两轴式五档变速器说明书打印

- 格式:doc

- 大小:1.60 MB

- 文档页数:19

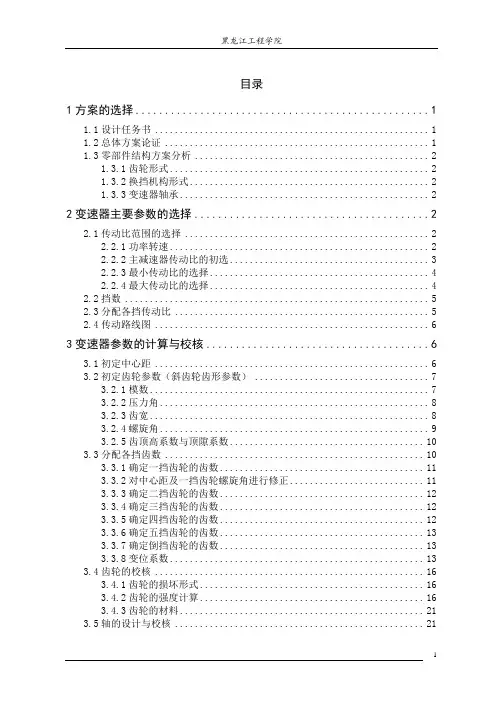

目录1方案的选择 (1)1.1设计任务书 (1)1.2总体方案论证 (1)1.3零部件结构方案分析 (2)1.3.1齿轮形式 (2)1.3.2换挡机构形式 (2)1.3.3变速器轴承 (2)2变速器主要参数的选择 (2)2.1传动比范围的选择 (2)2.2.1功率转速 (2)2.2.2主减速器传动比的初选 (3)2.2.3最小传动比的选择 (4)2.2.4最大传动比的选择 (4)2.2挡数 (5)2.3分配各挡传动比 (5)2.4传动路线图 (6)3变速器参数的计算与校核 (6)3.1初定中心距 (6)3.2初定齿轮参数(斜齿轮齿形参数) (7)3.2.1模数 (7)3.2.2压力角 (8)3.2.3齿宽 (8)3.2.4螺旋角 (9)3.2.5齿顶高系数与顶隙系数 (10)3.3分配各挡齿数 (10)3.3.1确定一挡齿轮的齿数 (11)3.3.2对中心距及一挡齿轮螺旋角进行修正 (11)3.3.3确定二挡齿轮的齿数 (12)3.3.4确定三挡齿轮的齿数 (12)3.3.5确定四挡齿轮的齿数 (12)3.3.6确定五挡齿轮的齿数 (13)3.3.7确定倒挡齿轮的齿数 (13)3.3.8变位系数 (13)3.4齿轮的校核 (16)3.4.1齿轮的损坏形式 (16)3.4.2齿轮的强度计算 (16)3.4.3齿轮的材料 (21)3.5轴的设计与校核 (21)3.5.1初选轴的直径 (21)3.5.2轴的可靠性分析 (21)3.6轴承的计算与校核 (27)3.6.1轴承形式的选择 (27)3.6.2轴承尺寸的选择 (27)3.6.3轴承寿命的计算 (29)4设计参数汇总(优化后) (34)4.1汽车主要参数 (34)4.2变速器主要设计参数 (34)参考文献 (37)1方案的选择1.1设计任务书根据给定的汽车性能参数,进行汽车变速箱传动方案设计,计算各部件的设计参数,绘出指定总成的装配图和部分零件图表1-1 乘用车传动系统的主要参数1.2总体方案论证变速器用来改变发动机传到驱动轮上的转矩和转速,目的是在原地起步、爬坡、转弯、加速等各种形式工况下,使汽车获得不同的牵引力和速度,同时使发动机在最有利的工况范围内工作。

汽车设计课程设计说明书设计题目:汽车五档变速器08级汽车制造与装配设计者:尤建超指导教师:梅彦利目录第一部分:车型基本参数---------------------------3第二部分:传动方案拟定---------------------------4第三部分:变速器主要参数的选择--------------------5第四部分:变速器齿轮的设计计算--------------------6第五部分:变速器轴的设计计算----------------------14第六部分:滚动轴承的选择和计算--------------------18第七部分:参考资料------------------------------20一.机械式变速器的概述及其方案的确定§1.1 变速器的功用和要求变速器的功用是根据汽车在不同的行驶条件下提出的要求,改变发动机的扭矩和转速,使汽车具有适合的牵引力和速度,并同时保持发动机在最有利的工况范围内工作。

为保证汽车倒车以及使发动机和传动系能够分离,变速器具有倒档和空档。

在有动力输出需要时,还应有功率输出装置。

对变速器的主要要求是:1.应保证汽车具有高的动力性和经济性指标。

在汽车整体设计时,根据汽车载重量、发动机参数及汽车使用要求,选择合理的变速器档数及传动比,来满足这一要求。

2.工作可靠,操纵轻便。

汽车在行驶过程中,变速器内不应有自动跳档、乱档、换档冲击等现象的发生。

为减轻驾驶员的疲劳强度,提高行驶安全性,操纵轻便的要求日益显得重要,这可通过采用同步器和预选气动换档或自动、半自动换档来实现。

3.重量轻、体积小。

影响这一指标的主要参数是变速器的中心距。

选用优质钢材,采用合理的热处理,设计合适的齿形,提高齿轮精度以及选用圆锥滚柱轴承可以减小中心距。

4.传动效率高。

为减小齿轮的啮合损失,应有直接档。

提高零件的制造精度和安装质量,采用适当的润滑油都可以提高传动效率。

经济型轿车机械式手动变速箱设计计算说明书目录1.设计任务书 (2)2.总体方案论证 (2)3.变速器主要参数及齿轮参数的选择 (5)4.变速器主要零部件的几何尺寸计算及可靠性分析 (15)4.1变速器齿轮 (15)4.2变速器的轴 (19)4.3变速器轴承 (24)5.驱动桥(主减速器齿轮)部分参数的设计与校核 (31)6.普通锥齿轮差速器的设计 (37)7.设计参数汇总(优化后) (45)*参考文献 (48)1设计任务书根据给定汽车车型的性能参数,进行汽车变速箱总体传动方案设计,选择并匹配各总成部件的结构型式,计算确定各总成部件的主要参数;详细计算指定总成的设计参数,绘出指定总成的装配图和部分零件图。

表1-1 轿车传动系统的主要参数2 总体方案论证变速器的基本功用是在不同的使用条件下,改变发动机传到驱动轮上的转矩和转速,使汽车得到不同的牵引力和速度,同时使发动机在最有利的工况范围内工作。

此外,应保证汽车能倒退行驶和在滑行时或停车时使发动机和传动系保持分离。

需要时还应有动力输出的功能。

变速器设计应当满足如下基本要求:☞具有正确的档数和传动比,保证汽车有需要的动力性和经济性指标;☞有空档和倒档,使发动机可以与驱动轮长期分离,使汽车能倒车;☞换档迅速、省力,以便缩短加速时间并提高汽车动力性(自动、半自动和电子操纵机构);☞工作可靠。

汽车行驶中,变速器不得跳挡、乱挡以及换挡冲击等现象发生;☞应设置动力输出装置,以便必要时进行功率输出;☞效率高、噪声低、体积小、重量轻便于制造、成本低。

变速器是由变速传动机构和操纵机构组成。

根据前进档数的不同,变速箱有三、四、五和多挡几种。

根据轴的不同类型,分为固定轴式和旋转轴式两大类。

而前者又分为两轴式、中间轴式和多中间轴式变速箱。

在已经给出的设计条件中,具体的参数说明如下:2.1 传动机构布置方案分析(1)传动方案的选取根据提供的参数及设计需求,变速器传动方案的选择如下:1—输入轴 2—输入轴一档齿轮 3—输入轴倒档齿轮 4—倒档轴 5—倒档轴倒档齿轮6—输入轴二档齿轮 7—输入轴三档齿轮 8—三、四档同步器 9—输入轴四档齿轮10—支撑 11—输入轴五档齿轮 12—五档同步器 13—输出轴 14—输出轴五档齿轮 15—输出轴四档齿轮 16—输出轴三档齿轮 17—输出轴二档齿轮 18—一、二档同步器19—输出轴倒档齿轮 20—差速器半轴齿轮 21——差速器星行星齿轮图2-1 变速器传动方案该方案的的特点是:变速器输出轴与主减速器主动齿轮做成一体,由于发动机横置,故主减速器不需要有改变转矩方向的作用,主减速器齿轮选用斜齿圆柱齿轮。

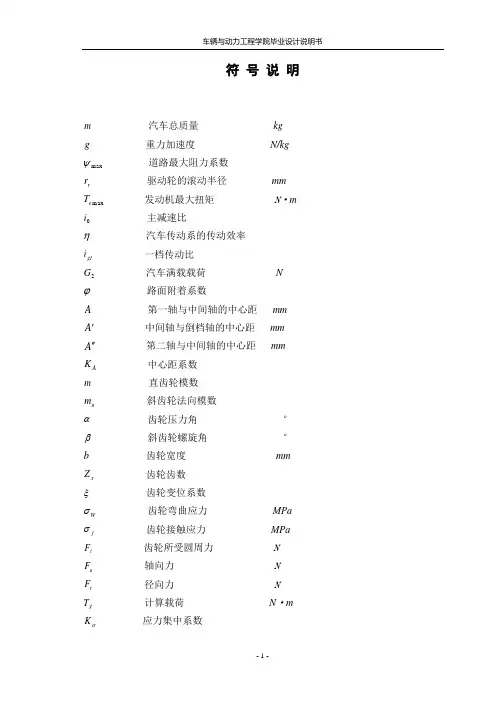

符号说明m汽车总质量kgg重力加速度N/kg ψ道路最大阻力系数maxr驱动轮的滚动半径mm rT发动机最大扭矩N·m emaxi主减速比η汽车传动系的传动效率i一档传动比gIG汽车满载载荷N 2ϕ路面附着系数A第一轴与中间轴的中心距mm A'中间轴与倒档轴的中心距mmA''第二轴与中间轴的中心距mmK中心距系数Am直齿轮模数m斜齿轮法向模数nα齿轮压力角°β斜齿轮螺旋角°b齿轮宽度mmZ齿轮齿数xξ齿轮变位系数σ齿轮弯曲应力MPa Wσ齿轮接触应力MPa jF齿轮所受圆周力NtF轴向力 N aF径向力NrT计算载荷N·m gK应力集中系数σf K 摩擦力影响系数E 齿轮材料的弹性模量 MPaK ε 重合度影响系数z r 主动齿轮节圆半径 mmb r 从动齿轮节圆半径 mmz ρ 主动齿轮节圆处的曲率半径 mmb ρ 从动齿轮节圆处的曲率半径 mmT τ 扭转切应力 MPaT W 轴的抗扭截面系数 3mmG 轴的材料的剪切弹性模量 MPaP I 轴截面的极惯性矩 4mmc f 垂直面内的挠度 mms f 水平面内的挠度 mm前言现在,每当人们观看F1大赛,总会被那种极速的感觉所折服。

此刻,大家似乎谈论得最多的就是发动机的性能以及车手的驾驶技术。

而且,不忘在自己驾车的时候体会一下极速感觉或是在买车的时候关注一下发动机的性能,这似乎成为了横量汽车品质优劣的一个标准。

的确,拥有一颗“健康的心”是非常重要的,因为它是动力的缔造者。

但是,掌控速度快慢的,却是它身后的变速器。

从现在市场上不同车型所配置的变速器来看,主要分为:手动变速器(MT)、自动变速器(AT)、手动/自动变速器(AMT)、无级变速器(CVT)。

一、手动变速器(MT)手动变速器(Manual Transmission)采用齿轮组,每档的齿轮组的齿数是固定的,所以各档的变速比是个定值(也就是所谓的“级”)。

本科学生毕业设计五档变速器设计系部名称:汽车与交通工程学院专业班级:车辆工程B07-2班学生姓名:常圣英指导教师:姚佳岩职称:副教授黑龙江工程学院二○一一年六月The Graduation Design for B achelor’s DegreeDesign of The Five gearTransmissionCandidate:ChangShengyingSpecialty:Vehicle EngineeringClass:B07-2Supervisor:Associate professor 。

YaoJiayanHeilongjiang Institute of Technology2011-06·Harbin摘要变速器用来改变发动机传到驱动轮上的转矩和转速,是汽车总成部件中的重要组成部分,是主要的传动系统.变速器的结构要求对汽车的动力性、燃料经济性、换档操纵的可靠性与轻便性、传动平稳性与效率等都有直接的影响.本文设计研究了三轴式五档手动变速器,其目的主要是基于对机械原理、机械设计、AutoCAD等知识的熟练运用和掌握,同时运用汽车构造、汽车设计、材料力学、互换性测量等学科知识,对三轴式变速器的各部件进行设计,并利用AutoCAD软件绘制装配图和零件图等六项内容.首先,本文将概述变速器的现状和发展趋势,介绍变速器领域的最新发展状况。

其次,对工作原理做了阐述,对不同的变速器传动方案进行比较,选择合理的结构方案进行设计。

再次,对变速器的各档齿轮和轴以及轴承做了详细的设计计算,并进行了受力分析、强度和刚度校核计算,并为为这些元件选择合适的工程材料及热处理方法.对一些标准件进行了选型以及变速器的传动方案设计。

简单讲述了变速器中各部件材料的选择。

最后,本文将对变速器换档过程中的重要部件—同步器以及操纵机构进行阐述,讲述同步器的类型、工作原理、选择方法以及重要参数。

关键词:变速器;传动比;轴;齿轮;花键;校核ABSTRACTTransmission to change the engine reached on the driving wheel torque and speed, Automotive transmission parts in the automobile assembly of an important part of the main drive system. Transmission of the power structure of the vehicle,economy,manipulation of the reliability and portability, the smooth drive and have a direct impact on efficiency。

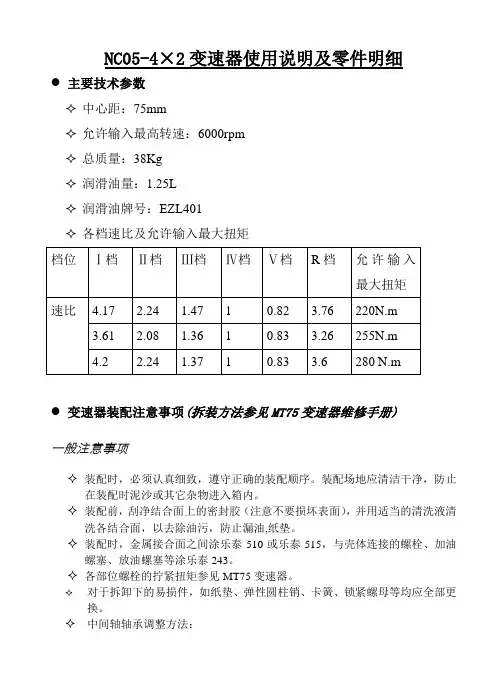

NC05-4×2变速器使用说明及零件明细●主要技术参数✧中心距:75mm✧允许输入最高转速:6000rpm✧总质量:38Kg✧润滑油量:1.25L✧润滑油牌号:EZL401✧各档速比及允许输入最大扭矩●变速器装配注意事项(拆装方法参见MT75变速器维修手册)一般注意事项✧装配时,必须认真细致,遵守正确的装配顺序。

装配场地应清洁干净,防止在装配时泥沙或其它杂物进入箱内。

✧装配前,刮净结合面上的密封胶(注意不要损坏表面),并用适当的清洗液清洗各结合面,以去除油污,防止漏油,纸垫。

✧装配时,金属接合面之间涂乐泰510或乐泰515,与壳体连接的螺栓、加油螺塞、放油螺塞等涂乐泰243。

✧各部位螺栓的拧紧扭矩参见MT75变速器。

✧对于拆卸下的易损件,如纸垫、弹性圆柱销、卡簧、锁紧螺母等均应全部更换。

✧中间轴轴承调整方法:1)调整前轴承外圈需高出1-2mm;2)用22±2N.m扭矩拧紧中间轴螺塞。

3)做标记。

4)松开中间轴螺塞80°±2.5°。

5)用黄铜棒指示两处凸台处施加5±0.5NS的冲击力。

6)拧紧中间轴螺塞20°±2.5°此时扭矩应大于6N·M。

如扭矩未能达到6N·M,松开中间轴螺塞20°±5°,如扭矩未能达到6N·M,松开中间轴螺塞20°±5°,重复(5)(6)操作。

7)锁紧中间轴螺塞。

变速箱使用注意事项:1、车辆行驶过程中,要经常检查离合器踏板行程,查看离合器是否彻底分离和完全接合。

否则,将影响变速箱换档性能和同步器寿命。

2、车辆在行驶中应尽可能使用较高档行驶,以保证发动机处于经济转速区,提高整车的动力性和经济性。

3、车辆起动中,不应频繁使用急剧加速或紧急制动。

4、车辆起动时,变速箱空档,离合器完全接合,应怠速运行3-5分钟,通过齿轮油的飞溅,使各档齿轮、同步器及各类型轴承得到充分地润滑,否则将影响变速箱性能及使用寿命。

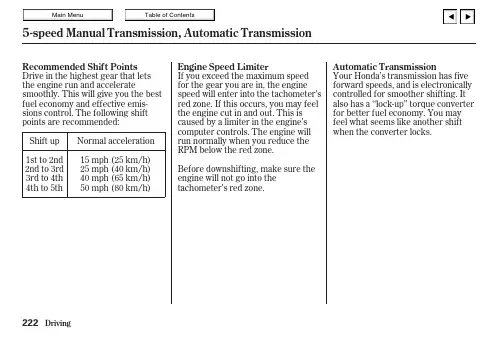

Drive in the highest gear that lets the engine run and acceleratesmoothly.This will give you the best fuel economy and effective emis-sions control.The following shift points are recommended:If you exceed the maximum speed for the gear you are in,the engine speed will enter into the tachometer’s red zone.If this occurs,you may feel the engine cut in and out.This is caused by a limiter in the engine’s computer controls.The engine will run normally when you reduce the RPM below the red zone.Before downshifting,make sure the engine will not go into the tachometer’s red zone.Shift up 1st to 2nd 2nd to 3rd 3rd to 4th 4th to 5thNormal acceleration 15mph (25km/h)25mph (40km/h)40mph (65km/h)50mph (80km/h)Your Honda’s transmission has five forward speeds,and is electronically controlled for smoother shifting.It also has a ‘‘lock-up’’torque converter for better fuel economy.You may feel what seems like another shift when the converter locks.5-speed Manual Transmission,Automatic TransmissionAutomatic TransmissionRecommended Shift Points Engine Speed Limiter222The ‘‘D’’indicator comes on for a few seconds when you turn the ignition switch to ON (II).If it flashes while driving (in any shift position),it indicates a possible problem in the transmission.Avoid rapid acceleration and have the trans-mission checked by an authorized Honda dealer as soon as possible.This indicator between the tacho-meter and speedometer shows which position the shift lever is in.Automatic TransmissionShift Lever Position Indicator223This position mechani-cally locks the e Park whenever you are turning off or starting the engine.To shift out of Park,you must press on the brake pedal and have your foot off the accelerator pedal.Press the release button on the side of the shift lever to move it.If you have done all of the above and still cannot move the lever out of Park,see Shift Lock Release on page .You must also press the release button to shift into Park.To avoid transmission damage,come to a complete stop before shifting into Park.The shift lever must be in Park before you can remove the key from the ignition switch.Use Neutral if you need to restart a stalled engine,or if it is necessary to stop briefly with the engine idling.Shift to Park posi-tion if you need to leave the car for any reason.Press on the brake pedal when you are moving the shift lever from Neutral to another e this position for your normal driving.The transmis-sion automatically selects a suitable gear (1through 5)for your speed and acceleration.You may notice the transmission shifting up at higher speeds when the engine is cold.This helps the engine warm up faster.226Automatic TransmissionPark (P)Neutral (N)Drive (D)224To shift to Second,press the release button on the side of the shift lever.This position locks the transmission in second gear.It does not downshift to first gear when you come to a stop.Secondgives you more power when climbing,and increased engine braking when going down steep e second gear when starting out on a slippery surface or in deep snow.It will help reduce wheelspin.To shift from Second to First,press the release button on the side of the shift lever.With the lever in this position,the transmission locks in First gear.By upshifting and downshifting through 1,2,D ,and D,you can operate this transmission much like a manual transmission without a clutch pedal.For faster acceleration when in D or D,you can get the transmission to automatically downshift by pushing the accelerator pedal to the floor.The transmission will shift down one or two gears,depending on your speed.This position is similar to D,except only the first threegears are selected instead of all e D when towing a trailer in hilly terrain,or to provide engine braking when going down a steep hill.D can also keep the transmission from cycling between third and fourth gears in stop-and-go driving.3333Second (2)First (1)Drive (D )Automatic Transmission3225This allows you to move the shift lever out of Park if the normal method of pushing on the brake pedal and pressing the release button does not work.Set the Parking brake.Remove the key from the ignition switch.If you exceed the maximum speed for the gear you are in,the engine speed will enter into the tachometer’s red zone.If this occurs,you may feel the engine cut in and out.This is caused by a limiter in the engine’s computer controls.The engine will run normally when you reduce the RPM below the red zone.Put a cloth on the edge of the Shift Lock Release slot cover next to the shift lever.Use a small flat-tipped screwdriver or finger nail file to remove the cover.Carefully pry off the edge of the cover.1.2. 3.Automatic TransmissionShift Lock ReleaseEngine Speed Limiter226If you need to use the Shift Lock Release,it means your car isdeveloping a problem.Have the car checked by your Honda dealer.Insert the key in the Shift Lock Release slot.4.Automatic Transmission227。

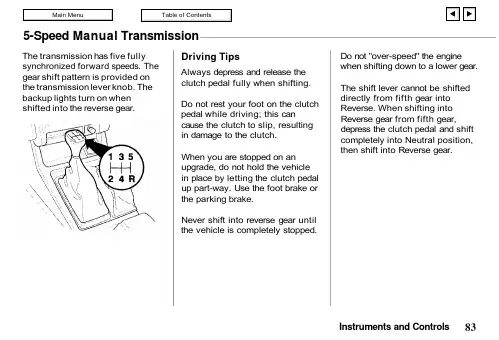

5-Speed Manual TransmissionThe transmission has five fully synchronized forward speeds. The gear shift pattern is provided on the transmission lever knob. The backup lights turn on when shifted into the reverse gear.Driving TipsAlways depress and release the clutch pedal fully when shifting.Do not rest your foot on the clutch pedal while driving; this cancause the clutch to slip, resulting in damage to the clutch.When you are stopped on an upgrade, do not hold the vehicle in place by letting the clutch pedal up part-way. Use the foot brake or the parking brake.Never shift into reverse gear until the vehicle is completely stopped.Do not "over-speed" the engine when shifting down to a lower gear.The shift lever cannot be shifted directly from fifth gear into Reverse. When shifting into Reverse gear from fifth gear,depress the clutch pedal and shift completely into Neutral position,then shift into Reverse gear.Instruments and ControlsShift Speed ChartThe lower gears of the transmission are used for normal acceleration of the vehicle to the desired cruising speed. The highest gear of the transmission is used to maintain the desired speed. The fifth gear is recommended for use in maintaining highway cruising speeds. Use of the fifth gear in city traffic is not recommended. The shift speed chart shows the speeds at which each upshift of the transmission should be made to get the best vehicle performance and fuel economy.For cruising, choose the highestgear for that speed (cruising speedis defined as a relatively constantspeed operation).The upshift indicator (U/S) lightsto show recommended upshiftpoints. (Refer to "IndicatorLights.")If the engine is "lugging" (thespeed you are traveling at is tooslow for the gear the transmissionis in), downshift to the next lowergear. You may need to downshifttwo or more gear positions tokeep the engine from "lugging" orto keep the performance at asatisfactory level.Transfer Control4WD ModelsThe "4WD" indicator lightilluminates when 4WD is engagedwith the 4WD-2WD switch."2H" (High Range, 2-WheelDrive)Use this for normal driving on drypavement. This position givesgreater economy, quieter ride andleast drivetrain wear.Instruments and ControlsMain Menu Table of Contents v w"4H" (High Range, 4-Wheel Drive)Use this for normal driving on gravel, wet, icy or snow-covered roads. This position provides greater traction than two-wheel drive. Top speed is limited to 65mph (105 km/h)."4L" (Low Range, 4-Wheel Drive)Use this for maximum power and traction. Top speed is limited to 65 mph (105 km/h). Use "4L" for climbing or descending steep hills, off-road driving, and hard pulling in sand, mud or deep snow.Operating the 4WD-2WD Switch 2H 4H: To shift betweenranges, push the switch with the vehicle going in a straight line at any speed below 65 mph (105 km/h). The 4WD indicator will blink for a short time as the system completes the shift.Taking your foot off the accelerator pedal for a moment will help to engage the new range.Shifting the Transfer Control Lever4H 4L: Stop the vehicle.Depress the clutch, then move the transfer control lever from 4H to 4L, or 4L to 4H.Move the transfer control lever quickly and securely between positions. Do not stop midway.The transfer gear box can bedamaged if the control lever is not firmly in gear. Some noise is normal when shifting.If the 4WD indicator continues to blink rapidly, it indicates that the system was shifted out ofsequence. Stop the vehicle, select 4WD with the 4WD-2WD switch,shift the lever from 4L to 4H, then select 2WD. Drive in a straight line to reset the system. If the indicator continues to blink, see your Honda dealer.Instruments and ControlsParking BrakeOperationTo set the parking brake, fully pull up on the handle between the seats. To release the parkingbrake, pull upward slightly. Then depress the pushbutton and push down all the way.To help remind you, the brake system warning light is designed to come on if the parking brakecontrol is not fully released when the key is on.Always pull the parking brake lever as far up as possible to make sure it sets fully. If the parking brake is not fully set, the vehicle could roll if it is parked on an incline.Parking TipsNever drive away with theparking brake still set. This may overheat the rear brakes, reducing their effectiveness and causing excessive wear or damage.Always apply the parking brake whenever you leave the vehicle,whether it is equipped with amanual or automatic transmission.If your vehicle is equipped with an automatic transmission, you should set the parking brake whenever you leave the driver's seat. If the vehicle is parked on a grade and the shift lever is placed in "P" (Park) position before the parking brake is set, the weight of the vehicle may exert so much force on the parking mechanism in the transmission that you may have difficulty moving the shift lever out of "P" (Park).To prevent this, apply the parking brake BEFORE you move the shift lever to "P " (Park) position.When preparing to drive away,move the shift lever out of the "P" (Park) position BEFORE you release the parking brake. It is good driving practice to set theInstruments and ControlsRELEASEparking brake first, then place the transmission in "P" (Park)position, even on level surfaces.When parking a vehicle equipped with a manual transmission on an upward slope or on a levelsurface, place the shift lever in the "1" (first gear) position.When parking a vehicle equipped with a manual transmission on a downward slope, place the shift lever in the "R" (Reverse)position.Accelerator PedalThe accelerator pedal is used to vary engine power and thusregulate engine and vehicle speed.Clutch PedalManual TransmissionThe clutch pedal is used to engage or disengage the clutch, thereby connecting or disconnecting the engine from the manualtransmission and driveline to the driving wheels.When the pedal is fully released,the clutch is engaged, driving the transmission and the drive wheels.Do not allow your foot to rest on the clutch pedal when not using the clutch.Instruments and ControlsACCELERATOR PEDALCLUTCHPEDAL。

本科学生毕业设计五档变速器设计系部名称:汽车与交通工程学院专业班级:车辆工程B07—2班学生姓名:常圣英指导教师:姚佳岩职称:副教授黑龙江工程学院二○一一年六月The Graduation Design for Bachelor's DegreeDesign of The Five gearTransmissionCandidate:ChangShengyingSpecialty:Vehicle EngineeringClass:B07-2Supervisor:Associate professor 。

YaoJiayanHeilongjiang Institute of Technology2011-06·Harbin摘要变速器用来改变发动机传到驱动轮上的转矩和转速,是汽车总成部件中的重要组成部分,是主要的传动系统。

变速器的结构要求对汽车的动力性、燃料经济性、换档操纵的可靠性与轻便性、传动平稳性与效率等都有直接的影响.本文设计研究了三轴式五档手动变速器,其目的主要是基于对机械原理、机械设计、AutoCAD等知识的熟练运用和掌握,同时运用汽车构造、汽车设计、材料力学、互换性测量等学科知识,对三轴式变速器的各部件进行设计,并利用AutoCAD软件绘制装配图和零件图等六项内容.首先,本文将概述变速器的现状和发展趋势,介绍变速器领域的最新发展状况。

其次,对工作原理做了阐述,对不同的变速器传动方案进行比较,选择合理的结构方案进行设计。

再次,对变速器的各档齿轮和轴以及轴承做了详细的设计计算,并进行了受力分析、强度和刚度校核计算,并为为这些元件选择合适的工程材料及热处理方法。

对一些标准件进行了选型以及变速器的传动方案设计。

简单讲述了变速器中各部件材料的选择。

最后,本文将对变速器换档过程中的重要部件—同步器以及操纵机构进行阐述,讲述同步器的类型、工作原理、选择方法以及重要参数。

关键词:变速器;传动比;轴;齿轮;花键;校核ABSTRACTTransmission to change the engine reached on the driving wheel torque and speed, Automotive transmission parts in the automobile assembly of an important part of the main drive system。

两轴式变速器-------------机械与材料工程学院B1042班张孟良35号(指导老师:刘鑫老师)摘要:二轴式变速器用于发动机前置前轮驱动的汽车,一般与驱动桥(前桥)合称为手动变速驱动桥。

目前,我国常见的国产轿车均采用这种变速器,如桑塔纳、捷达、富康、奥迪等。

关键字:二轴式、前置前轮驱动、手动式变速器一两轴式变速器特点两轴式变速器是前进挡的动力传递采用两根轴来实现的变速器,它的特点是动力的输人轴和输出轴不在一个轴线上,两根轴分别为第一轴(动力输人轴),第二轴(动力输出轴)。

通常第一轴为离合器的从动轴,第二轴同时也是主减速器的主动轴。

二发动机布置形式前置发动机有纵向布置和横向布置两种形式,与其配用的二轴式变速器也有两种不同的结构形式。

发动机纵置时,主减速器为一对圆锥齿轮,如奥迪100、桑塔纳2000轿车,如图3-3所示;发动机横置时,主减速器采用一对圆柱齿轮,如捷达轿车,如图3-4所示。

图3-3 发动机纵置的二轴式变速器传动示意图(桑塔纳2000)1-纵置发动机2-离合器3-变速器4-变速器输入轴5-变速器输出轴(主减速器主动锥齿轮)6-差速器7-主减速器从动锥齿轮8-前轮Ⅰ、Ⅱ、Ⅲ、Ⅳ、Ⅴ-一、二、三、四、五档齿轮R-倒档齿轮图3-4 发动机横置的二轴式变速器传动示意图(捷达)1-发动机2-离合器3-变速器4-主减速器5-差速器6-带等角速万向节的半轴三发动机结构与工作过程1.发动机纵向布置的二轴式变速器如图3-5、3-6所示分别为桑塔纳2000轿车二轴式变速器传动机构的结构图和示意图。

图3-5 桑塔纳2000轿车二轴式变速器传动机构的结构图1-四档齿轮2-三档齿轮3-二档齿轮4-倒档齿轮5-一档齿轮6-五档齿轮7-五档运行齿环8-换档机构壳体9-五档同步器10-齿轮箱体11-一、二档同步器12-变速器壳体13-三、四档同步器14-输出轴15-输入轴16—差速器图3-6 桑塔纳2000轿车二轴式变速器传动机构的示意图1-输入轴2-输出轴3-三、四档同步器4-一、二档同步器5-倒档中间齿轮Ⅰ-一档齿轮Ⅱ-二档齿轮Ⅲ-三档齿轮Ⅳ-四档齿轮Ⅴ-五档齿轮R-倒档齿轮1) 结构该变速器的变速传动机构有输入轴和输出轴,二轴平行布置,输入轴也是离合器的从动轴,输出轴也是主减速器的主动锥齿轮轴。

目录第1章绪论 .......................................................................... 错误!未定义书签。

1.1概述............................错误!未定义书签。

1.1.1 汽车变速器的设计标准 ......................................... 错误!未定义书签。

1.1.2国内外变速器的发展与现状 (2)1.2设计的步骤及方法 (2)第2章变速器传动机构与操纵机构............................ 错误!未定义书签。

2.1汽车变速器传动机构布置方案 ............................................... 错误!未定义书签。

2.1.1 汽车变速器传动方案分析与选择 ......................... 错误!未定义书签。

2.1.2 倒档布置方案 ......................................................... 错误!未定义书签。

2.1.3 其他零部件结构方案分析 ..................................... 错误!未定义书签。

2.2汽车变速器操纵机构布置方案 (5)2.2.1 概述 (5)2.3本章小结 (6)第3章变速器的设计与计算 (7)3.1汽车变速器主要参数的选择 (3)3.1.1 档数 (7)3.1.2 变速器传动比范围 (7)3.1.3 变速器各档传动比 (7)3.1.4 选择中心距 (10)3.1.5 变速器外形尺寸 (10)3.1.6 齿轮参数选择 (6)3.1.7 变速器各档齿轮齿数的分配及传动比的计算 (11)3.1.8 变速器齿轮的变位及齿轮螺旋角的调整 (11)3.19总结变速器各档齿轮参数 (11)3.2变速器齿轮强度校核 (13)3.2.1 齿轮材料的选择 (13)3.2.2 变速器齿轮弯曲强度校核 (18)3.2.3 变速器轮齿接触应力校核 (17)3.2.4 倒档齿轮的校核 (21)3.3轴的结构选择和尺寸设计 (27)3.3.1 初选轴的直径 (27)3.4轴的强度验算 (28)3.4.1 轴的刚度计算 (28)3.4.2 轴的强度计算 (36)3.5轴承选择与寿命计算校核 (39)3.5.1 输入轴轴承的选择与寿命校核 (33)3.5.2 输出轴轴承的选择与寿命校核 (35)3.6本章小结 (36)第4章变速器同步器及结构元件设计 (44)4.1同步器设计 (44)4.1.1 同步器的功能及分类 (44)4.1.2 惯性式同步器 (44)4.1.3 锁环式同步器主要尺寸选择与确定 (45)4.1.4 主要参数选择 (46)4.2变速器壳体 (48)4.3本章小结 (48)结论 (49)参考文献 (50)致谢 ............................................................................................ 错误!未定义书签。

本科毕业设计说明书某型乘用车五挡手动变速器设计PASSENGER CAR MANUAL TRANSMISSION DESIGN学院(部):机械工程专业班级:车辆工程11-1学生姓名:***指导教师:***2015 年06 月02 日某型乘用车五挡手动变速器设计摘要本次设计针对小型前置前驱乘用车,综合考虑乘用车对乘坐舒适性、操作简便性、动力性以及燃油经济性等方面需求,进行五挡机械式变速器设计。

变速器结构采用两轴式,同时采用锁环式同步器换挡机构,使换挡更及时、更准确、更平稳。

设计过程包括动力参数分析、传动比分配、变速器结构设计以及各个零部件强度的校核。

在结构设计中,运用CATIA软件进行三维建模和结构分析,最后根据确定的参数完成工程图纸的绘制。

关键词:乘用车,机械式变速器,结构分析,强度校核PASSENGER CAR MANUAL TRANSMISSION DESIGNABSTRACTThe design is directed at small front precursor passenger cars. It takes various requirements into comprehensive consideration, such as comfort, ease operation, power performance and fuel economy.With two shaft type transmission structure, and using the lock ring synchronizer shifting mechanism at the same time, makes the shifting more timely, more accurate, more stable.Design process including analysis, dynamic parameters distribution of transmission ratio, the transmission structure design and strength check every parts and components.In structure design, using CATIA software for 3 d modeling and structure analysis, according to the determined parameters to complete drawing engineering drawings.KEYWORDS: passenger vehicles, mechanical transmission, structure analysis and strength check目录摘要 (I)ABSTRACT (II)1 机械式变速器设计概述.......................................................................................... 12 变速器传动机构布置方案.................................................................................... 32.1传动机构布置方案分析................................................................................. 32.2 零、部件结构方案分析................................................................................ 62.2.1 齿轮形式............................................................................................ 62.2.2换挡机构形式....................................................................................... 62.2.3 变速器轴承.......................................................................................... 73 变速器主要参数的选择.......................................................................................... 93.1 变速器挡数的确定和各挡传动比分配........................................................ 93.1.1确定最大和最小传动比[6] ................................................................... 93.1.2 确定中间各挡传动比...................................................................... 103.2中心距A ..................................................................................................... 113.3 齿轮参数.................................................................................................... 113.4 各挡齿轮齿数分配.................................................................................... 133.5 各挡齿轮参数计算.................................................................................... 153.5.1变位前齿轮参数见表3.5................................................................. 153.5.2 变位齿轮参数计算.......................................................................... 164 轮齿强度校核...................................................................................................... 214.1齿轮材料的选择原则[2] ............................................................................. 214.2各轴转矩计算............................................................................................. 234.3轮齿强度校核计算..................................................................................... 234.3.1轮齿弯曲应力计算与校核............................................................... 234.3.2轮齿接触应力j 计算与校核........................................................... 265 轴的结构设计及强度校核.................................................................................. 315.1轴的结构设计............................................................................................. 315.2轴的载荷计算及危险截面分析................................................................. 335.3轴的强度校核............................................................................................. 405.3.1轴的刚度校核................................................................................... 405.3.2轴的强度校核................................................................................... 446 同步器设计.......................................................................................................... 546.1锁环式同步器结构及其工作原理[1] ......................................................... 546.2锁环式同步器主要尺寸的确定................................................................. 556.3同步环主要参数确定................................................................................. 566.4同步器花键参数确定与计算..................................................................... 577 汽车环境保护...................................................................................................... 587.1我国环境保护的原则和政策..................................................................... 587.2汽车及内燃机污染与危害......................................................................... 587.2.1汽车及内燃机污染的主要表现....................................................... 587.2.2汽车及内燃机污染的危害............................................................... 587.3汽车与内燃机污染防治措施..................................................................... 59结论.......................................................................................................................... 60参考文献.................................................................................................................. 61附录A 乘用车五挡变速器装配效果图................................................................ 62附录B 锁环式同步器装配图................................................................................ 63谢辞.......................................................................................................................... 641 机械式变速器设计概述变速器通过不同传动比的切换使汽车能够很好地适应各种复杂工况。

摘要汽车传动系是汽车的核心组成部分。

其任务是调节变换发动机的性能,将动力有效而经济地传至驱动车轮,以满足汽车的使用要求。

变速器是完成传动系任务的重要部件,也是决定整车性能的主要部件之一。

变速器的设计水平对汽车的动力性、燃料经济性、换挡操纵的可靠性与轻便性、传动平稳性与效率等都有直接的影响。

随着汽车工业的发展,轿车变速器的设计趋势是增大其传递功率与重量之比,并要求其具有更小的尺寸和良好的性能。

本设计以现有企业正在生产的车型CA7220变速器为基础,在给定发动机输出转矩、转速及最高车速、最大爬坡度等条件下,着重对变速器齿轮的结构参数、轴的结构尺寸等进行设计计算;并对变速器的传动方案和结构形式进行设计;同时对操纵机构和同步器的结构进行设计;从而提高汽车的整体性能。

关键词:变速器;齿轮;同步器;设计;结构目录第1章绪论 (3)1.1概述 (3)1.1.1 .................................... 汽车变速器的设计要求 31.1.2国内外汽车变速器的发展现状 (2)1.2设计的内容及方法 (2)第2章变速器传动机构与操纵机构 (5)2.1变速器传动机构布置方案 (5)2.1.1 ................................ 变速器传动方案分析与选择 52.1.2 ............................................ 倒档布置方案 52.1.3 ...................................... 零部件结构方案分析 62.2变速器操纵机构布置方案 (5)2.2.1 .................................................... 概述 52.3本章小结 (6)第3章变速器的设计与计算 (7)3.1变速器主要参数的选择 (9)3.1.1 .................................................... 档数 73.1.2 .............................................. 传动比范围 73.1.3 .................................. 变速器各档传动比的确定 73.1.4 ............................................ 中心距的选择 103.1.5 ........................................ 变速器的外形尺寸 103.1.6 .......................................... 齿轮参数的选择 123.1.7 ........................ 各档齿轮齿数的分配及传动比的计算 113.1.8 ...................... 变速器齿轮的变位及齿轮螺旋角的调整 183.19总结各档齿轮参数 (18)3.2变速器齿轮强度校核 (19)3.2.1 ...................................... 齿轮材料的选择原则 193.2.2 .................................. 变速器齿轮弯曲强度校核 183.2.3 ........................................ 轮齿接触应力校核 243.2.4 .......................................... 倒档齿轮的校核 283.3轴的结构和尺寸设计 (27)3.3.1 ............................................ 初选轴的直径 273.4轴的强度验算 (28)3.4.1 ............................................ 轴的刚度计算 283.4.2 ............................................ 轴的强度计算 363.5轴承选择与寿命计算 (39)3.5.1 .............................. 输入轴轴承的选择与寿命计算 433.5.2 .............................. 输出轴轴承的选择与寿命计算 443.6本章小结 (45)第4章变速器同步器及结构元件设计 (44)4.1同步器设计 (44)4.1.1 ...................................... 同步器的功用及分类 444.1.2 ............................................ 惯性式同步器 444.1.3 .............................. 锁环式同步器主要尺寸的确定 454.1.4 .......................................... 主要参数的确定 464.2变速器壳体 (48)4.3本章小结 (48)结论 (49)参考文献 (50)致谢 (53)第1章绪论1.1 概述随着汽车工业的迅猛发展,车型的多样化、个性化已经成为汽车发展的趋势。

第一章设计方案1.1 设计方案和基本数据乘用车(二轴式)基本参数如下表表1-1设计基本参数表1.2 变速器设计的基本要求对变速器如下基本要求.1)保证汽车有必要的动力性和经济性。

2)设置空挡,用来切断发动机动力向驱动轮的传输。

3)设置倒档,使汽车能倒退行驶。

4)设置动力输出装置,需要时能进行功率输出。

5)换挡迅速,省力,方便。

6)工作可靠。

汽车行驶过程中,变速器不得有跳挡,乱挡以及换挡冲击等现象发生。

7)变速器应当有高的工作效率。

除此以外,变速器还应当满足轮廓尺寸和质量小,制造成本低,维修方便等要求。

满足汽车有必要的动力性和经济性指标,这与变速器的档数,传动比围和各挡传动比有关。

汽车工作的道路条件越复杂,比功率越小,变速器的传动比围越大。

第二章变速器主要参数的选择2.1变速器主要参数的选择一、挡数增加变速器的挡数能改善汽车的动力性和经济性。

挡数越多,变速器的结构越复杂,并且是尺寸轮廓和质量加大。

同时操纵机构复杂,而且在使用时换挡频率也增高。

在最低挡传动比不变的条件下,增加变速器的当属会是变速器相邻的低挡与高挡之间传动比比值减小,是换挡工作容易进行。

要求相邻挡位之间的传动比比值在1.8以下,该制约小换挡工作越容易进行。

要求高挡区相邻挡位之间的传动比比值要比低挡区相邻挡位之间的传动比比值小。

近年来为了降低油耗,变速器的挡数有增加的趋势。

目前轿车一般用4~~5个挡位,级别高的轿车变速器多用5个挡,货车变速器采用4~~5个挡位或多挡。

装载质量在2~3.5T 的货车采用5挡变速器,装载质量在4~8T的货车采用6挡变速器。

多挡变速器多用于重型货车和越野车。

本次设计选用的是5挡变速器。

二、初选传动比1、主减速器传动比的确定发动机转速与汽车行驶速度之间的关系式为: og a i i rn u 377.0= 式中:a u 为汽车行驶速度(Km/h ),n 为发动机转速(r/min ),r 为车轮滚动半径(m ),g i 为变速器传动比,o i 为主减速器传动比。

设定的最高车速为144Km/h ,最高档为超速档,传动比取0.8,车轮滚动半径由所选用的轮胎规格185/60R14可得r=0.28m ,发动机转速p n =(1.4~2.0) n =4480~6400,取5000r/min 。

由公式可得ag o u i rni ⨯=377.0=1348.02768.05100377.0⨯⨯⨯=4.962、最低挡传动比的计算按最大爬坡度设计,满足最大通过能力条件,即用一档通过要求最大坡角max α坡道时,驱动力应大于或等于此时的滚动阻力和上坡阻力(加速阻力为零,空气阻力忽略不计)用公式表示为:max max max sin cos ααηG Gf ri i T tg o e +≥⋅⋅⋅式中:为G 为车辆总质量(N ),f 为坡道面滚动阻力系数(沥青路面中f =0.01~0.02),取0.016,max e T 为发动机最大扭矩(Nm ),t η为传动效率(0.85~0.90),max α为最大爬坡度(一般轿车要求爬上30%的坡,大约16.7°)。

由上式可得:to e g i T r mg mgf i ηαα⋅⋅+≥max max max 1)sin cos (=9.096.41052768.0)7.16sin 8.910407.16cos 016.08.91040(⨯⨯⨯︒⨯⨯+︒⨯⨯⨯=1.82即82.11≥g i根据驱动车轮件与地面附着条件:ϕη⋅≤⋅⋅⋅n tg o e F ri i 1max T即:to e n g i rF i ηϕ⋅⋅⋅⋅≤max 1T 式中:n F 为驱动轮的地面法向反力,n F =g m ⋅1;ϕ为驱动轮与地面的附着系数,在混凝土或沥青路面ϕ取0.7~0.8ϕ,取0.8。

此处1m 取1140Kg (前置前驱汽车的前轴轴荷47%~60%)。

89.29.09.41052768.08.06.08.910401=⨯⨯⨯⨯⨯⨯≤g i所以一档传动比的选择围是89.282.11≤≤g i 初选一档传动比为85.21=i 最低稳定车速: oa i i rn u 1minmin 377.0==5.9 Km/h<10Km/h 合格 分配各挡传动比:选五档 按等比级数分配q i i i i i i i i ====54433221 85.21=i 8.05=i 所以 q =1.37 07.237.185.212===q i i 51.137.107.223===q i i 10.137.151.134===q i i 8.05=i 三、初算中心距A初选中心距时,可根据下述经验公式31max g e A i T K A η= (4-1)式中:A —变速器中心距(mm );A K —中心距系数,乘用车:A K =8.9~9.3,商用车:A K =8.6~9.6,多挡变速器:A K =9.5~11.0;max e T —发动机最大转矩(Nm );1i —变速器一挡传动比;g η—变速器传动效率,取96%。

max e T =105N .m1i =2.8531max g e A i T K A η==3%9685.2105)3.99.8(⨯⨯~=58.7~62.36(mm)初选中心距A=62 mm2.2变速器齿轮的设计计算一、齿轮参数1、模数表1汽车变速器齿轮法向模数表2汽车变速器常用齿轮模数根据表1、表2本次设计,一、二、倒档齿轮的模数定为2. 5mm,三四五档模数为2.25。

2、压力角α压力角较小时,重合度大,传动平稳,噪声低;较大时可提高轮齿的抗弯强度和表面接触强度。

对轿车,为加大重合度已降低噪声,取小些。

变速器齿轮压力角为 203、螺旋角β斜齿轮在变速器中得到广泛的应用。

选斜齿轮的螺旋角,要注意他对齿轮工作噪声齿轮的强度和轴向力的影响。

在齿轮选用大些的螺旋角时,使齿轮啮合的重合度增加,因而工作平稳、噪声降低。

试验还证明:随着螺旋角的增大,齿的强度也相应提高。

不过当螺旋角大于30 时,其抗弯强度骤然下降,而接触强度仍然继续上升。

因此,从提高低挡齿轮的抗弯强度出发,并不希望用过大的螺旋角,以15 ~25 为宜;而从提高高挡齿轮的接触强度和增加重合度着眼,应选用较大螺旋角。

斜齿轮螺旋角可在下面提供的围选用:轿车两轴式变速器为 20 ~25°初选的螺旋角β=224、齿宽b应注意齿宽对变速器的轴向尺寸,齿轮工作平稳性,齿轮强度和齿轮工作时受力的均匀程度均有影响。

考虑到尽可能的减少质量和缩短变速器的轴向尺寸,应该选用较小的齿宽。

减少齿宽会使斜齿轮传动平稳的优点被削弱,还会使工作应力增加。

使用宽些的齿宽,工作时会因轴的变形导致齿轮倾斜,使齿轮沿齿宽方向受力不均匀并在齿宽方向磨损不均匀。

通常根据齿轮模数m 的大小来选定齿宽。

直齿:b=C K m , C K 为齿宽系数,取为4.5~8.0 斜齿:b=C K n m ,C K 取6.0~8.5第一轴常啮合齿轮副的齿宽系数,C K 可取大些,使接触线长度增加、接触应力降低,以提高传动平稳性和齿轮寿命。

二、各挡齿轮齿数的分配在初选中心距,齿轮模数和螺旋角以后,可根据变速器的挡数,传动比和传动方案来分配各挡齿轮的齿数。

一、二、三、四、五挡选用斜齿轮,倒挡选用直齿轮。

1、 齿轮齿数的确定一档: 85.2121==z z i 斜齿h z =2A βcos /n mh z =2A βcos /m=(2⨯62cos22)/2.5=45.98计算后取整h z =46,然后进行大小齿轮齿数的分配。

取1z =13 2z =33 所以54.21=i 二档:07.2342==z z i 98.45cos 243==+n m A z z β 取46解得:153=z 314=z 所以07.22=i 三档:51.1563==z z i 09.51cos 265==+n m A z z β取51解得:205=z 316=z 所以55.13=i 四档:10.1784==z z i 09.51cos 265==+n m A z z β取51解得:237=z 288=z 所以21.14=i 五档:8.09105==z z i 09.51cos 265==+nm A z z β取51 解得:289=z 2310=z 所以82.05=i2、对中心距进行修正因为计算齿数和h z 后,经过取整数使中心距有了变化,所以应根据h z 和齿轮变位系数新计算中心距,在以修正后的中心距作为各挡齿轮齿数分配的依据。

修正后中心距一二档: A '=02.6222cos 2465.2cos 2=⨯⨯=⋅βh n z m mm , 三四五档 :A '=88.6122cos 25125.2cos 2=⨯⨯=⋅βh n z m mm 。

3、确定倒挡齿轮齿数倒档齿轮选用的模数往往与一档接近,取模数为2.5,倒档齿轮R z 的齿数一般在21~23之间,选R z =21。

112131112.i z z z z i ≥=倒 A 5.02d 2d 13a a11≤++ 1111=z 2112=z 3213=z1A =25.41)(2111=+z z m R 2A =5.67)(2113=+z z m R 三、确定齿轮参数一挡齿轮变位后参数:角度变位后的端面压力角: t αtan =βαcos tan n所以 42.21=t α 端面啮合角:AA nn ααcos ''cos =解得38.21'=n α︒ 查表得变位系数和:ξ=0.211ξ=0.38 2ξ=-0.17008.0'-=-=nn m A A y=∆y ξ- n y =0.218分度圆直径: mm z m d n 05.35cos 11==ββcos 22z m d n ==88.95mm齿顶高 1a h =n am y h )ξ(1*∆-+=2.905mm 2a h =(y h ∆-+2*ξα)n m =1.53mm 齿根高1f h =(*a h +*c -1ξ)n m =2.175mm 2f h =(*a h +*c - 2ξ)n m =3.55mm全齿高 1h =1a h +1f h =5.08mm 2h =2a h +2f h =5.08mm 齿顶圆直径:1211a a h d d +==40.86mm 2222a a h d d +==92.01mm 齿根圆直径:1121f f h d d -==30.7mm 2222f f h d d -==81.85mm 当量齿数 1n z =31cos βz =16.3 2n z = 32cos βz =41.37 二档齿轮变位后参数:角度变位后的端面压力角: t αtan =βαcos tan n所以 ︒=42.21t α 端面啮合角:AA nn ααcos ''cos =解得38.21'=n α︒ 查表得变位系数和:ξ=0.211ξ=0.31 2ξ=-0.1008.0'-=-=nn m A A y=∆y ξ- n y =0.228分度圆直径: mm z m d n 45.40cos 33==ββcos 44z m d n ==83.55mm齿顶高 3a h =n am y h )ξ(1*∆-+=2.73mm 4a h =(y h ∆-+2*ξα)n m =1.705mm 齿根高3f h =(*a h +*c -1ξ)n m =2.35mm 4f h =(*a h +*c -2ξ)n m =3.375mm全齿高 3h =5.08mm 4h =5.08mm齿顶圆直径:4332a a h d d +==45.91mm 4442a a h d d +==86.96mm 齿根圆直径:3332f f h d d -==35.75mm 4442f f h d d -==76.8mm 当量齿数 3n z =33cos βz = 18.8 4n z = 34cos βz =38.86 三档齿轮变位后参数:角度变位后的端面压力角: t αtan =βαcos tan n所以 ︒=47.21t α端面啮合角:AA nn ααcos ''cos =解得75.21'=n α︒ 查表得变位系数和:ξ=0.321ξ=0.23 2ξ=0.09=-=nn m A A y '0.048=∆y ξ- n y =0.272分度圆直径: mm z m d n 63.48cos 55==ββcos 66z m d n ==75.37mm齿顶高 5a h =n am y h )ξ(1*∆-+=2.156mm 6a h =(y h ∆-+2*ξα)n m =1.84mm 齿根高5f h =(*a h +*c -1ξ)n m =2.295mm 6f h =(*a h +*c -2ξ)n m =2.61mm全齿高5h =4.45mm 6h =4.45mm齿顶圆直径:5552a h d da +==52.941mm 6662a h d da +==79.051mm 齿根圆直径:5552f f h d d -==44.04mm 6626f f h d d -==70.15mm 当量齿数 5n z =35cos βz =25.24 6n z = 36cos βz =39.12 四档齿轮变位后参数:角度变位后的端面压力角: t αtan =βαcos tan n所以 ︒=47.21t α 端面啮合角:AA nn ααcos ''cos =解得75.21'=n α︒ 查表得变位系数和:ξ=0.321ξ=0.18 2ξ=0.14=-=nn m A A y '0.048=∆y ξ- n y =0.272分度圆直径: mm z m d n 92.55cos 77==ββcos 88z m d n ==68.07mm齿顶高 7a h =n am y h )ξ(1*∆-+=2.043mm 8a h =(y h ∆-+2*ξα)n m =1.953mm齿根高7f h =(*a h +*c - 1ξ)n m =2.4075mm 8f h =(*a h +*c -2ξ)n m =2.495mm全齿高 7h =4.45mm 8h =4.45mm齿顶圆直径:7772a h d da +==60.006mm 8882a h d da +==71.976mm 齿根圆直径:7772f f h d d -==51.105mm 8828f f h d d -==63.08mm 当量齿数 7n z =37cos βz =30.28 8n z = 38cos βz =34.07 五档齿轮变位后参数:角度变位后的端面压力角: t αtan =βαcos tan n所以 ︒=47.21t α 端面啮合角:AA nn ααcos ''cos =解得75.21'=n α︒ 查表得变位系数和:ξ=0.321ξ=0.13 2ξ=0.19=-=nn m A A y '0.048=∆y ξ- n y =0.272分度圆直径: mm z m d n 08.68cos 99==ββcos 1010z m d n ==55.92mm齿顶高 9a h =n am y h )ξ(1*∆-+=1.9305mm 10a h =(y h ∆-+2*ξα)n m =2.066mm 齿根高9f h =(*a h +*c -1ξ)n m =2.52mm 10f h =(*a h +*c -2ξ)n m =2.385mm全齿高9h =4.45mm 10h =4.45mm齿顶圆直径:9992a h d da +==71.941mm 1010102a h d da +==60.051mm 齿根圆直径:9992f f h d d -==63.04mm 1010210f f h d d -==51.15mm 当量齿数 9n z =39cos βz =35.33 10n z = 310cos βz =29.02 倒档齿轮变位后参数:角度变位后的端面压力角: ︒==20n t αα 查表得变位系数和:ξ=01ξ=0.23 2ξ= -0.23 3ξ=0.23=-=nn m A A y '0=∆y ξ- n y =0分度圆直径: n m d 1111z ==27.50mm n m d 1212z ==52.50mm n m d 1313z ==80mm齿顶高 11a h =n am y h )ξ(1*∆-+=3.075mm 12a h =(y h ∆-+2*ξα)n m =1.925mm 13a h =n am y h )ξ(3*∆-+=3.075mm 齿根高11f h =(*a h +*c -1ξ)n m =2.55mm 12f h =(*a h +*c -2ξ)n m =3.70mm13f h =(*a h +*c -3ξ)n m =2.55mm全齿高11h =5.625mm 12h =5.625mm 13h =5.625mm齿顶圆直径:1111112a h d da +==33.65mm 1212122a h d da +==56.35mm 1313132a h d da +==86.15mm齿根圆直径:1111112f f h d d -==22.40mm 1212122f f h d d -==45.10mm 1313132f f h d d -==74.90mm第三章 齿轮的校核3.1 齿轮的损坏形式变速器齿轮的损坏形式主要有:轮齿折断,齿面疲劳剥落,移动换挡齿轮端部破坏以及齿面胶合。