检验试验计划(ITP)中英文

- 格式:doc

- 大小:3.49 MB

- 文档页数:53

itp质量检验计划的五个点英文回答:1. Define the scope of the quality inspection: The quality inspection plan (QIP) should clearly define the scope of the inspection, including the specific products, materials, or components to be inspected.2. Establish inspection criteria: The QIP should outline the specific criteria and standards that will be used to evaluate the quality of the products. This may include dimensions, performance specifications, material requirements, and any applicable industry standards or regulations.3. Determine inspection methods and tools: The QIP should specify the methods and tools that will be used to conduct the inspection, such as visual inspection, measurements, testing equipment, and sampling procedures.4. Identify responsible parties: The plan should designate the individuals or teams responsible for carrying out the inspection, as well as any third-party inspection agencies or suppliers involved in the process.5. Schedule and frequency of inspections: The QIP should include a schedule for when inspections will take place, as well as the frequency of inspections, whether they are pre-production, in-process, or final inspections.中文回答:1. 确定质量检验的范围,质量检验计划(QIP)应明确定义检验的范围,包括要检验的具体产品、材料或零部件。

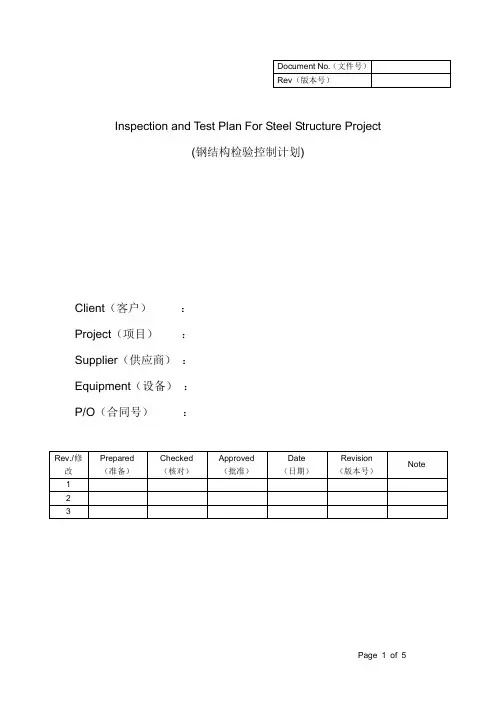

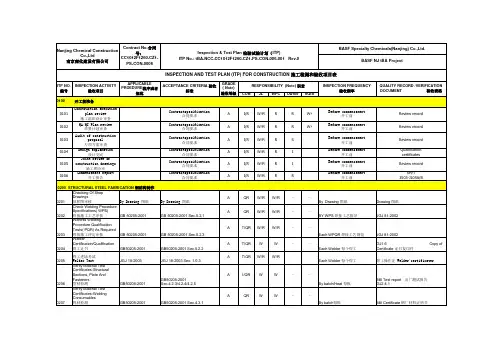

Inspection and testing plan检验和试验计划Project NameP.O. NumberEquipment NameItem No.VENDOR’S DOCUMENT NO.Rev.Date 日期Subject Of Revision 修改主题Prepared 编制Reviewed 审核Approved 批准5701No.序号Description ofinspection检验内容Standards for theInspection检验标准和依据1.ASME Code SectionVIII, Division 1ASME 规范第VIII 卷第1分册2.ASME Code Section II-AASME 规范第II 卷A 篇3.EN 10204 3.14.Approved drawings图纸要求5.MOM,Spec.Check the items核实内容1. The dimension and mark shall suit with the relevantrequirements. PMI shall be done as per the PMI procedure.所采购的材料尺寸规格及标记必须符合相应标准的要求。

按照PMI 程序对材料进行PMI 检验。

2. VT is required making sure there is no unacceptable surfacedefects.目视检查以确定没有无法接受的表面缺陷。

3 All material of all pressure retaining parts and its attachmentsshall be delivered with certificates, materials shall be deliveredwith mill certificates (Min. 3.1 certificates acc. to EN10204).所有受压元件材料及其附件材料应提供合格证书,合格证书至少符合EN 10204 3.1。

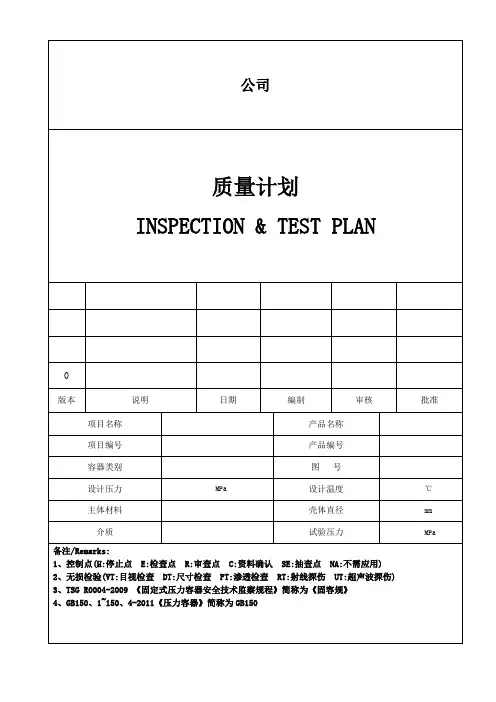

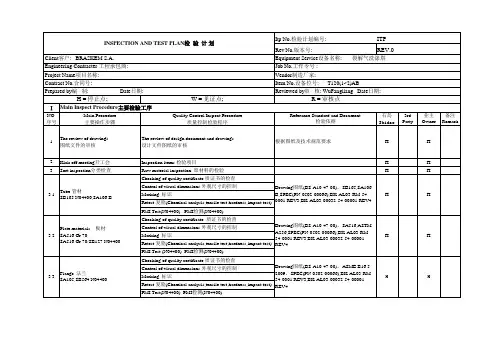

循环流化床锅炉检验&试验计划ITP for CFB BoilerEdited by: Huang Xiaoyan编制: 黄小燕Approved by: Zhang Minxian批准: 张敏娴无锡华光锅炉股份有限公司WUXI HUAGUANG BOILER CO.,LTD.2011Page 1 of 7 Supervisor监造方:The Customer 客户方: The Owner用户方: 循环流化床检验试验计划ITP for CFB BoilerAbbreviations 缩写词:R = Review W = Witness H = HoldApplicable Code: GBNo. 序号Test and Examinations Item测试和检查项Reference Document andAcceptance Norm参考文件及验收标准Format of Record记录形式Inspection检验点WHBC HDS Cambodia1. 汽包Drum1.1 原材料及焊材质量证明书Quality certificate of raw martial and welding materialJB/T3375质量证明书Quality CertificateH H1.2 原材料及焊材入厂验收Entrance inspection of raw martial and welding material.JB/T3375材料入厂检验报告& 材质传递卡Entrance inspection report&Material Travelling SheetH H1.3 切割、标识移植Cutting and Material marking transferring JB/T3375 / R R1.4 封头成型The forming of the head图纸、工艺Drawings & Procedure封头成型记录The forming record of theheadW R1.5 筒体卷制The Rolling of the shell图纸、工艺Drawings & Procedure检验记录The Inspection recordW W1.6 焊接工艺检查welding procedure inspection图纸、工艺Drawings & ProcedureWPS、PQR R R1.7 纵、环缝装配、焊接(对接间隙、坡口、尺寸、表面质量等Fit-up and welding for longitudinal & circumferential weld图纸、工艺Drawings & Procedure检验记录The Inspection recordW W1.8 焊后无损探伤NDE after welding图纸、工艺Drawings & Procedure无损探伤报告NDE reportH R1.9 划线和钻孔Layout and drilling holes图纸Drawings检验记录The Inspection recordW RPage 2 of 7 Supervisor监造方:The Customer 客户方: The Owner用户方: 循环流化床检验试验计划ITP for CFB BoilerAbbreviations 缩写词:R = Review W = Witness H = HoldApplicable Code: GBNo. 序号Test and Examinations Item测试和检查项Reference Document andAcceptance Norm参考文件及验收标准Format of Record记录形式Inspection检验点WHBC HDS Cambodia1.10 装配管接头和下降管Fitting up and welding nozzles and downcomers 图纸、工艺Drawings & Procedure检验记录The Inspection recordW W1.11 焊后无损探伤NDE after welding图纸、工艺Drawings & Procedure无损探伤报告NDE reportH R1.12 最终内部及外部焊缝及母材的外观检查Final visual inspection for all welds and materials both internally and externally图纸、工艺Drawings & Procedure检验记录The Inspection recordH W1.13 焊后热处理PWHT热处理工艺Heat treatment procedure热处理报告Heat treatment reportH R1.14 水压试验Hydrostatic test水压试验程序Hydraulic test procedure水压试验报告Hydrostatic test reportH H1.15 最终尺寸检查Final dimensional inspection图纸Drawings检验记录The Inspection recordW W1.16 表面清理和油漆Surface preparation and painting 表面处理和油漆程序Surface preparation and painting process/ W W1.17 标记和包装确认Marking & packing verification发货清单Packing list/ H W2. 集箱Header2.1 钢管材料质保书Quality certificate of steel pipe JB/T3375质量证明书Quality CertificateH R2.2 钢管入厂验收Entrance inspection report of pipe JB/T3375 材料入厂检验记录Entrance inspection recordH RPage 3 of 7 Supervisor监造方:The Customer 客户方: The Owner用户方: 循环流化床检验试验计划ITP for CFB BoilerAbbreviations 缩写词:R = Review W = Witness H = HoldApplicable Code: GBNo. 序号Test and Examinations Item测试和检查项Reference Document andAcceptance Norm参考文件及验收标准Format of Record记录形式Inspection检验点WHBC HDS Cambodia2.3 集箱管、端盖的下料、钻孔、加工和标记移植Cutting, drilling, machining of headers ends andheaders图纸Drawing/ W R2.4 装配、焊接集箱本体及端盖Fit-up and welding header to header or header to flat end图纸、工艺Drawings & Procedure检验记录The Inspection recordW W2.5 对接焊缝无损探伤DNE for butt weld图纸Drawing检验记录Inspection recordW R2.6 焊接管接头Welding nozzles图纸、工艺Drawings & Procedure检验记录Inspection recordW W2.7 角焊缝无损探伤DNE of nozzles welds图纸Drawing无损探伤报告NDE reportR R2.8 最终内部及外部焊缝及母材的外观检查Final visual inspection for all welds and materials both internally and externally图纸、工艺Drawings & Procedure检验记录The Inspection recordH W2.9 焊后热处理PWHT热处理工艺Heat treatment procedure热处理报告Heat treatment reportH R2.10 水压试验Hydrostatic test水压试验程序Hydraulic test procedure水压试验报告Hydrostatic test reportH W2.11 表面清理和油漆Surface preparation and painting 表面处理和油漆程序Surface preparation and painting process/ W W2.12 标记和包装确认Marking & packing verification发货清单Packing list/ H W3. 水冷壁Membrane wallPage 4 of 7 Supervisor监造方:The Customer 客户方: The Owner用户方: 循环流化床检验试验计划ITP for CFB BoilerAbbreviations 缩写词:R = Review W = Witness H = HoldApplicable Code: GBNo. 序号Test and Examinations Item测试和检查项Reference Document andAcceptance Norm参考文件及验收标准Format of Record记录形式Inspection检验点WHBC HDS Cambodia3.1 材料质保书Quality certificate of raw martial JB/T3375质量证明书Quality CertificateH R3.2 原材料入厂验收Entrance inspection report of raw martial JB/T3375 材料入厂检验记录Entrance inspection recordH R3.3 管子与鳍片焊接Fin and tube welding图纸、工艺Drawings & Procedure检验记录Inspection recordW W3.4 管屏上对开孔部位进行划线Layout the position of opening on the panel 图纸Drawing检验记录Inspection recordW R3.5 弯管Bending tube图纸Drawing/ W W3.6 管子装配对接Fit-up & welding tube to tube工艺Procedure检验记录Inspection recordW W3.7 对接焊缝无损探伤DNE of butt weld图纸、工艺Drawings & Procedure无损探伤报告NDE reportR R3.8 弯管外表面检查(外形尺寸、减薄量、椭圆度等External surface of bending tube(dimensional, thickness reduction, ellipticity图纸Drawing检验记录Inspection recordR W3.9 通球、水压试验Through ball & Hydrostatic test 水压试验程序Hydraulic test procedure水压试验报告Hydrostatic test reportH W3.10 水冷壁组片检查Panel inspection图纸Drawing检验记录Inspection recordW W3.11 表面清理和油漆Surface preparation and painting 表面处理和油漆程序Surface preparation and painting process/ W WRev. 1 Date: Page 5 of 7 Supervisor 监造方: The Customer 客户方: The Owner 用户方: No. 序号 Test and Examinations Item 测试和检查项标记和包装确认 Marking & packing verification 省煤器 Economizer 材料质保书 Quality certificate of raw martial 原材料入厂验收 Entrance inspection report of raw martial 管子对接焊 Tube to tube welding 对接焊缝无损探伤 DNE of butt weld 弯管外表面检查(外形尺寸、减薄量、椭圆度等) External surface of bending tube(dimensional, thickness reduction, ellipticity 装配&焊接管夹 Fit-up and weld strap 焊后无损探伤 NDE after welding 焊后热处理( 如需要 PWHT( if necessary 通球、水压试验 Through ball & Hydrostatic test 表面清理和油漆 Surface preparation and painting 循环流化床检验试验计划 ITP for CFB Boiler Abbreviations 缩写词: R = Review W = Witness H = Hold Applicable Code: GB Reference Document and Acceptance Norm 参考文件及验收标准发货清单Packing list Format of Record 记录形式 / Inspection 检验点 WHBC H HDS Cambodia 3.12 4. 4.1 4.2 4.3 4.4 W JB/T3375 JB/T3375I 工艺 Procedure 图纸 Drawings 图纸Drawing 图纸 Drawing 图纸 Drawings 热处理工艺 Heat treatment procedure 水压试验程序 Hydraulic test procedure 表面处理和油漆程序 Surface preparation and painting process 质量证明书 Quality Certificate 材料入厂检验记录 Entrance inspection record 检验记录 The Inspection record 检验记录 The Inspection record 检验记录 Inspection record / 无损探伤报告 NDE report 热处理报告 Heat treatment report 水压试验报告Hydrostatic test report / H H W R R R W R 4.5 R W 4.6 4.7 W R / R R W W 4.8 4.9 4.10 R H W 5Rev. 1 Date: Page 6 of 7 Supervisor 监造方: The Customer 客户方: The Owner 用户方: No. 序号 Test and Examinations Item 测试和检查项标记和包装确认 Marking & packing verification 过热器 Superheater 材料质保书 Quality certificate of raw martial 原材料入厂验收 Entrance inspection report of raw martial 管子对接焊 Tube to tube welding 对接焊缝无损探伤 DNE of butt weld 弯管外表面检查(外形尺寸、减薄量、椭圆度等) External surface of bending tube(dimensional, thickness reduction, ellipticity 装配附件 Fit-up attachment 焊后无损探伤 NDE after welding 焊后热处理( 如需要 PWHT( if necessary 通球、水压试验 Through ball & Hydrostatic test 表面清理和油漆 Surface preparation and painting 循环流化床检验试验计划 ITP for CFB Boiler Abbreviations 缩写词: R = Review W = Witness H = Hold Applicable Code: GB Reference Document and Acceptance Norm 参考文件及验收标准发货清单 Packing list 图纸 Drawings JB/T3375 JB/T3375 工艺 Procedure 图纸 Drawings 图纸 Drawing Format of Record 记录形式 / Inspection 检验点 WHBC H HDS Cambodia 4.11 5. 5.1 5.2 5.3 5.4 W 质量证明书 Quality Certificate 材料入厂检验记录 Entrance inspection record 检验记录 The Inspection record 检验记录 The Inspection record 检验记录Inspection record H H W R R R W R 5.5 R W 5.6 5.7 5.8 5.9 5.10 图纸 Drawing 图纸Drawings 热处理工艺 Heat treatment procedure 水压试验程序 Hydraulic test procedure 表面处理和油漆程序 Surface preparation and painting process / 无损探伤报告 NDE report 热处理报告 Heat treatment report 水压试验报告 Hydrostatic test report / W R W R R W W 6 R H WRev. 1 Date: Page 7 of 7 Supervisor 监造方: The Customer 客户方: The Owner 用户方: No. 序号 Test and Examinations Item 测试和检查项标记和包装确认 Marking & packing verification 再热器 reheater 材料质保书 Quality certificate of raw martial 原材料入厂验收 Entrance inspection report of raw martial 管子对接焊 Tube to tube welding 对接焊缝无损探伤 DNE of butt weld 弯管外表面检查(外形尺寸、减薄量、椭圆度等) External surface of bending tube(dimensional, thickness reduction, ellipticity 装配附件 Fit-up attachment 焊后无损探伤 NDE after welding 焊后热处理( 如需要 PWHT( if necessary 通球、水压试验 Through ball & Hydrostatic test 表面清理和油漆 Surface preparation and painting 循环流化床检验试验计划 ITP for CFB Boiler Abbreviations 缩写词: R = Review W = Witness H = Hold Applicable Code: GB Reference Document and Acceptance Norm 参考文件及验收标准发货清单 Packing list Format of Record 记录形式 / Inspection 检验点 WHBC H HDS Cambodia 5.11 6 61 6.2 6.3 6.4 W JB/T3375 JB/T3375 工艺 Procedure 图纸 Drawings 图纸 Drawing 质量证明书 Quality Certificate 材料入厂检验记录 Entrance inspection record 检验记录 The Inspection record 检验记录 The Inspection record 检验记录 Inspection record H H W R R R W R 6.5 R W 6.6 6.7 6.8 6.9 6.10 图纸 Drawing 图纸 Drawings 热处理工艺 Heattreatment procedure 水压试验程序 Hydraulic test procedure 表面处理和油漆程序Surface preparation and painting process / 无损探伤报告 NDE report 热处理报告 Heat treatment report 水压试验报告 Hydrostatic test report / W R W R R W W 7 R H WRev. 1 Date: Page 8 of 7 Supervisor 监造方: The Customer 客户方: The Owner 用户方: No. 序号 Test and Examinations Item 测试和检查项标记和包装确认 Marking & packing verification 锅炉钢结构 (立柱、横梁、大板梁 Boiler steel structure (column, beam,plate girder 钢材质保书 Quality certificate of steel 钢材入厂复验Entrance re-inspection of steel 钢材表面质量及尺寸检查 Surface quality & dimensional inspection of steel 焊缝表面质量( 外观、尺寸 External quality of weld (appearance、dimension 焊后无损探伤 NDE after welding 主要尺寸检查 Main dimension inspection 预组合检查 Pre-assemble inspection 表面清理和油漆 Surface preparation and painting 标记和包装确认 Marking & packing verification 循环流化床检验试验计划 ITP for CFB Boiler Abbreviations 缩写词: R = Review W = Witness H = Hold Applicable Code: GB Reference Document and Acceptance Norm 参考文件及验收标准发货清单Packing list Format of Record 记录形式 / Inspection 检验点 WHBC H HDS Cambodia 6.11 7 W 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 7.9 相关标准 Relevant standard JB/T3375 相关标准 Relevant standard 图纸 Drawings JB/T1620 图纸 Drawings JB/T1620 表面处理和油漆程序 Surface preparation and painting process 发货清单 Packing list 质量证明书Quality Certificate 材料复验报告 Re-inspection report 检验记录 Inspection record 检验记录 Inspection record 无损探伤报告 NDE report 检验记录 Inspection record 检验记录 Inspection record / / W W W W R W W W W R R W W R W W W W 8。

QC:Quality control,即质量控制,通称质检。

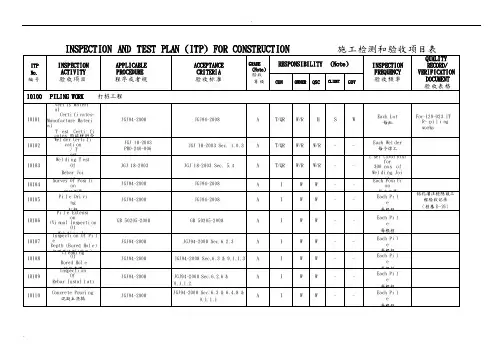

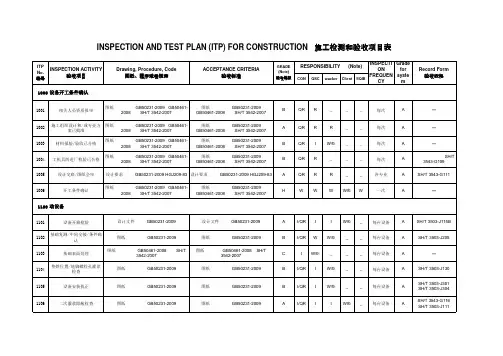

主要工作为:1)检查和试验计划(ITP)见证消点,即在施工活动中技术部需编制检查和试验计划,由质检部选择要控制的点(通常有H点W点R点),然后在施工过程中由施工部门通知质检部进行验证,已确定此工序是否满足要求,是否可进行下一道工序。

2)物项的验收。

质检部会参与物资部的物项验收工作,确定、核实进场物项是否满足要求。

3)施工过程巡视。

质检部对施工过程中发现的质量问题、不符合项有权开启质量问题单,要求责任部门、单位进行整改。

QA:quality assurance,即质量保证,通称质保。

主要工作为:1)负责编制项目质保大纲(也称质量手册),要求各部门依据质保大纲编制相应的程序文件,并在需要的时候对质保大纲进行修订升版。

2)验证项目执行质保大纲的有效性。

通过管理部门审查,质保监查等活动,验证各单位、部门执行质保大纲的有效性、充分性,并根据发现问题开启相关质量问题单。

3)项目整体施工情况监督。

质保部通过编制年度、月度等质保监督计划,对施工过程中重点控制对象进行监督,验证各单位、部门执行大纲、程序的有效性、充分性,并根据发现问题开启相关质量问题单。

4)质量问题分析。

质保部建立项目质量问题单(如不符合项NCR、纠正措施CAR、质量观察意见QOR等)数据库,并及时更新相关质量问题单开启、发布情况,根据质量问题单编制项目质量趋势分析报告,对项目质量趋势情况进行分析,并提出可行性纠正措施。

5)潜在供应商评价。

负责对潜在物项、服务供应商的评审工作。

上述主要介绍了QA与QC的工作,可以了解到一些职责分工的信息,但人常说质检、质保不分家,有的单位质保、质检是一个部门,陈QA/QC部。

质保、质检都是质量管理部门,平时工作要互相协作,共同努力,建设好项目、单位的质量控制工作。

值得说明的一点是,质保、质检部都是依据法规、标准来执行质量控制的部门,不参与实际工程施工。

IQC.OQC 都是品管的一个部分他们验货的对象不一样来区分的IQC 主要是验工厂进料(原材料部分) 也就是主要验我公司从外厂采购进来的东西.只有验OK了,我门才能让东西入库和上线生产的.OQC 只要针对的是我们公司自己生产的东西.只有验OK了才可以出货给我门的客户3、具体细分QC即英文QUALITY CONTROL的简称,中文意义是品质控制QA即英文QUALITY ASSURANCE 的简称,中文意思是品质保证IQC(incoming quality control)意思是来料的质量控制,简称来料控制OQC=Outgoing Quality Control “出货检验QS是食品“质量安全”(Quality Safety)的英文缩写SQA=Solfware Quality Assurance就是软件质量保证。