过滤机中文样本

- 格式:pdf

- 大小:4.56 MB

- 文档页数:66

反渗透水质处理器主要功能家用反渗透水质处理器,协调完成纯水制造的自动化过程。

在安装好的情况下,打开水源,低压开关自动闭合,反渗透水质处理器开始制水。

当储水桶的水满时,高压开关断开.饮用纯净水同时,储水桶内的压力会逐渐下降,反渗透水质处理器又开始制水。

当水源断水时,低压开关自动断开,反渗透水质处理器处于停机状态;反之,低压开关闭合开始制水.让您随时都可以喝到甘甜可口的纯净水。

新安装的反渗透水质处理器,应防掉一至二桶的纯水冲洗新机后,方可开始饮用.特别注意1.本机必须由专业人员安装,在使用前详细阅读说明书,以免对您正常饮水造成不必要的麻烦.2.用户若数天不用(外出),应关闭本机电源及水源。

3.以包装箱内实际配置为准4.安装完毕请检查螺帽是否紧固以免漏水,无地漏或者地漏不完善之场所严禁安装本公司产品,否则造成财产损失,本公司概不负责。

安装及使用注意事项为了防止危害使用者安全,损害他人财物事件的发生,请务必严守一下说明1.安装服务人员在安装前应先检查系统电路部分是否正常,因为在运输装卸过程中有可能引起接线松动,组件损坏.2.如果您要自选安装,请严守安装说明。

3.请勿随意更改电路和管路。

4.请勿自行调节高、低压开关等控制组件,如因自行调节造成损失,本公司概不负责。

5.出现故障请与当地经销商联系,请勿随意更改。

*不可在高于220V的电压下长时间运作**去除率=[(原水T。

D。

S值—纯水T。

D.S值)*100%]/原水T。

D。

S值***低于0.1Mpa需加装增压泵,高于0。

35Mpa需加装减压泵。

六级过滤,从粗到细,层层把关,确保水质第一级:pp5μm纤维滤芯,去除水中大于5μm的悬浮物,如沙石、铁锈、铜锈、磷污等第二级:颗粒活性炭滤芯,吸附书中的异色异味、氯及氯的副产物等第三级:烧结活性炭滤芯,可去除水中氯、有机化学物、异色、异味以及污泥悬浮物颗粒等第四级:最关键最核心部件采用反渗透RO膜。

彻底除去水中细菌、病毒、重金属、有机物等杂质。

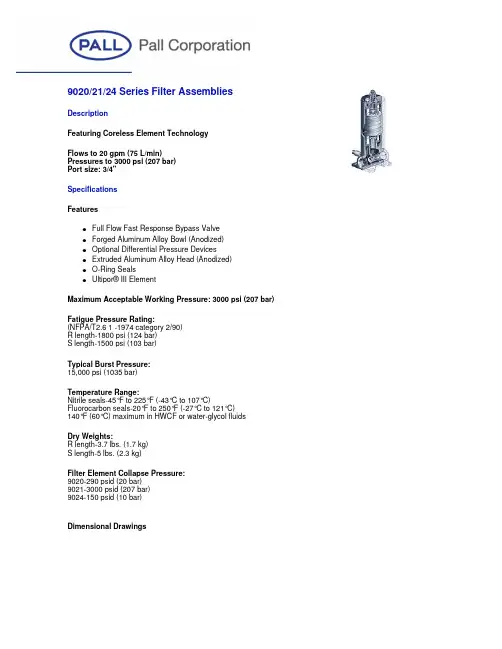

9020/21/24 Series Filter AssembliesFeaturing Coreless Element TechnologyFlows to 20 gpm (75 L/min)Pressures to 3000 psi (207 bar)Port size: 3/4"SpecificationsFeaturesFull Flow Fast Response Bypass ValveForged Aluminum Alloy Bowl (Anodized)Optional Differential Pressure DevicesExtruded Aluminum Alloy Head (Anodized)O-Ring SealsUltipor® III ElementMaximum Acceptable Working Pressure: 3000 psi (207 bar)Fatigue Pressure Rating:(NFPA/T2.6 1 -1974 category 2/90)R length-1800 psi (124 bar)S length-1500 psi (103 bar)Typical Burst Pressure:15,000 psi (1035 bar)Temperature Range:Nitrile seals-45°F to 225°F (-43°C to 107°C)Fluorocarbon seals-20°F to 250°F (-27°C to 121°C)140°F (60°C) maximum in HWCF or water-glycol fluidsDry Weights:R length-3.7 lbs. (1.7 kg)S length-5 lbs. (2.3 kg)Filter Element Collapse Pressure:9020-290 psid (20 bar)9021-3000 psid (207 bar)9024-150 psid (10 bar)Dimensional DrawingsPerformancePressure Drop InformationElement Pressure Drop FactorMultiply actual flow rate times factor to determine pressure drop with fluid at 150 SUS (32 cSt), 0.9 S.G.Correct for other viscosities by multiplying new viscosity in SUS/150 x new S.G/0.9.9020 Series Element P factor (psid/gpm)Length KZ KP KN KS KT4" 1.90 0.82 0.54 0.35 0.218" 0.96 0.41 0.27 0.18 0.119021 Series Element P factor (psid/gpm)Length DP DT4" 2.71 0.688" 1.35 0.349024 Series Element P factor (psid/gpm)Length KZ KP KN KS KT8" 1.12 0.48 0.31 0.21 0.13Ordering InformationAssembly P/N: H 902Table1 Table2 Table3 Table4 Table5 Table6 Table7 Table8Element P/N: HC 902 FTable2 Table5 Table6 Table1Note: Choose from the options in the following tables to compile the specific Product Number.Table 1: Seal OptionsCode SealsH NitrileZ FluorocarbonTable 2: Element OptionsCode Rating0290 psid (standard)13000 psid (high collapse)4150 psid (coreless)Table 3: Port Style OptionsCode Port StyleA SAE J514 straight threadL Manifold side mount*K Manifold mount*Contact factory for drawings.Table 4: Port Size OptionsCode Size12 3/4"TABLE 5: FILTER ELEMENT OPTIONSCODE ßx 200ßx(c)=1000 KZ <1 2.5KP 3 5KN 6 7KS 12 12KT 25 22DP* 3 5DT* 17 15*9021 series only.Table 6: Length Options*Assembly Code Element Code** R***4S8*Use code in second column for element part no.**Nominal length in inches***Not available for 9024 seriesTable 7: Bypass Valve OptionsCode DescriptionB50 psid-9020/9024 onlyW Non bypass 9021 onlyTable 8: Differential Pressure Device OptionsCode DescriptionP Visual indicator with thermal lockoutD Visual indicator with no thermal lockoutL Electrical switch (SPDT) with 6" leadsT Electrical switch with DIN connectorM'T' type switch with matching wiring capS Electrical switch with MS receptacleV Combined visual/electrical with DIN connectorB Plug in place of indicatorContact InformationFOR TECHNICAL ASSISTANCE CALL TOLL FREE 1-888-333-PALL (7255)© Copyright Pall CorporationVisit us on the Web at 。

产品使用说明书GL型板框式过滤机使用说明书目录一、概述 (2)二、规格与性能参数 (3)三、结构与工作原理 (4)四、安装与调整的注意事项 (5)五、操作与使用说明 (6)六、维护与保养 (10)七、随机附件 (10)一、概述不锈钢板框式过滤机是一种高级滤清、除菌设备,装配以不同型号的过滤介质可对酿酒、制药、饮料、化工等许多行业的液态制品进行精度不同的澄清过滤和除菌过滤。

本过滤器体积小,效率高,操作简便,应用范围广。

触液零件全部用1G18Ni9Ti不锈钢制造,耐磨蚀性能优越,使用寿命长。

根据不同的使用要求,该机配有塑料板框,价格低廉。

外形图:主视图右视图二、规格与性能参数规格:型号过滤板数有效过滤面积(m2)GL20 8~26 0.24~0.78GL30 19~29 1.4~2.1GL40~ 40 21~41 2.95~5.75 70 43~71 6.05~9.98 100 73~101 10.27~14.2GL60~ 100 70 23.31 150 120 39.96 200 170 56.61 250 220 73.26性能参数:型号过滤板数最大过滤量(升/片*小时)推荐工作压差(巴)澄清除菌澄清除菌GL20 8~26 20~40 10~20 3 1.5GL30 19~29 50~100 25~50 3 1.5GL40 21~101 100~200 50~100 3 1.5GL60 70~220 200~400 100~200 3 1.5(本机最高工作压力为4巴)三、结构与工作原理本过滤器是由前支架和尾架用两根主轴相连结成为一个水平放置的框架,在前支架和尾架中间有一个可以与前者平行移动的堵头,堵头的移动由安装在尾架上的丝杠拖动。

因此在前支架与堵头中间形成两个间距可调的平行平面,这两个平面就可以借助于丝杠压紧装在中间的过滤片组,整个机构类似于一个卧式双柱螺旋压力机构。

中间过滤片的两侧有通液甲(连通)和通液乙(不连通)各两个,当压紧时这些通液环由胶圈密封而形成四条通液管路。

TTF最大:500 L/min, 10 bar特点&好处典型应用• 垃圾车• 移动式起重机• 动力站• 轮式装载机• 钻井设备TTF 系列回油管路过滤器TTF 油箱顶置回油管路过滤器内设有磁铁和低阻滞的全流量旁通阀,具有预过滤功能。

由于采用了由里向外的过滤原理,受污染的油液因此不可能倒流回系统。

TTF 系列过滤器可处理的流量最大可达500l/min ,最大压力可达10bar ,用户可选过滤器端盖上的注油口,第二个回油口和用户自定义的扩散器。

也可提供集成式的(TSR 系列)带有4个回油口的过滤器滤头。

TTFTSR1345678101112131415169a9b类型 1-125/2-170/2-230/2-3002-400/2-500类型1-60/1-90/1-120滤芯安装间隙F8136最低油位安装孔B 137LHØ50Ø102±1Ø410.33.2BAAØ1656481814x ISO228G 1/8”(BSP)4x Ø1112工作压力:最大. 10 bar .安装方式:油箱顶置安装.接口:螺纹 BSP 接口.法兰接口可按要求提供集成式滤头TSR 可按要求提供流量可达 250 l/min.过滤器外壳:铝质滤头和端盖.密封材料:丁腈橡胶, 氟橡胶, 氯丁橡胶.工作温度范围:-40 - +120°C.旁通阀设定:开启压力 0.8 / 1.5 或 2 bar .其它要求请咨询过滤效果:决定于多次通过实验符合ISO 16889.液流疲劳特性:过滤材质可确保获得最佳的疲劳寿命过滤材质:Microglass III & Ecoglass III LEIF ®滤芯.也可提供10μm 纸质纤维和40μm 不锈钢金属网滤芯的爆破压力:10 bar (ISO 2941)压力指示器选项:设定值 0.7 或 1.2 bar .其他的设定值请咨询.目视压力表.电讯式压力继电器.选项:扩散器列类型 P (直管,无开孔板区域)扩散器 T (带有封闭的扩散器端帽和开孔板区域,当进入油箱的油液接近油箱底部或为了确保进入的油液处于油箱液位之下时推荐使用)磁铁组件:标准的 TTF400 和 500 作为标准供货不包括磁铁端盖上注油口(可选)堵塞.过滤器滤芯:LEIF ®滤芯带有可多次使用的金属滤芯护套 可选传统的带有碳钢端帽的滤芯.LEIF ®滤芯专利产品可保证使用真正原装产品。

All ELIMINATOR® driers have a solid core with binding material held to an absolute minimum. There are two types of ELIMINATOR® cores.Type DML driers have a core composition of 100% Molecular Sieve, while type DCL contain 80% Molecular Sieve with 20% activated alumina. ELIMINATOR® type DML driers are designed for applications requiring the highest moisture capacity.ELIMINATOR® type DCL driers are designed for applications requiring high moisture capacity and acid adsorption capacity.Available with solder (pure copper) and flare connections.Features The Core type DML• 100% 3Å Molecular Sieve core• High drying capacity minimizing the risk of acidformation (hydrolysis)• Recommended for use with HFO, HC, HFC andHCFC refrigerants• Will not deplete oil additivesThe Core type DCL• 80% 3Å Molecular Sieve with 20% activatedalumina• Perfect core blend for systems that operate athigh condensing temperatures and require highdrying capacity• Recommended for use with HFO, HC, HFC andHCFC refrigerants The Shell• UL approved for MWP 667 psig• Available with solder (pure copper) and flare connections• Corrosion resistant powder-painted finish. Special coating for marine applications available upon request• Allows installation with any orientation provided the arrow is in the flow direction• Available in sizes 3 – 75 cubic inchesThe Filter• 25 μm (0.001 in.) filter provides high retention with minimal pressure drop• Thermally stable up to 250 °FApprovals UL US, file no. SA 6398PED 97/23/EC - a3p3Compliant with ATEX hazard zone 2Note: Only solder versions (cu-plated / pure copper) andconnection sizes below 25 mm are approved for flammablerefrigerants now.Application Technical data ELIMINATOR® hermetic filter driers protectrefrigeration and air-conditioning systems fromWith these contaminants eliminated, systems aresafer from harmful chemical reactions and fromTCAESGN GBC DML / DCL GBC Flare connectionFilter drier volume(shell volume)(Total Acid Number)Technical data and capacities–R32: 990 ppm W - 50 ppm W–R134a: 1050 ppm W – 50 ppm W–R404A, R507: 1020 ppm W – 50 ppm W–R407C: 1020 ppm W – 50 ppm W–R410A: 1050 ppm W – 50 ppm W–R22: 1050 ppm W – 60 ppm Win accordance with ARI 710-20042) Given in accordance with ARI 710-2004 for–t e= 5 °F–t c= 85 °F–Δp = 1 psiFor technical data on other refrigerants, please contact your Danfoss Sales RepresentativeTechnical data and capacities(continued)–R32: 990 ppm W - 50 ppm W –R134a: 1050 ppm W – 50 ppm W–R404A, R507: 1020 ppm W – 50 ppm W –R407C: 1020 ppm W – 50 ppm W –R410A: 1050 ppm W – 50 ppm W –R22: 1050 ppm W – 60 ppm W in accordance with ARI 710-20042) Given in accordance with ARI 710-2004 for –t e = 5 °F –t c = 85 °F –Δp = 1 psiFor technical data on other refrigerants, please contact your Danfoss Sales RepresentativeConversionsSee ARI standard 710-2004 for recommended initial and final PPM values for different refrigerantsDrops of water =(lbs of refrigerant × (Initial PPM of water - Final PPM of water))110OrderingD a n f o s s 23Z 8403Ordering(continued)D a n f o s s 23Z 8404Ordering (continued)D a n f o s s 23Z 8403Ordering(continued)D a n f o s s 23Z 8404IdentificationExample for type codesDML 1.52x2/2s F i l t e r d r i e rS o l i d c o r eA p p l i c a t i o nS i z e (v o l u m e )C o n n e c t i o n (fi l t e r c o n n e c t i o n i n 1⁄8 o f a n i n c h i n c r e m e n t s )C o n n e c t i o n t y peF i l t e r d r i e rS o l i d c o r eA p p l i c a t i o nS i z e (v o l u m e )C o n n e c t i o n (fi l t e r c o n n e c t i o n i n 1⁄8 o f a n i n c h i n c r e m e n t s )D u a l c o n n e c t o r i n l e t / C o n n e c t i o n o u t l e t i n 1⁄8 o f a n i n . i n c r e m e n t sC o n n e c t i o n t y peSelection2) DCL Hermetic filter driers contain activated alumina, which is a polar material used for acid adsorption. Many oil additives are alsopolar substances and can be adsorbed by the activated alumina, rendering them useless, and reducing the drier’s acid capacity,though this is not harmful to the system.Selection example Select the appropriate type (DML or DCL) basedon refrigerant and oil type. Then select the driersize based on the adsorption and liquid capacityrequired.a. Amount of charge: 55 lbs R134a at tL = 75 °FTo dry 55 lbs R134a at 75 °F from 1050 to 60 ppmmoisture, a DML 16 is necessaryb. Cooling capacity: Qe = 5.7 TRTo obtain a mass flow corresponding to 5.7 TRcooling capacity with a DML 16 filter drier,a 3⁄8 in. connection must be chosen.Larger connections can be chosen in accordancewith the liquid line dimension c. ResultDML 163 or DML 163s can be usedIf the initial moisture content is very small or a planned change of the filter drier is considered, a smaller filter drier size can be chosen.The relatively large diameter of the hermetic filter drier means that the liquid flow velocity is suitably low and the pressure drop minimal.Powder formation is eliminated because the solid core grains are bonded and cannot move against each other.Design / Function DML 1.5DML / DCL 03DML / DCL 08, DML / DCL 16DML / DCL 60, DML / DCL 75DCL 1.5DML / DCL 05DML / DCL 30, DML / DCL 411. I nlet2. S pring3. S olid core4. P olyester mat5. P erforated plate6. S eal cap, flare connection7. S eal cap, solder connectionDimensions and weights Flare connectionsDimensions and weights (continued)Flare connectionsDimensions and weights (continued)Solder connectionsDML 1.52sDCL 1.52XL/2.8mm sDCL 1.52x2/2sDimensions and weights (continued)Solder connectionsDimensions and weightsSolder connections(continued)。

多介质过滤器使用说明书南京南自科林系统工程有限公司地址:南京浦口高新区星火路8号一、工艺原理:多介质过滤器为水处理系统的预处理设备,适用于浊度在1-10NTU的进水;目的除去水中的悬浮物、颗粒和胶体,降低进水的浊度和SDI值,满足除盐装置后续设备的进水要求;设备可以通过周期性的清洗来恢复它的截污能力。

二、技术参数:1.进水浊度: < 10 NTU2.出水浊度: < 1 NTU3.工作压力: < 0.6MPa4.工作温度: 5-50℃5.运行流速: 6-10m/h6.水反洗强度: 20-30m/h7.气擦洗强度: 15L/m2.s8.填料高度: 无烟煤400/石英砂8009.石英砂规格:0.5~1.2mm (不均匀系数<2 )无烟煤规格:0.8~1.8mm (不均匀系数<1.7 )10.承托层:(如设备要求)三、结构形式:设备由本体、布水装置、集水装置、外配管及仪表取样装置等组成。

进水装置为上进水、挡板布水,集水装置为多孔板滤水帽集水或穹形多孔板加承托层结构;设备的本体外部配管配带阀门并留有压力取样接口,便于用户现场安装和实现装置正常运行。

四. 设备的安装1)安装前检查土建基础是否按设计要求施工。

2)设备按设计图纸进行就位,调整支腿垫铁并检查进出口法兰的水平度和垂直度。

3)将设备和基础预埋铁板焊接固定,固定后再次校验进出口法兰的水平度和垂直度。

4)将设备本体配管按编号区分后依设计图纸进行组装,每段管道组装前应用干净抹布对内壁进行清洁工作,组装后应保持配管轴线横平竖直,阀门朝向合理(手动阀手柄朝前,气动阀启动头朝上)。

5)检查本体阀门开关灵活,有卡壳的情况及时整改。

6)设备本体配管完成后应对阀组进行必要的支撑工作等。

7)安装设备上配带的进出水压力表、取样阀等;进出水管道上如有流量探头座应用堵头堵住。

五、初次开车1). 冲洗考虑到设备和管道连接时的电焊残渣、管道初次投用时的表面污物,设备初次投入运行时应进行冲洗。

GPJ(Φ3000)系列盘式加压过滤机使用说明书山东莱芜煤矿机械有限公司地址:山东莱芜市凤城西大街329号目录目录使用说明书 (1)第一部分:机械部分 (3)一、产品概述 (3)二、技术特征 (4)三、结构特征及工作原理 (5)四、使用操作 (8)五、保养及维护 (10)六、故障分析及排除(见下表) (12)七、运输及贮存 (12)八、易损件 (13)第二部分:电控部分 (13)一、概述 (13)二.系统构成 (14)三.控制原理 (17)四、工控机 (18)五.可编程序控制器 (19)六.框图简介 (20)七. 监控画面 (27)八.操作 (28)九.故障处理 (31)十. 操作及维护注意事项 (32)十一. 附录 (33)第三部分:液压部分 (34)一.概述 (34)二.构特征与工作原理 (34)三.液压系统的主要性能及技术参数 (34)四.液压系统安装说明: (35)五.液压系统调试说明 (35)六.液压系统的操作与使用 (36)七.维修与保养 (36)八.常见故障及其排除方法:详见附表1 (36)九.附件及易损件:详见附表2 (36)第一部分:机械部分一、产品概述加压过滤技术是一项国际公认的先进的脱水技术,根据这一技术而设计的加压过滤机是目前国际上一种先进的固液分离设备,经过多年的研究和发展,现已达到技术和工艺成熟的阶段。

目前世界上只有极少数国家能制造可用于工业性生产的加压过滤机,而山东莱芜煤矿机械有限公司生产的φ3000盘式加压过滤机填补了国内加压过滤机的空白,被认定为国家级新产品。

实践证明,加压过滤机工艺原理合理,它的使用能取得良好的技术经济效益。

加压过滤机优越的脱水效果目前已被越来越多的选煤厂所重视,认为是迄今降低浮选精煤水分和原生煤泥脱水的最理想的设备。

而新一代盘式加压过滤机总结了之前盘式加压过滤机的制造、安装、调试和使用经验,同时吸收国外加压过滤机的先进技术,由我公司自行设计、制造的集机、电、液、气等控制于一体全自动化操作的高新科技产品。

LLW型转盘过滤器(或称滤布滤池)一、用途LLW型转盘过滤器(或称滤布滤池)是一种污水由滤布的外侧向内侧过滤(外进内出)的转盘式过滤装置,采用不锈钢滤布作为过滤介质,安装在配套设计的滤池内,其运行状态包括过滤、反冲洗和排泥等过程,它的作用在于去除污水中悬浮物等污泥细粒,使处理水SS浓度在10mg/l以下,处理效果稳定。

LLW型转盘过滤器广泛应用于给水处理、污水深度处理和中水回用处理、工业废水处理等领域。

二、工作原理与结构LLW型转盘过滤器主要由转盘过滤系统、清洗系统、排泥系统和自动控制系统等部分组成。

1. 过滤系统:转盘采用标准模块化设计,以多个伞形模块合成一个转盘,根据处理量的需要,在水平的中空轴上并列安装多个转盘。

过滤作业时,转盘处于停止转动状态,污水靠重力流入滤池内,通过转盘上的滤布由外向内进行连续过滤,滤液从中空轴排出。

2. 清洗系统:在过滤过程中,悬浮物等污泥细粒逐渐在滤布外侧吸附和积聚,过滤阻力渐增,造成滤池的水位升高,当水位到达设定值时,进入清洗程序。

清洗时,滤盘在连续过滤状态下,始作缓慢旋转,同时启动泵吸系统,将转盘内的过滤水连同滤布表面的积泥一并吸出。

过滤转盘通过阀组的切换,依次逐组交替清洗。

3. 排泥系统:在转盘滤池的池底设有集泥斗,池底采用穿孔管排泥,通过排泥泵将污泥回流至厂区处理系统。

4. 控制系统控制系统装有可编程序(PLC)控制器,采用手动/自动/远程三种操作方式,配备触摸屏,用于实时监视水位变化和滤盘的运行工况,运转数据的调整,以及各设备的报警和故障处理。

三、特点1. 将纤维滤布应用于微孔过滤技术中,高效阻截悬浮物。

2.采用重力进水过滤,毋须水泵提升水位。

3.转盘由扇形模块组合,连接简便,密封性能优越。

4.设计简洁,配套设备和附属部件少,全封闭机构,占地小。

5.整机采用全不锈钢制造,耐腐蚀性好,使用寿命长。

6.连续性运转,滤水能力大,设备闲置率低。

7.直接利用过滤水作反冲洗水,毋须外供冲洗水源。

新洁环保保护环境以人为本LTC脉冲滤筒除尘器说明书泊头市新洁环保有限公司LTC脉冲滤筒式除尘器一、概述除尘器问世以来, 在国内外不断得以广泛的应用和改进。

其中在净化含尘气体的性能及设备结构上, 已取得了较大的进展。

实践证明, 当前所大量使用的旋风、布袋等除尘器, 在除尘效率、检测工作量及运行可靠性等方面都存在着不同程度的问题。

我厂生产的LTC系列沉流式除尘器, 是在吸收国外八十年代同类产品先进技术基础上, 对除尘效率、结构性能及可靠性等方面进行了综合改进而成, 与国内同类产品相比, 具有以下显著优点:1、设备箱体部分利用含尘气体的自重与下行气流流型, 来达到其本身的自净和过滤。

这样就可降低运行费用, 提高过滤效率。

2、空气处理组合采用了新颖独特的滤筒装置, 在设备中呈90º安装。

其特点是过滤面积大(8-20m2/个)、滤尘效果好(可吸附0.1~0.2μm级尘粒)、更换清理方便、快捷、安全、耐用。

3、设备结构紧凑、布局合理、通用性好, 充分体现了除尘技术的先进水平。

在用户选用时, 可根据其具体工况来方便地进行不同的处理组合, 从而保证达到用户满意的工作效果。

4、设备采用先进的脉冲反吹清灰装置, 清灰效果明显, 并可根据其本身运行阻力的大小, 来控制脉冲喷吹时间、周期等, 从而节省能源、降低消耗。

二、工作原理含尘气体由除尘器下部进气口进入除尘器内部的过程中, 其中较大颗粒(直径100μm), 首先被沉降; 较小颗粒(直径0.1~50μm)在空气处理室被吸附在滤筒表面。

穿过滤筒的净化空气经排气室排出。

当设备运行阻力达到一定时, 脉冲控制仪触发电磁阀开启, 压缩空气(P=0.5~0.6Mpa)经喷吹管吹射滤筒内部, 使尘粒在瞬间高压气流作用下脱落, 从而降低过滤阻力来完成除尘清灰过程。

经过对滤筒表面灰尘周期性清理, 使设备运行阻力相对稳定, 是保证除尘系统正常工作的重要环节。

沉降及清理的灰尘集聚于灰斗内, 由排灰阀自动排出或聚于灰桶内, 定期人工排放。

液压注意 – 用户方责任 错误或不当地选择或使用本样本或有关资料阐述的产品,可能会导致人生伤亡及财产损失! 本样本以及其它由派克汉尼汾公司及其子公司、销售公司与授权分销商所提供的资料,仅供用户专业技术人员在对产品和系统的选型进行深入调查考证时参考。

用户应全面分析自身设备的运行工况、适用的工业标准,并仔细查阅现行的样本,以详细地了解产品及系统的相关信息,通过自己的分析和试验,对产品及系统的独立的最终选择负责,确保能满足自身设备的所有性能、耐用性、维修型、安全性以及预警功能等要求。

对于派克或其子公司或授权分销商而言,应负责按用户提供的技术资料和规范,选择和提供适当的元件或系统,而用户则应负责确定这些技术资料和规范对其设备的所有运行工况和能合理预见的使用工况是否充分和准确。

目录目录页次概述 1 订货代号 2 技术参数 4 变量控制器 5 控制选项 “C”, 压力限定(恒压)变量控制器 5 控制选项 “L”, 负载传感及压力限定变量控制器 6 控制选项 “AM”, 带遥控口的标准型先导式压力限定变量控制器 7 控制选项 “AN”, 带ISO 4401 NG06先导阀安装界面的先导式压力限定变量控制器 8 控制选项 “AE”及“AF”, 带电磁比例调节的先导式压力限定变量控制器 9 控制选项 “AMT”, “ALT”及“LOT”, 带最高压力限定的扭矩限定(恒功率)变量控制器 10 P1性能特性 11典型流量特性 11 典型总效率特性 13 典型轴输入功率特性 15 典型噪声特性 18 典型轴承寿命 20 PD性能特性 22典型流量特性 22 典型总效率特性 24 典型轴输入功率特性 26 典型噪声特性 29 典型轴承寿命 31 安装尺寸 33 P1/PD 018 33 P1/PD 028 36 P1/PD 045 40 P1/PD 060 44 P1/PD 075 49 P1/PD 100 54 P1/PD 140 59 变量控制器安装尺寸 65 可提供的扩展的液压产品 75派克汉尼汾备记派克汉尼汾概述简介, 优点派克汉尼汾简介 • 开式回路用轴向柱塞式变量液压泵 • 中压,连续工作压力280 bar • 高驱动转速型,适用于行走机械; 低噪声型,适用于工业应用 • 静音及高效的控制效能 优点 • 总结构尺寸紧凑 • 低噪声• 流量脉动小,进一步降低噪声• 采用弹性密封,不使用密封垫,从而避免外泄漏的产生• 总效率高,功耗小,减小发热• 采用带无泄漏调节装的简单变量控制器 • 符合SAE 及ISO 标准的安装法兰及油口 • 采用圆锥滚柱轴承,使用寿命长 • 全功率后驱动能力• 后部或侧面油口配置可选• 泄油口的配置对水平安装及驱动轴向上垂直安装均适用• 带有最大及最小排量调节选项 • 具有壳体至吸口单向阀选项,可延长轴封寿命 • 使用、维修方便 脉动容腔技术下列图表所示为侧向油口配置P1/PD 18, 28及45泵采用 “脉动容腔” 技术的效果,脉动容腔可降低泵出口处的压力脉动幅值40-60%,这样,无需增加成本来加装噪声缓冲元件,便可大大降低液压系统的整体噪声,P1系列 PD 系列出口压力p / bar平均压力脉动 / b a rP1 045出口压力脉动2600 rpm 无脉动容腔2600 rpm 带脉动容腔订货代号18 ml, 28 ml, 45ml派克汉尼汾P 类型 01 驱动轴 转向R 5密封材料E 油口配置0 壳体-吸口 单向阀 0 排量调节 018 排量 S 安装法兰 及油口 S 轴封 M 应用范围A 设计系列0 通轴驱动选项 C0控制选项0附加控制选项 00油漆 00修改代号系列 P D * 仅适用于045排量, “S”型安装法兰及油口00 标准型, 无修改M2 按要求修改 代号修改代号 * 适用于028及045排量 ** 仅适用于045排量 代号设计系列 A 现行设计系列5 氟碳橡胶 (FPM) 代号密封材料 A 82-2 SAE A M33x2 M27x2 BSPP 1/4”, 3/8” 101-2 SAE B M42x2 M27x2 BSPP 1/4”, 1/2” 101-2SAE B M48x2M33x2Ø38/25DN51/25BSPP 1/4”, 1/2”B ISO M33x2 M27x2 BSPP 1/4”,3/8”ISO M42x2 M27x2 BSPP 1/4”, 1/2” ISO M48x2M33x2Ø38/25DN51/25BSPP 1/4”, 1/2”代号 018排量 028排量 045排量 安装法兰及油口 安装 法兰 螺纹 油口 辅助 油口 安装 法兰 螺纹 油口 辅助 油口 安装法兰螺纹油口法兰 油口辅助 油口 S 82-2 SAE A SAE 16/12 SAE 4/6 101-2 SAE B SAE 20/12 SAE 4/8 101-2SAE B SAE 24/16Ø38/2561系列SAE 4/10M ISO M33x2 M27x2 M12x1.5 M16x1.5 ISO M42x2 M27x2 M12x1.5 M22x1.5 ISO M48x2M33x2Ø38/25DN51/25M12x1.5M22x1.5代号 018驱动轴 028驱动轴 045驱动轴 01 SAE A 11T 花键SAE B-B 15T 花键 SAE B-B 15T 花键02 SAE 19-1平键Ø0.75” SAE B-B 平键Ø1” SAE B-B 平键Ø1” 08— SAE B 13T 花键 SAE B 13T 花键 04 ISO/DIN 平键, Ø20ISO/DIN 平键, Ø25ISO/DIN 平键, Ø25 06 SAE A 9T 花键— — PD 工业液压用 代号 系列P1 行走机械用 代号 排量 018 18 ml/rev (1.10 in 3/rev) 028 28 ml/rev (1.71 in 3/rev) 045 45 ml/rev (2.75 in 3/rev) 代号 类型 P 开式回路用变量柱塞泵 U*通用 代号应用范围 S 工业液压 (PD) M 行走机械 (P1) R 顺时针 (右转)L 逆时针 (左转)代号 转向 代号 轴封 S 单唇轴封 * 并不具有控制功能,仅在运输时予以防护,详情见第7页的控制说明。

The New High Efficiency Hyperbaric Filtrationthrough PowerFilter TM新型高效PowerFilter TM加压过滤技术SEPARATION TECHNOLOGIESThe Andritz World Map安德里茨全球分布图You are making the right choice ……你正在做出正确的选择SEPARATION TECHNOLOGIES•4% of Group sales.•Plants, equipment, and services for the 9% of Group sales.Plants, equipment, and services for solid/liquid separation formunicipalities and industries (e. g. mining, chemical and petrochemical industries, food industry).17% of Group sales.30% of Group sales.Plants and services for 40% of Group sales.Electromechanical 水力发电制浆造纸金属环境与工艺食品与生物燃料SEPARATION TECHNOLOGIESAndritz Separation Technologiesfor Mining ApplicationMembrane and Chamber Filter PressesDecanter, Centrifuges Membrane and ChamberFilter PressesMembrane and Chamber Filter PlatesHyperbaric & Vacuum Filters and Belt PressesVibrating and Screen Bowl CentrifugesMembrane Filter Presses&Belt Presses箱式隔膜压滤机和带式压滤机Single or Combined Dewatering Systems can be SuppliedKind of “all safe”HYPERBARIC FILTRATION加压过滤TODAY‘S REQUIREMENTS当前的社会需求-Availability> 95% 设备利用率95%以上-24 h Operating 24小时连续运转-Emergency Spare parts紧急备件供应-Combination with other systems便于与其他系统的联合-Costs in RMB/ton DS/year become more important than investment 运行成本比初期投资更重要-Low moisture 产品水分低-Clear filtrate due to circulate and environmental aspects符合闭路循环和环保要求的清澈滤液-Ultrafines material treatment 极细物料处理-Engery savings节能SEPARATION TECHNOLOGIESHYPERBARIC FILTRATION 加压过滤Pressure Filters for highperformance filtration offines in ore and coalprep.plants as well asvarious industrialapplications加压过滤机用于金属矿、选煤厂及其他不同工业领域的细颗粒高效过滤脱水The Hyperbaric Filter has been found to be the most effective andproven dewatering technology for the increasing fine coal production.加压过滤机已经证明是处理细粒煤的最高效的脱水技术和设备SEPARATION TECHNOLOGIESSEPARATION TECHNOLOGIESHyperbaric 600-16000123456000-000Specific throughput [kg DS/m², h]V a c u u m F i l t e r O p e r a t i o n R a n g e Filter Range of OperationDifferential Pressure [bar]600-900750-12001500-2500900-1600300-600500-1500250-500180-500250-350Both the residual moisture and throughput increase significantly if the pressure difference is increased.工作压差的增加会使产品水分和处理量都能得到显著改善!!!HYPERBARIC FILTRATION 加压过滤Andritz HBF History安德里茨加压过滤机历史Andritz developed the first Hyperbaric Filter in the world安德里茨研制了世界第一台加压过滤机Andritz never stopped its study of application of HBF, that keeps Andritz always in advanced position in the world. On the similar productsmanufactured by other suppliers, we can always find the shadow of early form of Andritz HBF.安德里茨不断地进行加压过滤机的研发应用,在技术和性能方面一直保持领先的地位,从其它厂家的同类设备上我们都可以看到安德里茨早期加压过滤机的影子。

SEPARATION TECHNOLOGIESHYPERBARIC FILTRATION 加压过滤Andritz HBF History安德里茨加压过滤机历史•1986 First120 m2 HBF for coal filtration首台煤用加压过滤机•1991First HBF for Mineral 首台矿业用加压过滤机•1995First HBF in China 中国引进首台加压过滤机•1995 –2004 HBF in USA; Australia, Chile, Canada, Europe, China加压过滤机在美国、澳洲、智利、加拿大、欧洲和中国推广•2003First HBF in Russia 俄罗斯引进首台加压过滤机•2005Development of 168 m2 HBF 大型168 m2加压过滤机研制成功•20064Zone Filtration 四区过滤技术应用•2006Service Centre and Manufacturing in Foshan佛山工厂开始生产并组建服务中心•2007 Succesful start up of 5 lines HBF 168 m2五台168 m2大型加压过滤机调试成功•20088lines HBF 168 sold up to date 销售八台168 m2大型加压过滤机•2008First new120 m2sold, (delivery 2009) 首台新型120 m2加压过滤机SEPARATION TECHNOLOGIESHYPERBARIC FILTRATION加压过滤Andritz HBF Development安德里茨加压过滤机发展•Widely Applications of Coal, Copper, Lead, Zinc, Iron, Alumina, Bauxite, Red mud, Amylum and etc.应用涵盖了细煤泥、铜矿、铅矿、铁矿、锌矿、铝土矿、赤泥以及淀粉等的脱水•Special design and successful experience for ultra fine tailing coal dewatering 安德里茨近年来致力于研发尾煤的处理并取得了显著的成果,而且已经得到了成功的工业应用因此安德里茨加压过滤机在处理尾煤和泥化现象严重的煤泥方面具有独到的经验和实力。

•The new high efficiency product PowerFilter TM with more simple structure and more reliable running,结构更简单,运行更可靠的新型PowerFilter TM高效加压过滤机•The biggest PowerFilter TM in the world with168m2 filter area which will simplify the lay-out of whole plant and save investment cost.世界上最大的新型加压过滤机,它的过滤面积达168m2,,这样将可以进一步简化整个过滤车间的布置和投资。

SEPARATION TECHNOLOGIESHYPERBARIC FILTRATION加压过滤Convincing Technology for加压过滤技术优势•Continuous system -high throughput高处理量•Low residual moisture低残留水分•Reduction or virtual elimination of drying costs降低或完全省去干燥费用•Clear filtrate清澈的滤液•Low operation costs低运行成本•Fully automatic operation and easy plant monitoring全自动操作和方便的车间监控•Closed system封闭的系统SEPARATION TECHNOLOGIES1 -Pressure Vessel 加压仓2 –Manhole 人孔3 –Filterdisc 过滤盘4 -Control head 控制头5 -Filter drive 驱动单元6 -Filter trough 矿浆槽7 -Discharger 卸料闸门1234567SEPARATION TECHNOLOGIESHYPERBARIC FILTRATION 加压过滤成饼过程干燥过程吹饼过程HYPERBARIC FILTRATION加压过滤Filtration, Snap-blow& Discharging process 过滤、反吹和卸料过程Filtration 加压过滤过程Discharging自动卸料过程Snap-blow反吹卸料过程SEPARATION TECHNOLOGIES-Cycles of approximately 1 minute.循环周期约1分钟Controlled automatically by time switch or fillinglevel probe in the upper / cake receiving chamber.通过定时开关或者装在上仓的料位传感器自动控制卸料G. HaehlingNEW PowerFilter ™FILTRATION新型加压过滤•Up to 20% efficiency increase 效率可增加20%•Up to 5,8 bar for highest troughput and lowest moisture工作压力可高达5.8bar,有效保证最大处理量和最低产品水分•Up to 800 kg/m2/hr troughput产能高达0.8吨/平米/小时•Surface moisture10to 18% 产品外水可达10-18%•Availability more than8000 h/year每年运行时间可长达8000小时•With168 m220% reduction of specific investment costs采用168平米加压过滤机单位产量投资费用可减少20%•Reduction of infrastructural costs 减少基建投资•Systems combined with centrifuges can be offered可提供与离心机组成的联合工艺系统SEPARATION TECHNOLOGIESNEW PowerFilter ™FILTRATION新型加压过滤WhyAndritz HBFhas better quality and performance?为什么安德里茨加压过滤机有更高的质量和更优的性能?SEPARATION TECHNOLOGIESHYPERBARIC FILTRATION加压过滤New Development Technologies 最新技术应用1、New Patent High Throughput, High Reliability Powerfilter168新型大处理量、高可靠性的168m2高效加压过滤机专利技术2、New Control Head and Filtrate Pipes Design新型高效控制头和滤液管设计3、New Patent High Efficient Filterbag Cleaning System新型高效滤布清洗系统专利技术4、New Patent Slurry Paddle System新型矿浆搅拌专利技术5、New Patent Filter Cell Fixing System新型滤扇固定专利技术6、New Sealing System for Discharger新型卸料闸门密封系统SEPARATION TECHNOLOGIESNEW MODEL 168 m2 –Finite Elemente Optimised新型168m2矿浆槽体设计采用有限元分析优化-40% more throughputthan120 m2 but samemaintenance costs处理量增加40%,但维护成本相同-40% less specificmaintenance costs相当于维护成本降低40%SEPARATION TECHNOLOGIESSEPARATION TECHNOLOGIESHBF-Discharger –Type 3XL for more than 100 t/hthroughput -Designed for more than 100 t/hThroughput 设计通过能力超过100t/h-Special coat inside (on request)内部特殊涂层(选配)2layer ultra sliding material reduces wear of the wall and has excellent corrosion protection, resulting in increaded life time-New sealing system 新型密封装置(no screws inside 内部无螺栓)新型3XL 型卸料闸门通过量超过100t/hNew Discharger Sealing System ®新型卸料闸门密封装置Previous System 原设计Advanced System from OUTSIDE FIXED 新设计(从外部固定)-No srewing inside for changing sealing ring更换密封圈无需从内部拆装螺栓-80% faster than previous 比原设计更换速度提高80%-Fixed from outside 从外部固定-Long Life of sealing ring up to 12 months 密封圈使用寿命长达12个月SEPARATION TECHNOLOGIESQuick Fixing of Cells®滤扇快速固定设计-easy maintenance 方便维护-No screws!! 不需螺栓固定-production time 增加生产时间-safety 安全-no tools required 无需工具-all stainless steel parts 全不锈钢SEPARATION TECHNOLOGIESSEPARATION TECHNOLOGIES -No agitators outside-1 drive outside instead9 drives on top -Significant life time increase-reduced maintenance costs-increased productivity(aprx1 week/ year)-less energy consumptionIntegrated paddle agitator ®水平浆式搅拌装置New Design of Chain Conveyor配套新型刮板输送机-Bearings outside 轴承外部安装-Coupling outside 外部联轴器-Stainless trough 不锈钢槽体-New shaft & teeth design新型轮牙设计-Easy moving out 方便抽出更换Long life and Easy maintenance!!!寿命更长,更易维护!!!SEPARATION TECHNOLOGIESSEPARATION TECHNOLOGIESMultiple lights inside增强内部照明-Perfect maintenance and service -Safe operation -increasedlife timeSelf Filling Oil and Breath system 自动加油和透气装置Imported gear motors, bearings 进口高性能齿轮箱和轴承Control head in Coated Stainless steel(on request)不锈钢带涂层控制头(可选项)Options:-Stainless steel(on request)-Rubber coated inside(on request)Advantages:-Significant Increase in life time-Less service& maintenance SEPARATION TECHNOLOGIESSEPARATION TECHNOLOGIESControl disc material …Blue“®控制盘特殊材质Material …Blue“®UHDPP + special additives(Special design for wear applications)Advantage:-Multiple life time increase (for coal up to several years have been reported in long term tests )超强耐磨,实验证明煤炭应用使用寿命可长达数年!!!SEPARATION TECHNOLOGIESTrapeziform channels provide 20% more section area & throughput than normal round channels design.梯形流道设计比普通圆形流道设计多出20%的截面积,从而产生高出20%的处理量!Special channel design of control head and filtrate pipes 特殊的控制头和滤液管流道设计Andritz Special Design Local Normal DesignAndritz DesignSEPARATION TECHNOLOGIESAdvanced washing –access from outside for 120 m2改进型清洗装置—可从外部方便维护-Easy access to nozzles 方便清洗喷嘴-Saving of wash water energy due to new control philosophy根据新的控制逻辑节约清洗水消耗-No movement of washing nozzles requires less spare parts (no drive)清洗装置不运动,减少备件损耗(无需驱动)Power Filter™-Latest development 新研发成果4 Zone Filtration (cake formation, Array drying, snap blow, cleaning)4区域过滤(成饼、干燥、反吹、清洗)-Continuous cleaning duringoperation运行中滤布清洗-Gain:30 min production time/ day每天增加30分钟运行时间-apprx. 20% better productivity增加约20%产能-no agitators 无分体搅拌器Integrated cleaning综合清洗系统SEPARATION TECHNOLOGIESHBF-vessel – 4,8 m diameter for 168 m2 (standard) on request for 120m2 available 大直径加压仓和滤盘- Excellent space for maintenance and service 大空间更方便维护 - Reduced floor space in terms of filtration area / m2 floor space减少设备的占地面积 SEPARATION TECHNOLOGIES41HBF-vessel – 4,8 m diameter for 168 m2 and 120 m2 4.8m直径的加压仓Man Hole 1600 mm for perfect access and maintenance 1.6m 直径的大人孔 Large inspection windows (single washed) for excellent view 大直径的视窗 (带独立清洗)SEPARATION TECHNOLOGIES42On Line Moisture Measurement of cake after discharger (on request) 滤饼在线水分检测- Apply only the pressure what is necessary - Allows to optimise pressure - Wear and tear is reduced in consequence - Energy saving of compressor power 在线控制工作压力,尽量减少磨损和能耗!!!SEPARATION TECHNOLOGIES43Why should we choose Andritz HBF? 为什么我们应当选用安德里茨加压过滤机?• • • • • • • • Higher throughput 更高处理量 Lower cake moisture 更低滤饼水分 Less maintenance 更少维护量 Longer life 更长使用寿命 Higher reliability 更高可靠性 Full automatic 全自动控制 Best rate of performance/price 更高性价比 Quick after sale service 快捷的售后服务SEPARATION TECHNOLOGIES44The biggest HBF workshop in the world (Brazil) 世界最大的加压过滤车间(巴西)10 HBF filters in a row , 168 m2 each 10x168m2安德里茨加压过滤机 Feeding size: about 50% = 50μm Feeding solid: 50% w/w Throughtput: 140t DS/h each HBF168 Residual Moisture: 11-14% Filtrate: < 4g/lEnd user: Alunorte 用户 Application: Bauxite 应用:铝土矿SEPARATION TECHNOLOGIES45Test Results on RED MUD Pressure Filtration 1996 – 2007 加压过滤机赤泥试验On Pressure Filters 加压过滤• Lower Residual Moisture 更低滤饼水分• Higher Throughputs 更高处理量On Vacuum Filters 真空过滤•Dry Solids depends on type of sludge;滤饼干度取决于赤泥类型 •Slurries in South America show dryness from 22 to 25%;南美赤泥干度可达22-25% •Slurries in China show dryness between 32 to 35%;中国赤泥干度可达32-35% •Chemical composition (reactive surface) is of prime importance; 赤泥化学成分(表面活性)尤为重要 •Andritz tested slurries around the world; results from 22 to 35% depending on the source of sludge 安德里茨对世界各地的赤泥做过试验,滤饼水分基于赤泥性质不同可达22-35% SEPARATION TECHNOLOGIES46Test Results on RED MUD Pressure Filtration 1996 – 2007 加压过滤机赤泥试验报告数据Pressure Filtration 加压过滤 Residual Moisture外水 24 to 35 weight - % Throughput 处理量250 to 1000 kg/m2hPressure Filtration (Washing) 加压过滤(带清洗)24 to 35 weight - % 250 to 1000 kg/m2hSteam Pressure Filtration 蒸汽加压过滤22 to 35 weight - % 250 to 1000 kg/m2h100Percentage PassingDifferential Pressure: 3 to 5.8 bar 工作压差 Dry Solids Content of Slurry: 350 to 500 g/l 入料浓度 Feed Temperature: 70 to 92 °C 入料温度80604020Test work is required for sizing equipment 0应根据试验数据进行设备选型SEPARATION TECHNOLOGIES1101001000Particle Size [μm]47Copper Floatation Concentrate (Chile) 浮选铜精矿应用(智利)4 HBF filters, 2x120m2, 2x60m2 3台安德里茨加压过滤机 Feeding size: about 80% < 37μm Feeding solid: 1450-1800g/l Throughtput: 140t DS/h each HBF120 Residual moisture: 7-9%矿山管道 输送入料 到尾矿场 浮选机 磨机 铜精矿浓缩机浮选机 加压过滤机药剂准备浮选柱控制室和试验室End user: Anglo American 用户 Application: Copper Concentrate 应用:铜精矿SEPARATION TECHNOLOGIES钼矿分选铜精矿储运场办公楼钼精矿储运场 浓缩机Las Tórtolas Plant – 工艺流程图48Copper Floatation Concentrate (Russia) 浮选铜精矿应用(俄罗斯) 1x120m2 HBF filters1台安德里茨加压过滤机 Feeding size: about 60% < 32μm Feeding solid: 1300g/l Throughtput: 100t DS/h Residual moisture: 6-7%End user: GAYSKI GOK, CIS Application: Copper Floatation ConcentrateSEPARATION TECHNOLOGIES49Hyperbaric Filter instead of Vacuum Filtration + Drying Drum (Copper) 加压过滤机取代真空过滤机+转筒干燥机(铜矿)FiltrateFiltrate 100 t DS/h 7%FiltrateFiltrate100 t DS/h 7% Filtrate SEPARATION TECHNOLOGIES50。