超高压热平衡图

- 格式:pdf

- 大小:55.46 KB

- 文档页数:1

附件9.15:HRSG热平衡图目录1. Case1,Backpressure Condition,2GT,温度-4.4℃,100%负荷;2. Case2,Backpressure Condition,2GT,温度-4.4℃,75%负荷;3. Case3,Backpressure Condition,2GT,温度-4.4℃,50%负荷;4. Case4,Backpressure Condition,2GT,温度-4.4℃,30%负荷;5. Case5,Full Condensing Operation Condition,2GT,温度12.1℃,100%负荷;6. Case6,Full Condensing Operation Condition,2GT,温度12.1℃,75%负荷;7. Case7,Full Condensing Operation Condition,2GT,温度12.1℃,50%负荷;8. Case8,Full Condensing Operation Condition,2GT,温度12.1℃,30%负荷;9. Case9,Site Condition of Maximum Continuous Output,2GT,温度-4.4℃,100%负荷;10. Case10,Site Condition of Maximum Continuous Output,2GT,温度-4.4℃,75%负荷;11. Case11,Site Condition of Maximum Continuous Output,2GT,温度-4.4℃,50%负荷;12. Case12,Site Condition of Maximum Continuous Output,2GT,温度-4.4℃,30%负荷;13. Case13,Summer Operation Design Condition,2GT,温度26.3℃,100%负荷;14. Case14,Summer Operation Design Condition,2GT,温度26.3℃,75%负荷;15. Case15,Summer Operation Design Condition,2GT,温度26.3℃,50%负荷;16. Case16,Summer Operation Design Condition,2GT,温度26.3℃,30%负荷;17. Case17,ISO Operation Design Condition,2GT,温度15℃,100%负荷;18. Case18,ISO Operation Design Condition,2GT,温度15℃,75%负荷;19. Case19,ISO Operation Design Condition,2GT,温度15℃,50%负荷;20. Case20,ISO Operation Design Condition,2GT,温度15℃,30%负荷;21. Case21,Summer Operation Design Condition,1GT,温度26.3℃,100%负荷;22. Case22,Extraction and Condensing Condition,2GT,温度-4.4℃,100%负荷;23. Case23,ST Full Bypass Condition,2GT,温度-4.4℃,100%负荷;。

C25-8.83/0.785型汽轮机热力系统平衡图 1

热耗保证工况(THA)

C25-8.83/0.785型汽轮机热力系统平衡图 2

铭牌工况(TRL)

C25-8.83/0.785型汽轮机热力系统平衡图 3

最大连续保证出力工况(T-MCR)

C25-8.83/0.785型汽轮机热力系统平衡图 4

阀门全开工况(VWO)

C25-8.83/0.785型汽轮机热力系统平衡图 5

高加停用工况

C25-8.83/0.785型汽轮机热力系统平衡图 6

额定抽汽工况

C25-8.83/0.785型汽轮机热力系统平衡图 7

最大抽汽压力工况

C25-8.83/0.785型汽轮机热力系统平衡图 8

最小抽汽压力工况

C25-8.83/0.785型汽轮机热力系统平衡图 9

最大抽汽工况

C25-8.83/0.785型汽轮机热力系统平衡图 10

75%THA工况

C25-8.83/0.785型汽轮机热力系统平衡图 11

50%THA工况

C25-8.83/0.785型汽轮机热力系统平衡图 12

40%THA工况

C25-8.83/0.785型汽轮机热力系统平衡图 13

30%THA工况。

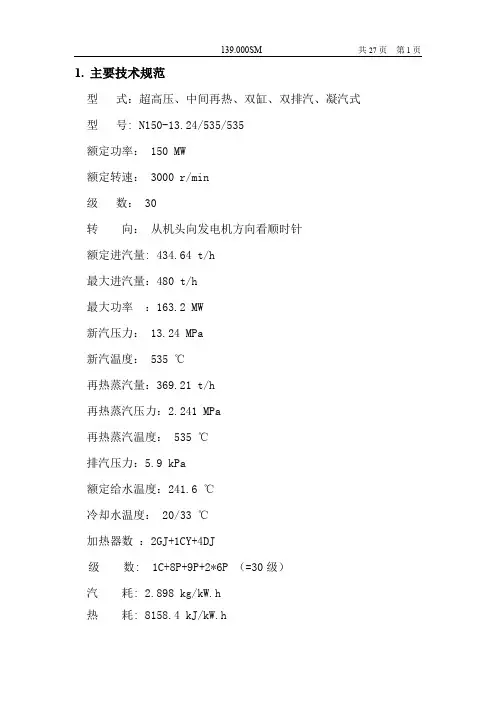

1.主要技术规范型式:超高压、中间再热、双缸、双排汽、凝汽式型号: N150-13.24/535/535额定功率: 150 MW额定转速: 3000 r/min级数: 30转向:从机头向发电机方向看顺时针额定进汽量: 434.64 t/h最大进汽量:480 t/h最大功率:163.2 MW新汽压力: 13.24 MPa新汽温度: 535 ℃再热蒸汽量:369.21 t/h再热蒸汽压力:2.241 MPa再热蒸汽温度: 535 ℃排汽压力:5.9 kPa额定给水温度:241.6 ℃冷却水温度: 20/33 ℃加热器数:2GJ+1CY+4DJ级数: 1C+8P+9P+2*6P (=30级)汽耗: 2.898 kg/kW.h热耗: 8158.4 kJ/kW.h2.概述N150-13.24/535/535型汽轮机汽轮机为超高压、双缸、中间再热、单轴、双分流、凝汽式汽轮机。

其特点是采用高压抗燃油数字电调系统,操作简便,运行安全可靠。

机组外形尺寸(长X宽X高)为13.7X7.8X5.4m,总重约为350t。

附图1为汽轮机纵剖面图附图2为汽轮机俯视图附图3为汽轮机侧视图主蒸汽从锅炉经2根主汽管道别到达汽轮机两侧的主汽阀和调节阀,并由4根主汽管及进汽插管进入设置在高压内缸的喷嘴室。

高压缸采用内外双层缸结构。

高压部分为反向布置,由1级单列调节级和8级压力级组成。

其中第2-7级隔板挂在高压内缸上,第8、9级隔板挂在1号隔板套上。

主蒸汽经过布置在高中压缸两侧的2个主汽阀和4个调节阀从位于高中压缸中部的上下各2个进汽口进入喷嘴室调节级,然后再流经高压缸各级。

第7级后部分蒸汽由一段抽汽口抽汽至2号高加。

高压缸排汽从下部排出经再热冷段蒸汽管回到锅炉再热器,其中部分蒸汽由二段抽汽口抽汽至1号高加。

从锅炉再热器出来的再热蒸汽经由再热热段蒸汽管到达汽轮机机头两侧的再热主汽阀与调节阀,然后经中压主汽管进入中压缸。

中压部分由9级压力级组成,第10-12级隔板挂在2号隔板套上,第13-15级隔板挂在3号隔板套上,第16-18级隔板挂在4号隔板套上。

IndexCCA9123NGr0101.56 kPa,a, 15.2 °C, 79.00 % RH Guarantee Ambient CCA9124NGr0101.56 kPa,a, 15.2 °C, 79.00 % RH Guarantee Ambient CCA9125NGr0101.56 kPa,a, 15.2 °C, 79.00 % RH Guarantee Ambient CCA9126NGr0101.56 kPa,a, 15.2 °C, 79.00 % RH Guarantee Ambient CCA9127NGr0102.63 kPa,a, 2.0 °C, 70.00 % RH Winter Ambient CCA9128NGr0102.63 kPa,a, 2.0 °C, 70.00 % RH Winter Ambient CCA9129NGr0102.63 kPa,a, 2.0 °C, 70.00 % RH Winter Ambient CCA9130NGr0102.63 kPa,a, 2.0 °C, 70.00 % RH Winter Ambient CCA9131NGr0100.38 kPa,a, 28.0 °C, 85.00 % RH Summer Ambient CCA9132NGr0100.38 kPa,a, 28.0 °C, 85.00 % RH Summer Ambient CCA9133NGr0100.38 kPa,a, 28.0 °C, 85.00 % RH Summer Ambient CCA9134NGr0100.38 kPa,a, 28.0 °C, 85.00 % RH Summer Ambient CCA9135NGr0101.35 kPa,a, 15.0 °C, 60.00 % RH ISOCCA9136NGr0101.35 kPa,a, 15.0 °C, 60.00 % RH ISOCCA9137NGr0101.35 kPa,a, 15.0 °C, 60.00 % RH ISOCCA9138NGr0101.35 kPa,a, 15.0 °C, 60.00 % RH ISOHPIHuaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBECCA9123NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 101.56 kPa,a, 15.2 °C, 79.00 % RHNatural Gas, DLN Guarantee AmbientGas Turbine: PG9351100% LoadSteam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *396,730* Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11Heat Consumption (10^6 kJ/hr)LHV2,474.8HHV2,747.01.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV6,237.9HHV6,924.11.3.2 Gross Equipment Thermal Efficiency (%)LHV57.71HHV51.991.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb15.2Wet Bulb13.1Ambient Relative Humidity (%)79.00Ambient Air Pressure (kPa,a)101.56Site Elevation (m above MSL) 6.800Compressor Inlet Temperature (°C)Dry Bulb15.2Compressor Inlet Relative Humidity (%)78.27Steam Turbine Exhaust Pressure (kPaA) 4.900GE COMPANY PROPRIETARYHPIHuaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBECCA9124NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 101.56 kPa,a, 15.2 °C, 79.00 % RHNatural Gas, DLN Guarantee AmbientGas Turbine: PG935175% LoadSteam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *297,560* Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11Heat Consumption (10^6 kJ/hr)LHV1,948.0HHV2,162.31.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV6,546.6HHV7,266.81.3.2 Gross Equipment Thermal Efficiency (%)LHV54.99HHV49.541.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb15.2Wet Bulb13.1Ambient Relative Humidity (%)79.00Ambient Air Pressure (kPa,a)101.56Site Elevation (m above MSL) 6.800Compressor Inlet Temperature (°C)Dry Bulb18.8Compressor Inlet Relative Humidity (%)62.16Steam Turbine Exhaust Pressure (kPaA) 4.372GE COMPANY PROPRIETARYHPIHuaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBECCA9125NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 101.56 kPa,a, 15.2 °C, 79.00 % RHNatural Gas, DLN Guarantee AmbientGas Turbine: PG935150% LoadSteam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *198,370* Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11Heat Consumption (10^6 kJ/hr)LHV1,424.1HHV1,580.81.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV7,179.0HHV7,968.71.3.2 Gross Equipment Thermal Efficiency (%)LHV50.15HHV45.181.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb15.2Wet Bulb13.1Ambient Relative Humidity (%)79.00Ambient Air Pressure (kPa,a)101.56Site Elevation (m above MSL) 6.800Compressor Inlet Temperature (°C)Dry Bulb28.6Compressor Inlet Relative Humidity (%)34.55Steam Turbine Exhaust Pressure (kPaA) 3.913GE COMPANY PROPRIETARYHPIHuaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBECCA9126NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 101.56 kPa,a, 15.2 °C, 79.00 % RHNatural Gas, DLN Guarantee AmbientGas Turbine: PG935130% LoadSteam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *119,020* Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11Heat Consumption (10^6 kJ/hr)LHV1,019.1HHV1,131.21.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV8,562.1HHV9,503.91.3.2 Gross Equipment Thermal Efficiency (%)LHV42.05HHV37.881.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb15.2Wet Bulb13.1Ambient Relative Humidity (%)79.00Ambient Air Pressure (kPa,a)101.56Site Elevation (m above MSL) 6.800Compressor Inlet Temperature (°C)Dry Bulb28.8Compressor Inlet Relative Humidity (%)34.18Steam Turbine Exhaust Pressure (kPaA) 3.625GE COMPANY PROPRIETARYHuaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBE CCA9127NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 102.63 kPa,a, 2.0 °C, 70.00 % RHNatural Gas, DLN Winter Ambient Gas Turbine: PG9351100% Load Steam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *414,550 * Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11 Heat Consumption (10^6 kJ/hr)LHV2,600.7HHV2,886.7 1.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV6,273.5HHV6,963.61.3.2 Gross Equipment Thermal Efficiency (%)LHV57.38HHV51.701.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb 2.0Wet Bulb.1 Ambient Relative Humidity (%)70.00 Ambient Air Pressure (kPa,a)102.63 Site Elevation (m above MSL) 6.800 Compressor Inlet Temperature (°C)Dry Bulb 2.0 Compressor Inlet Relative Humidity (%)69.36 Steam Turbine Exhaust Pressure (kPaA) 3.386Huaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBE CCA9128NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 102.63 kPa,a, 2.0 °C, 70.00 % RHNatural Gas, DLN Winter Ambient Gas Turbine: PG935175% Load Steam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *310,920 * Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11 Heat Consumption (10^6 kJ/hr)LHV2,030.9HHV2,254.3 1.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV6,531.9HHV7,250.41.3.2 Gross Equipment Thermal Efficiency (%)LHV55.11HHV49.651.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb 2.0Wet Bulb.1 Ambient Relative Humidity (%)70.00 Ambient Air Pressure (kPa,a)102.63 Site Elevation (m above MSL) 6.800 Compressor Inlet Temperature (°C)Dry Bulb 5.6 Compressor Inlet Relative Humidity (%)53.84 Steam Turbine Exhaust Pressure (kPaA) 3.386Huaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBE CCA9129NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 102.63 kPa,a, 2.0 °C, 70.00 % RHNatural Gas, DLN Winter Ambient Gas Turbine: PG935150% Load Steam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *207,280 * Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11 Heat Consumption (10^6 kJ/hr)LHV1,486.4HHV1,649.9 1.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV7,171.1HHV7,959.91.3.2 Gross Equipment Thermal Efficiency (%)LHV50.20HHV45.231.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb 2.0Wet Bulb.1 Ambient Relative Humidity (%)70.00 Ambient Air Pressure (kPa,a)102.63 Site Elevation (m above MSL) 6.800 Compressor Inlet Temperature (°C)Dry Bulb16.1 Compressor Inlet Relative Humidity (%)26.76 Steam Turbine Exhaust Pressure (kPaA) 3.386Huaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBE CCA9130NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 102.63 kPa,a, 2.0 °C, 70.00 % RHNatural Gas, DLN Winter Ambient Gas Turbine: PG935130% Load Steam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *124,370 * Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11 Heat Consumption (10^6 kJ/hr)LHV1,067.7HHV1,185.1 1.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV8,584.7HHV9,529.01.3.2 Gross Equipment Thermal Efficiency (%)LHV41.93HHV37.781.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb 2.0Wet Bulb.1 Ambient Relative Humidity (%)70.00 Ambient Air Pressure (kPa,a)102.63 Site Elevation (m above MSL) 6.800 Compressor Inlet Temperature (°C)Dry Bulb15.5 Compressor Inlet Relative Humidity (%)27.78 Steam Turbine Exhaust Pressure (kPaA) 3.386Huaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBE CCA9131NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 100.38 kPa,a, 28.0 °C, 85.00 % RHNatural Gas, DLN Summer Ambient Gas Turbine: PG9351100% Load Steam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *361,880 * Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11 Heat Consumption (10^6 kJ/hr)LHV2,290.4HHV2,542.3 1.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV6,329.1HHV7,025.31.3.2 Gross Equipment Thermal Efficiency (%)LHV56.88HHV51.241.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb28.0Wet Bulb25.9 Ambient Relative Humidity (%)85.00 Ambient Air Pressure (kPa,a)100.38 Site Elevation (m above MSL) 6.800 Compressor Inlet Temperature (°C)Dry Bulb28.0 Compressor Inlet Relative Humidity (%)84.21 Steam Turbine Exhaust Pressure (kPaA)7.508Huaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBE CCA9132NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 100.38 kPa,a, 28.0 °C, 85.00 % RHNatural Gas, DLN Summer Ambient Gas Turbine: PG935175% Load Steam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *271,410 * Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11 Heat Consumption (10^6 kJ/hr)LHV1,818.7HHV2,018.8 1.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV6,700.9HHV7,438.01.3.2 Gross Equipment Thermal Efficiency (%)LHV53.72HHV48.401.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb28.0Wet Bulb25.9 Ambient Relative Humidity (%)85.00 Ambient Air Pressure (kPa,a)100.38 Site Elevation (m above MSL) 6.800 Compressor Inlet Temperature (°C)Dry Bulb31.6 Compressor Inlet Relative Humidity (%)68.31 Steam Turbine Exhaust Pressure (kPaA) 6.838Huaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBE CCA9133NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 100.38 kPa,a, 28.0 °C, 85.00 % RHNatural Gas, DLN Summer Ambient Gas Turbine: PG935150% Load Steam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *180,940 * Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11 Heat Consumption (10^6 kJ/hr)LHV1,339.3HHV1,486.6 1.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV7,402.0HHV8,216.21.3.2 Gross Equipment Thermal Efficiency (%)LHV48.64HHV43.821.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb28.0Wet Bulb25.9 Ambient Relative Humidity (%)85.00 Ambient Air Pressure (kPa,a)100.38 Site Elevation (m above MSL) 6.800 Compressor Inlet Temperature (°C)Dry Bulb40.9 Compressor Inlet Relative Humidity (%)41.06 Steam Turbine Exhaust Pressure (kPaA) 6.301Huaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBE CCA9134NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 100.38 kPa,a, 28.0 °C, 85.00 % RHNatural Gas, DLN Summer Ambient Gas Turbine: PG935130% Load Steam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *108,560 * Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11 Heat Consumption (10^6 kJ/hr)LHV966.9HHV1,073.2 1.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV8,906.3HHV9,886.01.3.2 Gross Equipment Thermal Efficiency (%)LHV40.42HHV36.421.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb28.0Wet Bulb25.9 Ambient Relative Humidity (%)85.00 Ambient Air Pressure (kPa,a)100.38 Site Elevation (m above MSL) 6.800 Compressor Inlet Temperature (°C)Dry Bulb41.6 Compressor Inlet Relative Humidity (%)39.71 Steam Turbine Exhaust Pressure (kPaA) 5.879Huaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBE CCA9135NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 101.35 kPa,a, 15.0 °C, 60.00 % RHNatural Gas, DLN ISO Gas Turbine: PG9351100% Load Steam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *397,250 * Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11 Heat Consumption (10^6 kJ/hr)LHV2,470.6HHV2,742.4 1.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV6,219.3HHV6,903.51.3.2 Gross Equipment Thermal Efficiency (%)LHV57.88HHV52.151.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb15.0Wet Bulb10.8 Ambient Relative Humidity (%)60.00 Ambient Air Pressure (kPa,a)101.35 Site Elevation (m above MSL) 6.800 Compressor Inlet Temperature (°C)Dry Bulb15.0 Compressor Inlet Relative Humidity (%)59.45 Steam Turbine Exhaust Pressure (kPaA) 3.786Huaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBE CCA9136NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 101.35 kPa,a, 15.0 °C, 60.00 % RHNatural Gas, DLN ISO Gas Turbine: PG935175% Load Steam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *297,940 * Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11 Heat Consumption (10^6 kJ/hr)LHV1,942.2HHV2,155.9 1.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV6,518.9HHV7,235.91.3.2 Gross Equipment Thermal Efficiency (%)LHV55.22HHV49.751.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb15.0Wet Bulb10.8 Ambient Relative Humidity (%)60.00 Ambient Air Pressure (kPa,a)101.35 Site Elevation (m above MSL) 6.800 Compressor Inlet Temperature (°C)Dry Bulb18.6 Compressor Inlet Relative Humidity (%)47.19 Steam Turbine Exhaust Pressure (kPaA) 3.386Huaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBE CCA9137NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 101.35 kPa,a, 15.0 °C, 60.00 % RHNatural Gas, DLN ISO Gas Turbine: PG935150% Load Steam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *198,620 * Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11 Heat Consumption (10^6 kJ/hr)LHV1,419.7HHV1,575.8 1.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV7,147.7HHV7,933.91.3.2 Gross Equipment Thermal Efficiency (%)LHV50.37HHV45.371.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb15.0Wet Bulb10.8 Ambient Relative Humidity (%)60.00 Ambient Air Pressure (kPa,a)101.35 Site Elevation (m above MSL) 6.800 Compressor Inlet Temperature (°C)Dry Bulb28.4 Compressor Inlet Relative Humidity (%)26.14 Steam Turbine Exhaust Pressure (kPaA) 3.386Huaneng Jinling Gas Turbine Power PlantHuaneng Jinling by: RBE CCA9138NG Rev:09-Jun-2004109FA Single ShaftAmbient Conditions: 101.35 kPa,a, 15.0 °C, 60.00 % RHNatural Gas, DLN ISO Gas Turbine: PG935130% Load Steam Turbine: 2 x 33.5 in LSB1. Plant Performance1.1 Power (kW)Gross Equipment Power *119,170 * Gross Power At Generator Terminals Minus Excitation Power1.2 FuelFuel: Kela 2 NGSpecification - GEI 41040G Supplemental SpecificationsCombustion System - DLNHeating Value (kJ/kg)LHV48,686.3HHV54,041.8HHV/LHV 1.11 Heat Consumption (10^6 kJ/hr)LHV1,016.3HHV1,128.0 1.3 Heat Rate1.3.1 Gross Equipment Heat Rate (kJ/kWh)LHV8,527.8HHV9,465.81.3.2 Gross Equipment Thermal Efficiency (%)LHV42.22HHV38.031.4 Operating ConditionsAmbient Air Temperature (°C)Dry Bulb15.0Wet Bulb10.8 Ambient Relative Humidity (%)60.00 Ambient Air Pressure (kPa,a)101.35 Site Elevation (m above MSL) 6.800 Compressor Inlet Temperature (°C)Dry Bulb28.6 Compressor Inlet Relative Humidity (%)25.90 Steam Turbine Exhaust Pressure (kPaA) 3.386。

影响催化裂化热平衡诸因数的探讨一、前言研究催化裂化热平衡的目的,一方面是要知道为满足装置热平衡所需输入或输出的热量。

另一方面是为了了解影响热平衡的各种因素,以便提供解决热平衡的最好办法。

催化裂化热平衡种最主要的是反应-再生总热平衡。

影响热平衡的因素很多,其中包括许多独立变量,如原料性质、催化剂性质、原料预热温度、反应温度等。

还有一些非独立变量,如剂油比、再生温度等也会影响热平衡。

本文着重讨论影响热平衡的种种因素,试图提供一些分析、解决装置热平衡的思路及方法。

二、催化裂化热平衡的特点1催化裂化热平衡示意图:催化裂化热平衡示意图见图1,2和3。

图1是加工减压蜡油的流化催化裂化的热平衡示意图,在加工减压蜡油时,再生温度在680-760℃之间,热的再生催化剂提供反应段所需的大部分热量,大多数催化剂和再生器的材质都可以承受680-760℃温度。

处理重质原料时,例如常压渣油或掺炼部分减压渣油,过多的焦炭生成将导致过多的烧焦热量,过高的再生温度将会破坏再生器材质及大大加速催化剂的减活。

通过内、外取热设施来冷却催化剂,或采用单程操作、排放油浆、降低原料预热温度等时常用的降低再生器温度的方法。

图2给出了使用内、外取热设施时的热平衡示意图。

两段再生是解决处理重质原料热量过多的另一方法。

它既减少了烧焦放热,又保证了催化剂的再生效果。

图3是使用两段再生器的热平衡示意图。

2 影响装置热平衡的变量影响装置热平衡的变量有多种。

大体可分成两类,一类是独立变量(自变量),另一类是非独立变量(因变量)。

表1给出了影响热平衡诸因数的分类及其对热平衡的影响。

由表1还可见独立变量和非独立变量又分为影响取热的;影响生焦但不影响取热的;影响生焦、放热和取热等不同种类。

3催化裂化热平衡的特点:催化裂化热平衡最大的特点是自补偿性。

自补偿性是指:3.1 生焦量只有在能影响热负荷的变量发生变化时才会发生变化。

3.2 催化裂化装置总是处于热平衡状态,任何破坏热平衡的改变都将同时引起非独立变量的改变,如剂油比,再生器温度,使装置返回到热平衡状态。

200MW超高压抽凝式汽轮机组高背压改造的可行性研究周博【摘要】当今电力市场200 MW以下机组生存空间越来越小,在东北、内蒙等地区冬季供暖需求量大,通过高背压改造,提高了机组的排汽温度,实现了冬季供暖期间机组排汽余热的利用是拯救老200MW机组最有前景的方案之一.文中对C145/N200-12.7/535/535型汽轮机高背压改造的可行性进行了分析.【期刊名称】《机械工程师》【年(卷),期】2018(000)004【总页数】4页(P133-135,138)【关键词】汽轮机;低真空;光轴;供热;改造;安全【作者】周博【作者单位】哈尔滨汽轮机厂有限责任公司,哈尔滨150046【正文语种】中文【中图分类】TK2670 引言国家政策对现有机组能耗指标及排放标准越趋严格,导致当今电力市场200 MW 以下机组生存空间越来越小[1]。

但随着我国北方地区供热需求进一步增加、供热型式向大面积集中供热发展,整体所需供热量大幅增大。

在此形势下,将原200 MW凝汽式机组进行高背压供热改造就是拯救老200 MW机组最有前景的方案之一。

如今将机组进行高背压供热改造具体有两种方法:一种为低真空供热改造;另一种为高背压光轴改造。

具体改造方案下面分别会进行详细分析论述。

1 高背压改造具体方案分析1.1 循环水低真空供热技术低真空供热是指通过特定的手段降低凝汽器真空度,进而提高机组排汽背压、提高机组排汽温度,利用汽轮机排汽来加热热网循环水,并利用循环水对外进行供热的运行方式[2-7]。

图1 参考热平衡图以某厂200 MW超高压汽轮机为例,机组为三缸两排汽单轴结构型式,具有一次中间再热,进汽参数为12.75 MPa/535℃/535℃。

在原机组冷凝系统基础上,将凝汽器冷却水系统与热网循环水回路通过管道连接,使机组低真空运行时温度较高的凝汽器冷却水可以在热网换热站中释放热量,达到机组排汽为热用户供热的目的。

同时,机组乏汽大量余热得以利用,可以大幅提高机组循环热效率。