宁波恒力产品样本

- 格式:pdf

- 大小:4.33 MB

- 文档页数:62

答疑解惑11\10作者:马明东这次利用2020年的PTC国际液压展会期间,与液压界的一些牛人会面时,大家探讨了一下各自感兴趣的液压课题,与高手过招,收获至丰,受益匪浅。

例如,我提问一个问题,德国力士乐液压泵样本上有这么一段话;压力变化速率R A max-----16000bar/s。

压力变化速度R A、在整个压力范围内压力变化的最大允许升压/降压速率。

这段话,我所不解的是力士乐要表达什么意思?为什么要在样本上特意标注这么一项技术要求?如果柱塞泵超过了这项技术要求是什么后果?我查百度解译的意思是:速率;速率是物体运动的快慢,即速率是速度大小或等价于路程的变化率,它是运动物体经过路程Δs和通过这一路程所用的时间Δ的比做。

按照每秒压力变化速率为16000bar/s,哪么每ms为压力升/降16bar,即是一台柱塞压力从0ba上升到400ba时,所用时间为:25ms,如果泵是电机带动的,每分钟为:1500r pm时,25ms时间内,泵缸体只旋转了225°,还没有旋转一圈,只有5.6只柱塞各压缩油液一次,这是不可能的泵的压力上升速度能达到的这么高的速率的,出非是极小的容积,这对液压系统中应用的柱塞泵不会出现这样的速率,哪只是压力冲击到泵内。

石景林老师对此讲了一个实例:讲的是一个百吨吊车在起吊重物时,中途停止起吊时,所吊的重物对吊车的钢丝绳一戥,产生的压力冲击反馈到泵的压力输出口内,压力冲击是泵输出压力的几十倍。

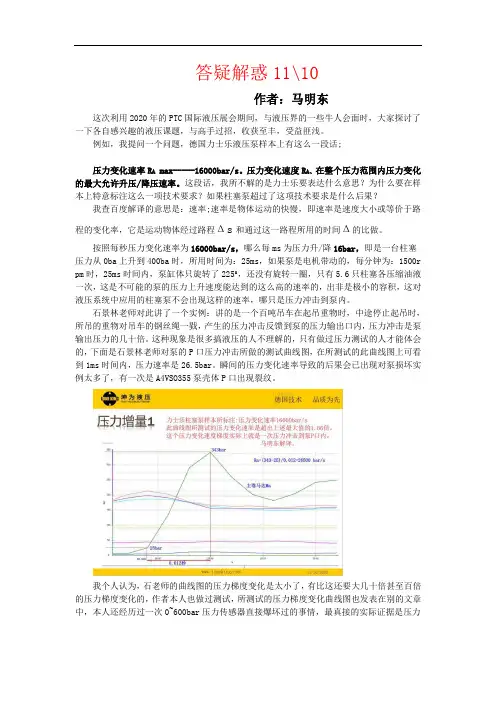

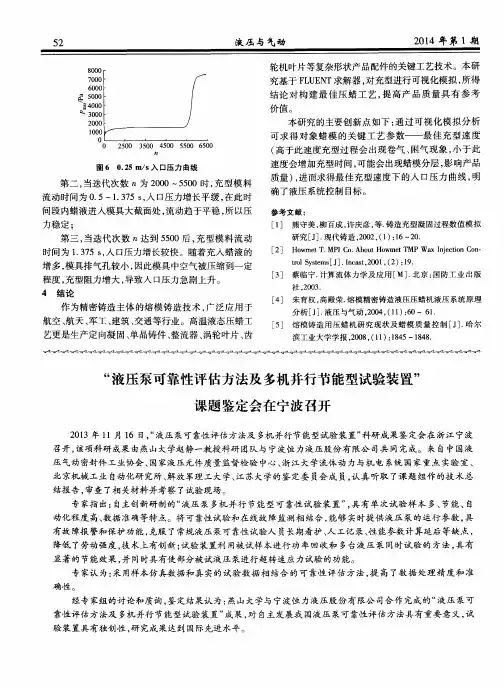

这种现象是很多搞液压的人不理解的,只有做过压力测试的人才能体会的,下面是石景林老师对泵的P口压力冲击所做的测试曲线图,在所测试的此曲线图上可看到1ms时间内,压力速率是26.5bar。

瞬间的压力变化速率导致的后果会已出现对泵损坏实例太多了,有一次是A4VSO355泵壳体P口出现裂纹。

我个人认为,石老师的曲线图的压力梯度变化是太小了,有比这还要大几十倍甚至百倍的压力梯度变化的,作者本人也做过测试,所测试的压力梯度变化曲线图也发表在别的文章中,本人还经历过一次0~600bar压力传感器直接爆坏过的事情,最真接的实际证据是压力冲击对泵壳体后盖、对泵配流盘,以及对泵缸体、柱塞、滑靴冲击损伤的照片,关于变类的照片我会拿出几百张的,下面就发表几张作为补证。

关于水乙二醇液压系统问:液压系统介质为水乙二醇需要注意什么由于需要,一液压系统介质需用水乙二醇,请问元件选型等设计需要注意什么和液压油有什么区别答:密封不能用脂类密封,只能用橡胶的还有就是注意下泵,能不能泵水乙二醇其他的跟液压油区别不大问:液压系统使用水乙二醇的利弊答:防火.抗爆炸.对密封件和电磁阀的要求较高.对环境污染小答:液压原件使用寿命缩短20%~50%,关键件是专用的,比如液压柱塞泵就是特殊的,泵内的零件也是专用的,泵的轴承是水基轴承.答:同时柱塞泵的最高使用压力将大大降低,一般重载泵压力不超过25MPa。

答:4楼的“液压青年”,柱塞泵是不可以用水乙二醇等乳化液的,这种水乙二醇水乳液多用于压力较低的场合,或用于压力的间接传递。

现在用于高压的水乙二醇液压泵等系统应该说在世界上还没有成熟的产品。

答:优点:防火.抗爆炸.缺点:对系统抗腐蚀能力要求高,对密封要求高,系统精度保证难度大!价格高!答:使用水乙二醇的系统,一般用于炼钢、高炉等高温、高火情的设备,防止由于系统泄露的介质造成大面积的火灾。

但是由于介质的化学性能,首先限制了液压元件的密封材料,需要采用成本比较昂贵的氟橡胶的材料。

其次是由于黏度的问题限制液压元件的结构形式。

另外介质本身需要投入比较多的时间去检验、维护;因为其中的成分随着水分的挥发会产生变化。

润滑性能比较差,使得元件性能、寿命都受到极大影响,所有这些都造成系统运行成本的上升。

答:油缸密封件应该用氟橡胶了,价格贵了问:水乙二醇液压系统最近在设计一个水乙二醇液压系统,我们知道这样的介质对密封件的影响不是太大,对轴承的材质影响到是很大的答:水乙二醇对系统要求好像比磷酸酯类宽泛一点,相对普通液压油好像也没有什么特殊的要求吧!希望有高手指导!答:我们有用水乙二醇的液压系统,我觉得主要考虑到系统由于介质黏度低、润滑性不好带来的问题。

水乙二醇系统的液压元件的损坏率很高的。

而且密封也容易老化,但不是主要问题,其中系统的清洁比矿物油为介质的系统要求更高些。

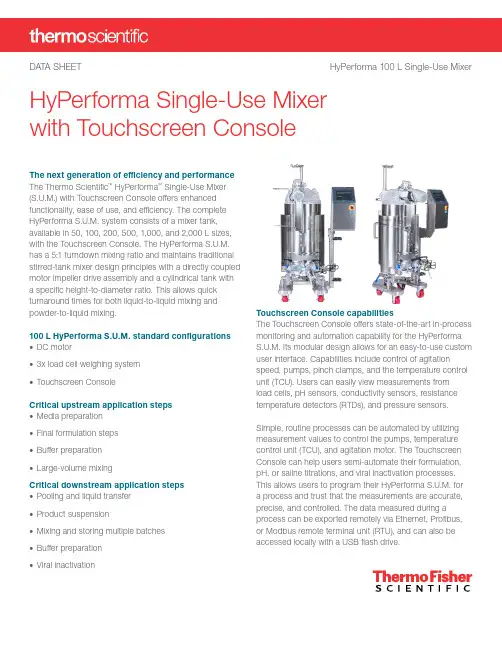

DATA SHEET HyPerforma 100 L Single-Use MixerHyPerforma Single-Use Mixer with Touchscreen ConsoleThe next generation of efficiency and performance The Thermo Scientific ™ HyPerforma ™ Single-Use Mixer (S.U.M.) with Touchscreen Console offers enhanced functionality, ease of use, and efficiency. The complete HyPerforma S.U.M. system consists of a mixer tank, available in 50, 100, 200, 500, 1,000, and 2,000 L sizes, with the Touchscreen Console. The HyPerforma S.U.M. has a 5:1 turndown mixing ratio and maintains traditional stirred-tank mixer design principles with a directly coupled motor impeller drive assembly and a cylindrical tank with a specific height-to-diameter ratio. This allows quick turnaround times for both liquid-to-liquid mixing and powder-to-liquid mixing.100 L HyPerforma S.U.M. standard configurations • DC motor• 3x load cell weighing system • Touchscreen ConsoleCritical upstream application steps • Media preparation • Final formulation steps • Buffer preparation • Large-volume mixingCritical downstream application steps • Pooling and liquid transfer • Product suspension• Mixing and storing multiple batches • Buffer preparation • Viral inactivationTouchscreen Console capabilitiesThe Touchscreen Console offers state-of-the-art in-process monitoring and automation capability for the HyPerforma S.U.M. Its modular design allows for an easy-to-use custom user interface. Capabilities include control of agitationspeed, pumps, pinch clamps, and the temperature control unit (TCU). Users can easily view measurements from load cells, pH sensors, conductivity sensors, resistance temperature detectors (RTDs), and pressure sensors. Simple, routine processes can be automated by utilizing measurement values to control the pumps, temperature control unit (TCU), and agitation motor. The Touchscreen Console can help users semi-automate their formulation, pH, or saline titrations, and viral inactivation processes. This allows users to program their HyPerforma S.U.M. for a process and trust that the measurements are accurate, precise, and controlled. The data measured during a process can be exported remotely via Ethernet, Profibus, or Modbus remote terminal unit (RTU), and can also be accessed locally with a USB flash drive.Note: Models without water jackets include the same features as the water-jacketed models shown here, but without the jacket and inlet/outlet ports. Optional load cells and cable management system are not shown. See the accessories section for more information about these items.HyPerforma S.U.M. design features and options 1. Powder hanger for 1 kg, 5 kg, and 25 kgThermo Scientific ™ Powdertainer ™ BioProcess Containers (BPCs)2. Mixing assembly with shield 3. Bearing port receiver with clamp 4. Mixer motor5. Shelves and basket (optional)6. Drive shaft, stored7. Liquid sight window8. Touchscreen Console9. Probe clip hangers 10. Probe access windows11. Cart assembly12. Standard tool set: 10 mm (3/8 in.) x 16.9 N-m(150 in.-lb.) square torque wrench; load cell and motor cap lockout wrench 13. 0.95 cm (3/8 in.) dimpled jacket 14. Stainless steel outer support container 15. Handles with cable management clips 16. Bottom cutouts/pins for BPC attachmentand alignment 17. Bleed valve (jacketed models only)18. 3.8 cm (1.5 in.) tri-clamp connection ports for waterinlet/outlet (jacketed models only)19. Casters (2 swiveling, 2 fixed)Front view Back view356891315101811912HyPerforma S.U.M. design specificationsHyPerforma S.U.M. DeltaV capability enhancement As an engineer-to-order product, the Thermo Scientific ™ HyPerforma ™ Single-Use Mixer (S.U.M.) with Touchscreen Console can be fully integrated with either Thermo Scientific ™ HyPerforma ™ G3 Bioprocess Controllers or controllers from other manufacturers—providing an open-architecture mixing solution configured to your uniquerequirements. The Touchscreen Console has the capability to integrate Thermo Scientific ™ TruBio ™ automation software powered by the DeltaV ™ Distributed Control Platform from Emerson, enabling users to optimize data acquisition while maintaining full compliance with 21 CFR Part 11.Top view217 cm (85.5 in.) Powdertainer BPC hanger height30 cm (11.8 in.)Electrical panel width57 cm (22.3 in.)Cart width92 cm (36.4 in.)Overall length58 cm (22.9 in.)Cart length43 cm (17.0 in.)Shelf width130 cm (51.1 in.)Overall width153 cm (60.2 in.) Motor height123 cm (48.4 in.) Tank height135 cm (53.1 in.) Touchscreen height 36 cm (14.1 in.) Tank bottom 19 cm (7.6 in.) Cart height 0 cm (0 in.)Front viewAccessoriesSensors and pinch valvesReusable pH and conductivity probes as well as single-use pressure sensors have been approved and qualified for use with the Touchscreen Console. pH and conductivity measurements can be used to control titration pumps, which enable automatic titration capabilities. Pressure sensors are used in the BPC or line sets to monitor the BPC or liquid pressure, respectively. The BPC can be filled with the proper amount of air when using the pressure sensor in the BPC. The liquid pressure module in the Touchscreen Console is used to control a transfer pump, based on the liquid pressure. Optional pneumatic pinch valves can be used on the fill and harvest lines. These valves automatically open and shut when using the fill and/or harvest modules in the Touchscreen Console.Ordering informationpH sensorThermo Fisher Scientific SV51147.02Mettler Toledo SV51147.01Broadley JamesSV51147.03Conductivity sensor JUMO SV51148.01Mettler Toledo SV51148.02Pressure sensor(single-use, included in BPC and/or fluid transfer assembly)PendoTECH 3/8 in. ID tubing SV20826.05PendoTECH 1/2 in. ID tubing SV20826.01Pinch valve, harvest line Thermo Fisher Scientific SV51108.08Pinch valve, fill line Thermo Fisher ScientificSV51108.05Probe clipsProbe clips are used to hold the probes in place on the S.U.M. tank. The independently movable probe clips hangon a thin brace above the probe port tank cutout.Heavy-duty tubing clampsHeavy-duty clamps are used to pinch off line sets that are not in use, to prevent process fluids from escaping. Prior to insertion of sterile probes, tubing clamps must be in place to close off probe ports.Load cellsLoad cells are typically radially mounted in sets of three. The mounting location varies slightly for each size in order to allow easy access to the bottom drain or spargingmechanisms and tubing.Ordering informationCat. No.Heavy-duty tubing clamp (single)SV20664.01Heavy-duty tubing clamp (10 pack)SV20664.04Ordering informationDescriptionCat. No.4 plastic probe clips SV50177P.01Cable management systemThe optional cable management system connects to the left side of the S.U.M. and is used to properly route tubing and cables along the side of the S.U.M.Powdertainer armA Powdertainer arm is available as an option forpowder-to-liquid applications. It holds the container of powder above the mixer and attaches it to the BPC with a clamp. The arm adjusts vertically and swivels to enable convenient lifting of the Powdertainer BPC onto the hanger.Powdertainer armPowdertainer hookPowdertainer-to-BPCport clampTank attachmentHandleProbeThreaded probe attachmentMoldedbellows cover Autoclave tray and probe assemblyThe autoclave tray holds the electrochemical probes and bellows in place during the autoclave sterilization process. Design elements include the following:• Fabricated from stainless steel• Plastic handle provides for easy transport right out of the autoclave• Positions probes on 15% incline for greater probe and membrane longevity• Prevents probe bellows from collapsing during sterilization• Probe holder accommodates two probesOrdering informationDescriptionCat. No.Autoclave tray (stainless steel with plastic carrying handle)SV50177.01Ordering informationDescriptionCat. No.Cable management system (50 L, 100 L)SV50992.01Ordering informationDescriptionCat. No.Powdertainer arm (50 L–1,000 L)SV51002.01Standard 100 L S.U.M. hardwareStandard 100 L S.U.M. hardware (cont.)Standard 100 L BPC for powder-to-liquid applications without probe portsEnd treatment1Addition line12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 122 cm (48 in.)Plugged 12.7 mm (1/2 in.) MPX insert 2Recirculation/sample line 12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 137 cm (54 in.) splits to 12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 61 cm (24 in.) and 12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 30 cm (12 in.)Capped 12.7 mm (1/2 in.) MPX insert Plugged 12.7 mm (1/2 in.) MPX body 3Powder addition port 76 mm (3 in.) sanitary fitting, tri-clampCap with gasket4Bottom drain12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 122 cm (48 in.)Capped 12.7 mm (1/2 in.) MPX bodyHyPerforma S.U.M. BPCsOpen-top or closed-top Thermo Scientific ™ BPC designs are available with Thermo Scientific ™ CX5-14 and Aegis ™ 5-14 film options.Back faceStandard 100 L BPC for liquid-to-liquid applications without probe portsDescriptionTubing set (inner diameter x outer diameter x length)End treatment1Bottom drain 12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 122 cm (48 in.) Capped 12.7 mm (1/2 in.) MPX body 2Fill line 12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 122 cm (48 in.) 38.1 mm (1 1/2 in.) tri-clamp (SterilEnz ™)3Vent filter 6.4 mm (1/4 in.) x 12.7 mm (1/2 in.) C-Flex x 10.2 cm (4 in.)Sterile hydrophobic vent filter (0.2 μm PVDF, Acro ™ 50)4Recirculation/sample line 12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 137 cm (54 in.) splits to 12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 61 cm (24 in.) and 12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 30 cm (12 in.)Capped 12.7 mm (1/2 in.) MPX insert Plugged 12.7 mm (1/2 in.) MPX body 5Addition line9.5 mm (3/8 in.) x 15.9 mm (3/4 in.) C-Flex x 61 cm (24 in.)Plugged 9.5 mm (3/8 in.) MPX insertFront faceStandard 100 L BPC for powder-to-liquid applications with probe portsTubing set (inner diameter x outer diameter x length)End treatment1Recirculation line 12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 137 cm (54 in.) splits to12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 61 cm (24 in.) and12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 30 cm (12 in.)Capped 12.7 mm (1/2 in.) MPX insertPlugged 12.7 mm (1/2 in.) MPX body2Addition line12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 122 cm (48 in.)Plugged 9.5 mm (3/8 in.) MPX insert3–4Probe ports (2)None Kleenpak™ aseptic connector KPCHT series (female)5Thermowell/small-volumesample lineThermowell adapter for 3.2 mm (1⁄8 in.) x6.4 mm (1/4 in.) C-Flex x 30 cm (12 in.)Luer and SmartSite™ valve port6Bottom drain12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 122 cm (48 in.)Capped 12.7 mm (1/2 in.) MPX body7Powderaddition port76 mm (3 in.) sanitary fitting, tri-clamp Cap with gasket Front faceBack faceBottom drainStandard open-top linerDescriptionCat. No.100 L standard open-top liner, 0 probes, CX3-9 film SH30762.06Standard impeller sleeveDescriptionCat. No.100 L impeller sleeve for open-top mixing*SH30749.14* The bearing hub needed for open-top mixing is automatically supplied with the tank hardware.Standard 100 L BPC for liquid-to-liquid applications with probe portsLine DescriptionTubing set (inner diameter x outer diameter x length)End treatment1–2Probe ports (2)NoneKleenpak aseptic connector KPCHT series (female)3Thermowell/ small-volume sample line Thermowell adapter for 3.2 mm (1⁄8 in.) x 6.4 cm (1⁄4 in.) C-Flex x 30 cm (12 in.)Luer and SmartSite valve port 4Recirculation line 12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 137 cm (54 in.) splits to 12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 61 cm (24 in.) and 12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 30 cm (12 in.)Capped 12.7 mm (1/2 in.) MPX insert Plugged 12.7 mm (1/2 in.) MPX body 5Fill line 12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 122 cm (48 in.)38.1 mm (1 1/2 in.) tri-clamp (SterilEnz)6Vent filter 6.4 mm (1⁄4 in.) x 12.7 mm (1⁄2 in.) C-Flex x 10.2 cm (4 in.)Sterile hydrophobic vent filter (0.2 μm PVDF, Acro 50)7Addition line 12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 122 cm (48 in.)Plugged 9.5 mm (3/8 in.) MPX insert 8Bottom drain12.7 mm (1/2 in.) x 19.1 mm (3/4 in.) C-Flex x 122 cm (48 in.)Capped 12.7 mm (1/2 in.) MPX bodyCustom BPC productsNote: Not all options are available for all ports. It is not possible to customize port type, port location, chamber dimensions, or mixing assembly.For additional information, please see the selection guides in the product catalog.11Find out more at /sumFor Research Use or Further Manufacturing. Not for diagnostic use or direct administration into humans or animals.© 2021 Thermo Fisher Scientific Inc. All rights reserved. All trademarks are the property of Thermo Fisher Scientific and its subsidiaries unless otherwise specified. Allen Bradley is a trademark of Allen-Bradley Company. Applisens is a trademark of Applikon B.V. Corporation. BioQuate is a trademark of General Electric Company. Broadley James is a trademark of Broadley-James Corporation. Clave is a trademark of ICU Medical, Inc. Colder Products Company and CPC are trademarks of Colder Products Company. DeltaV is a trademark of Emerson. Gore is a trademark of W. L. Gore & Associates. Kleenpak and Acro are trademarks of Pall Corporation. Lynx is a trademark of Merck KGaA. Mettler Toledo is a trademark of Mettler-Toledo AG. PreSense is a trademark of PreSens Precision Sensing GmbH. PharMed, PharmaPure, and C-Flex are trademarks of Saint-Gobain Performance Plastics Corporation. PendoTECH is a trademark of PendoTECH. SmartSite is a trademark of Carefusion 303, Inc. SterilEnz is a trademark of PAW BioScience Products, Inc. COL014582 0221Models without water jackets may have slightly different dimensions than the water-jacketed model shown in this data sheet. See the drawings provided with your unit for exact dimensions for non-jacketed models. Non-jacketed models do not have the capability to heat or cool the liquid inside the tank.12Ordering information Non-jacketed, DC motor, Touchscreen Console, with load cells SUM0100.9001Jacketed, DC motor, Touchscreen Console, with load cellsSUM0100.9002Standard powder-to-liquid BPC100 L 0CX5-14SH31046.01100 L 0Aegis 5-14SH31052.01Standard liquid-to-liquid BPC100 L 0CX5-14SH31046.03100 L 0Aegis 5-14SH31052.03Standard powder-to-liquid BPC *100 L3CX5-14SH31046.02100 L 3Aegis 5-14SH31052.02Standard liquid-to-liquid BPC *100 L 3CX5-14SH31046.04100 L3Aegis 5-14SH31052.04* All 100 L BPCs with probe ports are designed to allow probes to work properly at 5:1 turndown levels. These BPCs are only compatible with the HyPerforma hardware shown in this document. If you are using an older version of the S.U.M. hardware, do not use these items; instead refer to the legacy S.U.M. user manual or data sheets.。

基本信息中文名称:聚乙烯醇英文名称2:polyvinyl alcohol,viny)alcohol polymer,poval,简称PVACAS No.:9002-89-5分子式:[C2H4O]n[编辑本段]成分/组成信息有害物成分含量CAS No.聚乙烯醇9002-89-5[编辑本段]危险性概述健康危害:吸入、摄入或经皮肤吸收后对身体有害,对眼睛和皮肤有刺激作用。

燃爆危险:本品可燃,具刺激性。

第四部分:急救措施皮肤接触:脱去污染的衣着,用流动清水冲洗。

眼睛接触:提起眼睑,用流动清水或生理盐水冲洗。

就医。

吸入:脱离现场至空气新鲜处。

如呼吸困难,给输氧。

就医。

食入:饮足量温水,催吐。

就医。

[编辑本段]消防措施危险特性:粉体与空气可形成爆炸性混合物, 当达到一定浓度时, 遇火星会发生爆炸。

加热分解产生易燃气体。

有害燃烧产物:一氧化碳、二氧化碳。

灭火方法:消防人员须佩戴防毒面具、穿全身消防服,在上风向灭火。

灭火剂:雾状水、泡沫、干粉、二氧化碳、砂土。

[编辑本段]泄漏应急处理应急处理:隔离泄漏污染区,限制出入。

切断火源。

建议应急处理人员戴防尘面具(全面罩),穿防毒服。

避免扬尘,小心扫起,置于袋中转移至安全场所。

也可以用大量水冲洗,洗水稀释后放入废水系统。

若大量泄漏,用塑料布、帆布覆盖。

收集回收或运至废物处理场所处置。

[编辑本段]操作处置与储存操作注意事项:密闭操作。

密闭操作,提供良好的自然通风条件。

操作人员必须经过专门培训,严格遵守操作规程。

建议操作人员佩戴自吸过滤式防尘口罩,戴化学安全防护眼镜,穿防毒物渗透工作服,戴橡胶手套。

远离火种、热源,工作场所严禁吸烟。

使用防爆型的通风系统和设备。

避免产生粉尘。

避免与氧化剂接触。

搬运时要轻装轻卸,防止包装及容器损坏。

配备相应品种和数量的消防器材及泄漏应急处理设备。

倒空的容器可能残留有害物。

储存注意事项:储存于阴凉、通风的库房。

远离火种、热源。

应与氧化剂分开存放,切忌混储。

中国·海达Plastic Machinery Parameter塑料注射成型机参数表HDJS Servo Series /伺服系列HDX General Series /通用系列宁波市海达塑料机械有限公司NINGBO HAIDA PLASTIC MACHINERY CO.,LTD.DESIGN BY IDEA 2014.3 0574-********地址:宁波市镇海区俞范东路77号(石塘下) 邮编(P.C):315200Add:(Shitangxia) 77 Yufan East Road, Zhenhai, Ningbo, China 电话 (TEL):0086-574-86370758 86379155传真 (FAX):0086-574-86373405Http://E-mail:***************宁波市海达塑料机械有限公司是专业制造HDX、HDJS、HDJL系列全自动塑料注射成型机的生产厂家,系中国塑料机械工业协会副会长单位,宁波塑料机械协会副会长单位,公司在行业内享有较高的知名度。

历年来,公司已陆续获得国家火炬重点高新技术企业、国家免检产品、中国驰名商标、浙江省著名商标、浙江省名牌产品、浙江省知名商号等国家、省级荣誉。

公司于2000年获批自行进出口权,目前已在世界上十几个国家和地区办理商标注册。

自2001年以来已通过ISO9001质量认证和CE认证,2007年又分别通过ISO14001环境体系和OHSAS18001职业健康与安全认证。

公司于1992年创建以来,受到社会各界的大力支持,新老客户的惠顾认可,以及公司全体员工的共同努力,企业稳健良性发展,成为塑机行业中的后起之秀。

历年来累计投入近3.5亿元,目前公司占地面积10余万平方米,建筑面积5.5万平方米,并购置了一大批高精度加工设备,使公司的产品质量和生产能力大幅提高,同时建立省级工程研发中心,为创建海达著名品牌奠定了扎实的基础。

关于水乙二醇液压系统问:液压系统介质为水乙二醇需要注意什么?由于需要,一液压系统介质需用水乙二醇,请问元件选型等设计需要注意什么?和液压油有什么区别?答:密封不能用脂类密封,只能用橡胶的还有就是注意下泵,能不能泵水乙二醇其他的跟液压油区别不大问:液压系统使用水乙二醇的利弊?答:防火.抗爆炸.对密封件和电磁阀的要求较高.对环境污染小答:液压原件使用寿命缩短20%~50%,关键件是专用的,比如液压柱塞泵就是特殊的,泵内的零件也是专用的,泵的轴承是水基轴承.答:同时柱塞泵的最高使用压力将大大降低,一般重载泵压力不超过25MPa。

答:4楼的“液压青年”,柱塞泵是不可以用水乙二醇等乳化液的,这种水乙二醇水乳液多用于压力较低的场合,或用于压力的间接传递。

现在用于高压的水乙二醇液压泵等系统应该说在世界上还没有成熟的产品。

答:优点:防火.抗爆炸.缺点:对系统抗腐蚀能力要求高,对密封要求高,系统精度保证难度大!价格高!答:使用水乙二醇的系统,一般用于炼钢、高炉等高温、高火情的设备,防止由于系统泄露的介质造成大面积的火灾。

但是由于介质的化学性能,首先限制了液压元件的密封材料,需要采用成本比较昂贵的氟橡胶的材料。

其次是由于黏度的问题限制液压元件的结构形式。

另外介质本身需要投入比较多的时间去检验、维护;因为其中的成分随着水分的挥发会产生变化。

润滑性能比较差,使得元件性能、寿命都受到极大影响,所有这些都造成系统运行成本的上升。

答:油缸密封件应该用氟橡胶了,价格贵了问:水乙二醇液压系统最近在设计一个水乙二醇液压系统,我们知道这样的介质对密封件的影响不是太大,对轴承的材质影响到是很大的答:水乙二醇对系统要求好像比磷酸酯类宽泛一点,相对普通液压油好像也没有什么特殊的要求吧!希望有高手指导!答:我们有用水乙二醇的液压系统,我觉得主要考虑到系统由于介质黏度低、润滑性不好带来的问题。

水乙二醇系统的液压元件的损坏率很高的。

而且密封也容易老化,但不是主要问题,其中系统的清洁比矿物油为介质的系统要求更高些。