ABB机器人程序实例

- 格式:docx

- 大小:13.57 KB

- 文档页数:14

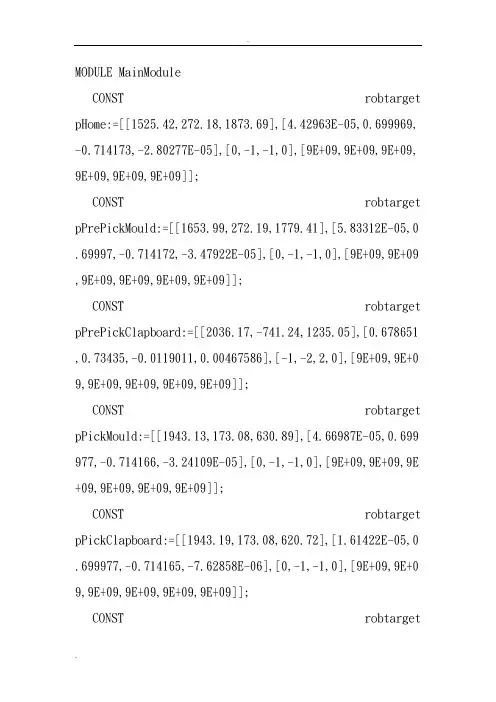

MODULE MainModuleCONST robtarget pHome:=[[1525.42,272.18,1873.69],[4.42963E-05,0.699969, -0.714173,-2.80277E-05],[0,-1,-1,0],[9E+09,9E+09,9E+09, 9E+09,9E+09,9E+09]];CONST robtarget pPrePickMould:=[[1653.99,272.19,1779.41],[5.83312E-05,0 .69997,-0.714172,-3.47922E-05],[0,-1,-1,0],[9E+09,9E+09 ,9E+09,9E+09,9E+09,9E+09]];CONST robtarget pPrePickClapboard:=[[2036.17,-741.24,1235.05],[0.678651 ,0.73435,-0.0119011,0.00467586],[-1,-2,2,0],[9E+09,9E+0 9,9E+09,9E+09,9E+09,9E+09]];CONST robtarget pPickMould:=[[1943.13,173.08,630.89],[4.66987E-05,0.699 977,-0.714166,-3.24109E-05],[0,-1,-1,0],[9E+09,9E+09,9E +09,9E+09,9E+09,9E+09]];CONST robtarget pPickClapboard:=[[1943.19,173.08,620.72],[1.61422E-05,0 .699977,-0.714165,-7.62858E-06],[0,-1,-1,0],[9E+09,9E+0 9,9E+09,9E+09,9E+09,9E+09]];CONST robtargetpPrePlace:=[[785.90,-957.40,1722.38],[0.00231652,0.0492 402,-0.998779,-0.00310842],[-1,-1,-1,0],[9E+09,9E+09,9E +09,9E+09,9E+09,9E+09]];CONST robtarget pPrePlace10:=[[-277.40,-1202.57,1621.17],[0.00183571,-0 .0139794,-0.999895,-0.00341408],[-2,-1,-2,0],[9E+09,9E+ 09,9E+09,9E+09,9E+09,9E+09]];CONST robtarget pPrePlace20:=[[-491.18,-1082.85,1505.90],[0.000663644,0 .69408,0.719887,0.00386364],[-2,0,-1,0],[9E+09,9E+09,9E +09,9E+09,9E+09,9E+09]];CONST robtarget pPlaceMould:=[[-92.13,-2580.19,1171.45],[0.000771646,0. 713144,0.701007,0.00383692],[-2,0,-1,0],[9E+09,9E+09,9E +09,9E+09,9E+09,9E+09]];CONST robtarget pPlaceClapboard:=[[1585.08,1761.04,787.33],[0.00645323, -0.00552996,-0.726358,-0.687263],[0,1,-1,0],[9E+09,9E+0 9,9E+09,9E+09,9E+09,9E+09]];CONST robtarget pPrePlaceClapboard:=[[1017.30,955.85,1443.17],[1.0621E-05,-0.00849593,-0.999964,4.01139E-05],[0,-1,0,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E+09]];CONST robtarget pPrePickClapboard10:=[[2257.17,-841.03,1579.56],[0.6675 17,0.74457,-0.00360206,0.00487631],[-1,-1,2,0],[9E+09,9 E+09,9E+09,9E+09,9E+09,9E+09]];CONST robtarget pPrePickMould10:=[[530.24,-1703.27,1762.63],[5.07659E-0 5,0.96161,0.274421,2.37287E-05],[-1,0,0,0],[9E+09,9E+09 ,9E+09,9E+09,9E+09,9E+09]];CONST num nOffs:=100;PERS num nCurOffs:=100;CONST num nLayer:=0;PERS num nCurLayer:=0;CONST num nThickness:=40;VAR bool bTimeOut:=FALSE;PERS bool bDryCycle:=FALSE;VAR intnum iDryCycle;VAR intnum iResDryCycle;VAR intnum iVacuum;PERS tooldatatGripper:=[TRUE,[[0,0,100],[1,0,0,0]],[88.5,[-3.7,-1.4, 132.1],[1,0,0,0],5.5,17.831,25.067]];PROC main()rInitAll;WHILE TRUE DOIF siDryCycle=1 or nCurLayer<1 thenrPickClapboard;ELSErPickMould;ENDIFWaittime 0.2;ENDWHILEENDPROCPROC rPickMould()DIWait diMouldready,1,3,"entrance Conveyer","ready for pick";DIWait diPlaceReady,1,3,"exit Conveyer","ready for remove";MoveJ pPrePickMould, v1500, z50, tGripper;IF BitCheck(nCurlayer,1) THENnCurOffs:=nOffs;ELSEnCurOffs:=-nOffs;ENDIFMoveLoffs(pPickMould,0,nCurOffs,100+nCurLayer*nThickness),v1000, z50, tGripper;MoveLoffs(pPickMould,0,nCurOffs,(nCurLayer-1)*nThickness),v200, fine, tGripper;GripClose;Decr nCurLayer;MoveLoffs(pPickMould,0,nCurOffs,100+nCurLayer*nThickness),v200, z50, tGripper;MoveJ pPrePickMould, v1000, z50, tGripper;DIWait diPlaceReady,1,3,"exit Conveyer","ready for remove";MoveJ pPrePlace10, v1500, z10, tGripper;MoveL offs(pPlaceMould,0,0,100), v1500, z10, tGripper;MoveL pPlaceMould, v200, fine, tGripper;GripOpen;MoveL offs(pPlaceMould,0,0,100), v200, z10, tGripper;MoveL pPrePlace10, v1500, z10, tGripper;MoveJ pPrePickMould, v1500, z10, tGripper;PulseDO\PLength:=2, doMouldPlaceOK;ENDPROCPROC rPickClapboard()DIWait diMouldready,1,3,"entrance Conveyer","ready for pick";MoveL offs(pPickClapboard,0,0,100), v1000, z50, tGripper;MoveL pPickClapboard, v200, fine, tGripper;GripClose;MoveL offs(pPickClapboard,0,0,100) ,v200, z50, tGripper;MoveL offs(pPickClapboard,0,0,500) ,v1000, z50, tGripper;MoveL pPrePlaceClapboard, v1000, z10, tGripper;DIWait diClapboardReady, 1, 3, "exit Conveyer", "ready for remove";MoveL offs(pPlaceClapboard,-700,-200,250), v1000, z10, tGripper;MoveL offs(pPlaceClapboard,00,-10,100), v1000, z10, tGripper;MoveL pPlaceClapboard, v100, fine, tGripper;GripOpen;MoveL offs(pPlaceClapboard,0,-50,100), v1000, z10, tGripper;MoveL offs(pPlaceClapboard,-700,-200,250), v1000, z10, tGripper;MoveL pPrePlaceClapboard, v1000, z10, tGripper;PulseDO\PLength:=1.0, doClapboardPickOK;MoveJ pHome, v1500, fine, tGripper;PulseDO\PLength:=1.0, doUnStackOk;WaitTime 2;DIWait diMouldready,0,3,"exit Conveyer","ready for remove";nCurLayer:=nLayer;ENDPROCPROC rInitAll()IF diVacuum1=0 THENWaitTime 1;ELSEErrWrite "The Rob1 gripper error! " ,"The gripper is not opened!"\RL2:="Check the gripper signal postion ."\RL3:=" open the gripper manually and take away the part from gripper.";Stop;Exit;ENDIFrMoveHome;nCurLayer:=nLayer;IDelete iVacuum;CONNECT iVacuum WITH tLostPart;ISignalDI diVacuum1, 1, iVacuum;ISleep iVacuum;ENDPROCROC GripClose()SetDO doVacuum,1;SetDO doBlow,0;WaitUntildiVacuum1=1\MaxTime:=10\TimeFlag:=bTimeOut;IF bTimeOut THENErrWrite "Rob Gripper Signal error ! " ,"Fatal error in Gripper"\RL2:="Check the gripper signal postion ."\RL3:=" change a new sensor .";Stop;ENDIFWaittime 0.5;IWatch iVacuum;ENDPROCPROC GripOpen()ISleep iVacuum;SetDO doVacuum,0;PulseDO \PLength:=2.0, doBlow;WaitUntil diVacuum1=0 \MaxTime:=5\TimeFlag:=bTimeOut;IF bTimeOut THENErrWrite "Rob Gripper Signal error ! " ,"Fatal error in Gripper"\RL2:="Check the gripper signal postion ."\RL3:=" change a new sensor .";Stop;ENDIFWaittime 0.5;ENDPROCPROC rMoveHome()VAR string HomeOffset;CONST num MinX:=-500;CONST num MaxX:=500;CONST num MinY:=-500;CONST num MaxY:=500;CONST num MinZ:=500;CONST num MaxZ:=1200;VAR robtarget ActualPos;VelSet 100,500;AccSet 70, 70;IF bCurrentPos(pHome,tGripper,50)=TRUE THEN M oveJ pHome,v500,fine,tGripper\WObj:=wobj0;ENDIFIFbCurrentPos(pPrePickMould,tGripper,50\wobj:=Wobj0)= TRUE THENM oveJ pHome,v500,fine,tGripper\WObj:=wobj0;ENDIFIFbCurrentPos(pPrePickClapboard,tGripper,100\wobj:=Wobj0) = TRUE THENM oveJ pHome,v500,fine,tGripper\WObj:=wobj0;ENDIFIFbCurrentPos(pPreplace,tGripper,100\wobj:=Wobj0)= TRUE THENM oveJ pHome,v500,fine,tGripper\WObj:=wobj0;ENDIFIF bCurrentPos(pHome,tGripper,100)=FALSE THEN! If no known position is found, check if the robot is in a specified! window and move him to the first position in the programActualPos:=CRobT(\Tool:=tGripper\WObj:=wobj0); IF ActualPos.trans.x<MinX OR ActualPos.trans.x>MaxX OR ActualPos.trans.y<MinY OR ActualPos.trans.y>MaxY OR ActualPos.trans.z<MinZ OR ActualPos.trans.z>MaxZ THENHomeOffset:="";IF ActualPos.trans.x<MinX THENHomeOffset:=HomeOffset+"X :"+NumToStr(MinX-ActualPos.tr ans.x,0)+" ";ELSEIF ActualPos.trans.x>MaxX THENHomeOffset:=HomeOffset+"X :"+NumToStr(MaxX-ActualPos.tr ans.x,0)+" ";ELSEHomeOffset:=HomeOffset+"X : OK ";ENDIFIF ActualPos.trans.y<MinY THENHomeOffset:=HomeOffset+"Y :"+NumToStr(MinY-ActualPos.tr ans.y,0)+" ";ELSEIF ActualPos.trans.y>MaxY THENHomeOffset:=HomeOffset+"Y :"+NumToStr(MaxY-ActualPos.tr ans.y,0)+" ";ELSEHomeOffset:=HomeOffset+"Y : OK ";ENDIFIF ActualPos.trans.z<MinZ THENHomeOffset:=HomeOffset+"Z :"+NumToStr(MinZ-ActualPos.tr ans.z,0)+" ";ELSEIF ActualPos.trans.z>MaxZ THENHomeOffset:=HomeOffset+"Z :"+NumToStr(MaxZ-ActualPos.tr ans.z,0)+" ";ELSEHomeOffset:=HomeOffset+"Z : OK ";ENDIFErrWrite HomeOffset,"Move robot manually near homeposition";WHILE OpMode()<>OP_MAN_PROG DOTPErase;TPWrite "Please switch robot to Manual mode"; !TPErase;Stop;ENDWHILEStop;MoveJ pHome,v500,fine,tGripper;!npallet:=4;ActualPos:=CRobT(\Tool:=tGripper\WObj:=wobj0);WHILE OpMode()<>OP_AUTO DOTPErase;TPWrite "Please switch robot to AUTO mode"; !TPErase;Stop;ENDWHILEENDIFENDIFVelSet 100,3000;ENDPROCTRAP tLostPartErrWrite "Part lost!" ,"Fatal error in Gripper"\RL2:="Check the gripper ."\RL3:=" check the vacuum .";Stop;ENDTRAPENDMODULE。

abb机器人程序实例随着科技的不断进步和人工智能的快速发展,机器人已经成为我们生活中不可或缺的一部分。

而abb机器人则是其中一种应用广泛的机器人程序。

本文将介绍abb机器人程序的实例和应用。

abb机器人程序是一种用于控制abb机器人的软件程序。

它可以让机器人具备自主的工作能力,完成各种任务,提高工作效率,减少人力成本。

下面我们将以工业领域中的应用为例,来具体介绍abb 机器人程序的实例。

abb机器人程序在汽车生产线上的应用非常广泛。

在汽车制造过程中,需要进行许多重复的工作,如焊接、喷漆、装配等。

通过编写abb机器人程序,可以将这些工作交给机器人来完成。

机器人根据程序指令,可以准确地进行焊接,保证焊接质量;可以均匀地喷漆,提高喷漆效率;可以精确地进行装配,保证装配的质量。

这样不仅提高了生产效率,还减少了工人的劳动强度,提高了产品质量。

除了汽车制造,abb机器人程序还在电子制造行业中得到了广泛应用。

在电子制造过程中,需要进行很多微小精细的操作,如电路板组装、元器件焊接等。

这些操作对操作者的技术要求很高,而且容易出错。

通过编写abb机器人程序,可以让机器人来完成这些操作,提高操作的准确性。

机器人可以根据程序指令,精确地完成电路板的组装,确保组装的准确性;可以精确地进行元器件的焊接,保证焊接的质量。

这样不仅提高了生产效率,还减少了产品的不良率。

abb机器人程序还可以在仓储物流行业中得到应用。

在仓储物流过程中,需要进行大量的物品搬运和装卸工作。

通过编写abb机器人程序,可以让机器人来完成这些工作,提高搬运和装卸的效率。

机器人可以根据程序指令,准确地搬运物品,避免了人工搬运的不准确和劳累;可以精确地进行装卸工作,保证装卸的速度和质量。

这样不仅提高了物流效率,还减少了人力资源的浪费。

总结起来,abb机器人程序在工业领域中的应用非常广泛。

通过编写abb机器人程序,可以让机器人具备自主的工作能力,完成各种任务,提高工作效率,减少人力成本。

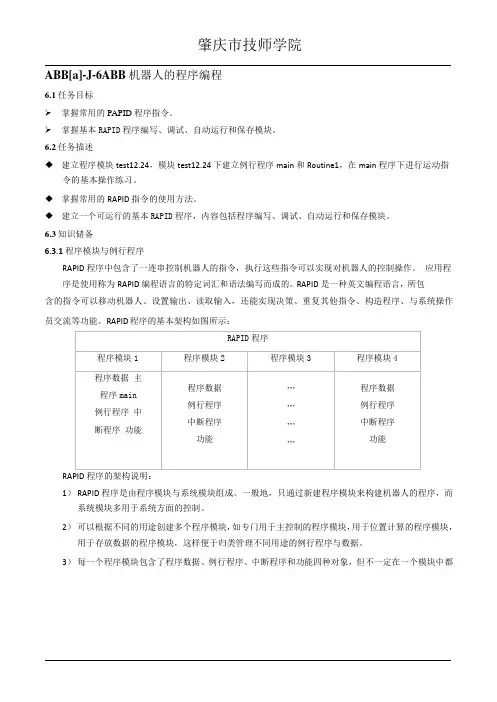

ABB[a]-J-6ABB 机器人的程序编程6.1 任务目标➢掌握常用的PAPID 程序指令。

➢掌握基本RAPID程序编写、调试、自动运行和保存模块。

6.2 任务描述◆建立程序模块test12.24,模块test12.24 下建立例行程序main 和Routine1,在main 程序下进行运动指令的基本操作练习。

◆掌握常用的RAPID 指令的使用方法。

◆建立一个可运行的基本RAPID程序,内容包括程序编写、调试、自动运行和保存模块。

6.3 知识储备6.3.1 程序模块与例行程序RAPID 程序中包含了一连串控制机器人的指令,执行这些指令可以实现对机器人的控制操作。

应用程序是使用称为RAPID 编程语言的特定词汇和语法编写而成的。

RAPID 是一种英文编程语言,所包含的指令可以移动机器人、设置输出、读取输入,还能实现决策、重复其他指令、构造程序、与系统操作员交流等功能。

RAPID 程序的基本架构如图所示:RAPID 程序的架构说明:1)RAPID 程序是由程序模块与系统模块组成。

一般地,只通过新建程序模块来构建机器人的程序,而系统模块多用于系统方面的控制。

2)可以根据不同的用途创建多个程序模块,如专门用于主控制的程序模块,用于位置计算的程序模块,用于存放数据的程序模块,这样便于归类管理不同用途的例行程序与数据。

3)每一个程序模块包含了程序数据、例行程序、中断程序和功能四种对象,但不一定在一个模块中都有这四种对象,程序模块之间的数据、例行程序、中断程序和功能是可以互相调用的。

4)在RAPID 程序中,只有一个主程序main,并且存在于任意一个程序模块中,并且是作为整个RAPID 程序执行的起点。

操作步骤:6.3.2 在示教器上进行指令编程的基本操作ABB 机器人的RAPID 编程提供了丰富的指令来完成各种简单与复杂的应用。

下面就从最常用的指令开始学习RAPID 编程,领略RAPID 丰富的指令集提供的编程便利性。

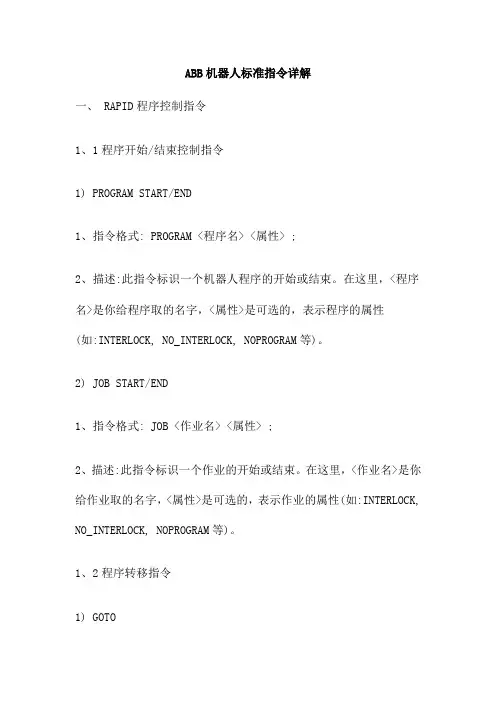

ABB机器人标准指令详解一、 RAPID程序控制指令1、1程序开始/结束控制指令1) PROGRAM START/END1、指令格式: PROGRAM <程序名> <属性> ;2、描述:此指令标识一个机器人程序的开始或结束。

在这里,<程序名>是你给程序取的名字,<属性>是可选的,表示程序的属性(如:INTERLOCK, NO_INTERLOCK, NOPROGRAM等)。

2) JOB START/END1、指令格式: JOB <作业名> <属性> ;2、描述:此指令标识一个作业的开始或结束。

在这里,<作业名>是你给作业取的名字,<属性>是可选的,表示作业的属性(如:INTERLOCK, NO_INTERLOCK, NOPROGRAM等)。

1、2程序转移指令1) GOTO1、指令格式: GOTO <行号>;2、描述:此指令将程序执行转移到指定的行号。

2) GOSUB1、指令格式: GOSUB <行号>;2、描述:此指令将程序执行转移到指定的行号,并在返回时继续执行当前行。

3) RETURN1、指令格式: RETURN;2、描述:此指令将程序执行从 GOSUB转移到父程序,并从 GOTO转移到原程序行。

1、3条件判断指令1) IF/THEN/ELSE/ENDIF;1、指令格式: IF <条件> THEN <表达式> ELSE <表达式> ENDIF;2、描述:如果满足条件<条件>,则执行 THEN后面的表达式;否则执行 ELSE后面的表达式。

2) CASE/ESAC/ENDCASE;1、指令格式: CASE <变量> IN <表达式1> / <表达式2> /... / ENDCASE;2、描述:此指令根据变量<变量>的值选择要执行的表达式。

【原创】ABB机器人编程之程序流程指令(含案例)导读:机器人程序的执行是从上到下的方式,从第一条指令逐次扫描至程序的结尾,不断循环。

但是在某种场合,需要程序的等待、程序的跳转以及程序的停止,这些场合都会影响到程序的流程。

例如:在机器人抓取物料的时候,机器人抓完了之后,需要等机器人抓稳了,机器人才移动,这就需要进行程序的等待!那接下来我们来看几个关于程序流程指令吧!1.waitTime:用于等待给定的时间例1:WaitTime 0.5;程序执行等待0.5秒程序执行等待的最短时间(以秒计)为0 s。

最长时间不受限制。

分辨率为0.001 s。

详解:机器人程序指针执行到此条指令,必须等待0.5秒以后才继续往下执行!例2:WaitTime \InPos,0.5详解:在WaitTime指令后面加入了Inpos参数的含义就是:机器人到位且完全停止后才开始计时,时间到达0.5秒以后才继续往下执行!例3:MoveJ p1, vmax, fine, tool2;WaitTime \InPos,0.5;MoveJ p2, vmax, z30, tool2;详解:机器人到达P1位置点之后,并且机器人完全停止下来,才开始计时,时间到达0.5秒以后才机器人继续执行到达P2位置点。

2. WaitDI:用于等待,直至已设置数字信号输入例1:WaitDI di4, 1;仅在已设置di4输入后,继续程序执行。

详解:机器人程序指针执行到此条指令,需要等待开关信号di4为1的时候,才往下执行。

例2:WaitDI di0,1\MaxTime:=3;详解:在WaitDI di0,1指令后面加上了可选参数MaxTime:=3,则表示允许的最长等待时间3秒。

如果在3秒时间以内di0还没有为1,机器人则报错处理。

3. WaitUntil:用于等待,直至满足逻辑条件。

例如,其可以等待,直至已设置一个或多个输入例1:WaitUntil di4 = 1;仅在已设置di4输入后,继续程序执行。

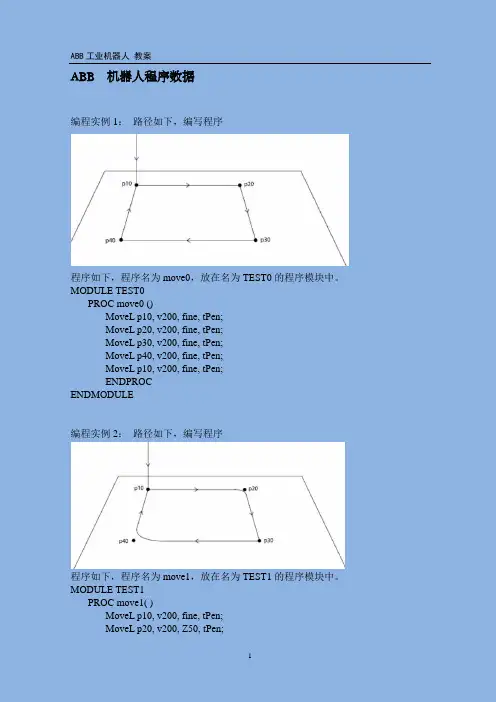

ABB 机器人程序数据编程实例1:路径如下,编写程序程序如下,程序名为move0,放在名为TEST0的程序模块中。

MODULE TEST0PROC move0 ()MoveL p10, v200, fine, tPen;MoveL p20, v200, fine, tPen;MoveL p30, v200, fine, tPen;MoveL p40, v200, fine, tPen;MoveL p10, v200, fine, tPen;ENDPROCENDMODULE编程实例2:路径如下,编写程序程序如下,程序名为move1,放在名为TEST1的程序模块中。

MODULE TEST1PROC move1( )MoveL p10, v200, fine, tPen;MoveL p20, v200, Z50, tPen;MoveL p30, v200, fine, tPen;MoveL p40, v200, Z50, tPen;MoveL p10, v200, fine, tPen;ENDPROCENDMODULE编程实例3:编写程序MoveL p1, v500, fine, tool1;MoveC p2, p3, v500, z20, tool1; P1、P2、P3三点确定一个圆弧MoveC p4, p1, v500, fine, tool1; P3、P4、P1三点确定一个圆弧如下图所示,不一定是一个圆,如右图所示,与P4点的位置有关。

一条MoveC指令最多只能转过240°,因此不可能通过一条指令完成一个圆。

编程实例4:利用MoveAbsJ让机器人返回机械原点位置提示:机械原点处轴1-6角度分别为0-0-0-0-30-0度。

(轴5的角度也可以设置为90°或其他角度,设为0°会出现奇异点)编程实例5:函数Offs()Offs(p1,x,y,z)代表一个离p1点X轴偏差量为x,Y轴偏差量为y,Z轴偏差量为z的点(坐标值的增量)。

ABB的程序编程ABB程序编程1、简介1.1 介绍ABB1.2 程序编程概述2、程序编程基础知识2.1 程序语言2.2 坐标系2.3 程序结构2.4 变量和常量2.5 条件语句2.6 循环语句2.7 子程序和函数2.8程序调试和错误处理3、运动控制3.1 示教运动模式3.2 直线运动3.3 圆弧运动3.4 运动速度控制3.5 轨迹规划3.6 动作指令4、传感器和外围设备4.1 连接外围设备4.2 传感器的使用方法4.3 数据采集和处理5、编程实例5.1 取放操作5.2 精确拼接操作5.3 装配操作5.4 机器视觉应用5.5 跟踪和检测任务6、编程调优技巧6.1 提高程序执行速度6.2 优化轨迹规划6.3 减小运动干涉6.4 编写可重用程序7、安全注意事项7.1 安全处理7.2 紧急停止和重置7.3 防护设备要求8、相关附件8.1 附件一、ABB编程示例代码8.2 附件二、模型示意图8.3 附件三、程序调试和错误处理流程图注释:1、ABB:ABB公司生产的工业系列产品。

2、示教运动模式:通过手动示教方式录制的运动轨迹。

3、轨迹规划:根据给定的目标位置和运动速度计算的运动轨迹。

4、机器视觉应用:利用摄像头和图像处理算法实现对物体的识别和定位。

5、安全处理:保证操作人员的安全,防止造成危险。

6、紧急停止和重置:在遇到危险情况时立即停止运动并进行系统重置。

7、防护设备要求:使用适当的安全设备,如安全围栏、光幕等。

8、附件:本文所提到的相关附件。

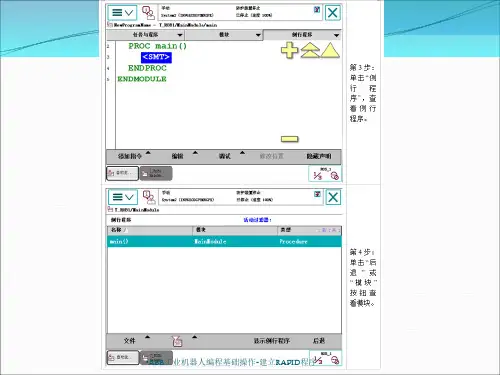

编写abb机器⼈离线程序(适合新⼿)操作⽅法

打开Robotstudio软件,运⾏虚拟⽰教器,打开⽰教器的虚拟程序编辑器建⽴第⼀个程序

操作⽅法

如图回到Robotstudio界⾯开始编辑离线程序

操作⽅法

编写第⼀个程序如图

⽅法/步骤2

回到⽰教器再次打开程序编辑器我们会发现Robotstudio的程序同步到⽰教器上⾯了,双击p10和p20这⾥我们将新建p10 p20这两个机器⼈位置

⽅法/步骤2

新建p20 p10 并确定

⽅法/步骤2

如图可以拖动机器⼈的按钮并拖到想要去的位置,也就是p10的位置

⽅法/步骤3

回到⽰教器并点击修改位置,p20位置修改⼀样的道理

⽅法/步骤3

这时候Robotstudio编程界⾯就出现了开始的P10,p20位置数据

⽅法/步骤3

点击图中的应⽤按钮就可以知道程序有没有出错,有错误找出并修改

⽅法/步骤4

确认⽆错误回到⽰教器并给电机上电

⽅法/步骤4

点击调试如图

⽅法/步骤4

点击运⾏按钮就可以看到机器⼈仿真界⾯来回运动了。

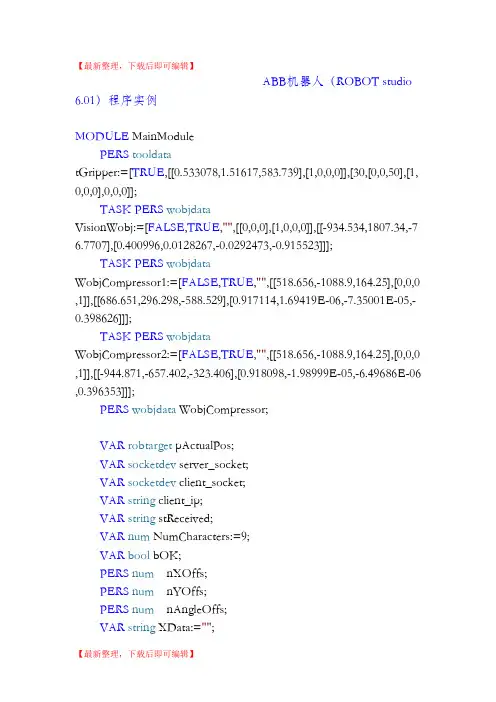

【最新整理,下载后即可编辑】ABB机器人(ROBOT studio 6.01)程序实例MODULE MainModulePERS tooldatatGripper:=[TRUE,[[0.533078,1.51617,583.739],[1,0,0,0]],[30,[0,0,50],[1, 0,0,0],0,0,0]];TASK PERS wobjdataVisionWobj:=[FALSE,TRUE,"",[[0,0,0],[1,0,0,0]],[[-934.534,1807.34,-7 6.7707],[0.400996,0.0128267,-0.0292473,-0.915523]]];TASK PERS wobjdataWobjCompressor1:=[FALSE,TRUE,"",[[518.656,-1088.9,164.25],[0,0,0 ,1]],[[686.651,296.298,-588.529],[0.917114,1.69419E-06,-7.35001E-05,-0.398626]]];TASK PERS wobjdataWobjCompressor2:=[FALSE,TRUE,"",[[518.656,-1088.9,164.25],[0,0,0 ,1]],[[-944.871,-657.402,-323.406],[0.918098,-1.98999E-05,-6.49686E-06 ,0.396353]]];PERS wobjdata WobjCompressor;VAR robtarget pActualPos;VAR socketdev server_socket;VAR socketdev client_socket;VAR string client_ip;VAR string stReceived;VAR num NumCharacters:=9;VAR bool bOK;PERS num nXOffs;PERS num nYOffs;PERS num nAngleOffs;VAR string XData:="";VAR string YData:="";VAR string AngleData:="";VAR num nPresenceOrAbsence; PERS num nPickH:=-400;PERS num nCountX;PERS num nCountY;PERS num nCountZ;PERS num nCount;VAR num nPlaceNo;PERS bool bSMPreOrAbs;PERS bool bInpos;VAR robtarget PVision;VAR robtarget Vision;VAR robtarget ppPick;VAR robtarget pPick;PERS robtarget Pick;PERS robtarget ErCiDingWeiPlace; PERS robtarget ErCiDingWeiPick; PERS robtarget pPlace;PERS robtarget PlaceVision; PERS robtarget PZhanban; PERS robtarget PZhanbanUp; PERS robtarget PZhanbanDown; PERS robtarget PlaceZhanban; PERS robtarget Place;PERS bool bKindChoose;VAR num nAngle;VAR num nX;VAR num nCamOut;VAR num nInpos;VAR num nTotalPalletHigh;VAR num nPalletHigh;PERS num nPalletHighUp;PERS num nPalletHighDown;VAR num Compensation{8,3};VAR num CompensationTwo{8,3};PERS numCompensationErr{8,3}:=[[999999,999999,999999],[999999,999999,999 999],[999999,999999,999999],[999999,999999,999999],[999999,999999, 999999],[999999,999999,999999],[999999,999999,999999],[999999,999 999,999999]];PERS jointtargetjposHome:=[[0,0,0,0,0,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E+09 ]];CONST robtargetpHome:=[[621.23,-975.96,1166.44],[0.00703884,-0.385671,-0.922573,-0 .00826231],[-1,0,-1,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E+09]];CONST robtargetPZhanbanSafe:=[[-162.69,-1703.07,2270.38],[0.0109452,-0.955357,-0.2 95179,-0.00645602],[-1,-1,-1,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9 E+09]];CONST robtargetVisionA:=[[-228.96,94.47,643.11],[0.00434955,-0.699954,0.714102,-0.0 101798],[-2,-1,0,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E+09]];CONST robtargetPickA:=[[90.09,79.65,61.29],[0.0102135,0.00299714,0.999935,-0.004170 93],[-2,-1,1,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E+09]];CONST robtargetPlaceA:=[[-644.46,-1019.60,396.56],[0.00841448,-0.692574,0.721298,0.000680825],[-1,-1,1,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E+09]];CONST robtargetPZhanbanUpA:=[[549.64,541.39,821.21],[0.000808037,-0.999985,-0.00 498684,-0.00209158],[-2,-1,-1,0],[9E+09,9E+09,9E+09,9E+09,9E+09, 9E+09]];CONST robtargetPZhanbanDownA:=[[548.40,560.53,179.18],[0.00417276,0.999929,-0.0 0436864,0.0102239],[-2,-1,-1,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9 E+09]];CONST robtargetPlaceZhanbanA:=[[2456.73,-1154.76,205.32],[0.0106126,-0.0247295,-0. 999603,0.00838785],[1,-1,0,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9 E+09]];PERS numCompensationA{8,3}:=[[0,0,0],[210,136,0],[430,264,99999999],[645,40 3,99999999],[855,533,99999999],[99999999,670,99999999],[99999999,8 00,99999999],[99999999,936,99999999]];PERS numCompensationA1{8,3}:=[[860,936,0],[0,0,0],[215,133,99999999],[430,2 64,99999999],[645,403,99999999],[99999999,533,99999999],[99999999, 670,99999999],[99999999,800,99999999]];PERS numCompensationA2{8,3}:=[[860,0,0],[0,133,0],[215,264,99999999],[430,4 03,99999999],[645,533,99999999],[99999999,670,99999999],[99999999, 800,99999999],[99999999,936,99999999]];CONST num nPalletHighUpA:=100;CONST num nPalletHighDownA:=200;CONST robtargetVisionB:=[[936.63,959.75,378.90],[0.00373262,0.105479,-0.994406,-0.0 0407233],[-1,0,0,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E+09]];CONST robtargetPickB:=[[1180.22,1009.95,213.74],[0.00373443,0.1055,-0.994404,-0.004 06331],[-1,0,0,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E+09]];CONST robtargetPlaceB:=[[-1194.30,-1552.83,582.17],[0.0062614,0.795938,-0.605346,-0. 000999941],[0,0,0,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E+09]];CONST robtargetPZhanbanUpB:=[[511.86,550.08,92.05],[0.00172284,-0.00758955,-0.99 997,-0.000606164],[-1,0,1,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E +09]];CONST robtargetPZhanbanDownB:=[[511.86,550.08,92.05],[0.00172284,-0.00758955,-0. 99997,-0.000606164],[-1,0,1,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9 E+09]];CONST robtargetPlaceZhanbanB:=[[511.86,550.08,92.05],[0.00172284,-0.00758955,-0.99 997,-0.000606164],[-1,0,1,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E +09]];PERS numCompensationB{8,3}:=[[0,0,300],[210,136,0],[430,264,99999999],[645, 403,99999999],[855,533,99999999],[99999999,670,99999999],[9999999 9,800,99999999],[99999999,936,99999999]];PERS numCompensationB1{8,3}:=[[860,936,300],[0,0,0],[215,133,99999999],[430 ,264,99999999],[645,403,99999999],[99999999,533,99999999],[9999999 9,670,99999999],[99999999,800,99999999]];PERS numCompensationB2{8,3}:=[[860,0,300],[0,133,0],[215,264,99999999],[430 ,403,99999999],[645,533,99999999],[99999999,670,99999999],[9999999 9,800,99999999],[99999999,936,99999999]];CONST num nPalletHighUpB:=100;CONST num nPalletHighDownB:=200;PERS speeddata vMinEmpty:=[1300,100,6000,1000];PERS speeddata vMidEmpty:=[1400,100,6000,1000];PERS speeddata vMaxEmpty:=[1500,100,6000,1000];PERS speeddata vBigMaxEmpty:=[1500,100,6000,1000];PERS speeddata vMinLoad:=[1200,100,6000,1000];PERS speeddata vMaxLoad:=[1300,100,6000,1000];PERS speeddata vBigMaxLoad:=[1400,100,6000,1000];TASK PERS wobjdatawobj1:=[FALSE,TRUE,"",[[0,0,0],[1,0,0,0]],[[1984.06,-1180.48,453.803] ,[0.661114,-0.659907,-0.252753,0.252124]]];PROC Main()rInitAll;WHILE TRUE DOrPickCal;rPick;ENDWHILEWaitTime 0.3;ENDPROCPROC rInitAll()AccSet 60,100;Compensation:=CompensationErr;CompensationTwo:=CompensationErr;reg1 :=0;reg2 :=0;nCountX:=1;nCountY:=1;nCount:=0;nCountZ:=1;nTotalPalletHigh:=0;nPalletHigh:=0;nInpos:=0;rKindChoose;rCheckHomePos;Reset do00_JawsOpen ;Reset do01_JawsClose ;Set do00_JawsOpen ;Reset do02_BigJaws1 ;WaitTime 0.3;Reset do03_BigJaws2;Reset do00_JawsOpen ;Reset do13_Placing;Reset do12_PlaceOK;ENDPROCPROC rPickCal ()Set do00_JawsOpen ;bSMPreOrAbs:=TRUE;IF nCount =0 THENrCompressorInPos;ENDIFWHILE bSMPreOrAbs=TRUE DOIncr nCount ;IF nCount =1 THENMoveL Offs(Vision ,0,0,Compensation{nCountZ,3}+100) ,vBigMaxEmpty ,z20 , tGripper\WObj:=WobjCompressor ;MoveJ Offs(Vision ,0,0,Compensation{nCountZ,3}),vBigMaxEmpty ,fine ,tGripper\WObj:=WobjCompressor ;GOTO C;ENDIFIncr reg2 ;rnXCal ;pVision:=Offs(Vision ,Compensation{nCountX,1} ,Compensation{nCountY,2} , Compensation{nCountZ,3});MoveLpVision,vMidEmpty ,fine,tGripper\WObj:=WobjCompressor;C:nPresenceOrAbsence:=1;! rServer;! socketsend client_socket \Str:="T1";! socketReceive client_socket \Str:=stReceived;! bOK:=StrToVal(stReceived,nPresenceOrAbsence);! IF nPresenceOrAbsence =2 OR nPresenceOrAbsence =3 THEN! bSMPreOrAbs:=FALSE ;! ELSEIF nPresenceOrAbsence =5 THEN! bSMPreOrAbs:=TRUE ;! IF di02_PhotoelectricSensor =1 THEN! TPErase ;! TPWrite "The camera get picture there is a problem, Please check it!(2) ";! SystemStopAction \Halt ;! ELSEIF di02_PhotoelectricSensor =0 THEN! reg2 :=0;! ENDIF! ELSEIF nPresenceOrAbsence =1 OR nPresenceOrAbsence =4 THEN! TPErase ;! TPWrite "The Camera is wrong, and camera will restart ,";! TPWrite "after a few seconds the robot will continue ";! Stop ;! ENDIFWaitTime 1;IF di02_PhotoelectricSensor =1 THENbSMPreOrAbs:=FALSE ;ELSEbSMPreOrAbs:=TRUE ;ENDIFIncr nCountX;! TEST di16_giBCD! CASE 1:IF nCountX=6 THENnCountX :=1;Incr nCountY;IF nCountY=9 THENnCountY :=1;SystemStopAction \Halt;ENDIFENDIFIF nCount =40 THENnCount :=0;Incr nCountZ;nCountX:=1;nCountY:=1;nInpos:=0;IF reg2=0 THENrZhanban ;IF nCountZ=2 THENrCompressorOutPos;nCountZ:=1;ENDIFENDIFreg2:=0;ENDIF! DEFAULT:! TPErase ;! TPWrite " The PLC communication there is a problem ,Please check it ";! ENDTESTENDWHILEENDPROCPROC rPick ()! TEST di16_giBCD! CASE 1:IF nCountX=1 THENCompensationTwo:=CompensationA1;ELSECompensationTwo:=CompensationA2;ENDIFpPick:=Offs(Pick,CompensationTwo{nCountX,1}+nX ,CompensationTwo{nCo untY,2},CompensationTwo{nCountZ,3});! CASE 2:! pPick:=Offs(Pick,CompensationTwo{nCountX,1}+nX ,CompensationTwo{nCo untY,2},CompensationTwo{nCountZ,3});! DEFAULT:! TPErase ;! TPWrite " The PLC communication there is a problem ,Please check it ";! ENDTESTWaitTime 0.2;nCamOut:=1;! rServer;! socketsend client_socket \Str:="T2";! socketReceive client_socket \Str:=stReceived;! XData:= StrPart(stReceived, 3, NumCharacters);! YData:= StrPart(stReceived, NumCharacters, NumCharacters);! AngleData:= StrPart(stReceived, 2*NumCharacters, NumCharacters);! bOK:=StrToVal(XData,nXOffs);! bOK:=StrToVal(YData,nYOffs);! bOK:=StrToVal(AngleData,nAngleOffs);rAngle;! ppPick :=RelTool (pPick,0,0,0\Rz:= -nAngleOffs+nAngle);ppPick :=RelTool (pPick,0,0,0\Rz:= nAngle);ConfL\Off;! MoveL Offs (ppPick,nXOffs ,nYOffs,120), vMinEmpty,fine , tGripper\WObj:=WobjCompressor;! MoveL Offs (ppPick,nXOffs ,nYOffs,0), v100, fine , tGripper\WObj:=WobjCompressor;MoveL Offs(ppPick,0 ,0,200), vMinEmpty, fine , tGripper\WObj:=WobjCompressor;MoveL Offs(ppPick,0 ,0,0), v100, fine ,tGripper\WObj:=WobjCompressor;Reset do00_JawsOpen ;Set do01_JawsClose ;WaitDI di00_JawsInClose,1;! MoveL Offs(ppPick,nXOffs,nYOffs,80),vMinLoad ,z10 ,tGripper\WObj:=Wobj Compressor ;! MoveL Offs(ppPick,nXOffs,nYOffs,400),vMaxLoad ,fine ,tGripper\WObj:=Wo bjCompressor ;MoveL Offs(ppPick,0,0,80),vMinLoad ,z10 ,tGripper\WObj:=WobjCompressor ;MoveL Offs(ppPick,0,0,400),vMaxLoad ,fine ,tGripper\WObj:=WobjCompresso r ;ConfL\On;rPlace;! TEST di16_giBCD! CASE 1:IF nCount =40 THENnCount :=0;nCountX:=1;nCountY:=1;reg2:=0;nInpos:=0;rZhanban ;IF nCountZ=2 THENrCompressorOutPos;nCountZ:=1;ENDIFENDIF! DEFAULT:! TPErase ;! TPWrite " The PLC communication there is a problem ,Please check it ";! ENDTESTENDPROCPROC rPlace ()MoveJ Offs (Place,0,0,200) ,vMaxLoad ,z40 , tGripper\WObj:= WobjCompressor ;Set do13_Placing;Waitdi di06_AssemblyLineOK, 0;MoveL Offs (Place,0,0,50) ,vMinLoad ,z5 , tGripper\WObj:= WobjCompressor;MoveL Place ,v100 ,fine , tGripper\WObj:= WobjCompressor;Reset do01_JawsClose ;Set do00_JawsOpen ;WaitDI di01_JawsInOpen ,1;MoveL Offs (Place,0,0,300) ,vMinEmpty ,fine, tGripper\WObj:= WobjCompressor;Reset do13_Placing ;WaitTime 0.4;Reset do00_JawsOpen ;ENDPROCPROC rnXCal()! TEST di16_giBCD! CASE 1:TEST nCountCASE1,2,3,4,5,11,12,13,14,15,21,22,23,24,25,31,32,33,34,35 :nX:=0;CASE 6,7,8,9,10,16,17,18,19,20,26,27,28,29,30,36,37,38,39,40 :nX:=65;ENDTEST! ENDTESTENDPROCPROC rAngle()! TEST di16_giBCD! CASE 1:TEST nCountCASE1,2,3,4,5,11,12,13,14,15,21,22,23,24,25,31,32,33,34,35 :nAngle:=0;CASE 6,7,8,9,10,16,17,18,19,20,26,27,28,29,30,36,37,38,39,40 :nAngle:=180;ENDTEST! ENDTESTENDPROCPROC rZhanban ()nTotalPalletHigh:=nTotalPalletHigh+nPalletHigh;TEST nCountZCASE 1:PZhanban:=PZhanbanUp;nPalletHigh:=nPalletHighUp;CASE 2:PZhanban:=PZhanbanDown;nPalletHigh:=nPalletHighDown;DEFAULT :TPErase ;TPWrite" The 'nCountZ' have a trouble ,Please check it ";ENDTESTMoveJ Offs( PZhanban,0,0,300) ,vBigMaxEmpty ,fine , tGripper \WObj:= WobjCompressor ;Set do02_BigJaws1 ;WaitTime 0.6;Set do03_BigJaws2;WaitDI di08_BigJawsInOpen, 1;MoveL PZhanban ,vMinEmpty ,fine, tGripper\WObj:= WobjCompressor ;WaitTime 0.5;Reset do02_BigJaws1 ;Reset do03_BigJaws2 ;WaitTime 0.3;WaitDI di08_BigJawsInOpen,1;pActualpos:=CRobT(\Tool:=tGripper\WObj:=WobjCompressor1);pActualpos.trans.z:=2000;MoveLpActualpos,vMinEmpty,z20,tGripper\WObj:=WobjCompressor1 ; ! MoveL Offs ( PZhanban,0,0,400) ,vMinEmpty ,z20 , tGripper\WObj:= WobjCompressor ;WaitDI di05_PalletInPos ,1;IF nInpos =2 THENMoveJ PZhanbanSafe ,vMinEmpty ,z20 , tGripper\WObj:= WobjCompressor ;ENDIFpActualpos:=PlaceZhanban;pActualpos.trans.z:=2000;MoveJpActualpos,vMinLoad,z20,tGripper\WObj:=WobjCompressor1 ;! MoveJ Offs( PlaceZhanban ,0,0,nTotalPalletHigh+700 ) ,v500 ,z5 , tGripper\WObj:= WobjCompressor ;MoveL Offs( PlaceZhanban ,0,0,nTotalPalletHigh) ,vMinLoad ,fine, tGripper\WObj:= WobjCompressor ;WaitTime 0.5;Set do02_BigJaws1 ;Set do03_BigJaws2;WaitDI di08_BigJawsInOpen,1;MoveL Offs( PlaceZhanban ,0,0,nTotalPalletHigh+700 ) ,vMaxEmpty ,fine, tGripper\WObj:= WobjCompressor ;Reset do03_BigJaws2;WaitTime 0.6;Reset do02_BigJaws1;WaitDI di07_BigJawsInClose, 1;rCompressorOutPos;IF nTotalPalletHigh>1200 THENset do06_PalletEmpty ;waittime 1;reset do06_PalletEmpty;nTotalPalletHigh:=0;nPalletHigh:=0;ENDIFENDPROCPROC rCompressorInPos()! bInpos:=TRUE;! WHILE bInpos=TRUE DO! IF di03_Compressor1InPos =1 THENWobjCompressor:=WobjCompressor1;bInpos:= FALSE;nInpos:=2;! ELSEIF di04_Compressor2InPos =1 THEN ! WobjCompressor:=WobjCompressor2; ! bInpos:=FALSE;! nInpos:=3;! ELSE! bInpos:=TRUE;! ENDIF! WaitTime 0.3;! ENDWHILEENDPROCPROC rCompressorOutPos()IF WobjCompressor=WobjCompressor1 THENSet do04_Compressor1Empty ;WaitTime 1;Reset do04_Compressor1Empty;ELSEIF WobjCompressor=WobjCompressor1 THENSet do05_Compressor2Empty ;WaitTime 1;Reset do05_Compressor2Empty;ENDIFENDPROCFUNC bool CurrentPos(robtarget ComparePos,INOUT tooldata TCP)VAR num Counter:=0;VAR robtarget ActualPos;ActualPos:=CRobT(\Tool:=TCP\WObj:=wobj0);IF ActualPos.trans.x>ComparePos.trans.x-25 AND ActualPos.trans.x<ComparePos.trans.x+25 Counter:=Counter+1;IF ActualPos.trans.y>ComparePos.trans.y-25 AND ActualPos.trans.y<ComparePos.trans.y+25 Counter:=Counter+1;IF ActualPos.trans.z>ComparePos.trans.z-25 AND ActualPos.trans.z<ComparePos.trans.z+25 Counter:=Counter+1;IF ActualPos.rot.q1>ComparePos.rot.q1-0.1 AND ActualPos.rot.q1<ComparePos.rot.q1+0.1 Counter:=Counter+1;IF ActualPos.rot.q2>ComparePos.rot.q2-0.1 AND ActualPos.rot.q2<ComparePos.rot.q2+0.1 Counter:=Counter+1;IF ActualPos.rot.q3>ComparePos.rot.q3-0.1 AND ActualPos.rot.q3<ComparePos.rot.q3+0.1 Counter:=Counter+1;IF ActualPos.rot.q4>ComparePos.rot.q4-0.1 ANDActualPos.rot.q4<ComparePos.rot.q4+0.1 Counter:=Counter+1;RETURN Counter=7;ENDFUNCPROC rCheckHomePos()IF NOT CurrentPos(pHome,tGripper) THEN pActualpos:=CRobT(\Tool:=tGripper\WObj:=wobj0);pActualpos.trans.z:=pHome.trans.z;MoveL pActualpos,v300,z30,tGripper;MoveJ pHome,v500,fine,tGripper;ENDIFENDPROCPROC rKindChoose()! IF di16_giBCD=1 THENCompensation:=CompensationA;nPalletHighUp:=nPalletHighUpA;nPalletHighDown:=nPalletHighDownA;Pick:= PickA;Vision :=VisionA;Place:=PlaceA;PZhanbanUp:=PZhanbanUpA;PZhanbanDown:=PZhanbanDownA;PlaceZhanban:=PlaceZhanbanA;! ELSEIF di16_giBCD=2 THEN! Compensation:=CompensationB;! nPalletHighUp:=nPalletHighUpB;! nPalletHighDown:=nPalletHighDownB;! Pick:= PickB;! Vision :=VisionB;! Place:=PlaceB;! PZhanbanUp:=PZhanbanUpB;! PZhanbanDown:=PZhanbanDownB;! PlaceZhanban:=PlaceZhanbanB;! ELSE! TPErase;! TPWrite "Please select product type in the PLC"; ! ENDIFENDPROCPROC rModPos ()MoveJ pHome, v1000, fine, tGripper\WObj:=Wobj0;MoveJ PZhanbanSafe, v1000, fine,tGripper\WObj:=WobjCompressor1;MoveJ PickA, v1000, fine, tGripper\WObj:= WobjCompressor1;MoveJ VisionA , v1000, fine,tGripper\WObj:=WobjCompressor1 ;MoveJ PlaceA, v1000, fine,tGripper\WObj:=WobjCompressor1;MoveJ PZhanbanUpA, v1000, fine, tGripper\WObj:= WobjCompressor1;MoveJ PZhanbanDownA, v1000, fine, tGripper\WObj:= WobjCompressor1;MoveJ PlaceZhanbanA, v1000, fine, tGripper\WObj:= WobjCompressor1;MoveJ PickB, v1000, fine, tGripper\WObj:= WobjCompressor1;MoveJ VisionB , v1000, fine,tGripper\WObj:=WobjCompressor1 ;MoveJ PlaceB, v1000, fine,tGripper\WObj:=WobjCompressor1;MoveJ PZhanbanUpB, v1000, fine, tGripper\WObj:= WobjCompressor1;MoveJ PZhanbanDownB, v1000, fine, tGripper\WObj:= WobjCompressor1;MoveJ PlaceZhanbanB, v1000, fine, tGripper\WObj:= WobjCompressor1;ENDPROCPROC rMoveAbsj()MoveAbsJ jposHome, v1000, fine, tGripper\WObj:=wobj0;ENDPROCPROC rServer()SocketClose server_socket;SocketClose client_socket;SocketCreate server_socket;SocketBind server_socket, "192.168.125.1", 3001;SocketListen server_socket;SocketAccept server_socket,client_socket\ClientAddress:=client_ip;ENDPROCPROC rClient()SocketClose client_socket;SocketCreate client_socket;SocketConnect client_socket, "192.168.125.120", 1000;SocketReceive client_socket \Str:=stReceived;ENDPROC ENDMODULE。

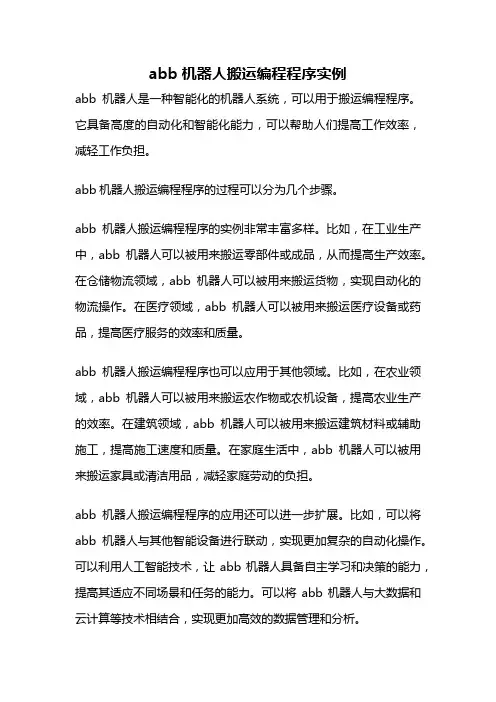

abb机器人搬运编程程序实例abb机器人是一种智能化的机器人系统,可以用于搬运编程程序。

它具备高度的自动化和智能化能力,可以帮助人们提高工作效率,减轻工作负担。

abb机器人搬运编程程序的过程可以分为几个步骤。

abb机器人搬运编程程序的实例非常丰富多样。

比如,在工业生产中,abb机器人可以被用来搬运零部件或成品,从而提高生产效率。

在仓储物流领域,abb机器人可以被用来搬运货物,实现自动化的物流操作。

在医疗领域,abb机器人可以被用来搬运医疗设备或药品,提高医疗服务的效率和质量。

abb机器人搬运编程程序也可以应用于其他领域。

比如,在农业领域,abb机器人可以被用来搬运农作物或农机设备,提高农业生产的效率。

在建筑领域,abb机器人可以被用来搬运建筑材料或辅助施工,提高施工速度和质量。

在家庭生活中,abb机器人可以被用来搬运家具或清洁用品,减轻家庭劳动的负担。

abb机器人搬运编程程序的应用还可以进一步扩展。

比如,可以将abb机器人与其他智能设备进行联动,实现更加复杂的自动化操作。

可以利用人工智能技术,让abb机器人具备自主学习和决策的能力,提高其适应不同场景和任务的能力。

可以将abb机器人与大数据和云计算等技术相结合,实现更加高效的数据管理和分析。

然而,abb机器人搬运编程程序的应用也面临一些挑战和限制。

首先,abb机器人的成本较高,不是所有企业或个人都能够负担得起。

其次,abb机器人的使用需要一定的技术和操作人员的培训,对于一些没有相关经验的人来说可能存在一定的学习成本。

此外,abb 机器人的安全性也是一个需要重视的问题,特别是在与人员共同工作的环境中,需要采取相应的安全措施。

总结起来,abb机器人搬运编程程序具备广泛的应用前景和潜力。

它可以在多个领域中发挥重要的作用,帮助人们提高工作效率,降低工作风险。

随着技术的不断进步和创新,abb机器人搬运编程程序的应用将变得越来越普遍,为人们的生活和工作带来更多的便利和效益。

ABB机器人编程100例简介ABB机器人是世界上领先的工业机器人制造商之一。

其强大的编程功能使得ABB机器人能够在各种工业应用中发挥重要作用。

本文将介绍一百个ABB机器人编程的例子,涵盖了常见的任务和应用场景。

目录1.机器人移动2.工具操作3.IO控制4.程序逻辑5.传感器应用机器人移动1.控制机器人向前移动一米:MoveL P[1, 0, 0, 0, 0, 0], v1000, fine, at1002.控制机器人向后移动一米:MoveL P[-1, 0, 0 , 0, 0, 0], v1000, fine, at1003.控制机器人向上移动一米:MoveL P[0, 0, 1, 0, 0, 0], v1000, fine, at1004.控制机器人向下移动一米:MoveL P[0, 0, -1, 0, 0, 0], v1000, fine, at1005.控制机器人绕X轴旋转90度:MoveL P[0, 0, 0, 1.5708, 0, 0], v1000, fine, at100工具操作1.启用机器人的外部工具:TOn2.禁用机器人的外部工具:TOff3.设置工具坐标系:TSet P[X, Y, Z, Rx, Ry, Rz]4.将机器人当前位置设为工具坐标系:THome5.重置工具坐标系:TLoad P[0, 0, 0, 0, 0, 0]IO控制1.设置输出IO端口的状态为高电平:SetDO Port, On2.设置输出IO端口的状态为低电平:SetDO Port, Off3.读取输入IO端口的状态:GetSensorType Port4.读取ADC端口的值:GetADC Port5.设置PWM端口的占空比:SetPwm Port, DutyCycle程序逻辑1.条件判断语句:IF condition THEN// do somethingELSE// do something elseEND_IF2.循环语句:FOR i FROM start TO end DO// loop bodyEND_FOR3.跳转语句:JUMP label4.调用子程序:PROC program_name5.返回主程序:RETURN传感器应用1.读取机器人当前位置:GetPos2.获取机器人末端坐标系的姿态角度:GetAngle3.读取机器人当前速度:GetSpeed4.检测A面切割器是否接触工件:IsOpen TCP_A5.读取机器人所有关节的角度:GetJointAngle以上是一些ABB机器人编程的例子,涵盖了机器人移动、工具操作、IO控制、程序逻辑和传感器应用等方面。

(完整版)ABB机器人SmarTac程序实例一、SmarTac 程序实例在实际的应用中,smartac有两种方法对焊缝进行纠偏,第一种是用search1D指令检测单个焊缝的偏移,比如寻找起弧点和收弧点,寻找的方向可以使1维的也可以是2维和3维的。

这种方法适用于每一条焊缝的变化都是相对对立的并且焊缝相对于检测方向不能有太大的角度变化,比如开关柜。

这种方法是直接找到偏移量然后用P-disp frame(P-DispSet指令)直接在工件坐标系里面偏移相应的坐标值。

例如:找点程序PDispOff;MoveJ *, v1000, z5, tSensor\WObj:=Wobj_StnA;MoveJ *, v1000, z5, tSensor\WObj:=Wobj_StnA;Search_1D Cs2401, *, scp2_4_x, v100, tSensor\WObj:=Wobj_StnA\SchSpeed:=3;MoveL *, v1000, z5, tSensor\WObj:=Wobj_StnA;MoveL *, v1000, z5, tSensor\WObj:=Wobj_StnA;Search_1D Cs2401,*,scp2_4_z,v100, tSensor\WObj:=Wobj_StnA\PrePDisp:=Cs2401\SchSpeed:=3;MoveL *, v1000, z5, tSensor\WObj:=Wobj_StnA;MoveL *, v1000, z5, tSensor\WObj:=Wobj_StnA;MoveL *, v1000, z5, tSensor\WObj:=Wobj_StnA;Search_1DCs2401,*,scp2_4_y,v100,tSensor\WObj:=Wobj_StnA\PrePDisp:=Cs2401\SchSpeed:=3;MoveL *, v1000, z5, tSensor\WObj:=Wobj_StnA;MoveJ *, v1000, z5, tSensor\WObj:=Wobj_StnA;Search_1D s2400,*, sp2400_x, v100, tSensor\WObj:=Wobj_StnA\SchSpeed:=3;MoveJ *, v1000, z5, tSensor\WObj:=Wobj_StnA;Search_1D s2400, *, sp2400_y, v100, tSensor\WObj:=Wobj_StnA\PrePDisp:=s2400\SchSpeed:=3;PDispSet Cs2401MoveJ *, v1000, z5, tSensor\WObj:=Wobj_StnA;MoveJ *, v1000, z5, tSensor\WObj:=Wobj_StnA;ArcLStart p2401, v1000, seam1,wd01_16\Weave:=Weave1,fine,tWeldGun\Wobj:=Wobj_StnA;PDispoff;PDispSet Cs2400;ArcLEnd p2400, v1000, seam1, wd01_16\Weave:=weave1, fine, tWeldGun\WObj:=Wobj_StnA;PDispOff;方法2:通过计算工件坐标(oframe)的变化来进行焊缝纠正,原理是当工件坐标系发生变化后,通过寻找在新的工件坐标系中相同坐标点的位置来纠正位置的变化。

abb机器人编程实例

ABB机器人是世界上著名的工业机器人品牌之一,其应用领域涵盖了汽车、电子、机械制造等多个行业。

ABB机器人编程的实例可以帮助工程师快速了解机器人的应用和编程方法,提高工程师的技术水平。

以下是一些ABB机器人编程的实例:

1. 拾取和放置:该示例展示了如何使用ABB机器人拾取和放置物体。

首先,机器人需要移动到物体的位置上,然后使用机器人手臂夹住物体并将其移动到另一个位置。

2. 焊接:该示例展示了如何使用ABB机器人进行自动焊接。

机器人需要在预设的位置上进行点焊和连续焊接,并且需要根据工件的形状和大小来调整焊接路径。

此外,机器人还需要自动识别焊接位置,并在需要时进行矫正。

3. 机器人视觉:ABB机器人还可以配备视觉系统,用于实现更高级的任务。

例如,机器人可以使用视觉系统来检测工件的位置和方向,并据此进行自动操作。

这可能包括将物体放置在正确的位置上,或者调整机器人的位置以对准物体。

4. 夹具设计:适当的夹具设计可以极大地简化机器人编程工作。

一个好的夹具设计应该考虑到工件的尺寸、形状和材料,同时还应该考虑机器人的可行性和夹具的成本。

ABB机器人可以使用常见的夹具类型,例如平面夹具和摆臂夹具,也可以根据需要定制夹具。

5. 机器人协作:ABB机器人还可以与其他机器人和设备进行协作,以实现更高效的生产流程。

例如,多个机器人可以协作完成复杂的装配任务,或者使用机器人和传送带来实现物流自动化。

MODULE MainModuleCONST robtarget pHome:=[[1525.42,272.18,1873.69],[4.42963E-05,0.699969,-0.7141 73,-2.80277E-05],[0,-1,-1,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9 E+09]];CONST robtargetpPrePickMould:=[[1653.99,272.19,1779.41],[5.83312E-05,0.69997, -0.714172,-3.47922E-05],[0,-1,-1,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E+09]];CONST robtarget pPrePickClapboard:=[[2036.17,-741.24,1235.05],[0.678651,0.73435 ,-0.0119011,0.00467586],[-1,-2,2,0],[9E+09,9E+09,9E+09,9E+09,9 E+09,9E+09]];CONST robtargetpPickMould:=[[1943.13,173.08,630.89],[4.66987E-05,0.699977,-0.7 14166,-3.24109E-05],[0,-1,-1,0],[9E+09,9E+09,9E+09,9E+09,9E+0 9,9E+09]];CONST robtargetpPickClapboard:=[[1943.19,173.08,620.72],[1.61422E-05,0.699977, -0.714165,-7.62858E-06],[0,-1,-1,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E+09]];robtarget pPrePlace:=[[785.90,-CONST957.40,1722.38],[0.00231652,0.0492402,-0.99 8779,-0.00310842],[-1,-1,-1,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E+09]];CONST robtarget pPrePlace10:=[[-277.40,-1202.57,1621.17],[0.00183571,-0.0139794, -0.999895,-0.00341408],[-2,-1,-2,0],[9E+09,9E+09,9E+09,9E+09,9E+09,9E+09]];CONST robtarget pPrePlace20:=[[-491.18,-1082.85,1505.90],[0.000663644,0.69408,0. 719887,0.00386364],[-2,0,-1,0],[9E+09,9E+09,9E+09,9E+09,9E+09 ,9E+09]];CONST robtarget pPlaceMould:=[[-92.13,-2580.19,1171.45],[0.000771646,0.713144,0 .701007,0.00383692],[-2,0,-1,0],[9E+09,9E+09,9E+09,9E+09,9E+0 9,9E+09]];CONST robtargetpPlaceClapboard:=[[1585.08,1761.04,787.33],[0.00645323,-0.00552 996,-0.726358,-0.687263],[0,1,-1,0],[9E+09,9E+09,9E+09,9E+09,9 E+09,9E+09]];CONST robtargetpPrePlaceClapboard:=[[1017.30,955.85,1443.17],[1.0621E-05,-0.00 849593,-0.999964,4.01139E-05],[0,-1,0,0],[9E+09,9E+09,9E+09,9E +09,9E+09,9E+09]];CONST robtarget pPrePickClapboard10:=[[2257.17,-841.03,1579.56],[0.667517,0.744 57,-0.00360206,0.00487631],[-1,-1,2,0],[9E+09,9E+09,9E+09,9E+0 9,9E+09,9E+09]];CONST robtarget pPrePickMould10:=[[530.24,-1703.27,1762.63],[5.07659E-05,0.961 61,0.274421,2.37287E-05],[-1,0,0,0],[9E+09,9E+09,9E+09,9E+09,9 E+09,9E+09]];CONST num nOffs:=100;PERS num nCurOffs:=100;CONST num nLayer:=0;PERS num nCurLayer:=0;CONST num nThickness:=40;VAR bool bTimeOut:=FALSE;PERS bool bDryCycle:=FALSE;VAR intnum iDryCycle;VAR intnum iResDryCycle;VAR intnum iVacuum;tooldata tGripper:=[TRUE,[[0,0,100],[1,0,0,0]],[88.5,[-3.7,-PERS1.4,132.1],[1,0,0, 0],5.5,17.831,25.067]];PROC main()rInitAll;WHILE TRUE DOIF siDryCycle=1 or nCurLayer<1 thenrPickClapboard;ELSErPickMould;ENDIFWaittime 0.2;ENDWHILEENDPROCPROC rPickMould()DIWait diMouldready,1,3,"entrance Conveyer","ready for pick";DIWait diPlaceReady,1,3,"exit Conveyer","ready for remove";MoveJ pPrePickMould, v1500, z50, tGripper;IF BitCheck(nCurlayer,1) THENnCurOffs:=nOffs;ELSEnCurOffs:=-nOffs;ENDIFMoveLoffs(pPickMould,0,nCurOffs,100+nCurLayer*nThickness), v1000, z50, tGripper;MoveL offs(pPickMould,0,nCurOffs,(nCurLayer-1)*nThickness), v200, fine, tGripper;GripClose;Decr nCurLayer;MoveLoffs(pPickMould,0,nCurOffs,100+nCurLayer*nThickness), v200, z50, tGripper;MoveJ pPrePickMould, v1000, z50, tGripper;DIWait diPlaceReady,1,3,"exit Conveyer","ready for remove";MoveJ pPrePlace10, v1500, z10, tGripper;MoveL offs(pPlaceMould,0,0,100), v1500, z10, tGripper;MoveL pPlaceMould, v200, fine, tGripper;GripOpen;MoveL offs(pPlaceMould,0,0,100), v200, z10, tGripper;MoveL pPrePlace10, v1500, z10, tGripper;MoveJ pPrePickMould, v1500, z10, tGripper;PulseDO\PLength:=2, doMouldPlaceOK;ENDPROCPROC rPickClapboard()DIWait diMouldready,1,3,"entrance Conveyer","ready for pick";MoveL offs(pPickClapboard,0,0,100), v1000, z50, tGripper;MoveL pPickClapboard, v200, fine, tGripper;GripClose;MoveL offs(pPickClapboard,0,0,100) ,v200, z50, tGripper;MoveL offs(pPickClapboard,0,0,500) ,v1000, z50, tGripper;MoveL pPrePlaceClapboard, v1000, z10, tGripper;DIWait diClapboardReady, 1, 3, "exit Conveyer", "ready for remove";MoveL offs(pPlaceClapboard,-700,-200,250), v1000, z10, tGripper;MoveL offs(pPlaceClapboard,00,-10,100), v1000, z10, tGripper;MoveL pPlaceClapboard, v100, fine, tGripper;GripOpen;MoveL offs(pPlaceClapboard,0,-50,100), v1000, z10, tGripper;MoveL offs(pPlaceClapboard,-700,-200,250), v1000, z10, tGripper;MoveL pPrePlaceClapboard, v1000, z10, tGripper;PulseDO\PLength:=1.0, doClapboardPickOK;MoveJ pHome, v1500, fine, tGripper;PulseDO\PLength:=1.0, doUnStackOk;WaitTime 2;DIWait diMouldready,0,3,"exit Conveyer","ready for remove";nCurLayer:=nLayer;ENDPROCPROC rInitAll()IF diVacuum1=0 THENWaitTime 1;ELSEErrWrite "The Rob1 gripper error! " ,"The gripper is not opened!"\RL2:="Check the gripper signal postion ."\RL3:=" open the gripper manually and take away the part from gripper.";Stop;Exit;ENDIFrMoveHome;nCurLayer:=nLayer;IDelete iVacuum;CONNECT iVacuum WITH tLostPart;ISignalDI diVacuum1, 1, iVacuum;ISleep iVacuum;ENDPROCROC GripClose()SetDO doVacuum,1;SetDO doBlow,0;WaitUntil diVacuum1=1\MaxTime:=10\TimeFlag:=bTimeOut;IF bTimeOut THENErrWrite "Rob Gripper Signal error ! " ,"Fatal error in Gripper"\RL2:="Check the gripper signal postion ."\RL3:=" change a new sensor .";Stop;ENDIFWaittime 0.5;IWatch iVacuum;ENDPROCPROC GripOpen()ISleep iVacuum;SetDO doVacuum,0;PulseDO \PLength:=2.0, doBlow;WaitUntil diVacuum1=0 \MaxTime:=5\TimeFlag:=bTimeOut;IF bTimeOut THENErrWrite "Rob Gripper Signal error ! " ,"Fatal error in Gripper"\RL2:="Check the gripper signal postion ."\RL3:=" change a new sensor .";Stop;ENDIFWaittime 0.5;ENDPROCPROC rMoveHome()VAR string HomeOffset;CONST num MinX:=-500;CONST num MaxX:=500;CONST num MinY:=-500;CONST num MaxY:=500;CONST num MinZ:=500;CONST num MaxZ:=1200;VAR robtarget ActualPos;VelSet 100,500;AccSet 70, 70;IF bCurrentPos(pHome,tGripper,50)=TRUE THENMoveJ pHome,v500,fine,tGripper\WObj:=wobj0;ENDIFIF bCurrentPos(pPrePickMould,tGripper,50\wobj:=Wobj0)= TRUE THENMoveJ pHome,v500,fine,tGripper\WObj:=wobj0;ENDIFIFbCurrentPos(pPrePickClapboard,tGripper,100\wobj:=Wobj0)= TRUE THENMoveJ pHome,v500,fine,tGripper\WObj:=wobj0;ENDIFIF bCurrentPos(pPreplace,tGripper,100\wobj:=Wobj0)= TRUE THENMoveJ pHome,v500,fine,tGripper\WObj:=wobj0;ENDIFIF bCurrentPos(pHome,tGripper,100)=FALSE THEN! If no known position is found, check if the robot is in a specified! window and move him to the first position in the programActualPos:=CRobT(\Tool:=tGripper\WObj:=wobj0);IF ActualPos.trans.x<MinX OR ActualPos.trans.x>MaxX OR ActualPos.trans.y<MinY OR ActualPos.trans.y>MaxY OR ActualPos.trans.z<MinZ OR ActualPos.trans.z>MaxZ THEN HomeOffset:="";IF ActualPos.trans.x<MinX THENHomeOffset:=HomeOffset+"X :"+NumToStr(MinX-ActualPos.trans. x,0)+" ";ELSEIF ActualPos.trans.x>MaxX THENHomeOffset:=HomeOffset+"X :"+NumToStr(MaxX-ActualPos.trans .x,0)+" ";ELSEENDIFIF ActualPos.trans.y<MinY THENHomeOffset:=HomeOffset+"Y :"+NumToStr(MinY-ActualPos.trans. y,0)+" ";ELSEIF ActualPos.trans.y>MaxY THENHomeOffset:=HomeOffset+"Y :"+NumToStr(MaxY-ActualPos.trans .y,0)+" ";ELSEHomeOffset:=HomeOffset+"Y : OK ";ENDIFIF ActualPos.trans.z<MinZ THENHomeOffset:=HomeOffset+"Z :"+NumToStr(MinZ-ActualPos.trans. z,0)+" ";ELSEIF ActualPos.trans.z>MaxZ THENHomeOffset:=HomeOffset+"Z :"+NumToStr(MaxZ-ActualPos.trans. z,0)+" ";ELSEENDIFErrWrite HomeOffset,"Move robot manuallynear homeposition";WHILE OpMode()<>OP_MAN_PROG DO TPErase;TPWrite "Please switch robot to Manualmode"; !TPErase;Stop;ENDWHILEStop;MoveJ pHome,v500,fine,tGripper;!npallet:=4;ActualPos:=CRobT(\Tool:=tGripper\WObj:=wobj0);WHILE OpMode()<>OP_AUTO DOTPErase;TPWrite "Please switch robot to AUTOmode"; !TPErase;Stop;ENDWHILEENDIFENDIFVelSet 100,3000;ENDPROCTRAP tLostPartErrWrite "Part lost!" ,"Fatal error inGripper"\RL2:="Check the gripper ."\RL3:=" check the vacuum .";Stop;ENDTRAPENDMODULE。