SC威索燃烧器说明书

- 格式:pdf

- 大小:5.53 MB

- 文档页数:28

7451燃烧控制器LFL1...燃烧控制器•用于燃油, 燃气或双燃料强制通风式的中等和大容量燃烧器•用于多段或连续比例的间歇运行燃烧器•带有风门检测•火焰监控– UV 火焰探测器 QRA...– 离子探针LFL1... 系列控制器特别适合于将燃烧控制集成到其产品的OEM厂家.用途-监控具有膨胀式火焰或引导火(点火)可遮断结构的强制通风式燃烧器-中到大容量-间歇运行 (至少每24小时有一次受控停机)-多段或连续比例式燃烧器-双燃料燃烧器-固定式空气预热器01和02系列的不同,对于装有引导火燃气阀的引导火(点火)燃烧器来说,主要在于安全时间的长短。

LFL1.638适合用于大容量的大气式燃烧器。

如果需要控制连续运行的燃烧器,请参阅 (LGK16...).的资料Siemens Building Technologies CC1N7451en为避免人员伤害,财产损失和破坏环境,必须遵守以下警告注意事项!不要随意打开、干预或是改动控制器单元!•所有行为(装配、安装和服务工作等)必须由专业人员来完成。

•在LFL1…的连接区域改变任何接线之前,要使控制器单元完全与主要电源隔离(两级断开)。

•要给燃烧控制器的接线柱提供充足的保护,确保控制器不会受到电击危险。

•检查并确保线路连接正确。

•锁定复位按钮仅限手动(所需压力不超过10N),不要使用其他任何工具或是尖状物体。

•按动控制器单元上的锁定复位按钮或是远程锁定复位按钮不要超过10秒,否则会损坏控制器单元内的锁定继电器。

•坠落或撞击会影响到安全功能。

这样的控制器单元不能正常运作,即使外观看起来一点损害也没有。

•在使用UV探测器QRA..进行火焰监测时,必须注意那些发光源,例如卤素灯、焊接设备、特殊灯具、点火火花,还有X射线和伽马射线,会产生错误的火焰信号。

安装指南•确保遵守相关的国家安全规则•使用2个UV探测器QRA..时,要确保探测器彼此不能探测到。

安装注意事项•控制器单元和其他电缆必须与高压点火电缆分开安装排列•不要混淆相线和中线火焰探测器的电气安装排除干扰,在信号传输中避免干扰是很重要的。

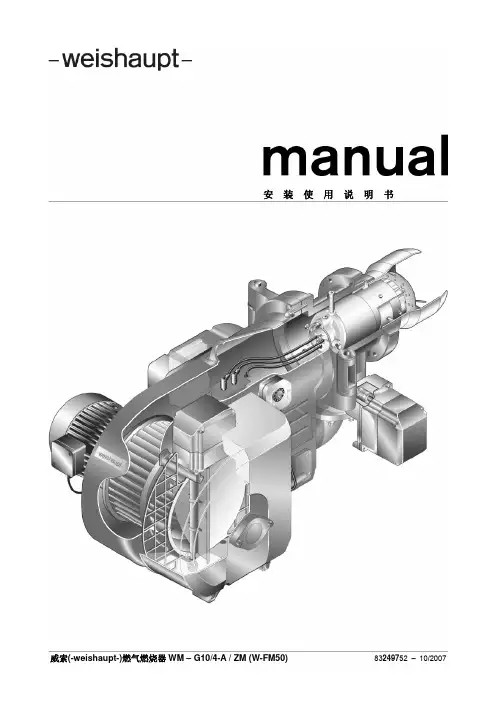

productInformation on compact burnersDigital combustion technology Weishaupt gas burners, WG10 to WG40 (12.5–550 kW)Hot for quality2Our motivation is technologicalp rogress, which has been driving us formore than 50 years to set news tandards for the combustion industry.Weishaupt’s own Research andD evelopment Centre is constantlyw orking on both new developments andthe optimisation of exisitng products.It is our goal and our responsibility to goabove and beyond current legislativer equirements in developing combustionsystems which produce fewer andf ewer emissions, save more and moreenergy, and in so doing combinee cology and economy in a practicalmanner.Therefore, not only do we invest inr esearch and technology but we alsoonly ever work on the best materialswith modern tools and we carry outm eticulous quality control checks.It has been proven over a million times in the field that heating specialists and customers hold Weishaupt burners to be reliable, long lasting, environmentally friendly and technoloically advanced. A fact also documented by numerous d esign and innovation prizes.Over 600 burners are manufactured daily at our ultra-modern production f acilities in Schwendi. Every single b urner is subjected to a mechanical and electrical function test. The combination of technology with an effective quality control system safeguards Weishaupt’s reknowned reputation for quality.A new burner is always an investment in the future. Cost needs to be well b alanced against use, but the final d eciding factors for long term sucess are quality, technology and safety. D eciding for Weishaupt burners is t herefore a safe investment in the f uture.Ultra-modern research and production methods and rigourous quality control ensures the quality forwhich Weishaupt is reknowned3A hallmark of practical combustion technology 5A safe investment in the futureReliable and economical: The millionfoldsucess of the Weishaupt compactb urners is the result of orienting withoutcompromise towards quality and thec ustomer. The technology has beenc onstantly developed and improved overdecades.The latest production methods ands tringent quality checks of all productsensure Weishaupt’s reputation forq uality. You are making a safeinvestment in the future.Large capacity rangeThe large capacity range of 12.5 to 550kW makes the burners suitable for thewidest range of heat exchangers.Electronic ignitionThe W-ZG 01 ignition unit used on allWeishaupt W burners is particularlyenergy efficient and extremely reliable.Digital combustion management for safety and ease of use Weishaupt is a pioneer in this field. D igital combustion management offers greater ease of use and simple s ervicing, even greater relaibility in o peration, and, last but not least, an e xtremely attractive price/capacity r elationship. Furthermore, this i ntelligent technology enables the b urner to be i ntegrated with complex automation systems.Valve proving as standard with W-FM10 and W-FM20 combustion managers The low gas pressure switch is used to check the tightness of the gas valves,thus providing valve proving without the need for any additional components or costs.Gas multifunction assembly The newly concieved gas multifunction assembly incorporates the following components/functions:• Servo-controlled gas pressure governor for continual gas pressure • 2 solenoid valves (Class A)• Filter • Gas pressure switch If the gas pressure falls too low, a low gas pressure program is started. The gas pressure switch also provides for automatic valve proving.Outstanding service Weishaupt has an extensive sales and sevice network worldwide. Customer service is available around the clock.Optimal in-house training at Weishaupt ensures our service engineers are of the highest calibre.Proven quality All burners are tested by an i ndependent body and conform to the following standards and EU directives:• EN 676• Gas Appliance Directive 90/396/EEC • Machinery Directive 98/37/EC • Electromagnetic Compatability Directive 89/336/EEC • Low Voltage Directive 73/23/EEC • Boiler Efficiency Directive 92/42/EEC WG30 and WG40 also comform to:• Pressure Equipment Directive97/23/ECCoded plugs for safe electrical connectionAll components are easily accessible Simple commissioning and diagnosis The right size Weishaupt burner for everysituationDigital combustion management:safe and easy to use6All Weishaupt W series burners aref itted with digital combustion managers as standard, whose microprocessorscontrol and monitor all burner functions.The result: Weishaupt burners are easyto use, precise and safe.The digital combustion managers alsooffer the possibility of communicatingwith other systems via an integratedeBUS port. This enables the heatingengineer to monitor the opration of theburner and remotely diagnose anye rrors.The key points:• The utilisation of identical units forgas and oil burners simplifiesc ommissioning and reduces then umber of spares required • Non-interchangeable plugc onnections ensure the correcte lectrical connection of allc omponents • Electrical remote reset is possible • Safety ensured with the use of two microprocessors (reciprocal m onitoring)• Vari-coloured LED lamp to indicate burner operational stage and fault conditions (WG10, WG20 versions LN and Z-LN)• LCD display with interrogation,s ervicing and parameter functions.the burner can be set directly via theoperating keys (WG10 – WG40v ersion ZM-LN)• Suitable for continuous operation of hot water plant (controlled shutdown and restart every 24 hours)• Suitable for air heaters and Group II III, and IV steam boilers (W-FM 21 o ptional)• The integrated eBUS interface offers the following functions: – Connection to a PC for display of the operational sequence and the setting of function parameters – Remote monitoring and diagnosis via a self dialling modem – Connection to modern building m anagement systems – Prepurge time can be set from a PC via the eBUS interface7The right mode of operation for every heating needTrustworthy technology8Even the visual impression afterr emoving the burner cover is convincing.All components are clearly arranged, theelectrical connections are obvious andnon-interchangeable. The technologymakes a good impression because it istypical Weishaupt.Compact constructionThe WG burners’ compact constructionmeans they can be easily installed byone person. Commissioning costs havebeen reduced to a minimum.Low NO x executionAll WG burners are Low NO x executionas standard. A specially designedm ixing head produces an intensivei nternal flue gas recirculation, resultingin exemplary emission levels.Sound attenuated air inletThe transverse fan is sound attenuatedon the suction side. These burnerst herefore operate particularly quietly.Electronically controlled air damper The electronically controlled air damper closes at burner shutdown to hinder the cooling-down of the combustion c hamber.Sevicing position A special bracket enables the burner to be put into a servicing position, which enabling easy access to the burner and mixing mon platform The common platform principle used with W burners simplifies the provision and storage of spare parts.Diagnosis via laptop A special software package and connection cables are available for i nterrogating the combustion bustion optimisation and fault a nalysis can thus be carried out easily via a laptop computer.Speed control (WG 30 and WG 40)Whereas normally a burner motor is operated at a constant speed, speed controlled burners vary the speed of the burner motor dependent on the burner load. The process is controlled by the d igital combustion manager. The e quipment assures the gas/air c ompound such that no additional speed monitoring is required.Speed controls offers the advantages of reduced electrical consumption and a considerable reduction in noise levels at partial load.The reduced noise levels can be of p articular benefit in the field. A 10 dB reduction in the sound level can be achieved at 50% burner load, which equates to a halving of noise emissions.9Model overview1011Burner capacities in relation to combustion chamber resistanceValve train selection1213Technical data1415We’re right where you need usMax Weis h aupt GmbH 88475 Schwen d i Te l (0 73 53) 8 30, Fax (0 73 53) 8 33 58www.weis h aupt.de Print No. 83205502, January 2011Printed in Germany. All rights reserved.A strong service network gives peace of mindWeishaupt equipment is available from good heating companies, with whom Weishaupt works in partnership. To support the specialists, Weishaupt maintains a large sales and service network. Delivery, spares and service are thus contiually ensured.Even in an emergency, Weishaupt is on call. The service department is available to Weishaupt customers around the clock, 365 days a year. A Weishaupt branch office or agency near you can answer all your questions on heating and Weishaupt burners.。

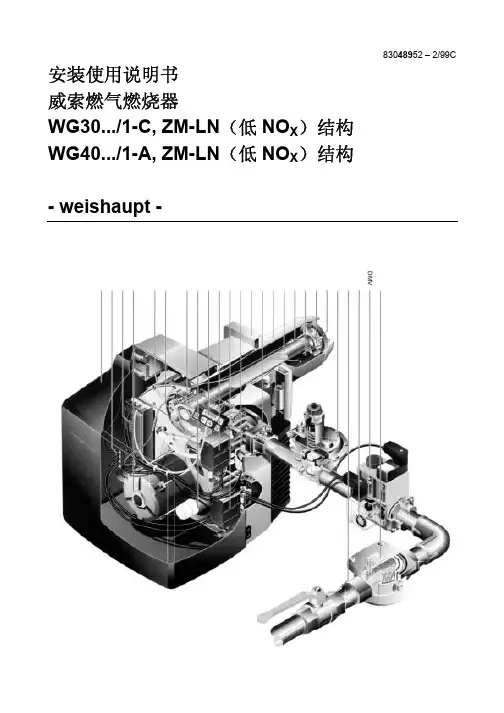

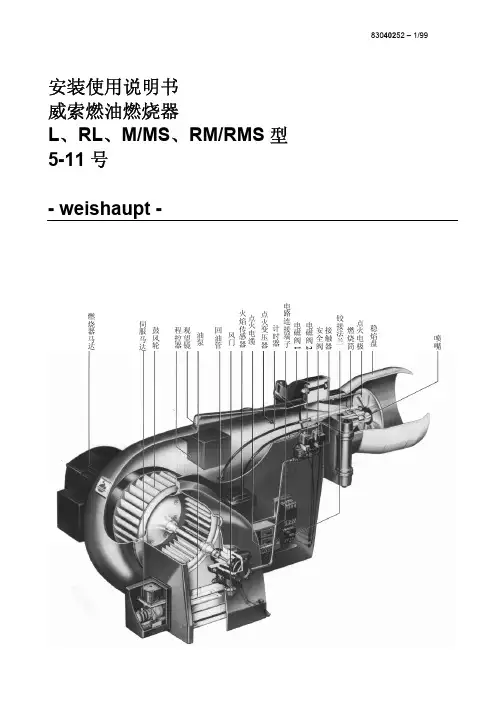

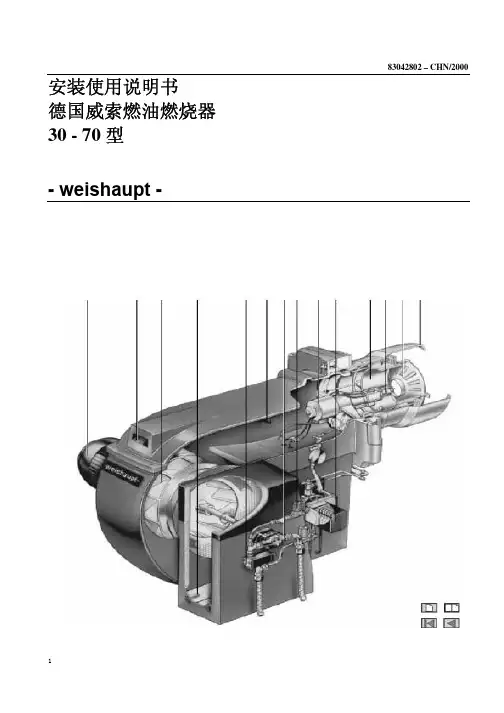

83048952 – 2/99C安装使用说明书 威索燃气燃烧器WG30.../1-C, ZM-LN (低NO X )结构 WG40.../1-A, ZM-LN (低NO X )结构- weishaupt -外壳接线插头燃烧器管理器燃烧器马达点火装置风门调节螺钉混合室外壳燃气蝶阀伺服马达马达电容器风压开关连接法兰燃烧头混合室离子电极分配星稳焰盘稳压阀球阀气压开关双重电磁阀DMV燃气过滤器液晶显示屏燃烧器法兰风门伺服马达点火电极2目录1 一般说明 32 安全说明 43 技术说明 6 3.1 使用注意事项 6 3.2 功能 6 3.3 操作面板 74 安装 8 4.1 安装安全注意事项 8 4.2 供货、运输、仓储 8 4.3 安装前的准备 8 4.4 燃烧器的安装 9 4.5 燃气阀组的安装 10 4.6 燃气阀组的气密性检验 12 4.7 电气连接 135 调试与操作 14 5.1 首次调试时的安全指示 14 5.2 在首次调试前的措施 14 5.3 首次调试 15 5.4 功能流程接线图 25 5.5 显示及操作面板 27 5.6 停机 286 故障原因及排除 297 保养 32 7.1 保养工作的安全说明 32 7.2 保养计划 32 7.3 混合室的拆卸与安装 33 7.4 混合室的调节 33 7.5 点火电极的设定 34 7.6 罩盖的保养位置 34 7.7 叶轮及燃烧器马达的拆卸与安装 35 7.8 风门伺服马达的拆卸与安装 35 7.9 风门传动机构的拆卸与安装 36 7.10 燃气蝶阀伺服马达的拆卸与安装 36 7.11 DMV 上电磁体的拆卸与安装 37 7.12 稳压阀内弹簧的拆卸与安装 37 7.13 燃气过滤器内部滤芯的拆卸与安装 38 7.14 燃烧管理器的拆卸与安装 388 技术数据 39 8.1 燃烧器配置 39 8.2 工作范围表 39 8.3 允许使用燃料 40 8.4 电气数据 40 8.5 允许的环境条件 40 8.6 尺寸 40 8.7 重量 41附录燃气流量的计算 42 燃烧值的检验43本安装使用说明书¾是燃烧器供货时同时提供的,在使用地点应能随时找到¾应由专业人员进行解释¾包含了燃烧器安装、调试及保养安全性方面的重要说明¾所有与燃烧器操作有关的人员都应加以注意移交及操作说明热能装置的供应方应最迟于移交设备时向接收方提供操作指导,并澄清该操作指导应保留在设备使用地点。

SIEMENS燃烧控制器燃烧控制器• 用于燃油,燃气或双燃料强制通风式的中等和大容量燃烧器•用于多段或连续比例的间歇运行燃烧器 • 带有风门检测 •火焰监控-UV 火焰探测器QRA...-离子探针LFL1...系列控制器特别适合于将燃烧控制集成到其产品的OEM 厂家.用途・ 曲控JI 仃膨胀式火焰或引F 火(点火)可遮断结构的强制通风式燃烧器 ・中到大容量・ 间歇运行(至少每24小时冇一次受控停机) ・多段或连续比例式燃烧器 ・双燃料燃烧器 ・固定式空气预热器01和02系列的不同,对十装仃引导火燃气阀的引亍火(点火)燃烧器來说,主要在于安全 时间的K短。

LFL1.638适合用于人容嚴的人气式燃烧器.如果需耍控制连续运行的燃烧器M 参阅(LGK16…)•的资料Siemens Building Technologies HVAC ProductsLFL1 …CC1N7451en 29.06.2004警吿注意事项A为避免人员伤害,财产损失和破坏环境,必须遵守以下警告注意事项!不要随意打开、干预或是改动控制器单元!••••••••所仃行为(装配、安装和服务工作等)必须山&业人员来完成。

在LFL1...的连接区域改变任何接线Z前.要便控制器单尤完全与主要电源隔离(两级断开). 耍给燃烧控制器的接线柱提供允足的保护.确保控制益不会受到电击危险。

检査并确保线路连接正确。

锁定奴位按钮仅限于•动(所需压力不超过10N)•不要使川其他任何丁具或足尖状物体. 按动控制器单元上的锁定复位按钮或是远程锁定复位按钮不要超过10秒.否则会损坏控制器单元内的锁定继电器。

坠落或撞击会影响到安全功能。

这样的控制益单元不能止常运作.即使外观看起来一点损害也没冇。

在使用uv探测Bqra..进行火焰监测时.必须注意那些发光源,例如卤素灯.焊接设爸、特殊灯具、点火火花.还冇X射线和伽®射线,会产牛错误的火焰信号。

安装指南•确保遵守相关的国家安全规则•使用2个UV探测器QRA.•时,耍确保探测器彼此不能探测到。

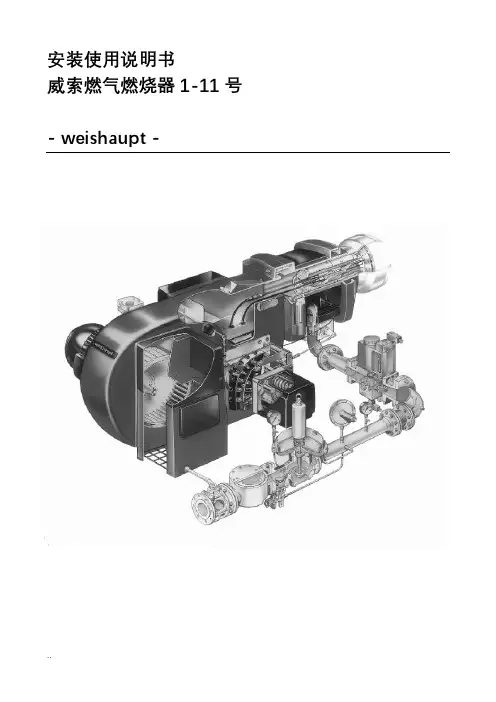

威索燃烧器中文说明书(总43页)-CAL-FENGHAI.-(YICAI)-Company One1-CAL-本页仅作为文档封面,使用请直接删除安装使用说明书威索燃气燃烧器1-11号- weishaupt -证明在此我们说明,威索(-weishaupt-)燃气燃烧器符合下列EC标准的基本要求:90/396/EEC Gas Equipment Guideline89/336/EWG Electromagnetic Compatibility73/23/EEC Low Voltage Guideline因此燃烧器上带有CE/0085标记。

其它质量保证体系由DIN EN ISO 9001认可。

德国麦克斯·威索有限公司目录1. 一般说明.................................................................. 错误!未指定书签。

2. 燃烧器的安装.............................................................. 错误!未指定书签。

3. 气路示意图................................................................ 错误!未指定书签。

4. 阀门组件说明.............................................................. 错误!未指定书签。

5. 阀门组件的安装............................................................ 错误!未指定书签。

6. 阀门组件的气密性检验...................................................... 错误!未定义书签。

7. 功能流程检验.............................................................. 错误!未指定书签。

安装使用说明书威索燃气燃烧器1-11号- weishaupt -证明在此我们说明,威索(-weishaupt-)燃气燃烧器符合下列EC标准的基本要求:90/396/EEC Gas Equipment Guideline89/336/EWG Electromagnetic Compatibility73/23/EEC Low Voltage Guideline因此燃烧器上带有CE/0085标记。

其它质量保证体系由DIN EN ISO 9001认可。

德国麦克斯·威索有限公司目录1. 一般说明 (2)2. 燃烧器的安装 (5)3. 气路示意图 (7)4. 阀门组件说明 (8)5. 阀门组件的安装 (16)6. 阀门组件的气密性检验 (19)7. 功能流程检验 (19)8. 准备第一次调试 (20)9.调试 (20)10.燃烧筒及稳焰盘的调整 (32)11. 工作范围表 (33)12. 设置点火电极 (36)13. 鼓风轮的固定 (36)14.工作流程 (37)15. 限制及辅助开关的凸轮位置设置 (44)16. 燃气流量的计算,从标准状态到实际状态的换算 (46)17. 常见故障及排除方法 (48)1. 一般说明简介下表为安装及调试中各个步骤的基本概括为了达到正确安装及调试的目的,请对此说明书中的所有说明加以注意。

步骤工作章节1 燃烧器的安装 22 安装燃气阀门组 53 燃气阀门组的气密性检验 64 检查燃气供气压力8.15 排去燃气阀门组中的空气8.26 功能流程检验77 检查燃烧头108 检查设备9.19 调试9.3 安全性要确保燃烧器的安全运行,必须由合格的专业人员按此说明书进行正确的安装及调试。

要特别注意相关的安全规定(如DIN-VDE,DIN-DVGW)。

火焰监测装置、限制装置,调节机构以及其它安全装置只能由制造厂或其委托单位进行安装。

不遵守规定可能导致人员伤亡及重大物质损失等严重后果。

威索燃烧器中文说明书 Hessen was revised in January 2021安装使用说明书威索燃气燃烧器1-11号- weishaupt -证明在此我们说明,威索(-weishaupt-)燃气燃烧器符合下列EC标准的基本要求:90/396/EEC Gas Equipment Guideline89/336/EWG Electromagnetic Compatibility73/23/EEC Low Voltage Guideline因此燃烧器上带有CE/0085标记。

其它质量保证体系由DIN EN ISO 9001认可。

德国麦克斯·威索有限公司目录1. 一般说明.................................................................. 错误!未定义书签。

2. 燃烧器的安装.............................................................. 错误!未定义书签。

3. 气路示意图................................................................ 错误!未定义书签。

4. 阀门组件说明.............................................................. 错误!未定义书签。

5. 阀门组件的安装............................................................ 错误!未定义书签。

6. 阀门组件的气密性检验...................................................... 错误!未定义书签。

7. 功能流程检验.............................................................. 错误!未定义书签。

创作编号:GB8878185555334563BT9125XW创作者:凤呜大王*安装使用说明书威索燃气燃烧器1-11号- weishaupt -1证明在此我们说明,威索(-weishaupt-)燃气燃烧器符合下列EC标准的基本要求:90/396/EEC Gas Equipment Guideline89/336/EWG Electromagnetic Compatibility73/23/EEC Low Voltage Guideline因此燃烧器上带有CE/0085标记。

其它质量保证体系由DIN EN ISO 9001认可。

德国麦克斯·威索有限公司目录1.一般说明 (3)2. 燃烧器的安装 (6)3. 气路示意图 (8)4.阀门组件说明 (9)5. 阀门组件的安装 (18)6.阀门组件的气密性检验 (21)7.功能流程检验 (21)8. 准备第一次调试 (23)9.调试 (23)10.燃烧筒及稳焰盘的调整 (36)11.工作范围表 (37)12. 设置点火电极 (41)13. 鼓风轮的固定 (41)14.工作流程 (42)15.限制及辅助开关的凸轮位置设置 (50)16. 燃气流量的计算,从标准状态到实际状态的换算 (52)17.常见故障及排除方法 (54)21.一般说明简介下表为安装及调试中各个步骤的基本概括为了达到正确安装及调试的目的,请对此说明书中的所有说明加以注意。

步骤工作章节1 燃烧器的安装 22 安装燃气阀门组 53 燃气阀门组的气密性检验 64 检查燃气供气压力8.15 排去燃气阀门组中的空气8.26 功能流程检验77 检查燃烧头108 检查设备9.19 调试9.3 安全性要确保燃烧器的安全运行,必须由合格的专业人员按此说明书进行正确的安装及调试。

要特别注意相关的安全规定(如DIN-VDE,DIN-DVGW)。

火焰监测装置、限制装置,调节机构以及其它安全装置只能由制造厂或其委托单位进行安装。

威索燃烧器中文说明书 LG GROUP system office room 【LGA16H-LGYY-LGUA8Q8-LGA162】安装使用说明书威索燃气燃烧器1-11号- weishaupt -证明在此我们说明,威索(-weishaupt-)燃气燃烧器符合下列EC标准的基本要求:90/396/EEC Gas Equipment Guideline89/336/EWG Electromagnetic Compatibility73/23/EEC Low Voltage Guideline因此燃烧器上带有CE/0085标记。

其它质量保证体系由DIN EN ISO 9001认可。

德国麦克斯·威索有限公司目录1. 一般说明..................................................................................2. 燃烧器的安装..............................................................................3. 气路示意图................................................................................4. 阀门组件说明..............................................................................5. 阀门组件的安装............................................................................6. 阀门组件的气密性检验..................................................... 错误!未定义书签。

83048952 – 2/99C安装使用说明书 威索燃气燃烧器WG30.../1-C, ZM-LN (低NO X )结构 WG40.../1-A, ZM-LN (低NO X )结构- weishaupt -外壳接线插头燃烧器管理器燃烧器马达点火装置风门调节螺钉混合室外壳燃气蝶阀伺服马达马达电容器风压开关连接法兰燃烧头混合室离子电极分配星稳焰盘稳压阀球阀气压开关双重电磁阀DMV燃气过滤器液晶显示屏燃烧器法兰风门伺服马达点火电极2目录1 一般说明 32 安全说明 43 技术说明 6 3.1 使用注意事项 6 3.2 功能 6 3.3 操作面板 74 安装 8 4.1 安装安全注意事项 8 4.2 供货、运输、仓储 8 4.3 安装前的准备 8 4.4 燃烧器的安装 9 4.5 燃气阀组的安装 10 4.6 燃气阀组的气密性检验 12 4.7 电气连接 135 调试与操作 14 5.1 首次调试时的安全指示 14 5.2 在首次调试前的措施 14 5.3 首次调试 15 5.4 功能流程接线图 25 5.5 显示及操作面板 27 5.6 停机 286 故障原因及排除 297 保养 32 7.1 保养工作的安全说明 32 7.2 保养计划 32 7.3 混合室的拆卸与安装 33 7.4 混合室的调节 33 7.5 点火电极的设定 34 7.6 罩盖的保养位置 34 7.7 叶轮及燃烧器马达的拆卸与安装 35 7.8 风门伺服马达的拆卸与安装 35 7.9 风门传动机构的拆卸与安装 36 7.10 燃气蝶阀伺服马达的拆卸与安装 36 7.11 DMV 上电磁体的拆卸与安装 37 7.12 稳压阀内弹簧的拆卸与安装 37 7.13 燃气过滤器内部滤芯的拆卸与安装 38 7.14 燃烧管理器的拆卸与安装 388 技术数据 39 8.1 燃烧器配置 39 8.2 工作范围表 39 8.3 允许使用燃料 40 8.4 电气数据 40 8.5 允许的环境条件 40 8.6 尺寸 40 8.7 重量 41附录燃气流量的计算 42 燃烧值的检验43本安装使用说明书¾是燃烧器供货时同时提供的,在使用地点应能随时找到¾应由专业人员进行解释¾包含了燃烧器安装、调试及保养安全性方面的重要说明¾所有与燃烧器操作有关的人员都应加以注意移交及操作说明热能装置的供应方应最迟于移交设备时向接收方提供操作指导,并澄清该操作指导应保留在设备使用地点。

KS40操作指南一、参数初始化(恢复出厂设置)同时按住▼键和▲键,给KS40上电,KS40就恢复到出厂设置。

这时可以依次按参数表重新设置参数。

二、KS40功能配置1.模式完成参数初始化后(重新上电时在模式)。

按住3秒后,显示;用▼键下翻至显示;按,显示;按,显示;这时按▼键和▲键调整值(功能代码,设置值为30);按,返回到起始画面。

操作顺序如下图:2.非模式设置完值后,按住,给KS40上电,进入模式。

按住3秒,显示;用▼键下翻至显示;按,进入菜单。

这时使用▼键和▲键改变参数名和参数值,使用确认参数值。

参数见表一。

操作结构图如下图:三、KS40参数设置配置完所有功能菜单后,进入原始画面,按住3秒,显示;按,进入菜单。

这时使用▼键和▲键改变参数名和参数值,使用确认参数值。

参数见表二。

操作结构图如上图:表一:功能配置类型 名称 设置值 类型 名称 设置值类型 名称 设置值0 019 11 00 01 010 01000 050 00 013 02 0630 13 01 00 040 510 010 1 00 0 0表二:参数配置类型 名称 设置值 类型 名称 设置值类型 名称 设置值10 0 010 0 040 5 10010 8 135OFF 0 0.510 135 410 20 4010 OFF 204 100 1200.1 10 OFF0.1 100 0.20 10 0.1OFF 200 OFF60 10 OFF0 200 0.1100 10Weishaupt燃烧机比例控制一、系统控制流程图二、风门比例调节器示意图三、KS40输入信号线形转换参数设置示意图(根据实际情况调整参数)。