动态热机械分析仪 - 梅特勒-托利多中国 METTLER …

- 格式:pdf

- 大小:2.14 MB

- 文档页数:14

梅特勒热机械分析仪安全操作及保养规程1. 引言梅特勒热机械分析仪是一种常用的实验室仪器,可用于热分析实验和材料性能测试。

为了确保仪器的正常运行和使用者的安全,本文将介绍梅特勒热机械分析仪的安全操作要点及保养规程,以便用户正确操作和维护该仪器。

2. 安全操作规程2.1 仪器准备在使用梅特勒热机械分析仪之前,确保以下准备工作已完成:•检查电源线和连接线是否正常。

•检查仪器表面是否干净,没有异物。

•确保安全设备(如紧急停止开关)正常运作。

2.2 启动和关闭仪器在启动和关闭梅特勒热机械分析仪时,请按照以下步骤进行操作:1.在接通电源之前,确保所有仪器连接和设备处于关闭状态。

2.检查仪器的各项指示灯,确保没有异常。

3.打开电源开关,等待仪器启动。

4.检查仪器的温度和时间显示是否正常。

5.在使用结束后,先关闭仪器内部加热装置,然后才关闭电源开关。

2.3 操作注意事项使用梅特勒热机械分析仪时,需注意以下事项:•在操作过程中,不要将手指或其他物体放入仪器内部,以免发生意外。

•不要在仪器正在工作时进行操作和维护,以免烫伤或触电。

•严禁改动仪器的内部线路或构造,以免影响测量准确性和安全性。

•使用合适的容器和工具,避免液体或固体溅出或破碎。

•注意避免与仪器的排烟口靠近,以免烟雾或有害气体吸入。

2.4 紧急情况处理在发生紧急情况时,如发生火灾或电气故障,应立即采取以下措施:1.立即关闭电源开关,切断电源供应。

2.使用灭火器材或其他灭火工具扑灭火灾。

若火势无法控制,请迅速报警并撤离现场。

3. 保养规程为了确保仪器的正常运行和使用寿命,以下是一些梅特勒热机械分析仪的保养规程:3.1 日常保养•定期清洁仪器表面,并注意避免使用腐蚀性或磨损性的清洁剂。

•检查仪器连接线是否牢固,如有松动及时紧固。

•定期对仪器进行校准和调整,保持测量的准确性。

•定期更换仪器的滤芯和滤纸,保持仪器内部的清洁。

3.2 长期保养•若仪器长时间不使用,请断开电源并进行防尘处理。

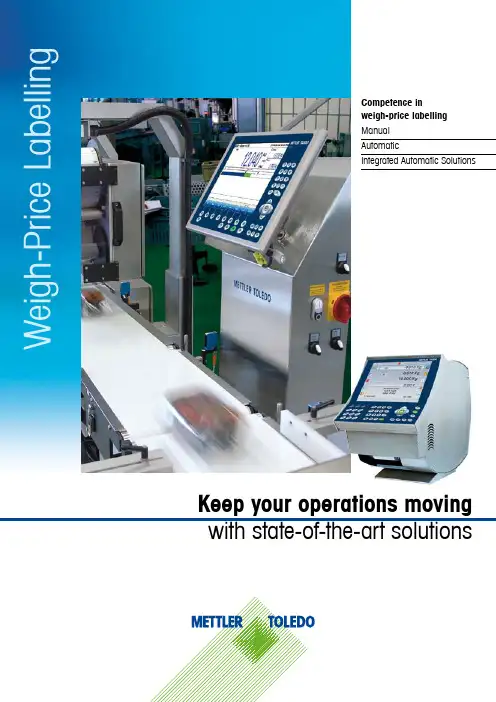

W e i g h -P r i c e L a b e l l i n gCompetence inweigh-price labelling Manual AutomaticIntegrated Automatic SolutionsKeep your operations moving with state-of-the-art solutions2O u r e x p e r t i s e f o r y o u r p e a c e o f m i n dProduct InspectionMetal detection, rejectstations, and bar code verification are standard METTLER TOLEDO solutions.Reliable weighingMETTLER TOLEDO is the world leader in industrial weighing. The millions of installed static and dynamic scales assure the right weight every time.Industrial terminalsFrom the simplest display, to complicated SQC calcula-tions and graphs, there is a METTLER TOLEDO terminal that fits the application.Rugged labellersPrinters with label applicators designed for ease of use, yet stand up under stress, keep downtime to a minimum.Application software Weigh-price labelling and other application software are second nature to METTLER TOLEDO.ETICA 7400All-in-one, manual weigh-price labeller with application, and printer. Choose the right METTLER TOLEDO scale platform to fit the operation.PAS 3008/3012Premium automatic weigh-price labelling at its finest. PAS fits most advanced operational requirements.METTLER TOLEDOYour requirements make our productsCompetence in weigh-price labelling Rely on our expertise3Choose the most cost effectiveMETTLER TOLEDO weighing platform.Large label rolls, robust yet simplemechanical parts, and a uniquelabel control system ensure the rightlabel keeps coming.For traceability, Etica has an optionalhandheld barcode reader supplyinginformation from most standardbarcode types.Cut processing times, eliminatecostly mistakes, and reduce opera-tor training with the ETICA intuitiveuser interface.Innumerable featuresOn screen label design, ingredient,label and text libraries, order andcustomer management, are only afew of the endless functions in theETICA product line. Yet whilst thereare many functions, the simplescreen layout, instinctive icons, andonly essential information, lead theuser through the weigh-price label-ling operations faultlessly.Unique graphic interface"Intuitive" icons and menus, com-bined with a large touchscreenmake operators more effective anddecrease registration errors. TheETICA line comes with the 10.4"colour touch screen, with an addi-tional keypad for fast entry of com-plicated operations.The 7000 provides all the ETICAfunctionality, without a printer.Connect a separate printerto meet special printing needs.Manual labellingSimple yet industrialETICAweigh-pricelabellersThe 7400 has a built in robustprinter to provide all the ETICAweigh-price labeling function-alities in one package.4The ETICA automatics decreaseproduction time by combining theETICA functionality with a simpleconveying, weighing and labellingsystem. The all stainless steel con-struction, innovative item guidancesystem, and A4 Gyro printer, makefor a superior automatic solution ata reasonable price. The automaticscan label 80m m wide labels up to50p cs per minute meeting mostcurrent weigh-price labellingrequirements.The ETICA automatic line, like themanual units, have a 10.4" colourtouch screen and can be deliveredin 3 and 4 belt versions, addingmore article handling control to thesystem.The ETICA automatics have thesame "intuitive" graphical user inter-face as the manual units, so opera-tors can easily focus on their tasks,keep ing your operations moving. The ETICA Line,rugged stain-less steel forindustrial use.The revolution-ary A4 Gyroprinter placeslabels in anylocation ororientation.Automatic solutionsAll the essentials and moreThe same ETICA intuitivegraphic interface is availableon the automatics as well ason the manuals.The item guidance system(skewed conveyors) andA4 Gyro printer make thechanging of items just afew key strokes on anETICA automatic.5Reduce labor costs and increase operational efficiency through inte-gration and automation of the PAS series. Labeling speeds can exceed 90 pcs/min (depending on label content and size). Top and bottom as well as multiple labels, reject, metal detection and checkweighing options, the PAS line can cover your weigh-price labelling and product inspection needs.Clear, specific operational informa-tion maintains uptime and reduces costly operational errors. Run yourown order or article management system right on the PAS unit, exchanging data with the weigh-price labelling functions of the PAS.For operations where high speed is not required, but product inspection and integration are, choose the more economical PAS 3008.Integrated automatic operations Meeting demanding requirementsHigh speed, multiple top and bottom labels are routine for the PAS product line.Ensure your quality through metal detection, barcode verifi- cation and SQC validation software (METTLER TOLEDO ®).Simple and fast label handling and roll exchange are char-acteristic of all the METTLER TOLEDO weigh-price labellers.P A S w e i g h -p r i c e l a b e l l i n g s y s t e ms6Multiple level contractsPlatinum, Gold and Silver level packages offer fixed benefits.Alternatively, design the package to suit your specific needs with our tailored service packages.Service XXLDesigned to meet your needsField based local engineer network The most comprehensive network of field based technicians and engineers for rapid local service.• Comprehensive technical support from field based engineers• Consistent service for APPROVED weigh-price labelling applications • Full product repair and spare parts service • Tailored agreements to meet your needs • Equipment performance verification audits • Technical help deskGenuine spares at your disposal METTLER TOLEDO high-quality spare parts and customised spare part kits available for express despatch.Equipment installation and per-formance verification packages Maximise the performance of your equipment from day one with our unique installation, commissioning and regular audit packages.Modular training programmesMaximising the benefits of your invest-ment by the development of operator skills, with bespoke training courses to suit all skill levels.7Weigh-price labelling is a combi- nation of many technologies: weigh- ing, printing and applying a label, user interface and product handling. All systems need to be intuitive and simple to operate. High speed auto- matic systems must weigh, price, print and apply a label in milli- seconds. Flexible solutions are the only way to fit operations and meet customer requirements.METTLER TOLEDO offers two lines of weigh-price labellers that meet the wide variety of applications and give excellent return on investment. ETICA, with its intuitive human ma-chine interface, fits perfectly in ope-rations that are manually intensive. METTLER TOLEDO weigh platforms and extra printers can be added to uniquely fulfil the installation.Flexible solutions Exceeding expectationsThe ETICA automatics have all the functionality to solve straightforward automated weigh-price labelling applications perfectly.The PAS line handles high speed labelling, multiple labels, complex larger labels, as well as options such as metal detection, reject sta-tions or barcode verification. The PAS line fits the larger more-techni-cally advanced enterprise.Both lines connect easily to host data systems, communicating essential information such as weights, articlenumbers, and expiration date.METTLER TOLEDO has the flexibility to meet your expectations.ETICA 7400 manualETICA 7430G automaticPAS 3012 automatic solutionFor more informationMTSI 44099299Subject to technical changes© Mettler-Toledo Garvens GmbH, D-31180 GiesenPrinted in Switzerland 1207Certifiedas per ISO 9001"Conformité Européenne"compliance with applicableindustry standards For all other countries: Mettler-Toledo AGPO Box VI-400, Greifensee, SwitzerlandTel. +41-44-944 22 11, Fax +41-44-944 31 70Mettler-Toledo AG8606 Greifensee, SwitzerlandTel. +41-44-944 22 11Fax +41-44-944 30 60N.V. Mettler-Toledo S.A., Leuvensesteenweg, 384, 1932 ZaventemTel.: (02) 334 02 11, Fax: (02) 334 03 34Mettler-Toledo spol, s.r.o., Trebohosticka 2283 / 2, 100 00 Praha 10Tel.:272123150,Fax:272123170,E-mail:*****************Mettler-Toledo A / S, Naverland 8, 2600 GlostrupTel.:(43)270800,Fax:(43)270828,E-mail:*****************Mettler-Toledo GmbH, Ockerweg 3, 35353 GießenTel.:(0641)5070,Fax:(0641)52951,E-mail:************************Mettler-Toledo S.A.E., C/Miguel Hernandez 69-71, 08908 Hospitalet De Llobregat BarcelonaTel.: (93) 223 76 00, Fax: (93) 223 76 01Mettler-Toledo S.A., 18/20 avenue de la Pépinière, 78220 ViroflayTel.:(01)30971717,Fax:(01)30971616,E-mail:****************Mettler Toledo, d.o.c, Mandlova 3, 10000 ZagrebTel.: 01 29 58 633, Fax: 01 29 58 140Mettler-Toledo S.p.A., Via Vialba 42, 20026 Novate MilaneseTel.:(02)333321,Fax:(02)3562973,E-mail:***********************Mettler-Toledo Kereskedelmi KFT, Teve u. 41, 1139 BudapestTel.:(01)2884040,Fax:(01)2884050,E-mail:****************Mettler-Toledo B.V., Franklinstraat 5, 4004 JK TielTel.:(0344)638363,Fax:(0344)638390,E-mail:*****************Mettler-Toledo A/S, Prof. Birkelandsvej 24c, 1008 Oslo,Tel.:22304490,Fax:22327002,E-mail:***************Mettler-Toledo Gesellschaft m.b.H., Südrandstr.17, 1230 WienTel.:(01)6041980,Fax:(01)6042880,E-mail:*******************************Mettler-Toledo Sp.z.o.o., Ul. Poleczki 21, 02-822 WarszawaTel.:(22)5450680,Fax:(22)5450688,E-mail:*************Mettler-Toledo Vostok, Sretensky Blv., 6 / 1 Office 6, 101000 MoskvaTel.:(095)9216812,Fax:(095)9216353,E-mail:**************Mettler-Toledo (Schweiz) GmbH, Im Langacher, 8606 GreifenseeTel.:(044)9444545,Fax:(044)9444510,E-mail:*******************Mettler-Toledo AB, Virkesvägen 10, Box 92161, 12008 StockholmTel.:(08)7025000,Fax:(08)6424562,E-mail:**************Mettler-Toledo spol, s.r.o., Hattalova 12 / A, 83103 BratislavaTel.:(2)44441220-2,Fax:(2)44441223,E-mail:*************Mettler-Toledo d.o.o., IOC Trzin, Peske 12, 1236 TrzinTel.: (01) 562 18 01, Fax: (01) 562 17 89Mettler-Toledo Ltd., 64 Boston Road, Beaumont Leys, Leicester, LE4 1 AWTel.:(0116)2350888,Fax:(0116)2365500,E-mail:*******************BelgieCeská RepublikaDanmarkDeutschlandEspañaFranceHrvatskaItaliaMagyar KöztársaságNederlandNorgeÖsterreichPolskaSchweizSverigeSlovenskoSlovenijaUnited Kingdom。

动态热机械分析仪动态热机械分析仪简介动态热机械分析仪是一种用于研究材料的物理特性和性能的分析工具。

它采用了动态机械载荷和热量加热的方法,通过监测样品在不同温度和应力条件下的热力学响应,来研究材料的热膨胀、热导性、热变形和热分解等特性。

动态热机械分析仪广泛应用于塑料、高分子材料、陶瓷、金属、复合材料等领域的材料研究和生产过程中。

动态热机械分析仪的工作原理动态热机械分析仪通过施加动态载荷和热量加热来模拟材料在实际使用条件下的力学和热学环境。

它由一个电炉、一个机械载荷系统和一个检测系统构成。

在实验中,样品被夹在两个机械夹具之间,然后施加动态载荷和恒定温度。

在载荷作用下,样品会发生热膨胀和热变形,通过检测样品的力学和热学响应,可以获得材料的热力学性质。

动态热机械分析仪的应用动态热机械分析仪可以用于研究材料的热膨胀性能。

材料的热膨胀是指随着温度的升高或降低,材料的体积发生变化的现象。

热膨胀性能对于很多工程应用来说是非常重要的,比如在航空航天、电子器件和建筑结构等领域。

通过动态热机械分析仪,可以测量材料在不同温度下的热膨胀系数,并进一步研究其与温度之间的关系。

此外,动态热机械分析仪还可以用于研究材料的热导性能。

热导性是指材料传导热量的性能,它与材料的导热系数和温度梯度有关。

测量材料的热导性能对于研究材料的导热机制和改善热耗散效果非常重要。

通过动态热机械分析仪,可以测量材料在不同温度下的热导率,并进一步研究其与温度和材料结构之间的关系。

此外,动态热机械分析仪还可以用于研究材料的热变形性能。

材料的热变形是指在高温下受力作用下的变形行为。

研究材料的热变形性能对于设计和制造高温工作环境下的零部件和结构件非常重要。

通过动态热机械分析仪,可以测量材料在不同应力和温度条件下的热变形行为,并进一步研究其与材料的晶体结构和成分之间的关系。

此外,动态热机械分析仪还可以用于研究材料的热分解性能。

材料的热分解是指在高温下分解为不同组分的过程。

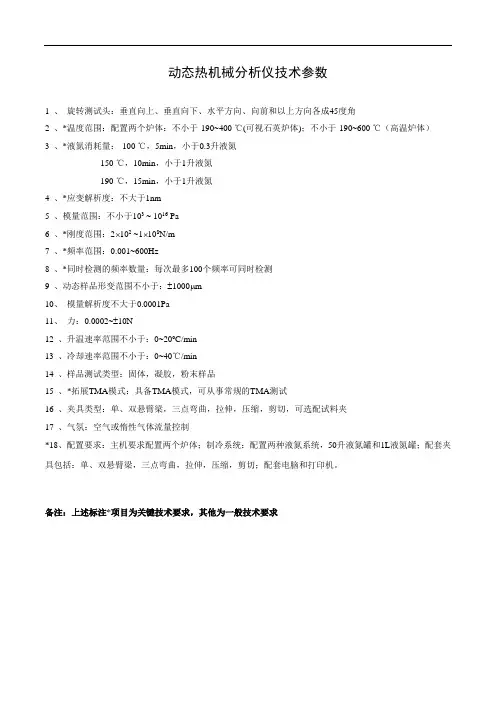

动态热机械分析仪技术参数

1 、旋转测试头:垂直向上、垂直向下、水平方向、向前和以上方向各成45度角

2 、*温度范围:配置两个炉体:不小于-190~400 ℃(可视石英炉体);不小于-190~600 ℃(高温炉体)

3 、*液氮消耗量:-100 ℃,5min,小于0.3升液氮

-150 ℃,10min,小于1升液氮

-190 ℃,15min,小于1升液氮

4 、*应变解析度:不大于1nm

5 、模量范围:不小于103 ~ 101

6 Pa

6 、*刚度范围:2⨯102 ~1⨯108N/m

7 、*频率范围:0.001~600Hz

8 、*同时检测的频率数量:每次最多100个频率可同时检测

9 、动态样品形变范围不小于:±1000μm

10、模量解析度不大于0.0001Pa

11、力:0.0002~±10N

12 、升温速率范围不小于:0~20o C/min

13 、冷却速率范围不小于:0~40℃/min

14 、样品测试类型:固体,凝胶,粉末样品

15 、*拓展TMA模式:具备TMA模式,可从事常规的TMA测试

16 、夹具类型:单、双悬臂梁,三点弯曲,拉伸,压缩,剪切,可选配试料夹

17 、气氛:空气或惰性气体流量控制

*18、配置要求:主机要求配置两个炉体;制冷系统:配置两种液氮系统,50升液氮罐和1L液氮罐;配套夹具包括:单、双悬臂梁,三点弯曲,拉伸,压缩,剪切;配套电脑和打印机。

备注:上述标注*项目为关键技术要求,其他为一般技术要求。

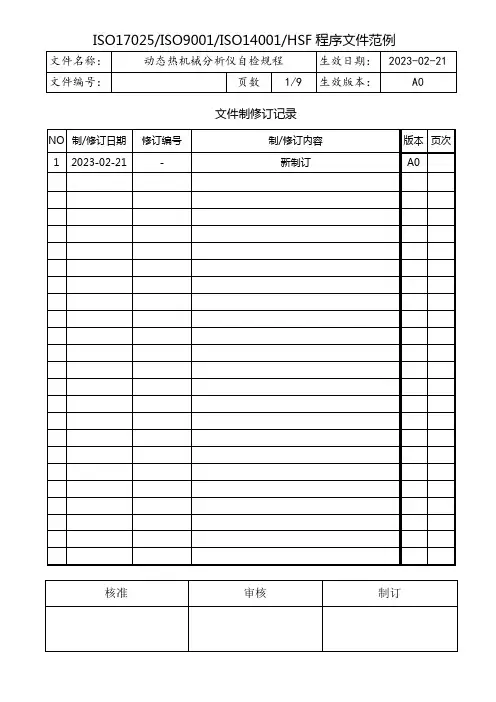

文件制修订记录1 前言本规程参考玻璃化转变温度测试国际标准ASTM E1640-18、温度校准国际标准ASTM E1867-2018、储能模量校准国际标准ASTM E2254-2018和损耗模量校准国际标准ASTM E2425-16与美国沃特世公司DMA Q800仪器操作说明书编写。

2 范围动态热机械分析仪(以下简称DMA)是研究材料在周期振动应力下,随温度或频率变化的力学性能和粘弹性能的仪器。

适用于热塑性聚合物、热固性聚合物和在玻璃化转变区间热稳定的部分结晶材料。

适用于温度范围为RT~300 o C,材料的弹性模量范围为1 MPa~1000 GPa,单悬臂夹具测试。

本规程适用于新安装、使用中和维修后的动态热机械分析仪的检定。

2.1 原理DMA是用来测量各种材料宽范围内的力学性质。

包括聚合物,其行为特征既像弹性固体又像粘性液体,因此具有粘弹性。

DMA在两个重要方面不同于其它的力学测试方法:第一,传统的拉伸测试设备仅关注弹性组份。

而在许多应用中,非弹性或粘性的组份是十分关键的。

第二,拉伸测试设备主要在材料的线性粘弹范围外进行测试。

而DMA主要在材料的线性粘弹区进行测试,因此DMA对材料的结构更加敏感。

DMA可通过瞬态实验或动态实验测定材料的粘弹性。

最常用的测试是动态振荡测试,在程序控温和频率等控制下,对材料施加正弦变化的应力(或应变),测量产生的正弦应变(或应力)响应。

同时也测量两个正弦波相位的偏移。

对于完全弹性的材料,相位角为0 o(图1a);而对于完全粘性的材料,相位角的偏移为90 o(图1b)。

粘弹性材料的相位角则居于二者之间,如图1c所示。

如图1d所示,模量的定义为应力/应变,由此计算复合模量E*,根据E*和测得的δ,可计算储能模量和损耗模量,如式(1)所示。

E´为储能模量是材料的弹性组份,与样品的刚度有关;E´´为损耗模量是材料的粘性组份,与样品分子运动中机械性能的弥散程度有关;Tan δ是储能模量与损耗模量的比值,它提供了弹性组份与粘性组份之间关系的信息。

梅特勒-托利多仪器(上海)梅特勒-托利多( 常州)称重设备系统部门:中国区市场运作中心 虞琼燕、黄丽丽 项 青目录第一章SI&P 产品知识 (3)1.1平台秤 (3)1.2台秤 ......................................................................................... 错误!未定义书签。

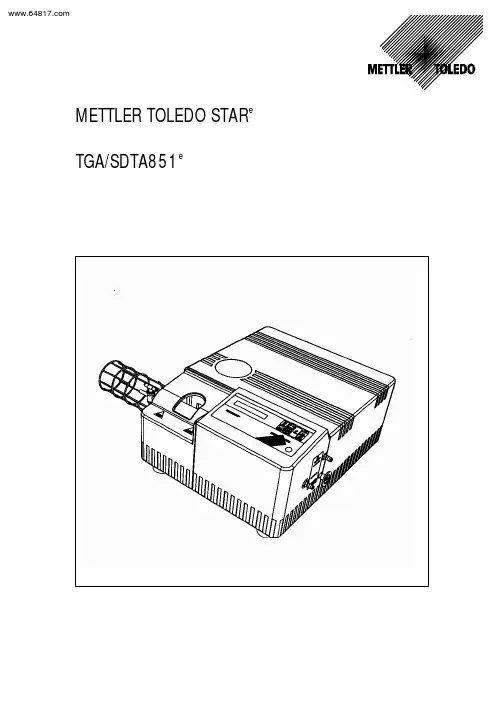

1.3计数秤 (8)1.4吊钩秤 (9)1.5仪表 (11)1.6传感器 (17)1.7模块 (22)1.8物流产品 (25)第二章VEH产品知识 (25)2.1汽车衡 (25)2.2轨道衡 (29)2.3轴重秤 (32)2.4车载称重系统 (33)第三章RET产品知识 (35)3.1条码秤 (35)3.2计重秤 (37)3.3收银秤 (38)3.4计价秤 (42)第四章SSBU产品知识 (42)4.1产品分类 (42)4.2行业细分 (42)4.3竞争对手 (43)4.4产品介绍 (43)第五章PI产品知识 (49)5.1自动检重秤(又称自动分选秤/动态秤) (49)5.2金属检测机(金属探测仪,金属探测器,金探仪) (50)5.3X射线影像检测系统 (51)第六章LAB产品知识 (51)6.1天平 (51)6.2卤素水份仪 (53)第七章ANA产品知识 (54)7.1全自动电位滴定仪 (54)7.2卡尔费休水分滴定仪 (55)7.3 P H/电导率仪 (56)7.4密度/折光率仪 (57)第八章过程检测 (58)8.1过程检测(I NGOLD产品、T HORNTON产品) (58)第九章TA热分析 (60)9.1热值分析系统 (60)9.2STAR E热分析系统 (61)第十章AC自动化化学 (62)10.1全自动反应器/反应量热器 (62)10.2在线红外分析系统 (63)第一章SI&P 产品知识1.1 平台秤台面较小、吨位较小,直接在地面上对物体称重的秤。

News实验室称量及分析2机械塑料及电子使用 DSC 分析橡胶弹性体材料为了确保最合适的材料被选用,需要测量一些重要特性,其中包括:■ 机械强度和弹性■ 热稳定性■ 填料组分■ 添加剂和媒介■ 硫化和固化反应图 1(下页)中的示例显示了如何根据简单的 DSC 测量确定各种商用密封圈的最低可使用温度。

某种材料的最低使用温度由其玻璃化温度确定。

因此,玻璃化温度可视为定义材料最低可用温度的一个特征值。

橡胶材料的稳定性、适应性和使用寿命对于汽车部件的开发、质量控制和生产来说非常重要。

一些很常见的人造橡胶汽车部件有密封条、O 型圈和风挡水刮叶片。

下面两个例子证明了如何使用差示扫描量热仪 DSC 表征橡胶,以及如何用于观察其固化反应。

通过 DSC 进行汽车部件开发在氮气气氛下,将四个由不同人造橡胶材料制成的密封圈样品以10K /m i n 的速度从 –100 °C 加热到了 25 °C 。

样品 B 、C 和 D 的 D S C 曲线显示它们的玻璃化温度分别为 –38.3 °C 、–25.7 °C 和 –17.1 °C 。

样品 A 在该测量温度范围内未表现出玻璃化转变。

但是,出现在 –70 °C 到 –40 °C 之间的熔融峰表明,结晶会限制该样品的应用。

图 2 中的示例说明了如何使用 D S C 1 来观察一种由两种组分组成的树脂的固化过程。

该过程是使用高级动力学模型公式 (AMFK) 进行的。

作为转换函数之一,该反应的活化能量计算要在不同的加热速度下至少执行三个动态测量。

D S C因此,固化度可以作为某一温度的时间函数进行评估,例如在 42 °C 时(表和右下角的红色曲线)。

为了检验动力学预测,首先在 42 °C 下将样品固化不同的时间。

然后使用 DSC 1 进行后固化测量,以测定先前的固化度(标记为蓝色)。

红色曲线和蓝色曲线之间的差异表明,即使经过了 36 个小时,该样品仍然尚未完全固化(玻璃化)。