Furnishing a replacement part, freight collect, in even exchange for the returned part, freight collect.2. Receiving the defective part, freight collect; repairing it; and returning it, freight collect.In addition to the three (3) year warranty stated above, Turbo Air warrants its hermetically and semi-hermetically sealed compressor to be free from defects in both material and workmanship under normal use and service for a period of two (2) additional years from the date of original installation but not to exceed five (5) years and three (3) months after shipment fr om manufacturer.Compressors determined by Turbo Air have been defective within this extended time period will, at Turbo Airʼs option, be either repaired or replaced with a compressor or compressor parts of similar design and capacity.The two (2) year extended compressor warranty applies only to hermetically and semi-hermetically sealed parts of the compressor and does not apply to any other parts or components, including, but not limited to, cabinet, paint finish, temperatu re control, refrigerant, metering device, driers, motor starting equipment, fan assembly any other electrical component, etcetera.The five year compressor warranty detailed above will be voided if the following procedure is not carefully adhered to:1. This system contains R134A refrigerant and polyol ester lubricant. The Polyol ester lubricant has rapid moisture absorbing qualities. If long exposure to the ambient conditions occur, the lubricant must be removed and replaced with new. Listed below are the approved lubricants for the Tecumseh compressors.1 ICI-Emkarate RL 1842 Emery-2927-A3 Mobile Artic 22AFailure to comply with recommended lubricant specification will void the compressor warranty.2. Dryer replacement is very important and must be changed when a system is opened for servicing. dryer must be used with XH-9 desiccant.3. Micron level vacuums must be achieved to insure low moisture levels in the system. 500 microns or lower must obtained.Turbo Airʼs sole obligation under this warranty is limited to either repair or replacement of parts, subject to the additional limitations below. This warranty neither assumes nor authorizes any person to assume obligations other than expressly covered b y this warranty.1. WARRANTY IS NOT TRANSFERABLE. This warranty is not assignable and applies only in favor of the originalpurchaser/user to whom delivered. ANY SUCH ASSIGNMENT OR TRANSFER SHALL VOID THE WARRANTIES HEREIN MADE AND SHALL VOID ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.2. NO CONSEQUENTIAL DAMAGES. TURBO AIR IS NOT RESPONSIBLE FOR ECONOMIC LOSS; PROFIT LOSS ORSPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIMITATION, LOSSES OR DAMAGES ARISING FROM FOOD OR PRODUCT SPOILAGE CLAIMS WHETHER OR NOT ON ACCOUNT OF REFRIGERATION FAILURE.3. ALTERATION, NEGLECT, ABUSE, MISUSE, ACCIDENT, DAMAGE DURING TRANSIT OR INSTALLATION, FIRE,FLOOD, ACTS OF GOD. TURBO AIR is not responsible for the repair or replacement of any parts that Turbo Air determines have been subjected after the date of manufacture to alteration, neglect, abuse, misuse, accident, damage during transit or installation, fire, flood, or an Act of God.4. NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THERE ARE NOOTHER WARRANTIES, EXPRESS, IMPLIED OR STATUTORY, EXCEPT THE THREE(3) YEAR WARRANTY AND THE ADDITIONAL TWO(2) YEAR COMPRESSOR WARRANTY AS DESCRIBED ABOVE. THESE WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, INCLUDING IMPLIED WARRANTY AND MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF.5. TRANSPORTATION COSTS. Turbo Air will accept parts covered under this warranty freight collect, provided that shipmenthas received prior approval. Turbo Air is not responsible for any other transporation costs, but will ship freight collect part s either repaired or replaced under these warranties.6. WARRANTY CLAIMS. All claims should include: model number of the cooler, the serial number of the cabinet, proof ofpurchase, date of installation, and all pertinent information supporting the existence of the alleged defect. Any action or bre ach of these warranty provisions must be commenced within three (3) year after that cause of action has accrued.4184 E. Conant St.Long Beach, CA 90808TEL : 310-900-1000FAX : 310-900-1077TOLL FREE : 1-800-627-0032(U.S.A. & Canada)Website : Warranty Claims...All claims for parts or labor must be made directly thorough Turbo Air.All claims should include: model number of the unit, the serial number of the cabinet, proof of purchase, date of installation, and all pertinent information supporting the alleged defect.In case of compressor replacement under warranty, either compressor or compressor tag must be returned to Turbo Air along withabove listed information.Failure to comply with warranty policies will result in voiding claims.Three Year Parts & Labor Warranty...Turbo Air warrants all new refrigerated components, the cabinet and all parts, to be free from defects in materials or workmanship,under normal and proper use and maintenance service as specified by Turbo Air and upon proper installation and start-up inaccordance with the instruction packet supplied with each Turbo Air unit. Turbo Airʼs obligation under this warranty is limited to a periodof three (3) year from the date of original installation or 39 months after shipment date from Turbo Air, whichever occurs first.Any part, covered under this warranty, that are by Turbo Air to have been defective within three (3) year of original installation or thirty-nine (39) months after shipment date from manufacturer, whichever occurs first, is limited to the repair or replacement, including labor charges, of defective parts or assemblies. The labor warranty shall include standard straight time labor charges only and reasonable travel time, as determined by Turbo Air.Additional Two Year Compressor Warranty...In addition to the three (3) year warranty stated adove, Turbo Air warrants its hermetically sealed compressor to be free from defects in both material and workmanship under normal and proper use and maintenance service for a period of two (2) additional years fromthe date of original installation, but not to exceed five (5) years and three(3) months after shipment from the manufacturer.Compressor determined by Turbo Air to have been defective within this extended period will, at Turbo Airʼs discretion, be eitherrepaired or replaced with a compressor or compressor parts of similar design and capacity.The two (2) year extended compressor warranty applies only to hermetically sealed parts of the compressor and does not apply to any other parts or components, including, but not limited to, cabinet, paint finish, temperature control, refrigerant, metering device, driers, motor starting equipment, fan assembly or and other electrical components, etcetera.404A / 134a Compressor Warranty...The five-year compressor warranty detailed above will be void if the following procedure is not carefully adhered to:1. This system contains R404A or R134a refrigerant and polyol ester lubricant. The polyol ester lubricant has rapid moisture absorbingqualities.2. Drier replacement is very important and must be changed when a system is opened for servicing. A620 copper drier or better ishighly recommended.3. Micron level vacuums must be achieved to insure low moisture levels in the system. 500 microns or lower must be obtained.4. When compressor is grounded, suction drier and 620 drier or better must be replaced.5. Compressor must be obtained through Turbo Air, unless otherwise specified in writing, through Turbo Airʼs warranty department.404A / 134a Compressor Warranty...Turbo Airʼs sole obligation under this warranty is limited to either repair or replacement of parts, subject to the additional limitations below. This warranty neither assumes nor authorizes any person to assume obligations other than those expressly covered by this warranty.NO CONSEQUENTIAL DAMAGES. TURBO AIR IS NOT RESPONSIBLE FOR ECONOMIC LOSS; PROFIT LOSS; OR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIMITATION, LOSSES, OR DAMAGES ARISING FROMFOOD OR PRODUCT SPOILAGE REGARDLESS OF WHETHER OR NOT THEY RESULT FROM REFRIGERATION FAILURE. WARRANTY IS NOT TRANSFERABLE, This warranty is not assignable and applies only in favor of the original purchaser/user towhom delivered. ANY SUCH ASSIGNMENT OR TRANSFER SHALL VOID THE WARRANNTIES HEREIN AND SHALL VOID ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR LABOR COVERAGE FOR COMPONENT FAILURE OR OTHER THE WARRANTY PACKET PROVIDED WITH THE UNIT.ALTERATION, NEGLECT, ABUSE, MISUSE, ACCIDENT, DAMAGE DURING TRANSIT OR INSTALLATION, FIRE, FOOD, ACTSOF GOD. Turbo Air is not responsible for the repair or replacement of any parts that Turbo Air determines have been subjected afterthe date of manufacture to alteration, neglect, abuse, misuse, accident, damage during transit or installation, fire, flood, or act of GOD. IMPROPER ELECTRICAL CONNECTIONS. TURBO AIR IS NOT RESPONSIBLE FOR THE REPAIR OR REPLACEMENT OFFAILED OR DAMAGED COMPONENTS RESULTING FROM ELECTRICAL POWER FAILURE, THE USE OF EXTENSION CORDS, LOW VOLTAGE, OR VOLTAGE DROPS TO THE UNIT. NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE; THERE ARE NO OTHER WARRANTIES, EXPRESSED, IMPLIED OR STATUTORY, EXCEPT THE THREE (3) YEAR PARTS & LABOR WARRANTY AND THE ADDITIONAL TWO (2) YEAR COMPRESSOR WARRANTY AS DESCRIBED ABOVE. THESE WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, INCLUDING IMPLIED WARRANTY AND MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THERE ARE NO WARRANTIES, WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF.Outside U.S.and Canada; This warranty does not apply to, and Turbo Air is not responsible for, any warranty claims made on products sold or used outside the continent of the United States and Canada.New Extended Warranty policy applies to all units sold by Turbo Air starting Dec.1, 2012。

冷凝器 EGK 2 Ex安装及使用说明书BC450008, 08/2011 Art. Nr. 90 31 128Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen请在安装和使用前仔细阅读此手册。

敬请特别注意所有安全守则,以避免不必要的意外伤害事故。

Bühler Technologies GmbH/德国比勒科技有限责任公司对由不当操作以及在未授权情况下擅自改动机器设备所引起的后果不承担任何责任。

目录页1概述 (3)2重要注意事项 (4)2.1安全注意事项概述 (5)3铭片说明 (6)4产品说明 (6)4.1产品概述 (6)4.2冷凝器工作原理 (7)4.3发货内容 (7)5运输及存储注意事项 (7)6安装及线路连接 (7)6.1基本要求 (7)6.2安装 (7)6.3线路连接 (8)6.4绝缘测试 (9)7操作 (9)7.1操作前的检查 (9)7.2操作 (10)8维护 (11)8.1维护 (12)8.1.1测试压力监督 (12)8.1.2检查启动电容器 (12)8.1.3清洁电容器(空气热交换器) (12)8.2零配件的更换 (13)8.2.1热交换器 (13)8.2.2Pt 100 (部件号45 90 999 6) (13)8.2.3电子板 (14)8.2.4更换启动电容器 (部件号45 90 999 2) (14)9故障及故障清除 (16)9.1检查 / 重设压力控制开关 (17)9.2启动时对压力开关的截断 (17)10维修与报废处理 (18)10.1报废处理 (18)11附件 (18)12化学物质稳定性表 (19)13维护记录(请复印) (20)1 概述冷凝器EGK 2 Ex 是气体预处理系统中的重要部件之一。

请注意附后的技术参数表中的参数值,有关特别应用的说明,所选材料,压力和温度范围。

此说明书描述冷凝器分别在230V/50Hz和115V/60Hz条件下的功能。

Circulating Fluid Temperature ControllerThermo-chiller Compact Type Series HRS4700 W /5100 W (50/60 Hz) cooling capacityadded! (HRS050)b Temperature stability: ±0.1°CbTemperature range setting:5 to 40°Cb High-lift pump available as standard(For HRS050)b Footprint reduced by 32%b Volume reduced by 42%bWeight reduced by 43%SeriesHRS050Weight (kg)69120Height (mm)9761150Depth (mm)592595Width (mm)377550b With earth leakage breakerb With automatic water supply functionb Applicable to DI water (deionized water) piping976 m m377 m m592m mCompact/Space-savingLightweightOptionsHRG (C )005(Conventional model)HRS050(Except HRS050)RoHSProduction of HRG(C)005 will be discontinued at the end of March 2011.Comparison with Conventional Model HRG (C )005ModelHRS012HRS018HRS024HRS050Cooling capacity (W)Cooling method Power supplyInternational standards1100/1300 (50/60 Hz)1700/1900 (50/60 Hz)2100/2400 (50/60 Hz)4700/5100 (50/60 Hz)Air-cooled refrigeration Water-cooled refrigeration Single-phase 100 VAC (50/60 Hz), 115 VAC (60 Hz)Single-phase 200 to 230 VAC (50/60 Hz)Single-phase 200 to 230 VAC (50/60 Hz)Single-phase 200 to 230 VAC (50/60 Hz)CE/UL ∗—Air-cooledrefrigeration∗ UL standards: Applicable to 60 Hz onlyVariationsNew NewScheduled for2011Weight69 kgInformationAkihabara UDX 15F,4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, JAPAN ©2011 SMC Corporation All Rights Reserved 10-E569D-DN Printing PQ 12450SZHRG (C )005(Conventional model)1C o u r t e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o mHow to OrderThermo-chillerSeries HRS018A 10Cooling capacity012018Cooling capacity 1100/1300 W (50/60 Hz)Cooling capacity 1500/1700 W (50/60 Hz)CE/ULCooling methodA WAir-cooled refrigeration Water-cooled refrigerationPipe thread typeNilF NRcG (with PT-G conversion fitting set)NPT (with PT-NPT conversion fitting set)Power supply Note)10Power supplySingle-phase 100 VAC (50/60 Hz)115 VAC (60 Hz)SymbolHRS OptionSymbol NilB J MOption b When multiple options are combined, indicatesymbols in alphabetical order.Specifications ∗ There are different values from standard specifications.Note 1) For water-cooled refrigeration Note 2) It should have no condensation.Note 3) If clear water is used, use water that conforms to Water Quality Standards of the Japan Refrigeration and Air Conditioning Industrial Association (JRA GL-02-1994 cooling water system - circulating type - make-up water).Note 4) q Ambient temperature: 25°C, w Circulating fluid temperature: 20°C, e Rated circulating fluid flow rate, r Circulating fluid: Clear water, tFacility water temperature: 25°C Note 5) Use a 15% ethylene glycol aqueous solution if operating in a place where the circulating fluid temperature is 10°C or less.Note 6) Outlet temperature when the circulating fluid flow is rated flow, and the circulating fluid outlet and return port are directly connected. Installation environment and the power supply are within specification range and stable. Note 7) The capacity at the Thermo-chiller outlet when the circulating fluid temperature is 20°C.Note 8) Required flow rate for cooling capacity or maintaining the temperature stability.The specification of the cooling capacity and the temperature stability may not be satisfied if the flow rate is lower than the rated flow.Note 9) Purchase an earth leakage breaker with current sensitivity of 15 mA or 30 mA separately. (A product with an optional earth leakage breaker (option B) is also available.)Note 10) Front: 1 m, height: 1 m, stable with no load, Other conditions → Note 4) Note 11) Weight in the dry state without circulating fluidsNote 12) Required flow rate when a load for the cooling capacity is applied at a circulating fluid temperature of 20°C, and rated circulating fluid flow rate and facility water temperature of 25°C.Note) UL standards: Applicable to 60 Hz onlyCooling method RefrigerantControl methodAmbient temperature/humidity Note 2)Noise level Note 10) (50/60 Hz) (dB)AccessoriesWeight Note 11) (kg)Circulating fluid Note 3)Temperature range setting Note 2) (°C)Cooling capacity Note 4) (50/60 Hz) (W)Temperature stability Note 6) (°C)Pump capacity Note 7) (50/60 Hz) (MPa)Rated flow Note 8) (50/60 Hz) (L/min)Tank capacity (L)Port size Wetted parts materialTemperature range (°C)Pressure range (MPa)Required flow rate Note 12) (50/60 Hz) (L/min)Inlet-outlet pressure differential of facility water (MPa)Port sizeWetted parts material Power supplyCircuit protector (A)Applicable earth leakage breaker capacity Note 9) (A)Rated operating current (50/60 Hz) (A)Rated power consumption Note 4) (50/60 Hz) (kVA)1100/13001500/17007.7/8.40.8/0.87.5/8.30.7/0.8————Fitting (for drain outlet) 1 pc., Input/output signal connector 1 pc., Power supply connector 1 pc.,Operation manual (for installation/operation) 1, Quick manual (with a clear case) 1,Alarm code list sticker 1, Ferritic core (for communication) 1 pc.(Except HRS050)RoHSNote) UL standards: Applicable to 60 Hz onlyNoneWith earth leakage breakerWith automatic water supply function Applicable to DI water (deionized water) pipingHRS012-A -10HRS012-W -10HRS018-A -10HRS018-W -10R407C (HFC)PID controlTemperature: 5 to 40°C, Humidity: 30 to 70%Clear water, 15% ethylene glycol aqueous solution Note 5)5 to 40±0.10.13/0.18 (at 7 L/min)7/7Approx. 5Rc1/2Air-cooled refrigerationWater-cooled refrigeration 151558/5540Single-phase 100 VAC (50/60 Hz), 115 VAC (60 Hz)Allowable voltage range ±10%Air-cooled refrigeration Water-cooled refrigeration5 to 400.3 to 0.580.3 or more ———— 5 to 400.3 to 0.5120.3 or moreStainless steel, Copper (Heat exchanger brazing), Bronze, Alumina ceramic,Carbon, Polypropylene, PE, POM, FKM, EPDM, PVCRc3/8Stainless steel, Copper (Heat exchanger brazing), Bronze, Synthetic rubberModelC i r c u l a t i n g f l u i d s y s t e mF a c i l i t y w a t e r s y s t e mE l e c t r i c a l s y s t e mNote 1)2C o u r t e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m018A20Cooling capacity012018024050Cooling capacity 1100/1300 W (50/60 Hz)Cooling capacity 1700/1900 W (50/60 Hz)Cooling capacity 2100/2400 W (50/60 Hz)Cooling capacity 4700/5100 W (50/60 Hz)CE/ULCooling methodA WAir-cooled refrigeration Water-cooled refrigerationSymbolCooling methodApplicable modelHRS012HRS018HRS024HRS050Pipe thread typeNilF NRcG (with PT-G conversion fitting set)NPT (with PT-NPT conversion fitting set)Power supply Note)20Power supplySymbolHRS How to OrderOptionSymbol NilB J M T GOption NoneWith earth leakage breaker With automatic water supply function Applicable to DI water (deionized water) pipingHigh-lift pump Note 1)High-temperature environment specifications Note 2)b When multiple options are combined, indicatesymbols in alphabetical order.Note 1) The cooling capacity reduces about 300W from the value in the catalog.For HRS050, high-lift pump is available as standard.Note 2) Air-cooled 200 V types, HRS012/018/024 onlyNot UL-compliant (scheduled for 2011)Specifications ∗ There are different values from standard specifications.Note 1) For water-cooled refrigerationNote 2) It should have no condensation.Note 3) If clear water is used, use water that conforms to Water Quality Standards of the Japan Refrigeration and Air Conditioning Industrial Association (JRA GL-02-1994 cooling water system - circulating type - make-up water).Note 4) q Ambient temperature: 25°C, w Circulating fluid temperature: 20°C, e Rated circulating fluid flow rate, r Circulating fluid: Clear water, t Facility water temperature: 25°C Note 5) Use a 15% ethylene glycol aqueous solution if operating in a place where the circulating fluid temperature is 10°C or less.Note 6) Outlet temperature when the circulating fluid flow is rated flow, and the circulating fluid outlet and return port are directly connected. Installation environment and the power supply are within specification range and stable. Note 7) The capacity at the Thermo-chiller outlet when the circulating fluid temperature is 20°C.Note 8) Required flow rate for cooling capacity or maintaining the temperature stability.The specification of the cooling capacity and the temperature stability may not be satisfied if the flow rate is lower than the rated flow.Note 9) Purchase an earth leakage breaker with current sensitivity of 30 mA separately. (A product with an optional earth leakage breaker (option B) is also available.)Note 10) Front: 1 m, height: 1 m, stable with no load, Other conditions → Note 4) Note 11) Weight in the dry state without circulating fluidsNote 12) Required flow rate when a load for the cooling capacity is applied at a circulating fluid temperature of 20°C, and rated circulating fluid flow rate and facility water temperature of 25°C.Note 13) It is not provided for HRS050.Note) UL standards: Applicable to 60 Hz onlyModelHRS012-A -20HRS012-W -20HRS018-A -20HRS018-W -20Cooling methodRefrigerantControl methodAmbient temperature/humidityNote 2)Noise level Note 10) (50/60 Hz) (dB)Accessories Weight Note 11) (kg)Circulating fluidNote 3)Temperature range setting Note 2) (°C)Cooling capacity Note 4) (50/60 Hz) (W)Temperature stability Note 6) (°C)Pump capacity Note 7) (50/60 Hz) (MPa)Rated flow Note 8) (50/60 Hz) (L/min)Tank capacity (L)Port sizeWetted parts materialTemperature range (°C)Pressure range (MPa)Required flow rate Note 12) (50/60 Hz) (L/min)Inlet-outlet pressure differential of facility water (MPa)Port sizeWetted parts materialPower supplyCircuit protector (A)Applicable earth leakage breaker capacity Note 9) (A)Rated operating current (50/60 Hz) (A)Rated power consumption Note 4) (50/60 Hz) (kVA)PID control Temperature: 5 to 40°C, High-temperature environment specifications (option): 5 to 45°C, Humidity: 30 to 70%Clear water, 15% ethylene glycol aqueous solution Note 5)5 to 40±0.1Approx. 5Rc1/2R407C (HFC)Air-cooled refrigeration Water-cooled refrigeration 1100/13001700/19002100/24004700/510023/284.6/5.10.9/1.0 5.1/5.91.0/1.210104.7/5.20.9/1.020208/111.7/2.265/686943Single-phase 200 to 230 VAC (50/60 Hz)Allowable voltage range ±10%Air-cooled refrigeration Water-cooled refrigeration HRS024-A -20Air-cooled refrigeration HRS024-W -20Water-cooled refrigeration HRS050-A -20Air-cooled refrigeration R410A (HFC)———— 5 to 400.3 to 0.580.3 or more ——————————————5 to 400.3 to 0.5120.3 or more 5 to 400.3 to 0.5140.3 or more Fitting (for drain outlet) 1 pc.Note 13), Input/output signal connector 1 pc., Power supply connector 1 pc. Note 13),Operation manual (for installation/operation) 1, Quick manual (with a clear case) 1 Note 13),Alarm code list sticker 1, Ferritic core (for communication) 1 pc. Note 13)Stainless steel, Copper (Heat exchanger brazing), Bronze, Alumina ceramic,Carbon, Polypropylene, PE, POM, FKM, EPDM, PVCRc3/8Stainless steel, Copper (Heat exchanger brazing), Bronze, Synthetic rubber 0.13/0.18 (at 7 L/min)7/70.24 (at 23 L/min)0.32 (at 28 L/min)60/61Note) UL standards: Applicable to 60 Hz onlyScheduled for 2011Scheduled for 2011Single-phase 200 to 230 VAC (50/60 Hz)C i r c u l a t i n g f l u i d s y s t e mE l e c t r i c a l s y s t e mF a c i l i t y w a t e r s y s t e mNote 1)3Thermo-chiller SeriesHRSC o u r t e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m[50 Hz]01020304050Circulating fluid temperature [°C]C o o l i n g c a p a c i t y [W ][60 Hz]01020304050Circulating fluid temperature [°C]C o o l i n g c a p a c i t y [W ][50 Hz]01020304050Circulating fluid temperature [°C]C o o l i n g c a p a c i t y [W ][60 Hz]01020304050Circulating fluid temperature [°C]C o o l i n g c a p a c i t y [W ][50 Hz]01020304050Circulating fluid temperature [°C]C o o l i n g c a p a c i t y [W ][60 Hz]01020304050Circulating fluid temperature [°C]C o o l i n g c a p a c i t y [W ][50 Hz]01020304050Circulating fluid temperature [°C]C o o l i n g c a p a c i t y [W ][60 Hz]25002000150010005001020304050Circulating fluid temperature [°C]C o o l i n g c a p a c i t y [W ][50 Hz]01020304050Circulating fluid temperature [°C]C o o l i n g c a p a c i t y [W ][60 Hz]01020304050Circulating fluid temperature [°C]C o o l i n g c a p a c i t y [W ]2500200015001000500025002000150010005002500200015001000500250020001500100050035003000250020001500100050002500200015001000500025002000150010005002500200015001000500350030002500200015001000500080007000600050004000300020001000001020304050Circulating fluid temperature [°C]C o o l i n g c a p a c i t y [W ][50 Hz]80007000600050004000300020001000001020304050Circulating fluid temperature [°C]C o o l i n g c a p a c i t y [W ][60 Hz]Cooling CapacityHRS012-A-10/HRS012-W-10 (Single-phase 100/115 VAC)HRS018-A-10/HRS018-W-10 (Single-phase 100/115 VAC)HRS024-A-20/HRS024-W-20 (Single-phase 200 to 230 VAC)HRS012-A-20/HRS012-W-20 (Single-phase 200 to 230 VAC)HRS018-A-20/HRS018-W-20 (Single-phase 200 to 230 VAC)25°C32°C 32°C40°C25°C40°C32°C25°C40°C32°C 25°C40°C32°C 40°C25°C32°C 32°C 40°C25°C40°C32°C25°C 32°C 25°C40°C40°C32°C 40°C25°C25°C32°C40°C32°C40°CAmbient temperatureAmbient temperatureHRS050-A-20Ambient temperature or facility water temperatureAmbient temperature or facility water temperatureAmbient temperature or facility water temperatureAmbient temperature or facility water temperatureAmbient temperature or facility water temperatureAmbient temperature or facility water temperatureAmbient temperature or facility water temperatureAmbient temperature or facility water temperature Ambient temperature or facility water temperatureAmbient temperature or facility water temperature 25°C25°C4Series HRSC o u r t e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o mHeating CapacityHRS --10 (Single-phase 100/115 VAC)HRS --20 (Single-phase 200 to 230 VAC)[50 Hz]Circulating fluid temperature [°C]1000800600400200051015202530354045[50 Hz]Circulating fluid temperature [°C]1000800600400200051015202530354045[60 Hz]Circulating fluid temperature [°C]1000800600400200051015202530354045[60 Hz]Circulating fluid temperature [°C]1000800600400200051015202530354045H e a t i n g c a p a c i t y [W ]H e a t i n g c a p a c i t y [W ]H e a t i n g c a p a c i t y [W ]H e a t i n g c a p a c i t y [W ]1020304050Facility water inlet temperature [°C]F a c i l i t y w a t e r f l o w r a t e [L /m i n ]∗ This is the facility water flow rate at the circulating fluid rated flow rate and the cooling capacity listed in the “Cooling Capacity” specifications.Required Facility Water Flow RateHRS012-W-, HRS018-W-, HRS024-W-20302520151050HRS018-W-HRS012-W-HRS024-W-20Pump CapacityHRS --10 (Single-phase 100/115 VAC)Circulating fluid flow rate [LPM]510152025303020100Pressure[MPa]Lifting height [m]0.300.250.200.150.100.050.00Outlet 60 [Hz]Outlet 50 [Hz]Return port012018024AW 012018024AW 012018AW HRS050-A-20 (Single-phase 200 to 230 VAC)1020102010201020HRS --20 (Single-phase 200 to 230 VAC)0.300.250.200.150.100.050.00302010Circulating fluid flow rate [LPM]51015202530Pressure[MPa]Lifting height [m]Outlet 60 [Hz]Outlet 50 [Hz]Return port012018024AW 010203040Circulating fluid flow rate [L/min]Outlet 60 [Hz]Outlet 60 [Hz]Return port504030201000.50.40.30.20.10.0Pressure[MPa]Lifting height [m]Ambient20°C Ambient 25°C Ambient 32°C Ambient 40°CAmbient20°C Ambient 25°C Ambient 32°CAmbient 40°CAmbient 5°C Ambient 5°CAmbient 20°CAmbient 25°C Ambient 32°C Ambient 40°CAmbient 5°CAmbient 20°CAmbient 25°CAmbient 32°CAmbient 40°CAmbient 5°C5Thermo-chiller SeriesHRSC o u r t e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m(35)615500(21)377Drain portwith O-ring sealing plug ∗2Circulating fluid outlet Rc1/2Caster (unfixed) with locking leverCaster (unfixed)Operation display panelCirculating fluid fill port lidFluid level indicatorDustproof filterHandlePower entry ∗1Power switchVentilation air inlet (Air-cooled only)Ventilation air outlet (Air-cooled only)Ventilation air inlet Ventilation air outletVentilation air outletVentilation air outletSerial communication(RS-485/RS-232C) connector D-sub female receptacle Rc1/2(Valve stopper)Rc1/2939707143101135323Maintenance connectorContact input/outputcommunication connector Optional connector 1Optional connector 2Circulating fluid return port Model no. label Circulating fluid outlet BreakerDrain port Rc1/4(Same for the opposite side)(Same for the opposite side)592Ventilation hole HandleCaster (unfixed) with locking leverCaster (unfixed)377Dustproof filterOperation display panelCirculating fluid fill port lidFluid level indicator976Circulating fluid return port Rc1/2(Grommet with membrane)Power supply cable entry Facility water outlet Rc3/8Facility water inlet Rc3/8Water-cooled refrigerationDimensionsHRS012/018/024HRS050∗1 The power supply cable is not provided. (The power supply connector is provided.)∗2 The conversion fitting (R3/8 male thread) is provided.6Series HRSC o u r t e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o mGlobal Manufacturing, Distribution and Service NetworkU.S. & Canadian Sales OfficesAtlantaBirmingham Boston Charlotte Nashville New Jersey Richmond Rochester Tampa MontrealAustinDallasLos Angeles Phoenix PortlandSan Francisco VancouverChicago Cincinnati Cleveland DetroitIndianapolis Milwaukee Minneapolis St. Louis Toronto WindsorEASTCENTRALWESTSMC Corporation of America10100 SMC Blvd., Noblesville, IN 46060 SMC Pneumatics (Canada) Ltd.www.pneumatics.ca(800) SMC.SMC1 (762-7621)e-mail:****************For International inquires: © 2011 SMC Corporation of America, All Rights Reserved.All reasonable efforts to ensure the accuracy of the information detailed in this catalog were made at the time of publishing. However, SMC can in no way warrant the information herein contained as specifications are subject to change without notice.OZ- 5M-PPVancouverChicagoIndianapolisAtlantaAustinLivemoreDetroitBostonMontrealTorontoWindsorSales BranchesRegional Distribution Centers Central warehouseGERMANY SMC Pneumatik GmbH SWITZERLAND SMC Pneumatik AG U.K. SMC Pneumatics (U.K.) Ltd.FRANCE SMC Pneumatique SASPAIN / PORTUGAL SMC España S.A.ITALY SMC Italia S.p.A.GREECE SMC HELLAS E.P.EIRELAND SMC Pneumatics (Ireland) Ltd.NETHERLANDS (Associated company) SMC Pneumatics BV BELGIUM (Associated company) SMC Pneumatics N.V./S.A.DENMARK SMC Pneumatik A/SAUSTRIA SMC Pneumatik GmbH (Austria)North & South AmericaU.S.A. SMC Corporation of America CANADA SMC Pneumatics (Canada) Ltd.MEXICO SMC Corporation(México), S.A. de C.V.BRAZIL SMC Pneumãticos do Brasil Ltda.CHILE SMC Pneumatics (Chile) S.A.COLOMBIA SMC Colombia Sucursal de SMC Chile S.A.ARGENTINA SMC Argentina S.A.BOLIVIA SMC Pneumatics Bolivia S.r.l.VENEZUELA SMC Neumatica Venezuela S.A.PERU (Distributor) IMPECO Automatización Industrial S.A.C.ECUADOR (Distributor) ASSISTECH CIA. LTDA.Europe/AfricaCHINA SMC(China)Co.,Ltd.CHINA SMC Pneumatics (Guangzhou) Ltd.HONG KONG SMC Pneumatics(Hong Kong)Ltd.TAIWAN SMC Pneumatics(Taiwan)Co.,Ltd.KOREA SMC Pneumatics Korea Co., Ltd.SINGAPORE SMC Pneumatics(S.E.A.)Pte.Ltd.MALAYSIA SMC Pneumatics(S.E.A.)Sdn.Bhd.THAILAND SMC (Thailand) Ltd.PHILIPPINES Shoketsu SMC Corporation INDIA SMC Pneumatics(India)Pvt.Ltd.ISRAEL (Distributor) Baccara Geva A.C.S. Ltd. INDONESIA (Distributor) PT. Sinar Mutiara Cemerlang VIETNAM (Distributor) Dy Dan Trading Co.,Ltd.PAKISTAN (Distributor) Jubilee CorporationSRI LANKA (Distributor) Electro-Serv(Pvt.)Ltd.IRAN (Distributor) Abzarchian Co. Ltd.U.A.E. (Distributor) Machinery People Trading Co. L.L.C.KUWAIT (Distributor) Esco Kuwait Equip & Petroleum App. Est.SAUDI ARABIA (Distributor) Assaggaff Trading Est.BAHRAIN (Distributor)Mohammed Jalal & Sons W.L.L. Technical & Automative Services SYRIA (Distributor) Miak Corporation JORDAN (Distributor) Atafawok Trading Est.BANGLADESH (Distributor) Chemie International AUSTRALIA SMC Pneumatics(Australia)Pty.Ltd.NEW ZEALAND SMC Pneumatics(N.Z.)Ltd.JAPAN SMC CorporationAsia/OceaniaAsia/OceaniaCZECH REPUBLIC SMC Industrial Automation CZ s.r.o.HUNGARY SMC Hungary Ipari Automatizálási Kft.POLAND SMC Industrial Automation Polska Sp. z o.o.SLOVAKIA SMC Priemyselná Automatizácia Spol s.r.o.SLOVENIA SMC Industrijska Avtomatika d.o.o.BULGARIA SMC Industrial Automation Bulgaria EOOD CROATIA SMC Industrijska Automatika d.o.o.BOSNIA AND HERZEGOVINA(Distributor) A.M. Pneumatik d.o.o.SERBIA(Distributor) Best Pneumatics RAINE(Distributor) PNEUMOTEC Corp.FINLAND SMC Pneumatics Finland Oy NORWAY SMC Pneumatics Norway AS SWEDEN SMC Pneumatics Sweden AB ESTONIA SMC Pneumatics Estonia OüLATVIA SMC Pneumatics Latvia SIALITHUANIA(LIETUVA) UAB “SMC Pneumatics”ROMANIA SMC Romania S.r.l.RUSSIA SMC Pneumatik LLC.KAZAKHSTAN SMC Kazakhstan, LLC.TURKEY (Distributor) Entek Pnömatik Sanayi ve. Ticaret S ¸irketi MOROCCO (Distributor) Soraflex TUNISIA (Distributor) BymsEGYPT (Distributor) Saadani Trading & Industrial Services NIGERIA (Distributor) Faraday Engineering Company Ltd.SOUTH AFRICA (Distributor) Hyflo Southern Africa (Pty.) Ltd.Europe/AfricaC o u r t e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m。

谷轮™涡旋灵冻™系列ZXV变频冷凝机组产品手册谷轮™涡旋灵冻™系列ZXV 变频冷凝机组艾默生为客户提供灵动系列的ZXV/ZXLV 直流变频冷凝机组,专为冷冻应用而设计。

总体而言,ZX 平台冷凝机组(ZX 和ZXB 中温,ZXL 低温,ZXD/ZXLD 数码变容量中温和低温,ZXV/ZXLV 直流变频中温和低温制冷)在全球尤其亚洲市场取得了巨大的成功,并以其节能和友好的电子控制功能获得普遍认可。

声明感谢您购买艾默生ZXV 冷凝机组。

ZX 平台的冷凝机组与市场上同类产品相比,其制冷能力与运行范围均表现出众,ZX 冷凝机组专为中温和低温制冷应用而设计,具有高可靠性和高效率的特点,并能持续监控压缩机运行状态,显示冷凝机组的运行或故障状态。

安装ZX 平台的冷凝机组必须遵循行业贸易惯例,以确保其安全可靠地运行。

冷凝机组应由专业人员选型、安装和维修。

本用户手册并未包含所有制冷设备安装需遵循的行业准则。

对于由无经验或未经专业培训的人员操作、或由于错误的安装设计造成的损失,将不作为合理的追责理由。

如有任何疑问,请向当地销售办公室提供机组铭牌上的机组型号和序列号进行咨询。

如随机附带的接线图与本手册中的接线图发生不符情况,请以随机附带的接线图为准。

ZX 平台冷凝机组简介ZX 和ZXB 中温、ZXL 低温、ZXD/ZXLD 数码变容量中温和低温、ZXV/ZXLV 变频中温和低温系列在亚洲市场取得了巨大成功,并以其节能和用户友好的电子控制功能享誉市场。

ZX 平台冷凝机组在亚洲范围内应用于著名的终端用户和冷链零售商现场。

灵冻系列平台产品在全球市场上得到广泛认可,特制开发的机型已出口美国、欧洲和中东市场。

收到机组的检查所有机组运输前均充有一定正压的干氮气。

机组和包装均贴有明显的标签。

机组截止阀上配有维修接口以便检查机组保压状态。

注意!当您从艾默生或授权代表处收到机组时,对每一台机组进行保压检查是非常重要的。

如发现保压已消失,请联系艾默生或授权代表。

目录

一、产品介绍 (1)

二、冷凝器的工作原理 (1)

三、冷凝器的规格 (1)

四、基本技术数据 (2)

五、结构与功能 (2)

六、设备的操作 (2)

七、设备的清洗和维护 (3)

八、注意事项 (3)

九、售后服务承诺 (4)

十、配置表 (4)

一、产品介绍

采用不锈钢材质制造,特别适合于制药、化工、生化、农副产品、水产品深加工、食品等行业的稀料液的蒸发浓缩操作,根据工艺的不同,可用于对水蒸气、有机蒸汽的冷凝等等,冷却介质可以为冷却水和冷媒,可根据用户的工艺要求进行选择,本产品可广泛用于各种需加热或冷却操作工序中,具有结构紧凑简单,成本低,使用方便及性价比高等特点。

二、冷凝器的工作原理

冷凝器是用来放热的。

制冷剂是被压缩机压缩到冷凝器,而冷凝器的末端有毛细管。

毛细管会产生阻力使压缩机压缩过来的气态制冷剂液化而达到放热的效果。

冷凝器是高压,只会是热的。

而蒸发器才会是冷的,

冷凝器的液态制冷剂经过毛细管后到达蒸发器会快速气化,蒸发吸热,而达到制冷效果。

冷量和热量就是这样不断循环产生的。

三、冷凝器的规格型号

本公司生产的冷凝器的型号规格如下:

依据换热面积分为:4㎡,6㎡,8㎡,10㎡,15㎡,20㎡,25㎡,30㎡,35㎡。

等。

还可根据客户所需实际换热面积定做。

四、基本技术数据

五、结构及功能

本固定管板列管换热器的结构,主要部分是由不锈钢封头、不锈钢筒体、高效换热管、管板、管箱、管箱及筒体法兰、鞍座等部件构成。

筒体管板形成的内腔构成壳程,管箱换热管的空间构成管程。

经过管、壳程的不同的冷热流体通过对流、热传导及热辐射等方式进行换热,从而达到工艺所需冷却或加热的目的。

本产品可用于诸如蒸发器中的加热器、冷却器等。

因换热管不易清洗,所以换热管一般走清洁且不易结垢的流体以防止堵塞换热管。

六、设备的操作

1、设备使用前应检查各法兰螺丝是否松动,密封垫圈是否良好。

2、使用前按1.25倍的操作压力分到进行水压试验,保压二十分钟无泄漏方可投产。

3、本设备使用前用清自来水进行20分钟左右清洗循环即可了。

4、在管路系统中应设有放气阀开启后应排出设备中空气防止空气停留

在设备中,降低传热效果。

5、冷热介质进出口接管之安装,应严格按出厂铭牌所规定方向连接。

否则,没能发挥设备最佳性能。

6、在冷凝器进出口应安装上压力表,确保不要超压使用。

七、设备的清洗和维护

1、一般情况可不解体清洗,用水以与介质流动反方向冲洗,可冲出杂物,但压力不得高于工作压力,也可用对不锈钢无腐蚀性的化学清洗剂清洗。

2、如长时间使用,管壳程会有一定的沉积物结垢而影响换热效果,因此须定期拆洗。

拆洗时将换热器解体,用棕刷洗刷管壳程内外表面污垢,也可用无腐蚀性的化学清洗剂洗刷。

注意不得用金属刷洗刷,以免损伤板片影响防腐能力。

对于换热管内部及壳的清洗,只有通过无腐蚀性的化学清洗剂洗刷

3、拆装方法:

拆开管箱及筒体法兰上的螺栓即可。

4、换热器使用一定时间后,如有螺栓松动,可再均匀压紧螺栓至不泄漏,但如 -〃密封垫老化,则必须对密封垫进行更换。

5、更换密封垫的方法,拉下旧垫片,用汽油浸泡密封槽内剩余胶水,清洗干净,干燥后,再在槽内和密封垫背面薄薄涂上一层801强力胶,将密封垫嵌入槽内,四周均匀压紧,72小时后方可组装使用。

八、操作规程

1、开始运行操作时,如两种介质压力不一样,要先应缓慢打开低压侧阀门,然后开入高压侧阀门。

2、停车运行时应缓慢切断高压侧流体,再切断低压流体,请注意这样

做将大大有助于本设备之使用寿命。

3、设备应在本产品规定的工作温度、压力范围下操作。

超温超压可能破坏密封性能造成泄漏。

禁止操作时猛烈冲击。

九、售后服务承诺:

1)及时向需方提供按合同规定的全部技术资料各图纸,有义务在必要

时邀请需方参与供方的技术设计审查。

2)按需方要求的时间到现场进行技术服务,指导需方按供方的技术资

料各图纸要求进行安装、分部与整套试运及试生产。

3)对于需方选购的与合同设备有关的配套设备,供方应主动提供满足

设备接口要求的技术条件各资料。

4)严格执行供需双方就有关问题如开会议的纪要或签订的协议。

5)根据需方的要求为需方举办有关设备安装、调试、使用、维护技术

的业务培训,保证需方运行、维修人员熟练掌握运行各维修技能。

6)加强售前、售中、售后服务,把“24小时服务”,“超前服务”,

“全过程服务”,“终身服务”贯彻在产品制造,安装、调试、大修的全过程。

7)接到需方反映的质量问题信息后,在24小时之内做出答复或派出服

务人员,尽快到达现场,做到用户不满意,服务不停止。

8)随时满足需方对备品备件的要求。

9)无论在何种情况下,供方决不以任何理由刁难需方。

十、配置表。