折叠纸盒包装结构大全英文_1

- 格式:pdf

- 大小:2.19 MB

- 文档页数:54

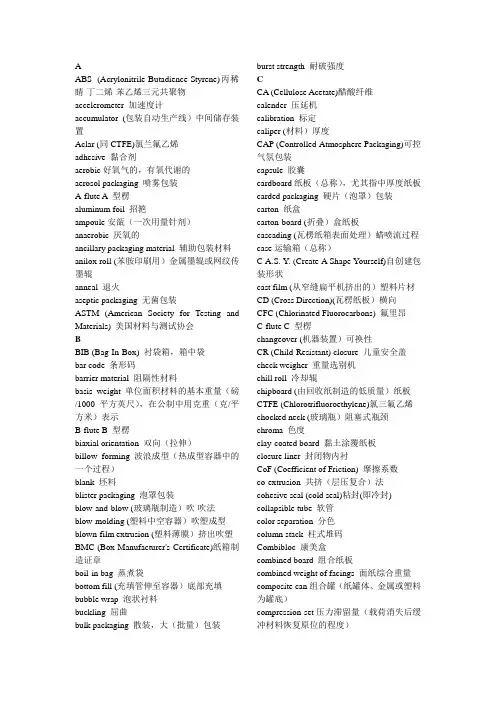

AABS (Acrylonitrile-Butadience-Styrene)丙稀睛-丁二烯-苯乙烯三元共聚物accelerometer 加速度计accumulator (包装自动生产线)中间储存装置Aclar (同CTFE)氯兰氟乙烯adhesive 黏合剂aerobic好氧气的,有氧代谢的aerosol packaging 喷雾包装A-flute A 型楞aluminum foil 招筢ampoule安瓿(一次用量针剂)anaerobic 厌氧的ancillary packaging material 辅助包装材料anilox roll (苯胺印刷用)金属墨辊或网纹传墨辊anneal 退火aseptic packaging 无菌包装ASTM (American Society for Testing and Materials) 美国材料与测试协会BBIB (Bag-In-Box) 衬袋箱,箱中袋bar code 条形码barrier material 阻隔性材料basis weight单位面积材料的基本重量(磅/1000平方英尺),在公制中用克重(克/平方米)表示B-flute B 型楞biaxial orientation 双向(拉伸)billow forming波浪成型(热成型容器中的一个过程)blank 坯料blister packaging 泡罩包装blow-and-blow (玻璃瓶制造)吹-吹法blow-molding (塑料中空容器)吹塑成型blown-film extrusion (塑料薄膜)挤出吹塑BMC (Box Manufacturer's Certificate)纸箱制造证章boil-in bag 蒸煮袋bottom fill (充填管伸至容器)底部充填bubble wrap 泡状衬料buckling 屈曲bulk packaging 散装,大(批量)包装burst strength 耐破强度CCA (Cellulose Acetate)醋酸纤维calender 压延机calibration 标定caliper (材料)厚度CAP (Controlled Atmosphere Packaging)可控气氛包装capsule 胶囊cardboard纸板(总称),尤其指中厚度纸板carded packaging 硬片(泡罩)包装carton 纸盒carton-board (折叠)盒纸板cascading (瓦楞纸箱表面处理)蜡喷流过程case运输箱(总称)C A.S. Y. (Create A Shape Yourself)自创建包装形状cast film (从窄缝扁平机挤出的)塑料片材CD (Cross Direction)(瓦楞纸板)横向CFC (Chlorinated Fluorocarbons) 氟里昂C-flute C 型楞changeover (机器装置)可换性CR (Child-Resistant) closure 儿童安全盖check weigher 重量选别机chill roll 冷却辊chipboard (由回收纸制造的低质量)纸板CTFE (Chlorotrifluoroethylene)氯三氟乙烯chocked neck (玻璃瓶)阻塞式瓶颈chroma 色度clay-coated board 黏土涂覆纸板closure liner 封闭物内衬CoF (Coefficient of Friction) 摩擦系数co-extrusion 共挤(层压复合)法cohesive seal (cold seal)粘封(即冷封) collapsible tube 软管color separation 分色column stack 柱式堆码Combibloc 康美盒combined board 组合纸板combined weight of facings 面纸综合重量composite can组合罐(纸罐体、金属或塑料为罐底)compression set压力滞留量(载荷消失后缓冲材料恢复原位的程度)compression strength 抗压强度conditioning (包装材料)的恒温恒湿试验条件(装置)constant-level filling等液位灌装法constant-volume filling 定容积充填法consumer package 销售包装(件)Container board 瓦楞纸板CT (continuous thread)连续(玻璃瓶口或盖的)螺纹线converter (将原材料制成包装用材料或容器)制造商copolymer 共聚物cork 软木塞corona treatment (改善塑料表面印刷适性的)电晕处理corrugated board 瓦榜纸板crate 板条箱,花格箱crease (瓦楞纸箱生产中的)折痕creep (cold flow)蠕变critical G 临界脆值crown closure 王冠盖cullet 碎玻璃curtain coating 幕(帘)式淋涂coefficient of restitution (缓冲材料)回弹性corrugating medium 瓦楞原纸corr ugator 瓦楞板轧制机cushioning material 缓冲(衬塾)材料cylinder board 圆网纸机生产的纸板cylinder machine 圆网纸机Ddead fold折叠充分deflection 变形demographics 人口统计学design brief设计大纲die-cut 模切distribution packaging 运输包装doctor blade 刮刀doublewall board 五层瓦楞板double seam (金属罐)二重卷缝draw-and-iron can 变薄拉深(两片)罐draw-and-red raw can 深冲拉拔(两片)耀drop height 跌落高度drum 圆桶dry-bond laminating 干法(层压)复合dynamic compression 动态压力dunnage (在回收再用包装容器内不作为缓冲垫的)填充物、衬板(如填补空隙、定位、隔开等)EECT (Edge Crush Test)边压测试E-flute E 型楞ergonomic 人机工程学equity产权,信誉,知名度E.R H. (Equilibrium Relative Humidity)平衡相对湿度essential oil感官活性剂(通过嗅觉可探测出的挥发性物质)EEA (EthyleneEthyl Acrylic acid)乙烯乙基丙烯酸盐EPE (Expanded Polyethylene)发泡聚乙烯EPS (Expanded Polystyrene)发泡聚苯乙烯EVA (EthyleneVinyl Acetate)乙烯-乙烯基醋酸盐EVAL (同EVOH)乙烯-乙烯醇EVOH (EthyleneVinyl alcohol)(同EV AL)乙烯-乙烯醇excelsior 细刨花,木丝export package 出口包装exterior package 外包装extruder 挤出机extrusion bonding 挤出點合extrusion coating 挤出涂覆extrusion blow molding (塑料中空容器)挤出吹塑成型eye-mark 定位标记Ffacing (face liner) 面纸fiberboard组合纸板(瓦楞或硬纸板)的总称FFS (form-fill-seal) machine 成型-充填-封口机fin seal (扉)边封finish 瓶口flap (瓦楞纸像)封舌flask filling容积法充填flexible packaging 软包装flexography柔性印刷flute (corrugation) 瓦楞状foam-in-place 现场发泡foil 箔folding carton 折叠式纸盒Fourdrinier machine 长网纸机fragility (产品的)脆值,易碎性free-flowing powder 自由流动粉料friction-fit pry-off closure 摩擦封口/翘开盖furnish纸浆配料Ggable-top carton 屋顶型盒gas permeability 透气性gauge材料厚度的计量单位:100gauge= 0.001 in.glassine paper 防油纸gob 一定量的熔化玻璃grammage (材料)克重gravure printing (rotogravure) 四版印刷Hheadspace 预留容量heat seal 热封heat-shrink property 热收缩特性heat-transfer printing 热传递印刷法HFFS (horizontal form-fill-seal)卧式成型-充填-封口HDPE (high-density polyethylene)高密度聚乙稀hot-melt adhesive 热融黏合剂hot-stamp (foil stamp) printing 烫印HRI (hospital-restaurant-institutional)医院-饭店-服务行业(需求大包装的领域)hue 色彩hygroscopic material 吸湿性材料Iimpact strength 抗冲击强度impulse sealing 脉冲封口incineration (包装废弃物处理方法)焚化incline impact test 斜面冲击测试injection blow molding (塑料中空容器)注射吹塑成型injection molding (塑料中空容器)注射成型injection stretch blow molding (塑料中空容器)注射延伸吹塑成型ink 油墨in-line 直列式inner/interior package 内包装intermittent-motion machine 间歇运动机械intermediate package 中包装(二次包装)internal overhang 载荷(在托盘)内在悬空IoPP (Institute of Packaging Professionals) 包装专业人员协会ISO (International Organization for Standardization)国际标准化组织ISTA (International Safe Transit Association) 国际安全运输协会Item 222美国国家公路货物运输规定(NMFC)中的一项条款。

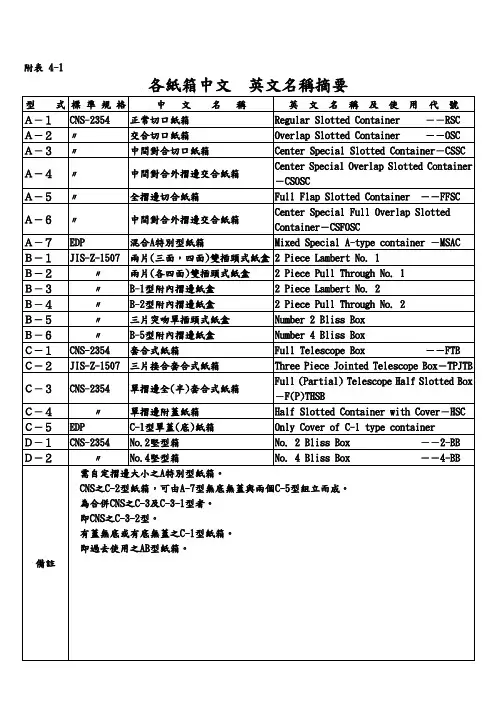

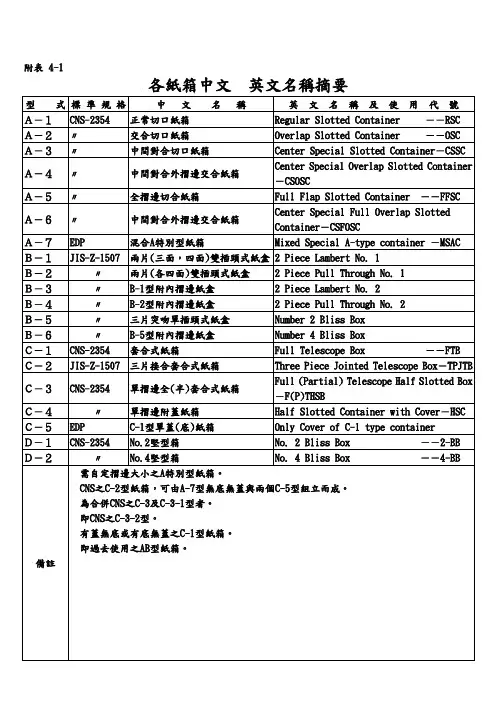

附表 4-1各紙箱中文英文名稱摘要型式標準規格中文名稱英文名稱及使用代號A-1CNS-2354 正常切口紙箱Regular Slotted Container --RSC A-2〃交合切口紙箱Overlap Slotted Container --OSC A-3〃中間對合切口紙箱Center Special Slotted Container-CSSCA-4〃中間對合外摺邊交合紙箱Center Special Overlap Slotted Container -CSOSCA-5〃全摺邊切合紙箱Full Flap Slotted Container --FFSCA-6〃中間對合外摺邊交合紙箱Center Special Full Overlap Slotted Container-CSFOSCA-7 EDP 混合A特別型紙箱Mixed Special A-type container -MSACB-1JIS-Z-1507 兩片(三面,四面)雙插頭式紙盒 2 Piece Lambert No. 1B-2〃兩片(各四面)雙插頭式紙盒 2 Piece Pull Through No. 1B-3〃B-1型附內摺邊紙盒 2 Piece Lambert No. 2B-4〃B-2型附內摺邊紙盒 2 Piece Pull Through No. 2B-5〃三片突吻單插頭式紙盒Number 2 Bliss BoxB-6〃B-5型附內摺邊紙盒Number 4 Bliss BoxC-1CNS-2354 套合式紙箱Full Telescope Box --FTBC-2 JIS-Z-1507 三片接合套合式紙箱Three Piece Jointed Telescope Box-TPJTBC-3 CNS-2354 單摺邊全(半)套合式紙箱Full (Partial) Telescope Half Slotted Box -F(P)THSBC-4〃單摺邊附蓋紙箱Half Slotted Container with Cover-HSC C-5 EDP C-1型單蓋(底)紙箱Only Cover of C-1 type containerD-1 CNS-2354 No.2堅型箱No. 2 Bliss Box --2-BB D-2〃No.4堅型箱No. 4 Bliss Box --4-BB備註需自定摺邊大小之A特別型紙箱。

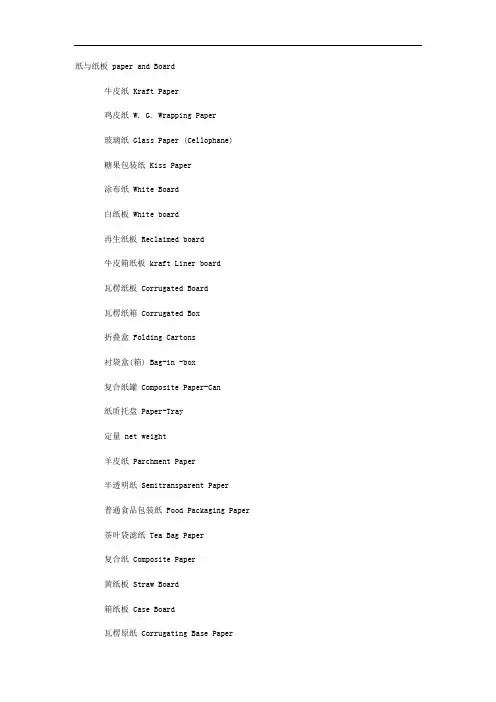

纸与纸板 paper and Board牛皮纸 Kraft Paper鸡皮纸 W. G. Wrapping Paper玻璃纸 Glass Paper (Cellophane)糖果包装纸 Kiss Paper涂布纸 White Board白纸板 White board再生纸板 Reclaimed board牛皮箱纸板 kraft Liner board瓦楞纸板 Corrugated Board瓦楞纸箱 Corrugated Box折叠盒 Folding Cartons衬袋盒(箱) Bag-in -box复合纸罐 Composite Paper-Can纸质托盘 Paper-Tray定量 net weight羊皮纸 Parchment Paper半透明纸 Semitransparent Paper普通食品包装纸 Food Packaging Paper茶叶袋滤纸 Tea Bag Paper复合纸 Composite Paper黄纸板 Straw Board箱纸板 Case Board瓦楞原纸 Corrugating Base Paper包装纸箱 Packaging Box纸盒 Paper Box固定盒 Set-up Box纸浆模制品 Pulp Mould复合纸杯 Composite Paper -Cup纸袋 Paper Bag塑料包装材料 Plastic Packaging Materials热塑性塑料 Thermo Plastic塑料树脂 Plastic Resin聚乙烯 Polyethylene高密度聚乙烯 High Density Polyethylene聚丙烯 Polypropylene聚氯乙烯 Polyvinyl Chloride聚酯 Polyethylene Terephthlate聚酰胺 Polyamide乙烯-乙烯醇共聚物 Ethylene-Vinyl Alcohol Copoyhner 离子型聚合物 Ionomer聚氨脂 Polyurethane环境可降解塑料 Environmental lysis film塑料薄膜 Plastic Film热收缩薄膜 Shrink Film复合薄膜 Compsite Fism蒸煮袋 Retortable Pouch生物降薄膜 Biolysis Film塑料瓶 Plastic Bottle热固性塑料 Thermoset Plastic低密度聚乙烯 Low Density Polyethylene线型低密度聚乙烯 Linear Low density Polyethylene聚苯乙烯 Polystyrene聚偏二氯乙烯 Poly vinylidene Chlorie (saran)聚碳酸酯 Polycarbonate聚乙烯醇 Polyvinyl Alcshol乙烯-醋酸乙烯共聚物 Ethylene Vinylacetate聚四氟乙烯(PTFE) Polyterafluoroethylene定向拉伸薄膜 Stretched Film弹性薄膜 Elastic Film塑料薄膜袋 Plastic film Bag可食薄膜 Edible Film光降解膜 Light ?lysis Film塑料桶 Plastic Drum塑料保温箱 Plastic Foam Box热成型容器 thermo Form Containers助剂(添加剂) Additives增塑剂 Plasticizers稳定剂 Stabilizers填充剂 Fillers着色剂 Colorants金属包装材料和容器 Metal Packaging Material and Containers镀锡薄钢板 Tinplate镀锌薄钢板 Enplate铝合金薄板 Aluminium Alloy Plate 铝箔 Aluminium Foil金属罐 Metal Can两片罐 Two-piece Can圆罐 Round Can方罐 Rectagular Can梯形罐 trapezoidal Can浅冲罐 Drawn Can钙塑瓦楞箱 Calp Box塑料片材 Plastic sheet毒性 Toxicity安全性 Safety透气性 Gas Permeability透湿性 Water Vapor Permeability 渗透性 Permeability镀铬薄钢板 Tin-free ?Steel-or TFS 低碳薄钢板 Low Carbon Steel真空镀铝膜 Al metallizing Fool三片罐 Three ?piece Can组合罐 Composite Can异形罐 Irregular Can椭圆罐 Oval Can缩颈罐 Necked-in Can深冲罐 deep Drawn Can变薄拉伸罐 Crawn and Ironed Can焊缝罐 Resistance Welding Can易开罐 Easy Open Can铝质罐 aluminum Can涂料罐 Lacquered Tin Plate Can罐盖 End (or Lid or Cover)全开盖 Full Open Can金属软管 Metal Collapsible Tube玻璃容器 Glass Containers瓶罐 Container轻量瓶 Light weight Container软饮料瓶 Sofe drink bottle陶瓷电装容器 Pottery and Porcelain Packaging Containers 包装辅助材料 ancillary Packaging Materials粘合剂 Adhesive聚醋酸乙烯 Poly vinyl Acetate水溶型粘合剂 Water-soluble Adhesive溶剂型粘合剂 Solvent Adhesive压敏型粘合剂 Pressure-sensitive Adhesive锡焊罐 Soldered Can粘接罐 Cono-weld Can卷开罐 Key Open Can索铁罐 Plain Tinplate Can顶开罐 Open Top Can易开盖 Easy Open End金属大桶 Metal Drum钠钙硅玻璃 Sode-lime-silica Glass小口瓶 Bottle啤酒瓶 Beer Bottle白酒瓶 White Spirit Bottle乳液型粘合剂 Emulsion Adhesive热熔型粘合剂 Hotmelt Adhesive胶乳 Latex淀粉粘合剂 Starch Adhesive阿拉伯树胶 Acacia Gum皮胶 Hide glue涂料 Coating Material酚醛树胶(PF) phenol ?formaldehyde Resin 丙烯酸树脂 Acrylics环氧树脂(EP) Epoxide Resin防雾滴涂料 Antidimming Paint桐油 Tung Oil封缄材料 Closure Material胶带 gummed Tape流体密封胶 Fluid Seal-gum糊精 Dextrin骨胶 bone glue干酪素 Casein天然树脂 Natural Resin氨基树脂 Amino Resin防腐涂料 Anticorrosive Paint防静电涂料 Anti-static Paint石蜡 Paraffin捆扎材料 Strapping Material压敏胶带 Pressure-sensitive Tape。

Packaging Box Common Packaging Materials and Methods (InternationalEnglish Resources)1. Packaging Materialsa. Corrugated cardboard: This material is widely used for its durability and excellent protective properties. Corrugated cardboard is made of multiple layers of paper witha fluted inner layer, providing strength and rigidity.b. Rigid cardboard: Also known as solid cardboard, this material is often used for luxury packaging due to its highquality appearance and strong protection. Rigid cardboard is suitable for products that require a sturdy and elegant presentation.d. Kraft paper: Known for its natural brown color, kraft paper is biodegradable and ecofriendly. It is often used for wrapping products or as an additional layer of protection inside the packaging box.e. Bubble wrap: Bubble wrap is an excellent choice for protecting fragile items during transportation. Its aircushioned bubbles provide shock absorption and prevent damage.2. Packaging Methodsa. Tuckend boxes: This popular method involves folding the flaps of the box into each other, creating a secure closure. Tuckend boxes are easy to assemble and are suitable for a wide range of products.b. Clamshell packaging: Clamshell packaging consists of a hinged, clear plastic blister that encases the product. It provides excellent visibility and protection, making it ideal for retail display.c. Slide boxes: Slide boxes, also known as drawer boxes, feature a base and lid that slide into each other. They are often used for premium products, offering a sophisticated and elegant presentation.d. Window boxes: Window boxes have a transparent plastic or acetate window that allows the product to be visible from the outside. This method is effective for showcasing the product and increasing customer appeal.3. Sustainability ConsiderationsAs environmental concerns grow, the importance of sustainable packaging cannot be overstated. Here are some considerations for ecofriendly packaging:a. Recycled materials: Opt for packaging materials made from recycled content. This reduces the demand for virgin materials and helps to close the loop in the recycling process.d. Ink and printing: Use waterbased inks and ensure that the printing process is ecofriendly. Avoid heavy metalbased inks and opt for minimalistic designs to reduce environmental impact.4. International Shipping Considerationsa. Custom regulations: Be aware of the customs regulations in the destination country. Some materials may be restricted or require special documentation.b. Language requirements: Include multilingual packaging information to cater to various markets. Ensure that important details are translated accurately.c. Transport durability: Packages must withstand longer travel times and varying conditions. Reinforced corners, additional cushioning, and stronger sealing methods may be necessary.5. User ExperienceThe packaging experience is an extension of the product itself. Here are some usercentric considerations:a. Easy opening: Design packaging that is easy to open without the need for sharp tools. This can include tear strips, perforations, or innovative opening mechanisms.b. Reusability: Consider packaging that can be repurposed or reused the consumer. This adds value and can enhance brand loyalty.c. Instructions and information: Clear instructions and product information should be included on the packaging. This can range from usage guides to care instructions and warranty details.d. Aesthetics: The visual appeal of packaging is crucial.A welldesigned box can make a strong first impression and convey the quality of the product inside.In wrapping up, the world of packaging is both diverse and dynamic, with endless possibilities to protect, promote, and please. By staying informed about the latest materials and methods, businesses can make informed decisions that not only safeguard their products but also align with their values and cater to the expectations of a global market.6. Advanced Packaging TechnologiesAs technology advances, so do the options for packaging. Here are some cuttingedge technologies that are shaping the future of packaging:a. Smart packaging: Incorporating sensors or indicators into packaging can provide realtime information about the product's condition, such as temperature, humidity, or tampering. This is particularly useful for perishable goods or pharmaceuticals.b. Active packaging: This type of packaging can interact with its contents to extend shelf life or improve safety.Examples include moisture absorbers, oxygen scavengers, and ethylene absorbers for produce.c. Digital printing: Digital printing technologies allow for more flexible and personalized packaging. Variable data printing can be used to customize packaging with unique s, images, or text, enhancing the consumer experience.d. RFID technology: RadioFrequency Identification (RFID) tags can be embedded in packaging to track and trace products throughout the supply chain. This improves inventory management and security.7. Cultural Sensitivity in PackagingWhen packaging for international markets, it's essential to consider cultural nuances:a. Color symbolism: Colors can have different meanings in various cultures. For instance, white symbolizes purity in Western cultures but is associated with mourning in many Asian cultures.b. Imagery and symbols: Be mindful of the imagery and symbols used on packaging. What is considered appealing or neutral in one culture may be offensive or inappropriate in another.c. Language localization: Translating is not enough; localization involves adapting the message to resonate withthe local culture. This includes idiomatic expressions and cultural references.d. Legal requirements: Different countries have specific legal requirements for packaging, such as ingredient listings, allergy warnings, and recycling symbols. Compliance iscrucial to avoid legal issues.8. Future TrendsKeeping an eye on emerging trends can help businessesstay ahead of the curve:a. Minimalism: Consumers are increasingly favoring minimalist packaging designs that focus on simplicity and functionality, reducing material use and emphasizing the product itself.c. Interactive packaging: Packaging that engages the consumer, such as games, puzzles, or augmented reality (AR) experiences, can create a memorable unboxing experience and build brand loyalty.d. Plantbased materials: Innovations in plantbased materials, such as bamboo, sugarcane, and seaweed, areoffering sustainable alternatives to traditional packaging materials.In conclusion, the landscape of international packagingis continually evolving, driven technological advancements, environmental concerns, and cultural diversity. By embracingthese changes and incorporating them into their packaging strategies, businesses can not only protect their products but also build stronger connections with their global customers.。

附表 4-1各紙箱中文英文名稱摘要型式標準規格中文名稱英文名稱及使用代號A-1CNS-2354 正常切口紙箱Regular Slotted Container --RSC A-2〃交合切口紙箱Overlap Slotted Container --OSC A-3〃中間對合切口紙箱Center Special Slotted Container-CSSCA-4〃中間對合外摺邊交合紙箱Center Special Overlap Slotted Container -CSOSCA-5〃全摺邊切合紙箱Full Flap Slotted Container --FFSCA-6〃中間對合外摺邊交合紙箱Center Special Full Overlap Slotted Container-CSFOSCA-7 EDP 混合A特別型紙箱Mixed Special A-type container -MSACB-1JIS-Z-1507 兩片(三面,四面)雙插頭式紙盒 2 Piece Lambert No. 1B-2〃兩片(各四面)雙插頭式紙盒 2 Piece Pull Through No. 1B-3〃B-1型附內摺邊紙盒 2 Piece Lambert No. 2B-4〃B-2型附內摺邊紙盒 2 Piece Pull Through No. 2B-5〃三片突吻單插頭式紙盒Number 2 Bliss BoxB-6〃B-5型附內摺邊紙盒Number 4 Bliss BoxC-1CNS-2354 套合式紙箱Full Telescope Box --FTBC-2 JIS-Z-1507 三片接合套合式紙箱Three Piece Jointed Telescope Box-TPJTBC-3 CNS-2354 單摺邊全(半)套合式紙箱Full (Partial) Telescope Half Slotted Box -F(P)THSBC-4〃單摺邊附蓋紙箱Half Slotted Container with Cover-HSC C-5 EDP C-1型單蓋(底)紙箱Only Cover of C-1 type containerD-1 CNS-2354 No.2堅型箱No. 2 Bliss Box --2-BB D-2〃No.4堅型箱No. 4 Bliss Box --4-BB備註需自定摺邊大小之A特別型紙箱。

All about carton 纸箱by Patrick Lee 2006 1. Corrugated board瓦楞纸:Corrugating medium 瓦楞Flutes 瓦楞的形状/大小Liner 裱纸F Flute is 1/32” thick, (1.2mm), 128 flutes per footE Flute is 1/16" thick, (1.5mm), 94 flutes per footC Flute is 3/32" thick, (4mm), 40 flutes per footB Flute is 1/8" thick, (3mm), 50 flutes per footA Flute is 1/4" thick, (5mm), 34 flutes per footSingle face corrugated board 一层瓦楞一层纸Single wall corrugated 单楞双纸 (单坑, 三层)Double wall双楞三纸 (双坑, 五层)Triple wall三楞四纸, (三坑, 七层)2. 其他有关用词:Carton box箱,Corrugated paper board瓦楞纸Cardboard tube 纸筒/芯 (卷布)Postal tube 纸筒 (放画稿)BDC=Bulk Distribution Carton (外运纸箱)BDCM= Bulk Distribution Carton Metric (公制尺寸)Corrugated cardboard cap/lid and tray 天地盖Board 纸板:Cardboard 纸板Ivory/white board白卡纸,Duplex board灰底白板,Triplex board白底白板纸Kraft Liner Board 牛皮纸Pads垫板, 放在箱底和面的纸板, 以防开箱时割破衣物或放中间以分开不同款式Tube方形纸筒, 用作充填空间Partition方筒或井字形, 用来分装小件物品Box Dimensions 纸箱量法:3. BOX CONTAINER STYLES 纸箱形状Regular Slotted Container (RSC) 这是最标准的外运纸箱其他一些不同的纸箱,供参考:Half Slotted Container (HSC)Overlap Slotted Container (OSC)Full Overlap Slotted Container (FOL)Center Special Slotted Container (CSSC)Center Special Overlap Slotted Container (CSO) Center Special Full Overlap Slotted Container (SFF)Snap or 1-2-3 Bottom Container with Tuck Top Snap or 1-2-3 Bottom Containers with RSC Top Full Bottom File BoxFull Telescope Half Slotted Box (FTHS) Test: 常见强度测试:Edge Crush Test (ECT) 边压试验Bursting Test (Mullen test) 破裂试验 (缪伦法)。

包装种类(m³)包装量Packing Unit裸装Nude箱Case纸箱Carton瓦椤纸箱Corrugated Carton旧瓦椤纸箱Old Corrugated Carton (O.C.C.)木箱Wooden Case板条箱Crate木条箱Wooden Crate竹条箱Bamboo Crate胶合板箱Plywood Case三层夹板箱3--Ply Plywood Case镀锡铁皮胎木箱Tin Lined Wooden Case盒Box木盒Wooden Box铁盒Iron Box塑料透明盒Plastic Transparency Box苯乙烯盒Styrol Box袋Bag(Sack)布袋Cloth Bag草袋Straw Bag麻袋Gunny Bag/Jute Bag旧麻袋Used Gunny Bag/Old Gunny Bag新麻袋New Gunny Bag尼龙袋Nylon Bag聚丙烯袋Polypropylene Bag聚乙烯袋Polythene Bag塑料袋Poly Bag塑料编织袋Polywoven Bag纤维袋Fibre Bag玻璃纤维袋Glass Fibre Bag玻璃纸袋Callophane Bag防潮纸袋Moisture Proof Pager Bag乳胶袋子Emulsion Bag三层牛皮纸袋3?ply Kraft Paper Bag锡箔袋Fresco Bag特大袋Jumbo Bag单层完整袋子Single Sound Bag桶Drum木桶Wooden Cask大木桶Hogshead小木桶Keg粗腰桶(琵琶桶) Barrel胶木桶Bakelite Drum塑料桶Plastic Drum铁桶Iron Drum镀锌铁桶Galvanized Iron Drum镀锌闭口钢桶Galvanized Mouth Closed Steel Drum 镀锌开口钢桶Galvanized Mouth Opened Steel Drum 铝桶Aluminum Drum麻布包Gunny Bale (Hessian Cloth Bag)蒲包Mat Bale草包Straw Bale紧压包Press Packed Bale铝箔包Aluminium Foil Package铁机包Hard-pressed Bale木机包Half-pressed Bale覃(缸)Jar陶缸Earthen Jar瓷缸Porcelain Jar壶Pot铅壶Lead Pot铜壶Copper Pot施Bottle铝瓶Aluminum Bottle陶瓶Earthen Bottle瓷瓶Porcelain bottle罐Can听Tin绕线筒Bobbin笼(篓、篮、筐)Basket竹笼(篓、篮、筐)Bamboo Basket柳条筐(笼、篮、筐)Wicker Basket集装箱Container集装包/集装袋Flexible Container拖盘Pallet包装单位件(支、把、个)Piece架(台、套)Set(Kit)安瓿Amp(o)ule(药针支)双Pair打Dozen令Ream匹Bolt(Piece)码Yard卷(Roll(reel)块Block捆Bundle瓣Braid度Degree辆Unit(Cart)套(罩)Casing包装形状Shapes of Packing 圆形Round方形Square三角形Triangular(Delta Type)长方形(矩形) Rectangular菱形(斜方形) Rhombus(Diamond)椭圆形Oval圆锥形Conical圆柱形Cylindrical蛋形Egg-Shaped葫芦形Pear-Shaped五边形Pentagon六边形Hexagon七边形Heptagon八边形Octagon长Long宽Wide高High深Deep厚Thick长度Length宽度Width高度Height深度Depth厚度Thickness 包装外表标志Marks On Packing下端,底部Bottom 顶部(上部) Top(Upper)小心Care 勿掷Don’t Cast易碎Fragile 小心轻放,小心装运Handle With Care起吊点(此处起吊) Heave Here 易燃物,避火Inflammable保持干燥,防泾Keep Dry 防潮keep Away from Moisture储存阴冷处Keep in a Cool Place 储存干燥处Keep in a Dry Place请勿倒置Keep Upright 请勿倾倒Not to Be Tipped避冷To be Protected from Cold 避热To be Protected from Heat在滚子上移动Use Rollers 此方向上This Side Up由此开启Open from This Side 爆炸品Explosive易燃品Inflammable 遇水燃烧品Dangerous When Wet有毒品Poison 无毒品No Poison不可触摩Hand off 适合海运包装Seaworthy Packing毛重Gross Weight (Gr.Wt.) 净重Net Weight (Nt.Wt)皮重Tare Weight 包装唛头Packing Mark包装容积Packing Capacity 包袋件数Packing Number小心玻璃Glass 易碎物品Fragile易腐货物Perishable 液体货物Liquid切勿受潮Keep Dry/Caution Against Wet 怕冷To Be Protected from Cold 怕热To Be Protected from Heat 怕火Inflammable上部,向上Top 此端向上This Side Up勿用手钩Use No Hooks 切勿投掷No Dumping切勿倒置Keep Upright 切勿倾倒No Turning Over。

Details of FEFCO Codes

This Code has been developed by FEFCO and ASSCO as an official system to substitute long and complicated verbal descriptions of fiberboard case constructions with simple symbols internationally understood by all, regardless of language and other differences. The references may be used in orders and specifications for packing cases.

Description of basic type groups (The terms Box and Case are interchangeable in the context of these descriptions.)

02 - Slotted-type boxes consist of basically one piece with a stitched, taped or glued manufacturer's joint and top and bottom flaps. They are shipped flat, ready to use and require closing using the flaps provided.

03 - Telescope-type boxes consist of more than one piece and are characterized by a lid and/or bottom telescoping over the body of the box.

04 - Folder-type boxes usually consist of only one piece of board. The bottom of the box is hinged to form two or all side walls and the cover. The boxes can be set up without stitching or taping. Locking tabs, handles, display panels etc., can be incorporated in the design.

05 - Slide-type boxes consist of several pieces of liners and sleeves sliding in different directions into each other. This group also includes outside sleeves for other cases.

06 - Rigid-type boxes consist of two separate end pieces and a body and require stitching or a similar operation before they can be used.

07 - Ready-glued cases consist of basically one piece, are shipped flat and ready to use by simple setting up.

09 - Interior fitments such as inside liners, pads, partitions, dividers, etc.

Closure of the boxes

Correct and effective closure of the packages is as important as the package construction itself. The package is not satisfactory if it cannot be closed so that the closures and joints are at least as strong as the other parts. As regards shipping containers, the following methods of closure are possible either singly or in combination.

Gummed paper tape

Self adhesive tape

Staples or stitches

Glue

Twines and banding

Diecut locks

Where tapes are used, an effective method should be employed to ensure full and adequate adhesion.

The FEFCO codes were never set out to illustrate flute direction, to dictate where the true internal dimension on some of the styles were taken, but admirably served to identify basic designs of cases. To aid the user, some of the more popular FEFCO codes are illustrated

with the most common flute direction shown. This does not mean that a flute direction opposite to the one illustrated is not valid in some instances.

FEFCO codes are an international standard. The format of the codes is:

XXXX / XXXX

For a normal 0200 series case the first part of the code represents the top flap's style and the second part of the code represents the bottom flap's style. So, a case with 0201 type top flaps and 0203 type bottom flaps would be written as:

0201 / 0203

Hand Holes

There are two styles of hand-hole: Fully stripped out or punched out, which is signified by a "P" on the enquiry and Hinged-hand-holes, which have a crease at their top. These are signified on the enquiry by a "U".

Manufacturer's Joint

The manufacturer's joint may be either Glued (identified as G), Wire Stitched (identified as S) or Taped (identified as T) .

Specification of Designs

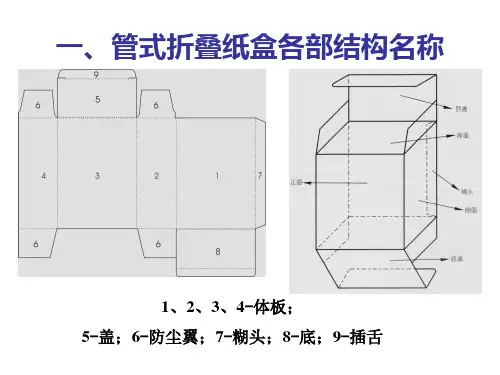

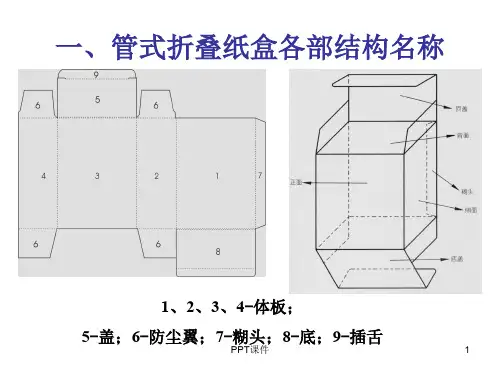

All drawings and packs shown in this file are viewed on the Inside facing. The panels of 0200 series cases are always numbered 1, 2, 3 and 4, starting from the flange side.

This page shows common tray designs, frequently produced on a Printer-Slotter, rather than by die-cutting. These designs are often referred to by their box and lid FEFCO designation, rather than the newer 045x numbers, even though only a tray is required.

i.e. it is not uncommon for a specification to call for an "0300 Tray", rather than 0452.

This page contains several additions to the usual FEFCO manual, which are given the "-A" suffix.

0900。