动力网站-三洋压缩机-技术手册

- 格式:pdf

- 大小:419.24 KB

- 文档页数:28

TECHNICAL & SERVICE MANUALSTB0810C1STB0811C1STB1010C1STB1023C1STB1020C1STB1123C1STB1220C1STB0823H1SANYO 26˝ THROUGH THE WALL AIR CONDITIONERS & HEAT PUMPSTB0810C1 STB0811C1STB1010C1 STB1023C1STB1020C1 STB1123C1STB1220C1 STB0823H1Destination: U.S.A.HOW TO USE THIS MANUALThis manual is designed to help service personnel to understand basic functions, operation and possible troubles and their remedies on SANYO 26˝ Through The Wall Air Conditioner. You can use this manual both as a reference to find specific information about the capacity, construction of the unit, and as a source of information to help you set up and maintain the air conditioner. Please use this manual to make your work easier, keep the air conditioner functioning well, and keep your customer satisfied.Please read IMPORTANT ! precautional information on the previous page before you start actual work.SANYO 26˝ THROUGH THE WALL A/C MODEL IDENTIFICATIONSANYO 26˝ Through The Wall Air Conditioner is identified by a model number. Cooling or heating capacity, electrical information and special features included on the air conditioner are indicated on the model number.Table of ContentsPage 1.OPERATING RANGE (1)2.SPECIFICATIONS2-1.Unit Specifications (2)2-2.Major Component Specifications (4)2-3.Other Component Specifications (6)3.DIMENSIONAL DATA (7)4.REFRIGERANT FLOW DIAGRAM (8)5.PERFORMANCE DATA5-1.Cooling Capacity (9)5-2.Heating Capacity (17)6.ELECTRICAL DATA6-1.Electrical Characteristics (18)6-2.Electrical Wiring Diagrams (21)6-3.P.C.B.Ass'y (Printed Pattern) (27)7.TROUBLESHOOTING7-1.Check before and after troubleshooting (28)7-2.Air conditioner does not operate (29)7-3.Some part of air conditioner does not operate (31)7-4.Air conditioner operates, but abnormalities are observed (33)7-5.If a sensor is defective (34)8.CHECKING ELECTRICAL COMPONENTS8-1.Measurement of Insulation Resistance (35)8-2.Checking Motor Capacitor (36)8-3.Checking Fan Motor Winding (36)8-4.Checking Compressor Motor Winding (36)8-5.Checking Thermistor (36)9.DISASSEMBLY PROCEDURE9-1.Removing Front Grille (37)9-2.Removing Wall Sleeve (37)9-3.Removing Electrical Component Box (37)9-4.Removing Electric Heater (38)9-5.Removing Blower Wheel (39)9-6.Removing Evaporator (39)9-7.Removing Condenser (40)9-8.Removing Propeller Fan (40)9-9.Removing Fan Motor (41)10.FUNCTION10-1.Room temperature Control (42)10-2.Defrosting Operation (Heating) (45)1.OPERATING RANGEs COOLING ONLY MODELModels STB0810C1STB1010C1STB1020C1STB1220C1s COOLING & ELECTRIC HEATING MODELModels STB0811C1STB1023C1STB1123C1s HEAT PUMP MODELModel STB0823H12.SPECIFICATIONS 2-1.Unit Specifications2-2.Major Component Specifications2-3.Other Component SpecificationsModels STB0810C1STB1010C1STB1020C1STB1220C1STB0811C1STB1023C1STB1123C1STB0823H1Room Thermostat YTB-2U136YTB-2U358 Model STB1020C1 STB0810C1STB0811C1 STB1023C1STB1220C1 STB1010C1 STB1123C1 Openrating temp.Cold°F ON: 65 / OFF: 61±3 (Diff: 4 Deg)Warm°F ON: 90 / OFF:86PTC Thermister (for compressor start up)PTH491A04AR470N500 Model STB0810C1 STB0811C1Resistance at 77°FΩ47±30%Relay (Heater)VC20A-115-S VC20A-230-S Model STB0811C1STB1023C1 STB1123C1 Coil rating AC115V , 60Hz AC208/230V , 60Hz Contact rating AC265V , 22A AC265V , 22AElectoric Heater Ass'y AH-H06S AH-H10S Model STB0811C1STB1023C1 STB0823H1STB1123C1 Heater Element Rating 1.22 kW , 115V 3.4 kW , 230VResistanceΩ 9.5±1.5% (at 68°F)13.6±1.5% (at 68°F)Watt Dinsty w/in28.913.2Dimension In Dia 3/8 , Leng 36Dia 3/8 , Leng 36 Heater Thermo.Type CS-7LOpenrating temp°F OFF : 122±5 / ON : 95±9 Fuse Type SF-152UOpenrating temp°F306±5Power Trnsformer ATR-J64ULN2Model STB0823H1Rating Primary AC220V , 60HzSecondary AC19V , 0.3AThermister (Room sensor)PBC-41E-S29Model STB0823H1Resistance at 32°F kΩ15±5%Thermister (Outdoor coil)PBC-41E-S14Model STB0823H1Resistance at 32°F kΩ15±5%4-way Valve (Solenoid coil)CHV-01AQ503UA1(Coil) / CHV-01U1(Valve) Model STB0823H1Coil raiting AC208/230V (60Hz) , 6W3.DIMENSIONAL DATAModels STB0810C1STB1010C1STB1020C1STB1220C1 STB0811C1STB1023C1STB1123C1STB0823H14.REFRIGERANT FLOW DIAGRAM Models STB0810C1STB1010C1STB1020C1STB1220C1 STB0811C1STB1023C1STB1123C1Model STB0823H15.PERFORMANCE DATA5-1.Cooling CapacityModel STB0810C1115 V Single phase 60 HzRATING CAPACITY8,200BTU/hAIR FLOW RATE270CFMEVAPORATOR CONDENSERENT. TEMP. °F (°C)OUTDOOR AMBIENT TEMP. °F( °C)W.B. D.B. 67 75 85 95 105 110(19.4) (23.9) (29.4) (35.0) (40.6) (43.3)TC8,2607,9007,5407,1806,7506,210CM0.600.650.700.750.790.8470 (21.1)SHC6,2606,1005,9405,7805,5805,3505973 (22.8)SHC7,3107,1506,9906,8306,6306,210(15.0)77 (25.0)SHC8,2607,9007,5407,1806,7506,21080 (26.7)SHC8,2607,9007,5407,1806,7506,21084 (28.9)SHC8,2607,9007,5407,1806,7506,21088 (31.1)SHC8,2607,9007,5407,1806,7506,210TC9,3508,4808,0907,7107,2506,670CM0.620.670.720.770.810.8670 (21.1)SHC5,1705,0104,8404,6804,4904,2606373 (22.8)SHC6,2206,0605,8905,7305,5405,310(17.2)77 (25.0)SHC7,2707,1106,9406,7806,5906,36080 (26.7)SHC8,3208,1607,9907,7107,2506,67084 (28.9)SHC8,8608,4808,0907,7107,2506,67088 (31.1)SHC8,8608,4808,0907,7107,2506,670TC9,4309,0208,610#8,2007,7107,090CM0.640.690.740.790.840.8970 (21.1)SHC4,0503,8903,7303,5703,3803,1506773 (22.8)SHC5,1004,9404,7804,6204,4304,200(19.4)77 (25.0)SHC6,1505,9905,8305,6705,4805,25080 (26.7)SHC7,2007,0406,8706,7206,5306,29084 (28.9)SHC8,2508,0907,9207,7707,5807,09088 (31.1)SHC9,3009,0208,6108,2007,7107,090TC10,0009,5609,1308,6908,1707,520CM0.660.710.760.820.860.9173 (22.8)SHC3,9703,8203,6603,5003,3203,0907077 (25.0)SHC5,0204,8604,7104,5504,3704,140(21.1)80 (26.7)SHC6,0705,9105,7605,6005,4205,19084 (28.9)SHC7,1206,9606,8106,6506,4706,24088 (31.1)SHC8,1708,0107,8607,7007,5207,290TC10,61010,1509,6709,1308,5407,950CM0.670.730.780.840.890.94 7377 (25.0)SHC3,8503,6903,5303,3603,1702,970(22.8)80 (26.7)SHC4,9004,7404,5804,4004,2204,02084 (28.9)SHC5,9505,7905,6305,4505,2605,07088 (31.1)SHC7,0006,8406,6806,5006,3106,120TC :Total Cooling Capacity (BTU/h)SHC :Sensible Heat Capacity (BTU/h)CM :Compressor Input (kW)Rating conditions (#Mark) areOutdoor Ambient Temp. 95°F (35°C) D.B.Model STB1010C1115 V Single phase 60 HzRATING CAPACITY10,200BTU/hAIR FLOW RATE270CFMEVAPORATOR CONDENSERENT. TEMP. °F (°C)OUTDOOR AMBIENT TEMP. °F( °C)W.B. D.B. 67 75 85 95 105 110(19.4) (23.9) (29.4) (35.0) (40.6) (43.3)TC10,2809,8309,3808,9408,3907,730CM0.800.870.93 1.00 1.06 1.1370 (21.1)SHC7,2207,0006,7906,5806,3206,0205973 (22.8)SHC8,2708,0507,8407,6307,3707,070(15.0)77 (25.0)SHC9,3209,1008,8908,6808,3907,73080 (26.7)SHC10,2809,8309,3808,9408,3907,73084 (28.9)SHC10,2809,8309,3808,9408,3907,73088 (31.1)SHC10,2809,8309,3808,9408,3907,730TC11,63010,55010,0709,5909,0108,290CM0.820.890.95 1.02 1.09 1.1570 (21.1)SHC6,1305,9105,7005,4905,2404,9306373 (22.8)SHC7,1806,9606,7506,5406,2905,980(17.2)77 (25.0)SHC8,2308,0107,8007,5807,3307,03080 (26.7)SHC9,2809,0608,8508,6308,3808,08084 (28.9)SHC10,33010,1109,9009,5909,0108,29088 (31.1)SHC11,03010,55010,0709,5909,0108,290TC11,73011,22010,710#10,2009,5908,820CM0.850.920.98 1.05 1.12 1.1970 (21.1)SHC5,0004,7804,5704,3604,1103,8106773 (22.8)SHC6,0505,8305,6205,4105,1604,860(19.4)77 (25.0)SHC7,0906,8806,6706,4606,2105,91080 (26.7)SHC8,1407,9307,7207,5107,2606,96084 (28.9)SHC9,1908,9808,7708,5608,3108,01088 (31.1)SHC10,24010,0309,8209,6109,3608,820TC12,43011,89011,35010,81010,1609,350CM0.870.94 1.01 1.08 1.15 1.2273 (22.8)SHC4,9004,6904,4804,2804,0403,7407077 (25.0)SHC5,9505,7405,5305,3305,0904,790(21.1)80 (26.7)SHC7,0006,7906,5806,3806,1405,84084 (28.9)SHC8,0507,8407,6307,4307,1906,89088 (31.1)SHC9,1008,8908,6808,4808,2407,940TC13,19012,62012,03011,35010,6309,880CM0.890.97 1.04 1.11 1.18 1.26 7377 (25.0)SHC4,7604,5504,3404,1003,8603,610(22.8)80 (26.7)SHC5,8105,6005,3905,1504,9004,65084 (28.9)SHC6,8506,6506,4406,2005,9505,70088 (31.1)SHC7,9007,7007,4907,2507,0006,750TC :Total Cooling Capacity (BTU/h)SHC :Sensible Heat Capacity (BTU/h)CM :Compressor Input (kW)Rating conditions (#Mark) areOutdoor Ambient Temp. 95°F (35°C) D.B.Model STB1020C1230 V Single phase 60 HzRATING CAPACITY9,700BTU/hAIR FLOW RATE270CFMEVAPORATOR CONDENSERENT. TEMP. °F (°C)OUTDOOR AMBIENT TEMP. °F( °C)W.B. D.B. 67 75 85 95 105 110(19.4) (23.9) (29.4) (35.0) (40.6) (43.3)TC9,7709,3508,9208,5007,9807,350CM0.760.820.880.940.97 1.0070 (21.1)SHC6,9806,7806,5806,3806,1405,8605973 (22.8)SHC8,0307,8307,6307,4307,1906,910(15.0)77 (25.0)SHC9,0808,8808,6808,4807,9807,35080 (26.7)SHC9,7709,3508,9208,5007,9807,35084 (28.9)SHC9,7709,3508,9208,5007,9807,35088 (31.1)SHC9,7709,3508,9208,5007,9807,350TC11,06010,0309,5709,1208,5707,890CM0.780.840.900.97 1.00 1.0270 (21.1)SHC5,8905,6905,4905,2905,0504,7606373 (22.8)SHC6,9406,7406,5406,3406,1005,810(17.2)77 (25.0)SHC7,9907,7907,5807,3907,1506,86080 (26.7)SHC9,0408,8408,6308,4408,2007,89084 (28.9)SHC10,0909,8909,5709,1208,5707,89088 (31.1)SHC10,49010,0309,5709,1208,5707,890TC11,15010,67010,180#9,7009,1208,390CM0.800.870.93 1.00 1.03 1.0670 (21.1)SHC4,7604,5604,3604,1603,9303,6506773 (22.8)SHC5,8105,6105,4105,2104,9804,700(19.4)77 (25.0)SHC6,8606,6606,4606,2606,0305,75080 (26.7)SHC7,9107,7107,5107,3107,0806,80084 (28.9)SHC8,9608,7608,5608,3608,1307,85088 (31.1)SHC10,0109,8109,6109,4109,1208,390TC11,82011,31010,80010,2809,6708,890CM0.830.890.96 1.03 1.06 1.0973 (22.8)SHC4,6704,4704,2804,0903,8603,5807077 (25.0)SHC5,7205,5205,3305,1404,9104,630(21.1)80 (26.7)SHC6,7706,5706,3806,1905,9605,68084 (28.9)SHC7,8207,6207,4307,2407,0106,73088 (31.1)SHC8,8708,6708,4808,2908,0607,780TC12,55012,00011,44010,80010,1109,400CM0.840.920.98 1.05 1.09 1.12 7377 (25.0)SHC4,5304,3404,1403,9203,6903,450(22.8)80 (26.7)SHC5,5805,3905,1904,9704,7404,50084 (28.9)SHC6,6306,4406,2406,0205,7905,55088 (31.1)SHC7,6807,4907,2907,0706,8406,600TC :Total Cooling Capacity (BTU/h)SHC :Sensible Heat Capacity (BTU/h)CM :Compressor Input (kW)Rating conditions (#Mark) areOutdoor Ambient Temp. 95°F (35°C) D.B.Model STB1220C1230 V Single phase 60 HzRATING CAPACITY11,500BTU/hAIR FLOW RATE270CFMEVAPORATOR CONDENSERENT. TEMP. °F (°C)OUTDOOR AMBIENT TEMP. °F( °C)W.B. D.B. 67 75 85 95 105 110(19.4) (23.9) (29.4) (35.0) (40.6) (43.3)TC11,59011,08010,58010,0709,4608,710CM0.920.99 1.06 1.14 1.21 1.2870 (21.1)SHC7,8807,6207,3707,1306,8306,4805973 (22.8)SHC8,9308,6708,4208,1807,8807,530(15.0)77 (25.0)SHC9,9809,7209,4709,2308,9308,58080 (26.7)SHC11,03010,77010,52010,0709,4608,71084 (28.9)SHC11,59011,08010,58010,0709,4608,71088 (31.1)SHC11,59011,08010,58010,0709,4608,710TC13,11011,89011,35010,81010,1609,350CM0.94 1.02 1.09 1.17 1.24 1.3170 (21.1)SHC6,7906,5306,2806,0405,7405,3906373 (22.8)SHC7,8407,5807,3307,0906,7906,440(17.2)77 (25.0)SHC8,8908,6308,3808,1407,8407,49080 (26.7)SHC9,9409,6809,4309,1908,8908,54084 (28.9)SHC10,99010,73010,48010,2309,9409,35088 (31.1)SHC12,04011,78011,35010,81010,1609,350TC13,22012,65012,070#11,50010,8109,950CM0.97 1.05 1.13 1.21 1.28 1.3570 (21.1)SHC5,6505,4005,1504,9004,6204,2606773 (22.8)SHC6,7006,4506,2005,9505,6705,310(19.4)77 (25.0)SHC7,7507,5007,2507,0006,7206,36080 (26.7)SHC8,8008,5508,3008,0507,7707,41084 (28.9)SHC9,8509,6009,3509,1008,8108,46088 (31.1)SHC10,90010,65010,40010,1509,8609,510TC14,02013,41012,80012,19011,46010,540CM 1.00 1.08 1.16 1.24 1.32 1.3973 (22.8)SHC5,5505,3005,0504,8104,5304,1907077 (25.0)SHC6,6006,3506,1005,8605,5805,230(21.1)80 (26.7)SHC7,6507,4007,1506,9106,6306,28084 (28.9)SHC8,7008,4508,2007,9607,6807,33088 (31.1)SHC9,7509,5009,2509,0108,7308,380TC14,88014,23013,56012,80011,98011,140CM 1.02 1.11 1.19 1.27 1.35 1.43 7377 (25.0)SHC5,3805,1404,8904,6204,3304,040(22.8)80 (26.7)SHC6,4306,1905,9405,6705,3805,09084 (28.9)SHC7,4807,2406,9906,7206,4306,14088 (31.1)SHC8,5308,2908,0407,7707,4807,190TC :Total Cooling Capacity (BTU/h)SHC :Sensible Heat Capacity (BTU/h)CM :Compressor Input (kW)Rating conditions (#Mark) areOutdoor Ambient Temp. 95°F (35°C) D.B.Model STB0811C1115 V Single phase 60 HzRATING CAPACITY8,000BTU/hAIR FLOW RATE250CFMEVAPORATOR CONDENSERENT. TEMP. °F (°C)OUTDOOR AMBIENT TEMP. °F( °C)W.B. D.B. 67 75 85 95 105 110(19.4) (23.9) (29.4) (35.0) (40.6) (43.3)TC8,0607,7107,3607,0106,5806,060CM0.590.640.680.730.790.8570 (21.1)SHC5,9705,8105,6505,4905,3005,0705973 (22.8)SHC6,9406,7806,6206,4606,2706,040(15.0)77 (25.0)SHC7,9107,7107,3607,0106,5806,06080 (26.7)SHC8,0607,7107,3607,0106,5806,06084 (28.9)SHC8,0607,7107,3607,0106,5806,06088 (31.1)SHC8,0607,7107,3607,0106,5806,060TC9,1208,2707,9007,5207,0706,500CM0.610.650.700.750.810.8770 (21.1)SHC4,9604,8004,6304,4704,2904,0506373 (22.8)SHC5,9305,7705,6105,4505,2605,030(17.2)77 (25.0)SHC6,9006,7406,5806,4206,2306,00080 (26.7)SHC7,8707,7107,5507,3907,0706,50084 (28.9)SHC8,6508,2707,9007,5207,0706,50088 (31.1)SHC8,6508,2707,9007,5207,0706,500TC9,2008,8008,400#8,0007,5206,920CM0.620.670.720.770.840.9070 (21.1)SHC3,9203,7503,6003,4403,2503,0206773 (22.8)SHC4,8904,7304,5704,4104,2203,990(19.4)77 (25.0)SHC5,8605,7005,5405,3805,2004,97080 (26.7)SHC6,8306,6706,5106,3506,1705,94084 (28.9)SHC7,8007,6407,4807,3307,1406,91088 (31.1)SHC8,7808,6108,4008,0007,5206,920TC9,7509,3308,9008,4807,9707,340CM0.640.690.740.800.860.9273 (22.8)SHC3,8403,6803,5303,3703,1902,9707077 (25.0)SHC4,8104,6604,5004,3504,1603,940(21.1)80 (26.7)SHC5,7905,6305,4705,3205,1304,91084 (28.9)SHC6,7606,6006,4406,2906,1105,88088 (31.1)SHC7,7307,5707,4207,2607,0806,850TC10,3509,9009,4308,9008,3407,750CM0.650.710.760.820.880.95 7377 (25.0)SHC3,7203,5703,4103,2303,0402,860(22.8)80 (26.7)SHC4,6904,5404,3804,2004,0203,83084 (28.9)SHC5,6605,5105,3505,1804,9904,80088 (31.1)SHC6,6406,4806,3206,1505,9605,770TC :Total Cooling Capacity (BTU/h)SHC :Sensible Heat Capacity (BTU/h)CM :Compressor Input (kW)Rating conditions (#Mark) areOutdoor Ambient Temp. 95°F (35°C) D.B.Model STB1023C1230 V Single phase 60 HzRATING CAPACITY9,500BTU/hAIR FLOW RATE250CFMEVAPORATOR CONDENSERENT. TEMP. °F (°C)OUTDOOR AMBIENT TEMP. °F( °C)W.B. D.B. 67 75 85 95 105 110(19.4) (23.9) (29.4) (35.0) (40.6) (43.3)TC9,5709,1608,7408,3207,8207,200CM0.740.800.860.920.96 1.0170 (21.1)SHC6,7006,5006,3006,1005,8605,5805973 (22.8)SHC7,6707,4707,2707,0706,8406,550(15.0)77 (25.0)SHC8,6408,4408,2408,0407,8107,20080 (26.7)SHC9,5709,1608,7408,3207,8207,20084 (28.9)SHC9,5709,1608,7408,3207,8207,20088 (31.1)SHC9,5709,1608,7408,3207,8207,200TC10,8309,8209,3808,9308,3907,720CM0.760.830.880.950.99 1.0370 (21.1)SHC5,6905,4905,2905,0904,8504,5706373 (22.8)SHC6,6606,4606,2606,0605,8305,540(17.2)77 (25.0)SHC7,6307,4307,2307,0306,8006,51080 (26.7)SHC8,6008,4008,2008,0007,7707,48084 (28.9)SHC9,5809,3709,1708,9308,3907,72088 (31.1)SHC10,2709,8209,3808,9308,3907,720TC10,93010,4509,980#9,5008,9308,220CM0.790.850.910.98 1.02 1.0770 (21.1)SHC4,6404,4404,2404,0403,8103,5306773 (22.8)SHC5,6105,4105,2105,0204,7904,500(19.4)77 (25.0)SHC6,5806,3806,1805,9905,7605,47080 (26.7)SHC7,5507,3507,1506,9606,7306,45084 (28.9)SHC8,5308,3208,1307,9307,7007,42088 (31.1)SHC9,5009,3009,1008,9008,6708,220TC11,58011,08010,57010,0709,4708,710CM0.810.870.94 1.01 1.05 1.1073 (22.8)SHC4,5504,3504,1603,9703,7403,4607077 (25.0)SHC5,5205,3305,1304,9404,7104,440(21.1)80 (26.7)SHC6,5006,3006,1005,9105,6905,41084 (28.9)SHC7,4707,2707,0806,8806,6606,38088 (31.1)SHC8,4408,2408,0507,8607,6307,350TC12,29011,76011,20010,5709,9009,210CM0.830.900.96 1.03 1.08 1.13 7377 (25.0)SHC4,4104,2204,0203,8003,5703,340(22.8)80 (26.7)SHC5,3805,1905,0004,7804,5404,31084 (28.9)SHC6,3606,1605,9705,7505,5205,28088 (31.1)SHC7,3307,1406,9406,7206,4906,250TC :Total Cooling Capacity (BTU/h)SHC :Sensible Heat Capacity (BTU/h)CM :Compressor Input (kW)Rating conditions (#Mark) areOutdoor Ambient Temp. 95°F (35°C) D.B.Model STB1123C1230 V Single phase 60 HzRATING CAPACITY11,300BTU/hAIR FLOW RATE250CFMEVAPORATOR CONDENSERENT. TEMP. °F (°C)OUTDOOR AMBIENT TEMP. °F( °C)W.B. D.B. 67 75 85 95 105 110(19.4) (23.9) (29.4) (35.0) (40.6) (43.3)TC11,38010,89010,4009,9009,3008,560CM0.900.98 1.04 1.12 1.19 1.2670 (21.1)SHC7,6107,3607,1106,8606,5706,2105973 (22.8)SHC8,5908,3308,0807,8307,5407,180(15.0)77 (25.0)SHC9,5609,3009,0508,8008,5108,16080 (26.7)SHC10,53010,28010,0209,7809,3008,56084 (28.9)SHC11,38010,89010,4009,9009,3008,56088 (31.1)SHC11,38010,89010,4009,9009,3008,560TC12,89011,68011,15010,6209,9809,190CM0.93 1.00 1.07 1.15 1.22 1.2970 (21.1)SHC6,6106,3506,1005,8505,5605,2006373 (22.8)SHC7,5807,3207,0706,8206,5306,170(17.2)77 (25.0)SHC8,5508,2908,0407,7907,5007,15080 (26.7)SHC9,5209,2709,0108,7708,4708,12084 (28.9)SHC10,49010,2409,9909,7409,4509,09088 (31.1)SHC11,47011,21010,96010,6209,9809,190TC13,00012,43011,870#11,30010,6209,770CM0.96 1.03 1.11 1.19 1.26 1.3370 (21.1)SHC5,5505,2905,0404,8004,5104,1606773 (22.8)SHC6,5206,2606,0205,7705,4805,130(19.4)77 (25.0)SHC7,4907,2406,9906,7406,4506,10080 (26.7)SHC8,4608,2107,9607,7107,4307,07084 (28.9)SHC9,4309,1808,9308,6908,4008,04088 (31.1)SHC10,41010,1509,9009,6609,3709,020TC13,77013,18012,58011,98011,26010,360CM0.98 1.06 1.14 1.22 1.30 1.3773 (22.8)SHC5,4505,2004,9504,7104,4304,0807077 (25.0)SHC6,4206,1705,9205,6805,4005,050(21.1)80 (26.7)SHC7,3907,1406,8906,6506,3706,02084 (28.9)SHC8,3608,1107,8707,6307,3406,99088 (31.1)SHC9,3309,0808,8408,6008,3107,970TC14,62013,98013,32012,58011,77010,950CM 1.00 1.09 1.17 1.25 1.33 1.41 7377 (25.0)SHC5,2905,0404,7904,5204,2303,940(22.8)80 (26.7)SHC6,2606,0205,7705,4905,2004,91084 (28.9)SHC7,2306,9906,7406,4606,1705,88088 (31.1)SHC8,2007,9607,7107,4307,1406,850TC :Total Cooling Capacity (BTU/h)SHC :Sensible Heat Capacity (BTU/h)CM :Compressor Input (kW)Rating conditions (#Mark) areOutdoor Ambient Temp. 95°F (35°C) D.B.Model STB0823H1230 V Single phase 60 HzRATING CAPACITY8,000BTU/hAIR FLOW RATE250CFMEVAPORATOR CONDENSERENT. TEMP. °F (°C)OUTDOOR AMBIENT TEMP. °F( °C)W.B. D.B. 67 75 85 95 105 110(19.4) (23.9) (29.4) (35.0) (40.6) (43.3)TC8,0607,7107,3607,0106,5806,060CM0.610.660.700.750.800.8570 (21.1)SHC5,9805,8105,6505,4905,3005,0705973 (22.8)SHC6,9506,7906,6306,4706,2706,040(15.0)77 (25.0)SHC7,9207,7107,3607,0106,5806,06080 (26.7)SHC8,0607,7107,3607,0106,5806,06084 (28.9)SHC8,0607,7107,3607,0106,5806,06088 (31.1)SHC8,0607,7107,3607,0106,5806,060TC9,1208,2707,9007,5207,0706,500CM0.620.670.720.770.820.8770 (21.1)SHC4,9604,8004,6404,4804,2904,0606373 (22.8)SHC5,9405,7705,6105,4505,2605,030(17.2)77 (25.0)SHC6,9106,7506,5806,4306,2406,00080 (26.7)SHC7,8807,7207,5607,4007,0706,50084 (28.9)SHC8,6508,2707,9007,5207,0706,50088 (31.1)SHC8,6508,2707,9007,5207,0706,500TC9,2008,8008,400#8,0007,5206,920CM0.640.690.740.800.850.9070 (21.1)SHC3,9203,7603,6003,4503,2603,0306773 (22.8)SHC4,8904,7304,5704,4204,2304,000(19.4)77 (25.0)SHC5,8705,7005,5505,3905,2004,97080 (26.7)SHC6,8406,6806,5206,3606,1705,95084 (28.9)SHC7,8107,6507,4907,3307,1506,92088 (31.1)SHC8,7808,6208,4008,0007,5206,920TC9,7509,3308,9008,4807,9707,340CM0.660.710.760.820.870.9273 (22.8)SHC3,8503,6903,5303,3803,2002,9707077 (25.0)SHC4,8204,6604,5104,3504,1703,950(21.1)80 (26.7)SHC5,7905,6305,4805,3205,1404,92084 (28.9)SHC6,7606,6106,4506,3006,1105,89088 (31.1)SHC7,7407,5807,4207,2707,0906,860TC10,3509,9009,4308,9008,3407,750CM0.670.730.780.840.900.95 7377 (25.0)SHC3,7303,5703,4103,2403,0502,860(22.8)80 (26.7)SHC4,7004,5504,3904,2104,0203,83084 (28.9)SHC5,6705,5205,3605,1805,0004,81088 (31.1)SHC6,6406,4906,3306,1505,9705,780TC :Total Cooling Capacity (BTU/h)SHC :Sensible Heat Capacity (BTU/h)CM :Compressor Input (kW)Rating conditions (#Mark) areOutdoor Ambient Temp. 95°F (35°C) D.B.5-2.Heating Capacity (Heat pump Performance)6.ELECTRICAL DATA6-1.Electrical CharacteristicsModel STB0810C1Outdoor Unit Complete UnitFan Motor CompressorPerformance at115V 1-phase 60HzRating Conditions Running Amps.A 1.267.048.3Power Input kW0.1450.7950.94 Full Load Conditions Running Amps.A 1.268.349.6Power Input kW0.1450.935 1.08Model STB1010C1Outdoor Unit Complete UnitFan Motor CompressorPerformance at115V 1-phase 60HzRating Conditions Running Amps.A 1.269.3410.6Power Input kW0.145 1.055 1.20 Full Load Conditions Running Amps.A 1.2611.0412.3Power Input kW0.145 1.255 1.40Model STB1020C1Outdoor Unit Complete UnitFan Motor CompressorPerformance at230 / 208V 1-phase 60HzRating Conditions Running Amps.A0.61/0.64 4.39/ 4.66 5.0/ 5.3Power Input kW0.142/0.1320.998/0.978 1.14/ 1.11 Full Load Conditions Running Amps.A0.61/0.64 4.99/ 5.26 5.6/ 5.9Power Input kW0.142/0.132 1.118/ 1.098 1.26/ 1.23Model STB1220C1Outdoor Unit Complete UnitFan Motor CompressorPerformance at230 / 208V 1-phase 60HzRating Conditions Running Amps.A0.61/0.64 5.49/ 5.96 6.1/ 6.6Power Input kW0.142/0.132 1.208/ 1.198 1.35/ 1.33 Full Load Conditions Running Amps.A0.61/0.64 6.29/ 6.96 6.9/7.6Power Input kW0.142/0.132 1.428/ 1.438 1.57/ 1.57Rating Conditions: Indoor Air Temperature 80°F (26.7°C) D.B. / 67°F (19.4°C) W.B.Outdoor Air Temperature 95°F (35°C) D.B.Full Load Conditions: Indoor Air Temperature 90°F (32.2°C) D.B. / 73°F (22.8°C) W.B.Outdoor Air Temperature 110°F (43.3°C) D.B.Model STB0811C1Outdoor Unit Complete UnitFan Motor CompressorPerformance at115V 1-phase 60HzRating Conditions Running Amps.A 1.267.048.3Power Input kW0.1450.7750.92 Full Load Conditions Running Amps.A 1.268.349.6Power Input kW0.1450.945 1.09Model STB1023C1Outdoor Unit Complete UnitFan Motor CompressorPerformance at230 / 208V 1-phase 60HzRating Conditions Running Amps.A0.61/0.64 4.39/ 4.66 5.0/ 5.3Power Input kW0.142/0.1320.978/0.958 1.12/ 1.09 Full Load Conditions Running Amps.A0.61/0.64 4.99/ 5.26 5.6/ 5.9Power Input kW0.142/0.132 1.128/ 1.088 1.27/ 1.22Model STB1123C1Outdoor Unit Complete UnitFan Motor CompressorPerformance at230 / 208V 1-phase 60HzRating Conditions Running Amps.A0.61/0.64 5.39/ 5.86 6.0/ 6.5Power Input kW0.142/0.132 1.188/ 1.178 1.33/ 1.31 Full Load Conditions Running Amps.A0.61/0.64 6.29/ 6.86 6.9/7.5Power Input kW0.142/0.132 1.408/ 1.408 1.55/ 1.54Rating Conditions: Indoor Air Temperature 80°F (26.7°C) D.B. / 67°F (19.4°C) W.B.Outdoor Air Temperature 95°F (35°C) D.B.Full Load Conditions: Indoor Air Temperature 90°F (32.2°C) D.B. / 73°F (22.8°C) W.B.Outdoor Air Temperature 110°F (43.3°C) D.B.Model STB0823H1COOLINGOutdoor Unit Complete UnitFan Motor CompressorPerformance at230 / 208V 1-phase 60HzRating Conditions Running Amps.A0.61/0.64 3.59/ 3.86 4.2/ 4.5Power Input kW0.142/0.1320.798/0.7880.94/0.92 Full Load Conditions Running Amps.A0.61/0.64 4.29/ 4.46 4.9/ 5.1Power Input kW0.142/0.1320.948/0.918 1.09/ 1.05Rating Conditions: Indoor Air Temperature 80°F (26.7°C) D.B. / 67°F (19.4°C) W.B.Outdoor Air Temperature 95°F (35°C) D.B.Full Load Conditions: Indoor Air Temperature 90°F (32.2°C) D.B. / 73°F (22.8°C) W.B.Outdoor Air Temperature 110°F (43.3°C) D.B.HEATINGOutdoor Unit Complete UnitFan Motor CompressorPerformance at230 / 208V 1-phase 60HzRating Conditions Running Amps.A0.61/0.64 3.39/ 3.66 4.0/ 4.3Power Input kW0.142/0.1320.738/0.7380.88/0.87 Full Load Conditions Running Amps.A0.61/0.64 4.09/ 4.51 4.7/ 5.2Power Input kW0.142/0.1320.898/0.888 1.04/ 1.02Rating Conditions: Indoor Air Temperature 70°F (21.1°C) D.B.Outdoor Air Temperature 47°F (8.3°C) D.B. / 43°F (6.1°C) W.B.Full Load Conditions: Indoor Air Temperature 80°F (26.7°C) D.B.Outdoor Air Temperature 75°F (23.9°C) D.B. / 65°F (18.3°C) W.B.6-2.Electrical Wiring DiagramsModelsSTB0810C1STB1010C1LAYOUT FOR ELECTRIC PARTSModel STB0823H1Model STB0823H1Capacitor (FM)VaristorCapacitor (CM)Power transformer Power pack control PCB Thermistor room temp.Main control switch Control switch temp.settingLAYOUT FOR ELECTRIC PARTSBEFORE OPENING THE BOXFan switchLidPower cordAFTER OPENING THE BOX6-3.P.C.B. Ass'y (Printed Pattern) POW–STBH (For model STB0823H1)7.TROUBLESHOOTING7-1.Check before and after troubleshooting7-1-1.Check power supply.q Check that voltage is in specified range (±10% of the rating).q Check that power is being supplied.7-1-2.Check lead wires and connectors.q Check that coating of lead wires is not damaged.q Check that lead wires and connectors are firmly connected.q Check that wiring is correct.7-2.Air conditioner does not operate.7-2-1.Circuit breaker trips (or fuse blows).A. When the circuit breaker is set to ON, it is tripped soon. (Resetting is not possible.)q There is a possibility of ground fault.q Check insulation resistance.If resistance value is 2MΩor less, insulation is defective (“NO”).NOTE1.If any poorly insulated part is found, exclude that part from circuit with other parts properly connected, and thenmeasure insulation resistance of entire air conditioner again to locate defective part.2.Replace defective part with new one.B. Circuit breaker trips in several minutes after turning the air conditioner on. q There is a possibility of short circuit.7-2-2.Neither fan motor nor compressor motor runs.A. Power is not supplied.B. Check "MODE selector" on the control panel.C. Check transformer.(Only for heat pump model)7-3.Some part of air conditioner does not operate. 7-3-1.Only fan does not run.7-3-2.Electric heater does not work.7-3-3.Only compressor unit does not run.A. Check setting temperature.B. Check compressor and electrical parts.NOT restart it immediately, as this7-4.Air conditioner operates, but abnormalities are observed. 7-4-1.Operation does not switch from HEAT to COOL (or COOL to HEAT).7-4-3.Excessive cooling or heating.。

DF-G系列第三章操作和排除故障项目页次3-1总则 ................................................................................................................................ 3-1 3-2清洗机身润滑系统 ........................................................................................................ 3-2 3-3冷却水要求 .................................................................................................................... 3-3 3-3.1 充水冷却系统 .................................................................................................... 3-43-3.2 调节冷却水系统............................................................................................. 3-4 3-4润滑机身和运动部件 ................................................................................................. 3-4 3-4.1 油压和油温..................................................................................................... 3-53-4.2 油过滤器......................................................................................................... 3-6 3-5润滑气缸 ..................................................................................................................... 3-6 3-6初次启动和试车 ........................................................................................................ 3-11 3-6.1 有润滑气缸的试车步骤................................................................................ 3-113-6.2 无油润滑气缸试车步骤................................................................................3-123-6.3注油流量...........................................................................................................3-123-6.4 开车前的检查................................................................................................3-13 3-7压缩机运行 ................................................................................................................3-14 3-7.1 操作气动盘车动力缸....................................................................................3-14 3-8安全停车回路 ............................................................................................................3-14 3-9操作记录 ....................................................................................................................3-15 3-10日常操作和维护保养检查 ......................................................................................3-15 3-10.1 小时检查......................................................................................................3-153-10.2 日检查(每8小时)..................................................................................3-153-10.3 月检查..........................................................................................................3-163-10.4 维护停车(每3年或根据经验和操作条件缩短时间)..........................3-163-10.5 周期性检查(根据经验和操作条件而定)..............................................3-16 3-11较长时期停车 ..........................................................................................................3-17 3-11.1 长时间停车保护措施..................................................................................3-17 3-12排除故障 ..................................................................................................................3-183-1总则本章内容应由操作和维修保养人员仔细地阅读,在初开车之前就必须彻底理解压缩机安全和高效操作的有关要求。

目录绪言第一章控制系统的功能1.1基本功能1.2特殊功能1.3安全保护功能1.4可选功能第二章控制系统的组成与安装控制系统的组成控制系统的安装第三章液晶界面操作及参数说明概述键操作说明液晶显示流程图及参数说明窗口及操作说明机房选层操作第四章系统的调试与运行通电前的检查通电和检查系统参数设定慢车试运行井道自学习运行快车试运行电梯舒适感调试平层精度的调整端站安装位置的确定第五章 LED显示说明LED显示定义LED故障说明附件一异步电机控制柜安川616G5、676GL5-JJ变频器参数附件二异步电机控制柜安川G7A变频器参数设置表附件三异步电机控制柜科比(KEB)变频器参数设置表版附件四异步电机控制柜富士G11UD变频器参数设置表附件五故障代码及说明附录六微机板LED故障显示说明绪言SANYO5000-2007电梯控制系统是日本三洋电梯有限公司最新推出的智能化更高、功能更强、调试与维护更方便的高技术产品。

它除了具有一般电梯控制系统的基本功能外,在系统参数设置、电梯功能选择、电梯调试与维护、现场适应能力等各方面有独到之处。

本系统的基本控制方式为串行通讯(CAN总线)与变频调速;可满足电梯楼层64层以下,电梯速度小于4米/秒,包括永磁同步电机在内的各种电梯电机的控制要求。

SANYO5000-2007型电梯电脑控制器的主板、操纵盘板、呼梯板的核心芯片为Philips的32位高速CPU,系统更可靠的高端产品,集成度、可靠性堪称世界一流;软件设计充分体现了功能齐备,参数设置界面层次分明,调试及故障诊断信息充分,抗干扰能力强及干扰强度评价独具匠心的技术特点。

对电梯控制系统以外的电气元件设计了诊断与检测界面。

使电梯故障判断有的放矢,真正使该电梯控制系统做到了高性能与可靠性的完美统一,高水平与实用性的完美统一,高科技与应用简便的完美统一。

三洋电梯(珠海)有限公司是由日本三洋电梯有限公司投资的外商独资企业,此说明书由三洋电梯(珠海)有限公司翻译,并拥有版权。

>8?<B:=.51340,产品样本*-.540,62+/特点轻量紧凑设计高效率高可靠性低噪声低振动C-SC C-SBC-SB系列剖面图C-SC系列剖面图技术参数适用于欧洲和中国的电源制式*1表示该型号压缩机带均油管接口 *2 表示该型号压缩机带油位传感器接口测试条件R22 R407C℉ ℉ 冷凝温度 54.4 130 54.4 130 蒸发温度 7.2 45 7.2 45 液体温度 46.1 115 43.8 115 吸气温度18.365 18.3 65* R407C 的冷凝温度和蒸发温度按中间温度法技术参数适用于北美的电源制式测试条件R22/R410A R407C ℉℉冷凝温度 54.4 130 54.4 130 蒸发温度 7.2 45 7.2 45 液体温度 46.1 115 43.8 115 吸气温度18.36518.365* R407C 的冷凝温度和蒸发温度按中间温度法技术参数适用于日本的电源制式*1表示该型号压缩机带均油管接口*2 表示该型号压缩机带油位传感器接口测试条件R22R407C ℉ ℉冷凝温度 54.4 130 54.4 130 蒸发温度 7.2 45 7.2 45 液体温度 46.1 115 43.8 115 吸气温度 18.3 65 18.365* R407C 的冷凝温度和蒸发温度按中间温度法C-SB系列配线图C-SC系列配线图C-SB系列外形尺寸C-SC系列外形尺寸C-SC603H8HC-SC753H8HC-SC903H8HR22系列使用标准与使用极限*在超出本标准书的范围内进行商品设计时另行商定G表压其他注意事项1.压缩机在开封状态下请勿放置15分钟以上2.请勿压缩空气3.在真空状态下请勿通电4.充入制冷剂后应运转23秒使运动部件充分润滑5.搬运时请勿倾斜和滑落6.请勿划伤保护漆7.作为一条规定生产日期之后12个月内应完成安装8.当第6项压缩机停机时的低限不能保持时需要加装曲轴箱加热器9.运转时各相间的电压偏差应在额定电压的2%以内10.请勿反向旋转11.过滤网应安装在吸气及回油系统侧R407C系列使用标准与使用极限*在超出本标准书的范围内进行商品设计时另行商定G表压其他注意事项1.压缩机在开封状态下请勿放置15分钟以上2.请勿压缩空气3.在真空状态下请勿通电4.搬运时请勿倾斜和滑落5.请勿划伤保护漆6.作为一条规定生产日期之后12个月内应完成安装7.当第6项压缩机停机时的低限不能保持时需要加装曲轴箱加热器8.运转时各相间的电压偏差应在额定电压的2%以内9.请勿反向旋转10.过滤网应安装在吸气及回油系统侧一般事项下列事项适用于大连三洋压缩机有限公司DSA 制造的高温用涡旋压缩机1压缩机外观涂装 压缩机机体表面喷涂成黑色 2 压缩机说明压缩机铭牌包含如下项目压缩机代号 压缩机型号 电源电压频率相数制冷剂名称 所使用的冷冻油的名称及充入量制造日期 制造编号3 记号的使用说明 压缩机代号压缩机型号。

压缩机使用阐明书1.概述2.重要性能参数3.各系统阐明4.主机重要部件和机组辅助设备阐明5.安装阐明6.压缩机拆卸与装配7.压缩机重要装配间隙8.压缩机运转和操作9.压缩机筹划检修10.压缩机常用故障及解决办法11.压缩机油封和启封12.备件清单13.专用工具14.整体导向环热套规程1.概述ZW-64/35型氧气压缩机为立式、四级四列、双作用、水冷却、无润滑、活塞式氧气压缩机。

可用于大中型空分设备和石油化工等其他工业部门。

该机重要特点为:a.构造紧凑、占地面积小、重量轻。

b.动力平衡性好、运转平稳可靠。

c.振动和噪音小。

d.运营经济性好。

e.导向环、活塞环、填料磨损均匀、寿命长。

f.外形美观。

2.重要参数3.各系统阐明请参阅6235LC流程图3.1 气体系统低压氧气,经吸入滤清器过滤,再经各级压缩及冷却后,送入后装置。

详细走向如下:吸入滤清器→一级气缸压缩→一级排气缓冲器→一级换热器→二级吸气缓冲器→二级气缸压缩→二级排气缓冲器→二级换热器→三级进气缓冲器→三级气缸压缩→三级排气缓冲器→三级换热器→四级进气缓冲器→四级气缸压缩→四级排气缓冲器→后续装置。

四级排气缓冲器后设有排气截止阀及放空阀,放空阀为气体紧急放空、吹除及试车用。

3.2冷却系统通往一台压缩机组(主机和各换热器)冷却水来自一根上水总管。

然后由进水总管分七条支管分别连接各级气缸和各换热器进水口。

其中DN50支管三条,分别接到各换热器进水口;DN40支管一条,接油冷却器进水口;DN32支管二条,分别接到一、四级气缸和二、三级进水口;DN15支管一支,接四级填函进水口。

各排水管管径分别与各自相应进水管管径相似,各级排水管上均设有测温装置,各进水管和各排水管用地沟均由顾客依照需要和现场位置自行设计,冷却水管所有采用钢管。

3.3润滑油系统由于导向环、活塞环和填料采用自润滑材料,因而气缸不需要注油润滑,只需润滑其他运动部件,该任务由本机组齿轮油泵来完毕。

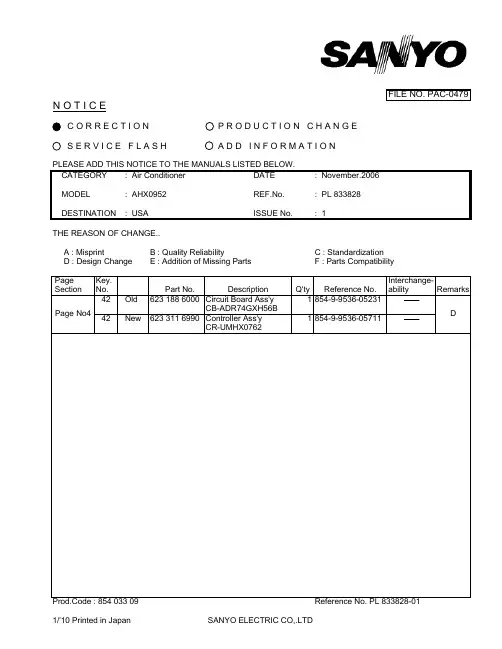

FILE NO. PAC-0479N O T I C EPLEASE ADD THIS NOTICE TO THE MANUALS LISTED BELOW. CATEGORY : Air Conditioner DATE : November.2006 MODEL: AHX0952REF.No. : PL 833828 DESTINATION : USA ISSUE No.: 1THE REASON OF CHANGE.. A : MisprintB : Quality ReliabilityC : StandardizationD : Design ChangeE : Addition of Missing PartsF : Parts CompatibilityParts ListAir Conditioner INDOOR UNITA HX0952Made in JapanR EFERENCE No.PL 833828-01KeyNo.Part No.Description Q'ty Reference No.* 1 623 189 4968 Heat Exch Ass'y 1 854-0-4124-559002 623 175 2213 Strainer Ass'y 1 854-0-4522-29100 * 3 623 175 2251 Solenoid Control Valve UKV-18D31 1 854-2-4548-202004 623 178 3767 Strainer Ass'y 1 854-0-4522-302005 623 189 4951 Capillary Tube 1 854-2-4237-485006 623 189 4944 Capillary Tube 1 854-2-4237-486007 623 189 4937 Capillary Tube 1 854-2-4237-487008 623 189 4920 Capillary Tube 1 854-2-4237-488009 623 201 6352 Cabinet Plate 1 854-2-1105-431H210 623 189 5026 Cabinet Plate 1 854-2-1105-4310111 623 201 6345 Insulation 1 854-2-1413-406H212 623 189 5002 Plate Partition Blower 1 854-2-2505-2690113 623 189 4999 Side Cover Ass'y, Left 1 854-2-1107-761H114 623 189 4982 Side Cover Ass'y, Right 1 854-2-1108-479H115 623 178 3958 Support Fan Motor 2 854-2-2516-3840116 623 189 4975 Support Fan Motor 1 854-2-2516-4060117 623 201 1791 Joint Drain 1 854-2-2334-2021018 623 189 5040 Mounting Plate 2 854-2-1136-2300119 623 000 0735 Eyelet 1 3-9041-0150020 623 171 4891 Hook Plate 4 854-2-1130-2610121 623 201 6369 Packing 4 854-2-1362-32110 * 22 623 175 2206 Magnetic Coil(PMV) UKV-U030E 1 1FA-4-L8A0-30500 * 23 623 171 4877 Thermistor Ass'y(E1) PBC-41E-AS4 1 854-0-5259-64600 * 24 623 176 0157 Thermistor Ass'y(E3) PBC-41E-AS12-1 1 854-0-5259-74100 * 25 623 178 5624 Thermistor(BL) KTEC-35-S103-2 1 1FA-4-V2E0-2700026 623 054 6073 Insulation Tube 1 852-2-4514-2860027 623 081 5254 Insulation, Thermostat 1 854-2-4312-1200028 623 160 8206 Insulation Special 1 854-2-2411-2411029 623 201 6376 Insulation Special 1 854-2-2411-5681030 623 090 0172 Mounting Rubber, Tube 1 854-2-4315-1610031 623 192 9929 Spacer SPRF-10 2 854-2-2349-2170032 623 132 0078 Mounting Thermostat 1 852-2-5303-1920133 623 201 1777 Elec. Wiring Diagram 1 8FA-2-5250-0560034 638 020 7220 Vibration Insulation 1 854-2-2475-1720035 623 189 5095 Mounting Plate,Evaporator 1 854-2-2303-39101 * 36 623 189 5088 Switch Ass'y FS-0218-103 1 8FA-0-5152-02000 * 37 623 201 6390 Motor Pump Ass'y 1 8FA-0-5264-0420038 638 004 9523 Cushion Rubber 3 854-2-2318-1380039 623 171 4778 Clip 1 854-2-2315-1070040 623 201 6383 Cover Plate 1 854-2-2342-857H2 NOTE:Metal and plastic parts will be supplied basicallywith necessary heat insulation pads or packing.Each key number with an asterisk (*) means therecommended service parts.KeyNo.Part No.Description Q'ty Reference No.41 623 189 5118 Elec Component Box Ass'y 1 854-0-5311-04401* 42 623 311 6990 Controller Ass'y CR-UMHX0762 1 854-9-9536-05711 * 43 623 179 0444 Fuse BET5A 1 1FJ-4-S3A0-00500 * 44 623 171 4884 Thermistor Ass'y(TA) KTEC-35-S98 1 854-0-5259-64500 * 45 623 177 7124 Terminal Base HP-T3041-C3E4-S 1 1FA-4-J3A0-2390046 623 192 9912 Spacer SPRH-10 4 854-2-2349-2160047 623 027 4990 Bushing 1 800-2-5337-1790048 623 160 1450 Blower Casing 1 854-2-2506-19210* 49 623 201 6413 Fan Motor DK8-63E280HB 1 1FA-4-M4A0-13400 * 50 623 160 1351 Fan Ass'y 1 854-0-2501-2273051 623 160 1474 Blower Casing 1 854-2-2506-1931052 623 189 5149 Cover Plate 1 854-2-2342-8560153 623 178 3880 Cover,ponent Box 1 854-0-5304-58401* 54 623 201 6406 Drain Pan Ass'y 1 854-0-2301-647H155 623 189 5125 Drain Hose 1 854-2-4297-2090056 623 171 4839 Clip 1 854-2-2315-1080157 623 171 4907 Packing 1 854-2-1362-19500* 58 623 179 1502 P.C.B. Ass'y FIL-XDR94GXH56 1 8FA-0-5178-1940059 623 097 1677 Spacer SPLSN-6 4 851-2-5366-0380060 623 201 6444 Mounting Plate 1 854-2-2362-1680161 623 201 6437 Packing 1 854-2-2370-0110062 623 201 6420 Cover Terminal 1 854-2-5305-21801* 63 638 010 7827 Fuse BET6.3A 1 1FJ-4-S3A0-00600 623 201 1050 Operation Manual 1 854-6-4189-83700 NOTE:Metal and plastic parts will be supplied basicallywith necessary heat insulation pads or packing.Each key number with an asterisk (*) means therecommended service parts.For Parts or Service Assistance please contact your local Sanyo HVAC Contractor or DistributorUnited States: SCS, HVAC Solutions Canada: Sanyo Canada Inc.Web: Web: Parts:********************.comParts/Service:**************.comService:**********************.comJan / '10 Printed in Japan。

Electronics R elated Products GuideAs the need for automation and labor saving increases, the number of small motors, which are key to theirimplementation, is also expected to increase. For the cases that requires high reliability, such as for robots, we can make proposals that are optimized for the operating environment.Electronics SectorDC Motor & Induction MotorMotors consume 50% of the world’s electricity and increased miniaturization, rotation speed, and e ciency are progressing in response to demand for further increases in functionality. With these changes, the adhesives used require heat resistance and high strength.Electronics SectorBrushless-DC MotorSmart phones that are now essential goods for daily living are composed of alot of electronic components and modules and lots of glue.Attachment of a cover panel to a display panel with a UV-curable sheet-likeadhesive enables a screen to be easily watched, and use of a low-temperaturecurable/UV-curable sealant for a case can produce “waterproof and drip-proof”devices.In addition, ThreeBond's sealants and adhesives contribute to making smart phonesand their electronic components and modules thinner and more sophisticated. Electronics SectorSmartphoneby little due to downsizing.ThreeBond's sealants and adhesives can meet all needs.adhesives that cure fast at low temperature are needed to shorten theA lot of adhesives are used for the mechanical components of cameras including a single lens re ex camera. As the design of a camera has been smaller and thinner, UV-LED light source-curable adhesives are needed in order to bond a di erent type of material to another, to reduce the amount of heat applied to materials, and to reduce power consumption in camera manufacturing processes.ThreeBond develops and manufactures adhesives that are the most appropriate to a customer's manufacturing processes and provide such products on a global basis.Electronics SectorDigital CameraDigital CameraPentaprismGlass and resin lensStrobeAF sensorApplication Pentaprism xing Product ThreeBond 3030 SeriesCure conditionUV curingCharacteristics1. High adhesion to resin materials (PC, PPS, etc.)2. Flexible3. Adhesion to di erent materials Application Bonding of lenses Product ThreeBond 3017 Series ThreeBond 3020BCure conditionUV curingCharacteristics1. High strength of adhesion to materials di cult to bond (ole n-based)2. Good surface curability3. Less distortion (TB 3017 Series)Application AF sensor xing Product ThreeBond 1535 Series ThreeBond 3017 SeriesCure conditionMoisture curing / UV curingCharacteristics1. Good impact resistance2. Adhesion to di erent materials3. Shadow-zone curing possible (TB 1535 Series)Application Strobe periphery xing Product ThreeBond 1535 Series ThreeBond 3164DCure conditionMoisture curing / UV curingCharacteristics1. Good impact resistance2. Adhesion to di erent materials3. Shadow-zone curing possible Image sensorApplication Image sensor xing Product ThreeBond 3036 Series ThreeBond 3114 SeriesCure condition UV curing Characteristics1. Low cure shrinkage2. Low linear expansion coe cient3. High adhesive strength Case / Lens mountApplication Waterproof / Dustproof Product ThreeBond 3081 Series ThreeBond 3166Cure condition* CIPG (Cured In Place Gasket)UV curing (CIPG)Characteristics1. Low compression permanent distortion2. Flexibility3. Reworkable Application Heat dissipation Product ThreeBond 1225 Series ThreeBond 2955 SeriesCure conditionMoisture curingCharacteristics1. High thermal conductivity (1.59 to 4.8W/m•K)2. Low outgassing (TB 2955 Series)3. Low molecular weight cyclic siloxane reduced product Image stabilizer unitApplication Vibration absorption Product ThreeBond 3168ECure conditionUV curingCharacteristics1. High and low temperature resistance2. Soft gel3. Vibration absorbability * ThreeBond is abbreviated to TB.In recent years, increasing awareness of global security has been accompanied by spreading adoption of surveillance cameras as a deterrent to crime and terrorism.For many years, our UV-curable resin has contributed to security cameras, mainly to the adhesive application for optical parts.Increasing numbers of pixels in recent years have brought an increasing need for “thermal conductivity” as protection against overheating, and for “Sealants” as waterproo ng and protection from insects.Electronics SectorSurveillance Cameraconferences as telework becomes more prevalent, so production levels areincreasing signi cantly. Furthermore, as earphones become more expensive,consumers expect them to last longer, so adhesives must improve productivitythrough “fast curing” and high reliability with a focus on “impact resistance”.Wireless Earphone As automation advances as a substitute for the ve senses of humanbeings, adoption of these devices is expected to further increase. AtThreeBond, we propose the optimal products for sensors and MEMSdevices that require high reliability.Sensor / MEMS DeviceStations for 5G communication are starting to be set up everywhere, evenoutdoors, so adhesives must be incredibly reliable to ensure operationcontinues despite weather conditions. Our lineup includes case sealants,thermally conductive materials used to protect electronic substrates fromheat and more.Electronics Sector5G Base Station The spread of 5G communications has greatly increased the amountof data ying around the world. As for optical transceivers needed forhigh-speed communications, we have a wide range of products,mainly UV resins and heat-conducting materials for parts requiringprecision xation.Electronics SectorOptical TransceiverViscosity comparison[Cyanoacrylate Adhesives]Viscosity comparison[UV Curing Resins]Viscosity comparison[Epoxy resin] Electronics SectorProduct map by viscosity / hardnessWatch our video to see viscosity imagesElectronics SectorAdhesive selection table by materialApplication Equipmentas the equipment to apply and pressure feed them to maximize their performance.As a manufacturer with full knowledge of sealants and adhesives, ThreeBond enables to reduce cost and improve developing such equipment.To provide further added value for customers, ThreeBond has been making e orts to develop and sell the equipment that incorporates new application and pressure feeding technologies.Tank for 250g/1kg bottle or can (TG1-T)Dispense valve (HPNV-50)Pressure feed controller (coater S4)Small capacity precision type ofManual application cartridge pump (ACB-20)Pump for pails (PBIII)+Constant-velocity discharge head ( xed-quantity booster)Air gun for sealant- Lineup of products for improvement of productivity and workability - The RTM and RTM-H Series enable products that meet customer requirements to be designed and manufactured.- A lineup of devices that can handle small-amount and large-amount sealants and adhesives is available.- They are suitable for the bead application of solvent-volatilization-type and moisture-curable-type liquid gaskets.- Dispensers that can apply a xed quantity of a sealant and an adhesive without waste are available.- A unit that can reduce the amount of a remaining liquid agent in a pail is available as an option. (Some conditions must be met.)* ACB...Automatic Cartridge Booster * PCB...Power Cartridge Booster * RTM...Rotary Transfer Motor* RTA-H...Rotary Transfer Air-motor by HandApplicationTB1100, TB1300 seriesSingle-component xed-quantity booster ( xed-quantity booster) Application Equipment Sector- Lineup of products for improvement of productivity and workability - Applicators suitable to a wide range of adhesives, such as solvent-volatilization type, moisture-curable type, and aqueous pressure-sensitive type, can be selected.- Application of an instantaneous adhesive that is di cult to handle is automated, which enables a work environmentand application quality to be improved.* LVCT-AC...Low Viscosity Cartridge Tank - Automatic Connection * HPNV-50...Pressure Needle Valve - Type 50* DPB-40...Diaphragm Power Booster* TDV...Triple Diaphragm ValveApplicationTB1500 seriesCartridge-type tank (TC2)Dispensing valve (HPNV-50)Controller for pressure (coater S4)Desktop robot (RT7 Series) Application Equipment Sector- Lineup of products for improvement of productivity and workability - Applicators are available for each of the single-component type and the two-component type.- The two-component type can be set, according to a mixing ratio.* CIPG...Cured in Place GasketSingle-acting pump for pails (PBIII-45)This is a high-pressure feeding pump for automatic application. When it isApplication Equipment Sector- UV-curing type, anaerobic-curing type, and moisture-curing type Applicators for each of the above types are available.- Auxiliary equipment needed for the process from application to curing is available.- Equipment suitable for CIPG application (design of a special-purpose machine)Cartridge-type tank (TC2)Dispensing valve (HPNV-50)Controller for pressure (coater S4)Desktop robot (RT7 Series)Application Equipment SectorAK2022035 22 • 11 • SK。

注意:1.未经三洋书面许可,不得以任何形式复制本手册的任何部分。

2.本手册的内容如有变更,恕不另行通知。

3.本手册如有任何不清楚之处或任何错误、遗漏之处,请与三洋联系。

SANYO Electric Biomedical Co.,Ltd.版权所有日本付印目录安全操作预防措施P. 2使用注意事项P. 6环境条件P. 7保存箱部件P. 8 控制面板和键盘P.10 安装安装场所P.11安装P.12 选购件温度记录仪P.13辅助冷却装置P.15独立内门P.15保存架P.16 启动设备P.17温度设定保存室温度P.18键锁定功能P.18报警温度设定P.19 报警和安全功能P.20报警自动恢复时间设置P.21远距离报警端子P.22设备状态监视P.23压缩机延时启动时间更改P.24门报警延时时间更改P.25日常保养清洁保存箱P.26清洗冷凝器过滤网P.26内壁除霜P.27更换电池P.27 故障排除P.28设备报废处理P.28充电电池回收P.29规格P.30性能P.32安全检查单P.33本手册包括有重要的安全规定,请用户务必遵照执行。

这里所介绍的事项和规程旨在使你能正确安全地使用本设备。

如果遵照执行此处所述的预防措施,则将使用户和任何其他人免于可能发生的伤害。

“警告”和“注意”示意如下:^警告如没有遵守警告标志下的事项,则有可能给人员带来危险,引发严重伤害或死亡事故。

△注意如没有遵守注意标志下的事项,则有可能引起人员受伤和造成设备损坏及相关财产损失。

以下为标识的含意:△该标识指注意。

Q该标识指禁止。

■该标识指务必遵守的规定。

务必将本手册保存在本设备用户方便取用的地方。

<设备上的标签〉此标识被标注于高电压的电器罩盖上,用来防止触电意外的发生。

△△ 此电器罩盖只能由合格的工程师或维修服务人员移开。

公警告任何使用CO2气体的设备,在它的周围都有氧气耗尽的可能。

因此请事先确认工作场地的周围有没有良好的通风环境。

如果通风受到限制,则必须考虑采取其它的方法确保有一个安全的工作环境,这可能包含了空气监测和警告设备。

中间补气涡旋压缩机使用手册 大连三洋压缩机有限公司1. 技术背景......................................................................................32. 压缩机命名规则..........................................................................33. 系统运行流程..............................................................................44. 压缩机运行范围..........................................................................55. 配套附件清单..............................................................................71. 技术背景普通涡旋压缩机在低蒸发温度下运行时,会发生吸气比容增大、压比升高,排气温度快速升高等问题,造成压缩机性能急剧下降和制热量不足以及难以运行,为解决这一问题,开发了带有中间补气功能的涡旋压缩机。

中间补气涡旋压缩机即在压缩机压缩中间腔补充中压气体,增加排气量,降低排气温度,提升制热能力,使热泵空调器在低环境温度也能提供足够的制热能力。

同时,补气通道的开启和关闭可以做为一种容量卸载调节的辅助手段。

2. 压缩机命名规则在涡旋压缩机的设计开发、改进工作中,需要对新的压缩机型号命名。

为了规范压缩机型号命名,本公司制定了压缩机命名规则。

此规则适用于由大连三洋压缩机有限公司(DSA)涡旋工厂所设计、开发、改进的涡旋压缩机型号命名。

补气涡旋压缩机命名规则如下(补气压缩机系列代号见表1):C - SB R 120 H 38 Q1 2 3 4 5 61—— 涡旋B系列压缩机2—— 标准R22机型3—— 公称冷冻能力= 60Hz 公称冷冻能力(W)/ 1004—— 用途:高温用5—— 电制:三相B8 50Hz 380,415V / 60Hz 440,460V6—— 开发代号:补气系列表1 补气压缩机系列代号马力/HP 型号3.5 C-SBR120H38Q4 C-SBR145H38Q5 C-SBR180H38Q8 C-SCR295H38Q10 C-SCR370H38Q3.系统运行流程压缩机图1 压缩机设计系统运行流程图该设计系统的运行流程如图1所示,压缩机排出的高温、高压制冷剂气体,经冷凝器将热量传递给载热介质后变为液体,从冷凝器出来的高压制冷剂液体经储液器,通过干燥过滤器、视液镜后分为两路,主路的制冷剂液体直接进入经济器内,辅路的制冷剂液体先经过一个电磁阀,再经过膨胀阀节流降压后变为气液混合物后也进入经济器内,二者在经济器中产生热交换,辅路的制冷剂液体吸热后变为气体后被压缩机的辅助进气口吸入,主路的制冷剂放热变为过冷液体经膨胀阀节流降压后进入蒸发器。

第五章DF-G系列常用数据说明页次表5-1 DF-G系列技术参数.............................................................................................................. 5-1表5-2DF-G系列零部件尺寸........................................................................................................ 5-2表5-3DF-G系列零部件材料........................................................................................................ 5-2表5-4DF-G系列运行参数............................................................................................................ 5-2表5-5 DF-G系列机身润滑油规格................................................................................................ 5-3表5-6标准扭矩表............................................................................................................................... 5-5表5-7扭矩扳手值............................................................................................................................... 5-5表5-8液压上紧值............................................................................................................................... 5-6表5-9DF-G装配间隙..................................................................................................................... 5-6表5-10气缸镜面磨损量..................................................................................................................... 5-7表5-11镜面/缸套表面粗糙度............................................................................................................ 5-7表5-12最大允许活塞环侧隙............................................................................................................. 5-8表5-13最大允许活塞环端开口值..................................................................................................... 5-8表5-14最大允许活塞杆磨损............................................................................................................. 5-8表5-15最大允许活塞杆锥度............................................................................................................. 5-9表5-16最大允许活塞杆不圆度......................................................................................................... 5-9表5-17密封环/刮油环侧隙................................................................................................................ 5-9表 5-18 公制螺纹标准扭矩表……………………………………………………………………5-10表5-1 DF-G系列技术参数注1:额定功率随气缸结构、操作工况以及负荷最大气缸在曲轴上某一拐设置的位置而变化,因而对于给定的压缩机其在特定的工况下许可的功率既可能高于也可能低于额定功率。