钢板超声波检测报告(中英文)

- 格式:xls

- 大小:32.00 KB

- 文档页数:1

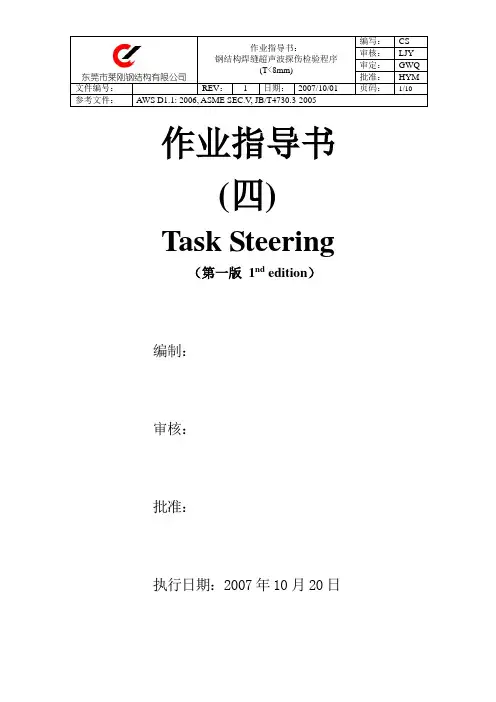

作业指导书(四) Task Steering (第一版1nd edition)编制:审核:批准:执行日期:2007年10月20日1、简介General1.1本工艺旨在叙述薄板焊缝,如外板对接缝的超声波探伤(UT)方法。

本工艺介绍的方法目前在AWS D1.1中未详述,但在其它应用中被证明可行。

The workmanship is describled about welding seam of thin palte,such as method of UT to butt joint seam of external plate.This workmanship introduction is describled in AWS D1.1,but in other experiments are to be proved useful.1.2AWS D1.1:2006附录K通常用于板厚小于8mm的焊件的超声波检测。

AWS D1.1:2006 attach K usually do UT for less than 8mm thickness weldment.2、工艺要求Workmanship Requirement2.1用本工艺可检测的焊缝类型The type of welding seam what this workmanship can inspect使用埋弧焊(SAW),药芯焊丝气体保护焊(FCAW),气体保护钨极电弧焊(GTAW)或药皮焊条电弧焊(SMAW)焊接,两母材板厚相同的对接焊缝均可使用此工艺进行检测。

其它焊缝形式须单独鉴定和单独的工艺。

This workmanship can inspect SAW,FCAW,GTAW or SMAW,butt joint seam of the same thickness of base material.Other welding seam must have individual inspect and workmanship.2.2可用于检测的设备类型Equipment type of inspection符合6.22.1(AWS D1.1:2006)要求的任何超声波检测设均可使用。

超声波探伤报告英语全文共四篇示例,供读者参考第一篇示例:Ultrasonic testing reportIntroduction:Purpose of the test:The purpose of this ultrasonic testing is to assess the integrity and quality of a weld joint in a steel structure. The weld joint is a critical part of the structure and must be free from any defects that could compromise its strength and durability.Procedure:Results:第二篇示例:Ultrasonic testing (UT) is a non-destructive testing technique that uses high frequency sound waves to detect internal flaws or characterize materials. It is commonly used in various industries such as aerospace, automotive, construction, and manufacturing to ensure the quality and integrity of materials and components.In this ultrasonic testing report, we will discuss the basic principles of UT, the equipment and procedures used, and provide an example of a UT inspection report.1. Basic Principles of Ultrasonic Testing2. Equipment and ProceduresThe procedure for conducting an ultrasonic test involves the following steps:Date: May 15, 2021Client: ABC Manufacturing Company第三篇示例:超声波探伤(Ultrasonic Testing,UT)是一种常用于材料和结构检测的无损检测技术,它利用超声波在材料内部传播的原理,通过探头发射超声波进入被检测材料内部,根据超声波的传播和反射情况来判断材料的内部结构和缺陷情况。

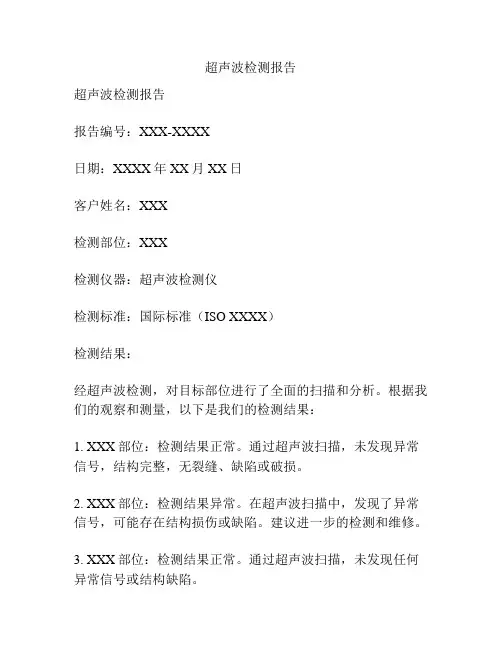

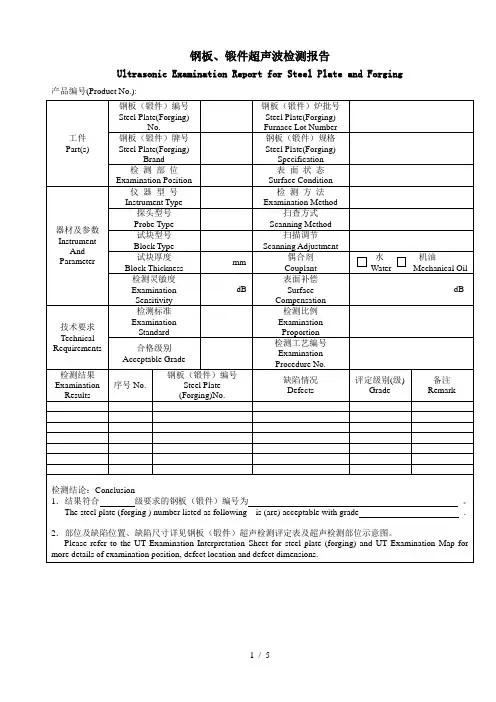

超声波检测报告

超声波检测报告

报告编号:XXX-XXXX

日期:XXXX年XX月XX日

客户姓名:XXX

检测部位:XXX

检测仪器:超声波检测仪

检测标准:国际标准(ISO XXXX)

检测结果:

经超声波检测,对目标部位进行了全面的扫描和分析。

根据我们的观察和测量,以下是我们的检测结果:

1. XXX部位:检测结果正常。

通过超声波扫描,未发现异常信号,结构完整,无裂缝、缺陷或破损。

2. XXX部位:检测结果异常。

在超声波扫描中,发现了异常信号,可能存在结构损伤或缺陷。

建议进一步的检测和维修。

3. XXX部位:检测结果正常。

通过超声波扫描,未发现任何异常信号或结构缺陷。

综上所述,由超声波检测得出的结果显示部分部位存在异常,需要进行进一步的检测和维修。

建议根据我们的报告,采取相应的措施,以确保目标部位的安全和可靠性。

备注:本报告仅针对超声波检测结果,不考虑其他可能影响结论的因素。

如需进一步信息或疑问,请及时与我们联系。

此致

XXX超声波检测中心

联系人:XXX

联系方式:XXX。

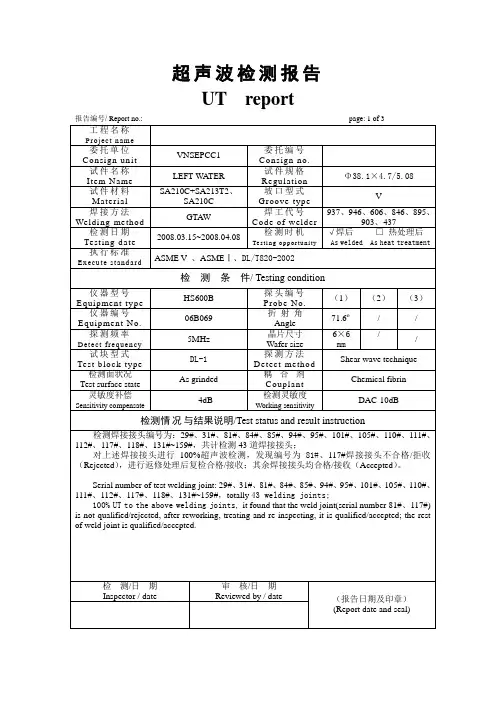

超声波检测报告UT report报告编号/ Report no.:page: 1 of 3 工程名称Proj e ct n am e委托单位Cons ign u n it VNSEPCC1委托编号Cons ign n o.试件名称Item N am e LEFT WA TER试件规格Re gu lat io nΦ38.1×4.7/5.08试件材料Ma ter ia l SA210C+SA213T2、SA210C坡口型式Groov e ty peV焊接方法We ld ing met hod GTA W焊工代号Cod e of w e ld er937、946、606、846、895、903、437检测日期Test ing dat e 2008.03.15~2008.04.08检测时机Test i n g opp or t uni t y√焊后□热处理后As welded As heat treatment执行标准E xec ut e st and ar dASME V 、ASMEⅠ、DL/T820-2002检测条件/ Testing condition仪器型号Eq u ipm ent typ e HS600B探头编号Probe No.(1)(2)(3)仪器编号Eq u ipm ent No.06B069折射角Angle71.6º/ /探测频率Det e ct fr eq ue ncy 5MHz晶片尺寸Wafer size6×6mm//试块型式Test b loc k ty pe DL-1探测方法Det ec t met hodShear wave technique检测面状况Test surface state As grinded耦合剂Cou p la ntChemical fibrin灵敏度补偿Sensitivity compensate 4dB检测灵敏度Working sensitivityDAC-10dB检测情况与结果说明/Test status and result instruction 检测焊接接头编号为:29#、31#、81#、84#、85#、94#、95#、101#、105#、110#、111#、112#、117#、118#、131#~159#,共计检测43道焊接接头;对上述焊接接头进行100%超声波检测,发现编号为81#、117#焊接接头不合格/拒收(Rejected),进行返修处理后复检合格/接收;其余焊接接头均合格/接收(Accepted)。

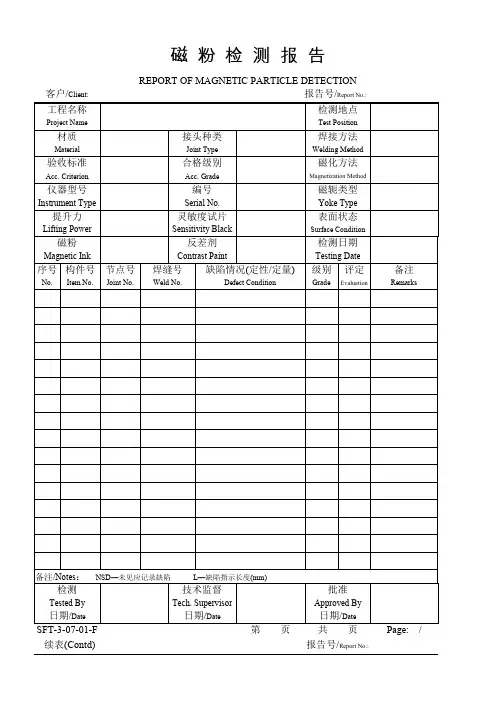

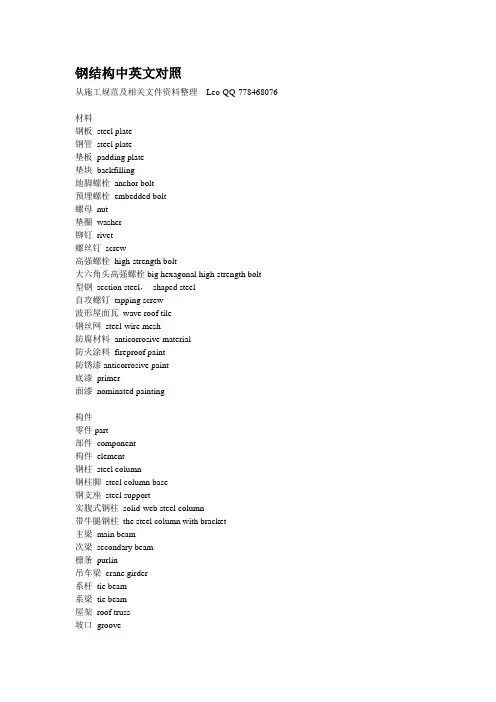

钢结构中英文对照从施工规范及相关文件资料整理Leo-QQ-778468076材料钢板steel plate钢管steel plate垫板padding plate垫块backfilling地脚螺栓anchor bolt预埋螺栓embedded bolt螺母nut垫圈washer铆钉rivet螺丝钉screw高强螺栓high-strength bolt大六角头高强螺栓big hexagonal high-strength bolt型钢section steel,shaped steel自攻螺钉tapping screw波形屋面瓦wave roof tile钢丝网steel-wire mesh防腐材料anticorrosive material防火涂料fireproof paint防锈漆anticorrosive paint底漆primer面漆nominated painting构件零件part部件component构件element钢柱steel column钢柱脚steel column base钢支座steel support实腹式钢柱solid-web steel column带牛腿钢柱the steel column with bracket主梁main beam次梁secondary beam檩条purlin吊车梁crane girder系杆tie beam系梁tie beam屋架roof truss坡口groove屋盖roof system屋面板roof board,roof slab,roof plate天窗架skylight truss拱形屋架arch-shaped roof truss三角形屋架triangle roof truss梯形屋架trapezoid roof truss中拼单位intermediate assembled structure空间刚度单元space rigid unit环境温度ambient temperature预拼装test assembling连接connection螺栓连接钢构bolted steel structure摩擦型高强螺栓连接high-strength bolted friction-type connection 不焊透对接焊接partial penetrated butt weld焊透对接焊接penetrated butt weld焊钉(栓钉)焊接stud welding数据及单位抗震设计earthquake-resistant design层高storey height净高net height计算长度effective length计算高度effective height计算跨度effective span净跨net span净重net weight吨ton千克kilogram面积area立方的cubic平方(正方形的,矩形的)square容积capacity米meter厘米centimeter毫米millimeter微米micrometer工具及机械焊机welding machine自动焊机automatic welding machine自动埋弧焊机submerged arc automatic welding machine手动电弧焊机manual arc welding machine二氧化碳埋弧焊机CO2(carbon dioxide)shield arc welding machine 电渣焊机electro-slag welding machine焊条electrode锤子hummer力矩扳手torque spanner,torque wrench螺丝钳clamp电钻electric drill钻机driller冲击钻(电锤)electric hammer手动摇臂钻manually operated whipping driller磁力钻magnetic driller铣床milling machine碘钨灯iodine tungsten lamp安全照明灯safety flare空压机air compressor钢丝绳steel cable吊车crane(150t)履带式吊车(150t)crawler crane吊钩crane hook液压校直机hydraulic calibrator经纬仪theodolite水平仪(水准仪)gradienter,level安全防护安全网safety net安全帽helmet安全带safety belt劳保鞋hard shoes护目镜goggles防护罩shield安全手套safety gloves防护手套protective gloves绝缘工作服insulating coverall耐火工作服fire-resistance coverall耐酸工作服acid-proof working suit耳塞earplug焊接过程及焊接质量和其他除锈车间blasting workshop焊接weld焊缝welding joint焊缝质量等级quality grade of weld横向焊缝transverse weld对接焊缝butt weld缺陷defect变形deformation凹坑pit麻面pock mark夹渣slag inclusion,slag joint咬边undercut焊缝中未熔焊点non-welded welding裂缝leakage,crack气孔air hole表面瑕疵surface defect不正确焊接尺寸incorrect welding size返工rework外观质量appearance quality检测方法和试验焊缝无损检测non-destructive inspection of weld非破损检测non-destructive test射线检测ray test磁粉检测magnetic particle testing超声波检测extra-sound test放大检测法magnetic test色彩检测法color test放大镜(扩大20倍)magnifier (within 20 times magnification)破坏试验damage test物理和化学成分physical and chemical properties机械性能试验mechanical character test拉伸试验extension test弯曲试验bending test冲击试验colliding test金相测试metelloge test高强螺栓连接副set of high-strength bolt抗滑移系数slip merged of faying surface质量焊接标准welding standard误差tolerance尺寸偏差dimensional轴线grid line标高elevation,levelAA垂直度degree of gravity vertical for AA,verticalityBB 平整度degree of plainness for BB水平度level水平位置position不合格点non-compliance不合格项non-conformance相关对话句子1,These drawings are well done and complied with the requirement of the specification.这些图制作得非常好且符合规范要求。

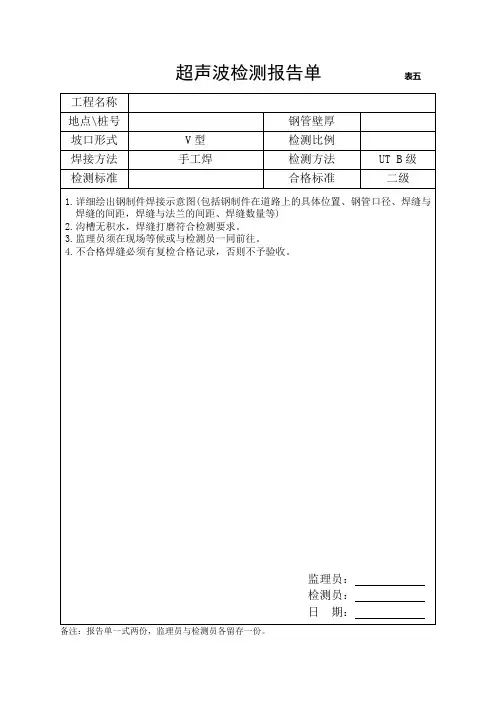

钢结构焊缝超声波检验报告

本报告是对常州动力装备产业园标准厂房8#车间工程中

___所提供的H型钢梁进行钢结构焊缝超声波检验的结果报告。

验收规范为GB-2001《钢结构工程质量验收规范》。

母材材质为Q235B,焊缝类型为对接焊缝,试块为CSK-1A和RB-2.检

验仪器为GTS-22,检验标准为JC11-2-25.

本次检验共检验了10个构件,焊接方法为气体保护焊,

耦合剂为浆糊。

探伤面为45度对接面,探头规格为Φ3-16dB,灵敏度为2.5P8×12K2.5.检验日期为2014年9月25日,检验

地点为厂内。

构件数量为10个,质量等级为Ⅱ级。

本次检验结果显示,受检焊缝均符合GB-2001《钢结构工程质量验收规范》标准二级焊缝要求,评定等级均为Ⅱ级,焊缝质量等级也为Ⅱ级。

因此,本次检验结果合格。

报告批准人、审核人和校核人的信息未在文章中提供,需要补充完整。

受控编号:

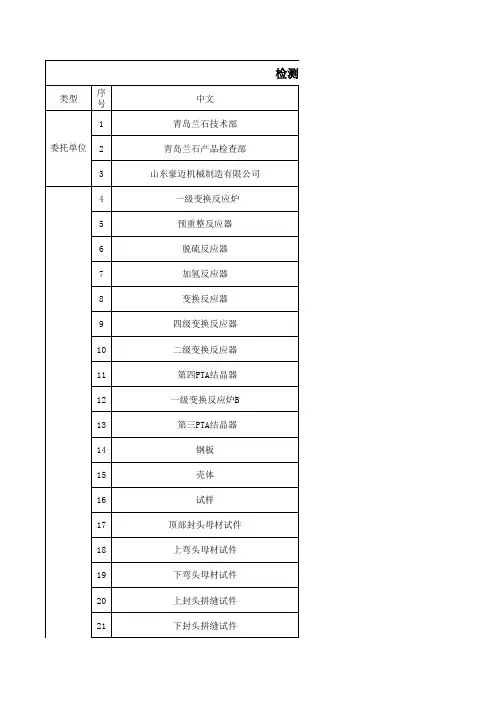

工程质量检测报告

工程名称:

检测内容: 钢结构超声波检测

单位名称

委托单位:

设计单位:

施工单位:

见证单位:

检测单位:

声明

1、本报告无检验检测报告专用章及其骑缝章无效;

2、本报告无检测、审核、批准人签名无效;

3、本报告涂改、增删无效;

4、报告复印页数不全、未加盖检验检测报告专用章无效;

5、对本报告若有异议,应于收到报告之日起十五日内向本检测单位提出。

检测单位资质证书编号:

检测单位地址:

邮政编码:

电话:

钢结构超声波检测结果

检测: (证号: ) (证号: ) 审核:

批准:

钢结构超声波检测结果汇总表

附图:检测构件/节点/焊缝示意图

现场检测工作及关键节点照片

附件

说明:1、本表由见证单位填写,作为检测报告的附件。

2、见证单位由监理单位担任,如无监理单位则由委托方担任。