YUY-08 模具陈列柜

- 格式:docx

- 大小:201.32 KB

- 文档页数:3

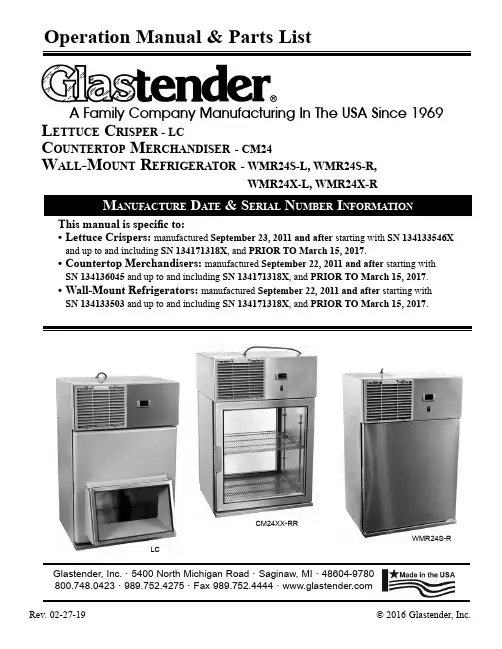

Glastender, Inc. · 5400 North Michigan Road · Saginaw, MI · 48604-9780800.748.0423 · 989.752.4275 · Fax 989.752.4444 · L ettuce c risper - Lcc ountertop M erchandiser- cM24W aLL -M ount r efrigerator - WMr24s-L, WMr24s-r,WMr24X-L, WMr24X-r© 2016 Glastender, Inc.Rev. 02-27-19A Family Company Manufacturing In The USA Since 1969M anufacture d ate & s eriaL n uMber i nforMationThis manual is specific to:• Lettuce Crispers: manufactured September 23, 2011 and after starting with SN 134133546Xand up to and including SN 134171318X , and PRIOR TO March 15, 2017.• Countertop Merchandisers: manufactured September 22, 2011 and after starting with SN 134136045 and up to and including SN 134171318X , and PRIOR TO March 15, 2017.• Wall-Mount Refrigerators: manufactured September 22, 2011 and after starting with SN 134133503 and up to and including SN 134171318X , and PRIOR TO March 15, 2017.CM24XX-RRWMR24S-RLC1Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780800.748.0423 • 989.752.4275 • Fax 989.752.4444 • This manual describes the operation features of the Lettuce Crisper, Countertop Merchandiser, and Wall-Mount Refrigerator. Please review this information before attempting installation and operation. Long term, trouble-free operation will follow if good housekeeping and maintenance procedures are followed. Thank you for selecting Glastender, Inc. products..u tiLity r equireMents and c onnectionsElectrical: 115 V olt AC, 1 Phase, 60 Hz, 6.64 full load amps. A separate 15 amp circuit isrequired. A 10-foot grounded cord is included.Plumbing: Automatic condensate evaporator. No drain connection required.u ncrating and s tart -up i nstructionsAll models are shipped in one carton. These steps should be followed:1. If legs are included, bolt them to the base with bolts provided.2. For lettuce crisper and wall-mount refrigerator wall mounting instructions, see page3. 3. Position unit. It must be level and plumb.4. Plug into 115 volt AC outlet.5. Your Glastender equipment is now ready for use.i ntroductionIMPORTANT !! Attention Service Companies IMPORTANT !!Please review the important warranty information on page 10. If you believe a service call should be coveredby the factory, please call the factory for authorization between 8AM and 5PM EST, Monday through Friday.2Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780800.748.0423 • 989.752.4275 • Fax 989.752.4444 • INSTRUCTIONS:NOTE: Mounting instruction applies to both the lettuce crisper andwall-mount refrigerator. Lettuce crisper shown in illustration.NOTE: 8″ of air space is required above unit to allow for air flow out. WARNING: Compressor failure due to restriction or blockage of air flow will void warranty.1. Mark a level line at the bottom of the lettuce crisper / wall-mount refrigerator.2. From this line measure up 24¾″ and mark another level line.3. On this line drill holes to match the holes in the wall mount bracket.4. Install wall mount bracket.5. Attach lettuce crisper / wall-mount refrigerator.6. If lettuce crisper / wall-mount refrigerator is not on an existing shelf, secure with bottom bracket.NOTE: At least two (2) of the mounting holes in the bracket should line up with studs in the wall for safe, secure mounting.ESTIMATED CLEANING TIME: 5 to 10 minutes per unit daily, 20 minutes weekly.FREQUENCY: Daily cleaning of exterior & door gaskets. Weekly cleaning of interior.PROCEDURE:1. A non-chlorine based cleaner or mild detergent and warm water applied with a soft cloth or sponge to all contact surfaces.2. Immediately rinse off cleaning agent(s), using clean warm water, clean soft cloth or sponge.3. Dry with a soft clean cloth, removing standing water as soon as possible.4. A more thorough cleaning of the interior should be done weekly (more frequently as necessary).5. The condensing unit air filter (front top left) should be removed and thoroughly rinsed in hot clean water at least once per quarter.NOTES:1. Never use hydrochloric acid, wire brushes, steel wool, scrapers, or chlorine based cleaners on stainless steel surfaces, since they willbreak down the passivity layer and allow corrosion to occur.2. On stainless steel surfaces, you may use a soft bristle brush or Scotch-Brite ® pad for more stubborn stains. Always scrub with thedirection of the grain. Follow with a thorough cleaning as described above.3. Deposits from food preparation must be properly removed. Even hard water deposits will rust stainless steel, if not removed.4. Door gaskets are most often overlooked when cleaning. Failure to clean them regularly will lead to premature failure, since alcoholand moisture build-up breaks down the gasket material.c Leaning i nstructionsC LBO TTOM BRACKET3Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780800.748.0423 • 989.752.4275 • Fax 989.752.4444 • The lettuce crisper, countertop merchandiser, and wall-mount refrigerator are programmed to automatically defrost four times daily for approximately twenty minutes. During defrost, the fan inside the cooler will remain on and the refrigeration system will turn off. To initiate defrost manually, push and hold the DEFROST button for more than two seconds.The thermostat controller does not have an “OFF” function. To turn the unit off, the unit must be unplugged or power to the electrical branch circuithas to be turned off via a circuit breaker or switch.The operating temperature range is preset at the factory according to the table below and can be adjusted up or down within the limits shown.To see the set point - push and immediately release the SET button. The set point will be displayed.To return to normal visualization - Push and immediately release the SET button or wait five seconds.To change the set point - push and hold the SET button for more than two seconds. When the º F display begins flashing, push the up arrow or down arrow buttons to adjust the set point to the desired value.To save the new set point and return to the temperature display mode - push and release the SET button or wait ten seconds.Models LC, CM24, and WMR24 regarding the Dixell digital thermostat controllerThe thermostat control probe wire connector maybecome disconnected when the front cover is removed. This will result in thermostat P1 code. While the P1 code is flashing the compressor will cycle 5 minutes on and 5 minutes off and may cause icing of the evaporator coil. Service calls to reconnect the probewiring are not covered by factory warranty.connector4Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780800.748.0423 • 989.752.4275 • Fax 989.752.4444 • The following electrical and refrigeration specifications apply:d esignr efrigerantp ressureM odeL e LectricaLt ypec harge h igh L oW R134a LC115V , 1 Ph., 60 Hz., 5.5 AMPR134a8.0 oz.23288Cond FanS t a r t R e l a yCSROverloadStart CapacitorWhiteC o m p r e s s o rWhiteGreenBlack12346789ControllerWhite BlueOrange Orange J BoxWhiteBlue 120/240VAC 50/60HZ12 VDCTransformerEvap FanBlueWhite Blue (-)(+)Power Supply 120VAC 60HZ 1PH Lights Per Unit VariesBrownLight SwitchOptional230VAC 50HZ 1PHLights for WMR / CM / UCR / FV5Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780800.748.0423 • 989.752.4275 • Fax 989.752.4444 • 67*81213*04/27/2017 -7. 11000131 has been discontinued6Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780800.748.0423 • 989.752.4275 • Fax 989.752.4444 • p art n o .d escriptionp ricee LectricaL c oMponents1217167Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780800.748.0423 • 989.752.4275 • Fax 989.752.4444 • 8Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780800.748.0423 • 989.752.4275 • Fax 989.752.4444 • 06009699p rices:All prices are LIST. Applicable taxes will be added.q uotations:Unless otherwise stated, quotations are effective for 30 days only.a cceptance:All orders are subject to acceptance by Glastender, Inc.’s headquarters in Saginaw, Michigan. Possession of the Product Directory and Price List is not an offer to sell.s hipMents:F.O.B. factory in Saginaw, Michigan. Freight terms are Third Party or Collect if shipped directly to you. Prepay and Add to Invoice freight terms are available upon request. The approximate shipping weights of all products are listed with the prices. Partial shipments will be made unless otherwise specified by the customer. Surface freight classifica-tions are:• GT-24/GT-30/GW24 Glasswashers - Class 175• GT-18 Glasswashers - Class 250• All Underbar Equipment - Class 175• Bar Die Orders – Class 250• Portable Bars - Class 175• Remote refrigerators (i.e., no compressor) or dry storage back bar equipment - Class 175• Self-contained refrigeration equipment - Class 150• Ice Display Units (IDU and GDU) - Class 85• Lighted Liquor Displays - Class 85• Beer line chillers and beer towers (beverage dispensing equipment) - Class 92.5• Bottle Disintegration System - Class 150• Ice Cream Freezers - Class 77.5All small items are evaluated to see the most cost effective means for shipment. Many small items ship via UPS or FedEx; however, when dimensional weight is excessive, LTL carriers are the most cost effective choice. Spare parts orders received before 1:00 PM EST can usually be shipped the same day.The order department is happy to assist with routing or shipping questions. p ayMent t erMs:Cash should be included with all orders unless credit terms have been arranged. To establish credit, banking and trade references are required.A convenient credit application is available upon request. Payment via credit card is not our normal means of receiving payment. Visa and MasterCard will be accepted, but must be charged at the time of ship-ment. In addition, a payment via credit card for orders totaling more than $500 will incur a 3% convenience fee on the total transaction amount.d eLivery:The majority of equipment is manufactured to order and typically ships within three to six weeks after complete order information is received by the factory. In-stock equipment typically ships within two to three days of the factory receiving complete order information.r eturns:Items specified as “Manufactured to Order” are NOT returnable.A Return Authorization number must be issued by the factory in advance for any items that are returnable. The number MUST be noted on the outside of the returned package. Returns must be received within 90 days of the issue date. Shipping charges must be prepaid. A mini-mum 20% restocking charge will be applied to all authorized returns if received in new, unused condition in the original packaging.The above conditions apply to spare part returns, except spare part returns must be received within 30 days of original shipment for elec-tronic or electrical parts or within 90 days for all other parts.L oss or d aMage:For customer routed shipments, Glastender, Inc. is not responsible for any loss, damage, or delay of merchandise during shipment. Such transit claims must be filed with the carrier. Merchandise must be examined on arrival. If shortages occur, Glastender, Inc. must be notified in writing within five (5) days of delivery to honor any shortage claim. Glastender will assume responsibility for freight claims on Prepay and Add ship-ments but the customer must inspect freight and note any damage upon receipt. Failure to do so may result in losses at the customer’s expense.c ustoM o rders:Custom orders must be paid in advance and are not subject to cancellation.L aMinates:Some products include common, readily available plastic laminates of the customer’s selection. There may be an additional charge if uncom-mon varieties are ordered.12/14/179Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780800.748.0423 • 989.752.4275 • Fax 989.752.4444 • 10Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780800.748.0423 • 989.752.4275 • Fax 989.752.4444 • Glastender, Inc. warrants all products to be free of defects in mate-rial and workmanship. One-year labor and parts warranty applies to all glasswashers, self-contained refrigeration models, and BDS model bottle disintegration units. In established areas, a start up is included with GT-24 and GT-30 model glasswashers. Warranty is effective for one year from the date of installation or up to 18 months from date of factory shipment, whichever occurs sooner. Glastender, Inc. will replace any part or assembly found defective under normal use and service.For warranty labor claims beyond 15 months from the date of factory shipment, proof of date of installation or occupancy must be provided. Authorization for labor must be obtained from Glastender within the warranty period and prior to the service being bor warranty applies to the United States and Canada only.Remote refrigeration models and beer line chillers include a one-year parts warranty only. There is no labor warranty on these products.Field replacement parts not covered under the original warranty include a 90-day part warranty from the date of installation.FOUR YEAR ADDITIONAL COMPRESSOR WARRANTY: Glastender will warrant to the original user the compressor for all self-contained refrigeration models for an additional four years following the regular one-year warranty period. This plan applies to the compressor only.A completed warranty claim form MUST accompany all returned defec-tive parts or assemblies. Upon request, a defective part or assembly must be returned to Glastender, Inc., Saginaw, Michigan, with all transporta-tion and delivery charges prepaid. Warranty repairs or replacements will be shipped FOB factory in Saginaw, Michigan. Reimbursement for applicable freight charges covers ground service only.Glastender provides in-warranty repairs during a service company’s regular working days and hours. There is no provision for payment of a premium rate during “overtime” hours. When warranty service is requested during other than normal working hours, the end user will be charged the premium portion of the overtime rate.The warranty covers substantiated travel expenses for up to 2 hours / 100 miles round trip up to a maximum of $150. Any additional costs due to installations that require extra work, time, or travel to gain access for service are the sole responsibility of the equipment purchaser. Any exceptions to these travel and access limitations must be pre-approved by a factory representative.The warranty does not cover door gaskets, chemical tubing, pump squeeze tubing, and/or any equipment subjected to accidents, freight damage, alterations from the original design, improper power and/or plumbing hookups, improper chemical use, general misuse, or lack of routine required maintenance as determined by Glastender, Inc. Installation, normal control adjustments, general maintenance, correct-ing an installation error, or service calls that reveal the unit is function-ing normally will not be reimbursed under warranty.Condenser coils on self-contained refrigeration products must be cleaned regularly. Failure to provide adequate air flow to a refrigeration unit will void the warranty.Glastender shall not be liable for loss of use, revenue, or profit, or for any other indirect, incidental, special, or consequential damage includ-ing, but not limited to, product spoilage or loss.This warranty is conditioned upon Glastender receiving notice of any defect subject to this warranty within sixty (60) days of its discovery by the end user or dealer. All products are warranted only for the initial place of installation. Removal of a product automatically terminates this warranty.SECOND YEAR EXTENDED PARTS & LA BO R WARRANTY:Glastender’s one-year parts and labor warranty on self-contained refrig-eration units, excluding beer line chillers, can be extended to two years with the purchase of a two year parts and labor warranty. Specify part number EWR2 ($150 net price) when ordering.EXPORT WARRANTY - One year parts only.EXCLUSION OF WARRANTIESEXCEPT AS PROVIDED A BO VE, GLASTENDER MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY , FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT.LIMITATION OF REMEDIES AND DAMAGES If Buyer makes a valid and timely claim as outlined above, Glastender’s liability and Buyer’s remedies under this agreement will be limited solely to labor charges authorized and/or replacement or credit, at Glastender’s option, with respect to Products returned at Buyer’s expense within thir-ty (30) days after warranty repair. GLASTENDER’S LIABILITY WILL IN NO EVENT BE GREATER IN AMOUNT THAN THE PURCHASE PRICE OF THE RETURNED PRODUCTS. GLASTENDER WILL NOT BE LIABLE UNDER ANY CIRCUMSTANCE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING, BUT NOT LIMITED TO, LA BO R COSTS EXCEPT AS COVERED UNDER OUR WARRANTY , LOST PROFITS OR THE LOSS OF PERISHABLE PRODUCTS RESULTING FROM THE USE OF OR INABILITY TO USE OUR PRODUCTS OR FROM OUR PRODUCTS’ INCORPORATION INTO OR BECOMING A COMPONENT OF ANY OTHER PRODUCT. NEITHER PARTY WILL HA VE ANY NEGLIGENCE OR OTHER TORT LIABILITY TO THE OTHER, OR TO ANY THIRD PARTY , ARISING FROM ANY BREACH OF THIS AGREEMENT.GOVERNING LAW - JURISDICTIONThe terms and conditions of an order are to be governed and construed according to the laws of the State of Michigan, without regard to conflict of laws principles. Buyer hereby consents to the jurisdiction and venue of the courts located in Saginaw County, Michigan.No representative, distributor, dealer, or any other person is authorized to modify this warranty. This warranty replaces all other written or verbal warranties.NOTE: Glastender, Inc.’s policy of constant quality improvement means that prices, specifications, and policies are subject to change without notice. Questions regarding this warranty should be directed to Glastender’s Warranty Administrator.04-19-17APPLICABLE TO ALL PRODUCTS SOLD WITHIN THE UNITED STATES AND CANADA。

YUY-WJMNJ 透明五金冲压模拟机

一、概述

透明五金冲压模拟机是对生产用机进行了微缩和改进,具有体种小、可随意移动,适用于课堂教学的微型实验台。

该产品以完成冲裁、拉伸、成型等动作。

具有结构简单,操作方便,且价格低廉的优点,无噪音无污染,并且可采用220V电压,可在任何有电场所使用。

填补了模具教学中无实验用机的空白。

本机可对透明拆装模具进行课堂上模拟演示,能在实验中看到模具的运动过程,提供设计人员对模具设计中的各机构产生更为实际的思维。

二、主要特点

1、机身及配套模具全部采用进口有机玻璃制作,该有机玻璃材料,耐腐蚀、抗磨

性能好,长久不变色演示效果逼真。

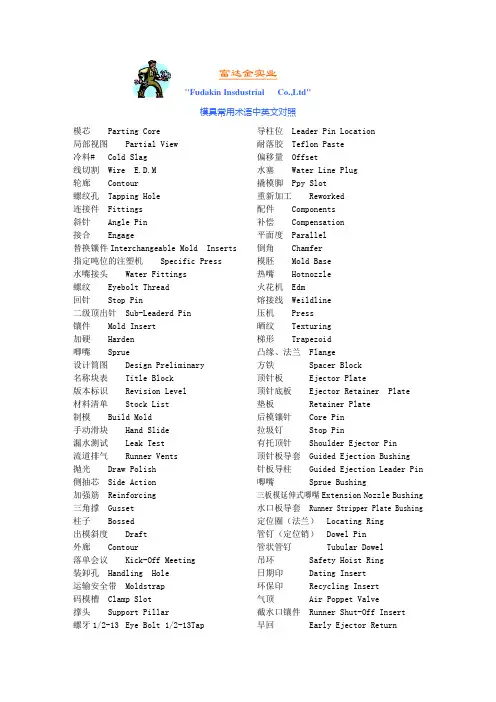

富达金实业"Fudakin Insdustrial Co.,Ltd"模具常用术语中英文对照模芯Parting Core局部视图Partial View冷料# Cold Slag线切割Wire E.D.M轮廊Contour螺纹孔Tapping Hole连接件Fittings斜针Angle Pin接合Engage替换镶件Interchangeable Mold Inserts 指定吨位的注塑机Specific Press水嘴接头Water Fittings螺纹Eyebolt Thread回针Stop Pin二级顶出针Sub-Leaderd Pin镶件Mold Insert加硬Harden唧嘴Sprue设计筒图Design Preliminary名称块表Title Block版本标识Revision Level材料清单Stock List制模Build Mold手动滑块Hand Slide漏水测试Leak Test流道排气Runner Vents抛光Draw Polish侧抽芯Side Action加强筋Reinforcing三角撑Gusset柱子Bossed出模斜度Draft外廊Contour落单会议Kick-Off Meeting装卸孔Handling Hole运输安全带Moldstrap码模槽Clamp Slot撑头Support Pillar螺牙1/2-13 Eye Bolt 1/2-13Tap导柱位Leader Pin Location 耐落胶Teflon Paste偏移量Offset水塞Water Line Plug撬模脚Ppy Slot重新加工Reworked配件Components补偿Compensation平面度Parallel倒角Chamfer模胚Mold Base热嘴Hotnozzle火花机Edm熔接线Weildline压机Press晒纹Texturing梯形Trapezoid凸缘、法兰Flange方铁Spacer Block顶针板Ejector Plate顶针底板Ejector Retainer Plate垫板Retainer Plate后模镶针Core Pin拉圾钉Stop Pin有托顶针Shoulder Ejector Pin顶针板导套Guided Ejection Bushing针板导柱Guided Ejection Leader Pin 唧嘴Sprue Bushing三板模延伸式唧嘴Extension Nozzle Bushing 水口板导套Runner Stripper Plate Bushing 定位圈(法兰)Locating Ring管钉(定位销)Dowel Pin管状管钉Tubular Dowel吊环Safety Hoist Ring日期印Dating Insert环保印Recycling Insert气顶Air Poppet Valve截水口镶件Runner Shut-Off Insert早回Early Ejector Return加速项Accelerated Ejector客户Client产品名Part Name产品编号Part No缩水Shrinkage版本Rev模胚Mold Base下模镶件Core Block上模镶件Cavity Block小镶件Sub-Insert下模小镶件Core Sub-Insert上模小镶件Cavity Sub-Insert行位Slide行位镶件Slide Insert压条Gib压紧块(铲机)Jaw硬片(摩擦片)Wear Plate水口铁Runner Bar上模水口铁Upper Runner Bar下模水口铁Lower Runner Bar弹簧Spring水口勾针Sprue Puller Pin顶针Ejector Pin撑头Support Pillar直身锁Side Lock斜度锁Interlock锁模板Safety Bar‘O’令(密封圈)O'Ring喉塞Plug隔水片Baffle波子螺丝(行位定位螺丝)Ball-Catch斜顶Lifter控制开关Switch回针Return Pin斜导柱Angle Pin推板Stripper PlateA’板A'PlateB’板B'Plate方铁(垫铁)Spacer Block顶针板Ejector Plate顶针底板Ejector Retainer Plate垫板Retainer Plate垃圾钉Stop Pin有托顶针Shoulder Ejector Pin 顶针板导套Guided Ejection Bushing针板导柱Guided Ejection Leader Pin 唧嘴Sprue Bushing三板模延伸式唧嘴Extension Nozzle Bushing 水口板导套Runner Stripper Plate Bushing 定位圈(法兰)Locating Ring管钉(定位销)Dowel Pin管状管钉Tubular Dowel吊环Safety Hoist Ring日期印Dating Insert环保印Recycling Insert气顶Air Poppet Valve截水口镶件Runner Shut-Off Insert早回Early Ejector Return加速顶Accelerated Ejector扁顶Blade出模斜波Draft手动滑块模具Hand Slide-In Type Mold 回针板Backup合模Shutoff空隙槽Clearance Slot导柱及导套Leader Pin Bushing水口拉钩Spuer Puller模框镶件Pocket Insert成型热固性塑胶模具Thermoset Mold三板模3-Plat Mold分型面Parting Line司筒Ejector Sleeve垫圈Washer熔接线(夹水纹) Weldline吸针Sucker Pin回针板Retainer Plate顶出板Knock -Out Plate电动安全开关Electrical-Safety Switch 脱开Cut Of Position预先决定Preload缓冲器Bumper衬垫Cushion公差Tolerance突然性动作Slam销针Dowel钩槽Gib精磨Finished通框Through Window粘后模Sticking Core粘水口Sticking Sprue夹水纹Weld Line变形Warpage走水不平均Filling Uneven 走不齐Short Shot挂成品Part Hanging漏水Water Leakage刮花(擦伤)Galling漏电Ele Leakage困气Air Trapping温度Temperature注塑模Injection Mold入水Gate试板Sampling压力Pressure倒圆Fillet顶棍Ejector顶白Stress Mark粘前模Sticking Cav名称块表Title Block版本标识Revision Level材料清单Stock List斜导柱(斜边)Angle PinA板 A'plateB板 B'plate倒扣Under-Cut披峰Flash缩水Sink Mark氮化Nitride不规则四边形Trapezoid缩水Shrinkage连续的Consecutive雕刻Engrave出模角Draft分模面Parting Surface擦位Shut-Off(S/0)导套Bushing回针Return Pin加硬Harden唧嘴Sprue设计筒图Design Preliminary 丝印Silkprint不干胶Adhesive Sticker 导向针Guide Din公差Tolerance 线切割Wire-Cut电火花Edm抛光Polishing蚀纹Texture探热针Thermocouple三打螺丝毫(限螺丝)Stripper Bolt 盖板Cover Plate齿轮Gear油唧Hydraulic Cylinder司筒Ejector Sleeve导柱Leader Pin冷料# Cold Slag线切割Wire E.D.M.轮廓Contour螺纹孔Tapping Hole连接件Fittings斜针Angle Pin接合Engage替换镶件Interchangeable Mold Inserts 指定吨位的注塑机Specific Press水嘴接头Water Fittings螺纹Eyebolt Thread回针Stop Pin二级顶出针Sub-Leader Pin镶件Mold Insert锁定位Lock楔子(铲鸡) Wedge高产量模量High Volume Running Mold 剖面图Cross Section模具结构Mold Construction模芯Parting Core局部视图Partial View热流道Manifold热嘴Hot Nozzle型腔数Cav No模号Mold No胶料Material尺寸Dimension重要尺寸Critical Dimension雕刻Engrave托司 EJ.GUIDE PIN。

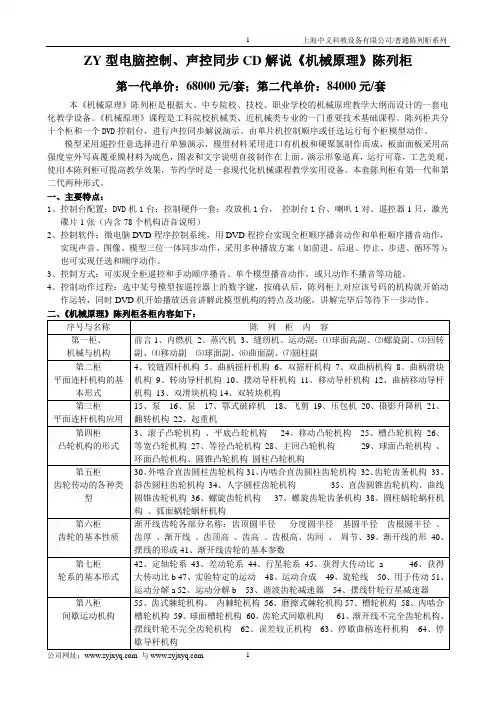

ZY型电脑控制、声控同步CD解说《机械原理》陈列柜第一代单价:68000元/套;第二代单价:84000元/套本《机械原理》陈列柜是根据大、中专院校、技校、职业学校的机械原理教学大纲而设计的一套电化教学设备。

《机械原理》课程是工科院校机械类、近机械类专业的一门重要技术基础课程。

陈列柜共分十个柜和一个DVD控制台,进行声控同步解说演示。

由单片机控制顺序或任选运行每个柜模型动作。

模型采用遥控任意选择进行单独演示,模型材料采用进口有机板和硬聚氯制作而成,板面面板采用高强度室外写真覆亚膜材料为底色,图表和文字说明直接制作在上面。

演示形象逼真,运行可靠,工艺美观,使用本陈列柜可提高教学效果,节约学时是一套现代化机械课程教学实用设备。

本套陈列柜有第一代和第二代两种形式。

一、主要特点:1、控制台配置:DVD机1台;控制硬件一套;攻放机1台,控制台1台、喇叭1对、遥控器1只,激光碟片1张(内含78个机构语音说明)2、控制软件:微电脑DVD程序控制系统,用DVD程控台实现全柜顺序播音动作和单柜顺序播音动作,实现声音、图像、模型三位一体同步动作,采用多种播放方案(如前进、后退、停止、步进、循环等);也可实现任选和顺序动作。

3、控制方式:可实现全柜遥控和手动顺序播音、单个模型播音动作,或只动作不播音等功能。

4、控制动作过程:选中某号模型按遥控器上的数字键,按确认后,陈列柜上对应该号码的机构就开始动作运转,同时DVD机开始播放语音讲解此模型机构的特点及功能,讲解完毕后等待下一步动作。

二、《机械原理》陈列柜各柜内容如下:三、主要技术参数:1、输入电源:AC220V±10%(单相)50HZ2、工作环境:-10℃±40℃3、功率:0.5kw4、第一代陈列柜结构:上柜采用铝合金制作,下柜柜式结构。

5、第二代陈列柜结构:上下柜整体框架全部采用彩色铝塑钢制作,外形美观,坚固耐用。

6、陈列柜尺寸:1250×430×1780mm《机械基础》示教陈列柜第一代单价:71000元/套;第二代单价:87000元/套本设备是根据大中专院校、职业学校的教学大纲设计的机械陈列柜,《机械基础》电化教学设备。

YUY-15 机械零件陈列柜

一、概述

机械零件是现代各行业的基础,是物质生产的基本工具,其应用水平是一个国家技术水平和现代化程度的重要标志,也是信息化产业的基础。

设计则是产品生产的第一道工序,其成败很大程度上是在本阶段决定的。

在课程体系中的地位:专业基础课性质:是一门论述机械零件设计理论、研究机械零件设计方法的设计性技术基础课。

是多学科知识的综合运用。

具有综合性、设计性。

本公司专业生产机械系列陈列柜,为了配合教学需要,教具产品逐步走向现代化发展,在原有基础上,研制了一套机械零件示教陈列柜。

该套共分二十个柜400余种物零件模型。

柜体采用SPCC冷扎板焊成,坚固美观,表面采用中温磷化防锈漆、平光漆,静电喷涂。

模型材料采用进口有机板制造,板面附有必要的图表和文字说明,演示形象逼真,运行可靠,制作工艺美观,使用本陈列柜可提高教学效果,节约学时是一套现代化机械课程教学应用实验室设备。

陈列柜尺寸:1050×400×1800mm

机械制图示教陈列柜,各柜内容如下:。

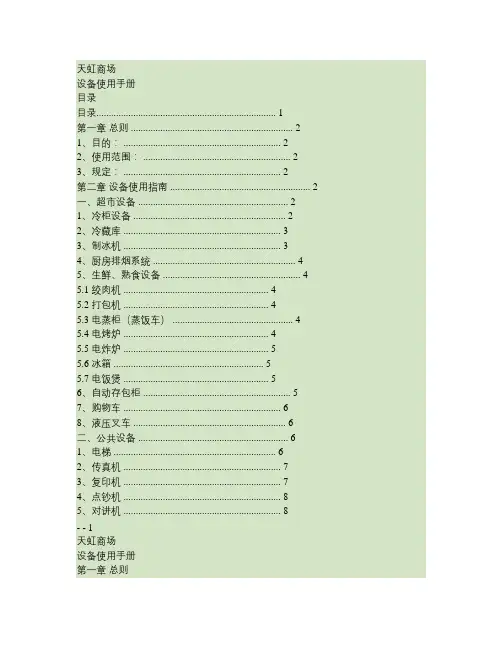

天虹商场设备使用手册目录目录 (1)第一章总则 (2)1、目的: (2)2、使用范围: (2)3、规定: (2)第二章设备使用指南 (2)一、超市设备 (2)1、冷柜设备 (2)2、冷藏库 (3)3、制冰机 (3)4、厨房排烟系统 (4)5、生鲜、熟食设备 (4)5.1 绞肉机 (4)5.2 打包机 (4)5.3 电蒸柜(蒸饭车) (4)5.4 电烤炉 (4)5.5 电炸炉 (5)5.6 冰箱 (5)5.7 电饭煲 (5)6、自动存包柜 (5)7、购物车 (6)8、液压叉车 (6)二、公共设备 (6)1、电梯 (6)2、传真机 (7)3、复印机 (7)4、点钞机 (8)5、对讲机 (8)- - 1天虹商场设备使用手册第一章总则1、目的:为加强对公司设备使用的监督与管理,进一步规范设备使用,使公司设备的使用科学化、合理化,有效减少设备使用故障,保障设备运行状态良好,特制定本手册。

2、使用范围:本规定适用于深圳分店和异地店的重点设备的使用。

3、规定:①公司设备管理工作由工程部统一管理。

具体由商场(部门)进行管理使用。

②公司设备是公司财产的一部分,是保证公司正常运作的必备条件之一。

各使用商场(部门)要按照设备使用手册进行操作,确保公司设备能使用合理。

③各商场(部门)的设备要保证经常处于完好和可用状态,管理和使用必须实行岗位责任制,责任到人。

④使用商场(部门)应努力做到降低公司的设备使用成本,如有闲置设备应及时报工程部备案,杜绝在设备使用中的不合理现象。

⑤本使用手册由工程部负责维护更新。

第二章设备使用指南一、超市设备1、冷柜设备1.1冷柜使用的环境要求:⑴室内温度应在27℃以下⑵相对湿度在70%以下⑶周围风速在0.2米/秒以下1.2风幕的正确使用:能有效的节省能源以降低运行成本⑴商场内的门和空调的出风口不要正对着陈列柜以免破坏风幕⑵商品摆放时不要超出柜内最高承载线,不要人为的阻塞出、回风口1.3夜间卷帘的管理:⑴营业结束后应将柜内的夜帘拉下勾在柜边沿的挂钩上以达到节能的目的⑵营业前请将夜帘或夜间盖打开,注意不要让冷凝水掉入柜内1.4 化霜管理⑴在正常化霜的时候柜内温度会相应的升高,但在化霜时间过后的一小段时间内温度会动恢复到正常的柜温⑵正常化霜---中温柜每天6次/15~30分钟、低温柜每天4次/20~30分钟⑶强制化霜---在异常霜堵的情况下人为的进行除霜,一般将霜化干净为止1.5 冷柜清洁⑴冷柜柜体部分:a、外装板清洁---用湿毛巾擦拭柜体上的水渍、污渍、锈点、除去胶带痕迹。

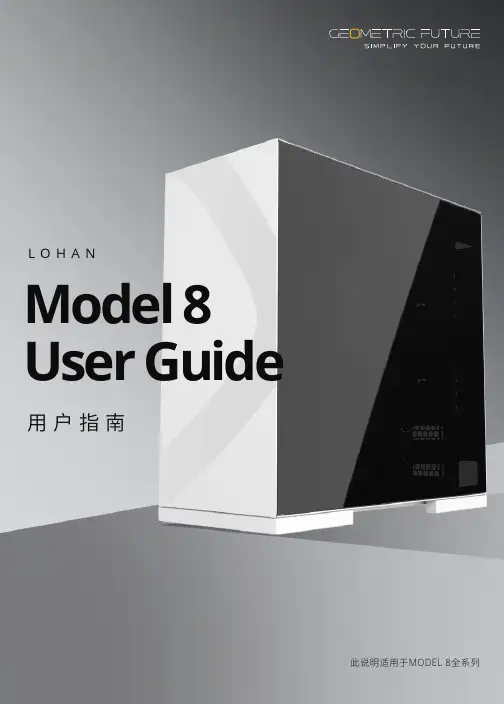

Model 8 User GuideL O H A N用户指南Model 8 罗汉简而不失其华!约而不显其涩!优雅白净,大气磅礴的logo线条,展现浑然天成的简约之美!Modle 8 User GuideCONTENTS产品目录040506081012131616171819202425拆除侧板及顶盖Remove side panels and top panel 安装主板I/O挡片Install the motherboard I/O baffle安装主板Install the motherboard 安装显卡Install the graphics card侧装显卡Side-mounted graphics card风扇及水冷安装选项Fan and water cooling mounting options安装后板 120/240/360水冷Mount rear panel120/240/360 water cooler安装底部风扇/水冷Mount the bottom fan/water cooler安装底部磁吸滤网Mount the bottom magnetic suction filter screen 安装顶部风扇/水冷Mount the top fan/water cooler锁装电源Install the power cord安装电源延长线Install the Power Extension Cord安装硬盘Install hard drive线材整理绑线位置Cable management & routing装回侧板与顶盖Put back the end panel and top panel01产品规格Specifications 02产品特点Feature26前置I/O接线示意Front I/O wiring schematic, provided for premium cases27注意事项Precautions28保修范围Warranty零件包内容03Parts Kit Includes04安装步骤How to assembleCPU Heatsink Height <170mm01Modle 8 User GuideFEATURE产品特点Excellent Heat DissipationSuperior CompatibilityEasy AccessPersonalized Installation Durable Materials 12" x 13" motherboard / 7 x fan mounts / dual 360/420mm water cooling mounts / cpu cooler height: 170mm / rtx™ 30series graphics card space: 400mm (l) x 175mm (w) x 61mm (h) / up to 6 hard drive brackets (4 optional )Removable & cleanable top panel / multifunctional hard drive bracket / removable & cleanable magnetic filterIndeformable vertically mounted graphics card /large cable routing space / multiple tubing options for water-coolingT1.0mm coated steel / t4.0mm tempered glassMinimalist Style Perfect Handfeel 极致触感头层真皮 / 航空针织面料 / 细软麻料 …极简视效扎实用料安装可靠度便捷操作超强兼容性优秀散热全面屏双侧透 / 全面网顶盖 / 阳极拉丝铝 / 极佳主视角光效全烤漆钢板 T1.0mm / 全钢化玻璃 T4.0mm竖装显卡无形变 / 超大背线空间 / 水冷多路走管可拆洗顶盖 / 多功能硬盘架 / 可拆洗磁吸滤网主板 12”x 13”/ 7组风扇位 / 双360水冷 / 420水冷 / CPU散热器高170mm 30系大显卡兼容空间 长400 x 宽175 x 厚61mm / 最多6组硬盘位垂直三面风道 / 全面网高通风率顶盖 / 电源风道优化Glass panels on two sides / meshy top panel / anodized brushed aluminum / main perspective exquisite lighting effectGenuine leather / aerospace-grade knitted fabric / soft fine linen...Vertical airflow/ full ventilation on three sides/ fast-ventilating meshy top panel / optimized安装主板I/O挡片1PH2拆除侧板 及 顶盖拧松侧板螺丝 / 并依箭头指示方向拆除两侧板依箭头指示方向拆除顶盖Remove side panels and top panel Loosen end panel screwsRemove both side panels and top panel in the direction indicated by arrows钢化玻璃拆装注意轻拿轻放!安装主板I/O挡片 2Install the motherboard I/O baffle3主板孔位对照表ITXMicro—ATX ATX E-ATXI A M EEA / E A / EEE M M I / M / A / EM / A / EEMotherboard mounting hole locations table3PH2X 9X 9X 14PH2拆显卡封条PH24锁装显卡Step 25侧装显卡( 显卡转接板组需另购 )PH2Side-mounted graphics card (graphics card adapter board needs to be purchased separately)拆显卡封条Step 1PH25侧装显卡Side-mounted graphics card 锁装显卡Step 26PH2( 尺寸限制参照产品规格表描述 )420360120280240140120360280240140120(refer to product specifications for size limitation)Modle 8 User Guide HOW TO ASSEMBLE 安装步骤7安装后板 120/240/360水冷PH2Step 1 拆取水冷支架 及 底部磁吸滤网Step 2 锁装水冷支架与冷排Mount rear panel 120/240/360 water cooler Remove water cooler bracket and bottom magnetic suction filter screenMount the water cooler bracket and radiator.7PH2 Step 3 锁装水冷模组于机箱内Mount the water cooler module in the casePH2Step 4如下图翻转水冷支架B面可支持140/280/420水冷安装12A BAB 翻转后翻转支架B面120/240/360140/280/420翻转B面后安装水冷支架Turn over water cooler bracket as shown below, and the B side can mount 140/280/420 water cooler Turn over the B side of the bracket. Turn over the B side and install the water cooler bracket.锁图示螺丝孔位置AB 翻转后 After the B side is turned over. Screw on the screws at the hole locations shown in the figure.Modle 8 User GuideHOW TO ASSEMBLE 安装步骤8安装底部风扇/水冷9安装底部磁吸滤网PH2Mount the bottom magnetic suction filter screenMount the bottom fan/water cooler10安装顶部风扇/水冷PH2 Mount the top fan/water cooler顶部水管路径示意Modle 8 User GuideHOW TO ASSEMBLE安装步骤11锁装电源PH2X 4Install the power cord1213PH2(最多支持6组硬盘位 / 不同机种标配硬盘支架数量不等)手拧螺丝 / 拆取硬盘支架Screw by hand / Remove the hard drive bracketPH2 14锁装2.5”HDD3.5”HDD3.5”HDD2.5”HDD2.5”HDDPH2X 8Mount the 2.5”HDD锁装 3.5”HDD支架锁装硬盘支持多个方向选择3.5”HDD 2.5”HDD 2.5”HDD2.5”HDD3.5”HDDPH2X 814Hard drive may be installed in several directionsMount the 3.5”HDD硬盘安装完成示意图14Schematic diagram of hard drive installation15虚线为线材路径 黄色块为扎线位置A出线孔B出线孔X 8where dotted line is wire routing and yellow block is cable bundle position16PH2Modle 8 User GuideFRONT I/O WIRING SCHEMATIC前置I/O接线示意PH2POWER SW HDD LED POWER LEDUSB 2.0HD AUDIOUSB 3.0TYPE-C( 高阶版标配 )(Provided For Premium Cases )RESET SWModle 8 User GuidePRECAUTIONS注意事项注意事项1.请严格依照本使用手册所示步骤进行安装。

YUY-04 机械设计、课程设计示教陈列柜

概述:

本陈列柜通过典型减速器展示,突出传动方案比较,和装配图设计过程和装配图设计错误分析等内容,使陈列柜更加对学生有启发性,设计中的实用性。

性能规格特点:

1、陈列柜中的每个模型都配备了指示灯和创新原理分析及设计过程文字说明,电动模型采用微电机用手控开关和单板机驱动两种,连续运转了1小时无卡死现象。

2、遥控控制、解说词播放100M房内声音宏亮。

3、输入电压:交流200V,功率400W。

4、陈列柜外形尺寸:1200㎜宽×530㎜厚×1900㎜高,柜内板面超豪华铝塑夹层板,柜内大标牌采用中英文对照

5、柜体门采用玻璃门配备照明日光灯。

陈列柜内容如下:。

4” Legs P/N 840774” Legs P/N 840774” Legs P/N 840774” Legs P/N 840774” Legs P/N 840774” Legs P/N 840774” Legs P/N 840774” Legs P/N 840774” Legs P/N 84077Drive Chain (x3) P/N 88102 Master Link DriveChain (x3) P/N 87044Idler Sprocket P/N 69824Drive Sprocket P/N 87353Spring P/N 68734Middle/Back Idler Assy (x2)P/N 68906Idler Assy Front P/N 68747Positraction Sprocket (x15)P/N 87988Assembly Bracket WeldmentP/N 88053Outer Retainer (x15)P/N 88228Drive Chain (x3) P/N 88102 Master Link DriveChain (x3) P/N 87044Idler Sprocket P/N 69824Drive Sprocket P/N 87353Spring P/N 68734Middle/Back Idler Assy (x2)P/N 68906Idler Assy Front P/N 68747Positraction Sprocket (x15)P/N 87988Assembly Bracket WeldmentP/N 88053Outer Retainer (x15)P/N 88228Drive Chain (x3) P/N 88102 Master Link DriveChain (x3) P/N 87044Idler Sprocket P/N 69824Drive Sprocket P/N 87353Spring P/N 68734Middle/Back Idler Assy (x2)P/N 68906Idler Assy Front P/N 68747Positraction Sprocket (x15)P/N 87988Assembly Bracket WeldmentP/N 88053Outer Retainer (x15)P/N 88228Drive Chain (x3) P/N 88102 Master Link DriveChain (x3) P/N 87044Idler Sprocket P/N 69824Drive Sprocket P/N 87353Spring P/N 68734Middle/Back Idler Assy (x2)P/N 68906Idler Assy Front P/N 68747Positraction Sprocket (x15)P/N 87988Assembly Bracket WeldmentP/N 88053Outer Retainer (x15)P/N 88228Drive Chain (x3) P/N 88102 Master Link DriveChain (x3) P/N 87044Idler Sprocket P/N 69824Drive Sprocket P/N 87353Spring P/N 68734Middle/Back Idler Assy (x2)P/N 68906Idler Assy Front P/N 68747Positraction Sprocket (x15)P/N 87988Assembly Bracket WeldmentP/N 88053Outer Retainer (x15)P/N 88228Drive Chain (x3) P/N 88102 Master Link DriveChain (x3) P/N 87044Idler Sprocket P/N 69824Drive Sprocket P/N 87353Spring P/N 68734Middle/Back Idler Assy (x2)P/N 68906Idler Assy Front P/N 68747Positraction Sprocket (x15)P/N 87988Assembly Bracket WeldmentP/N 88053Outer Retainer (x15)P/N 88228Drive Chain (x3) P/N 88102 Master Link DriveChain (x3) P/N 87044Idler Sprocket P/N 69824Drive Sprocket P/N 87353Spring P/N 68734Middle/Back Idler Assy (x2)P/N 68906Idler Assy Front P/N 68747Positraction Sprocket (x15)P/N 87988Assembly Bracket WeldmentP/N 88053Outer Retainer (x15)P/N 88228Drive Chain (x3) P/N 88102 Master Link DriveChain (x3) P/N 87044Idler Sprocket P/N 69824Drive Sprocket P/N 87353Spring P/N 68734Middle/Back Idler Assy (x2)P/N 68906Idler Assy Front P/N 68747Positraction Sprocket (x15)P/N 87988Assembly Bracket WeldmentP/N 88053Outer Retainer (x15)P/N 88228Drive Chain (x3) P/N 88102 Master Link DriveChain (x3) P/N 87044Idler Sprocket P/N 69824Drive Sprocket P/N 87353Spring P/N 68734Middle/Back Idler Assy (x2)P/N 68906Idler Assy Front P/N 68747Positraction Sprocket (x15)P/N 87988Assembly Bracket WeldmentP/N 88053Outer Retainer (x15)P/N 88228Drive Chain (x3) P/N 88102 Master Link DriveChain (x3) P/N 87044Idler Sprocket P/N 69824Drive Sprocket P/N 87353Spring P/N 68734Middle/Back Idler Assy (x2)P/N 68906Idler Assy Front P/N 68747Positraction Sprocket (x15)P/N 87988Assembly Bracket WeldmentP/N 88053Outer Retainer (x15)P/N 88228Drive Chain (x3) P/N 88102 Master Link DriveChain (x3) P/N 87044Idler Sprocket P/N 69824Drive Sprocket P/N 87353Spring P/N 68734Middle/Back Idler Assy (x2)P/N 68906Idler Assy Front P/N 68747Positraction Sprocket (x15)P/N 87988Assembly Bracket WeldmentP/N 88053Outer Retainer (x15)P/N 88228Drive Chain (x3) P/N 88102 Master Link DriveChain (x3) P/N 87044Idler Sprocket P/N 69824Drive Sprocket P/N 87353Spring P/N 68734Middle/Back Idler Assy (x2)P/N 68906Idler Assy Front P/N 68747Positraction Sprocket (x15)P/N 87988Assembly Bracket WeldmentP/N 88053Outer Retainer (x15)P/N 88228。

飞模台生产厂家深圳飞模工作台

深圳飞模工作桌

深圳市欧比迪工业设备有限公司:主营产品有铁木工作台钳工桌,防静电钳工工作桌,工具桌,模具桌,单门中堂3A钢板钳工桌

双门,带抽屉,带挂板,复合工作台,复合工作桌模具架,仓储货架,工具柜,工作台深圳市欧比迪工业工作桌特点现场组装的工作桌桌体组装简便,强度高,可使工作桌承受额定重量。

深圳市欧比迪工业设备有限公司

多种工作桌桌面选择,可配合不同的使用要求。

重型工作桌桌脚上预留电源孔,方便客户安装电源插座。

加装工具柜后,更能合理地使用空间,存放工具及零配件。

选用合适的桌面可直接在工作桌上加装台钳,适合钳工工作。

深圳市欧比迪工业设备有限公司

工作桌可加装挂板,电器板,灯顶板、搁板等桌上部件,具有多种选择,能够满足各种工位的需求。

深圳市欧比迪工业设备有限公司

工作桌规格:1500*750*800mm 1800*750*800mm

2100*750*800mm可按要求定做模具工作台采用优质冷扎板精工制作而成,坚固的工作桌框架,牢固平稳,可使工作桌承重1000kg以上

深圳市欧比迪工业设备有限公司

工作桌面选择,可配合不工使用的要求;工具吊柜(箱),侧柜(箱),外形美观;层板,抽屉质量上乘,承重大,抽屉内可根据需要任意分隔;节约空间,适用性强。

深圳市欧比迪工业设备有限公司

检验平板模具工作台适用于各种检验工作,精密测量用的基准平面;用于机床机械检验测量基准;检查零件的尺寸精度或形为偏差,并作紧密划线,在机械制造中也是不可缺少的基本工具。

深圳市欧比迪工业设备有限公司。

折弯模具的选择1)折弯模具的类型折弯模具有L型、R型、U型、Z型等折弯类型。

上模主要有90°、88°、45°、30°、20°、15°等不同角度。

下模有4~18V不同槽宽的双槽和单槽,有R下模、锐角下模、压平模等。

上下模分为分段和整体。

上模分段一般为:300mm、200mm、100mm、50mm、40mm、20mm、15mm、10mm,整体为835mm。

下模分段一般分为:400mm、200mm、100mm、50mm、40mm、20mm、15mm、10mm,整体为835mm。

2)绝对不能超过模具所标注的压力折弯模具采用优质钢材,经特殊热处理制作而成,具有硬度高、不易磨损、承受压力大等特点,但每套模具都有它承受的极限压力,所以在使用模具时要正确选用模具的长度,即考虑每米要加多少压力,绝对不能超过模具所标注的压力。

模具标识的耐压是单位长度上的负荷。

模具能够承受的最大负荷=模具上标识的耐压×加压部分的长度。

超过模具耐压最大负荷的话,模具破裂飞散的可能性非常大,是极其危险的违规使用。

如果上模与下模耐压的标识不同,那么应该以耐压低的一方作为标准,来计算模具的最大耐压负荷。

举例如下:模具上的耐压标识为MAXTONS 50/METER时:加压部分的长度是0.835m的情况下,模具可以使用的最大负荷是50t/m×0.835m=41.75t;加压部分的长度是0.415m的情况下,模具可以使用的最大负荷是50t/m×0.415m=20.75t。

3)根据工件的材质硬度、厚度、长度来选用上、下模在使用模具时,要根据金属板料的材质硬度、厚度、长度来选用上、下模,一般按照56T的标准使用下模,长度要比板料长一些。

材质越硬、厚度越大的料,应用槽较宽的下模。

4)有角度要求时在作为锐角或压死角时,应选用30°模具,先折锐角,后压死边。

carrier bar 模具专业术语

Carrier bar 模具专业术语Carrier bar 模具是一种用于制造混凝土制品的模具,常用于生产预制混凝土构件,如墙板、地板、梁等。

以下是一些与 Carrier bar 模具相关的专业术语:1. Carrier bar(载杆):Carrier bar 是 Carrier bar 模具的主要组成部分,通常由钢材制成。

它是模具的主体结构,用于支撑混凝土和传递载荷。

2. Side formwork(侧模):Side formwork 是 Carrier bar 模具的侧面结构,用于固定混凝土并确定其形状。

它通常由木材或钢板制成。

3. Bottom formwork(底模):Bottom formwork 是 Carrier bar 模具的底部结构,用于支撑混凝土并确定其厚度和平整度。

它通常由木材。