S4800扫描电镜(SEM)操作手册课件

- 格式:ppt

- 大小:412.50 KB

- 文档页数:36

Loading Procedure for Hitachi 48001)login the computer with your active directory passwd, SEM program will startautomatically, just leave the blank when prompt for S4800 password2)Turn on IR lamp and cameraSample loading1)Mount your sample to sample holder and check height (make sure it is lower2)Check the computer monitor to make sure the stage is at EXC (exchangeposition), use mouse to select EXC to move the stage to exchange position,and make a note in the log sheet.3)Press AIR button to vent the load-lock4)After AIR button stop flashing (indicating vent complete), open the load-lockdoor (Do Not use the loading stick to open the door to avoid bending)5) Push the loading stick out a little bit and mount your sample holder to theloading stick. (Do Not touch the loading stick to avoid removing the grease on it)6) Pull back the loading stick all the way out to avoid it get suck in when start pumping later.7) Close the load-lock door (Do Not use the loading stick to close the door to avoid bending)8) Press EVAC to pump the load-lock9) After EVAC button stop flashing (indicating loadlock pressure is lowenough), press OPEN to open the gate valve10) After OPEN (take a few second, be patient ) button stop flashing (indicating gate valve is fully open) push the loading stick in. After the sample holder engaged to the stage , unlock the loading stick and pull back the loading stick all the way out .11) Press CLOSE to close the gate valve while keeping another hand to hold the loading stick to avoid it from sucking in.Sample imaging2. click “HOME” position to move the sample to the center1 inch3.4.When asked to flash, please use intensity 1, HV must be off to flash the tip.5.Turn on the HV by clicking “ON”6.Click “H/L” to go to LM (low magnification) to find the area you need to look at7.Go back to High Mag after locating the area you need to look at8.Adjust “focus”, “astigmatism”, “brightness/contrast”, “Mag”1Magnification Astigmatism FocusBrightness/ContrastBeam shift9. can be used for automatic brightness contrast control.10.choose “Slow3” icon for slow scan image capture11.capture.12.PCI software can be use for image analysis.Sample unloading1)Turn off High voltage from the computer2)Move the stage back to EXC (exchange position) by using mouse to selectEXC3)press OPEN to open the gate valve4)After OPEN button stop flashing (indicating gate valve is fully open) push theloading stick in. After the sample holder engaged to the loading stick, lock theloading stick to sample holder and pull back the loading stick all the way out.5)Press CLOSE to close the gate valve.6)After CLOSE button stop flashing (indicating gate valve is fully close), pressAIR button to vent the load-lock.7)After AIR button stop flashing (indicating vent complete), open the load-lockdoor (Do Not use the loading stick to open the door to avoid bending)8)Remove the sample holder from the loading stick9)Close the load-lock door (Do Not use the loading stick to close the door toavoid bending)10)Press EVAC to pump the load-lockAccess SEM image over network1.Right click “My computer”2.Select “Map Network Drive”3.Choose any unused Drive letter4.Enter \\\image for folder5.when enter your login name, you may need to put uofi\ before your netid6.uncheck Reconnect at logon7.Click “Finish”。

扫描电镜S-4800操作规程一、日常开机打开Display开关,电脑自动开机进入s-4800用户界面,PC_SEM程序自运行,点击确认进入软件界面。

二、装样品1.将样品台装在样品座上,根据标尺调整高度及确认样品位置后旋紧。

2.按下AIR键,当AIR灯变绿时拉开样品交换室,水平向前推出交换杆,把样品座插在交换杆上,逆时针旋转交换杆(即按照杆上的标示转至LOCK)锁定样品座后,将交换杆水平向后拉回原处。

3.关闭交换室,按下EV AC键,当EV AC绿灯亮时,按OPEN键至绿灯亮样品室阀门自动打开。

4.水平插入交换杆,直至样品座被卡紧为止,顺时针旋转交换杆(即按照杆上的标示转至UNLOCK)后水平向后拉回原处,点CLOSE键至绿灯亮样品室阀门自动关闭。

三、图像观察1.加高压点击屏幕左上方的高压控制窗口,弹出HV Control对话窗。

选择合适的观察电压和电流,点击ON,弹出提示样品高度的对话框,点击确定出现HV ON 提示条,待图像出现后,关闭HV Control对话窗。

2.在低倍、TV模式下,找到所要观察的样品,点击H/L按钮切换到高倍模式,通过调节样品位置,找到所要观察的视场。

3.聚焦、消像散选好视场后,放大到合适的倍数聚焦消像散。

先调节聚焦粗调和细调旋钮,使图像达到最佳状态,若图像有拉长现象,则需进行消像散。

调节STIGMATOR/ALIGNMENT X使图像在水平方向的拉长消失,再调节STIGMATOR/ALIGNMENT Y使图像在垂直方向的拉长消失。

4.图像采集及保存用A.B.C.键或BRIGHTNISS/CONTRAST旋钮自动或手动调节图像的对比度和亮度,扫描速度变为慢扫,点击抓拍按钮进行采集。

采集后暂时存放在窗口下侧,选中要保存的图像,点击Save,弹出Image Save对话框,输入文件名,选好存储位置保存即可。

5.对中调整改变加速电压和电流时,或图像在高倍聚焦发生漂移时,需要进行对中调整,方法如下:(1)选取样品上一个具有明显特征的位置放在视场中心。

冷场发射扫描电子显微镜S4800操作说明(普通用户)燕山大学材料学院材料管A104(场发射,钨灯丝)编写人:李月晴吕益飞普通用户在熟练操作1个月后,如无不良记录,可申请高级用户培训。

高倍调清晰:局部放大(Red) →聚焦Focus→消像散一、日常开机1,开启冷却循环水电源。

2,按下Display开关至,PC自动开机进入用户界面并自动运行PC_SEM程序,以空口令登入。

3,打开信号采集开关,位置打到1,为打开。

4,打开电源插排的开关。

5,打开装有EDS软件的主机电源。

6,记录仪器运行参数(右下角Mainte),即钨灯丝真空度。

如:IP1:0.0×10-8Pa;IP2:0.0×10-8Pa;IP3:9.6×10-7Pa。

PeG-1,<1×10-3;PeG-2,<1×10+2。

注意:PeG≤1×10-3Pa时才能加高压测量。

记录的参数:①点Flashing时会显示:In2(Ie)Flashing时电流最大值,如32.9μA;②加上高压后会显示,V ext=3.4kV。

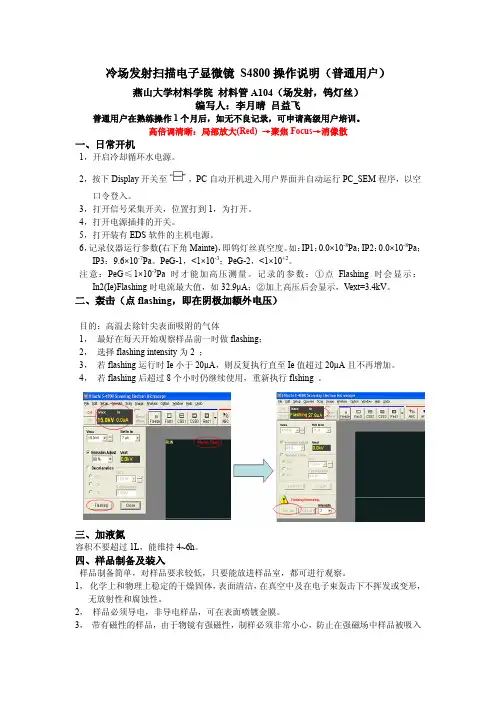

二、轰击(点flashing,即在阴极加额外电压)目的:高温去除针尖表面吸附的气体1,最好在每天开始观察样品前一时做flashing;2,选择flashing intensity为2 ;3,若flashing运行时Ie小于20µA,则反复执行直至Ie值超过20µA且不再增加。

4,若flashing后超过8个小时仍继续使用,重新执行flshing 。

三、加液氮容积不要超过1L,能维持4~6h。

四、样品制备及装入样品制备简单,对样品要求较低,只要能放进样品室,都可进行观察。

1,化学上和物理上稳定的干燥固体,表面清洁,在真空中及在电子束轰击下不挥发或变形,无放射性和腐蚀性。

2,样品必须导电,非导电样品,可在表面喷镀金膜。

3,带有磁性的样品,由于物镜有强磁性,制样必须非常小心,防止在强磁场中样品被吸入物镜或分散在样品室中,工作距离(WD) 要大于8.0mm。

S-4800日立扫描电子显微镜(SEM)简易操作指南一、开机前准备1.1制备样品(带口罩与手套进行)SEM样品制备相对简单,原则上只要能放入样品室的样品,都可进行观察。

但需注意以下事项:a)样品在物理上和化学上必须要保持稳定,在真空中和电子束轰击下不挥发或变形,没有腐蚀性和放射性。

(通常是干燥固体。

)b)由于光源是电子,样品必须导电,非导电样品可喷镀金膜。

金膜在一定程度上会影响样品原有形貌。

(若样品本身导电,衬底不导电,如蓝宝石上的ZnO,只需用导电胶把样品表面连到样品台。

)c)由于物镜有强磁性,带有磁性的样品制样必须非常小心,防止在强磁场中样品被吸入物镜或分散在样品室中。

通常磁性样品必须退磁,且工作距离(WD)须大于8mm。

具体操作过程:(1) 按待测样品数量选择样品台,(支持直径d=5mm,15mm,1 inch,2 inch等规格,若要观测截面可选择带角度的样品台)。

(2) 剪一小段导电胶,粘到样品台上。

若样品为粉末,则把粉末撒到导电胶上,用吸耳球或高压氮气吹扫掉导电胶上未粘紧的粉末;若是块状样品,则把样品牢牢粘到导电胶上,用手轻轻推,样品不会左右晃动。

(为观测时方便定位,将样品排列成行(或列),并在行下方(或列左侧)标上数字编号。

)(3) 样品粘贴完成后,用吸耳球或高压氮气吹扫掉样品台上的粉末、灰尘、水珠、唾沫等(会影响照片质量,甚至使真空度下降而无法加高压,推荐认真执行。

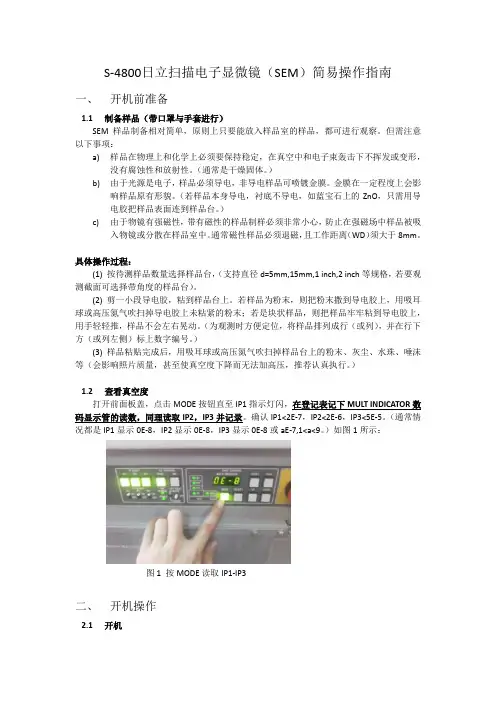

)1.2查看真空度打开前面板盖,点击MODE按钮直至IP1指示灯闪,在登记表记下MULT INDICATOR数码显示管的读数,同理读取IP2,IP3并记录。

确认IP1<2E-7,IP2<2E-6,IP3<5E-5。

(通常情况都是IP1显示0E-8,IP2显示0E-8,IP3显示0E-8或aE-7,1<a<9。

)如图1所示:图1 按MODE读取IP1-IP3二、开机操作2.1开机a)开启冷却循环水电源,循环水温度显示应在15-20℃,水位应浸没金属线圈。

P r o c e d u r e f o r FIRST USER ofFIRST USER of day1.Turn on CPU power (inside lower cabinet)2.Turn on Computer Monitor3.Login to Windows (no password)4.Login to S-4800 software by clicking icon PC-SEM to open control panel (nopassword)5.Click box (Vacc, Ie) upper left of Toolbar (if dialog box w/FLASHING button isnot open)6.Click Flashing.7.“Flashing Execute ok?” Click Execute (Intensity 2 is normally ok).8.Repeat steps 5 & 6; Ie will transiently register current – should be between 20 and40 µA.9.Check Evacuation Control Panel for ion pump readings (IP1, 2, 3). Values are in10-3 Pa (For Lab Manager Only)ALL USERSU s e r S e t-u p f o r ALL1.For sample exchange, be sure that the sample stage settings – Rotation (R) = 0.0,Tilt (T) = 0.0, X = 25.0, Y = 25.0 and Z = 8.0 are all set to these positions asindicated on the front of the microscope.2.Click AIR button on right side of microscope – after a few seconds, air isadmitted to the Sample Exchange Chamber (SEC). There is a beep when the SEC is at atmospheric pressure.3.Pull open and turn black knob CW to UNLOCK position and remove sampleholder.4.While wearing gloves and at workbench, not on stage, install new sample onsample holder and adjust the height using the fixture console. See pictures taped to wall for details. This will give a working distance of 8 mm when the sample is inserted into the sample stage.5.Insert sample holder aligning to dual bayonet connectors in the SEC; rotate blackknob CCW to LOCK position. Then pull SEC and rod out to guide endpoint.(Check that rod is pulled out to endpoint). CLOSE SEC door.6.Press EVAC button – air is pumped out of the SEC. A beep sounds when vacuumis attained.7.Press OPEN to open the chamber door – a beep sounds when the chamber door isopen. Visually examine to check that stage is in chamber.8.Push rod all the way in until the sample holder fully engages the sample stage;rotate black knob CW to UNLOCK position.9.Grasp black knob and pull back to end of guides. Then make sure that the sampleholder remains on the stage.10.Press CLOSE to close the chamber door. Beep sounds when the door is closedand the vacuum is ready.11.To turn HV ON. Click ON (left of gray box on Toolbar) – for normal operation,V acc=15 kV and I e=10 µA. I e will drop during the first ~30 minutes of usage due to formation of a monolayer of absorbed gas on the tungsten emitter tip. To set Accl Voltage (VAcc) click large black arrow and set KV at .5 to 30. The lower the KV the more surface detail imaged and greater the KV will increase imaging the interior structure/views. Periodically click SET (right side of Toolbar) to re-set the emission to ~10 µA (this will increase V ext).12.Scan rate is selectable on the toolbar – TV1, Slow1 and Slow3.13.H/L button on toolbar selects low magnification (30 X – 2 KX) or highmagnification (800X – 500KX) modes. The magnification can be adjusted with the knob on the control box.14.ABC button on toolbar is Auto Brightness / Contrast. These can also be adjustedusing the Brightness and Contrast knobs on the control box.15.At the beginning of a session, it is important to check the alignment of theelectron beam. Click H/L and set magnification at ~5000X. While increasing magnification Beep will occur at 2000X. The beep is a reminder to click on H/L to reset mag to high. Click ALIGN on the toolbar. A menu box will appear.Click on BEAM ALIGN and center the beam using X and Y knobs(stigma/alignment) on the control box. Click STIGIMATION X, and stopmovement of image using X and Y knobs on control box. Click STIGIMATION Y and stop image movement using X and Y knobs. Click APERTURE ALIGN and stop movement of image using X and Y knobs on control box.Click OFF in ALIGN menu box.16.Adjust coarse focus until WD is ~ 5mm. It may be required to click on “resetfocus condition” in popup dialogue box.17.To obtain the best image resolution, carefully adjust coarse, fine focus, x-stigmation and y-stigmation KNOBS at a high magnification. Adjust brightness and contrast, and observe image in Slow2 mode (button on toolbar). N.B., set Working Distance (WD) only in Hi Mag mode to ~ 5mm by using the Z adjust knob18.Set magnification at ~ 1000X. Then lower Z by turning Z knob on scope.19.Find field of interest by moving X/Y stage. Set to required magnification.20. Before Image captur, be sure to set slow scan mode for best image quality.21.To capture an image, click the 1280 button on the toolbar to the right of the H/Lbutton. This will capture a 1280 x 960 image. The resolution can be changed using the pull-down arrow.22.When the image is captured, it is displayed in the lower left, highlighted inyellow.23.Click the PCI button in the lower left to export the image to QuartzPCI imageanalysis software.24.In QuartzPCI, click File – can SAVE or EXPORT image (e.g. to a JPEG file).Clicking SAVE will actually create 3 files of which one is PCI format. EXPORT, which creates 1 file, is more efficient choice.25.Back in S-4800 software, click RUN on toolbar to resume scanning.S h u t D o w n P r o c e d u r e1.Turn off beam2.Return stage to proper settings.3.Press OPEN4.Insert rod at unlocked position5.Turn rod to locked position6.Pull rod and sample out to endpoint.7.Press CLOSE8.Press AIR, wait for beep9.Slide open SEC10.Turn black knob to UNLOCK and remove sample11.If done, close SEC and press evacuate to pump down chamber12.Turn off monitorCommon Abbreviations and DefinitionsVext (Extracting voltage) Voltage that is applied between the cathode and first anode.Electrons are emitted from the cathode.Vacc (Accelerating voltage) electrons are accelerated by an accelerating voltage.Flashing- cleansing of the cathode (FE tip) by turning on the flashing power supply in order to remove absorbed gas on the surface of the cathode. This is to be done,before usage, first thing in the morning or the evening.Ie (emission current) is generally set to 10 μA for normal operation.HV (high voltage) Applies HV to the electron gun and controls the extracting voltage to obtain the emission current.Beam monitor (adjustment of the reference voltage) is provided to reduce tip noise, which is a low frequency noise caused by fluctuations of the emission current.Dividing the image signal by a reference signal that is proportional to probe current can stabilize it. It is recommended to keep the beam monitor on for normaloperations.Beam indicator (box with cross hairs) to reset image shift to the center, click theindicator areaUnder signal selection box, L.A is low angle. When BSE is selected, the amount of BSE signal is controlled by BSE ratio selection box. Low angle BSE will be detected with L.A0 to L.A100. With the larger number, the amount of SE is suppressed and results in a BSE richer image.HR is high resolution mode where the short working distance range is limited and it is easier to use at a longer working distance (>5mm).UHR is ultrahigh resolution mode where the full working distance range is availableUnder scan size…Small screen mode has faster frame speeds and in some cases results in better image quality.Dynamic focus allows you to focus the beam for the entire field of view.Condenser lens 1 setting to lower values (1-16 range) results in weaker excitation and larger Probe Current and larger “spot size” and vice versa. Recommended value is 5. Unclicking box will turn off lens and this condition is typically used for mechanical alignments.Focus depth is recommended to be set at 1.0 or larger to increase focus depth.Degauss button should be clicked after changing focus widely or before making the electron optical axis alignment (You can do this by hitting the F2 hotkey)To select many images, press and hold down the control keyLayout button opens the Report Generation window for printing the imageSC stands for the specimen chamberApt heat should be set at auto. If the objective aperture lens is contaminated, charging will degrade image quality and the image will drift because of micro discharge. Such problems are noticeable at low accelerating voltages. The aperture is heated to about 150C to remove contaminants to one tenth or less of what it would be at room temperature.The display switch is on when the line is depressed (a 1 or switch is up is on)For use at high magnifications or low accelerating voltages, the use of the anti-contamination trap is recommended to prevent specimen contamination by hydrocarbon build-up. Fill the trap with liquid nitrogen (LN2). The Dewar is usable for about 5 hours at room temperature. ** Before introducing air into the chamber, wait for a few hours until the LN2 Dewar has completely emptied so that the trap will not frost up and deteriorate the vacuum. The air introduction value does not have a protection link with the cold trap.WD (working distance) is the distance between the bottom face of the objective lens and the surface of the specimen. At a shorter working distance, higher resolution is obtainable. At a longer WD, a larger tilt angle and a greater depth of focus are obtainable. To change the WD, move the Z to a lower #, which moves the stage up. Short-Cut KeysCtrl O Open SEM Data ManagerCtrl P PrintCtrl C Copy ImageCtrl L Open Captured Image windowF1 Help can be openedF2 Activates Degauss functionF5 Runs or stops scanning alternatelyF4 Changes alignment mode to the next stepShift F4 Changes alignment mode to previous stepNotes for AdministratorPassword is “hitachi”To preset magnifications, open the Image Tab of the Setup dialog window and input desired values in the three Preset Magnification boxes. A PM mark is indicated in the Magnification indicator area when the preset magnification is set.Setting up logins: Option menu, login setting (must be logged in as S-4800) to create or change login names and passwords for each user. Can also change password setting under Option menu.TroubleshootingWhen operating at short working distances and experiencing uneven brightness at low magnifications, turn specimen bias voltage off.Magnetic samples such as iron can cause astigmatism correction to be difficult.The use of double-sided adhesive tape may cause specimen drift. Use the least amount possible to minimize out gassing.Perform beam and aperture alignment when you change HV value, accelerating voltage, probe current mode, or setting of Cond Lens1. For all alignments, either drag the mouse in the grid area of the Alignment dialog window or adjust theSigma/alignment X and Y knobs on the control panel. Set the magnification at 5, 000X for aperture alignment.The lowest magnification that can be obtained at a WD of 25mm or more is 20X.To maximize brightness and contrast, start B/C monitor mode by double clicking the MontiF button or operate menu, BC monitor. When the maximum and minimum values of the waveform are adjusted to fit within the upper and lower reference lines, appropriate brightness and contrast will be obtained. To terminate this mode, click the cancel button in the BC monitor mode message or one of the scanning speed buttons.To maximize focus, set magnification to 1,000X and start the focus monitor by clicking the Monitor button (MontiF) on the control panel and focus the image so that the waveform shows sharp peaks. To close the focus monitor, click the cancel button in the focus monitor mode or click one of the scanning speed buttons.Auto focus or auto stigma functions will not work correctly with little or no surface detail on the specimen or when the specimen is charging. These functions should also be performed at magnifications higher than 5,000X.For high magnification work, staging locking is recommended for better mechanical stability. The Z and T axes are locked or released by the Lock button on the specimen stage. ** If the Z or T axis is moved while the stage is locked, the stage mechanism may be damaged. X, Y, and R axes are free and movable when the stage is locked.Objective lens apertures are 50 μm for settings 2 or 3. The electron optical column of the HRSEM is designed to achieve highest resolution with a 50 μm aperture. Suggestions on getting better image quality:1.Higher spatial resolution can be obtained at higher accelerating voltages2.For uncoated, insulator specimens, accelerating voltages less than 1kV arerecommended for minimizing charging. In some cases, high accelerating voltages (20kV or higher) may produce a better image.3.Influence of contamination at lower voltages is more pronounced4.Disturbances by leakage magnetic field (wobbling or distortion of the image) aregreater at low accelerating voltages.5.Generally a soft-tone image is obtained at low accelerating voltages because moreSEs are detected than BSEs.6.Ion Pump readings should be this or better:IP1: 2 x 10^-7 PaIP2: 2 x 10^-6IP3: 5 x 10^-5SC: 2 x 10^-3Stereo ImagingPg 3-165BSE ImagingA mixed signal is available. When +BSE is selected, the amount of BSE signal is controlled by the BSE ratio selection box. Low angle BSE will be detected with LA0 to LA100. With a larger number, the amount of SE is suppressed and this will result in a BSE richer image. HA results in a high angle BSE image.Refer to sections 3.5.1 SE Detector and 3.5.1.2 Signal control。

S4800型SEM操作指南S-4800具体操作过程1.日常开机按下DISPLAY开关至“━”,PC自动开机进入用户界面并自动运行PC_SEM程序,以空口令登入。

2.轰击(flashing)FE-SEM在作样之前,必须要进行轰击(作为电子源的FE尖端的清洁)。

在开始使用时,轰击频率为一次。

但是,电压外加时间累计超过8小时,发射电流开始不稳定,需要再次轰击。

轰击后可以立即观察图象。

但是在最初的1小时左右,有时会有图象干扰(图象中出现明暗的横线)。

进行高分辨率的观察时,最好在轰击完1小时以上之后进行观察。

执行过程:(1)点击控制面板上的加速电压显示区域,出现加速电压HV设定画面。

(2)点击“Flashing”键后,出现轰击执行窗口。

(3)确认轰击强度是否确实是“2”后,点击“执行”键。

HV的Ie(发射电流)显示器显示2秒钟轰击产生的发射电流,电流值大约为20uA-30uA,有时仅轰击一次,达不到所要求的值,这时需要连续轰击2-3次。

(为了保护FE灯丝,中间间隔30秒钟后,才可以进行下一次轰击。

)3.样品制备及装入3.1 样品制备相对简单,原则上只要能放入样品室的样品,都可进行观察。

高度保持在2cm以内,直径在4cm以内。

但是,样品在化学上和物理上必须要保持稳定,在真空中和电子束轰击下不挥发或变形,没有腐蚀性和放射性。

由于光源是电子,样品必须导电,非导电样品可喷镀金膜。

金膜在一定程度上会影响样品原有形貌。

带有磁性的样品,由于物镜有强磁性,制样必须非常小心,防止在强磁场中样品被吸入物镜或分散在样品室中。

操作过程:(1) 剪一小段导电胶,粘到样品台上。

(非导电样品可以用双面胶。

)(2) 把粉末撒到导电胶上,用吸耳球或高压氮气吹扫掉导电胶上未粘紧的粉末;若是块状样品,则把样品牢牢粘到导电胶上,用手轻轻推,样品不会左右晃动。

(3)样品若不导电,需要喷镀金膜。

3.2 样品装入:(1)把样品台装入样品座并调节样品表面与标尺在同一高度,旋紧。

场发射扫描电子显微镜(S-4800)操作规程开机1. 检查真空、循环水状态。

2. 开启“Display”电源。

3. 根据提示输入用户名和密码,启动电镜程序。

样品放置、撤出、交换1. 严格按照高度规定高样品台,制样,固定。

2. 按交换舱上“Air”键放气,蜂鸣器响后将样品台放入,旋转样品杆至“Lock”位,合上交换舱,按“Evac”键抽气,蜂鸣器响后按“Open”键打开样品舱门,推入样品台,旋转样品杆至“Unlock”位后抽出,按“Close”键。

观察与拍照1. 根据样品特性与观察要求,在操作面板上选择合适的加速电压与束流,按“On”键加高压。

2. 用滚轮将样品台定位至观察点,拧Z轴旋钮(3轴马达台)。

3. 选择合适的放大倍数,点击“Align”键,调节旋钮盘,逐步调整电子束位置、物镜光阑对中、消像散基准。

4. 在“TV”或“Fast”扫描模式下定位观察区域,在“Red”扫描模式下聚焦、消像散,在“Slow”或“Cssc”扫描模式下拍照。

5. 选择合适的图像大小与拍摄方法,按“Capture”拍照。

6. 根据要求选择照片注释内容,保存照片。

关机1. 将样品台高度调回80mm。

2. 按“Home”键使样品台回到初始状态。

3. “Home”指示灯停止闪烁后,撤出样品台,合上样品舱。

4. 退出程序,关闭“Display”电源。

注意1. 每天第一次加高压后,进行灯丝Flashing去除污染。

2. 冷场发射电镜一般不断电,如遇特殊情况需要大关机时,依次关闭主机正面的“Stage”电源、“Evac”电源,半小时后关闭离子泵开关和显示单元背面的三个空气开关,关闭循环水。

开机时顺序相反。

3. 每半个月旋开空压机底阀放水一次。

4. 待测样品需烘干处理,不能带有强磁性,不能采用铁磁性材料做衬底制样。

5.实验室温度限定在25±5℃,相对湿度小于70% 。

仪器维护1. 每月进行电镜离子泵及灯丝镜筒烘烤。

2. 每半年进行一次机械泵油维护或更新。

Operating Procedure for Hitachi S-4800 Scanning Electron MicroscopeCFN Laboratory1L-32C.Black/G.WrightOperation of the Hitachi S-4800 Scanning Electron Microscope (SEM) requires specific user training and authorization. This operating procedure is meant as a general overview of tool operation and is NOT A SUBSTITUTE for obtaining proper training and authorization.Users should have reserved tool access via the FOM calendar.NIRTRILE GLOVES ARE TO BE WORN AT ALL TIMES when handling sample specimens, sample stages, and any parts to be introduced into the tool vacuum chamber. Suitable gloves are located on the workbench to the left of the Hitachi SEM.Sample PreparationSuitable samples for imaging will be mounted on solid flat substrates such as silicon or glass.Sample specimens must be mounted on a sample holder for insertion into the tool. Several different sample holder sizes are available. Sample holders are located on the workbench.Mount sample on sample holder. Specimens should be mounted using either double-sided sticky tape or clips. Silver paint is to be used only if absolutely necessary.Samples may be blown free of dust and debris using the can of compressed air located onthe laboratory workbench.Clean and organize sample preparation area when finished.Microscope PreparationObserve that microscope is energized and ready for operation. If any warning lights indicate a problem then STOP and contact a staff member.Log into the FOM and activate your reserved session to turn on the Hitachi computer.Loading a sampleAfter mounting sample on a sample holder, adjust the specimen height using the specimen height gauge located on the workbench. To adjust the height, loosen the lock screw and adjust the specimen height so that the height of the highest point of the specimen is the same as the bottom of the height gauge. Then tighten the lock screw by holding the fixed upper part of the holder..Move to the SEM console. Verify that there is no sample stage already loaded in the chamber by looking at the small camera monitor showing a view inside the chamber.Click the EXC button on the control panel. The stage inside the SEM will move to the specimen exchange position. Once this occurs the indicator beside the button will turn green. (Normally the stage will be left in the exchange position.)Press the AIR button on the specimen exchange chamber. After 15 sec. a buzzer will sound indicating that the chamber has been vented.Open the exchange chamber door. Be SURE to use the handle to open the chamber door and DO NOT USE THE SAMPLE LOAD ARM. Pulling on the arm in this way can damage the sample lock vacuum. The exchange chamber door is interlocked and will not open unless all vacuum conditions are satisfied.Confirm that the specimen exchange rod is in the UNLOCKED position by turning clockwise until the UNLOCK mark faces upwardsInsert the two spring pins at the end of the rod into holes of the specimen holder.While holding the specimen holder, turn the knob of the specimen exchange rod counterclockwise until the LOCK mark comes upwards. The sample holder is now lockedonto the load arm.Pull out the sample exchange rod completely and close the exchange chamber door.Press the EVAC button on the specimen exchange chamber. This will pump out the loadlock. Press the OPEN button to open the gate valve to the chamber, which will happen when a suitable low pressure has been achieved.After the gate valve opens, slide the specimen exchange rod all the way into the chamber WHILE LOOKING INTO THE CHAMBER on the small microscope screen toensure that the specimen holder inserts into the guide rails.Turn the specimen rod knob to the UNLOCKED position.Pull out the specimen exchange rod completely while VISUALLY WATCHING that the rod disengages from the sample holder.Press the CLOSE button on the specimen exchange chamber to close the gate valve. The sample is now loaded into the chamber.Applying the SEM high voltageClick the ON button on the control panel at the left of the HV DISPLAY area. You will be asked to verify the size (diameter and height) of the sample holder you are using. If the one displayed is in fact the one you are using, click OK. If not, clickCANCEL. Set the size of the sample holder you are using in the STAGE menu. If you are using the cross- section stage then you should select a stage size of 4 inches.High voltage can be applied only if the HV DISPLAY area on the control panel is blinking in yellow and blue. If the indicator is solid blue then the SEM conditions are not appropriate for high voltage application. Once the high voltage has been applied the indicator will display (nonblinking) yellow.Use the HV CONTROL dialog window to set SEM accelerating voltage and emission current.To set the accelerating voltage, select a voltage from the Vacc list box.To set an emission current, set a current in the SET Ie to list box. Hitachi recommends 10uA emission current for normal SEM operation.Click the ON button on the control panel at the left of the HV DISPLAY area. The SEM will automatically turn on the accelerating voltage, the extracting voltage, and the emission current. These values are displayed in the HV DISPLAY area. The electron gun airlock valve will automatically open upon completion of gun turn-on.Once the high voltage is applied the ON button will change to SET, allowing the user to set the emission current during high voltage operation. The OFF button turns off the high voltage. Note that during SEM operation the current will drop gradually over time. You can reset to the specified emission current (typically 10uA) by pressing SET.After high voltage turn-on a message will appear saying: “Stage is at specimen exchange position. Move to Home position?” Selecting YES will move the stage to the Home position such that the center of the sample holder will be directly underneath the electron beam.Obtaining a sample imageThere are many possible imaging variations for using the Hitachi S-4800 tool and these depend on the type of sample being imaged. We include here a summarized list of many commonly- used possibilities but do not provide detailed descriptions or an exhaustive list. The user is directed to the tool operating manual (located on the workbench to the left of the Hitachi SEM) for a complete discussion.Imaging mode:Selecting a Magnification Mode: The SEM has two magnification modes, HIGH MAG and LOW MAG. Most common applications will utilize the HIGH MAG mode.Within HIGH MAG magnification mode, user specifies:Probe current mode: NORMAL of HIGH. Most applications will utilizeNORMALFocus mode: UHR or HR. UHR mode allows full range of working distances.Working distance (WD). Shorter WD means higher resolution. Longer WDallows greater depth of focus and more sample tilting.Focus depth: Best resolution attainable with this value set to 1.0Specimen bias voltage: Specimen can be voltage-biased during imaging tominimize sample charging effects.Magnetic sample: Use this mode for observation of ferromagnetic samplesDegauss operation:Setting ABCC link: Automatically adjusts brightness and contrast during sample imaging.Column Alignment Operation: Obtaining the highest resolution image will involve aligning the electron optical column. This operation is done entirely through an electromagnetic alignment (i.e., using the computer interface) without need for touching any knobs on the SEM column. Alignment conditions are saved for each accelerating voltage and probe current setting such that only minimal alignment adjustment should be necessary.Press TV1 to obtain an image on the screen.Typically the beam can be tuned up using only an APERTURE ALIGNMENT. The procedure is as follows:Set the magnification to about 5,000 and position a point of interest in the center of the display.Focus the image and correct astigmatism.Click APERTURE ALIGN in the ALIGNMENT dialog box and make adjustments such that the wobbling motion of the image is minimized.Turn off the APERTURE ALIGN mode by clicking the OFF button.Sample imagingDetector selection: The SEM has two secondary electron detectors, the UPPER and the LOWER detectors. User can select either detector or alternatively image using a mixture of the two signals. Select a detector on the SIGNAL SELECT block of the OPERATION panel.Image Magnification: Select image magnification by dragging the mouse in the MAGNIFICATION INDICATION area on the CONTROL PANEL. The magnification can also be set by rotating the MAGNIFICATION knob on the control box.Focus and astigmatism correction: Iteratively adjust focus and astigmatism using the knobs on the SEM control box.Brightness and Contrast: Adjust brightness and contrast either manually by using BRIGHTNESS and CONTRAST knobs on SEM control panel or by pressing ABCC button for automatic control.The recorded images are stored in a memory buffer and displayed across the screen bottom. At the end of the session you will need to save them in the appropriate folder.Unloading sampleRemember to wear gloves when unloading samples.When finished imaging, turn off the high voltage by clicking OFF on the HV DISPLAY area. Move the sample stage to the exchange position by clicking the EXC button on the control panel. Once this occurs the indicator beside the button will turn green.Press the OPEN button on the specimen exchange chamber to open the gate valveTurn the knob on the specimen exchange rod clockwise so that the UNLOCK mark is facing upwards.Insert the specimen exchange rod straight into the chamber and fit the two spring pins into the holes at the end of the specimen holderTurn the knob counterclockwise so the LOCK mark comes upwards to hook on the sample holder.VISUALLY INSPECT that the sample holder comes out with the rod as you pull the rod all the way out of the chamber.Press the CLOSE button on the specimen exchange chamber to close the gate valve. Press AIR to vent the loadlock.Open the exchange door (by its handle) and turn knob clockwise to UNLOCK position. The sample holder can now be disengaged from the sample rod.Close specimen exchange chamber door and press EVAC to pump the loadlock back down.CleanupLog into the FOM computer and end your session. This will turn off the Hitachi computer.Unmount your samples from the sample holder.Return sample stage to appropriate stage storage box located near the workbench at the rear of the laboratory.Clean workbench area and properly dispose of any materials used during sample preparation.TURN OFF laboratory lights when leaving the room。

扫描电镜S-4800操作规程

一、日常开机

打开Display开关,电脑自动开机进入s-4800用户界面,PC_SEM程序自

运行,点击确认进入软件界面。

二、装样品

1.将样品台装在样品座上,根据标尺调整高度及确认样品位置后旋紧。

使图像达到最佳状态,若图像有拉长现象,则需进行消像散。

调节STIGMATOR/ALIGNMENT X使图像在水平方向的拉长消失,再调节STIGMATOR/ALIGNMENT Y使图像在垂直方向的拉长消失。

4.图像采集及保存

用键或BRIGHTNISS/CONTRAST旋钮自动或手动调节图像的对比度和亮度,扫描速度变为慢扫,点击抓拍按钮进行采集。

采集后暂时存放在窗口下侧,

选中要保存的图像,点击Save,弹出Image Save对话框,输入文件名,选好存储位置保存即可。

5.对中调整

改变加速电压和电流时,或图像在高倍聚焦发生漂移时,需要进行对中调整,方法如下:

(1)选取样品上一个具有明显特征的位置放在视场中心。

可下载。

六、日常关机

依次关闭PC_SEM软件、电脑、Display开关。