爱普生机器人软件安装及使用教程精编版

- 格式:doc

- 大小:622.00 KB

- 文档页数:14

![2024版爱普生机器人软件编程操作培训[1]](https://uimg.taocdn.com/fa676ba26394dd88d0d233d4b14e852458fb39af.webp)

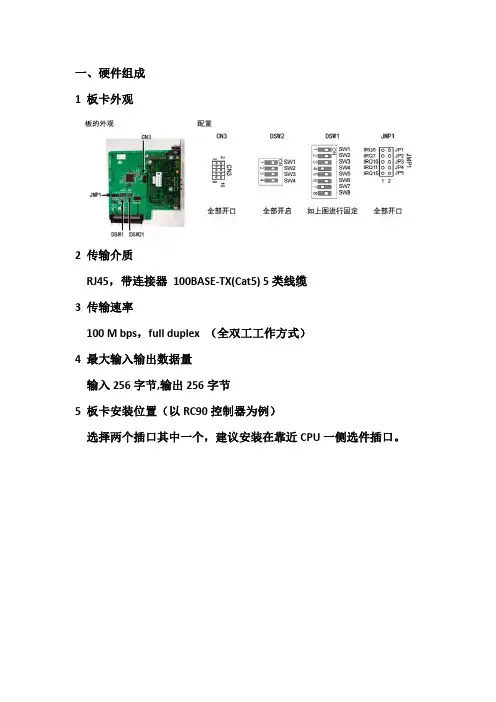

一、硬件组成

1板卡外观

2传输介质

RJ45,带连接器100BASE-TX(Cat5)5类线缆

3传输速率

100M bps,full duplex(全双工工作方式)

4最大输入输出数据量

输入256字节,输出256字节

5板卡安装位置(以RC90控制器为例)

选择两个插口其中一个,建议安装在靠近CPU一侧选件插口。

二、软件设置部分

1输入输出字节数

板卡如果安装完成,控制器正常自动识别板卡,如果不能自动识别请检查板卡安装。

根据点位要求设置1-256字节(和PLC或者其他主站控制器保持一致,DAP模式对于新版本控制器一般默认选择Ver.2

2PLC软件设置

首先把RC软件中得GSD文件找到提供给PLC或者其他主站控制器,机械手控制器是RC90就选择RC90的GSD文件

以西门子S7-1200为例,在设备概览中Interface表示设备已经建立连接,在组合输入输出状态时,请先分配输出状态,地址范围和机械手设置的字节数相同

三、板卡LED灯状态说明

1正常状态下LNK/ACTLED绿灯闪烁说明PLC或者其他主站已经和控制器建立通讯连接。

2正常状态下MS和CS LED绿色灯亮,如果MS红灯亮请检查PLC 分配地址是否正确或者IP地址设置等。

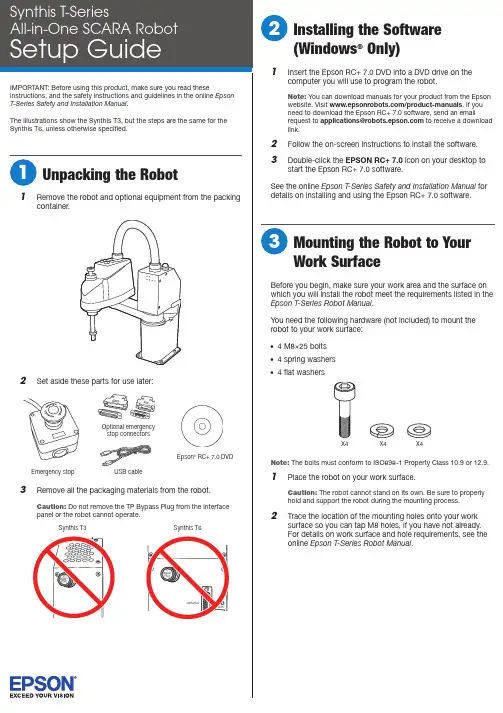

2 C onnect the emergency stop connector to theEMERGENCY port on the robot’s interface panel.3 CA ttaching a Power Adapterand Turning on the RobotThe power cable is already attached to the robot’s power supply. You must attach a power adapter plug to the other end of the power cable. See the example power adapter plugs below:220 V110 V2 orWarning: Improperly connecting the ground wire may cause a fireor electric shock.2 O n your computer, double-click the EPSON RC+ 7.0 iconon your Windows desktop to start the Epson RC+ 7.0software.3 In the Connection list, select USB.The robot’s PROGRAM light starts flashing.4 O pen the Project menu and select New to create a testproject.5 Enter a test project name and click OK .6 Open the Tools menu and select Robot Manager.7 W hen the control panel appears, click Reset to clear theemergency stop condition.2 Plug the robot’s power cable into a power outlet.The lights on the front of the robot flash for about 30PROGRAMlights flash alternately in a steady pattern.Now you can create a test project and test the robot using the Epson RC+ 7.0 software.Note: See the online Epson T-Series Safety and Installation Manual for details on using the Epson RC+ 7.0 software.1 B efore testing the robot, position it as follows:• Rotate the J1 and J2 joints counterclockwise to themiddle-of-reach position as shown here.Front viewTop view• Press and hold the Brake Release Switch button and push the J3 (Z axis) down about 1 inch (2.54 cm) asshown here.8 M ake sure no one is standing near the robot, then selectMOTOR ON and select Yesto continue.Warning:on the motor and whenever the large orange light is on.9 S elect the Jog & Teach tab (1) and click the Continuousradio button (2).10 C lick one of the directional arrows to move the robot in theindicated direction.11 W hen you finish testing, close the control panel window andselect File > Exit to exit the Epson RC+ 7.0 software.The robot is now ready to program and use. See the online Epson RC + 7.0 User’s Guide to get started with programming.Where to Get HelpFor technical support, do one of the following:• Visit /customer-service anytime.• Call 1-866-ROBOTS1 (U.S. only, toll free) or 1-562-290-5900(U.S. and elsewhere, toll or long distance charges may apply), 6 am to 4:30 pm , Pacific Time, Monday through Friday.EPSON is a registered trademark and EPSON Exceed Your Vision is a registered logomark of Seiko Epson Corporation.Windows is a registered trademark of Microsoft Corporation in the United States and/or other countries.General Notice: Other product names used herein are for identification purposes only and may be trademarks of their respective owners. Epson disclaims any and all rights in those marks.This information is subject to change without notice.© 2018 Epson America, Inc., 6/18Printed in U.S.A.CPD-54750R1。

爱普生机器人软件安装及使用教程Company Document number:WUUT-WUUY-WBBGB-BWYTT-1982GT爱普生机器人软件安装及使用教程一、EPSONRC+开发软件的安装打开EpsonRC50文件夹,双击开始安装。

出现上面显示的界面后,按按钮。

出现上面显示的界面后,再接着按按钮。

目标驱动器不必选择,直接按按钮。

上面可勾选部分为手册和模拟器实例,可以按默认安装,直接按按钮进行到安装的下一步。

按按钮选择继续安装。

会出现下面的安装进度界面,大约需要等待几分钟,整个EpsonRC50软件安装完成。

安装完成后,将弹出下面的窗口。

按按钮完成软件的安装。

此时,在用户的桌面上会出现下面两个图标前一个图标用于软件的开发和调试,后面的图标用于对工作流程的监视。

二、IP地址的设置用普通网线连接机器人和开发用电脑。

打开本地连接,弹出“本地连接属性”页面。

双击项,将打开Internet协议(TCP/IP)属性页面,修改IP地址等项为下图的值。

按键。

完成IP的设定。

三、EPSONRC+软件使用双击图标,启动EPSONRC+软件。

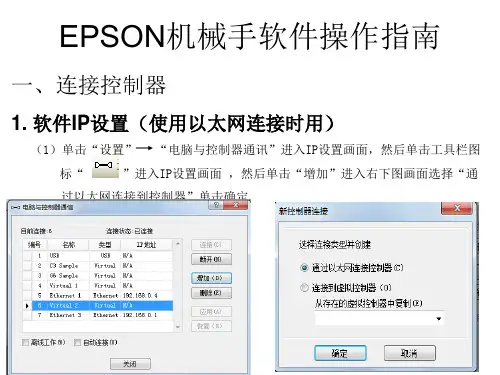

1.网络通讯的设置在EPSONRC+软件菜单中点击“设置”菜单项,单击选择项目。

将弹出下面“电脑与控制器通信”页面。

点击按钮。

选择选项,按键,完成添加网络通讯功能。

按钮,完成软件中连接IP的设置。

设置完成后页面显示为下图。

检查网线连接是否正常,正常则单击新添加的Ethernet项,按按钮,弹出下面页面。

选项表示电脑只作为监视器使用,不能进行程序的编制、修改等操作,不能对机器人控制点进行示教,也不能对外部I/O进行控制。

不影响已经存在的网络连接。

选项将首先中断目前和控制器的网络连接,将软件切换到程序模式,在此模式下可以进行控制程序的编制、修改工作,机器人控制点的示教和对外部I/O进行实时控制。

为了进行控制程序的编写、修改和调试,我们需要选择项目并按键切换到程序模式。

此后EPSONRC+软件将开始尝试连接RC170机器人控制器,连接成功后页面为下图状态。

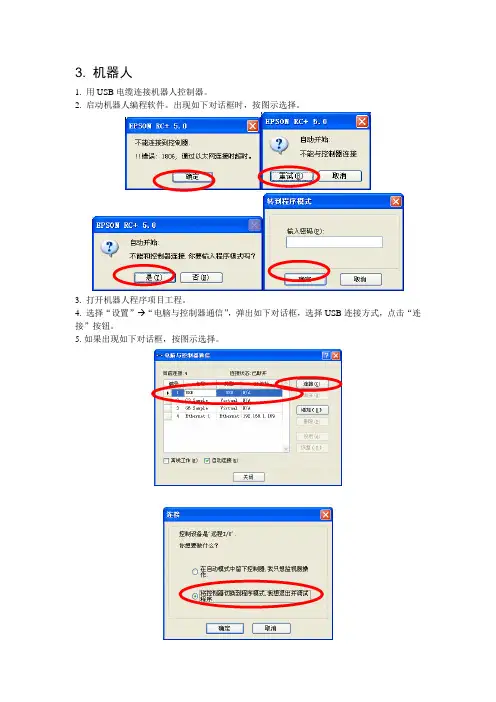

3. 机器人1. 用USB电缆连接机器人控制器。

2. 启动机器人编程软件。

出现如下对话框时,按图示选择。

3. 打开机器人程序项目工程。

4. 选择“设置” “电脑与控制器通信”,弹出如下对话框,选择USB连接方式,点击“连接”按钮。

5.如果出现如下对话框,按图示选择。

6.选择“设置” “控制器”,按下述图示设置参数。

“配置”菜单:“IP地址”设定为192.168.1.169;“控制设备”设定为远程I/O;“参数”菜单:勾选第一条“重置命令时关闭输出”“远程控制”菜单:“输入”:Start设为0、Stop设为1、Reset设为2,其余设为空闲;“输出”:全部设为空闲;“RS232”菜单:“端口1”:“波特率”:57600;“终端”:CR;“TCP/IP”菜单:“端口201”:“IP地址”:192.168.1.169;“终端”:“CR”“端口202”:“IP地址”:192.168.1.169;“终端”:“CR”7. 选择“工具” “机器人管理器”,出现如下提示下载程序的对话框。

8.点击“是”按钮,程序即被下载到机器人控制器中。

随后出现机器人管理器对话框,按如下图示设置机器人的夹爪重量和惯性参数。

“重量”:“重量”:0.500;“长度”:255.0009. 选择“工具” “控制器”,在弹出的对话框中选择“恢复控制器”,按如下图示恢复控制器数据。

该步骤主要是为了将各加工程序对应的点表文件恢复到机器人控制器中,如不需要恢复点表文件,则不必执行该步骤。

10.在CCD标定之前,可选择“运行” “显示变量”,在变量设定对话框中,手动设置CCD 已标定的标志。

(修改变量前,必须勾选变量设置对话框中的“编辑”选项。

修改变量后,按“写入”按钮)。

其他变量也可以按下表预先设定。

3 机器人DO:DO0 机器人真空产生V161DO1 CCD拍照触发ZOC11KA2DO2 CCD平台真空产生V141DO3 CCD平台真空破坏V142DO4 助焊剂泄压阀打开ZOC11KA5DO5 助焊剂上喷启动ZOC11KA6DO6 助焊剂下喷启动ZOC11KA7DO7 助焊剂水阀ZOC12KA1DO8 助焊剂气阀ZOC12KA2。

Software de programación EPSON RC+ 7.0Manipulador T3 T6VT6CPD-60432Seguridad e instalación del sistema de robot (T, VT/ EPSON RC+ 7.0) Mod.16Seguridad e instalación del sistema de robot(T, VT / EPSON RC+ 7.0)Rev.16Copyright 2017-2020 SEIKO EPSON CORPORATION.Todos los derechos reservados Seguridad e instalación del sistema de robot (T, VT/ EPSON RC+ 7.0) Mod.16iii Seguridad e instalación del sistema de robot (T, VT/ EPSON RC+ 7.0) Mod.16PRÓLOGOGracias por comprar nuestros productos de robot.Este manual contiene la información necesaria para el uso correcto del sistema derobot. Lea atentamente este manual y otros manuales relacionados antes de instalarel sistema de robot.Mantenga este manual a la mano para un acceso fácil en todo momento.GARANTÍAEl sistema de robot y las piezas opcionales se envían a nuestros clientes solo despuésde haberlos sometido a los más estrictos controles, pruebas e inspecciones de calidadpara certificar que cumplen con nuestras altas normas de rendimiento.Los productos que tengan un mal funcionamiento como resultado de lamanipulación u operación normales se repararán en forma gratuita durante elperíodo normal de la garantía. (Comuníquese con el proveedor de su región paraobtener información sobre el período de garantía).Sin embargo, se cobrarán al cliente las reparaciones en los siguientes casos (aunquesucedan dentro del período de garantía):1. Daño o mal funcionamiento provocados por un uso inadecuado que no sedescribe en este manual o por uso descuidado.2. Mal funcionamiento provocado por el desmontaje no autorizado delproducto por parte de los clientes.3. Daños debido a ajustes inadecuados o a intentos de reparación noautorizados.4. Daño provocado por desastres naturales, como terremotos, inundaciones,etc.Advertencias, precauciones, uso:1. Si el equipo asociado al sistema de robot no se usa de acuerdo con lascondiciones de uso y las especificaciones del producto descritas en losmanuales, esta garantía queda nula.2. Si no sigue las ADVERTENCIAS y PRECAUCIONES de este manual, nopodemos hacernos responsables de ningún mal funcionamiento o accidente,incluso si tienen como resultado lesiones o la muerte.3. No podemos prever todos los posibles peligros y consecuencias. Por lotanto, este manual no puede advertir al usuario de todos los posiblespeligros.Seguridad e instalación del sistema de robot (T, VT/ EPSON RC+ 7.0) Mod.16iiiMARCAS COMERCIALESMicrosoft, Windows y el logotipo de Windows son marcas registradas o marcascomerciales de Microsoft Corporation en los Estados Unidos y otros países. Otrasmarcas y nombres de productos son marcas comerciales o marcas registradas de susrespectivos titulares.NOTACIÓN DE MARCAS COMERCIALES EN ESTE MANUAL Sistema operativo Microsoft® Windows® 8Sistema operativo Microsoft® Windows® 10En todo este manual, Windows 8 y Windows 10 se refieren a los respectivos sistemasoperativos ya citados. En algunos casos, Windows se refiere en forma genérica aWindows 8 y Windows 10.AVISONinguna parte de este manual se puede copiar o reproducir sin autorización.El contenido de este manual está sujeto a cambios sin previo aviso.Notifíquenos si encuentra errores en este manual o si tiene comentarios con respectoa su contenido.FABRICANTESeiko Epson Corporation3-3-5 Owa, Suwa-shi, Nagano, 392-8502URL :/company/: http://www.epson.jp/prod/robots/Toyoshina PlantRobotics Solutions Operations Division6925 Toyoshina Tazawa,Azumino-shi, Nagano, 399-8285JapónTEL. : +81-(0)263-72-1530FAX : +81-(0)263-72-1685iv Seguridad e instalación del sistema de robot (T, VT/ EPSON RC+ 7.0) Mod.16PROVEEDORES (País/Región)América del Nortey del Sur Epson America, Inc.Factory Automation/Robotics1650 Glenn Curtiss StreetCarson, CA 90746EE. UU.TEL. : +1-562-290-5910FAX : +1-562-290-5999 CORREOELECTRÓNICO:*****************.comEuropa Epson Deutschland GmbHRobotic SolutionsOtto-Hahn-Str.4D-40670 MeerbuschAlemaniaTEL. : +49-(0)-2159-538-1800FAX : +49-(0)-2159-538-3170CORREOELECTRÓNICO:****************URL: : www.epson.de/robotsChina Epson (China) Co., Ltd.Factory Automation Division4F, Tower 1, China Central Place,81 Jianguo Road, Chaoyang District,Beijing, 100025, PRCTEL. : +86-(0)-10-8522-1199FAX : +86-(0)-10-8522-1125Taiwán Epson Taiwan Technology & Trading Ltd.Factory Automation Division15F., No.100, Song Ren Road., Xinyi Dist., Taipei City, 11073TaiwánTEL. : +886-(0)-2-8786-6688FAX : +886-(0)-2-8786-6600Seguridad e instalación del sistema de robot (T, VT/ EPSON RC+ 7.0) Mod.16vCorea Epson Korea Co., Ltd.Marketing Team (Robot Business)10F Posco Tower, Teheranro 134(Yeoksam-dong)Gangnam-gu, Seoul, 06235CoreaTEL. : +82-(0)-2-3420-6632FAX : +82-(0)-2-558-4271Sudeste Asiático Epson Singapore Pte. Ltd.Factory Automation System1 HarbourFront Place, #03-02,HarbourFront Tower One,Singapur 098633TEL. : +65-(0)-6586-5500FAX : +65-(0)-6271-2703India Epson India Pvt. Ltd.Sales & Marketing (Factory Automation)12th Floor, The Millenia, Tower A, No. 1,Murphy Road, Ulsoor, Bangalore,India 560008TEL. : +91-80-4566-5000FAX : +91-80-4566-5005Japón Epson Sales Japan CorporationFactory Automation Systems Department29th floor, JR Shinjuku Miraina Tower, 4-1-6Shinjuku, Shinjuku-ku, Tokyo 160-8801JapónTEL. :+81-(0)3-5919-5257FAX :+81-(0)3-5919-5402vi Seguridad e instalación del sistema de robot (T, VT/ EPSON RC+ 7.0) Mod.16En relación con la eliminación de la bateríaLa etiqueta con el basurero con ruedas tachado que se puede encontrar en el producto indica que este producto y las baterías incorporadas no se deben eliminar en el flujo normal de desechos domésticos. Para evitar los posibles daños ambientales o a la salud humana, separe este producto y las baterías de otros flujos de desechos para garantizar que se puedan reciclar de una manera ambientalmente correcta. Para conocer más detalles acerca de las instalaciones de recolección, comuníquese con la oficina gubernamental local o con el vendedor minorista donde compró este producto. El uso de los símbolos químicos Pb, Cd o Hg indica si estos metales se usan en la batería.Esta información solo se aplica a los clientes de la Unión Europea, de acuerdo con la DIRECTIVA 2006/66/EC DEL PARLAMENTO EUROPEO Y DEL CONSEJO DEL 6 de septiembre de 2006 acerca de las baterías y acumuladores y de las baterías y acumuladores de desecho y por la que se deroga la Directiva 91/157/EEC y la legislación, transponiéndose e implementándose en diversos sistemas legales nacionales.Para otros países, comuníquese con su gobierno local para investigar la posibilidad de reciclar su producto.El procedimiento de retiro y reemplazo de la batería se describe en los siguientes manuales:Manual del manipulador Mantenimiento: Reemplazo de la batería de litioSolo para clientes de CaliforniaLas baterías de litio de este producto contienenMaterial de perclorato: Se pueden aplicar procedimientos de manipulación especiales. Consulte la página /hazardouswaste/perchlorate (solo disponible eninglés).Seguridad e instalación del sistema de robot (T, VT/ EPSON RC+ 7.0) Mod.16viiviii Seguridad e instalación del sistema de robot (T, VT/ EPSON RC+ 7.0) Mod.16 Antes de leer este manual“T” y la “serie T” descritas en este manual corresponden a los siguientesmodelos:Serie T3Serie T6“VT” y la “serie VT” descritas en este manual corresponden al siguiente modelo:Serie VT6Los manipuladores T y de la serie T pueden utilizar el Teach Pendant (TP2 y TP3). No conecte los demás dispositivos al puerto TP , salvo los dispositivosTP2 y TP3. Conectar otros dispositivos puede provocar el mal funcionamiento del dispositivo, ya que las asignaciones de los pines son distintas. Con respecto a la compatibilidad de seguridad para la conexión de red:La función de conexión de red (Ethernet) de nuestros productos supone el uso en la red local, como la red LAN de la fábrica. No la conecte a la red externa, como Internet.Además, tome medidas de seguridad, como contra virus de la conexión de red, mediante la instalación de un software antivirus .Compatibilidad de seguridad para la memoria USB: Asegúrese de que la memoria USB no esté infectada con virus cuando se conecte al controlador.☞ NOTA☞ NOTA ☞ NOTA☞ NOTAConfiguración del sistema de controlEl sistema de manipulador de la serie T se configura con una combinación delos siguientes softwares.T3-401SFirmware del controlador Versión 7.3.51.1 o posteriorEPSON RC+ 7.0 Anterior a laversión 7.3.0Versión 7.3.1 oposteriorOKT6-602S Firmware del controlador Ver.7.3.53.0 o posteriorEPSON RC+ 7.0 Anterior a laversión 7.3.3Ver.7.3.4 oposteriorOKOK: Compatible Todas las funciones de EPSON RC+ 7.0 y el controlador estándisponibles.: Compatible La conexión está bien. Se recomienda usar las siguientes versioneso posteriores. Es posible que la pantalla o el control no funcionencorrectamente.T3-401S : EPSON RC+7.0 Ver.7.3.1T6-602S : EPSON RC+7.0 Ver.7.3.4Seguridad e instalación del sistema de robot (T, VT/ EPSON RC+ 7.0) Mod.16ixEl sistema de manipulador de la serie VT se configura con una combinación de los siguientes softwares.Firmware del controlador VT6-A901S, VT6-A901C, VT6-A901P Ver.7.4.56.2 o posteriorVT6-A901S-DC Ver.7.4.57.1 o posteriorEPSON RC+ 7.0 Anterior a laversión 7.4.6Ver.7.4.7 oposteriorOKOK: Compatible Todas las funciones de EPSON RC+ 7.0 y el controlador estándisponibles.: Compatible La conexión está bien. Se recomienda usar las siguientes versioneso posteriores. Es posible que la pantalla o el control no funcionencorrectamente.EPSON RC+ 7.0 Ver.7.4.7x Seguridad e instalación del sistema de robot (T, VT/ EPSON RC+ 7.0) Mod.16RoHS de ChinaEsta hoja y etiqueta de período de uso de protección ambiental se basan en elreglamento de China. No es necesario preocuparse por esto en otros países.产品中有害物产的名称及含量机器人型号名称T VT部件名称有害物产产汞产六价产多溴产苯多溴二苯产(Pb) (Hg) (Cd) (Cr(VI)) (PBB) (PBDE)机器人部× ○○○○○产机(产行器产元、产机产元)× ○○○○○减速机产元× ○○○○○产磁制产器× ○○○○○同步皮产○○○○○○产池产元(产池、产池固定架、产池基板)× ○○○○○密封(密封填料、油封、密封脂、产片、O型产)× ○○○○○产滑脂○○○○○○产产(M/C产产、产接产产)× ○○○○○散产片○○○○○○LED指示灯○○○○○○产路板× ○○○○○产珠产杠花产 (T系列)○○○○○○制产解除开关× ○○○○○外罩○○○○○○扎产○○○○○○原点产产○○○○○○气管接产× ○○○○○产件VT相机板产元× ○○○○○外部配产配套元件○○○○○○工具适配器(ISO法产) ○○○○○○相机安装板○○○○○○可产机械产产○○○○○○T相机安装板× ○○○○○兼容板× ○○○○○本表格依据SJ/T 11364的产定产制。

爱普生机器人软件安装及使用教程一、EPSONRC+5.0开发软件的安装打开EpsonRC50文件夹,双击setup.exe开始安装。

出现上面显示的界面后,按按钮。

出现上面显示的界面后,再接着按按钮。

目标驱动器不必选择,直接按按钮。

上面可勾选部分为手册和模拟器实例,可以按默认安装,直接按按钮进行到安装的下一步。

按按钮选择继续安装。

会出现下面的安装进度界面,大约需要等待几分钟,整个EpsonRC50软件安装完成。

安装完成后,将弹出下面的窗口。

按按钮完成软件的安装。

此时,在用户的桌面上会出现下面两个图标前一个图标用于软件的开发和调试,后面的图标用于对工作流程的监视。

二、IP地址的设置用普通网线连接机器人和开发用电脑。

打开本地连接,弹出“本地连接属性”页面。

双击项,将打开Internet协议(TCP/IP)属性页面,修改IP地址等项为下图的值。

按键。

完成IP的设定。

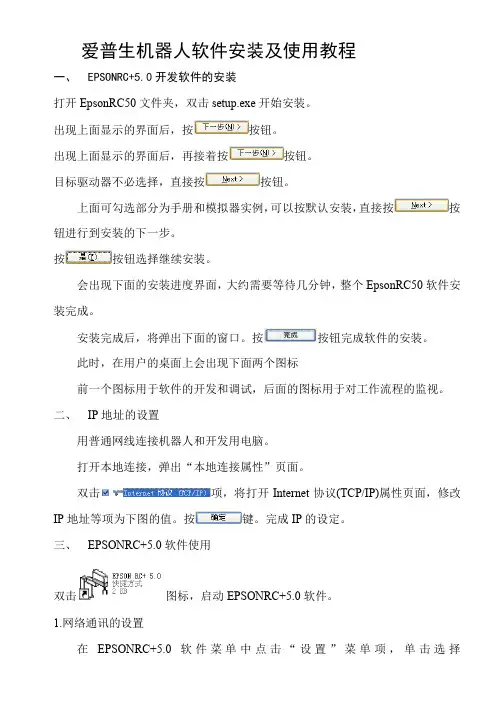

三、EPSONRC+5.0软件使用双击图标,启动EPSONRC+5.0软件。

1.网络通讯的设置在EPSONRC+5.0软件菜单中点击“设置”菜单项,单击选择项目。

将弹出下面“电脑与控制器通信”页面。

点击按钮。

选择选项,按键,完成添加网络通讯功能。

按钮,完成软件中连接IP的设置。

设置完成后页面显示为下图。

检查网线连接是否正常,正常则单击新添加的Ethernet项,按按钮,弹出下面页面。

选项表示电脑只作为监视器使用,不能进行程序的编制、修改等操作,不能对机器人控制点进行示教,也不能对外部I/O进行控制。

不影响已经存在的网络连接。

选项将首先中断目前和控制器的网络连接,将软件切换到程序模式,在此模式下可以进行控制程序的编制、修改工作,机器人控制点的示教和对外部I/O进行实时控制。

为了进行控制程序的编写、修改和调试,我们需要选择项目并按键切换到程序模式。

此后EPSONRC+5.0软件将开始尝试连接RC170机器人控制器,连接成功后页面为下图状态。

按按钮离开设置界面。

机器人软件安装的说明书欢迎使用我们的机器人软件!本说明书将为您详细介绍机器人软件的安装步骤和注意事项,以确保您能够顺利地安装和使用该软件。

一、系统要求在开始安装机器人软件之前,请确保您的电脑符合以下最低系统要求:- 操作系统:Windows 7及以上版本,或者Mac OS X 10.10及以上版本。

- 处理器:英特尔或AMD 1GHz以上处理器。

- 内存:至少2GB的可用内存。

- 硬盘空间:至少200MB的可用硬盘空间。

- 显示器分辨率:建议使用1024x768或更高分辨率。

二、软件安装步骤请按照以下步骤进行机器人软件的安装:1. 下载软件安装包请前往我们的官方网站(请勿在文章中出现网址链接)下载最新版本的机器人软件安装包。

确保下载的安装包与您的系统兼容并且来源可靠。

2. 打开安装包双击下载的安装包,然后根据系统提示选择安装语言并确认开始安装。

3. 安装目标路径在安装向导中,您可以选择软件的安装目标路径。

您可以接受默认路径,也可以选择其他路径进行安装。

4. 完成安装跟随安装向导的指示完成安装过程。

请耐心等待,直到安装进程完成。

三、软件使用指南以下是机器人软件的基本使用指南,帮助您更好地利用软件的功能:1. 启动软件双击机器人软件的桌面图标或者在开始菜单中找到软件并打开。

2. 注册账户首次启动软件时,您需要创建一个账户并进行注册。

请按照软件界面上的步骤完成注册过程。

3. 连接机器人在成功注册后,您需要将机器人与软件进行连接。

请按照软件提供的指示,通过USB或者Wi-Fi等方式与机器人进行连接。

4. 软件设置您可以根据个人喜好和需要对软件进行设置。

例如,设置语言、音量、互动模式等。

5. 软件功能机器人软件提供丰富的功能,例如语音识别、人脸识别、文字聊天等。

请在软件界面中探索和使用这些功能,以满足您的需求。

四、注意事项在安装和使用机器人软件时,请务必注意以下事项:1. 安全性请确保下载软件安装包的来源可信,并且避免从非官方渠道下载软件,以确保您的电脑和数据的安全。

Robot Controller Control Unit RC700RC700-ADrive Unit RC700DURC700DU-A Programming Software EPSON RC+7.0 Manipulator G1 G3 G6 G10 G20 seriesRS series C4 C8 series N2 N6 seriesX5 seriesRobot System Safety and Installation (RC700 / EPSON RC+7.0) Rev.19Robot System Safety and Installation(RC700 / EPSON RC+7.0)Rev.19Copyright 2012-2019 SEIKO EPSON CORPORATION. All rights reserved. Safety and Installation (RC700 / EPSON RC+ 7.0) Rev.19 iFOREWORDThank you for purchasing our robot products.This manual contains the information necessary for the correct use of the robotsystem.Please carefully read this manual and other related manuals before installing therobot system.Keep this manual handy for easy access at all times.WARRANTYThe robot system and its optional parts are shipped to our customers only afterbeing subjected to the strictest quality controls, tests, and inspections to certify itscompliance with our high performance standards.Product malfunctions resulting from normal handling or operation will be repairedfree of charge during the normal warranty period. (Please contact the supplier ofyour region for warranty period information.)However, customers will be charged for repairs in the following cases (even if theyoccur during the warranty period):1. Damage or malfunction caused by improper use which is not described inthe manual, or careless use.2. Malfunctions caused by customers’ unauthorized disassembly.3. Damage due to improper adjustments or unauthorized repair attempts.4. Damage caused by natural disasters such as earthquake, flood, etc.Warnings, Cautions, Usage:1. If the robot system associated equipment is used outside of the usageconditions and product specifications described in the manuals, thiswarranty is void.2. If you do not follow the WARNINGS and CAUTIONS in this manual, wecannot be responsible for any malfunction or accident, even if the result isinjury or death.3. We cannot foresee all possible dangers and consequences. Therefore, thismanual cannot warn the user of all possible hazards.ii Safety and Installation (RC700 / EPSON RC+ 7.0) Rev.19TRADEMARKSMicrosoft, Windows, and Windows logo are either registered trademarks ortrademarks of Microsoft Corporation in the United States and/or other countries.Other brand and product names are trademarks or registered trademarks of therespective holders.TRADEMARK NOTATION IN THIS MANUALMicrosoft® Windows® 7 Operating systemMicrosoft® Windows® 8 Operating systemMicrosoft® Windows® 10 Operating systemThroughout this manual, Windows 7, Windows 8, and Windows 10 refer to aboverespective operating systems. In some cases, Windows refers generically toWindows 7, Windows 8, and Windows 10.NOTICENo part of this manual may be copied or reproduced without authorization.The contents of this manual are subject to change without notice.Please notify us if you should find any errors in this manual or if you have anycomments regarding its contents.MANUFACTURERSeiko Epson Corporation3-3-5 Owa, Suwa-shi, Nagano, 392-8502URL :/company/: http://www.epson.jp/prod/robots/Toyoshina PlantRobotics Solutions Operations Division6925 Toyoshina Tazawa,Azumino-shi, Nagano, 399-8285JapanTEL : +81-(0)263-72-1530FAX : +81-(0)263-72-1495Safety and Installation (RC700 / EPSON RC+ 7.0) Rev.19 iiiSUPPLIERS (Country/Region)North & South America Epson America, Inc.Factory Automation/Robotics 18300 Central AvenueCarson, CA 90746USATEL : +1-562-290-5900FAX : +1-562-290-5999E-MAIL :*****************.comEurope Epson Deutschland GmbHRobotic SolutionsOtto-Hahn-Str.4D-40670 MeerbuschGermanyTEL : +49-(0)-2159-538-1800FAX : +49-(0)-2159-538-3170E-MAIL :****************URL: : www.epson.de/robotsChina Epson (China) Co., Ltd.Factory Automation Division4F, Tower 1, China Central Place,81 Jianguo Road, Chaoyang District,Beijing, 100025, PRCTEL : +86-(0)-10-8522-1199FAX : +86-(0)-10-8522-1120Taiwan Epson Taiwan Technology & Trading Ltd.Factory Automation Division15F., No.100, Songren Rd., Sinyi Dist., Taipei City, 11073TaiwanTEL : +886-(0)-2-8786-6688FAX : +886-(0)-2-8786-6600iv Safety and Installation (RC700 / EPSON RC+ 7.0) Rev.19Korea Epson Korea Co., Ltd.Marketing Team (Robot Business)10F Posco P&S Tower, Teheranro 134(Yeoksam-dong)Gangnam-gu, Seoul, 06235KoreaTEL : +82-(0)-2-3420-6692FAX : +82-(0)-2-558-4271Southeast Asia Epson Singapore Pte. Ltd.Factory Automation System1 HarbourFront Place, #03-02,HarbourFront Tower One,Singapore 098633TEL : +65-(0)-6586-5696FAX : +65-(0)-6271-3182India Epson India Pvt. Ltd.Sales & Marketing (Factory Automation)12th Floor, The Millenia, Tower A, No. 1,Murphy Road, Ulsoor, Bangalore,India 560008TEL : +91-80-3051-5000FAX : +91-80-3051-5005Japan Epson Sales Japan CorporationFactory Automation Systems Department29th floor, JR Shinjuku Miraina Tower, 4-1-6Shinjuku, Shinjuku-ku, Tokyo 160-8801JapanTEL :+81-(0)3-5919-5257FAX :+81-(0)3-5919-5402Safety and Installation (RC700 / EPSON RC+ 7.0) Rev.19 vRegarding battery disposalThe crossed out wheeled bin label that can be found on your product indicates that this product and incorporated batteries should not be disposed of via the normal household waste stream. To prevent possible harm to the environment or human health please separate this product and its batteries from other waste streams to ensure that it can be recycled in an environmentally sound manner. For more details on available collection facilities please contact your local government office or the retailer where you purchased this product. Use of the chemical symbols Pb, Cd or Hg indicates if these metals are used in the battery.This information only applies to customers in the European Union, according to DIRECTIVE 2006/66/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL OF 6 September 2006 on batteries and accumulators and waste batteries and accumulators and repealing Directive 91/157/EEC and legislation transposing and implementing it into the various national legal systems.For other countries, please contact your local government to investigate the possibility of recycling your product.The battery removal/replacement procedure is described in the following manuals:Controller manual / Manipulator manual(Maintenance section)For California customers onlyThe lithium batteries in this product containPerchlorate Material - special handling may apply,See /hazardouswaste/perchlorate.vi Safety and Installation (RC700 / EPSON RC+ 7.0) Rev.19Safety and Installation (RC700 / EPSON RC+ 7.0) Rev.19 viiBefore Reading This ManualConcerning the security support for the network connection:The network connecting function (Ethernet) on our products assumes the use in the local network such as the factory LAN network. Do not connect to the external network such as Internet.In addition, please take security measure such as for the virus from the network connection by installing the antivirus software.Security support for the USB memory:Make sure the USB memory is not infected with virus when connecting to the Controller.Control System ConfigurationRobot Controller Drive Unit RC700DU is available for the following version.EPSON RC+ 7.0 Ver.7.1.0 or laterRobot Controller RC700-ARobot Controller Drive Unit RC700DU-A is available for the following version.EPSON RC+ 7.0 Ver.7.1.2 or laterManipulators can be connected with the following versions. C4 series : EPSON RC+ 7.0 Ver.7.0.0 C8 series (C8XL) : EPSON RC+ 7.0 Ver.7.1.3 C8 series (C8, C8L) : EPSON RC+ 7.0 Ver.7.1.4 C8 series (wall mounting) : EPSON RC+ 7.0 Ver.7.2.0 N2 series: EPSON RC+ 7.0 Ver.7.2.0 N6 series (N6-A1000**) : EPSON RC+ 7.0 Ver.7.3.4 N6 series (N6-A850**R) : EPSON RC+ 7.0 Ver.7.4.1G1, G3, G6, G10, G20, RS series : EPSON RC+ 7.0 Ver.7.1.2 X5 series: EPSON RC+ 7.0 Ver.7.3.0☞NOTE☞NOTEChina RoHSThis sheet and environmental protection use period label are based on theregulation in China. These are not necessary to be concerned in othercountries.viii Safety and Installation (RC700 / EPSON RC+ 7.0) Rev.19产品环保使用期限的使用条件关于适用于在中华人民共和国境内销售的电器电子产品的环保使用期限,在遵守该产品的安全及使用注意事项的条件下,从生产日期开始计算,在标志的年限内,本产品中含有的有害物质不会对环境造成严重污染或对人身、财产造成严重损害。

EPSON JavaPOS ADK手册 安装指南1.13版本 Dec. 2011注意(1) 严禁以任何方式复制本文档的任何部分。

(2) 本文档的内容如有变更,恕不另行通知。

(3) 敬请对本文档中的任何错误予以批评和指正。

(4) 本软件不可使用于其他的指定外设备。

(5) 爱普生公司对因使用本文档中的任何信息而导致的后果不承担任何责任。

商标Microsoft®,Windows®,Windows Server®和Windows Vista®是微软公司在美国及/或其它国家的商标或注册商标。

Linux是Linus Torvalds先生在美国及/或其它国家的商标或注册商标。

Red Hat是红帽公司的注册商标。

SUSE是SuSE Linux AG公司的注册商标,Novell公司的业务之一。

JBuilder是Borland软件公司在美国及其它国家的商标。

EPSON和ESC/POS是精工爱普生公司的注册商标。

Java和JavaPOS是太阳微系统公司在美国及其它国家的商标或注册商标。

此处所使用的其它产品和公司名称仅为区分之用,且可能是其各自公司的商标或注册商标。

爱普生公司在此声明上述商标的所有权利。

Copyright (c) 2005-2011 SEIKO EPSON CORPORATION目录第 1 章 简介 (1)第 2 章 安装 (2)2.1 安装Java (2)2.2 安装Java Advanced Imaging (JAI) (2)2.3 配置您的环境 (3)2.4 启动安装程序 (3)2.5 选择语言 (4)2.6 预安装检查 (4)2.7 简介 (5)2.8 许可协议 (6)2.9 选择一个Java虚拟机 (7)2.10 选择安装类型 (8)2.11 选择要安装的组件 (9)2.12 选择快捷文件夹 (10)2.13 选择用户Classpath (11)2.14 选择通讯方法 (12)2.15 jpos.xml的位置 (13)2.16 升级 (14)2.17 安装前摘要 (16)2.18 完成 (18)第 3 章 卸载 (19)3.1 更改已安装的项目并启动卸载 (19)3.2 确认卸载 (19)3.3 删除电子日志数据文件 (20)第 4 章 无提示安装/卸载 (21)4.1 静态安装的顺序 (21)4.2 设备注册信息的准备 (21)4.3 创建一个安装脚本 (22)4.4 运行安装和卸载 (24)第 5 章 强行卸载 (25)5.1 使用强行卸载选项 (25)iii第 6 章 Windows信息 (26)6.1 配置环境变量 (26)第 7 章 Linux信息 (27)7.1 安装Java (27)7.2 配置环境变量 (27)SuSE (27)Red Hat/CentOS (28)7.3 安装Java Advanced Imaging (JAI) (29)7.4 安装libusb (29)7.5 串行设置 (29)COM3或更高级设置 (29)用户组设置 (30)iv第 1 章简介当安装EPSON JavaPOS ADK程序时,以下的硬件和软件配置是必需的。

EPSON RC+ 5.4.3 SP1 Release NotesFebruary 1, 2012Thank you for using EPSON RC+ 5.4.3. This document contains the latest information for this release. Please read before using this software.DOCUMENTATION (2)GETTING STARTED (2)INSTALLING SERVICE PACK 1 (2)H OW TO VERIFY IF S ERVICE P ACK 1 IS INSTALLED (2)H OW TO INSTALL S ERVICE P ACK 1 (2)H OW TO UNINSTALL S ERVICE P ACK 1 (2)WHAT’S FIXED IN VERS ION 5.4.3 SP1 (2)WHAT’S NEW IN VERSI ON 5.4.3 (3)WHAT’S FIXED IN VERS ION 5.4.3 (3)SIMULATOR (4)C OLLISION MARGIN FOR ROBOT HAND CANNOT BE SET (4)R OBOT MOTION TIME MAY APPEAR TO BE INCORRECT (4)VB GUIDE 5.0 (4)U SING WITH V ISUAL S TUDIO 2010 AND .NET F RAMEWORK 4.0 (4)C REATING 32 BIT APPLICATION ON 64 BIT W INDOWS (5)E XECUTING S PEL COMMANDS WITHIN A BUTTON CLICK EVENT (5)E XECUTING S PEL MOTION COMMANDS IN A SEPARATE THREAD (5)VISION GUIDE 5.0 (6)I MAGE F ILE P ROPERTY (6)U SING ONE CAMERA FROM TWO CONTROLLERS (6)O FFLINE M ODE (6)I MPORTING FROM EPSON RC+3.X AND 4.X WITH V ISION G UIDE (7)C AMERA CONNECTED TO ANOTHER PC WARNING MESSAGE (7)DocumentationAll RC+ manuals are in PDF format and are installed on the PC hard disk. These manuals are accessible from the RC+ environment Help menu.Getting StartedRead the Getting Started chapter in the EPSON RC+ 5.0 User's Guide. This chapter will refer you to the RC170/RC180 or RC90 Controller manual Installation chapter. This contains information for initial connections and start up.Installing Service Pack 1EPSON RC+ 5.0 Ver.5.4.3 Service Pack 1 is included on the current Ver.5.4.3 installation DVD. It is not automatically installed with the Ver.5.4.3 installation program. It must be installed separately. If your system was configured at the factory, the service pack will already be installed.How to verify if Service Pack 1 is installed1.Run EPSON RC+ 5.0.2.Select Help | About.3.If the service pack is installed, the version number will be 5.4.3 SP1.How to install Service Pack 1To install Service Pack 1:1.Navigate to the \EpsonRC50\Service_Packs directory on the installation DVD.2.Run the file erc543sp1.exe and follow the on screen instructions.How to uninstall Service Pack 1To uninstall Service Pack 1:1.Open Add / Remove Programs in the Windows Control Panel.2.Select EPSON RC+ 5.0 and run it to uninstall.3.Run the EPSON RC+ 5.0 Ver.5.4.3 installer from the installation DVD to re-install it.What’s Fixed in version 5.4.3 SP11.Fixed problem for large Geometric models when connected to the controllervia USB. Communication timeout errors were occurring during someoperations, such as ShowModel.2.Fixed problems for Test Auto Mode and I/O Monitor. If I/O Monitor wasopen before executing Test Auto Mode, the Operator Window was closedimmediately after being displayed. Or if the I/O Monitor was opened fromthe Operator Window and not closed before closing the Operator Window, thenan exception occurred.3.Fixed problem for virtual controllers where any G3 series robot could not beadded.4.Fixed Startup preferences when running on 64 bit Windows. The Auto Startand Windows Login settings were not working.5.Fixed problem for GSet. If an integer was expected, but a real or double wasused, an exception occurred.6.Fixed some simulator drawing processing problems for 2D Layout and 3Dviews.7.Fixed problems for Japanese help.8.Fixed the error message when attempting connection with a controller that isnot finished booting. Previously, a "USB Driver not installed" error wasoccurring.What’s New in version 5.4.31.Added GUI Builder option.2.Added USB driver for 64 bit Windows Vista and Windows 7.3.Added support for Remote RS232.4.VB Guide5.0 now supports 64 bit applications.What’s Fixed in version 5.4.31.Fixed a problem for some project dialogs (new, open, copy, save as, import).An exception occurred when the dialog was opened if one or more drivevolume labels on the system could not be read (access denied).2.Fixed a problem where sometimes don't care pixels were not being saved.3.Added VB Guide 5.0 Spel EnableEvent method.4.Fixed a problem where vision files were being sent to the controller duringevery project build.5.Now the Camera dropdown list is not displayed on the Operator window ifvideo display is disabled and EPSON RC+ is connected to a real controller.6.Fixed a problem where sometimes edges for Geometric objects were not beingdisplayed on the Operator window or Run window.SimulatorCollision margin for robot hand cannot be setYou cannot set the Collision Margin for robot hand in this version.Robot motion time may appear to be incorrectOn some PCs, when you run a program that moves the robot, the speed may seem incorrect. There are settings you can change to help correct the problem. Select Setup | Controller | Simulator and increase the Performance setting to 16 and the Position Precision to 20. You may need to experiment with other values.See Simulator Specifications and Restrictions, Time progress difference by PC condition in the manual or help for more details.VB Guide 5.0Using with Visual Studio 2010 and .NET Framework 4.0If you create an application using Visual Studio 2010 and the target framework version is 4.0, then you need modify the project to allow SpelNetLib.dll to be used. SpelNetLib.dll was created with .NET Framework 3.5. By default, applications that target .NET Framework 4.0 cannot load assemblies from previous .NET Framework versions. You must add and modify the app.config file for the solution and set the useLegacyV2RuntimeActivationPolicy property.For VB and C#:1.In Solution Explorer, check if app.config exists. If it does, go to step 4.2.From the Project menu, select Add New Item.3.Select Application Configuration File and click Add. The app.config XML filewill appear.4.In the app.config file, add the following XML code inside the configurationproperty.<configuration><startup useLegacyV2RuntimeActivationPolicy="true"><supportedRuntime version="v4.0"/></startup></configuration>For VC++:1.Create a config file for the application that uses the same name as the exe file with".config" appended. For example, if you exe file name is myapp.exe, then theconfig file would be named myapp.exe.config.2.In the config file, add the configuration code:<configuration><startup useLegacyV2RuntimeActivationPolicy="true"><supportedRuntime version="v4.0"/></startup></configuration>3.Copy the config file to both the debug and release folders. You can use a postbuild event that performs this automatically. For an example, see the VB Guide5.0 VC++ demo project.Creating 32 bit application on 64 bit WindowsTo successfully create a VB Guide 5.0 32 bit application on 64 bit Windows, you must set the Visual Studio build target to x86 (32 bit). When using Visual Studio Express versions, you will need to first create the x86 target after enabling Expert Mode. Executing Spel commands within a button click eventIn .NET, if you execute a method in a button click event, you cannot click another button to execute another method on the first click. For example, if you execute the Go method in a button click event, and attempt to click another button to execute the Abort method, the second button will not respond the first time. This is true even if VB Guide is not used. Instead, use the button MouseDown event to execute the Go method, or execute Spel commands in a separate thread as described in the following topic.Executing Spel motion commands in a separate threadIf you will be executing Spel motion commands from your .NET application, it is recommended that you execute them in a separate thread. This will allow other methods such as Abort to be executed from other buttons. The example below shows a separate thread for Spel motion commands.private void btnStartCycle_Click(object sender, EventArgs e){btnStartCycle.Enabled = false;btnStopCycle.Enabled = true;m_stop = false;m_spel.ResetAbort();// Start the robot cycleSystem.Threading.Thread t = new System.Threading.Thread(RobotCycle); t.Start();}private void btnStopCycle_Click(object sender, EventArgs e){m_stop = true;m_spel.Abort(); // Optional. This will immediately stop the cyclebtnStopCycle.Enabled = false;btnStartCycle.Enabled = true;}private void RobotCycle(){try{do{m_spel.Jump("pick");m_spel.On("GripOn");m_spel.Delay(100);m_spel.Jump("place");m_spel.Off("GripOn");m_spel.Delay(100);} while (!m_stop);}catch (SpelException e){// If the error is not "Command aborted by user",// then show the error messageif (e.ErrorNumber != 10101)MessageBox.Show("Spel error occurred¥n¥n" + e.Message);}}Vision Guide 5.0ImageFile PropertyThe EPSON Smart Camera supports one image file stored in each camera project. When an ImageFile is specified for a sequence, it is copied to the camera when the sequence is selected from the Vision Guide GUI.You can use the SaveImage property to save an unlimited number of images on the PC.Using one camera from two controllersThe EPSON Smart Camera supports two vision projects. Each vision project can be used by one controller, so two controllers can use the same camera. Project 1 is used by default. To use project 2, change the camera project number from RC+ Project | Properties | Vision.Offline ModeWhen you open the Vision Guide window, RC+ attempts to communicate with the Smart Cameras configured in Setup | Vision. If communication cannot be initiated, a message box is displayed stating that one or more Smart Cameras cannot be connected and asking if you would like to open Vision Guide in offline mode. Answer Yes to enter Offline Mode. In Offline Mode, you can edit Sequences, Objects, and Calibrations. To enter Online Mode, close the Vision Guide window, then open it again.Importing from EPSON RC+ 3.x and 4.x with Vision GuideYou can import projects that were created in EPSON RC+ 3.x and 4.x that used the Vision Guide option.To import a project:4.In EPSON RC+5.0, select Project | Import.5.Select PC and click Next.6.Select EPSON RC+ 3.x / 4.x for the Project Type.7.Select the drive and project to import and continue with the wizard.Please review the following information regarding imported EPSON RC+ 4.x projects: - Vision calibrations are imported, but the associated calibration data is not imported. You will need to run your calibrations after import.- the RobotU vision result is changed. In EPSON RC+ 4.x, RobotU was reported with 0 degrees aligned with the robot world Y axis. Now RobotU is reported with 0 degrees aligned with the robot world X axis.- Maximum NumberToFind is changed. In Vision Guide 5.0, the maximum NumberToFind for any multi-result object is 100. During import, NumberToFind is reduced to 100 if necessary.- Calibration properties cannot be set at runtime.- VCalPoints and VCal are not supported. Vision calibrations cannot be executed at runtime.- Vision model properties cannot be set at runtime.- VTeach is not supported. Vision models cannot be taught at runtime.- OCR and Code Reader objects are currently not supported in Vision Guide 5.0.During import, OCR objects are converted to Correlation objects, and Code Reader objects are converted to Blob objects.Camera connected to another PC warning messageNormally, if one PC tries to connect to a Smart Camera that is already connected to another PC or controller, you will see a message box stating this.However, sometimes if the Ethernet cable is disconnected or if the RC+ process is terminated while connected to a Smart Camera, then on the next connection attempt, you may receive the message described above. In this case, reset the camera from Setup |Vision, or power cycle the camera. Then rebuild the current project using Project | Rebuild. Smart Camera firmware v1.0.0.4 reduces the occurrence of this problem.。

Programming Software EPSON RC+ 7.0Manipulator T3 T6VT6Robot System Safety and Installation (T, VT/ EPSON RC+ 7.0) Rev.13Robot System Safety and Installation(T, VT / EPSON RC+ 7.0)Rev.13Copyright 2017-2019 SEIKO EPSON CORPORATION. All rights reserved Safety and Installation (T, VT / EPSON RC+ 7.0) Rev.13 iFOREWORDThank you for purchasing our robot products.This manual contains the information necessary for the correct use of the robotsystem.Please carefully read this manual and other related manuals before installing therobot system.Keep this manual handy for easy access at all times.WARRANTYThe robot system and its optional parts are shipped to our customers only afterbeing subjected to the strictest quality controls, tests, and inspections to certify itscompliance with our high performance standards.Product malfunctions resulting from normal handling or operation will be repairedfree of charge during the normal warranty period. (Please contact the supplier ofyour region for warranty period information.)However, customers will be charged for repairs in the following cases (even if theyoccur during the warranty period):1. Damage or malfunction caused by improper use which is not described inthe manual, or careless use.2. Malfunctions caused by customers’ unauthorized disassembly.3. Damage due to improper adjustments or unauthorized repair attempts.4. Damage caused by natural disasters such as earthquake, flood, etc.Warnings, Cautions, Usage:1. If the robot system associated equipment is used outside of the usageconditions and product specifications described in the manuals, thiswarranty is void.2. If you do not follow the WARNINGS and CAUTIONS in this manual, wecannot be responsible for any malfunction or accident, even if the result isinjury or death.3. We cannot foresee all possible dangers and consequences. Therefore, thismanual cannot warn the user of all possible hazards.ii Safety and Installation (T, VT / EPSON RC+ 7.0) Rev.13TRADEMARKSMicrosoft, Windows, and Windows logo are either registered trademarks ortrademarks of Microsoft Corporation in the United States and/or other countries.Other brand and product names are trademarks or registered trademarks of therespective holders.TRADEMARK NOTATION IN THIS MANUALMicrosoft® Windows® 7 Operating systemMicrosoft® Windows® 8 Operating systemMicrosoft® Windows® 10 Operating systemThroughout this manual, Windows 7, Windows 8, and Windows 10 refer to aboverespective operating systems. In some cases, Windows refers generically toWindows 7, Windows 8, and Windows 10.NOTICENo part of this manual may be copied or reproduced without authorization.The contents of this manual are subject to change without notice.Please notify us if you should find any errors in this manual or if you have anycomments regarding its contents.MANUFACTURERSeiko Epson Corporation3-3-5 Owa, Suwa-shi, Nagano, 392-8502URL :/company/: http://www.epson.jp/prod/robots/Toyoshina PlantRobotics Solutions Operations Division6925 Toyoshina Tazawa,Azumino-shi, Nagano, 399-8285JapanTEL : +81-(0)263-72-1530FAX : +81-(0)263-72-1685Safety and Installation (T, VT / EPSON RC+ 7.0) Rev.13 iiiiv Safety and Installation (T, VT / EPSON RC+ 7.0) Rev.13SUPPLIERS (Country/Region) North & SouthAmericaEpson America, Inc. Factory Automation/Robotics 1650 Glenn Curtiss Street Carson, CA 90746 USATEL : +1-562-290-5900FAX : +1-562-290-5999E-MAIL :*****************.com EuropeEpson Deutschland GmbHRobotic Solutions Otto-Hahn-Str.4 D-40670 Meerbusch GermanyTEL : +49-(0)-2159-538-1800FAX : +49-(0)-2159-538-3170E-MAIL :****************URL: : www.epson.de/robots ChinaEpson (China) Co., Ltd.Factory Automation Division 4F, Tower 1, China Central Place, 81 Jianguo Road, Chaoyang District, Beijing, 100025, PRCTEL : +86-(0)-10-8522-1199FAX : +86-(0)-10-8522-1120TaiwanEpson Taiwan Technology & Trading Ltd.Factory Automation Division 15F., No.100, Songren Rd., Sinyi Dist., Taipei City, 11073 TaiwanTEL : +886-(0)-2-8786-6688FAX : +886-(0)-2-8786-6600Korea Epson Korea Co., Ltd.Marketing Team (Robot Business)10F Posco P&S Tower, Teheranro 134(Yeoksam-dong)Gangnam-gu, Seoul, 06235KoreaTEL : +82-(0)-2-3420-6692FAX : +82-(0)-2-558-4271Southeast Asia Epson Singapore Pte. Ltd.Factory Automation System1 HarbourFront Place, #03-02,HarbourFront Tower One,Singapore 098633TEL : +65-(0)-6586-5696FAX : +65-(0)-6271-3182India Epson India Pvt. Ltd.Sales & Marketing (Factory Automation)12th Floor, The Millenia, Tower A, No. 1,Murphy Road, Ulsoor, Bangalore,India 560008TEL : +91-80-3051-5000FAX : +91-80-3051-5005Japan Epson Sales Japan CorporationFactory Automation Systems Department29th floor, JR Shinjuku Miraina Tower, 4-1-6Shinjuku, Shinjuku-ku, Tokyo 160-8801JapanTEL :+81-(0)3-5919-5257FAX :+81-(0)3-5919-5402Safety and Installation (T, VT / EPSON RC+ 7.0) Rev.13 vRegarding battery disposalThe crossed out wheeled bin label that can be found on your product indicates that this product and incorporated batteries should not be disposed of via the normal household waste stream. To prevent possible harm to the environment or human health please separate this product and its batteries from other waste streams to ensure that it can be recycled in an environmentally sound manner. For more details on available collection facilities please contact your local government office or the retailer where you purchased this product. Use of the chemical symbols Pb, Cd or Hg indicates if these metals are used in the battery.This information only applies to customers in the European Union, according to DIRECTIVE 2006/66/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL OF 6 September 2006 on batteries and accumulators and waste batteries and accumulators and repealing Directive 91/157/EEC and legislation transposing and implementing it into the various national legal systems.For other countries, please contact your local government to investigate the possibility of recycling your product.The battery removal/replacement procedure is described in the following manuals:Manipulator Manual Maintenance: Replacing the Lithium BatteryFor California customers onlyThe lithium batteries in this product containPerchlorate Material - special handling may apply,See /hazardouswaste/perchlorate.vi Safety and Installation (T, VT / EPSON RC+ 7.0) Rev.13Safety and Installation (T, VT / EPSON RC+ 7.0) Rev.13 viiBefore Reading This Manual"T" and "T series" described in this manual are the following models.T3 seriesT6 series"VT" and "VT series" described in this manual are the following model. VT6 seriesT series and VT series Manipulators can use the Teach Pendant (TP2, TP3). Do not connect the other devices to TP port except TP2 and TP3. Connecting other devices may result in malfunction of the device since the pin assignments are different. Concerning the security support for the network connection:The network connecting function (Ethernet) on our products assumes the usein the local network such as the factory LAN network. Do not connect to the external network such as Internet.In addition, please take security measure such as for the virus from the network connection by installing the antivirus software .Security support for the USB memory: Make sure the USB memory is not infected with virus when connecting to the Controller.☞ NOTE ☞NOTE ☞ NOTE ☞ NOTEControl System ConfigurationT series Manipulator system are configured by a combination of the followingsoftware.T3-401S Controller FirmwareVer.7.3.51.1 or laterEPSON RC+ 7.0 Before Ver.7.3.0Ver.7.3.1 or later OKT6-602S Controller FirmwareVer.7.3.53.0 or laterEPSON RC+ 7.0 Before Ver.7.3.3Ver.7.3.4 or later OKOK: Compatible All functions of the EPSON RC+ 7.0 and the Controller areavailable.: Compatible Connection is OK. It is recommended to use the followingversions or later. Display or control may not be operatedproperly.T3-401S : EPSON RC+7.0 Ver.7.3.1T6-602S : EPSON RC+7.0 Ver.7.3.4viii Safety and Installation (T, VT / EPSON RC+ 7.0) Rev.13VT series Manipulator system are configured by a combination of the following software.VT6-A901S, VT6-A901C, VT6-A901P Controller FirmwareVer.7.4.56.2 or laterEPSON RC+ 7.0 Before Ver.7.4.6Ver.7.4.7 or later OKOK: Compatible All functions of the EPSON RC+ 7.0 and the Controller are available.: Compatible Connection is OK. It is recommended to use the following versions or later. Display or control may not be operatedproperly.EPSON RC+ 7.0 Ver.7.4.7China RoHSThis sheet and environmental protection use period label are based on the regulation in China. These are not necessary to be concerned in other countries.产品中有害物质的名称及含量机器人型号名称T VT 部件名称有害物质铅汞镉 六价铬 多溴 联苯多溴 二苯醚(Pb)(Hg)(Cd) (Cr(VI))(PBB)(PBDE)机器人部× ○ ○ ○ ○ ○电机 (执行器单元、电机单元) × ○ ○ ○ ○ ○ 减速机单元 × ○ ○ ○ ○ ○ 电磁制动器 × ○ ○ ○ ○ ○ 同步皮带 ○ ○ ○ ○ ○ ○ 电池单元(电池、电池固定架、电池基板) × ○ ○ ○ ○ ○ 密封(密封填料、油封、密封脂、 垫片、O 型环) × ○ ○ ○ ○ ○ 润滑脂 ○ ○ ○ ○ ○ ○ 电缆 (M/C 电缆、连接电缆) × ○ ○ ○ ○ ○ 散热片 ○ ○ ○ ○ ○ ○ LED 指示灯 ○ ○ ○ ○ ○ ○ 电路板× ○ ○ ○ ○ ○ 滚珠丝杠花键 (T 系列) ○ ○ ○ ○ ○ ○ 制动解除开关 × ○ ○ ○ ○ ○ 外罩 ○ ○ ○ ○ ○ ○ 扎带○ ○ ○ ○ ○ ○ 原点标记 ○ ○ ○ ○ ○ ○ 气管接头× ○ ○ ○ ○ ○ 选件VT 相机板单元× ○ ○ ○ ○ ○ 外部配线配套元件 ○ ○ ○ ○ ○ ○ 工具适配器(ISO 法兰) ○ ○ ○ ○ ○ ○ 相机安装板○ ○ ○ ○ ○ ○ 可调机械挡块 ○ ○ ○ ○ ○ ○ T相机安装板 × ○ ○ ○ ○ ○ 兼容板×○○○○○本表格依据SJ/T 11364的规定编制。

EPSON编程EPSON编程范本:1. 简介1.1 背景1.2 目的1.3 范围2. 系统要求2.1 硬件要求2.2 软件要求3. 安装与设置3.1 安装EPSON软件3.2 配置控制器3.3 连接控制器与计算机4. 基本概念与术语4.1 控制器4.2 程序4.3 坐标系4.4 轨迹规划4.5 传感器接口4.6 通信接口5. 编程环境介绍5.1 EPSON编程语言概述 5.2 EPSON编程软件界面 5.3 创建新程序5.4 编辑程序5.5 调试程序5.6 程序到控制器6. 运动控制6.1 基本运动指令6.2 坐标系转换6.3 关节运动与直线运动 6.4 运动限制与碰撞检测 6.5 运动示教与记录6.6 运动轨迹优化7. 运动规划7.1 运动轨迹规划算法7.2 运动规划参数调整7.3 高级运动规划功能介绍8. 传感器接口与应用8.1 常见传感器接口类型8.2 传感器数据读取与处理8.3 传感器应用案例9. 通信接口与控制9.1 通信接口介绍9.2 通信协议配置与使用9.3 远程控制与监控10. 故障排除与维护10.1 常见故障代码与解决方案10.2 维护保养与日常检查11. 参考资料与附件11.1 参考文献11.2 相关网址11.3 附件列表本文档涉及附件:附件1:EPSON编程示例程序附件2:EPSON编程软件安装文件本文所涉及的法律名词及注释:1. 控制器:一种用于控制运动、进行编程和调试的硬件设备。

2. 坐标系:用于描述空间位置与方向的数学坐标系。

3. 轨迹规划:计算机运动轨迹的算法或方法。

4. 传感器接口:用于与控制器连接外部传感器的接口。

5. 通信接口:用于与控制器进行数据通信与远程控制的接口。

爱普生机器人软件安装及使用教程

一、EPSON RC+ 5.0开发软件的安装

打开EpsonRC50文件夹,双击setup.exe开始安装。

出现上面显示的界面后,按按钮。

出现上面显示的界面后,再接着按按钮。

目标驱动器不必选择,直接按按钮。

上面可勾选部分为手册和模拟器实例,可以按默认安装,直接按按钮进行到安装的下一步。

按按钮选择继续安装。

会出现下面的安装进度界面,大约需要等待几分钟,整个EpsonRC50软件安装完成。

安装完成后,将弹出下面的窗口。

按按钮完成软件的安装。

此时,在用户的桌面上会出现下面两个图标

前一个图标用于软件的开发和调试,后面的图标用于对工作流程的监视。

二、IP地址的设置

用普通网线连接机器人和开发用电脑。

打开本地连接,弹出“本地连接属性”页面。

双击项,将打开Internet 协议(TCP/IP)属性页面,修改IP地址等项为下图的值。

按键。

完成IP的设定。

三、EPSON RC+ 5.0软件使用

双击图标,启动EPSON RC+ 5.0软件。

1. 网络通讯的设置

在EPSON RC+ 5.0软件菜单中点击“设置”菜单项,单击选择项目。

将弹出下面“电脑与控制器通信”

页面。

点击按钮。

选择选项,按键,完成添加网络通讯功能。

点击IP地址单元项,将里面机器人控制器对应的IP改为192.168.0.1,单击按钮,完成软件中连接IP的设置。

设置完成后页面显示为下图。

检查网线连接是否正常,正常则单击新添加的Ethernet项,

按按钮,弹出下面页面。

选项表示电脑只作为监视器使用,不能进行程序的编制、修改等操作,不能对机器人控制点进行示教,也不能对外部I/O进行控制。

不影响已经存在的网络连接。

选项将首先中断目前和控制器的网络连接,将软件切换到程序模式,在此模式下可以进行控制程序的编制、修改工作,机器人控制点的示教和对外部I/O进行实时控制。

为了进行控制程序的编写、修改和调试,我们需要选择

项目并按键切换到程序模式。

此后EPSON RC+ 5.0软件将开始尝试连接RC170机器人控制器,连接成功后页面为下图状态。

按按钮离开设置界面。

2. 控制器的设置

在菜单项里单击“设置”项,再单击“控制器”选项。

将弹出下面界面。

单击“配置”项,弹出下面界面

修改“控制设备(O)”项目。

如果需要本机调试,可修改为PC,如需要使用按钮盒,则需要修改为“远程I/O”状态。

修改

完成后,按键关闭设置页面。

完成上面设置后,机器人已经处于可操作状态。

3. 机器人的示教

在菜单项里单击“设置”项,再单击“机器人管理器”选项。

将进入机器人管理器页面。

其中可进行多种操作,目前我们可使用控制面板、步进示教和点数据三个项目。

⑴.控制面板

单击控制面板,弹出下面页面

复机器人的可运行状态。

按钮:关闭机器人

按钮:启动机器人

按钮:在按下“急停”后,机器人进入锁定,必须按下

状态。

⑵.步进示教。