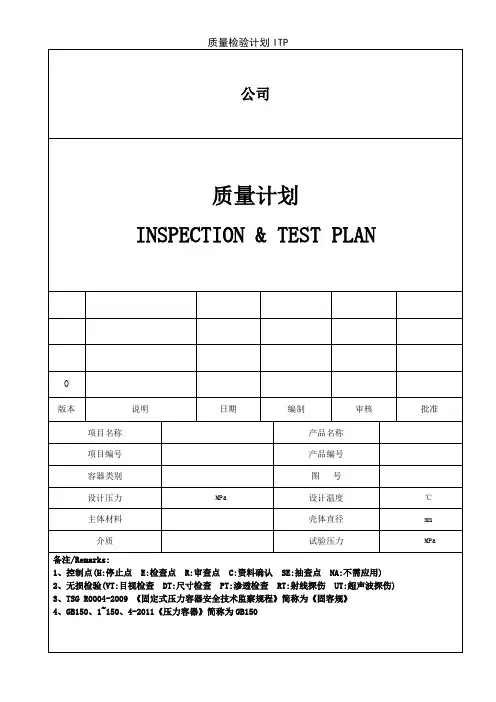

检验试验计划(ITP)中英文

- 格式:doc

- 大小:4.01 MB

- 文档页数:53

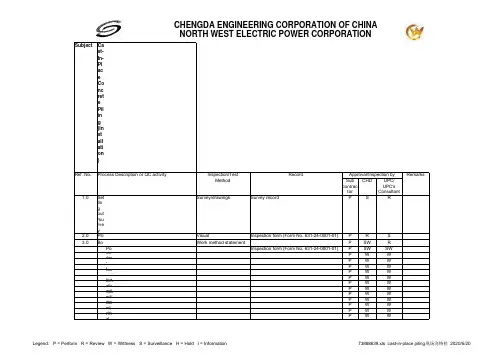

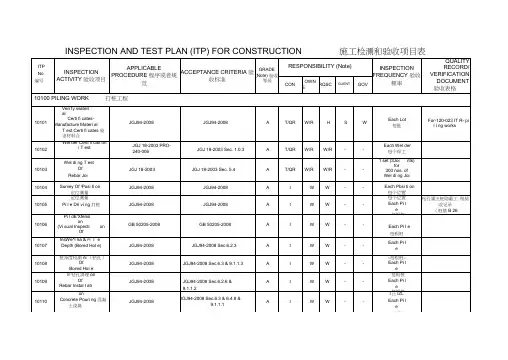

SubjectCast-In-Place Concrete Piling (Installation)Sub contrac tor CHD UPC/UPC's Consultant 1.0Setting out/surveySurvey/drawings Survey recordP S R 2.0Piling equipment preparation VisualInspection form (Form No. 631-24-0001-01)P R S 3.0BoringWork method statementP SW R Position and alignment checkInspection form (Form No. 631-24-0001-01)P SW SW Underground servicesP W W Surface casing size & condition P W W First casing installationP W W Correct borehole size & side P W W VerticalityP W W Length of boreholeP W W Cleanliness of bottom boreholeP W W Collection for soil sample (if required)P W W Temporary casing size & condition (if any) P W W Bored Soil RemovalP W W Equipment Specification Requirement P W W Final Site ClearingP W W 4.0ReinforcementWork method statement Inspection form (Form No. 631-24-0001-02)4.1MaterialStandard Lab tests Material certificateH R W 4.2P W S 4.3P W S 4.4P W W 4.5P W S 4.6P W S 4.7P W S 4.8P W R 4.9P W R P W W 4.10P W W 4.11P W W 4.12P W W 5.0RecordInspection form (Form No. 631-24-0001-03)Date P W S TimeP W S Bored Depth P W W Soil Description P W R Bentonite checkedPW R 6.0Concrete6.1Material Standard Lab testsMaterial certificateH R W 6.2SupplyWork method statementInspection form (Form No. 631-24-0001-04)P SW SW Concete Class / Grade P W R Mix Design No.P W R Attached conc. delivery slips P W S Discharge Time P W S Concrete Quantity P W S Placing Method P W S Batch TimePWSProcess Description or QC activityRef. No.Number & length tube testing (if any)The top elevation of the re-bar cage Embeded method_______________Quality embeddingInspection/TestMethodRemarksRecordApproval/Inspection by Correct re-bar size, type & length Number of re-bars usedCorrect diameter, length & number of cage Re-bar spacingCorrect spacer for cover & sufficient numbers Overhang of cage______cm Embeded length______cmCleanliness of re-barSubjectCast-In-Place Concrete Piling (Installation)Sub contractor CHD UPC/UPC's Consultant Process Description or QC activityRef. No.Inspection/TestMethodRemarksRecordApproval/Inspection by。

幕墙工程itp质量检验计划英文回答:Quality Inspection Plan for Curtain Wall Project ITP.Introduction:The purpose of this Quality Inspection Plan is to ensure that the curtain wall project meets the required quality standards and specifications. The plan outlines the inspection procedures, responsibilities, and documentation requirements for the quality control of the curtain wall installation.Inspection Procedures:1. Pre-Installation Inspection: Before the installation of the curtain wall, a pre-installation inspection will be conducted to check the materials, dimensions, and alignment of the components.2. Installation Inspection: During the installation process, inspections will be carried out to verify the correct installation of the curtain wall panels, frames, and sealants.3. Final Inspection: Upon completion of the installation, a final inspection will be conducted to ensure that the curtain wall meets the design specifications and quality standards.Responsibilities:The project manager is responsible for overseeing the implementation of the Quality Inspection Plan and ensuring that all inspections are carried out according to the schedule.The quality control team will be responsible for conducting the inspections and documenting the inspection results.The construction team is responsible for addressing any non-conformities identified during the inspections and ensuring that corrective actions are taken.Documentation Requirements:Inspection Checklists: Detailed checklists will be used to record the results of each inspection, including anynon-conformities and corrective actions taken.Inspection Reports: Comprehensive reports will be prepared for each inspection, documenting the findings and any follow-up actions required.Non-Conformance Reports: If any non-conformities are identified, non-conformance reports will be raised to document the issue and the corrective actions taken.Conclusion:By implementing this Quality Inspection Plan, we aim to ensure that the curtain wall project is installed to therequired quality standards and specifications. Through thorough inspections and documentation, we will be able to identify and address any quality issues in a timely manner, ultimately delivering a high-quality curtain wall system.中文回答:幕墙工程ITP质量检验计划。

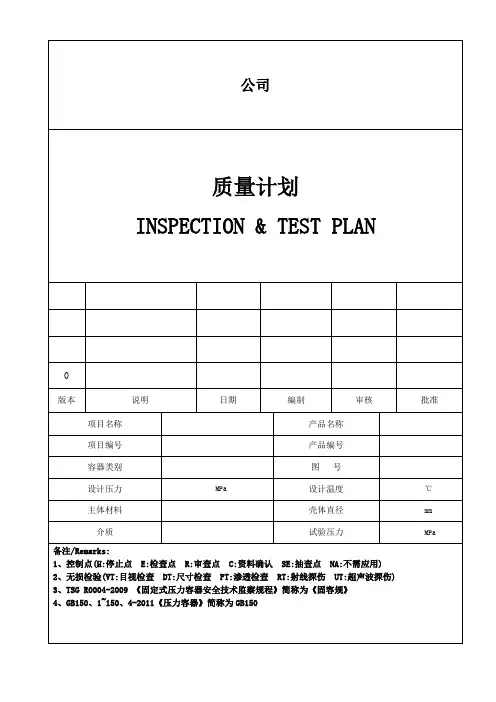

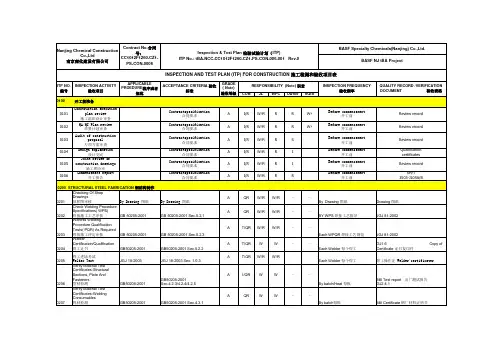

Inspection and testing plan检验和试验计划Project NameP.O. NumberEquipment NameItem No.VENDOR’S DOCUMENT NO.Rev.Date 日期Subject Of Revision 修改主题Prepared 编制Reviewed 审核Approved 批准5701No.序号Description ofinspection检验内容Standards for theInspection检验标准和依据1.ASME Code SectionVIII, Division 1ASME 规范第VIII 卷第1分册2.ASME Code Section II-AASME 规范第II 卷A 篇3.EN 10204 3.14.Approved drawings图纸要求5.MOM,Spec.Check the items核实内容1. The dimension and mark shall suit with the relevantrequirements. PMI shall be done as per the PMI procedure.所采购的材料尺寸规格及标记必须符合相应标准的要求。

按照PMI 程序对材料进行PMI 检验。

2. VT is required making sure there is no unacceptable surfacedefects.目视检查以确定没有无法接受的表面缺陷。

3 All material of all pressure retaining parts and its attachmentsshall be delivered with certificates, materials shall be deliveredwith mill certificates (Min. 3.1 certificates acc. to EN10204).所有受压元件材料及其附件材料应提供合格证书,合格证书至少符合EN 10204 3.1。

itp质量检验计划的五个点英文回答:1. Define the scope of the quality inspection: The quality inspection plan (QIP) should clearly define the scope of the inspection, including the specific products, materials, or components to be inspected.2. Establish inspection criteria: The QIP should outline the specific criteria and standards that will be used to evaluate the quality of the products. This may include dimensions, performance specifications, material requirements, and any applicable industry standards or regulations.3. Determine inspection methods and tools: The QIP should specify the methods and tools that will be used to conduct the inspection, such as visual inspection, measurements, testing equipment, and sampling procedures.4. Identify responsible parties: The plan should designate the individuals or teams responsible for carrying out the inspection, as well as any third-party inspection agencies or suppliers involved in the process.5. Schedule and frequency of inspections: The QIP should include a schedule for when inspections will take place, as well as the frequency of inspections, whether they are pre-production, in-process, or final inspections.中文回答:1. 确定质量检验的范围,质量检验计划(QIP)应明确定义检验的范围,包括要检验的具体产品、材料或零部件。

越南汪秘电厂单位工程ITP检测与计划(中英文对照)SubjectCast-In-Place Concrete Piling (Installation)Sub contrac tor CHD UPC/UPC's Consultant 1.0Setting out/surveySurvey/drawings Survey recordP S R 2.0Piling equipment preparation VisualInspection form (Form No. 631-24-0001-01)P R S 3.0BoringWork method statementP SW R Position and alignment checkInspection form (Form No. 631-24-0001-01)P SW SW Underground servicesP W W Surface casing size & condition P W W First casing installationP W W Correct borehole size & side P W W VerticalityP W W Length of boreholeP W W Cleanliness of bottom boreholeP W W Collection for soil sample (if required)P W W T emporary casing size & condition (if any) P W W Bored Soil RemovalP W W Equipment Specification Requirement P W W Final Site ClearingP W W 4.0ReinforcementWork method statement Inspection form (Form No. 631-24-0001-02)4.1MaterialStandard Lab tests Material certificateH R W 4.2P W S 4.3P W S 4.4P W W 4.5P W S 4.6P W S 4.7PW S 4.8P W R 4.9P W R P W W 4.10P W W 4.11P W W 4.12P W W 5.0RecordInspection form (Form No. 631-24-0001-03)Date P W S TimeP W S Bored Depth P W W Soil Description P W R Bentonite checkedPW R 6.0Concrete6.1Material Standard Lab testsMaterial certificateH R W 6.2SupplyWork method statementInspection form (Form No. 631-24-0001-04)P SW SW Concete Class / Grade P W R Mix Design No.P W R Attached conc. delivery slips P W S Discharge Time P W S Concrete Quantity P W S Placing Method P W S Batch Time PWSProcess Description or QC activityRef. No.Number & length tube testing (if any)The top elevation of the re-bar cage Embeded method_______________Quality embeddingInspection/TestMethodRemarksRecordApproval/Inspection by Correct re-bar size, type & length Number of re-bars usedCorrect diameter, length & number of cage Re-bar spacing Correct spacer for cover & sufficient numbers Overhang of cage______cm Embeded length______cmCleanliness of re-barSubjectCast-In-Place Concrete Piling (Installation)Sub contractor CHD UPC/UPC's Consultant Process Description or QC activityRef. No.Inspection/TestMethodRemarksRecordApproval/Inspection by。