多喷嘴对置式水煤浆加压气化孙正泰23页PPT

- 格式:ppt

- 大小:2.58 MB

- 文档页数:23

多喷嘴对置式水煤浆气化工艺流程英文回答:Multi-Injection Opposed Coal-Water Slurry Gasification Technology Process.Introduction.Multi-injection opposed coal-water slurry gasification technology is an innovative and efficient method for converting coal-water slurry (CWS) into syngas, a versatile fuel used in a wide range of applications. This advanced technology offers numerous advantages over conventional gasification processes, including increased efficiency, reduced emissions, and flexibility in fuel utilization.Process Description.The multi-injection opposed coal-water slurry gasification process comprises several key stages:1. Slurry Preparation: Coal is crushed and blended with water to form a homogeneous coal-water slurry.2. Injection: The CWS is injected into the gasification reactor through multiple nozzles.3. Reaction: The CWS undergoes a series of chemical reactions in the reactor, including pyrolysis, gasification, and combustion.4. Syngas Production: The product of the gasification process is syngas, a mixture of hydrogen, carbon monoxide, and other gases.5. Purification: The syngas is purified to remove impurities and contaminants.6. End Use: The purified syngas can be used as a fuelfor various applications, such as power generation,industrial heating, and transportation.Advantages of Multi-Injection Opposed Coal-Water Slurry Gasification.High Efficiency: The multi-injection design optimizes reaction conditions, leading to more efficient conversion of CWS into syngas.Low Emissions: The technology minimizes emissions of pollutants, such as sulfur dioxide and nitrogen oxides, by controlling combustion and utilizing advanced purification techniques.Fuel Flexibility: The gasification process can handle a wide range of coal types and qualities, providing operational flexibility.Compact Design: The reactor design is compact and modular, allowing for easier installation and maintenance.Economic Viability: The technology offers competitive operating costs and potential revenue streams from syngas utilization.Applications.Multi-injection opposed coal-water slurry gasification technology has a broad range of applications, including:Power Generation: Syngas can be used as a clean and efficient fuel for power plants.Industrial Heating: Syngas can be utilized forindustrial processes that require high-temperature heat.Hydrogen Production: The syngas can be processed to extract hydrogen, a valuable clean fuel.Chemical Feedstock: Syngas is an essential feedstockfor the production of various chemicals and pharmaceuticals.Environmental Impact.Multi-injection opposed coal-water slurry gasification technology has a positive impact on the environment:Reduced Carbon Emissions: By converting coal into syngas, the technology reduces carbon dioxide emissions compared to direct coal combustion.Air Pollution Control: Advanced purification techniques effectively remove pollutants from the syngas, mitigating air pollution.Sustainable Fuel Source: The utilization of coal-water slurry provides a sustainable fuel option for various industries.Conclusion.Multi-injection opposed coal-water slurry gasification technology is a promising and environmentally friendly solution for converting coal into a versatile fuel source. Its high efficiency, low emissions, and fuel flexibility make it an attractive option for a wide range of applications. As the demand for clean and sustainable energy sources grows, this innovative technology is poisedto play a significant role in the energy transition.中文回答:多喷嘴对置式水煤浆气化工艺流程。

主流煤气化技术及市场情况系列展示(之一)多喷嘴对置式水煤浆气化技术技术拥有单位:兖矿集团有限公司、华东理工大学编者按:煤气化装置是煤化工的龙头,选择适合的煤气化技术直接关系到整个煤化工装置的安全稳定运行和经济效益,煤气化技术的选择是煤化工装置和煤化工企业的关键点之一。

为了帮助煤化工企业合理地选择气化技术,从本期起,本刊将陆续介绍目前国内主要煤气化技术,从技术特点、主要技术参数、煤种适应性、研发过程、市场开发、典型运用案例、最新动态等方面,全面地展示各种煤气化技术的特点。

此次气化技术展示的所有材料,由相关企业提供,均不代表本刊倾向和观点。

山东兖矿国拓科技工程有限公司是由兖矿集团控股,会同国内著名科研机构、院校、勘察设计单位和企业组建的化工技术研发、推广和技术服务的高科技企业,依靠兖矿集团良好的企业形象、强大的技术研发和技术服务能力,主要从事化工技术开发、技术服务、技术转让、化工工程勘察、设计、施工等业务。

公司立足兖矿自身化工技术的研发与工业化装置,依托华东理工大学、水煤浆气化及煤化工国家工程研究中心、中国天辰工程公司等科研和设计机构,团队具有一流理论水平和实践经验,是典型的产、学、研结合运作模式。

山东兖矿国拓科技工程有限公司与华东理工大学一起向业界推广多喷嘴气化技术,并提供技术理论和工程技术服务支持,公司自2010年7月成立以来,已签订多喷嘴气化技术转让合同15家,与国内外煤化工企业达成合作意向10余项,另与国外多家科研机构和化工企业达成合作意向。

具有完全自主知识产权的多喷嘴对置式煤气化技术由华东理工大学和兖矿集团共同研发,八五期间华东理工大学建立了多喷嘴气化技术数学模型,进行了实验室小试,九五期间兖矿集团承担了多喷嘴气化技术中试,并在兖矿国泰化工有限公司建设多喷嘴气化技术示范工程,2005年第一台千吨级多喷嘴对置式煤气化大型气化炉在兖矿国泰开车成功,由此拉开了我国水煤浆洁净煤大型化的序幕。

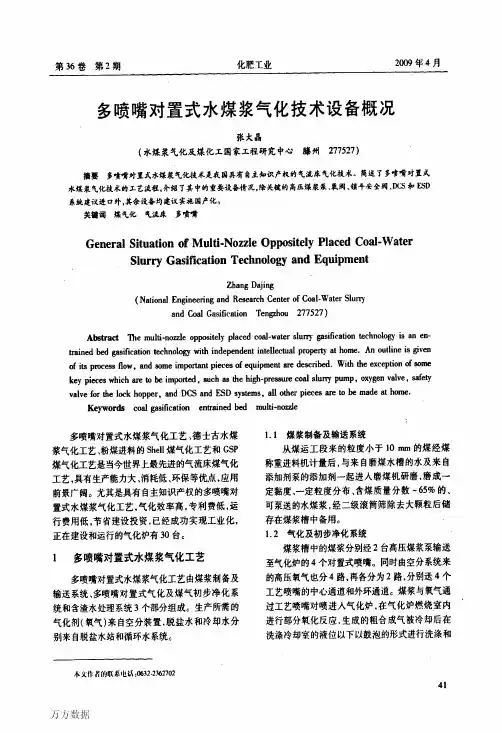

多喷嘴对置式水煤浆气化技术主要特征介绍如下:一气化技术特点多喷嘴对置式水煤浆气化工艺是以氧气和水煤浆为原料,采用气流床反应器,在加压非催化条件下进行部分氧化反应,生成以一氧化碳和氢气为有效成分的粗煤气,作为氨和甲醇合成的合成气,或制氢(煤液化、燃料)的原料气、IGCC 发电的燃料气。

科技成果——多喷嘴对置式水煤浆气化技术适用范围化工行业煤制合成气行业现状同等产量条件下常压固定床技术:比氧耗380Nm3O2/kNm3(CO+H2);有效气成分CO+H2含量60%-70%;碳转化率78%;年消耗71万tce。

成果简介1、技术原理水煤浆、氧气进入气化室后,相继进行雾化、传热、蒸发、脱挥发分、燃烧、气化等6个物理和化学过程,煤浆颗粒在气化炉内经过湍流弥散、振荡运动、对流加热、辐射加热、煤浆蒸发与挥发份的析出和气相反应等,最终形成以CO、H2为主的煤气及灰渣。

产生的合成气经分级净化达到后序工段的要求,同时采用直接换热式渣水处理系统。

2、关键技术多喷嘴对置式水煤浆气化技术采用四喷嘴撞击流、预膜式喷嘴,加强混合,强化热质传递。

关键技术设备包括:(1)由喷淋床与鼓泡床组成的复合床高温煤气洗涤冷却设备;(2)合成气“分级”净化。

由混合器、分离器、水洗塔组成的高效节能型煤气初步净化系统;(3)直接换热式含渣水处理系统;(4)预膜式长寿命高效气化喷嘴;(5)结构新颖的交叉流式洗涤水分布器;(6)国内首次成功实施停运气化烧嘴在线带压投料的操作技术。

3、工艺流程通过喷嘴对置、优化炉型结构及尺寸,在炉内形成撞击流,以强化混合和热质传递过程,并形成炉内合理的流场结构。

主要包括煤浆制备、输送单元,多喷嘴对置式水煤浆气化单元,煤气初步净化单元和含渣水处理单元,其中关键单元为气化、煤气初步净化和含渣水热回收。

图1 多喷嘴对置式水煤浆气化工艺流程图主要技术指标与引进的水煤浆气化技术相比,采用该技术可使比氧耗降低7.9%,比煤耗降低2.2%。

以北宿煤为原料,合成气有效气成分(CO+H2)含量84.9%,比氧耗309Nm3O2/1000Nm3(CO+H2),降低7.9%;比煤耗535kg/1000Nm3(CO+H2),降低 2.2%;碳转化率98.8%,提高2%-3%;产气率2.20Nm3/kg;有效气成分提高2%-3%;CO2含量降低2%-3%。

多喷嘴对置式水煤浆气化工艺流程英文回答:Water-coal slurry gasification is a process that converts coal into a gaseous fuel by mixing it with water and then subjecting it to high temperatures and pressures. This process has gained attention due to its potential to produce clean and efficient energy. In a multi-nozzle opposed configuration, multiple nozzles are used to inject the water-coal slurry into the gasifier, which enhances the gasification efficiency and improves the overall performance of the system.One advantage of the multi-nozzle opposed configuration is the ability to distribute the slurry evenly throughout the gasifier. This ensures that the coal particles are exposed to the optimal conditions for gasification, leading to a more efficient conversion of coal into syngas. Additionally, the use of multiple nozzles allows for better control of the slurry flow rate and distribution, which canhelp to prevent channeling and ensure uniform gasification.Another benefit of the multi-nozzle opposed configuration is the increased residence time of the slurry in the gasifier. By injecting the slurry from multiple nozzles at different locations, the slurry is exposed to the high temperatures and pressures for a longer period of time. This extended residence time promotes the complete gasification of the coal, resulting in higher syngas yields and improved overall gasification efficiency.Furthermore, the multi-nozzle opposed configuration offers flexibility in terms of operation and control. By adjusting the flow rate and location of the slurry injection, the gasifier can be optimized to accommodate different coal types and varying operating conditions. This flexibility allows for better adaptability to changes in coal quality and enables the system to operate at its maximum efficiency.In conclusion, the multi-nozzle opposed configurationin water-coal slurry gasification processes offers severaladvantages, including improved slurry distribution, increased residence time, and operational flexibility. These benefits contribute to higher gasification efficiency and syngas yields. By utilizing this configuration, the potential of water-coal slurry gasification as a clean and efficient energy production method can be fully realized.中文回答:多喷嘴对置式水煤浆气化工艺流程通过将煤与水混合,并在高温高压条件下进行气化,将煤转化为可燃气体燃料。

多喷嘴对置式水煤浆加压气化技术闫吉臣【摘要】In this paper , ifrstly, it takes a brief introduction of the signiifcance of coal gasiifcation technology and study the role of coal gasif ication technology research and the infuence on the whole economic society, besides, it focus on analyzing the application research of pressurization and gasiifcation of current opposed multi-nozzle water-coal-slurry, and then takes introduction of the process and characteristics of pressurization and-gasiifcation of current opposed multi-nozzle water-coal-slurry technology, and master the speciifc water-coal-slurry pressurization and gasiifcation technology and related technologies, ifnally through the concrete cases to analyze opposed multi-nozzle coal-water slurry pressurization and gasiifcat-ion technology. We hope the research in this article can bring more comprehensive knowledge and understanding for China’s opposed multi-nozzle water-coal-slurry pressurization and gasiifcation technology level, so that to promote effectively thedevelop ment of China’s coal gasiifcation technology industry.%本文首先对煤气化技术的意义进行简单介绍,了解进行煤气化技术研究的作用以及对整个经济社会的影响,重点分析目前多喷嘴对置式水煤浆加压气化技术的应用研究,然后对多喷嘴对置式水煤浆加压气化工艺的流程及特点进行介绍,掌握具体的水煤浆加压气化工艺及相关技术,最终通过具体的案例分析多喷嘴对置式水煤浆加压气化技术。

多喷嘴对置式水煤浆气化流程一、引言多喷嘴对置式水煤浆气化是一种高效利用煤炭资源的气化技术,其通过将水煤浆喷嘴垂直对置,使喷嘴之间的气化反应得到充分利用,提高气化效率。

二、多喷嘴对置式水煤浆气化流程1. 煤炭破碎和干燥:将原料煤炭进行破碎和干燥处理,以提高煤炭的可燃性和流动性。

2. 水煤浆制备:将破碎和干燥后的煤炭与适量的水混合,制备成水煤浆,以提高煤炭的可泵性和传输性。

3. 进料系统:将制备好的水煤浆通过泵送至气化炉的进料系统。

4. 喷嘴系统:多喷嘴对置式水煤浆气化的核心部分是喷嘴系统。

喷嘴系统通常由多个喷嘴组成,这些喷嘴垂直对置,形成一个喷嘴阵列。

喷嘴的数量和布置方式可以根据实际需求进行设计。

5. 气化炉:水煤浆通过进料系统进入气化炉,喷嘴系统将水煤浆喷入气化炉内。

在气化炉内,水煤浆与气化剂(通常是氧气或蒸汽)发生反应,产生可燃气体和灰渣。

6. 气体处理:从气化炉中产生的可燃气体经过净化处理,去除其中的硫化物、氮氧化物和颗粒物等杂质,以提高气体的纯度和热值。

7. 热能回收:在气体处理过程中,通过余热回收装置,将气体中的热能回收利用,用于加热水煤浆或产生蒸汽等。

8. 产品分离:经过气体处理和热能回收后的可燃气体可以用于发电、制取合成气等用途。

而气化炉中产生的灰渣可以通过分离装置进行分离,其中的可燃物质可以作为燃料继续利用,而其他固体废弃物则需要进行处理和处置。

三、多喷嘴对置式水煤浆气化的优势1. 高效利用煤炭资源:多喷嘴对置式水煤浆气化能够将煤炭中的可燃气体充分释放出来,提高煤炭的利用效率。

2. 灵活性高:多喷嘴对置式水煤浆气化技术适用于不同种类的煤炭,具有较高的适应性和灵活性。

3. 环保节能:多喷嘴对置式水煤浆气化过程中,通过热能回收装置回收余热,提高能源利用效率,减少对环境的影响。

4. 产品多样化:多喷嘴对置式水煤浆气化可以产生多种产品,如合成气、发电、燃料气等,具有较广泛的应用前景。

四、结论多喷嘴对置式水煤浆气化是一种高效利用煤炭资源的气化技术,其具有高效利用煤炭资源、灵活性高、环保节能和产品多样化等优势。

多喷嘴对置式水煤浆气化技术随着我国工业化的不断进步和发展,我国对于能源的需求量也与日俱增,而我国的能源整体特点是多煤缺油少气,这就迫使我国每年需要大量的进口石油以及天然气等资源来满足工业及经济发展需求。

随着国家能源市场的变动及制约,我国需要根据我国资源特点进行研究,开发出新的煤炭利用技术以满足我国的能源需求。

在“九五”期间,华东理工大学及兖矿集团有限公司通过全面的产学研合作开发出了一种新型的水煤浆气化炉—多喷嘴对置式水煤浆气化炉,这一技术的出现极大的提供了对于煤炭资源的利用程度。

本文主要对多喷嘴对置式水煤浆气化炉技术和优势进行简要介绍,并对其发展方向和存在的一些问题进行简要概述。

标签:多喷嘴;对置式;水煤浆气化0 引言随着我国工业化发展进程的加速,我国对于能源的需求量十分庞大,世界三大能源中的煤炭、石油和天然气中,我国只具有丰富的煤炭矿藏,而石油和天然气都处于稀少的状态。

这些条件都使得我国对于煤炭资源的开发和利用极为重视,煤炭资源的高效、深度利用对于我国的发展具有十分重要的战略意义。

其中煤气化技术又是其他多个工业行业的重要基础,煤气化后可以作为燃气、发电发热、液化等多种用途。

我国自主研发的多喷嘴对置式水煤浆气化技术极大的促进了我国煤化工产业的发展,也给我们的能源高效利用提供了很好的示范,这一技术的大规模使用也标志了我国的水煤浆气化技术已经处于国际先进水平。

1 多喷嘴对置式水煤浆气化技术1.1 技术简介多喷嘴对置式水煤浆气化技术其实本质是一种气流床气化技术,以大规模的煤炭高效气化技术为基础,将煤炭的深度加工与多种清洁能源生产进行结合的一种大型加压煤化工设备。

气化技术一种重要的煤炭高效利用的技术,可以将煤炭进行深度化学转化,生成天然气等多种清洁能源,现阶段已经成为煤化工产业的核心技术。

气流床气化技术是煤炭气化中最成熟的技术。

我国早期引进的是国外的德士古水煤浆气化设备,随着多喷嘴对置式水煤浆气化技术和设备的研发,我国的煤炭气化产业得到了快速的发展。