沃尔沃D 发动机资料

- 格式:ppt

- 大小:8.65 MB

- 文档页数:62

Excellent Performance and Cruising RangeThe D12-715 marine diesel engine is spe-c ial l y designed and developed for in s tal -la t ions in fast planing craft fea t ur i ng the lat e st advanced diesel technology. Excellent performance is assured with a rich torque curve matched to the high pow e r output for quick out of the hole ac-c el e r a t ion and high top and cruising speed. Low fuel consumption for long cruising range and low emission levels is assured with:–Electronic Unit Injectors–4-valve technology–Electronically controlled injection tim i ng –High pressure 8-hole injector nozzles–EDC governingThis technology combined optimizesen g ine performance and effi ciency, en s ures effi cient combustion by injecting the right quan t i t y of fuel at the right time, which min-i m iz e s quantity of unburned fuel, re d uc i ng fuel consumption and exhaust emis s ion lev-e ls. The Volvo Penta D12-715 fuel system is designed to give full output regardless of fuel temperature.This technology, in combination with the high power output, gives the boat a wid e r operating range in combination with higher speed.High qualityThe D12-715 is built in the world’s most high l y automated diesel engine factory line with a totally robotic machining and as-s em b ly line with computer controlled audit checks, which ensures the highest quality level.The D12-715 is a further development of the well-proven Volvo Penta in-line six en-g ine concept which ensures high re l i a bil i t y and long term durability.Operation and comfort Electronic remote controls, push button twin engine synchronization and changeof active station ensures easy and smooth op e r a t ion and maneuvering.The electrical control levers are op e r a t e d more smoothly and precisely, requiring much less force.and main t e n ance points contributes tothe ease of ser v ice of the engine.Worldwide service supportin more than 100 countriesThe Volvo Penta parts and servicedeal e r network is a truly internationalop e r a t ion with authorized service deal-e rs around the world. These servicecenters offer Gen u i ne Volvo Penta partsas well as skilled per s on n el to en s ure thebest pos s i b le ser v ice. Con t in u o us andthor o ugh product and ser v ice train i ngen s ures that Vol v o Pen t a prod u cts arewell sup p ort e d.D12-715 – a true marineengine from a true marineengine companyThe D12-715 is a true marine engine asit is developed by a true marine com-p a n y with the best there is to be foundin ma r ine experience and know-how,and built and assembled with the bestpro d uc t ion method there is to be foundin the world.The D12-715 delivers excellent per-f or m ance and cruising range, high re li -abil i t y and durability, in combination withthe high e st level of quality.Automatic twin engine synchronizationre d uc e s noise and vibration levels, andin c reas e s service life of engine.This in combination with the well-bal-a nced D12-715 in-line six cylinder enginewith powerfully dimensioned crankshaftbear i ngs and vibration damper on cam-s haft ensures smooth, vibration-free op-e r a t ion with low noise levels.Low exhaust emissionlevelsThe D12-715 advanced diesel technologygreatly contributes to more effi cient com-b us t ion with higher power and reducednox i ous exhaust emissions.The D12-715 is certifi ed according toIMO.Easy installationThe D12-715 gives a time saving and re-l i a ble installation, as it is a complete de l iv -ered compact and tailor-made propulsionsys t em from one single supplier.Plug-in water-protected harnesses andconnectors, compact dimensions and theEDC system ensures an easy, simple andtime-saving installation.Ease of service andmaintenanceThe EDC system features a self-di a g -nos t ic facility. Easily accessible service* Power rating – see Technical DataD12-715Technical DataEngine designation.......................................D12-715 No. of cylinders and confi guration.............in-line 6 Method of operation.....................................4-stroke,direct-injected, turbocharged diesel engine with aftercooler Bore, mm (in.)............................................131 (5.16) Stroke, mm (in.).........................................150 (5.91) Displacement, l (in3)...........................12.13 (740.2) Compression ratio...........................................16.5:1 Dry weight, kg (lb).................................1400 (3086) Dry weight with reverse gearZF 325A-EB, kg (lb).............................1570 (3461) Crankshaft power,kW (hp) @ 2300 rpm ................................526 (715) Max. torque,Nm (lbf.ft) @ 1600 rpm.......................2925 (2159) Recommended fuel toconform to.........................ASTM-D975 1-D & 2-D, ..............................................EN 590 or JIS KK 2204 Specifi c fuel consumption,g/kWh (lb/hph) @ 2300 rpm................228 (0.369) T echnical data according to ISO 3046 Fuel Stop Power andISO 8665. Fuel with a lower calorifi c value of 42700 kJ/kg and density of 840 g/liter at 15 °C (60 °F). Merchant fuel may differ from this spec ific a t ion which will infl uence engine power output and fuel con s ump t ion.Rating: 5The engine is certifi ed according to IMO.Technical description:Engine and block—Cylinder block and cylinder head made ofcast-iron—One piece cylinder head—Replaceable wet cylinder liners and valve seats/guides—Drop forged crankshaft with induction hard-e ned bearing surfaces and fi llets with sev e n main bearings —Four valve per cylinder layout with over-h ead camshaft—Each cylinder features cross-fl ow in l et andexhaust ducts—Gallery oil-cooled forged aluminum pis t ons—Three piston ringsLubrication system—Integrated oil cooler in cylinder block—Twin full fl ow oil fi lter of spin-on type andby-pass fi lterFuel system—Six Electronic Unit Injectors, one per cyl-i n d er, vertically positioned at the center inbetween the four valves—Gear-driven fuel pump, driven by tim i nggear—Electronically controlled central pro c ess i ngsystem (EDC – Electronic Die s el Con t rol)—Electronically controlled injection tim i ng—8-hole high pressure injector noz z les—Single fi ne fuel fi lter of spin-on type, withwater separatorTurbocharger—Freshwater-cooled turbo chargerCooling system—Freshwater-cooled charge air cooler—Gear-driven coolant pumps—Tubular heat exchanger or single-cir c uitkeel coolingElectrical system—24V electrical system, 24V/60A al t er n a t orReverse gear—ZF 325A-EB, elec t ri c al l y shiftedOptional equipmentContact your Volvo Penta representative.Not all models, standard equipment and accessories are avail-a ble in all countries. All spec ific a t ions are sub j ect to changewithout notice.The engine illustrated may not be entirely identical to pro-d uc t ion standard engines.3-23©23ABVolvoPenta.AB Volvo PentaSE-405 08 Göteborg, SwedenDimensions D12-715 with ZF 325A-EB Not for installationFuel consumptionRpmPower1.Crankshaft pow errpmTorqueRpm。

沃尔沃发动机性能介绍Volvo Penta工业发动机的用户遍及世界各地,不管是移动的仍是固定式的用途,在那些能够想象取得的苛刻工作环境里,你都能够找到它们。

历经了90连年的发动机制造历史,Volvo Penta那个品牌已经成为运行靠得住、技术创新、性能一流和利用寿命的象征。

咱们相信这些特点也正是你对新的Volvo Penta 工业发动机所期盼和要求的。

产品介绍瑞典沃尔沃发动机采纳完全电喷油操纵技术,高性能指标、高靠得住性。

具有起动性能优良、电压稳固、运行靠得住、低排放、低噪音、保护方便等优势,有良好的经济性,良好的高原适应能力。

所有的发动机均装有电子操纵治理系统(EMS 2)、涡轮增压器、中冷器、恒温操纵的冷却系统及电子调速技术说明发动机和气缸体气缸体和气缸盖采纳合金铸铁制造7挡主轴颈经感应淬硬的曲轴可改换的温式气缸套有润滑油冷却的铸铝活塞3道活塞环。

顶环为“梯形”环有7挡轴承、感应淬硬的顶置的凸轮轴第缸4气门可改换的气门座圈和气门导管燃油系统燃油供给采纳微处置器的操纵单元(EMS 2)齿轮驱动的供油泵中心布置的带电磁操纵燃油阀的泵喷嘴旋装式二级燃油滤清器和油水分离器润滑系统水冷的润滑油冷却器齿轮驱动的润滑油泵2个全流和1个旁通的旋装式润滑油滤清器增压系统涡轮增压器冷却系统带澎胀水箱的散热器空气冷却的中冷器皮带驱动的水泵活塞式节温器电气系统24V电气系统带充电传感线的充电发电机,80A(110A可选)装在发动机上的紧急停机按扭EMS 2EMS 2(Engine Management System)是一个具有CAN(Controller Area Network-操纵器区域网络)通信功能的电子系统,用以实现对柴油机的操纵。

此系统由Volvo Penta开发,包括燃油操纵和诊断功能。

概述系统包括传感器、操纵单元和泵喷嘴。

传感器发送输入信号给操纵单元,操纵单元依次操纵泵喷嘴。

输入信号操纵单元从以下零部件处接收有关发动机的运行状况等输入信号:冷却液温度传感器增压压力/增压空气温度传感器曲轴箱压力传感器凸轮轴相位传感器飞轮转速传感器活塞冷却油压力传感器冷却液液位传感器润滑油压力传感器润滑油油位和温度传感器燃油压力传感器燃油进水指示器空气滤清器阻塞指不器进气温度传感器输出信号操纵单元依照收到的输入信号操纵以下零部件泵喷嘴起动马达主继电器预热继电器传感器提供有关当前运行状况的准确信息,以使操纵单元中的处置器计算出精准的燃油喷油量和正时,并检查发动机的状况等。

VOLVO(沃尔沃)系列柴油发电机组:瑞典 VOLVO (沃尔沃)集团是众所周知的世界久负盛名的大公司之一,其下属的VOLVO PENTA 公司是生产柴油发电机组用、专用车辆用及船用等柴油发动机专业公司,VOLVO 只专注于直列六缸柴油机生产,它在此技术上傲视群雄,如今已有超过100万台的VOLVO PENTA 柴油机之发电机组在世界各地运行。

VOLVO公司在一百多个国家建立起了全球性的服务网络。

1) 直列六缸、水冷、废气涡轮增压、四冲程、进气为水对空气中冷式(TWD 型),或进气为空气对空气中冷式(TAD型),直喷式燃油系统。

2) 低惯量增压器和直列式柱塞喷油泵、一体式的机械式调速器或GAC电子调速器,多孔式喷油器所组成的反应讯速的喷油系统,使发动机具备了在很短的恢复时间内有高的承受载荷能力。

3) 湿式可更换缸套,带阻火台肩,可使汽缸头抗高温。

铸铁缸体优化力的分布,无多余重量,整机特别地轻。

氮—碳处理的曲轴及传动齿轮适合重载运行,曲轴上有7个轴承以降低主轴承的负荷。

4) 在进气歧管中的电加热器可使发动机在冬季低温时起动快捷、可靠,并可降低废气排放。

采用先进的技术优化燃烧过程,显著地降低了燃油消耗。

优化的平衡器及精确匹配的增压器及低速冷却风扇,使发动机运行平稳、噪声低。

5) 全新设计的全电喷发动机还具有:可靠性更高,无大修时间超过3万小时,达到业界领先水平;更低的油耗,使成本降低;符合欧盟二号排放标准;高海拔功率下降少,每上升1000米功率下降≤2.5%;分步负载性能更优异,转速降少且恢复时间更短;更佳的低温冷启动性能;许较大的排烟背压,这意味着可进行更有效的消音或使用更长的排烟管华动牌柴油发电机组发电机采用英国独资无锡新时代斯坦福发电机和华动牌发电机英国独资无锡新时代斯坦福发电机简介:总部设在英国的新时代国际有限公司是世界交流发电机技术先导和首屈一指的生产商,交流4级5KW—3000KW发电机在世界市场上占有30%以上份额,在英国、印度、美国、印度尼西亚及中国的无锡设有生产厂,斯坦福交流发电机是在国际标准ISO9001要求中按多种国际认可标准完成。

VOLVO PENTA GENSET ENGINE TAD1641GE473kW (643 hp) at 1500 rpm, 546 kW (743 hp) at 1800 rpm, acc. to ISO 3046 The TAD1641GE is a powerful, reliableand economical Generating Set DieselEngine built on the dependable in-line sixdesign.Durability & low noiseDesigned for easiest, fastest and mosteconomical installation. Well-balancedto produce smooth and vibration-freeoperation with low noise level.To maintain a controlled working tem-perature in cylinders and combustionchambers, the engine is equipped withpiston cooling. The engine is also fittedwith replaceable cylinder liners and valveseats/guides to ensure maximum dura-bility and service life of the engine.Low exhaust emissionThe state of the art, high-tech injectionand charging system with low internallosses contributes to excellent combus-tion and low fuel consumption.The TAD1641GE complies with EUStage 2 exhaust emission regulations.Easy service & maintenanceEasily accessible service and mainte-nance points contribute to the ease ofservice of the engine.Technical descriptionEngine and block– Optimized cast iron cylinder block with opti-mum distribution of forces without the blockbeing unnecessary heavy.– Wet, replaceable cylinder liners– Piston cooling for low thermal load on pis-tons and reduced ring temperature– Tapered connecting rods to reduce risk of piston cracking– Crankshaft induction hardened bearing surfaces and fillets with seven main bear-ings for moderate load on main and big-end bearings– Nitrocarburized transmission gears for heavy duty operation– Keystone top compression rings for long service life– Viscous type crankshaft vibration damper– Replaceable valve guides and valve seats– Over head camshaft and four valves per cylinder equipped with camshaft damper to reduce noise and vibrations. Lubrication system– Full flow oil cooler– Full flow disposable spin-on oil filters, for extra high filtration– The lubricating oil level can be measured during operation (Standard dipstick only)– Gear type lubricating oil pump, gear driven by the transmission Fuel system– Self de-aerating system. When replacingfilters all fuel stays in the engine.– Non-return fuel valve– Electronic unit injectors– Fuel prefilter with water separator and wa-ter-in-fuel indicator / alarm– Gear driven low-pressure fuel pump– Fine fuel filter with manual feed pump andfuel pressure switch– Fuel shut-off valve, electrically operatedCooling system– Efficient cooling with accurate coolant con-trol through a water distribution duct in thecylinder block. Reliable sleeve thermostatwith minimum pressure drop– Belt driven, maintenance-free coolant pumpwith high degree of efficiency– Coolant filter as standardTurbo charger– Efficient and reliable turbo charger– Extra oil filter for the turbo chargerElectrical system– Engine Management System 2 (EMS 2), anelectronically controlled processing systemwhich optimizes engine performance. It alsoincludes advanced facilities for diagnosticsand fault tracing– The instruments and controls connect to theengine via the CAN SAE J1939 interface,either through the Control Interface Unit(CIU) or the Digital Control Unit (DCU). TheCIU converts the digital CAN bus signal toan anolog signal, making it possible to con-nect a variety of instruments. The DCU is acontrol panel with display, engine control,monitoring, alarm, parameter setting and di-agnostic functions. The DCU also presentserror codes in clear text.– Sensors for oil pressure, oil temp, boostpressure, boost temp, coolant temp, fueltemp, water in fuel, fuel pressure and twospeed sensors. Crank case pressure, pistoncooling pressure, oil level and air filter pres-sure drop sensors.– Alternator 24V / 80AFeatures– Maintained performance, air temp 40°C– Tropical cooling system (55°C)– Fully electronic with Volvo Penta EMS 2– Dual frequency switch (between 1500 rpm and 1800 rpm)– High power density– Emission compliant– Low noise levels–Gen Pac configurationPower StandardsThe engine performance corresponds to ISO 3046, BS5514 and DIN 6271. The technical data applies to an engine without cooling fan and operating on a fuel with calorific value of 42.7 MJ /kg (18360 BTU/lb) and a density of 0.84 kg/liter (7.01 lb/US gal), also where this involves a deviation from the standards. Power output guaranteed within 0 to +2% att rated ambient conditions at delivery. Ratings are based on ISO 8528. Engine speed governing in accordance with ISO 3046/IV, class A1 and ISO 8528-5 class G3Exhaust emissionsThe engine complies with EU stage 2 emission legislation according to the Non Road Directive EU 97/68/EEC. The engine also complies with TA-luft -50% exhaust emission regulations.Rating GuidelinesPRIME POWER rating corresponds to ISO Standard Power for continuous operation. It is applicable for supplying electrical power at variable load for an unlimited number of hours instead of com-mercially purchased power. A10 % overload capability for govering purpose is available for this rating.MAXIMUM STANDBY POWER rating corresponds to ISOStandard Fuel Stop Power. It is applicable for supplying standby electrical power at variable load in areas with well established electrical networks in the event of normal utility power failure. No overload capability is available for this rating.1 hp = 1 kW x 1.36InformationFor more technical data and information, please look in the Gener-ating Set Engines Sales Guide.TAD1641GEAB Volvo PentaSE-405 08 Göteborg, SwedenTechnical DataGeneralEngine designation ........................................................................TAD1641GE No. of cylinders and configuration .......................................................in-line 6Method of operation ...............................................................................4-stroke Bore, mm (in.) .....................................................................................144 (5.67)Stroke, mm (in.) ..................................................................................165 (6.50)Displacement, l (in³) ....................................................................16.12 (983.7)Compression ratio .....................................................................................16.5:1Dry weight, kg (lb) ..........................................................................1480 (3263)Dry weight with Gen Pac, kg (lb) ...............................................1910 (4211)Wet weight, kg (lb) ........................................................................1550 (3417)Wet weight with Gen Pac, kg (lb) ..............................................2020 (4453)Performance1500 rpm 1800 rpm with fan, kW (hp) at: Prime Power430 (585) 485 (660)Max Standby Power473 (643)546 (743)Lubrication system 1500 rpm 1800 rpm Oil consumption, liter/h (US gal/h) at:Prime Power 0.10 (0.026) 0.11 (0.029)Max Standby Power 0.10 (0.026) 0.12 (0.032)Oil system capacity incl filters, liter ................................................................42Fuel system1500 rpm 1800 rpm Specific fuel consumption at:Prime Power, g/kWh (lb/hph) 25 % 223 (0.361) 232 (0.376)50 % 201 (0.326) 202 (0.327)75 % 196 (0.318) 197 (0.319) 100 %198 (0.321) 200 (0.324)Max Standby Power, g/kWh (lb/hph) 25 % 218 (0.353) 228 (0.370)50 % 199 (0.323) 201 (0.326)75 % 195 (0.316) 197 (0.319)100 %198 (0.321)205 (0.332)Intake and exhaust system 1500 rpm 1800 rpm Air consumption, m³/min (cfm) at: Prime Power 32 (1130) 42 (1483)Max Standby Power 35 (1236) 45 (1589)Max allowable air intake restriction,kPa (In wc) 5 (20.1) 5 (20.1)Heat rejection to exhaust, kW (BTU/min) at: Prime Power 326 (18539) 373 (21212)Max Standby Power 356 (20245) 442 (25136)Exhaust gas temperature after turbine, °C (°F) at: Prime Power 475 (887) 435 (815)Max Standby Power 490 (914) 470 (878)Max allowable back-pressure in exhaust line,kPa (In wc) 10 (40.2) 10 (40.2)Exhaust gas flow, m³/min (cfm) at:Prime power 79.0 (2790) 97.0 (3426)Max Standby Power 84.9 (2998) 106.6 (3765)Cooling system 1500 rpm 1800 rpm Heat rejection radiation from engine,kW (BTU/min) at:Prime Power 30 (1706) 32 (1820)Max Standby Power 34 (1934) 33 (1877)Heat rejection to coolant kW (BTU/min) at:Prime Power 172 (9781) 185 (10521)Max Standby Power 176 (10009) 199 (11317)Fan power consumption, kW (hp) 11 (15)19 (26)Standard equipmentEngineGen PacEngineAutomatic belt tensioner • •Lift eyelets • •FlywheelFlywheel housing with conn. acc. to SAE 1 • •Flywheel for 14” flex. plate and flexible coupling • •Vibration dampers • •Engine suspension Fixed front suspension • •Lubrication system Oil dipstick• •Full-flow oil filter of spin-on type • •By-pass oil filter of spin-on type • •Oil cooler, side mounted • •Low noise oil sump • •Fuel systemFuel filters of disposable type • •Electronic unit injectors• •Pre-filter with water separator • •Intake and exhaust systemAir filter with replaceable paper insert • •Air restriction indicator• •Air cooled exhaust manifold• •Connecting flange for exhaust pipe • •Exhaust flange with v-clamp • •Turbo charger, low right side • •Cooling systemTropical radiator incl intercooler •¹) •Belt driven coolant pump • •Fan hub • •Thrust fan •¹) •Fan guard − •Belt guard−•Control systemEngine Management System (EMS) with CAN-bus interface SAE J1939 ••CIU, Control Interface Unit – –AlternatorAlternator 80A / 24V • •Starting systemStarter motor, 7.0kW, 24V• •Connection facility for extra starter motor • •Instruments and sendersTemp.- and oil pressure for automatic ••stop/alarm 103°C Other equipmentExpandable base frame − •Engine Packing Plastic wrapping••1)must be ordered, se order specification − optional equipment or not applicable • included in standard specificationNote! Not all models, standard equipment and accessories are available in all countries. All specifications are subject to change without notice.The engine illustrated may not be entirely identical to production standard engines.E n g l i s h 12-2006. © 2006 A B V o l v o P e n taA* = 1587 mm / 62.5 in B* = 1120 mm / 44.1 in C* = 1976 mm / 77.8 inD = 2296 mm / 90.5 in (During transport)D = Max 3311 mm / 130.5 in* Including radiator and intercooler。

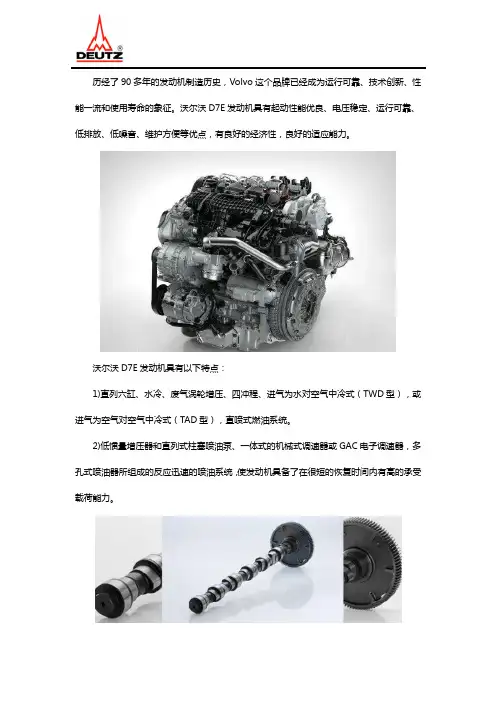

历经了90多年的发动机制造历史,Volvo这个品牌已经成为运行可靠、技术创新、性能一流和使用寿命的象征。

沃尔沃D7E发动机具有起动性能优良、电压稳定、运行可靠、低排放、低噪音、维护方便等优点,有良好的经济性,良好的适应能力。

沃尔沃D7E发动机具有以下特点:1)直列六缸、水冷、废气涡轮增压、四冲程、进气为水对空气中冷式(TWD型),或进气为空气对空气中冷式(TAD型),直喷式燃油系统。

2)低惯量增压器和直列式柱塞喷油泵、一体式的机械式调速器或GAC电子调速器,多孔式喷油器所组成的反应迅速的喷油系统,使发动机具备了在很短的恢复时间内有高的承受载荷能力。

3)湿式可更换缸套,带阻火台肩,可使汽缸头抗高温。

铸铁缸体优化力的分布,无多余重量,整机特别地轻。

氮—碳处理的曲轴及传动齿轮适合重载运行,曲轴上有7个轴承以降低主轴承的负荷。

4)在进气歧管中的电加热器可使发动机在冬季低温时启动快捷、可靠,并可降低废气排放。

5)全新设计的全电喷发动机还具有:可靠性更高,无大修时间超过3万小时;更低的油耗,使成本降低;符合欧盟二号排放标准;高海拔功率下降少,每上升1000米功率下降≤2.5%;分步负载性能更优异,转速降少且恢复时间更短;更佳的低温冷启动性能;较大的排烟背压。

沃尔沃发动机购买和售后维修服务推荐北京沃博。

北京沃博内燃柴油机械有限公司是一家具有多年历史,从事销售维修德国道依茨(DEUTZ),瑞典VOLVO及VOLVO-PENTA发动机和配件的专业化的服务企业!为客户提供相关技术咨询和售后服务和发动机大中修业务。

本公司经营理念的根本是:透过完善的技术服务和优质优价的配套产品来创造业内新的服务标准;透过积极主动的策略让客户获得更大的满足,并透过严谨的管理体系来落实。

本公司资深的销售、技术人才,凭借丰富的专业经验和竭诚服务的良好作风,在全国建立了良好的声誉和客户群体。

本公司以专业经营道依茨发动机总成和发动机配件为主,道依茨风冷发动机FL912, 913,914,413,513系列,水冷发动机FM1011, 1012, 1013, TCD2011,2012,2013,2015系列!公司按市场客户的业务需求下设:整机销售部,配件销售部,售后维修服务部,并设立业务在线咨询,提供24小时服务!本公司同时销售服务“燃气机组一绿色动力”业务。

DH12D 发动机设计与功能学生手册DH12D发动机目录 本手册主要介绍了发动机的设计与功能。

关于其维修以及特殊工具的使用在Volvo维修手册中有专门介绍。

1 DH12D型发动机.................32 发动机标识....................43 缸盖..........................64 缸体..........................75 活塞,缸套和密封圈............86 配气机构......................97 正时齿轮.....................108 曲轴.........................119 润滑系统.....................1210 润滑系统的工作过程...........1311 机油冷却器和机油泵...........1512 燃油系统.....................1613 燃油系统组成.................1714 燃油喷射系统.................1915 整体式喷油器充油相位.........2016 整体式喷油溢流油相位.........2117 整体式喷油器喷油相位.........2218 整体式喷油器减压相位.........2319 进气口和空气滤清器...........2420 涡轮增压器...................2521 充气冷却和启动预热...........2622 废气压力调节器...............2723 发动机制动...................2924 控制阀.......................3125 凸轮轴和排气摇臂.............3226 排气门操作...................3427 压缩制动工作过程.............3528 冷却系统.....................3629 冷却液循环...................3730 散热风扇.....................391 DH12D型发动机 DH12D是一款12升发动机标识,该款发动机用于Volvo B 12M和B12B型客车。

The D8K350, EU6SCR is an in-line six-cylinder diesel engine wi th a di splacement of 7.7 li tres, equi pped wi th a turbocharger and intercooler. The engine produces 350 hp and 1400 Nm of torque. The eng ne meets the EU exhaust em ss ons requirements according to the Euro 6 standards.The engine has a single cylinder head and an overhead camshaft which operates four valves per cylinder via rocker arms. The engine’s functions are controlled electronically. Fuel injection takes place using common rail technology. In combination with SCR emission control, the engine emissions meets the Euro 6 emission standards. Through optimized calibration of the electronic engine control system, particulate emissions have been cut by 50 % and NOx by 80 % compared with the corresponding Euro 5 levels. As a result, this engine is environmentally optimised and particularly suitable for vulnerable city environments and metropolitan green zones that impose tough particulate and smoke emission standards.Ready for alternative fuelThe engine is also certified for usage of HVO - EN15940 (Hydrotreated Vegetable Oil). It reduce the emissions of greenhouse gases dramatically and is the perfect option if you want to help environment and enjoy (if applicable) the incentives in your market.• Excellent driveability thanks to a wide torque range and swift response to the accelerator.• Efficient combustion and exhaust filtration with SCR and DPF technology contribute to low fuel consumption, long service intervals and very low emissions.FEATURES AND BENEFITSExcellent driveabilityThe engine has a particularly wide torque range, which means that it is possible to stay within the economy rev band easily and with minimal gear changing. The engine has a VGT (Variable Geometry Turbine) turbocharger. It provides excellent torque from low revs, which results in quick response to the accelerator and enhanced driveability at low speeds.One contributing factor to the excellent driveability is fuel injection using common rail technology. The fuel is injected under high pressure (2000 bar). Injection pressure and injection timing are controlled electronically, which results in precisely metered and exceptionally finely atomised fuel being sprayed into the combustion chamber. The control function is adjusted instantaneously to suit current operating conditions and the possibility of also injecting fuel after the main charge adds considerable flexibility. Efficient combustionLow emission ratings and low fuel consumption with the help of electronic engine control – EMS – make for precise fuel injection and efficient combustion.The piston crowns feature a recess that forces the gases out towards the edges of the combustion chamber, thus contributing to efficient combustion. The shape of the inlet ducts in the cylinder head leads to slower rotation speed and lower pressure drop. This contributes to lower exhaust emissions and a higher efficiency rating. Low noise levelThe timing of the fuel injection is variable. This has a positive effect on the engine’s noise level and emissions. Before the main injection charge, small amounts of fuel are injected, thus significantly reducing ignition delay and lowering the noise created during the main combustion sequence.Exhaust emission control with SCR technology for Euro 6 fulfilmentVolvo has chosen to supplement optimum combustion technology with SCR (Selective Catalytic Reduction) technology for after-treatment of the exhaust gases. In this process, an additive (AdBlue) is injected into the exhaust gases before they pass through an SCR catalytic converter. In the catalytic converter, the AdBlue reacts with the nitrogen oxides in a process that ignificantly reduces emissions. This takes place through conversion of the nitrogen oxides into nitrogen gas and water vapour. The pre-catalyst increases the SCR catalyst efficiency at low exhaust temperatures. It also improves the life-time durability of the SCR catalyst in the muffler. The SCR technology is robust and dependable, resulting in low service costs and long service intervals.The electronically controlled and water-cooled EGR valve improves gas-flow, ensuring that the exhaust gases reach an optimal temperature before entering the after-treatment system – EATS. The after-treatment process starts in the diesel oxidation catalyst (DOC) where NO2 is generated. This is necessary in order to create an optimal particle combustion in the DPF filter. The procedure provides the heat needed for regeneration in cold conditions as well. The heat for active DPF regeneration is created by oxidizing diesel fuel from a 7th injector.The second step of the process is the diesel particle filter where the particles are stored until the autoregeration function is activated (and the particles are burned off). Then, the emissions reach the mixing zone/Selective Catalyst Reduction (SCR), where they are sprayed with AdBlue. This process turns the nitrogen oxides into harmless nitrogen gas and water. As the exhaust gases reach the final step in the process, Ammonia Slip Catalyst (ASC), remaining ammonia (if any) is removed.Long service lifeThe cylinder block and cylinder head are made of cast-iron which gives a strong but light frame. The cylinder liners are of the dry type. The engine can either be equipped with open crankcase ventila-tion or with a closed version (min -25° C).The oil change interval is depending on different operating conditions for the truck. For Volvo FE with VDS 4 or VDS 4.5 oil, it is up to 100 000 km (or once every second year).Volvo Truck Corporation800600100012001400160018002000220024002600800500400 300900Volvo retains the right to modify design and specifications without prior notification.SPECIFICATIONType designation .................................................................D8K350, EU6SCR Max power at 2200 r/min ...................................................350 hp (258 kW)Max revs ..............................................................................................2650 r/min Max torque at 1200 – 1600 r/min ...................................................1400 Nm No. of cylinders ....................................................................................................6Bore ............................................................................................................110 mm Stroke ........................................................................................................135 mm Displacement ..........................................................................................7.7 dm3Compression ratio ......................................................................................17,5:1Economy rev range ............................................................1200 – 1600 r/min Exhaust brake output (EBR-EPG) ............................137 kW at 2650 r/min Engine brake output with EBR-CEB(compr. brake) .................................................................................................................................170 kW at 2650 r/min Oil-change volume incl. oil filter ......................................................25,5 l (FE)Cooling system, total volume ................................................................17 litres Oil filter ........................................................................Green Oil filter, 1full-flow Dry weight (base engine) .........................................................approx. 732 kgRear engine PTO (+ 28 kg)• 600 Nm at 800-1200 r/min • Position at 12 ‘o clock• Ratio 1.1: DIN5462, SAE1410, DIN100Power hpTorque NmEngine speed r/min。

D13A发动机不同的市场需求意味着可能与此说明的某些部分存在不同。

D13A是沃尔沃为FM和FH车型全新设计的13升发动机的名称,该发动机将于2005年秋季问世。

该发动机为带有涡轮增压器、中间冷却器和电控燃油喷射(EMS - 发动机管理系统)的直列六缸直喷式柴油机。

它具有五种功率输出机型:360 hp、400 hp、440 hp、480 hp 和520 hp。

D13A是全新的设计,但基本原理是基于带有后部正时驱动装置、整体式缸盖、顶置凸轮轴、单体泵以及VEB或EPG型发动机制动的D9/D16C发动机。

D13A型发动机符合欧3排放要求并且在2006年进行进一步的环保方面的改进,使该发动机将能满足欧4排放要求。

发动机可选择开式或闭式曲轴箱通风。

闭式曲轴箱通风消除了滴油的风险,并且这是敏感环境下运输业诸多市场广受欢迎的特性。

发动机整个名称(D13A440)的含义是:• D = 柴油•13 = 气缸容积(升)• A = 代•440 = 类型(输出功率,单位:马力)发动机标识摇臂室盖左侧固定有两个标签(1和2),用于识别不同的发动机类型。

控制单元后部的标签(3) 上还压印有发动机系统的数据(包括零件号)。

发动机缸体左侧,靠近顶部的地方压印有发动机序列号(4),而在同一侧铸有发动机缸体铸造日期和其它数据(5)。

标签1包括:底盘号(车辆)、发动机序列号及其条形码。

标签2 主要包括一些其它信息:•喷油嘴类型:1 = 发动机拥有E3型单体泵•排气制动:VEB = 沃尔沃发动机制动EPG = 排气制动•发动机型号:EC01 = 欧3排放等级发动机缸盖缸盖用一块铸铁铸造而成,这可以确保顶置凸轮轴有稳定的支撑基础。

凸轮轴由装有可更换轴瓦的七个水平分离式轴承支架制成。

后端的轴承支架上的轴瓦还设计为止推轴承。

冷却液节温器壳体直接在缸盖上机加工而成,位于缸盖右前侧(A)。

每个气缸在缸盖一侧都有一个独立的进气室,在另一侧都有一个独立的排气室,使该发动机成为横流式发动机(B)。

D13A发动机不同的市场需求意味着可能与此说明的某些部分存在不同。

D13A是沃尔沃为FM和FH车型全新设计的13升发动机的名称,该发动机将于2005年秋季问世。

该发动机为带有涡轮增压器、中间冷却器和电控燃油喷射(EMS - 发动机管理系统)的直列六缸直喷式柴油机。

它具有五种功率输出机型:360 hp、400 hp、440 hp、480 hp 和520 hp。

D13A是全新的设计,但基本原理是基于带有后部正时驱动装置、整体式缸盖、顶置凸轮轴、单体泵以及VEB或EPG型发动机制动的D9/D16C发动机。

D13A型发动机符合欧3排放要求并且在2006年进行进一步的环保方面的改进,使该发动机将能满足欧4排放要求。

发动机可选择开式或闭式曲轴箱通风。

闭式曲轴箱通风消除了滴油的风险,并且这是敏感环境下运输业诸多市场广受欢迎的特性。

发动机整个名称(D13A440)的含义是:• D = 柴油•13 = 气缸容积(升)• A = 代•440 = 类型(输出功率,单位:马力)发动机标识摇臂室盖左侧固定有两个标签(1和2),用于识别不同的发动机类型。

控制单元后部的标签(3) 上还压印有发动机系统的数据(包括零件号)。

发动机缸体左侧,靠近顶部的地方压印有发动机序列号(4),而在同一侧铸有发动机缸体铸造日期和其它数据(5)。

标签1包括:底盘号(车辆)、发动机序列号及其条形码。

标签2 主要包括一些其它信息:•喷油嘴类型:1 = 发动机拥有E3型单体泵•排气制动:VEB = 沃尔沃发动机制动EPG = 排气制动•发动机型号:EC01 = 欧3排放等级发动机缸盖缸盖用一块铸铁铸造而成,这可以确保顶置凸轮轴有稳定的支撑基础。

凸轮轴由装有可更换轴瓦的七个水平分离式轴承支架制成。

后端的轴承支架上的轴瓦还设计为止推轴承。

冷却液节温器壳体直接在缸盖上机加工而成,位于缸盖右前侧(A)。

每个气缸在缸盖一侧都有一个独立的进气室,在另一侧都有一个独立的排气室,使该发动机成为横流式发动机(B)。