铝箔有哪些缺陷

- 格式:doc

- 大小:23.50 KB

- 文档页数:2

铝板带箔常见主要缺陷及控制浅析摘要:随着社会发展,带动着我国各行业的高速发展。

由于铝及铝合金具有一系列的优异特性,近年来发展速度非常快,同时客户对产品质量的要求也越来越高,各大企业对铝加工产品缺陷的控制也越来越重视,本文重点阐述铝板带箔产品缺陷的分类及生产过程中常见的典型缺陷产生的原因及预防措施,方便企业进行产品缺陷特征分析和预防。

进而通过对缺陷的周期进行分析,可准确推断出此类缺陷产生的位置及原因,为有效改善铝板带箔产品质量提供了良好基础。

另外对目前各大铝加工企业存在的现状问题进行分析,并供同行参考资料。

关键词:铝板带箔;轧制;周期性缺陷;技术人才;引言中国的铝板带箔加工企业,多数只是掌握了一般产品生产线的工艺技术,对高精端产品和特殊生产线的工艺技术尚处于模仿阶段。

比如,中国已经建成了多条铝合金厚板生产线,其生产能力占世界总产能的一半以上,但因工艺技术不成熟,实际生产能力还不足三分之一;中国建成了一条2000mm级当今世界最大的连铸连轧生产线,年生产能力超过250kt,却因工艺技术没有完全掌握,开机率还不足五分之一,成品率普遍偏低,产品加工费用偏高;中国从二十世纪八十年代末期就开始研发并生产PS版铝板基,目前超过10家以上企业拥有专门生产PS版铝板基的生产线,而因产品质量缺陷的控制及技术工艺始终没有获得突破,产品至今还处于中低端水平[1]。

1、铝板带箔加工企业铝合金带材缺陷的分类1.1铝合金带材缺陷分类按照缺陷出现的原因分类如下:1.1.1轧制缺陷。

有厚差、板形不良、表面波、金属或非金属压入、压折(斜角)、水迹(腐蚀)、皱折、打折、开缝、松卷、串层(塔形)、针孔、亮点、不规则亮带、张力线、辊印或辊眼、油污或条印、亮印、裂边和翘边。

1.1.2包装和储运缺陷。

有磕碰伤、压陷和腐蚀不同的缺陷分类方法适台于不同的场合.例如,按生产工艺流程来分,对购买毛料的厂家很有参考意义;按缺陷性质分类,有助于用技术手段解决问题,按缺陷形态分类,便于成品检验。

铝箔轧制常见缺陷的一般特征、原因及措施在轧辊的表面与机体中形成高微裂纹的铬层。

这种高高微裂纹的网状结构有利于轧制油吸附在轧辊表面,以便润滑。

网状结构的铬层可以承受轧制力高达2000吨以上的的压力。

以下是其与传统镀铬的金相结构图的比较对照表:轧辊镀铬的铬层硬度是随着镀铬的技术条件变化而变化的。

科德工作辊服务集团的镀铬层硬度通过其技术的创新可以达到900-1100VICKERS PN。

这么高的硬度值就是所谓的“镀硬铬”技术。

通过这样的硬度值来增加轧辊的耐磨性能。

它的硬度要比通常的铸铁或者热处理的锻钢工作辊的硬度还要高。

镀铬层的摩擦系数更低,以下是一些金属表面的摩擦系数表:铝箔轧辊的镀铬对铝箔的生产带来了较好的效果。

工作辊—所有机架(粗轧→中轧)冷轧镀铬辊的所有绩效在铝箔轧辊上都能体现出来,此外,还具备以下优点:(1)、能够成倍减缓随通过量轧制速度下降的趋势从而获得稳定的轧制速度;(2)、能够从窄到宽的变规格轧制;(3)、大幅度改善润滑状态减少了不明断带;(4)、获得稳定一致的板型和表面质量。

在生产10—30um的箔材中,由于支撑辊的原因常常损坏工作辊。

而对支撑辊的镀铬可以改善工作辊的损伤,减少氧化物的产生和线条的产生。

在铝箔精轧中,使用镀铬工作辊可以获得更稳定均匀的表面质量,延缓线条产生。

抑制原料带来色差的倾向。

分切常见缺陷及调整措施工艺参数与铝箔质量产量的关系COMALCOFOIL DIVISIONDEFECT CATALOGUEDanyang Training VisitMay 1992Comalco Aluminium Ltd SMP 7479.00Yennora Words Page 1 of xxxFoil Division Date 9.9.91Standard Metallurgical Practices Prepared by: C. Cleary Foil Division Defect CatalogueScopeThis S.M.P. is for all foil personnel and covers the description and classification of various defects found in the Foil Division. It describes defects which occur during rolling, slitting and annealing.This catalogue describes the defect, why it occurs and when possible, tells you how to eliminate it.The numbering system follows the Comalco Claim System used site wide for categorizing claims from external customers (see page 2 and 3 for a full listing).This S.M.P. covers the following defects:0.1 Stickiness0.1.1 Orange Peel0.1.2 Exploded Areas0.2 Wettability1.6.1 Hot Spots1.9 Tension Cuts2.1 Water Stain2.2.1 Herringbone2.2.2 Line of Holes2.2.3 Roll Holes2.2.4 Chatter2.2.5 Mill Lines2.2.6 Bruised coil2.2.7 Indents2.2.8 Splits2.5.1 Dross2.5.2 Staining2.6.1 Chicken Tracks2.7 Broken Matte2.7.1 Streaky Matte6.3 Step Outs6.4 Telescoping6.5 Out of Round6.7.1 Edge Cracks6.7.2 Laminations6.10 BridgingFULL LISTING OF SITE WIDE DEFECTS0.0 Annealing 0.1 Stickiness 0.1.1 Orange Peel 0.1.2 Exploded Areas 0.2 Wettability1.0 Dimensional 1.1 Gauge1.2 Width1.3 Lateral Bow1.4 Length1.6 Flatness 1.6.1 Hot Spots1.6.2 Creasing1.7 Edge Burr1.8 Mass1.9 Tension Crease2.0 Surface 2.1 Water Stain2.2 Metal Surface 2.2.1 Herringbone2.2.2 Line of Holes2.2.3 Roll Holes2.2.4 Chatter2.2.5 Mill Lines2.2.6 Bruised Coil2.2.7 Indents2.2.8 Splits2.3 Surface Condition2.4 Applied Coating2.5 Surface Contamination 2.5.1 Dross2.5.2 Staining2.6 Blade Marks 2.6.1 Chicken Tracking 2.7 Broken Matte 2.7.1 Streaky Matt3.0 Metallurgy 3.1 Alloy3.2 Mechanical Properties3.3 Earing3.4 Inclusion3.5 Failure To Form Cans4.0 Document 4.1 Specification4.2 Planning4.3 Sales5.0 Packaging 5.15.2 Identification6.0 Coil Cond n 6.1 Loose Wraps6.2 Broken Welds6.3 Step Outs6.4 Telescope6.5 Out of Round6.6 Coil Size6.7 Broken Edge 6.7.1 Edge Cracks 6.7.2 Laminations 6.8 Edge Damage6.9 Handling Damage6.10 Bridging7.0 Transport 7.1 Seafreight7.2 Road/Rail8.0 Acc Reject9.0 No Defect 9.1 BU/CP Wrecks0.1 StickinessWhat is stickiness?Stickiness is a measure of how difficult it is to pull a single layer of foil from the coil. This defect can cause problems, especially when it occurs in light gauge foils such as insulation and flexible packaging metal.When does stickiness occur?When the annealing process is out of specification or the wrong annealing cycle has been used for a particular product if the metal is kept at the incorrect temperature.Why does stickiness occur?* incorrect conditions in the annealing furnace:-any residual rolling oil left from the rolling process can polymerise and form weak bonds with the meta.What can you do about it?* monitor the annealing cycle closely and watch the:-heat up rate-soak time-temperature-cool down rate;* report any furnace problems-e.g. burner failure;* keep excess coolant carryover to a minimum.STICKY COILIT REQUIRES FORCE TO PULL THESINGLE SHEET FROM THE COIL FREE UNWIND COILTHE METAL SHEET EASILY FALLS AWAYFROM THE COIL UNDER ITS OWN WEIGHT0.1.1 Orange Peel EffectWhat is orange peel effect?Orange peel effect is a change in the surface of the metal. It becomes mottled, like the surface of an orange peel. This defect is always associated with high stickiness levels (see 0.1).When does orange peel effect occur?This defect mainly occurs on medium gauge coils (30 to 70 microns) and of a soft alloy and O Temper.Why does orange peel effect occur?* too much coolant left on the coil:-during annealing, the excess coolant between the foil layers forms a vapour.-the pressure from the vapour deforms the foil in localized pockets.What can you do about it?Minimize the amount of coolant left on the coil:* always use the splash guard when rolling the final. pass on No. 1 foil mill; * make sure the air wiper system is working properly;* check the amount of residual coolant on the metal when it is on the slitter -if the level is high, make a note of this on the lot ticket.0.1.2 Exploded AreasWhat are exploded areas?Exploded areas are small blister-like bubbles that occur between layers of light gauge foil after it has been annealed. You will find this defect mainly on annealed household foil coil.When do exploded areas occur?When light gauge foil is annealed.Why do exploded areas occur?* too much coolant left on the coil:-as the foil is annealed, the excess coolant between the foil layers forms a vapour-the foil is deformed by pressure from the vapour in localized pockets, this causes an exploded blistered effect.* incorrect anneal practice-too high an annealing temperature will also cause exploded areas.What can you do about them?* keep the amount of the coolant left on the coil to a minimum: -make sure the mill air wiper system is working properly,-check the amount of residual coolant on the metal when it is on the slitter.Make a note on the lot ticket if the level is high.* make sure the metal is annealed correctly and check:-heat up rate-soak time-temperature-cool down rate0.2 WettabilityWhat is wettability?Wettability is a measure of the amount of rolling lubricant left on the foil strip after annealing. If there is too much, it can interfere when plastics and inks are applied to the metal at the customers plant.When does wettability occur?When there is too much rolling lubricant left on the metal after it has been anneal.Why does wettability occur?* excess coolant carryover on the mill;* incorrect conditions in the annealing furnace.Why can you do about it?* monitor the annealing cycle closely and watch the:-heat up rate-soak time-temperature-cool down rate;* report any furnace problems-e.g. burner failure;* keep excess coolant carryover to a minimum.A GRADE WETTABILITYWHEN WATER IS APPLIED TO A SHEET OF FOILIT STAYS ON THE FOIL e.g. IT WETS THE SURFACEB BRADE WETTABILITYWHEN WATER IS APPLIED TO A SHEET OF FOILIT DOES NOT STAY ON THE FOIL SURFACE1.6.1 Hot SpotsWhat are hot spots?Hot spots are a continuous buckle (or belly) anywhere on the width of the exit strip. Provided the exit tension is not too high, hot spots are very easy to see when you are rolling. The buckled area is a lower gauge and longer than the rest of the strip. As a result it ‘puckers’.When do hot spots occur?When excess heat builds up in a section of a work roll or backup roll, the roll expands more in this area. The metal which comes into contact with this area is rolled to a lower gauge than the rest of the strip.Why do hot spots occur?Excess heat in a localized section of a work roll or backup roll is caused by: * foreign objects rubbing against the roll;* too mach wiper pressure in one area of the roll;* a blocked coolant spray;* coolant sprays which are not correctly aligned;* too much thermal crown;* local hard or soft spots on the roll;* disturbed oxide layer in the area of the buckle.What can you do about them?* check for foreign objects and remove any you find;* check the pressure on the wiper and alter it if uneven or too high;* unblocked any blocked coolant sprays;* make sure the coolant sprays are correctly aligned;* check the coolant pressure and increase it if necessary;* change the work rolls.Hot Spot \ Shape Defect Description1.9 Tension CutsWhat are tension cuts?Tension cuts are stretched bands of broken metal on the edges of the strip. They point towards the centre of the strip and spread out as they reach the edges. This defect is very easy to identify during rolling.When do tension cuts occur?When the strip wrinkles or folds over as it enters the mill bite.Why do tension cuts occur?* if the unwind tension is too low to hold the strip flat as it enters the work roll bite, the strip edges can wavy and wrinkle;* if the bridle is uneven or out of alignment, it may not hold the strip flat.What can you do about them?* increase the unwind tension until you can’t see any more fractures;* make sure the bridle is correctly aligned and the strip is flat as it enters the mill bite.2.1 Water stainsWhat are water stains?Water stains are a white or grey discolouration on the surface of the metal. Water reacts with the metal, causing surface oxidation and the formation of a metal oxide. This oxide stain is harder than the rest of the strip. When it passes through the mill bite, it can cause the strip to break.When do water stains occur?When the metal comes into contact with water.Why do water stains occur?* direct exposure to water;* condensation caused by rapid temperature changes in the metal:* when water is trapped between two closely packed metal surfaces there is no air circulating and the metal surface reacts with the water, this is known as surface oxidation.What can you do about them?* keep water away from the aluminium at all time- store away from roof leaks or keep the metal covered- keep the metal off the floor;* make the wooden boxes have low moisture content when you pack coils in them; * make sure the coils are cool before you pack them;* cover coils when transporting them from No. 1 to No. 2 mill on an overcast day.How to determine where the water staining occurredUsing a Scanning Electron Microscope, a good understanding of where the staining occurred can be achieved. With this type of microscope the stain can be studied, and other elements other than Aluminium can be detected. These will give you a rough estimate of the nature of the stain.* If Sodium or Chlorine are detected, then the stain is probably from sea water. * If Sulphur is detected, then the stain could be caused by acid rain.* If Calcium or Iron is detected, then the water source could possibly be unclean tap water.These generalizations can only be used as a rough guide when determining where the water staining has occurred..01 5.12 KeV Typical SEM Trace for a salt water caused “Waterstain”.2.2.1 HerringboneWhat is Herringbone?Herringbone is a surface marking along the strip which resembles a string of corpo ral’s stripes or the backbone of a fish.When does herringbone occur?There are a number of possible reasons:* the coolant may not be lubricating the strip well enough under the extreme pressure of the mill bite;* the strip may have a poor shape either from a previous pass or the present one; * the gauge reduction may be too great;* an earlier annealing treatment may have been missed* work roll finish may be incorrectly ground.What can you do about it?Herringbone is probably not the fault of your rolling technique, so you should follow or report on these matters:* check the composition of the coolant to ensure it has the correct levels of additives to give lubrication. The Rolling Superintendent or Foil Metallurgist keeps records of coolant additive levels;* check the previous rolling and annealing history of the coil from the Lot Ticket - report any ways in which this differs from the process schedule;* check the Roll Grind Requisition form, ensuring that the rolls have had the correct grinding performed on them.2.2.2 Lines of HolesWhat is lines of holes?Lines of holes are a continuous line of little holes in the metal. It varies in severity and can sometimes occur consistently throughout a coil. Lines of holes often cause strip break during the last single and the final doubling passes.When does lines of holes occur?This defect occurs when the metal has been scratched at any stage of processing or when a source of pick-up is introduced to the roll bite.Why do lines of holes occur?When the surface of the strip has been broken, by:* mechanical failure, for example- pulling the strip over a seized roll- a scratch on the work roll surface;* careless handling of the metal;* the work rolls have been ground with no relief on the ends. This results in small pieces of work roll surface breaking off and being forced through the bite.What can you do about it?Try to protect the metal throughout the process:* check and maintain a high level of cleanliness on the mill regularly;* when you detect lines of holes, the coil should be isolated and put on hold. The coil should not be processed any further;* check the work rolls for signs of spoiling.2.2.3 Roll HolesWhat are roll holes?Roll holes are small marks or holes that repeat at a regular interval along the metal strip. This defect is very difficult to see during rolling.When do roll holes occur?When a roll work become damaged and the damaged portion imprints a mark onto the metal surface.Why do roll holes occur?The work rolls can be damaged by a number of things:* grit;* dirt;* dust;* an inclusion in the strip.What can you do about them?* make sure the mill is cleaned thoroughly- after a PM- after a strip break;* make sure the metal stays off the ground;* wear clean gloves when you handle the metal;* remove one wrap from the feed coil if it has been standing for a long time; * if the holes are repeating at an interval of about 1 metre when you measure them along the length of the strip, then the mark is caused by your work rolls - change the rolls;* if the holes are about 2 metres apart, they were caused before you received the coil- there is nothing you can do about them.2.2.4 ChatterWhat is chatter?Chatter is evenly spaced, two tone lines which run across the width of the strip. If you could see the edge of the strip magnified, it would look similar to the edge of a piece of corrugated iron. You will hear chatter occurring before see it.When does chatter occur?Chatter often occurs during mill acceleration and deceleration, for short periods only. Only when this occurs at longer periods of times does the defect become a problem.Why does it occur?Chatter is caused by machine resonance. Machine resonance can occur under the following condition:* the coolant is out of specification;* the feed strip is a hard alloy;* the pass line is incorrect;* the drive transfer box is worn;* the drive couplings are worn.What can you do about it?* if you want to finish the coil, try altering the mill speed and unwind tension,then stop rolling and look for the problem;* make sure the coolant is within specification at all times - if it is not, stop the mill until you can correct it;* change the product or program until someone alters the mill; * if the pass line is wrong, check the mill shims;* change the work rolls.THE LINES ON THE STRIP IF MAGNIFIEDWOULD SHOW VARIATIONS OF GAUGE WHICH WOULD GIVETHE CROSS SECTION A CORRUGATED EFFECT AS SHOWN ABOVE 2.2.5 Mill LinesWhat are mill lines?Mill lines are very narrow stripes which run along the strip in the rolling direction. To see them clearly, you need to straight down onto the strip.When do mill lines occur?When the work rolls or backup rolls are damaged.Why do mill lines occur?There are a number of reasons:* there is a scratch on the work roll;* the oxide layer on the work roll is uneven;* there are lines on the work roll caused by the damaged backup roll - the backup roll can be damaged by a worn wiper.What can you do about them?* if the defect is present in the following products, you must do a roll change - R No. 62715 Leigh Mardon .040mm x 592mm- R No. 62780 Leigh Mardon .040mm x 674mm- R No. 62576 Leigh Mardon .050mm x 675mm- R No. 62303 Leigh Mardon .040mm x 643mm* if there are lines on the backup roll, there is no point in changing the work rolls because the damaged backup roll will mark the new rolls- remove the mark from the backup roll with emery paper or a fine grinding wheel - if you can not remove the lines, change the backup roll;* if only the work roll is damaged, change the work rolls.2.2.6 Bruised CoilWhat is a bruised coil?A bruised coil is an area of discolouration which repeats along the metal strip at regular interval.When does a bruised coil occur?When a work roll has an impact placed upon it. The bruise can occur at any upstream process and can manifest itself upon further reductions as a discolouration on the metal or shape problems with the coil.Why does a bruised coil occur?* when the tail of a coil passes through the roll bite and damages the work rolls. This mark is then transferred onto the strip.- this occurs most often on heavier gauges and when you roll hard alloys (e.g.3003 and 3004 alloys).What can you do about it?* when you are rolling a breakdown pass, stop the mill before the tail of the strip passes through the mill bite;* cut the tail in an arc, reduce the load and pull the tail through;* when programming semi-rigid container metal on No. 1 Mill, always programme 8001 and other soft alloys before 3003 and 3004 alloys. The 3003 and 3004 alloys are harder than the 8001 alloy and are therefore less susceptible to the effect of bruising the work rolls.2.2.7 IndentsWhat are indents?Indents are small depressions that appear on the surface of the metal as the coil unwinds.When do indents occur?This defect mainly occurs on medium gauge coils (30 to 70 microns). It is most obvious on O-Temper metal.Why do indents occur?* small particles of dust, dirt and grit get trapped between the metal layers as the coil is slit- the problem gets worse when the metal is annealed because the metal is softer and more prone to mark.What can you do about them?* clean the slitter thoroughly before you use it- this is especially important if the slitter has not been used for a while; * keep the metal off the floor;* handle the metal with clean gloves;* when slitting metal on the 755 slitter always use rotary blades, as razer blades tend to produce a larger amount of swarf which then deposits on the metal strip.2.2.8 SplitsWhat are splits?Splits are very thin creases which have been rolled into the metal. These creases weaken the metal and will easily break apart during rolling. When you are rolling, a split looks like a continuous black line, usually on the centre of the rewinding coil, but sometimes on other side. Take care you don’t confuse this defect with mill lines which look very similar.When do splits occur?When you roll a fold or crease into the strip.Why do splits occur?There are a number of reasons:* incorrect pass line- if the pass line is wrong, the strip will not be level when it enters the mill bite;* the unwind tension is too high, cause a crease in the unwinding strip - this occurs mainly in light gauge strips;* the entry bridle is not correctly aligned.* the backup roll has recently been changed and the work roll camber has not been change to accommodate this change.* the work roll finish may be incorrectly ground.What can you do about them?* carry out a pass line check whenever you change the top backup roll;* make sure the pass line is correct;* make sure the unwind tension is correct;* make sure the correct shims are inserted at every work roll change;* check that the entry bridle is correctly aligned.* ensure that the correct work roll camber is used after the backup rolls have been change.2.5.1 DrossWhat is dross?Dross is a mark or hole in the strip. In very severe cases, it ban lead to web break.When does dross occur?True dross is very rare. It occurs when the metal has not been sufficiently drossed off during casting. Many other defects are mistakenly reported as dross.Why does dross occur?* oxidational impurities form in the metal during casting and hard oxide particlesbecome embedded in the aluminium;* during rolling the oxide particles do not deform as readily as the aluminium and can damage the work rolls;* this leads to marks and holes in the strip and finer gauge strips may disintegrate.What can you do about it?* there is nothing you can do about true dross because the defect is already in the metal before you receive it;* by keeping the metal clean, you can avoid defects which show similar characteristics, but are not in reality dross.2.5.2 StainingWhat is staining?Staining is a black or brown mark which appears or the coil after annealing.When does staining occur?When there are organic compounds left on the strip during annealing, they burn on and cause staining.Why does staining occur?Staining can occur on different parts of the coil:* on the side- if the staining compound was deposited during rolling;* on the side, but only near a join- if the compound was left when the coil was being joined or welded;* on the outside wraps- if the compound came into contact with the metal inside the furnace;* if there is ‘wet lube’ on the furna ce tree when it enters the furnace, the lube evaporates, concentrates and burns on the coil- this could come from a side arm tree that has had container coils on it.What can you do about it?* make sure the coils do not have excess coolant left on them- use the splash guards during the final pass on No. 1 foil mill;* make sure the side arm trees do not have any wet lube on them before you place a coil on them for annealing;* make sure the mill air wiper system is working properly;* check that there is no tape or other foreign matter on the coil before you anneal it.* always ensure that furnace exhaust vents are working properly.2.6.1 Chicken trackingWhat is chicken tracking?Chicken tracking is a slit defect that looks like lines on the edge of a slit coil which radiate from the centre to the outside.When does chicken tracking occur?This defect is a result of slitter blade flutter.Why does chicken tracking occur?Slitter blade flutter can be caused by following:* a damaged female knife roll:* a loose knife;* badly shaped feed metal.What can you do about it?* make sure the knives are firm;* make sure the female knife roll is in good condition.2.7 Broken MatteWhat is broken matte?Broken matte are shiny spots scattered over the dull, matte side of the metal.When does broken matte occur?Broken matte occurs when you are doubling strips and the two strips weld together in spots. As the strips are separated, the welded areas break leaving shiny spots.Why does broken matte occur?There are a number of possible reasons:* not enough inter lap solvent used;* too much speed when rolling;* uneven roll grind;* the two entry strips have different surface textures;* in some alloys, broken matte can occur if the inter lap solvent has a higher lubrication capability than the coolant (e.g. alloy 1145).What can you about it?* make sure you use enough inter lap solvent;* make sure the mill speed is correct;* change the work rolls if you suspect the roll grind is mismatched.2.7.1 Streaky MatteWhat is streaky matte?Streaky matte is also known as no matte and is exactly as the name suggests, a section of the metal strip on the matte surface where there is no matte.When does streaky matte occur?When you are doubling two strips and the solvent application is not consistent you get varied lubrication characteristics in different areas of the strip.Why does streaky matte occur?* there is not adequate inter lap solvent being deposited across the whole strip of foil.What can you do about it?* use plenty of inter lap solvent;* ensure that none of the inter lap sprays have become blocked;* if you increase the mill speed during doubling, then ensure that the inter lap sprays are accordingly adjusted to a greater outflow.6.3 Step OutsWhat are step outs?Step outs are uneven wraps in the coil that have deviated from the normally smooth end face of the coil.When do step outs occur?When you alter variables such as steering or tension during rolling or slitting.Why do step outs occur?* when you alter variables such as steering or tension during rolling or slitting. What can you do about them?* if you need to change any variables when the metal is either being slit or rolled, then do so gradually and smoothly. Any quick changes could result in step outs.6.4 TelescopingWhat is telescoping?The wraps of the coil slip out sideways and result in a telescoped effect.When does telescoping occur?Telescoping generally occurs when there are steerage problems on the slitter or mill.Why does telescoping occur?* incorrect steerage on the slitter- because of badly shaped feed metal;* insufficient tension during rolling/slitting can result in a loose coil, that may slip to one side during coil handling.What can you do about it?* increase the ironing roll pressure on the side of the coil that the telescoping is steering away from;* increase the unwind tension on the side of the coil that the telescoping is steering towards.LATERAL MOVEMENT OF FOIL LAYERS RELATIVE TOEACH OTHER HAS CAUSED THE COIL TO GELESCOPE6.5 Out of RoundWhat is out of round?This term describes a coil which is not perfectly round. To measure the extent of the defect, find the maximum distance between the core and the outside diameter (shown by the bottom arrow in the diagram) and from this, take the minimum distance (shown by the top arrow in the diagram).maximum distance – minimum distance = extent of defectNote: this diagram has been exaggeratedNORMAL SLIT COILTELESCOPING OF SLIT COILWhen does out of round occur?Out of round generally occurs on insulation coils and wide flexible packaging coils.Why does out of round occur?* the bulk of the metal sags to the bottom of the coil during annealing - the cool down rate is particularly important, if the cooldown rate is too high it creates a thermal gradient in the coil. This defect is minised by using 152mm cores.What can you do about it?* make sure the cool down rate is within specification.6.7.1 Edge CracksWhat are edge cracks?Edge cracks are cracks or small splits along the edge of the strip. They are generally 0.2 to 0.3 mm long. Edge cracks are particularly a problem in hard alloys and can make it difficult, Sometimes impossible to roll the final pass.When do edge cracks occur?When the coolant composition, the pass schedule or the condition of the strip are out of specification.Why do edge cracks occur?There are a number of reasons:* too much friction during rolling;* the gauge reduction may be too great;* the edges of the strip may be shorter than the body of the strip, putting more tension on the edges.What can you do about them?* bend the edges of the coil, to do this:- turn positive bending off- increase negative bending to -2- increase the load;。

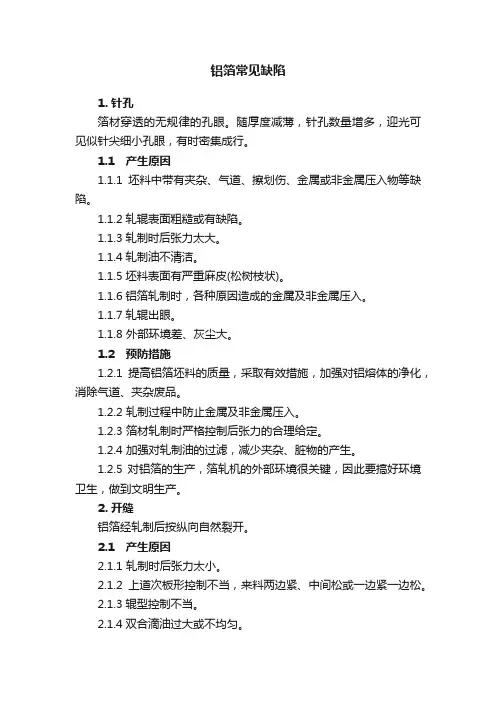

铝箔常见缺陷1.针孔箔材穿透的无规律的孔眼。

随厚度减薄,针孔数量增多,迎光可见似针尖细小孔眼,有时密集成行。

1.1 产生原因1.1.1坯料中带有夹杂、气道、擦划伤、金属或非金属压入物等缺陷。

1.1.2轧辊表面粗糙或有缺陷。

1.1.3轧制时后张力太大。

1.1.4轧制油不清洁。

1.1.5坯料表面有严重麻皮(松树枝状)。

1.1.6铝箔轧制时,各种原因造成的金属及非金属压入。

1.1.7轧辊出眼。

1.1.8 外部环境差、灰尘大。

1.2 预防措施1.2.1提高铝箔坯料的质量,采取有效措施,加强对铝熔体的净化,消除气道、夹杂废品。

1.2.2 轧制过程中防止金属及非金属压入。

1.2.3 箔材轧制时严格控制后张力的合理给定。

1.2.4 加强对轧制油的过滤,减少夹杂、脏物的产生。

1.2.5 对铝箔的生产,箔轧机的外部环境很关键,因此要搞好环境卫生,做到文明生产。

2.开缝铝箔经轧制后按纵向自然裂开。

2.1 产生原因2.1.1 轧制时后张力太小。

2.1.2上道次板形控制不当,来料两边紧、中间松或一边紧一边松。

2.1.3辊型控制不当。

2.1.4双合滴油过大或不均匀。

2.2 预防措施2.2.1 轧制时,在允许的范围内尽量增大后张力。

2.2.2 控制来料的板形,使其平整。

2.2.3 轧制时合理的控制冷却润滑油的喷射量和位置。

2.2.4 轧辊磨削严格按规定的参数执行。

2.2.5 双合滴油时,使滴油嘴畅通并控制滴油量。

3.松树枝状花纹(麻皮)箔材表面呈现的有规律的松树枝状花纹。

表面有明显的色差,但较光滑。

3.1产生原因3.1.1轧制时道次压下量过大,金属在轧辊间由于摩擦力大,流动速度慢,产生滑移。

3.1.2辊型不好,温度不均。

3.1.3轧辊粗糙度不均。

3.1.4由于添加剂含量不够等原因造成油膜强度不够。

3.1.5 轧辊局部温度过高。

3.2预防措施3.2.1 轧制时适当控制道次压下量。

3.2.2 控制冷却润滑油的喷射量和位置,获得良好的板形。

铝箔的主要缺陷有:(1)针孔。

针孔是铝箔材的主要缺陷。

原料中,轧辊上,轧制油中,甚至空气中的尘埃尺寸达到6μm左右进入辊缝均会引起针孔,所以6μm铝箔没有针孔是不可能的,只能用多少和大小评价它。

由于铝箔轧制条件的改善,特别是防尘与轧制油有效地过滤和方便的换辊系统的设置,铝箔针孔数目愈来愈依赖于原料的冶金质量和加工缺陷,由于针孔往往是原料缺陷的脱落,很难找到与原缺陷的对应关系。

一般认为,针孔主要与含气量、夹杂、化合物及成分偏析有关。

采取有效的铝液净化、过滤、晶粒细化均有助于减少针孔。

当然采用合金化等手段改善材料的硬化特性也有助于减少针孔。

优质的热轧材轧制的6μm铝箔针孔可在100个/㎡以下。

铸轧材当净化较好时,6μm铝箔针孔在200个/㎡以下。

在铝箔轧制过程中,其他造成针孔的因素也很多,甚至是灾难性的,每平方米数以千计的针孔并不稀奇。

轧制油的有效过滤,轧辊短期更换及防尘措施均是减少铝箔针孔所必备的条件,而采用大轧制力,小张力轧制也会对减少针孔有所帮助。

(2)辊印、辊眼、光泽不均。

它主要是轧辊引起的铝箔缺陷,分为点、线、面三种。

最显著的特点三周期出现。

造成这种缺陷的主要原因为:轧辊不正确的磨削;外来物损伤轧辊:来料缺陷印伤轧辊;轧辊疲劳;辊间撞击、打滑等。

所有可以造成轧辊表面损伤的因素,均可对铝箔轧制形成危害。

因为铝箔轧制辊面光洁度很高,轻微的光泽不均匀也会影响其表面状态。

定期的清理轧机,保持轧机的清洁,保证清辊器的正常工作,定期换辊,合理磨削,均是保证铝箔轧后表面均匀一致的基本条件。

(3)起皱。

由于板形严重不良,在铝箔卷取或展开时会形成皱折,其本质为张力不足以使箔面拉平。

对于张力维20MPa的装置,箔面的板形不得大于30I,当大于30I时,必然起皱。

由于轧制时铝箔往往承受比后续加工更大的张力,一些在轧制时仅仅表现为板形不良,包括轧辊磨削不正确,辊型不对,来料板形不良及调整板形不正确。

(4)亮点、亮痕、亮斑。

铝箔轧制常见缺陷1、串层:铝卷层与层相互错动,两端不齐。

在铝箔轧制的各个工序都会发生。

其实质为铝箔在卷取过程中受到与轧制方向垂直的横向力的作用,卷取时料卷偏离了铝卷实际对中线。

产生的原因:来料串层;展平辊压力不足或展平辊两端的压力不一样;展平辊与料卷中心线不平行;操作参数变化太快。

预防措施:适当降低轧制速度;操作过程中正确调整展平辊的倾斜或压力;通知钳工调整展平辊;工艺参数缓慢变化。

2、铝粉重主要与轧辊的粗糙度以及轧制油的酸值有关。

3、毛刺:切边后的铝箔端面出现尖须状的铝屑。

其实质是切边后的铝箔边部不平滑,有裂口。

主要由切边刀引起:切边刀刃不锋利,刀与刀槽的间隔与深浅不当;所对应的刀槽有损伤;刀刃有豁口。

防治措施:更换切边刀;重新调刀。

4、松卷、箭头:铝卷缠绕不紧,卷取后端面有V字形的的箭头。

在中精轧时出现,主要是分切纵剪,厚卷较厚时一般以燕窝的形式出现。

松卷箭头的实质是料在卷取时,内松外紧。

产生原因:卷取张力小,或卷取张力不稳定,或卷取张力先小后大;展平辊压力小;打底不良;双合的料卷未上料架,受挤压产生。

预防措施:调整好展平辊压力;选择合适的卷取张力;双合料坚持上料架;保证打底质量;检查设备控制参数是否合适。

5、亮点、亮条:双合面的两张铝箔的双合面对应位置上出现的弥散分布的亮点或亮条。

实质是双合的铝箔在轧制时局部油膜破裂形成。

产生原因:来料表面脏;双合油粘度大;压下量大;来料表面粗糙;双合铝箔质地不同(光洁度不均)。

预防措施:减少道次压下量,采用低粘度的双合油;降低双合轧制时的油温;正确调整工艺。

6、起皱:铝箔表面产生的纵向或斜向的皱褶。

铝箔出口厚度在0.05mm以下都有可能发生,且随厚度减小起皱可能性增大。

实质是铝箔在卷取过程中张力不足以展平铝箔。

其产生原因比较复杂,主要分为:板型局部过松;展平辊两端对料的压力不一致或卷中心线不平行;卷取张力偏小。

防治措施:提高操作水平,加强对板形的在线判断能力;在工艺范围内,及时地调整好轧制工艺参数;对松处加强冷却、加大前张力等;检查是否有轧制油从背面甩入;适当的调整展平辊;考虑是否要更换工作辊。

锂离子电池铝箔外观不良缺陷锂离子电池是现代电子设备中广泛使用的一种电池类型。

它以其高能量密度、轻量化和长循环寿命等优点受到了广泛的关注和应用。

然而,就像其他制造品一样,锂离子电池也可能存在一些外观不良缺陷,其中之一就是铝箔的问题。

铝箔作为锂离子电池中的重要组成部分,起着包括电流传导、隔离电解液和防止电池短路等关键作用。

因此,铝箔的外观质量直接影响着电池性能和安全性。

以下是一些常见的铝箔外观不良缺陷及其对锂离子电池的影响。

首先,铝箔的凹陷和气泡是常见的外观不良缺陷。

凹陷可能由于材料不均匀或加工过程中的机械力导致,气泡则可能是氧化反应导致的。

这些缺陷会导致铝箔表面不平滑,降低其导电性能,同时还可能成为电池发生短路的潜在隐患。

其次,铝箔的表面存在氧化、污染和划伤等问题。

铝与空气中的氧气会发生氧化反应,形成氧化铝层。

虽然氧化铝有助于保护铝箔,但太厚的氧化层会增加电阻,影响电池性能。

此外,铝箔在制造过程中容易受到污染和划伤,这些污染物和划痕会破坏铝箔的完整性和导电能力。

最后,锂离子电池铝箔的颜色和纹路也可能存在问题。

正常情况下,铝箔应该具有均匀的颜色和纹路,这样才能确保铝箔的均匀性和一致性。

如果出现颜色不均匀、纹路不清晰等问题,可能是原材料质量或加工工艺存在问题,这会直接影响电池的整体品质。

针对上述问题,制造商可以采取一系列措施来解决和预防铝箔外观不良缺陷。

首先,采购高质量的原材料,并加强供应链管理,确保原材料的可追溯性和稳定性。

此外,制造商可以加强生产工艺的管控,对每个生产环节进行严格的质量检查和控制,确保铝箔的制造质量。

同时,制造商还可以优化包装和运输过程,减少铝箔在运输过程中的受损和污染。

总之,锂离子电池铝箔的外观不良缺陷对电池性能和安全性都会产生不利影响。

制造商应该重视这些问题,并采取措施来解决和预防这些问题。

通过提高原材料的质量、控制生产工艺和优化包装运输,制造商可以提高铝箔的外观质量,提升锂离子电池的整体品质和可靠性。

铝板带箔常见主要缺陷及控制研究摘要:铝板带箔主要指的是铝带、铝板和铝箔,该材料主要应用于电池生产方面,但在使用过程中,极易产生割裂缺陷,影响电池的质量。

基于此,本文通过调查目前铝板带箔常见的主要缺陷,重点研究能够控制铝板带箔常见主要缺陷的策略,以期促进我国电池生产行业健康发展。

关键词:铝板带箔;表面缺陷;组织缺陷引言:在实际的生产过程中,铝板带箔常常会出现各种缺陷,有表面缺陷、组织缺陷以及尺寸形状缺陷等,而这会给后续工作带来极大的困扰。

而铝板带箔常用于变压器和电池方面,这对其质量具有较高的要求。

因此,研究铝板带箔常见主要缺陷和有效的控制方法是十分必要的。

1.研究铝板带箔的常见主要缺陷从目前现状来看,铝板带箔常见的主要缺陷可以按两个方面进行分类,分别是产品品种和缺陷类型。

具体而言,以产品品种为基准对铝板带箔的常见主要缺陷进行分类时,主要分为两种产品类型,一是铝板带,在该产品类型下的铝板带箔,出现的主要常见缺陷有:分层、夹渣、油斑、表面出现气泡、松卷、金属压入、明暗条纹、波浪、热带、黑白条、厚度超标、非金属压入、翘边、毛刺、凹板以及腐蚀等;二是铝箔,在该产品类型下的铝板带箔,出现的主要常见缺陷有:非金属压入、箭头、人字纹、划伤、孔洞、擦伤、针孔、除油不净、起鼓、腐蚀、印痕、表面起泡、油污、碰伤、亮线、裂边、暗面色差、松卷以及气道等。

若按照缺陷类型对铝板带箔的常见主要缺陷进行分类,主要从三个缺陷类型进行,一是与铝板带箔表面有关的缺陷,主要有表面起泡、除油不净、非金属压入、印痕、热带、油斑、油污、亮点、明暗条纹、压过划伤、碰伤、孔洞以及金属压入等;二是与铝板带箔尺寸形状有关的缺陷,主要有:塌卷、波浪、凹板、塔形、燕窝、厚度超标、毛刺、中凸度超标、错层、起棱以及板形不良等;三是与铝板带箔组织性能有关的缺陷,主要有:夹渣、分层、白条、晶粒粗大、性能不合格、黑白条以及气道等[1]。

2.研究控制铝板带箔常见主要缺陷的有效方法2.1避免表面缺陷出现的控制方法铝板带在表面缺陷方面的控制方法:①若是出现热带缺陷,主要是因为铸轧的温度高、速度快,外加冷却强度不足,从而在开展带材出轧作业时未完全凝固。

怎样分辨铝箔好坏?史上最全铝箔质量缺陷集锦实图讲解在铝箔的生产过程中,要经过轧制、精整、退火、包装等多道工序,环环相扣的生产工艺,任何一个环节出现问题都有可能导致铝箔质量问题。

买回来的铝箔产品出现了质量缺陷不仅会影响美观,而且直接影响生产出来的产品质量,更甚者直接导致铝箔拉断停机从而大大影响生产效率。

那怎样分辨铝箔的好坏呢?根据铝业人的经验总结,分辨铝箔质量的好坏大都可以直接用你的“慧眼”检测出来。

但是,要分辨铝箔的好坏我们首先应该了解常见的铝箔质量缺陷有哪些,只有心里有了数,再对照常见的铝箔质量问题进行一一排查,才能杜绝将有质量缺陷的铝箔入库。

今天,小慧为大家整理出史上最全的铝箔质量缺陷问题,并附上问题铝箔高清大图,当我们把铝箔买回来后,只要针对这批铝箔进行一遍问题的诊断,其质量是好是坏自然就可以得出来啦!1.铝箔碰伤▲ 铝箔碰伤是指箔材在搬运或存放过程中,与其他物体碰撞后在表面或端面产生的损伤。

碰伤的情况大多是由于铝箔包装时不注意造成的。

2.腐蚀▲ 铝箔表面与周围介质接触,发生化学反应或电化学反应后,在铝箔表面产生的缺陷,被腐蚀的铝箔表面会失去光泽,严重时还会产生灰色腐蚀产物。

被腐蚀后的铝箔对终端生产出来的产品美观程度会产生很大的影响。

3.表面气泡▲ 出现表面气泡缺陷的铝箔,其箔材表面会有不规则的圆形或条状空腔凸起;凸起的边缘圆滑,两面不对称,分布无规律,表面气泡使铝箔带各点的受力不均衡,很有可能导致拉断停机。

4.暗面条纹▲ 暗面条纹大都出现在双合产品上,暗面有沿轧制方向的明显的明暗相间的条状花纹,影响美观。

5.印痕▲ 有多种情况会导致铝箔表面出现印痕,如轧辊或导辊表面有缺陷或者粘有金属屑等脏物,套筒或管芯表面不清洁或局部存在光滑凸起,或者卷取时箔材表面粘有异物等等。

出现印痕的箔材表面一般会存在单个或周期性的凹陷或凸起,很容易辨别。

6.油斑▲ 常见的铝箔油污是退火后形成的,一般呈淡黄色、棕色,黄褐色斑痕。

鋁箔紙的缺點

尽管铝箔纸在许多方面都非常实用,但它也有一些缺点,包括:

1.不可降解:铝箔纸是一种非可降解的材料,意味着它不能被自

然分解。

当大量铝箔被丢弃或不适当处理时,它可能对环境造

成负面影响。

2.生产成本:铝箔的制造过程相对复杂,需要大量能源和资源。

这可能导致高的生产成本,同时也会对环境产生一定的影响。

3.对健康的潜在影响:有一些研究表明,使用铝箔在烹饪食物时,

特别是在酸性食物(如柠檬汁或番茄)中,可能导致铝元素渗

入食物。

虽然目前尚无确凿证据证明这对人类健康有害,但这

一问题仍在被研究和讨论中。

4.可重复使用性有限:铝箔通常可以使用多次,但它容易被撕裂

或破损,因此可重复使用性有限。

这可能导致频繁更换和浪费。

5.导热性:铝箔的良好导热性使其在烹饪和包装食物时非常有用。

然而,这也可能导致在烹饪时食物底部过度受热,容易烧焦或

粘连,需要额外的注意。

6.重量轻,易飞散:铝箔非常轻,容易被风吹走或飞散,这可能

会引起垃圾问题或环境污染。

总的来说,铝箔纸在许多情况下都是非常实用的,但也需要考虑其潜在的环境和健康影响,以及对可持续性的考虑。

在使用时,可以尽量减少浪费,鼓励回收和正确处理以减少不利影响。

铝箔轧制缺陷产生的原因和解决措施1、夹渣产生的原因• 铝熔体铸造前过滤、除气除渣不彻底,Al2O3 、炉渣等夹渣物被带入铝熔体中,最终带入坯料中。

• 更换过滤片时Al2O3 、炉渣等夹渣物被带入铝熔体中。

• 铝熔体纯净度太差,非金属异物太多,除气除渣无法彻底。

解决措施• 采取更有效的过滤、除渣方式(如Ar+Cl2两级精练, 高吸附能力的泡沫陶瓷双级过滤)。

• 改变过滤片的更换方式。

• 选择良好的原铝和废料。

2、气道产生的原因• 铝溶体氢气含量高,铸轧嘴前沿结渣,铝溶体向前流动时受阻,在结渣处的后面形成负压,铝溶体中的氢气析出,在铸轧板中形成通长的气孔叫气道,当铝箔轧制到比较薄时,由于此处的铝是两层的,延伸性能差,被轧裂。

气道一般只发生在亨特(倾斜式)铸轧机上。

解决措施• 加强精练,降低氢气含量和渣含量,氢含量应控制在0.15ml/100gAl以下。

3、氧化产生的原因• 铝和水发生化学反应生成Al2O3(开始颜色发白,随着时间的延长逐渐变黑)。

• 水的来源:— 轧制油含有游离水。

— 蚊虫带入轧辊。

— 候湿热、坯料、铝箔放置时间太长。

2Al+3H2O ═ Al2O3+3H2↑解决措施• 轧制油含水量应小于150PPm。

• 灭蚊虫。

• 铝产品应放置在通风干燥的区域,如果放置在密闭区间,应有足量的干燥剂。

• 放置时间越短越好。

非金属压入非金属异物在铝材生产过程中带入变形区后压入铝基体中,形成非金属压入物。

这些非金属压入物大多数会在后来的轧制中脱落,在铝箔表面留下痕迹,最终可能产生针孔、孔洞或颜色不均。

产生原因• 环境卫生差,空气中灰尘多。

• 生产设备、使用的吊具等工具脏。

• 过滤纸克重小或厚度不均,造成过滤土泄漏,再通过油喷嘴喷入轧制变形区。

• 轧制油过滤精度不够,轧制油中有非金属颗粒。

解决措施• 加强5S管理,改善环境清洁度。

•久置的铝材应扒去外层。

• 控制好轧制油的过滤质量。

废料(断带)产生原因•断带后碎铝箔未处理干净,附在机架内,轧制时入口侧的碎铝箔掉下,被带入轧制变形区,造成该区域铝箔变形不均而压裂(正常区域只有两层铝箔,有废料的区域至少三层),产生断带现象。

编写刘晓霞箔材常见缺陷审核批准发布本规程描述了铝箔生产过程中常见缺陷的定义、特征、产生原因及预防消除措施。

1.针孔箔材穿透的无规律的孔眼。

随厚度减薄,针孔数量增多,迎光可见似针尖细小孔眼,有时密集成行。

1.1产生原因1.1.1坯料中带有夹杂、气道、擦划伤、金属或非金属压入物等缺陷。

1.1.2轧辊表面粗糙或有缺陷。

1.1.3轧制时后张力太大。

1.1.4轧制油不清洁。

1.1.5坯料表面有严重麻皮(松树枝状)。

1.1.6铝箔轧制时,各种原因造成的金属及非金属压入。

1.1.7轧辊出眼。

1.1.8外部环境差、灰尘大。

1.2预防措施1.2.1提高铝箔坯料的质量,采取有效措施,加强对铝熔体的净化,消除气道、夹杂废品。

1.2.2轧制过程中防止金属及非金属压入。

1.2.3箔材轧制时严格控制后张力的合理给定。

1.2.4加强对轧制油的过滤,减少夹杂、脏物的产生。

1.2.5对铝箔的生产,箔轧机的外部环境很关键,因此要搞好环境卫生,做到文明生产。

2.开缝铝箔经轧制后按纵向自然裂开。

2.1产生原因2.1.1轧制时后张力太小。

2.1.2上道次板形控制不当,来料两边紧、中间松或一边紧一边松。

2.1.3辊型控制不当。

2.1.4双合滴油过大或不均匀。

2.2预防措施2.2.1轧制时,在允许的范围内尽量增大后张力。

2.2.2控制来料的板形,使其平整。

2.2.3轧制时合理的控制冷却润滑油的喷射量和位置。

2.2.4轧辊磨削严格按规定的参数执行。

2.2.5双合滴油时,使滴油嘴畅通并控制滴油量。

3.松树枝状花纹(麻皮)箔材表面呈现的有规律的松树枝状花纹。

表面有明显的色差,但较光滑。

3.1产生原因3.1.1轧制时道次压下量过大,金属在轧辊间由于摩擦力大,流动速度慢,产生滑移。

3.1.2辊型不好,温度不均。

3.1.3轧辊粗糙度不均。

3.1.4由于添加剂含量不够等原因造成油膜强度不够。

3.1.5轧辊局部温度过高。

3.2预防措施3.2.1轧制时适当控制道次压下量。

铝箔生产中常见质量缺陷与检测方法

(作者:李军单位:无锡创视新科技有限公司)

在带坯轧制成各种铝箔半成品和成品的过程中,以及在箔材精整、退火、转运、包装等工序的生产过程中,不可避免的会出现一些缺陷。

这些缺陷的产生,一部分是铸锭、铸轧带坯本身的缺陷.有时在注锭、铸轧工序可暴露,有时不能发现,而在后续的进一步加工过程中才能暴露;另一部分是在带箔材轧制、精整、退火、转运、包装等工序生产过程中产生的。

这些缺陷的产生大部分是由于设备故障、违反操作规程、工艺参数调整不当、操作人员技术不够熟练和其他种种原因造成的。

在铝箔的生产过程中,造成铝箔质量缺陷有许多种,主要是大量的针孔、厚度超差、平整度差、各种原因的断带等,减少这些缺陷,对提高箔材质量是很有意义的。

铝箔是在很薄状态下轧制的,对材料的厚度均匀性、轧制速度、张力、轧制油等都很敏感,在各种缺陷中最关键的是解决断带和针孔,尤其对高速轧机更为重要。

断带和针孔的产生与铝箔坯料的质量极为密切。

铸轧、热轧坯料中的夹杂、气道、轧制过程中的金属和非金属压人、擦、划伤以及厚度不均等都能给铝箔轧制造成很大困难.引起断带、针孔、厚度超差等。

且这些缺陷互相影响,铝悄越薄针孔越多,针孔越多则越容易断带,断带多,轧制升速中头尾必定有一部分箔材厚度超差。

机器视觉是以图像处理理论为核心,属于人工智能范畴的一个领域,它是以数字图像处理、模式识别、计算机技术为基础的信息处理科学的重要分支,广泛应用于各种无损检测技术中。

基于机器视觉的创视MVC-

LB铝箔针孔检测仪基本原理是:一定的光源照在待测金属表面上,利用高速CCD 摄像机获得铝箔表面图像,通过图像处理提取图像特征向量,通过分类器对表面缺陷进行检测与分类。

(1)针孔。

针孔是铝箔材的首要缺点。

原猜中,轧辊上,轧制油中,乃至空气中的尘土尺度到达6μm摆布进入辊缝均会导致针孔,所以6μm铝箔没有针孔是不可能的,只能用多少和巨细评估它。

因为铝箔轧制条件的改进,特别是防尘与轧制油有用地过滤和方便的换辊体系的设置,铝箔针孔数目愈来愈依赖于质料的冶金质量和加工缺点,因为针孔通常是质料缺点的掉落,很难找到与原缺点的对应联系。

通常以为,针孔首要与含气量、搀杂、化合物及成分偏析有关。

采纳有用的铝液净化、过滤、晶粒细化均有助于削减针孔。

当然选用合金化等手法改进材料的硬化特性也有助于削减针孔。

优质的热轧材轧制的6μm铝箔针孔可在100个/㎡以下。

铸轧材当净化较好时,6μm铝箔针孔在200个/㎡以下。

在铝箔轧制过程中,其他构成针孔的要素或许多,乃至是灾难性的,每平方米数以千计的针孔并不稀罕。

轧制油的有用过滤,轧辊短期替换及防尘办法均是削减铝箔针孔所必备的条件,而选用大轧制力,小张力轧制也会对削减针孔有所帮助。

(2)辊印、辊眼、光泽不均。

它首要是轧辊导致的铝箔缺点,分为点、线、面三种。

最明显的特色三周期呈现。

构成这种缺点的首要缘由为:轧辊不正确的磨削;外来物损害轧辊:来料缺点印伤轧辊;轧辊疲惫;辊间撞击、打滑等。

一切能够构成轧辊外表损害的要素,均可对铝箔轧制构成损害。

因为铝箔轧制辊面光洁度很高,细微的光泽不均匀也会影响其外表状况。

定时的整理轧机,保持轧机的清洗,确保清辊器的正常作业,定时换辊,合理磨削,均是确保铝箔轧后外表均匀共同的基本条件。

(3)起皱。

因为板形严峻不良,在铝箔卷取或打开时会构成皱折,其本质为张力缺乏以使箔面拉平。

关于张力维20MPa的设备,箔面的板形不得大于30I,当大于30I时,必然起皱。

因为轧制时铝箔通常接受比后续加工更大的张力,一些在轧制时只是表现为板形不良,包含轧辊磨削不正确,辊型不对,来料板形不良及调整板形不正确。

(4)亮点、亮痕、亮斑。

双合面因为双合油运用不当导致的亮点、亮痕、亮斑,首要是因为双合油油膜强度缺乏,或轧辊面不均导致轧制不均变形,外观呈麻皮或异物压入状。

选用合理的双合油,保持来料清洗和轧辊的辊面均匀是处理这类缺点的有用办法。

当然改动压下量和挑选优良的铝板也是必要的。

(5)厚差。

厚差难于操控是铝箔轧制的一个特色,3%的厚差在板材出产时或许不难,而在铝箔出产时却非常艰难。

缘由在于厚度薄,其他微量条件均可构成影响,如温度、油膜、油气浓度等。

铝箔轧制一卷可达几十万米,轧制时刻长达10h摆布,随时刻延伸,厚差很易构成,而对厚度调整的手法仅有张力速度。

这些要素均构成了铝箔轧制的厚控艰难,所以,真实操控厚差在3%以内,需求许多条件来确保,难度相当大

(6)油污。

油污是指轧制后铝箔外表带上了剩余的油,即除轧制油膜以外的油。

这些油通常由辊颈处或轧机出口上、下方甩、溅、滴在箔面上,且较脏,成分杂乱。

铝箔外表带油污比其他轧制材带油污损害更大,一是因为铝箔成品大都作为装修或包装材料,必须有一个洁净的外表;二是其厚度薄,在后道退火时易构成泡状,并且因为油量较多在该处构成过多的残留物而影响运用。

油污缺点多少是评估铝箔质量的一项很重要的指标。

(7)水斑。

水斑是指在轧制前有水滴在箔面上,轧制后构成的白色斑迹,较细微时会影响箔面外表状况,严峻时会导致断带。

水斑是因为油中有水珠或轧机内有水珠掉在箔面上构成的,操控油内水分和水源是防止水斑的专一办法。

(8)振痕。

振痕是指铝箔外表周期性的横波。

发生振痕缘由有两种:一种是因为轧辊磨削时构成的,周期在10~20mm摆布;另一种是轧制时因为油膜不连续构成振荡,常发生在一个速度区间,周期为5~10mm。

发生振痕的底子缘由是油膜强度缺乏,通常能够选用改进光滑状况来消除。

(9)张力线。

当厚度到达0.015mm以下时,在铝箔的纵向构成平行条纹,俗称张力线。

张力线距离在5~20 mm摆布,张力愈小,张力线愈宽,条纹愈明显。

当张力到达必定值时,张力线很细微乃至不见。

厚度愈小发生张力线的可能性愈大,双合轧制发生张力线的可能性较单张大。

增大张力和轧辊粗糙度是减轻、消除张力线的有用办法,而大的张力必须以杰出的板形为根底。

(10)开缝。

开缝是箔材轧制特有的缺点,在轧制时沿纵向平直地裂开,常伴有金属丝线。

开缝的底子缘由是进口侧打折,常发生在中心,首要因为来猜中心松或轧辊不良。

严峻的开缝无法轧制,而细微的开缝在今后的分切时裂开,这通常构成许多废品。

(11)气道。

在轧制时刻断呈现条状压碎,边际呈液滴状曲线,有必定宽度,轻度的气道未压碎,呈白色条状并有密布针孔。

在压碎铝箔的前后端存在密布针孔是判断气道与其他缺点的首要象征。

气道来源于质料,挑选含气量低的材料作为铝毛坯是非常重要的。

(12)卷取缺点。

卷取缺点首要指松卷或内松外紧。

因为铝箔接受的张力有限,卷取硬卷就很艰难。

取得里紧外松的卷是最理想的,而足够的张力是构成必定张力梯度的条件。

所以,卷取质量终究依赖于板形好坏,内松外紧的卷会构成横棱,而松卷则会构成椭圆,这均会影响今后加工。

铝箔轧制缺点品种虽然许多,但终究首要表现为:以孔洞为特征的针孔、辊眼、开缝、气道;以外表状况为特征的油污、光泽不均、振痕、张力线、水斑、亮点亮斑;以影响后工序加工的板形、起皱、打折、卷取不良;以尺度为特征的厚差等。

实质上,铝箔特有的缺点只有针孔一类,其他几种缺点板材也相同有,只不过表现的严峻程度不同或需求不同罢了。