PVCAD用户手册说明书

- 格式:doc

- 大小:95.00 KB

- 文档页数:10

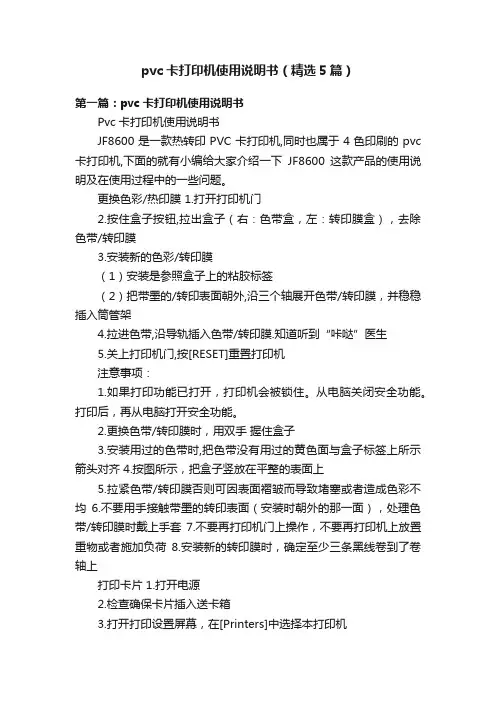

pvc卡打印机使用说明书(精选5篇)第一篇:pvc卡打印机使用说明书Pvc卡打印机使用说明书JF8600是一款热转印PVC卡打印机,同时也属于4色印刷的pvc 卡打印机,下面的就有小编给大家介绍一下JF8600这款产品的使用说明及在使用过程中的一些问题。

更换色彩/热印膜 1.打开打印机门2.按住盒子按钮,拉出盒子(右:色带盒,左:转印膜盒),去除色带/转印膜3.安装新的色彩/转印膜(1)安装是参照盒子上的粘胶标签(2)把带墨的/转印表面朝外,沿三个轴展开色带/转印膜,并稳稳插入筒管架4.拉进色带,沿导轨插入色带/转印膜.知道听到“咔哒”医生5.关上打印机门,按[RESET]重置打印机注意事项:1.如果打印功能已打开,打印机会被锁住。

从电脑关闭安全功能。

打印后,再从电脑打开安全功能。

2.更换色带/转印膜时,用双手握住盒子3.安装用过的色带时,把色带没有用过的黄色面与盒子标签上所示箭头对齐4.按图所示,把盒子竖放在平整的表面上5.拉紧色带/转印膜否则可因表面褶皱而导致堵塞或者造成色彩不均6.不要用手接触带墨的转印表面(安装时朝外的那一面),处理色带/转印膜时戴上手套7.不要再打印机门上操作,不要再打印机上放置重物或者施加负荷8.安装新的转印膜时,确定至少三条黑线卷到了卷轴上打印卡片 1.打开电源2.检查确保卡片插入送卡箱3.打开打印设置屏幕,在[Printers]中选择本打印机4.确保打印机的液晶控制面板上出现[Ready]字样后,开始打印注意事项1.如果您在打印的液晶控制面板上看到[Initializing...]或者[Preheating...]字样,这表示打印机尚未做好准备。

在打印机做好准备前,无法进行打印。

2.在卡片带磁条的一面上打印,可能会造成打印错误,或损坏卡片功能。

如果您要这么做,请事先跟商家进行沟通补充卡片 1.把送卡箱的旋钮设置在open上2.上提,取下送卡箱外盖3.对齐卡片方向,把卡片放进打印机4.装上送卡箱外盖注意事项1.如果安全功能已打开,送卡箱会被锁住,从电脑关闭安全功能。

Don’t s____________________________♦Do not use edible oils such as Crisco as a gasket lubricant.♦Do not use petroleum or solvent-based sealants, lubricants, or fi re stop materials.♦Do not install tape, insulated wire or cable in direct contact with CPVC.♦Do not use any glycol-based solutions as an anti-freeze.♦Do not mix glycerin and water solutions in contaminated containers.♦Do not use solvent cement that exceeds its shelf life or has become discolored or jellied.♦Do not allow solvent cement to plug the sprinkler head orifi ce.♦Do not connect rigid metal couplers to CPVC grooved adapters.♦Do not thread, groove, or drill CPVC pipe.♦Do not use solvent cement near sources of heat, open fl ame, or when smoking.♦Do not pressure test with air.♦Do not pressure test until recommended cure times are met.♦Do not use ratchet cutters below 50°F.♦Do not use CPVC pipe that has been stored outdoors, unprotected and is faded in color.♦Do not allow threaded rod to come in contact with the pipe.♦Do not install Spears® FlameGuard® CPVC Fire Sprinkler Products in cold weather without allowing for expansion.♦Do not install Spears® FlameGuard® CPVC Fire Sprinkler Products in dry systems.Note: This list does not constitute a complete installation guide.Do s______________________________♦Read the manufacturer’s installation instructions.♦Follow recommended safe work practices.♦Make certain that thread sealants, gasket lubricants, or fi restop materials are compatible with CPVC.♦Keep pipe and fi ttings in original packaging until needed.♦Cover pipe and fi ttings with an opaque tarp if storedoutdoors.♦Follow proper handling procedures.♦Use tools specifi cally designed for use with plastic pipe andfi ttings.♦Use the proper solvent cement and follow applicationinstructions.♦Use a drop cloth to protect interior fi nishes.♦Cut the pipe ends square.♦Deburr and bevel the pipe end with a chamfering tool.♦Rotate the pipe ¼ turn when bottoming pipe in fi tting socket.♦Avoid puddling of cement in fi ttings and pipe.♦Make certain no solvent cement is on sprinkler head andadapter threads.♦Make certain that solvent cement does not run and plug thesprinkler head orifi ce.♦Follow the manufacturer’s recommended cure times prior topressure testing.♦Flush the entire system including drops to remove pipeshavings, dirt and debris left from installation.♦Fill lines slowly and bleed the air from the system prior topressure testing.♦Support sprinkler head properly to prevent lift up of the headthrough the ceiling when activated.♦Keep threaded rod within 1/16" of the pipe or use a surgearrestor.♦ Install Spears® FlameGuard® CPVC Fire Sprinkler Productsin wet systems only.♦Use only glycerin and water solutions for freeze protection.♦Allow for movement due to expansion and contraction.♦Renew your Spears® FlameGuard® CPVC Fire SprinklerProducts installation training every two years.Recommended Practicesand PrecautionsDo s and Don’t sPACIFIC SOUTHWEST15860 Olden St.Sylmar (Los Angeles), CA 91342(818) 364-1611 • (800) 862-1499Fax (818) 367-3014ROCKY MOUNTAIN4880 Florence St.Denver, CO 80238(303) 371-9430 • (800) 777-4154Fax (303) 375-9546NORTHEAST590 Industrial Dr., Suite 100Lewisberry (Harrisburg), PA 17339-9532(717) 938-8844 • (800) 233-0275Fax (717) 938-6547MIDWEST1 Gateway Ct., Suite ABolingbrook (Chicago), IL 60440(630) 759-7529 • (800) 662-6330Fax (630) 759-7515NORTHWEST4103 C St., NE Suite 200Auburn (Seattle), WA 98002(253) 939-4433 • (800) 347-7327Fax (253) 939-7557UTAH5395 West 1520 SouthSalt Lake City, UT 84104(303) 371-9430 • (800) 777-4154Fax (303) 375-9546SOUTH CENTRAL1000 Lakeside ParkwayFlower Mound, TX 75028(469) 528-3000 • (800) 441-1437Fax (469) 528-3001FLORIDA9563 Parksouth CourtOrlando, FL 32837(407) 843-1960 • (800) 327-6390Fax (407) 425-3563SOUTHEAST4205 Newpoint Pl., Suite 100Lawrenceville (Atlanta), GA 30043(678) 985-1263 • (800) 662-6326Fax (678) 985-5642INTERNATIONAL SALES15853 Olden St.Sylmar (Los Angeles), CA 91342(818) 364-1611 • Fax (818) 898-3774SPEARS® MANUFACTURING COMPANYCORPORATE OFFICE15853 Olden St., Sylmar, CA 91342PO Box 9203, Sylmar, CA 91392(818) 364-1611 • © Copyright 2007 Spears® Manufacturing Company. All Rights Reserved.Printed in the United States of America 06/07. FG-3A-0607Certifi cation BoardInternational LaboratoriesAmerican Society forTesting and MaterialsResearch CorporationRecommended Cut-in Procedures for SystemModifi cation or RepairExisting system modifications or repairs can be made using Spears® FlameGuard® CPVC Fire Sprinkler Products. In order to maintain full system integrity, the following procedure must be followed when making a system tie-in or repair by cutting into an existing system line. A careful review of all Joining Procedures must be made prior to making a cut-in on an existing system and the Minimum Cut-in Cure Times listed below must be followed. A variety of fi tting combinations can be used to tie into an existing system or replace a section between fixed cut-in points. These include using a socket Tee for add-ons or a socket Coupling for repairs in combination with a mechanical joint such as a union grooved coupling adapter, or flange. Regardless of the components selected, the following must be adhered to:1 System modification cut-ins should be made on the smallest diameter pipe section, in close proximity to the area of modifi cation, capable of properly supplying the system change.2 Carefully plan and measure prior to cutting into existing system. Be sure to provide adequate space and insure that full insertion into fi tting sockets can be made during assembly. Note: Allowance must be made for making a 1/4-turn twist when inserting the pipe into the fitting during assembly of the tee (or other component), especially on 1-1/2" and larger pipe sizes. This may require assembly of components in combination with the cut-in tee to create a short spool piece for fi nal connection using socket unions, fl anges, or grooved coupling adapters.3 Review all Installation & Joining procedures prior to commencing cut-in (including square cutting, deburring & beveling, cleaning, dry fi t checks).4 Depressurize and drain existing line prior to making the cut-in.5 Connect to the existing system prior to proceeding with the modifi cation or repair.6 All pipe shavings, dirt, debris must be removed fromthe cut-in system and, water and residual moisture must beremoved from all solvent cement areas. Vacuum lines and wipedry with a clean dry rag. Moisture and dirt will slow the curing andcan affect joint strength.7 Use only a new can of approved solvent cementwhen making cut-in connections. Verify cement expiration dateon can prior to use.8 The cut-in joint must be allowed to cure prior topressure testing as shown in the table at the right.9 Following completion and proper cure, inspectfor proper alignment and hanger placement prior to pressuretesting.10 To pressure test the system, slowly fill the systemwith water and make sure that all air is bled from the farthest andhighest point before test pressure is applied. The system MUSTbe pressure tested in accordance with NFPA 13, NFPA 24, or anyother applicable NFPA standard requirement. The system mustbe tested with water. The purpose of the hydrostatic pressuretest is to check for leakage, and it may not identify improperlyassembled joints. This test MUST NOT be considered a substitutefor full compliance to these published installation instructions.It is recommended that the portion of the sprinkler systemcontaining the cut-in tee be isolated for pressure test wherepossible. The applied test pressure should not exceed 50 psiover the system pressure in order to minimize water damage inthe event that a leak occurs.WARNING: Spears® FlameGuard® CPVC Fire Sprinkler Productsmust never be used or tested in a system of compressed air orother gases. Air must be removed from piping systems. Entrappedair can generate excessive surge pressures, regardless of thepiping materials used. Failure to follow this warning could resultin product failure, property damage and severe personal injuryor death.Note 1: Solvent cement can be applied at temperatures below 40°F (4°C) in all sizes. For the 2-1/2" & larger, the temperaturemust be raised to 40°F (4°C) or above and allowed to cure for the recommended times before the system is fi lled and pressurized.Cement, pipe or fi ttings brought in from colder outside temperatures must be brought up to room temperature before using the 60°Fto 120°F cure schedule.Cut-ins for modifi cations or system repairs are often made under less than ideal situations as compared to new installations. As aresult, the following specifi ed Minimum Cut-in Cure times must be used.。

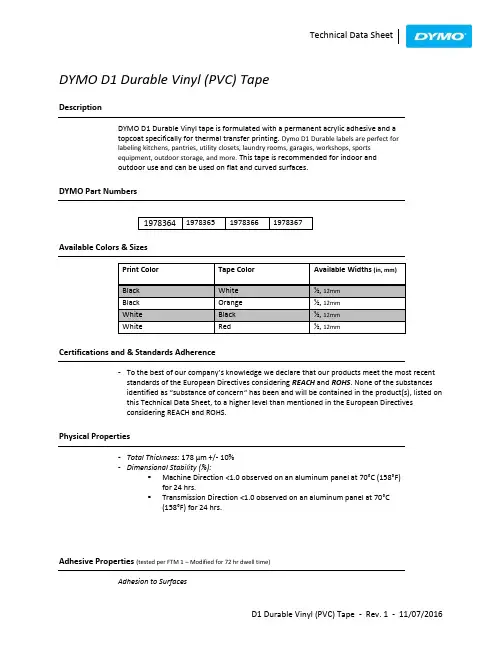

DYMO D1 Durable Vinyl (PVC) TapeDescriptionDYMO D1 Durable Vinyl tape is formulated with a permanent acrylic adhesive and atopcoat specifically for thermal transfer printing. Dymo D1 Durable labels are perfect forlabeling kitchens, pantries, utility closets, laundry rooms, garages, workshops, sportsequipment, outdoor storage, and more.This tape is recommended for indoor andoutdoor use and can be used on flat and curved surfaces.DYMO Part NumbersAvailable Colors & SizesCertifications and & Standards Adherence-To the best of our company’s knowledge we d eclare that our products meet the most recentstandards of the European Directives considering REACH and ROHS. None of the substancesidentif ied as “substance of concern“ has been and will be contained in the product(s), listed onthis Technical Data Sheet, to a higher level than mentioned in the European Directivesconsidering REACH and ROHS.Physical Properties-Total Thickness: 178 µm +/- 10%-Dimensional Stability (%):▪Machine Direction <1.0 observed on an aluminum panel at 70°C (158°F)for 24 hrs.▪Transmission Direction <1.0 observed on an aluminum panel at 70°C(158°F) for 24 hrs.Adhesive Properties (tested per FTM 1 – Modified for 72 hr dwell time)Adhesion to Surfaces-Tack (ASTM D 2979):800gm/cm²Temperature RatingsChemical ResistanceTest Method: Crockmeter, 900g weight/arm1. Printed with black ribbon:2. Printed with white ribbon:UV Light ResistanceHumidity Resistance-Printed labels adhered to aluminum surface for 30 days at 45°C (113°F), 85% Relative Humiditywith no visible effect on text or background; Slight shrinkage of materialShelf life of label cassette-Two years stored at 21°C (69.8°F) and 50% Relative HumidityNotice-This product is not developed to be used on humans, animals and/or in direct foodcontact. It is not recommended to be used in dish-washers.All of the descriptive information, performance data, and recommendations for the use of DYMO products shall be used only as a guide and do not reflect the specification or specification range for any particular property of the product. Furnishing such information is an attempt to assist you and in no event will constitute a warranty of any kind by DYMO or DYMO distributors. All purchasers of DYMO products shall be responsible for independently determining the suitability of the material for the purposefor which it is purchased.。

DRENAJEVENTAJASInnumerables son las ventajas para quien utiliza tubos y conexiones para drenaje de la marca TIGRE; estas son las más significativas:Mejor desempeño hidráulico. Por sus paredes internas lisas y por su mayor área de perforación por metro, los drena-jes corrugados y perforados TIGRE presentan mayor desem-peño hidráulico.Ligereza. Peso reducido en comparación a los materiales tradicionales.Economía. Debido a su flexibilidad, reducido peso y pérdi-das por quiebra prácticamente nulas, se torna un producto económico y de fácil transporte.Mayor vida útil. Posee aberturas adecuadamente dimen-sionadas, los drenajes de PVC TIGRE impiden la penetración y depósito del material filtrante, asegurando una mayor vida útil para el sistema.Facilidad en la instalación. Los tipos de unión, tanto soldable, elástica o simples encajes, le dan gran velocidad a la instalación, por la facilidad del montaje.Gran flexibilidad. Las propiedades de los materiales plásti-cos, aseguran la continuidad de la línea drenaje en los casos de deformaciones del suelo.Elevada resistencia a la compresión diametral. Las corrugaciones a lo largo del tubo aumentan su resisten-cia a la compresión diametral, dando mayor garantía a las cargas externas.Elevada resistencia química. No sufren la acción química del suelo, los tubos TIGRE para drenaje, garantizan una mayor vida útil a la red de drenaje.Largos. Fabricados en tiras de 6 metros para el tubo rígido, y rollos de 100 y 50 metros los tubos reducen mucho la mano de obra de la instalación.Conexiones. En el caso de los tubos flexibles se puede disponer de todas las conexiones del sistema Ramat domici-liario, siendo su unión perfecta.RECOMENDACIONES PARA INSTALACIÓNTIGRE ofrece a los ingenieros y técnicos esta nueva opción para drenaje subterráneo, presentando una línea de productos, introduciendo nuevos conceptos en las tradicionales técnicas hasta entonces utilizadas.No sólo la calidad de los drenajes de PVC TIGRE contribu-ye decisivamente para la preferencia de los proyectistas e instaladores, sino también las ventajas inherentes de estos productos, entre las cuales citamos: liviandad, elevada resistencia diametral, mayor área de perforación por metro y gran facilidad en la instalación, representando una mayor vida útil para el sistema de drenaje.Más adelante presentamos algunas orientaciones sobre la instalación de estos productos y recomendamos sean estudiados, con la finalidad de proporcionar el mayor desempeño y aprovechamiento de las ventajas que los mismos pueden ofrecer.02Para unir los tubos entre sí, usar la unión sencilla de 100 mm. Para desagües, con adhesivo Tigre para PVC. No utilizar anillo de goma.INSTALACIÓNCARACTERISTICAS DEL ACOPLAMIENTOLas piezas del acoplamiento del sistema DRENOFLEX, básicamente cuplas y adaptadores, presentan un sistema exclusivo de garras (desenvolvimiento TIGRE) que permi-ten introducir fácilmente el tubo y poseen una resistencia elevada al desmontaje (buena traba). La instalación puede proseguir con facilidad y sin peligro de desacoplamiento de las juntas que ya fueron montadas. A continuación se evidencia la facilidad del mecanismo de instalación.TUBO DRENOFLEXCONEXIÓN(LINEA RAMAT)ø 101,6DN 10003CARACTERÍSTICAS DIMENSIONALESCARACTERÍSTICAS DIMENSIONALES DE LOS TUBOSCARACTERÍSTICAS DIMENSIONALES DE LAS BOBINAS La planilla de abajo, son indicaciones con dimensiones aproximadas, cuyo objetivo es facilitar el planeamiento de transporte y el stock del material (volúmenes y pesos), también sirve como orientación para el desenvolvimiento de dispositivos de meca-nización de instalaciones, o para facilitar controles de stock y recibimiento de obra.0405APLICACIONESUtilizado en los más diversos tipos de drenaje, como ser edificaciones, carreteras, vías férreas, muros de contención, empasta-dos, campos deportivos, agricultura, y otros. Destacamos a continuación las más importantes, presentando nuestras recomen-daciones para que se obtenga un mejor desempeño de los mismos.Entre las aplicaciones en la Construcción Civil, destacamos el drenaje de muros de apoyo y el rebaje del nivelAPLICACIONES EN LA CONSTRUCCIÓN CIVILDrenaje en muros de apoyo• La calidad de los tubos de drenaje aplicados dependerá de la capacidad del filtro, extensión y altura del muro.• Normalmente, se hace más de una camada de tubos de drenaje para el escurrimiento del agua.• La aplicación de los tubos internos favorece la rapidez en el escurrimiento.• El filtro utilizado junto a la parte interna del muro deberá ser dimensionado para evitar la salida de partículas finas del material contenido.Rebaje del nivel freáticoLa protección de los predios contra las aguas de infiltración es otra de las aplicaciones usuales de los tubos de drenaje. Como en todas las aplicaciones, la distancia entre los drena-jes es en función de su profundidad y la capacidad del tubo es en función de la calidad del agua a drenar.Así, en esta aplicación, recomendamos mantener el declive constante y procurar no ahogar el drenaje.06APLICACIONES EN CAMINOS PAVIMENTADOSEs posible la utilización de la línea de drenaje para este fin pero es importante atender fin las especificaciones del proyectista. Las consideraciones generales se pueden apreciar en el gráfico.Fig. 3Fig. 4Para esas aplicaciones las formas de las líneas drenantes más empleadas son las espina de pez y paralelas.APLICACIÓN EN JARDINES Y CAMPOS DEPORTIVOSEn este caso, recomendamos:• Las distancias entre los drenajes, varían en función del suelo, pero como dato práctico, se puede adoptar la siguiente distancia:10 metros – para terrenos con más de 70 % de arcilla 15 metros – para terrenos con media mezcla (40% de arcilla).20 metros – para terrenos con un máximo de 20 % de arcilla.• P rocurar mantener la pendiente en todas las líneas, eliminando los posibles depósitos, debidos a la velocidad constante.• La profundidad deberá estar entre 0,8 a 1 metro.APLICACIONES EN LA INFILTRACIÓN DE DESAGÜES SANITARIOSLos tubos de drenaje presentan una práctica solución en la disposición de los afluentes de Cámaras Sépticas, (Fosas) ,a través del sistema de infiltración en el terreno.En esta aplicación, recomendamos observar los siguientes puntos:• Mantener una distancia mínima de 30 metros, entre las líneas de infiltración y la fuente de abastecimiento del agua.• El declive entre la cámara séptica y la caja de distribución debe ser mantenido en 2%, en cuanto que para la infiltración• La granulometría del cascajo para el lecho de la línea de riego deberá estar comprendida entre 1 a 6 cm.• Las dimensiones y el tipo de relleno de zanja deberán seguir el esquema de la Fig.7.• Todas las salidas de la caja de distribución deberán estar en el mismo nivel.•Fig. 6Fig. 70708APLICACIONES EN EL DRENAJE AGRÍCOLALa opción del tipo de drenaje: de descarga (paralelo o espina de pez) o interceptor; el cálculo del espacio entre los drenajes y su dimensionamiento y requieren estudiosDe una manera general, la profundidad de los drenajes para regiones áridas está entre 1,5 a 2 metros, en cuanto que para regiones húmedas, de 1 a 1,5 metros.ASENTAMIENTODeberán ser tomadas medidas de precaución para el asentamiento, previendo un material de buen soporte lateral para cuando el tubo estuviera sujeto a grandes cargas de compresión, a fin de evitar una deformación diametral, no compatible con el uso.En cuanto al filtro que envuelve los tubos, se debe prever su correcto dimensionamiento, para que con el correr del tiempo, tengamos siempre un buen sistema drenante.Para eso determinadas condiciones como uniformidad y permeabilidad del filtro deberán ser observadas.En la página siguiente presentamos una tabla con datos de los tubos TIGRE de PVC para drenaje, que auxiliarán los cálculos del sistema drenante.FIG. 909COLOCACIÓN PUNTERA HEMBRAEN TUBO RÍGIDOA – Material necesario: trapo, pincel, lija Nº100, solución limpiadora TIGRE y adhesivo TIGRE.B – Lijar internamente la bolsa deltubo, hasta sacar todo el brillo.C – Lijar externamente la punta del tubo, hasta sacar el brillo.D – Limpiar con el trapo humedecido con solución limpiadora TIGRE, lapuntera hembra y el tubo ya lijados.E – Medir la profundidad de la bolsa.F – Marcar en la punta del tubo laprofundidad de la bolsa.G – Utilizar el pincel para aplicar, sin exceso, el adhesivo TIGRE en la bolsa del tubo.H – Aplicar igualmente el adhesivo TIGRE, en la puntera.Si el tubo fuera Drenoflex se puede considerar la utilización de una cupla deslizante de 110 de la línea Ramat. En caso de lecho nitrificante consultar al departamento técnico.I – Introducir la punta del tubo en elfondo de la bolsa, observando laposición de la marca hechaanteriormente.J – La junta soldada está lista.REPARACIÓN DE PEQUEÑAS ROTURASA –Cuando hay pequeñas roturas enla red, utilizar una sierra para cortar eltrecho damnificado.B – Cortar una cupla doble en elsentido longitudinal.C – Lijar (lija nº100) externamente lasextremidades del tubo cortado einternamente la cupla.D – Con el trapo humedecido con lasolución limpiadora TIGRE, limpiar laspartes lijadas.E – Utilizando un pincel aplicaradhesivo TIGRE sobre las superficiesdel tubo anteriormente lijadas.F – Aplicar igualmente el adhesivoTIGRE, en la parte interna de la cupla.G – Ejerciendo presión manual, abrirla cupla para encajarla sobre el tubo.H – La ejecución de la reparaciónestá lista.1011ROTURAS MAYORES CATÁLOGO DE PIEZASY DIMENSIONESRoturas mayores Cuando existe una rotura mayor en el tubo, se corta, con ayuda de un sierra, el trecho damnificado, y de otro tubo se corta una parte con el mismo largo al de la parte retirada menos dos veces la anchura del anillo de la cupla.Se coloca este tubo en el espacio de la línea. Se suelda con adhesivo TIGRE una cupla en una de las extremidades de la tubería, con una de las extremidades del tubo intercalado.Para completar el reparo de la otra extremidad, se corta una cupla en el mismo sentido longitudinal y por medio del adhe-sivo se fija la misma sobre la enmienda existente, comple-tándose de esta manera el arreglo.Para la ejecución del pegado de las dos cuplas, sólo hay que seguir las especificaciones apuntadas para el reparo de la red anterior.Enmiendas de tubos cortados Cuando se hace necesario el acoplamiento o el aprovecha-miento de pedazos de tubos cortados, la unión de los mismos deberá ser hecha con la ayuda de la cupla, que es insertada sobre la corrugación helicoidal de los tubos. DrenoflexCotas (mm)L (mm)DE (mm)Ø 65Ø 110Código 008000815000500065.2110Di(mm)58101.40085Cotas (mm)L (mm)DE(mm)Ø 100Código 6000101.6Drenaje RígidoCotas (mm)A (mm)B (mm)Ø100X101.6Código 324114265C (mm)55D (mm)101.6DE (mm)101.6Reducción 110x100Cotas (mm)A (mm)D(mm)Ø 100Código 1339132110Puntera Hembra。

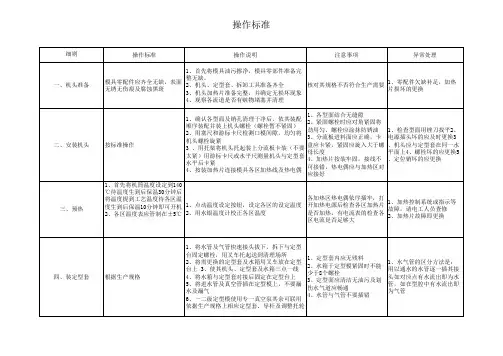

退刀应灵活

2、锯片不应有掉齿现象2、找一节型材进行切割看是否有大的破口

汽缸下

、

1、标准操作工

依据制造异常处理方法处理

2、自然光线下目测其外观

未设标准操作工艺卡者反映

1、用游标卡尺量取型材配合尺寸,几何尺寸

3、真空度不够

4、物料温度偏低

5、模头与定型模距离太远

6、真空度不够

7、一级定型套内有物料3、增加密封,提高真空度 ,调试真空泵

4、调整模头与挤出机温度(生温度)

5、减小模头与定型模之间的距离

6、条件允许时,可在收缩痕部位增加气孔

7、清理定型套

堵塞

3、牵引速度太慢(挤出和牵引不匹配)

4、型材局部出料不均匀

5、局部温度失控

6、机身模头温度不稳定,忽高忽低

7、定型模进料口导入斜度过小过短

8、定型模堵模处尺寸小2、检查,调整牵引机

3、提高牵引速度

4、调整间隙至均匀

5、检查加热板是否失控

6、检查温控系统,调整温度稳定

7、增大定型模进料口模斜度和长度

8、加大其尺寸

2、第一节定型模真空度太高或太稳定

3、定型模不在一条直线上,阻力过大

4、局部阻力过大

5、冷却不充分2、适当降低真空,检查真空泵

3、检查定型模是否在一条直线上

4、在许可时减少供料,修正定型模,增大间隙

5、降低水温,局部拐弯第一节加强冷却

2、牵引速度过快或过慢

3、型材两侧大面供料不够

4、冷却不充分

5、牵引机压力过大2、调节牵引速度使型材到达标准重量

3、加强两侧供料

4、降低冷却水温或加大冷却水量

5、适当降低牵引机压力。

Windows 2000 English with Service Pack 4 is used as operating system for controlling and operating PC.采用Windows 2000 English with Service Pack 4 操作系统。

Visual system with VAC_NT, Version 3.0 带VAC_NT的可视化系统, 3.0版本Graphic visualization of all data, set points, process states and user inputs 所有数据,设定点,过程状态和用户输入的图像可视化Menu-controlled process operating with keyboard and touch pad.带键盘和触摸板的菜单控制过程操作Manual operation for selected functions. 已选功能的人工操作Automatic operation for processes using parameters 使用参数过程的自动操作Database-oriented control and management of procedures 数据库导向控制和管理程序Event-controlled message logging 事件控制信息的录入Protocol recording during the process run 工艺运行过程的协议记录Diagnosis function (I/O list) 诊断功能(I/O 清单)1.3 Installation instruction for the main components 主要元件的安装指示For the installation of the SIMATIC peripheral components see the section in the System manual “Local peripheral equipment ET200M” (Order No.: 6ES7 153-1AA01-8AA0). SIMATIC外围元件的安装参见系统手册“Local peripheral equipment ET200M” (Order No.: 6ES7 153-1AA01-8AA0).For SINEC-L2 connection comply with the Technical Description and the Installation Guidelines in the Manual “CP5613”. SINEC-L2的连接遵守技术描述和和安装向导,在手册“CP5613”。

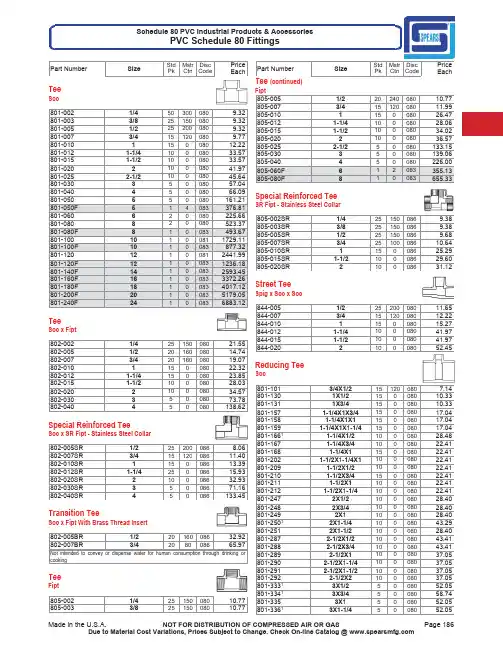

PVC Schedule 80 FittingsPRODUCTContact Spears® for any Information not found.TeesPart Number Size StdPkMstrCtnProdCodeMSRPTeeSocket x Socket x Socket801-0021/45030008019.46 801-0033/82515008019.46 801-0051/22520008019.46 801-0073/41512008020.40 801-010*********.53 801-0121-1/410008070.16 801-0151-1/210008070.16 801-020*********.73 801-0252-1/210008095.36 801-030350080119.20 801-040450080138.11 801-050550080336.89 801-050F514083787.41 801-060620080471.56 801-0808200801093.69 801-080F8100831031.61 801-10010100813613.30 801-100F10100831833.30 801-12012100815102.99 801-120F12100832583.21 801-14014100826424.61 801-140F14100835419.46 801-160F16100837046.96 801-180F181********.51 801-200F201008310822.56 801-240F241008314383.50 Tee - ReducingSocket x Socket x Socket801-1013/4X1/21512008014.94 801-1301X1/215008021.56 801-1311X3/415008021.56 801-1571-1/4X1X3/415008035.61 801-1581-1/4X1X115008035.61 801-1591-1/4X1X1-1/415008035.61 801-16611-1/4X1/210008059.52 801-1671-1/4X3/410008046.83 801-1681-1/4X115008046.83 801-2021-1/2X1-1/4X110008046.83 801-2091-1/2X1/210008046.83 801-2101-1/2X3/415008046.83 801-2111-1/2X110008046.83 801-2121-1/2X1-1/410008046.83 801-2472X1/210008059.32 801-2482X3/410008059.32 801-2492X110008059.32Part Number SizePk Ctn CodeMSRP Tee - Reducing (continued)Socket x Socket x Socket801-2502X1-1/410008090.46 801-2512X1-1/210008059.32 801-25412X2X450080414.42 801-2872-1/2X1/210008090.69 801-2882-1/2X3/410008090.69 801-2892-1/2X110008077.40 801-2902-1/2X1-1/410008077.40 801-2912-1/2X1-1/210008077.40 801-2922-1/2X210008077.40 801-33313X1/250080108.77 801-3343X3/460080122.77 801-3353X150080108.77 801-33613X1-1/450080108.77 801-3373X1-1/250080108.77 801-3383X250080108.77 801-3393X2-1/260080108.77 801-41514X1/250080215.12 801-41614X3/450080215.12 801-4174X150080215.12 801-41814X1-1/450080215.12 801-4194X1-1/250080175.78 801-4204X250080175.78 801-42114X2-1/250080316.42 801-4224X350080175.78 801-42614X640080861.43 801-48215X1-1/440080696.93 801-482F5X1-1/415083465.98 801-48415X1-1/240080759.78 801-484F5X1-1/215083474.78 801-48615X240080661.09 801-486F5X215083474.78 801-48715X2-1/240080769.06 801-487F5X2-1/214083541.38 801-48815X340080661.09 801-488F5X314083559.09 801-49015X440080524.37 801-490F5X414083596.86 801-52316X1/240080457.14 801-52416X3/460080457.14 801-5256X160080351.22 801-525F16X140083406.29 801-52616X1-1/440080457.14 801-52716X1-1/240080457.14 801-527F6X1-1/214083474.78 801-5286X260080351.22 801-52916X2-1/240080456.74 801-5306X350080351.22 801-530F6X313083519.23 801-5326X450080471.56 801-533F6X513083992.62 801-537F6X10100833863.58 801-539F6X12100834289.86 801-57318X1/2200801342.00 801-57518X1200801342.80TeesPart Number Size StdPkMstrCtnProdCodeMSRPTee - Reducing (continued)Socket x Socket x Socket801-57818X2200801276.83 801-578F8X212083875.84 801-57918X2-1/2200801404.88 801-579F8X2-1/212083883.96 801-58018X3200801276.83 801-580F8X312083893.89 801-5828X4200801276.83 801-582F8X412083939.92 801-583F8X5100831270.67 801-5858X6200801093.69 801-59118X12100817802.17 801-621F10X2120831315.67 801-622F10X2-1/2100831374.14 801-623110X3100813366.52 801-623F10X3100831411.03 801-624110X4100813366.52 801-624F10X4100831461.81 801-625F10X5100831572.01 801-62610X6100813179.71 801-626F10X6100831653.21 801-628110X8100813742.09 801-628F10X8100831854.64 801-632F10X12100834568.57 801-661F12X2100831701.29 801-662F12X2-1/2100831774.71 801-663F12X3100831832.63 801-664112X4100816103.62 801-664F12X4100831944.08 801-665F12X5100832037.26 801-666112X6100815758.62 801-666F12X6100832146.64 801-66812X8100814730.49 801-668F12X8100832303.08 801-670112X10100816334.78 801-670F12X10100832559.19 801-678F12X181008311407.49 801-691F14X2100832131.71 801-692F14X2-1/2100832239.48 801-693F14X3100832617.16 801-694F14X4100832884.08 801-696F14X6100833113.37 801-698114X8100827328.99 801-698F14X8100833273.89 801-700114X10100825204.68 801-700F14X10100833497.60 801-70214X12100826058.66 801-702F14X12100833693.23 801-706F14X16100838885.56 801-751F16X2100832733.58 801-752F16X2-1/2100832907.52 801-753F16X3100832949.20Part Number SizePk Ctn CodeMSRP Tee - Reducing (continued)Socket x Socket x Socket801-620F10X1-1/2100833245.37 801-754F16X4100833226.49 801-756F16X6100833432.48 801-758F16X8100833812.51 801-760F16X10100834132.80 801-762F16X12100834554.43 801-764F16X14100835251.63 801-781F18X2100833142.42 801-783F18X3100833826.03 801-784F18X4100835875.80 801-786F18X6100836364.06 801-788F18X8100836636.57 801-790F18X10100837109.79 801-792F18X12100837513.62 801-794F18X14100837985.10 801-796F18X16100838087.12 801-814F20X4100837206.31 801-816F20X6100837609.11 801-818F20X8100837842.99 801-820F20X10100838167.11 801-822F20X12100838757.22 801-824F20X14100839390.93 801-826F20X161008310065.36 801-828F20X181008310579.51 801-904F24X4100838972.80 801-906F24X6100839316.46 801-908F24X8100839558.70 801-910F24X101008310146.97 801-912F24X121008310521.37 801-914F24X141008310955.53 801-916F24X161008311460.94 801-918F24X181008313862.66 801-920F24X201008314126.00 1 Sized with BushingTeeSocket x Socket x Fipt802-0021/42515008045.02 802-0051/22016008030.81 802-0073/42016008039.84 802-010*********.63 802-0121-1/415008049.82 802-0151-1/210008058.58 802-020*********.26 802-0252-1/250080143.58 802-030350080154.18 802-040450080289.67 802-060F620083596.53 802-080F8120841277.44TeesPart Number Size StdPkMstrCtnProdCodeMSRPTee - ReducingSocket x Socket x Fipt802-1013/4X1/21512008028.29 802-1301X1/250008029.40 802-1311X3/415008037.78 802-1661-1/4X1/225008048.07 802-16711-1/4X3/415008048.07 802-1681-1/4X110008095.42 802-20911-1/2X1/225008059.52 802-21011-1/2X3/420008059.52 802-2111-1/2X110008059.52 802-2121-1/2X1-1/410008059.52 802-2472X1/210008067.99 802-2482X3/410008067.99 802-2492X110008090.46 802-25012X1-1/410008090.46 802-25112X1-1/2100080126.14 802-2872-1/2X1/2100080156.54 802-28812-1/2X3/4100080156.54 802-28912-1/2X1100080156.54 802-29012-1/2X1-1/4100080156.54 802-29112-1/2X1-1/2100080156.54 802-29212-1/2X2100080174.78 802-33313X1/250080122.77 802-33413X3/450080122.77 802-33513X150080147.66 802-33613X1-1/450080147.66 802-33713X1-1/250080147.66 802-33813X250080188.54 802-33913X2-1/250080265.17 802-41514X1/250080216.03 802-41614X3/450080216.03 802-41714X150080216.03 802-41814X1-1/450080216.03 802-41914X1-1/250080216.03 802-42014X250080322.90 802-42114X2-1/250080322.90 802-42214X350080361.48 802-52516X140080502.66 802-52616X1-1/440080502.66 802-52716X1-1/240080502.66 802-52816X240080502.66 802-528F26X213083915.40 802-52916X2-1/240080502.66 802-53016X340080701.71 802-53216X420080735.21 802-532F26X4140831134.37 802-57818X2200801370.02 802-578F8X2120831225.94 802-58018X3200801370.02Part Number SizePk Ctn CodeMSRP Tee - Reducing (continued)Socket x Socket x Fipt802-580F8X3120831225.94 802-58218X4200801370.02 802-582F28X4120831358.81 802-621110X2100813498.68 802-621F10X2100831488.66 802-623110X3100803498.68 802-623F10X3100831609.18 802-624110X4100813498.68 802-624F210X4100831787.72 802-661112X2100815543.58 802-661F12X2100831890.92 802-663112X3100815543.58 802-663F12X3100832051.81 802-664112X4100815543.58 802-664F12X4100832264.691 Sized with Bushing2 Fiberglass reinforcedTee - Special ReinforcedSocket x Socket x SR Fipt - Stainless SteelCollar802-005SR1/250008616.83 802-007SR3/41512008623.82 802-010SR115008627.96 802-012SR1-1/425008633.30 802-015SR1-1/210008635.17 802-020SR210008668.81 802-030SR350086148.71 802-040SR450086278.86 Tee - Special Reinforced ReducingSocket x Socket x SR Fipt - Stainless SteelCollar802-072SR1/2X1/42515008616.83 802-098SR3/4X1/42510008621.88 802-101SR3/4X1/250008621.88 802-128SR11X1/4108008651.80 802-130SR1X1/250008626.99 802-131SR1X3/415008651.80 802-164SR11-1/4X1/454008655.22 802-166SR1-1/4X1/225008636.61 802-168SR1-1/4X110008637.34 802-207SR11-1/2X1/410008664.44 802-211SR1-1/2X110008640.44 802-212SR1-1/2X1-1/410008640.44 802-245SR12X1/410008674.42 802-247SR2X1/210008674.42 802-248SR2X3/410008674.42 802-287SR2-1/2X1/210008654.86 802-331SR13X1/450086142.10 802-333SR13X1/250086146.23TeesPart Number Size StdPkMstrCtnProdCodeMSRPTee - Special Reinforced Reducing (continued)Socket x Socket x SR Fipt - Stainless Steel Collar802-413SR14X1/450086195.69 802-415SR14X1/250086212.681 Sized with BushingTee - Brass TransitionSocket x Socket x Fipt With Brass Thread Insert802-005BR1/22012008668.79 802-007BR3/42080086137.84 Not intended to convey or dispense water for human consumption through drinking or cookingTee - Brass Transition ReducingSocket x Socket x Fipt With Brass Thread Insert802-072BR1/2X1/42012008674.14 802-101BR3/4X1/250008685.84 Not intended to convey or dispense water for human consumption through drinking or cookingTee - ReducingSocket x Fipt x Socket803-0953/4X1/2X3/450008026.51 Tee - Special Reinforced ReducingSocket x SR Fipt - Stainless Steel Collar xSocket(See also Gauge & Instrument Fittings for additional configurations)803-095SR3/4X1/2X3/415008627.56TeeFipt x Fipt x Fipt805-0021/42515008022.52 805-0033/82515008022.52 805-0051/22024008022.52 805-0073/41512008025.04 805-010*********.30 805-0121-1/410008058.63 805-0151-1/210008071.08 805-020*********.41 805-0252-1/250080278.26 805-030350080290.60 805-040450080472.24Part Number SizePk Ctn CodeMSRPTee (continued)Fipt x Fipt x Fipt805-060F6120801019.09 805-080F8100802007.19 Tee - Special ReinforcedSR Fipt x SR Fipt x SR Fipt - Stainless SteelCollar805-002SR1/42515008619.62 805-003SR3/82515008619.62 805-005SR1/22515008620.23 805-007SR3/42510008622.23 805-010SR115008652.82 805-015SR1-1/210008661.86 805-020SR210008665.02 Tee - StreetSpigot x Socket x Socket844-0051/22520008024.34 844-0073/41512008025.53 844-010*********.92 844-0121-1/410008087.73 844-0151-1/210008087.73 844-0202100080109.6290° Ells90° EllSocket x Socket806-0021/450300080 6.88 806-0033/825150080 6.88 806-0051/220240080 6.88 806-0073/4201600808.82 806-010*********.22 806-0121-1/410008019.04 806-0151-1/225008020.38 806-020*********.62 806-0252-1/25008057.64 806-03036008064.80 806-04045008098.54 806-045F4-1/212083453.07 806-050540080252.63 806-050F514083505.88 806-060640080280.41 806-080820080772.90 806-080F812083776.54 806-10010100813458.96 806-100F10100831380.41 806-12012100814509.01 806-120F12100832256.3390° EllsPart Number Size StdPkMstrCtnProdCodeMSRP90° Ell (continued)Socket x Socket806-14014100825055.59 806-140F14100832878.21 806-160F16100833579.58 806-180F181********.70 806-200F20100836109.23 806-240F24100839381.49 806-33813X250080158.84 806-42214X350080237.27 1 Sized with Bushing90° Ell SweepSocket x Socket806-005S1/22515008017.22 806-007S3/42510008022.28 806-010S120008035.91 806-012S1-1/425008047.53 806-015S1-1/220008051.04 806-020S225008061.86 90° Ell - Long SweepSocket x Socket806-005LSF1/22520008359.70 806-007LSF3/425008367.01 806-010LSF125008374.92 806-012LSF1-1/4250083126.68 806-015LSF1-1/2125083128.30 806-020LSF2110083138.69 806-025LSF2-1/217083238.16 806-030LSF315083259.81 806-040LSF414083291.34 806-060LSF612083446.27 806-080LSF810083935.26 806-100LSF10100831591.33 Not Listed for Electrical Conduit Use90° EllSocket x Fipt807-0021/42545008027.16 807-0033/82515008027.16 807-0051/22024008027.16 807-0073/42024008031.96 807-010*********.58 807-0121-1/4104008039.84 807-0151-1/210008047.56 807-020*********.56Part Number SizePk Ctn CodeMSRP 90° Ell (continued)Socket x Fipt807-030350080147.08 807-040450080277.38 807-0601630080643.59 1 Thread outlet sized with Female Adapter90° Ell - ReducingSocket x Fipt807-1013/4X1/2106008016.47 807-13011X1/2108008026.28 807-13111X3/4108008026.28 1 Sized with Bushing90° Ell - Special ReinforcedSocket x SR Fipt - Stainless Steel Collar807-005SR1/22024008616.14 807-007SR3/475008619.18 807-010SR150008619.39 807-012SR1-1/425008626.09 807-015SR1-1/210008632.21 807-020SR210008636.93 807-030SR35008693.82 807-040SR450086165.7690° Ell - Special Reinforced ReducingSocket x SR Fipt - Stainless Steel Collar807-101SR3/4X1/250008619.12 807-130SR1X1/250008621.4890° Ell - Brass TransitionSocket x Fipt With Brass Thread Insert807-005BR1/22024008660.44 807-007BR3/420160086106.99 Not intended to convey or dispense water for human consumption through drinking or cooking90° Ell - Brass Transition ReducingSocket x Fipt With Brass Thread Insert807-101BR3/4X1/22012008675.40 Not intended to convey or dispense water for human consumption through drinking or cooking90° EllsPart Number Size StdPkMstrCtnProdCodeMSRP90° EllFipt x Fipt808-0021/42545008017.12 808-0033/82515008017.12 808-0051/22012008015.98 808-0073/42024008019.93 808-01011512008025.04 808-0121-1/4104008026.99 808-0151-1/210008038.28 808-020*********.12 808-0252-1/250080167.94 808-030350080270.84 808-040450080476.53 90° Ell - Special ReinforcedSR Fipt x SR Fipt - Stainless Steel Collar808-003SR3/8251500869.43 808-005SR1/2201200869.43 808-007SR3/42012008611.86 808-010SR150008613.82 808-012SR1-1/425008614.73 808-015SR1-1/210008622.99 808-020SR210008625.88 90° Street EllSpigot x Socket809-0051/2502000808.67 809-0073/450008011.04 809-010*********.80 809-0121-1/425008023.82 809-0151-1/210008025.53 809-020*********.82 809-02512-1/25008073.03 809-03035008086.46 809-040440080131.38 809-0601610080373.89 809-08018200801030.53 809-100110100814610.68 809-100F10100831840.61 809-120112*********.17 809-120F12100833008.46 809-140114*********.52 809-140F14100833676.73 809-160F16100833977.36 809-180F181********.48 809-200F20100839568.28Part Number SizePk Ctn CodeMSRP 90° Street Ell (continued)Spigot x Socket809-240F241008314867.64 1 = Assembled with Molded Components90° Street EllMipt x Fipt812-0021/45030008036.86 812-00511/22515008030.59 812-0073/42515008034.74 812-0101150008047.24 812-01211-1/410008054.28 812-01511-1/210008088.92 1 Sized with AdapterNon 90° Ells11-1/4° EllSocket x Socket811-005F1/215208355.89 811-007F3/412008356.28 811-010F115008361.56 811-012F1-1/412608366.69 811-0151-1/225008055.74 811-020*********.33 811-025F2-1/212508381.71 811-0303100080175.19 811-040440080314.84 811-045F4-1/2118083178.01 811-050F514083213.50 811-060F6110083218.49 811-080F814083357.64 811-100F1012083633.84 811-120F1212083926.40 811-140F14100831418.23 811-160F16100831895.80 811-180F181********.34 811-200F20100834222.22 811-240F24100835037.4930° EllSocket x Socket815-005F1/212508355.89 815-007F3/412508356.28 815-010F113008361.56 815-012F1-1/411508366.69 815-015F1-1/212508367.61 815-020F212508373.73 815-025F2-1/211808381.71Non 90° EllsPart Number Size StdPkMstrCtnProdCodeMSRP30° Ell (continued)Socket x Socket815-030F312008389.12 815-040F416083116.84 815-045F4-1/2118083178.01 815-050F514083213.50 815-060650080396.38 815-080F813083357.64 815-100F1012083633.84 815-120F1212083926.40 815-140F14100831418.23 815-160F16100831895.80 815-180F181********.33 815-200F20100834222.22 815-240F24100835037.49 22-1/2° EllSocket x Socket816-0051/22024008015.34 816-0073/42024008023.39 816-01012016008035.06 816-010F112508333.82 816-015F1-1/212508358.97 816-0121-1/420008044.63 816-0151-1/220008052.77 816-020*********.33 816-0252-1/250080140.43 816-025F2-1/211808381.71 816-030350080175.19 816-040440080314.84 816-045F4-1/2118083178.01 816-050F518083213.50 816-060640080396.38 816-060F618083218.49 816-080840080859.60 816-080F814083357.64 816-100F1012083633.84 816-120F1212083926.40 816-140F14100831418.23 816-160F16100831895.80 816-180F181********.34 816-200F20100834222.22 816-240F24100835037.49 45° EllSocket x Socket817-0021/42545008024.80 817-0033/85030008024.80 817-0051/22024008012.98Part Number SizePk Ctn CodeMSRP 45° Ell (continued)Socket x Socket817-0073/42024008019.87 817-01011512008029.77 817-0121-1/4108008037.92 817-0151-1/210008044.84 817-020*********.14 817-0252-1/250080122.08 817-030350080148.62 817-040450080267.57 817-045F4-1/212083185.37 817-050540080320.13 817-050F514083252.96 817-060640080336.97 817-080820080730.60 817-10010100812300.20 817-100F1012083970.76 817-12012100812967.10 817-120F12100831365.72 817-14014100823483.84 817-140F14100832226.08 817-160F16100832725.26 817-180F181********.07 817-200F20100834556.18 817-240F24100835643.5615° EllSocket x Socket818-005F1/212508355.89 818-007F3/412308356.28 818-010F112008361.56 818-015F1-1/212508367.61 818-020F212508373.73 818-025F2-1/2118083240.69 818-030F313508389.12 818-040F4120083116.84 818-045F4-1/2118083178.01 818-050F514083213.50 818-060F618083218.49 818-080F814083357.64 818-100F1012083633.84 818-120F1212083926.40 818-140F14100831418.23 818-160F16100831895.80 818-180F181********.34 818-200F20100834222.22 818-240F24100835037.4945° EllFipt x Fipt819-0021/42545008028.16Non 90° EllsPart Number Size StdPkMstrCtnProdCodeMSRP45° Ell (continued)Fipt x Fipt819-0033/82515008028.16 819-0051/22515008025.68 819-0073/4106008027.58 819-0101106008034.61 819-0121-1/4108008052.78 819-0151-1/210008066.36 819-020*********.39 819-0252-1/250080194.67 819-030350080313.13 819-040450080449.30 45° Ell - Special ReinforcedSR Fipt x SR Fipt - Stainless Steel Collar819-005SR1/22515008614.82 819-007SR3/42530008616.22 819-010SR1106008626.82 60° EllSocket x Socket824-005F1/217083155.12 824-007F3/4125083183.14 824-010F1125083199.26 824-012F1-1/4116083203.17 824-015F1-1/2116083217.02 824-020F2116083275.31 824-025F2-1/2110083324.11 824-030F314083324.73 824-040F414083417.23 824-060F612083745.18 824-080F812083903.16 824-100F10120831543.11 824-120F12100832015.52 824-140F14100832509.76 824-160F16100832835.76 824-180F181********.89 824-200F20100835540.52 824-240F24100839239.07 45° Street EllSpigot x Socket827-0051/25040008012.98 827-0073/450008019.87 827-010*********.77 827-0121-1/425008037.92 827-0151-1/225008044.84Part Number SizePk Ctn CodeMSRP 45° Street Ell (continued)Spigot x Socket827-020*********.14 827-02512-1/212008076.67 827-0303100080148.62 827-040450080267.57 827-050F512083323.72 827-060640080396.38 827-080820080859.60 827-100110100812706.21 827-120112*********.72 827-140F14100832054.62 827-160F16100833295.88 827-180F181********.46 827-200F20100834847.16 827-240F24100837707.37 1 = Assembled with Molded Components22-1/2° Street EllSpigot x Socket842-0051/25040008015.91 842-0073/450008024.49 842-010*********.46 842-0121-1/420008047.90 842-0151-1/225008054.28 842-020*********.33 842-0252-1/250080178.43 842-030350080195.88 842-040440080344.46 842-040F415084219.46 842-060660080489.58 842-060F616083275.31 842-0808120801058.48 842-080F814083363.34 842-100F1010083742.57 842-120F1212084967.57CrossesCrossSocket x Socket x Socket x Socket820-0021/42515008096.03 820-0051/250008096.03 820-0073/4500080101.03 820-0101500080118.31 820-0121-1/4250080141.96 820-0151-1/2250080153.02 820-0202100080189.49 820-0252-1/2100080258.36 820-030350080322.23 820-040430080560.66CrossesPart Number Size StdPkMstrCtnProdCodeMSRPCross (continued)Socket x Socket x Socket x Socket820-060F6100831347.24 820-080F8100831969.94 820-100F10100833177.33 820-120F12100834474.42 820-140F14100837191.16 820-160F16100838149.83 820-180F181********.39 820-200F201008312447.26 820-240F241008318704.54 Cross - ReducingSocket x Socket x Socket x Socket820-10113/4X1/2500080111.29 820-13011X1/2250080144.19 820-1311X3/4200080144.19 820-16611-1/4X1/2250080138.49 820-1671-1/4X3/4250080127.79 820-16811-1/4X1250080182.10 820-20911-1/2X1/2200080206.53 820-2101-1/2X3/4150080206.53 820-21111-1/2X1250080206.53 820-21211-1/2X1-1/4250080206.53 820-24712X1/2100080264.93 820-24812X3/4100080264.93 820-24912X1100080264.93 820-25012X1-1/4100080264.93 820-25112X1-1/2100080264.93 820-2892-1/2X1150080264.93 820-29012-1/2X1-1/4100080388.11 820-29112-1/2X1-1/2100080388.11 820-29212-1/2X240080388.11 820-33513X140080526.30 820-33613X1-1/440080526.30 820-33713X1-1/240080526.30 820-33813X240080526.30 820-33913X2-1/240080526.30 820-42014X230080845.58 820-420F4X214083825.79 820-42214X330080845.58 820-527F6X1-1/212083979.86 820-528F6X2140831045.56 820-530F6X3120831099.22 820-532F6X4120831310.18 820-533F6X5120831553.34 820-578F8X2120831349.19 820-580F8X3100831420.29 820-582F8X4100831466.86 820-585F8X6100831585.13 820-621F10X2100831796.03Part Number SizePk Ctn CodeMSRP Cross - Reducing (continued)Socket x Socket x Socket x Socket820-622F10X2-1/2100831846.34 820-623F10X3100831947.42 820-624F10X4100832021.44 820-626F10X6100832115.43 820-628F10X8100832720.53 820-661F12X2100832009.42 820-663F12X3100832164.90 820-664F12X4100832304.07 820-666F12X6100832675.62 820-668F12X8100833196.19 820-670F12X10100832173.78 820-691F14X2100832883.31 820-693F14X3100833103.03 820-694F14X4100833407.03 820-696F14X6100833763.12 820-698F14X8100834280.78 820-700F14X10100834946.01 820-702F14X12100835594.37 820-751F16X2100833607.10 820-753F16X3100833884.57 820-754F16X4100834309.28 820-756F16X6100834660.61 820-758F16X8100835212.84 820-760F16X10100835680.43 820-762F16X12100836380.10 820-764F16X14100837990.12 820-784F18X4100836082.96 820-786F18X6100836348.99 820-788F18X8100836813.63 820-790F18X10100837277.97 820-792F18X12100837621.12 820-794F18X14100838074.88 820-796F18X16100838413.97 820-814F20X4100837627.49 820-816F20X6100838785.79 820-818F20X8100838884.48 820-820F20X10100839498.20 820-822F20X121008310184.58 820-824F20X141008311372.04 820-826F20X161008311593.79 820-828F20X181008312220.06 820-904F24X4100839106.12 820-906F24X6100839679.12 820-908F24X81008310057.10 820-910F24X101008310200.77 820-912F24X121008310666.74 820-914F24X141008312691.98 820-916F24X161008313553.70 820-918F24X181008315551.56 820-920F24X201008318595.20 1 Sized with BushingPage 13See MSRP-1 Sheet or Check Spears®****************************.comforPricingCouplingsCodeRepair Coupling- FabricatedGasket x GasketCoupling - No StopSocket x Socket - No Pipe Stop0811360.07CouplingSocket x Socket(continued)0832593.64Coupling - ReducerSocket x SocketMade in the U.S.A.Suitable for Oil-Free air handling to 25 psi, not for distribution of compressed air or gasSee MSRP-1 Sheet or Check Spears®****************************.comforPricing Page 14CouplingsPart Number Size StdPkMstrCtnProdCodeMSRPCoupling - Reducer (continued)Socket x Socket829-491F5X4-1/2110083179.47 829-52816X260080619.33 829-52916X2-1/240080742.72 829-53016X3120080625.69 829-530F6X3110083233.50 829-5326X440080504.51 829-534F6X4-1/215083204.10 829-533F6X515083214.03 829-579F8X2-1/216083807.89 829-580F8X316083592.16 829-5828X4200801528.04 829-582F8X416083552.59 829-583F8X514083607.42 829-5858X6200801528.04 829-621F10X212083953.18 829-623F10X312083892.37 829-624F10X412083842.19 829-625F10X514083765.78 829-62610X6100811788.90 829-626F10X614083690.16 829-62810X8100811788.90 829-628F10X814083359.18 829-663F12X3120831375.86 829-664F12X4120831175.32 829-665F12X5120831090.40 829-666F12X6100831016.69 829-66812X8100812035.61 829-668F12X810083787.21 829-670F12X1010083531.79 829-691F14X2100831253.41 829-694F14X4100831354.11 829-696F14X6100831446.44 829-698F14X8100831323.59 829-700F14X10100831294.54 829-702F14X1210083776.46 829-754F16X4100832542.51 829-756F16X6100832299.49 829-758F16X8100832019.58 829-760F16X10100831793.88 829-762F16X12100831512.08 829-764F16X14100831147.82 829-783F18X3100835516.88 829-784F18X4100835364.63 829-786F18X6100835014.70 829-788F18X8100834748.09 829-790F18X10100834295.18 829-792F18X12100833535.44 829-794F18X14100832393.36 829-796F18X16100832043.28 829-814F20X4100835311.04 829-816F20X6100834889.99Part Number SizePk Ctn CodeMSRP Coupling - Reducer (continued)Socket x Socket829-818F20X8100834673.89 829-820F20X10100834509.97 829-822F20X12100833901.50 829-824F20X14100833891.22 829-826F20X16100833574.47 829-828F20X181********.87 829-904F24X4100838495.49 829-906F24X6100838366.14 829-908F24X8100838184.84 829-910F24X10100837987.41 829-912F24X12100837266.14 829-914F24X14100836702.06 829-916F24X16100836107.99 829-918F24X181********.21 829-920F24X20100835267.91 1 Sized with BushingCoupling - Eccentric ReducerSocket x Socket829-101FE3/4X1/225008380.59 829-130FE1X1/211608356.52 829-131FE1X3/415008382.94 829-168FE1-1/4X111208365.72 829-209FE21-1/2X1/2125083104.11 829-210FE21-1/2X3/4125083107.76 829-211FE1-1/2X112508370.60 829-212FE1-1/2X1-1/412008368.29 829-249FE2X112508397.36 829-250FE2X1-1/412508390.46 829-251FE2X1-1/211008386.32 829-289FE22-1/2X1112083103.51 829-290FE22-1/2X1-1/4120083134.11 829-291FE22-1/2X1-1/2120083130.36 829-292FE2-1/2X2110083100.68 829-335FE23X1120083132.09 829-336FE23X1-1/4110083127.20 829-337FE23X1-1/2110083122.22 829-338E3X2150080131.29 829-338FE3X212008378.07 829-339FE3X2-1/2110083253.49 829-417FE34X1118083321.04 829-418FE34X1-1/4110083315.33 829-419FE34X1-1/2112083305.31 829-420FE24X2110083213.17 829-421FE24X2-1/216083177.77 829-422FE4X3110083266.52 829-490FE5X418083214.51 829-528FE36X216083377.82 829-529FE36X2-1/216083344.83 829-530FE26X316083332.81 829-532FE6X415083240.96Page 15Suitable for Oil-Free air handling to 25 psi, not for distribution of compressed air or gas Spears ® Manufacturing CompanySee MSRP-1 Sheet or Check Spears ®****************************.comforPricingCouplingsPart Number SizeStd Pk Mstr Ctn Prod CodeMSRPCoupling - Eccentric Reducer (continued)Socket x Socket 829-533FE 6X515083222.21829-575FE 58X110083770.73829-577FE 58X1-1/210083859.60829-578FE 48X214083876.44829-580FE 38X312083510.22829-582FE 28X412083416.78829-583FE 28X512083415.88829-585FE 8X614083320.48829-624FE 310X410083705.23829-625FE 310X510083802.90829-626FE 210X612083699.57829-628FE 10X812083553.04829-664FE 412X4100831078.44829-666FE 312X610083887.53829-668FE 212X810083766.80829-670FE 12X1012083490.12829-696FE 314X6100831756.77829-698FE 214X8100831444.68829-700FE 14X10100831198.20829-702FE 14X1210083769.77829-756FE 416X6100833245.70829-758FE 316X8100832972.12829-760FE 216X10100832162.14829-762FE 216X12100831919.61829-764FE 16X14100831486.87829-786FE 518X6100834480.40829-788FE 418X8100834288.91829-790FE 318X10100834007.89829-792FE 318X12100833577.34829-794FE 218X14100832949.31829-796FE18X1610832877.82CouplingFipt x Fipt 830-0021/42545008014.98830-0033/82515008014.98830-0051/22515008013.96Part NumberSizePk Ctn CodeMSRPCoupling (continued)Fipt x Fipt 830-0073/42530008019.94830-0101159008021.42830-0121-1/41012008026.49830-0151-1/2108008058.90830-020*********.86830-0252-1/250080147.67830-030350080173.14830-040450080299.83830-060F 618083377.89830-080F 816083555.69830-100F1012083755.79Coupling - Special ReinforcedSR Fipt x SR Fipt - Stainless Steel Collar 830-005SR 1/2251500867.71830-007SR 3/42515008610.97830-010SR 12520008611.72830-012SR 1-1/41012008614.63830-015SR 1-1/2108008632.33830-020SR21008633.89Coupling - ReducerFipt x Fipt 830-07211/2X1/45030008018.83830-07311/2X3/82515008018.83830-1013/4X1/25020008016.62830-21111-1/2X1104008081.081Sized with BushingCoupling - Special Reinforced ReducerSR Fipt x SR Fipt - Stainless Steel Collar 830-101SR 3/4X1/2502000869.97830-130SR 1X1/250008614.80830-131SR 1X3/42520008614.80830-168SR 1-1/4X125008631.78830-210SR 1-1/2X3/425008647.23830-211SR 1-1/2X1108008647.23830-212SR 1-1/2X1-1/4108008647.23830-249SR 2X125008662.60830-251SR2X1-1/210008662.60Grooved Coupling AdapterGroove x Socket 833-0121-1/4106008034.69833-0151-1/2108008038.77。

Pvc卡打印机使用说明书JF8600是一款热转印PVC卡打印机,同时也属于4色印刷的pvc卡打印机,下面的就有小编给大家介绍一下JF8600这款产品的使用说明及在使用过程中的一些问题。

更换色彩/热印膜1.打开打印机门2.按住盒子按钮,拉出盒子(右:色带盒,左:转印膜盒),去除色带/转印膜3.安装新的色彩/转印膜(1)安装是参照盒子上的粘胶标签(2)把带墨的/转印表面朝外,沿三个轴展开色带/转印膜,并稳稳插入筒管架4.拉进色带,沿导轨插入色带/转印膜.知道听到“咔哒”医生5.关上打印机门,按[RESET]重置打印机注意事项:1.如果打印功能已打开,打印机会被锁住。

从电脑关闭安全功能。

打印后,再从电脑打开安全功能。

2.更换色带/转印膜时,用双手握住盒子3.安装用过的色带时,把色带没有用过的黄色面与盒子标签上所示箭头对齐4.按图所示,把盒子竖放在平整的表面上5.拉紧色带/转印膜否则可因表面褶皱而导致堵塞或者造成色彩不均6.不要用手接触带墨的转印表面(安装时朝外的那一面),处理色带/转印膜时戴上手套7.不要再打印机门上操作,不要再打印机上放置重物或者施加负荷8.安装新的转印膜时,确定至少三条黑线卷到了卷轴上打印卡片1.打开电源2.检查确保卡片插入送卡箱3.打开打印设置屏幕,在[Printers]中选择本打印机4.确保打印机的液晶控制面板上出现[Ready]字样后,开始打印注意事项1.如果您在打印的液晶控制面板上看到[Initializing...]或者[Preheating...]字样,这表示打印机尚未做好准备。

在打印机做好准备前,无法进行打印。

2.在卡片带磁条的一面上打印,可能会造成打印错误,或损坏卡片功能。

如果您要这么做,请事先跟商家进行沟通补充卡片1.把送卡箱的旋钮设置在open上2.上提,取下送卡箱外盖3.对齐卡片方向,把卡片放进打印机4.装上送卡箱外盖注意事项1.如果安全功能已打开,送卡箱会被锁住,从电脑关闭安全功能。