斯伦贝谢分段压裂技术

- 格式:pdf

- 大小:114.73 KB

- 文档页数:2

固井滑套分段压裂工艺简介1.固井滑套分段压裂简介该工艺技术是贝壳休斯公司在固井技术的基础上结合了开关式固井滑套而形成的多层分段压裂完井技术。

该技术利用可开关式固井滑套选择性的放置在油层位置,固井完成后,利用钻杆,油管或连续油管代开关工具将滑套打开,然后用同一趟管柱进行压裂作业。

该压裂完井体系可根据油藏产层情况,选择多个CM滑套,实现多层压裂投产或选择性压裂开采。

该完井体系中CM系列滑套内外表面进行了特殊镀层处理,保证了工具开关性能。

该技术可应用到任何利用压裂措施投产的井。

另外,根据以后生产的需要还可以调整油藏层间矛盾。

提高油藏的利用率。

2.作业步骤1)根据油藏产层情况,确定各CM滑套位置;2)按照确定的深度将滑套和套管管柱一趟下入井内,然后进行常规固井;3)下入压裂和滑套开关服务工具,有选择性地打开滑套进行压裂作业。

4)压裂完一层之后,通过上提下放管柱将压裂层位滑套关闭,随后打开下一层滑套进行压裂。

5)所有层位压裂完成之后,通过上提下放管柱将所有需要生产的层位的滑套打开,起出管柱,进行生产。

6)在生产过程中,如果出现产水层或者由于别的原因,需要将某个层位关闭,可下入滑套开关工具将其关闭。

如果还需打开,还可以下入开关工具将其打开。

3.优点:1)随套管一趟下入,无需射孔。

压裂作业一趟连续完成,节省了时间。

2)无需射孔,无需额外的封隔器卡层,节省了成本。

3)压裂完成之后套管内保持通径,方便了以后的修井作业。

4)滑套可以多次开关:根据生产需要,滑套可以随时关闭和打开,大大增强了其实用性。

5)在每一层压裂后,可以关闭滑套,保护地层不受污染。

4. 可用规格尺寸尺寸(in) 压力级别(psi) 温度级别(°F) 抗拉强度(lb) 抗扭力(ft-lb) 2 3/8 96,000 1,7822 7/8 140,000 3,5003 1/2 10,000 375 182,600 4,0004 7,500 291,900 5,700 4 1/2 8,200 325 270,000 6,000 5 7,300 315,000 5,5005 1/2 6,300 351,000 6,2007 7,000 300 628,000 8,7005. 图例CM 滑套示意图 CM 滑套进行特殊涂层处理之后,水泥固井图。

金正纵横信息咨询有限公司

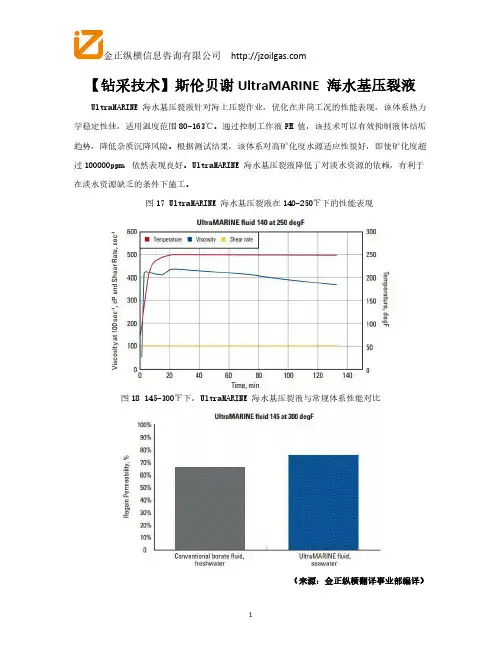

1【钻采技术】斯伦贝谢UltraMARINE 海水基压裂液UltraMARINE 海水基压裂液针对海上压裂作业,优化在井筒工况的性能表现,该体系热力学稳定性佳,适用温度范围80-163℃。

通过控制工作液PH 值,该技术可以有效抑制液体结垢趋势,降低杂质沉降风险。

根据测试结果,该体系对高矿化度水源适应性很好,即使矿化度超过100000ppm,依然表现良好。

UltraMARINE 海水基压裂液降低了对淡水资源的依赖,有利于在淡水资源缺乏的条件下施工。

图17UltraMARINE 海水基压裂液在

140-250℉下的性能表现

图18145-300℉下,UltraMARINE

海水基压裂液与常规体系性能对比

(来源:金正纵横翻译事业部编译)。

水平井分段压裂完井技术调研报告现代完井工程水平井分段压裂完井技术调研报告目录1 研究目的及意义1 2 水平井分段压裂技术2 2.1 国外水平井分段压裂技术研究现状 2 2.1.1 斯伦贝谢公司Stage FRACTM系统3 2.1.2 哈里伯顿公司固井滑套分段压裂系统3 2.1.3 贝克·休斯公司Frac Piont System分段压裂系统4 2.2 国内水平井分段压裂技术研究现状5 2.2.1 水力喷射分段压裂技术5 2.2.2 双卡上提压裂多段技术5 2.2.3 分段环空压裂技术5 2.2.4 液体胶塞隔离分段压裂技术5 2.2.5 机械桥塞隔离分段压裂技术6 2.2.6 限流压裂技术6 2.3 本章小结6 3 水平井分段压裂数值模拟方法7 3.1 笛卡尔网格的加密法7 3.2 PEBI网格加密法9 3.3 表皮因子法9 3.4 直角网格加密法9 3.5 本章小结9 4 水平井完井技术10 4.1 筛管分段完井技术10 4.2 水平井砾石充填防砂技术10 4.3 鱼骨状水平分支井完井技术10 4.4 膨胀管完井技术11 4.5 套管射孔分段压裂完井技术11 4.6 裸眼分段压裂完井技术11 4.7 本章小结11 参考文献13 1 研究目的及意义所谓分段压裂技术,就是在井筒内沿着水平井眼的方向,根据油藏物性和储层特征,在储层物性较好的几个或更多水平段上,采用一定的技术措施严格控制射孔孔眼的数量、孔径和射孔相位,通过一次压裂施工同时压开几个或更多水平段油层的技术。

这是一套有效改造低渗透油气藏的水平井技术。

2008年全球非常规石油资源规模达449.5Gt[1]。

目前我国低渗透油气藏已探明储量近60亿吨,已经动用储量近30亿吨。

近50已探明的低渗透油气藏由于单井自然产能低、开采效益差难以动用。

水平井可以增加井筒与油层的接触面积,提高油气的产量和最终的采收率,但随着石油勘探开发时间的延长,中高渗等常规油田逐步减少,低渗透等非常规油气藏储量不断增加,低渗透油气藏的重要性便日益凸显。

成像测井技术目录1电成像测井 (2)1.1 地层微电阻率扫描成像测井技术[1] (2)1.2 阵列感应成像测井技术 (3)1.3方位电阻率成像测井技术 (4)2声波成像测井 (4)2.1超声波成像测井 (5)2.2偶极横波成像测井 (6)3核磁共振成像测井 (6)4成像测井技术的应用 (7)4.1岩性识别 (7)4.2沉积构造识别[4] (10)4.3沉积微相研究[5] (12)4.4裂缝系统的分析 (14)4.5地应力分析[11] (29)5成像测井的发展趋势 (32)参考文献 (33)成像测井技术测井起源于1927年的法国,当时只有测量视电阻率、自然电位、井温等仪器,经过近80年的发展,如今发展成为以电法测井仪、声波测井仪与核磁共振测井仪等系列的测井仪器。

回顾测井技术的发展历程,测井技术经历了从模拟测井到数字测井、数控测井、成像测井的发展历程。

成像测井技术是美国率先推出的具有三维特征的测井技术,是当今世界最新的测井技术。

它是在井下采用阵列传感器扫描测量或旋转扫描测量,沿井眼纵向、径向大量采集地层信息,利用遥传将采集到的地层信息从井下传到地面,通过图像处理技术得到井壁二维图像或井眼周围某一探测范围内的三维图像。

因此,成像测井图像比以往的曲线表达方式更精确、更直观、更方便。

传统的测井只能获取井下地层井眼周向和径向上单一的信息,它适用于简单的均质地层。

而实际上地层是非均质的,尤其是裂缝性油气层的非均质性最为明显,在地层的周向和径向上的非均质性也非常突出。

这促使人们开始利用非均质和非线性理论来设计测井仪器。

成像测井技术就是在此理论基础上发展起来的,它能获取井下地层井眼周向方位上和径向上多种丰富的信息,能够在更复杂、更隐蔽的油气藏勘探和开发方面有效的解决一系列问题:薄层、薄互层、裂缝储层、低孔隙低渗透层、复杂岩性储层评价;高含水油田开发中剩余油饱和度及其分布的确定;固井质量、压裂效果、套管井损坏等工程测井问题以及地层压力、地应力等力学参数的求取等等。

StageFRACSIMPLE, EFFICIENT, AND EFFECTIVEStageFRAC services enable multistage hydraulic fractures of an uncemented completion in one pumping treatment.Openhole packers are run on conventional casing to segment the reservoir with ball-activated sleeves placed between each set of openhole packers.During pumping, balls are dropped from the surface to shift each sliding sleeve open and isolate previously frac-tured stages.This mechanical diversion combined withSchlumberger advanced fracturing fluid systems allows for precise fluid placement, complete zonal coverage, and greater effective fracture conductivity.The StageFRAC service also offers a relatively simple completion: The production casing is not cemented,there are no perforating operations, no bridge plugs are required for isolation, no overflushing of the stimulation treatment is needed, and no intervention is required once stimulation is completed. Finally,the entire wellbore is fracture stimulated in one pumping operation, reducing cycle times from days to hours.The service permits selective opening and closing of the ports to shut off unwanted fluids, thus maxi-mazing well production life.FIELD-PROVEN TECHNOLOGYSince the first StageFRAC well was completed in June of 2002, the technology has been used to complete more than 2,750 stages in more than 1.25 million ft of open hole, and more thanAPPLICATIONSIHydraulically fractured horizontal,deviated, and vertical wells IOpenhole and some cased hole completionsIHigh-temperature, high-pressure,H 2S, and CO 2environments ISandstone, carbonate, shale, and coal formationsBENEFITSIMaximize reservoir productivity with up to 17 stimulation stages in one wellboreICut completion timesfrom days to hours and shorten time to marketIMaximize well longevity by shutting out unwanted fluids IReduce fracture fluid damage through immediate flowbackFEATURESIImproved access to natural fracturesIAbility to space sleeves at optimal distances as dictated by reservoir conditionsIPost-stimulation intervention not requiredI Single, continuous operation IMaximized stimulation coverage in horizontal wells I Reliable isolation in open hole IRigless operations during fracturingISleeves that can be shifted to assist with reservoir managementMaximize reservoir drainageThe StageFRAC*†multistage fracturing service provides effective reservoir drainage through multistage fracturing of open-hole wellbores and reduces completion times from days to hours.The mechanical openhole packer with tandem elements is rated to 68.9 MPa [10,000 psi] and 218 degC [425 degF]./reservoircontact†Incorporating Packers Plus ®technology*Mark of SchlumbergerCopyright © 2007 Schlumberger. All rights reserved. 07-ST-028StageFRACThe Galaxie stimulation vessel mobilizing to treat the first StageFRAC job performed offshore West Africa.。

页岩⽓藏⽔平井分段压裂技术页岩⽓藏⽔平井分段压裂技术摘要:据中⽯油勘探开发研究院廊坊分院2008年预测数据显⽰,我国页岩⽓资源量为30万亿⽴⽅⽶,这在很⼤程度上能够有效地缓解我国能源紧缺的局⾯[1]。

页岩⽓藏属于典型的低渗透率、低孔隙度的⾮常规天然⽓藏,由于其特殊的地质条件,常规的开发技术⽆法直接适⽤于页岩⽓藏的⽣产。

因此,页岩⽓藏能够成功开发的关键在于压裂技术的进步,⽽⽔平井分段压裂技术已成为开发页岩⽓的关键技术。

本⽂根据页岩⽓藏的分布、地质条件以及发展前景,通过详细介绍⽔平井分段压裂技术与微地震监测技术,以期能解决当前⽔平井分段压裂技术相关难题,并对裂缝进⾏实时监测以提⾼采收率,加快页岩⽓开采进程。

关键字:页岩⽓藏;⽔平井;分段压裂技术;裂缝监测技术;增产;开采前⾔页岩⽓藏属于典型的低渗透率、低孔隙度的⾮常规天然⽓藏,在我国油⽓资源⾥占有很⼤的⽐重。

但其开发成本⾼、难度⼤,⽽其特殊的储层特征⼜决定了开发这类储层必须采⽤强化⼿段——储层压裂改造技术,改善油⽓流渗流条件,从⽽达到有效的开采⽬的。

压裂改造储层不仅可使页岩⽓以⾼的初始产⽓量,较快地收回⽣产投资,⽽且可以延长压裂初始⾼产后的相对稳产期,使⽓井寿命持续30年左右。

储层实施压裂改造后需要有效的⽅法来确定压裂作业效果,获取压裂诱导裂缝、导流能⼒、⼏何形态、复杂性及其⽅位等诸多信息,改善⽓藏压裂增产作业效果以及⽓井产能并提⾼页岩⽓采收率。

1 页岩⽓藏基本特征1.1 页岩⽓藏的分布根据地质历史及其变化特点,可将我国的页岩⽓发育区划分为四⼤区域:南⽅、华北⼀东北、西北及青藏四⼤地区(见图1)。

南⽅古⽣界发育寒武系、志留系、⼆叠系海相⿊⾊页岩建造,分布稳定,埋藏深度浅,有机质丰度⾼,在保存条件好的地区,有利于页岩⽓的形成与富集。

其中,寒武系页岩较为典型,厚度在200~1000m,分布较稳定;有机碳含量在1.5%~ 5.0%,普遍较⾼;热演化程度⼀般在2%以上,以热成熟⽓为主。

2014斯伦贝谢公司石油工程新技术(二)1. KickStart压力启动式破裂盘循环阀KickStart压力启动式破裂盘循环阀由两个阀片组成,通常作为套管柱的一部分被下入井中。

通过采用KickStart循环阀,作业者不再需要通过连续油管作业对井的趾部区段进行射孔,因此每口井成本可节省超过100000美元。

2. 新型微地震地面采集系统新型微地震系统用来对地表和浅层网微地震进行勘察。

其通过发现水力压裂时发射在地表或近地表的小型微地震信号,并对该信号质量进行优化来改进几何水力压裂裂缝的图像质量。

该微地震系统配备了一流的地震检波器加速计和超低噪音的电子设备,因此在工业中拥有最宽范围的信号检测能力。

3. MicroScope HD技术MicroScope HD技术能够在随钻测量的时候提供油藏高分辨率图像,有助于油藏结构模型和沉积分析,以及更好地还原裂缝细节特性并优化导电钻井液。

它的垂直分辨率能达到0.4英寸,能够使作业者看清井底环境。

MicroScope HD技术能够优化完井设计和增产方案,识别薄的或者未波及的产层,在复杂的裂缝网络中提高井眼轨迹定位效果以及通过裂缝描述来预防钻井风险。

4. PeriScope HD多层地层界面检测技术PeriScope HD多层地层界面检测技术通过将反演模型和方位角测量设备相结合,来对高级井位的地层边界和多产层进行精准定位和描述。

PeriScope HD已经在中东、欧洲、亚洲和南美的储藏试验过,同时也在北美的薄储层试验过。

无论是在导电或非导电的钻井液中,该技术都能检测到地层边界位置。

5. Mangrove完井模拟系统Mangrove完井模拟系统是一款储层增产设计软件,用于水力压裂工程设计和模型模拟。

该软件以储层三维地质模型中的单井为中心,来设计多级压裂增产的系统策略。

Mangrove软件提供了建立预测模型和评价非常规储层水力压裂处理的具体设计流程,同时也继续支持常规储层的流程与建模。

压裂技术(jìshù)现状及发展趋势(长城(Chángchéng)钻探工程技术(jìshù)公司(ɡōnɡsī)) 在近年(jìn nián)油气探明储量中,低渗透储量所占比例上升速度在逐年加大。

低渗透油气藏渗透率、孔隙度低,非均质性强,绝大多数油气井必须实施压裂增产措施后方见产能,压裂增产技术在低渗透油气藏开辟中的作用日益明显。

1、压裂技术发展历程自1947年美国Kansas的Houghton油田成功进行世界第一口井压裂试验以来,经过60多年的发展,压裂技术从工艺、压裂材料到压裂设备都得到快速的发展,已成为提高单井产量及改善油气田开辟效果的重要手段。

压裂从开始的单井小型压裂发展到目前的区块体积压裂,其发展经历了以下五个阶段[1]:(1)1947年-1970年:单井小型压裂。

压裂设备大多为水泥车,压裂施工规模比较小,压裂以解除近井周围污染为主,在玉门等油田取得了较好的效果。

(2)1970年-1990年:中型压裂。

通过引进千型压裂车组,压裂施工规模得到提高,形成长缝增大了储层改造体积,提高了低渗透油层的导流能力,这期间压裂技术推动了大港等油田的开辟。

(3)1990年-1999年:整体压裂。

压裂技术开始以油藏整体为单元,在低渗透油气藏形成为了整体压裂技术,支撑剂和压裂液得到规模化应用,大幅度提高储层的导流能力,整体压裂技术在长庆等油田开辟中发挥了巨大作用。

(4)1999年-2005年:开辟压裂。

考虑井距、井排与裂缝长度的关系,形成最优开辟井网,从油藏系统出发,应用开辟压裂技术进一步提高区块整体改造体积,在大庆、长庆等油田开始推广应用。

(5)2005年-今:广义的体积压裂。

从过去的限流法压裂到现在的直井细分层压裂、水平井分段压裂,增大储层改造体积,提高了低渗透油气藏的开发效果。

2、压裂技术(jìshù)发展现状经过五个阶段的发展,压裂技术(jìshù)日益完善,形成为了三维压裂设计软件和压裂井动态预测(yùcè)模型,研制(yánzhì)出环保(huánbǎo)的清洁压裂液体系和低密度支撑剂体系,配备高性能、大功率的压裂车组,使压裂技术成为低渗透油气藏开辟的重要手段之一。

分析纳米袭来,压裂革新!“纳”些不得了的技术几年前,人们普遍认为纳米技术需要过很多年才能真正用于油田实践;但在今天,大量的纳米技术产品已经在油气勘探和开发领域发挥着关键作用。

贝克休斯走在油田纳米技术应用的最前沿,本文将介绍几种对油气勘探开发产生重大影响的纳米技术新产品。

纳米技术包括纳米级的科学、工程和技术领域,涵盖了纳米成像、测量、模拟以及纳米级物质操控。

BakerHughes是为全球油气行业提供油田服务、产品和技术的领军企业之一,一直走在油田纳米技术导向产品应用的前沿。

纳米技术产品所实现的功能是其他产品无法企及的,IN-Tallic可降解压裂球就是该技术的一个代表。

IN-Tallic可降解压裂球是由纳米级可控电解金属材料组成,该材料比铝轻、比低碳钢强度大,但在特定流体条件下会降解。

降解过程通过电化学反应来完成,其主要受复合颗粒结构的纳米级包覆层所控制。

上述纳米结构材料具有常规材料所不具备的高强度和独特化学特性。

IN-Tallic可降解压裂球在压裂过程中能够保持其原有形状和强度,随后在井投产前或投产后短时间内降解。

浸泡在盐水中的压裂球会随着时间的推移而逐渐降解,也就是说降解过程通常发生在压裂液和井筒流体存在的情况下,无需人为添加其他特殊流体。

Baker Hughes的FracPoint分段压裂系统采用IN-Tallic压裂球,这种带活化压裂球的压裂系统能够快速连续地进行水力压裂。

上述系统安装好后,使用裸眼封隔器或水泥环对储层段进行分段。

之后压裂管柱开始作业,将各种尺寸的压裂球借助泵注的压裂液从地表投到目的层段,从而实现连续压裂过程。

压裂完成后,油气井可以立即投产,IN-Tallic压裂球在井内降解,以确保油气流动通道畅通且无油管阻力。

整个压裂过程避免了起下钻操作,减少泵注时间的同时,实现了油藏泄油面积的最大化。

Baker Hughes的SHADOW系列压裂桥塞是一种永久性桥塞,生产过程中被设计留在了井底,完全省去了分段射孔完井时钻穿桥塞的阶段。

StageFRAC

SIMPLE, EFFICIENT, AND EFFECTIVE

StageFRAC services enable multistage hydraulic fractures of an uncemented completion in one pumping treatment.

Openhole packers are run on conventional casing to segment the reservoir with ball-activated sleeves placed between each set of openhole packers.During pumping, balls are dropped from the surface to shift each sliding sleeve open and isolate previously frac-tured stages.

This mechanical diversion combined with

Schlumberger advanced fracturing fluid systems allows for precise fluid placement, complete zonal coverage, and greater effective fracture conductivity.The StageFRAC service also offers a relatively simple completion: The production casing is not cemented,

there are no perforating operations, no bridge plugs are required for isolation, no overflushing of the stimulation treatment is needed, and no intervention is required once stimulation is completed. Finally,the entire wellbore is fracture stimulated in one pumping operation, reducing cycle times from days to hours.

The service permits selective opening and closing of the ports to shut off unwanted fluids, thus maxi-mazing well production life.

FIELD-PROVEN TECHNOLOGY

Since the first StageFRAC well was completed in June of 2002, the technology has been used to complete more than 2,750 stages in more than 1.25 million ft of open hole, and more than

APPLICATIONS

I

Hydraulically fractured horizontal,deviated, and vertical wells I

Openhole and some cased hole completions

I

High-temperature, high-pressure,H 2S, and CO 2environments I

Sandstone, carbonate, shale, and coal formations

BENEFITS

I

Maximize reservoir productivity with up to 17 stimulation stages in one wellbore

I

Cut completion times

from days to hours and shorten time to market

I

Maximize well longevity by shutting out unwanted fluids I

Reduce fracture fluid damage through immediate flowback

FEATURES

I

Improved access to natural fractures

I

Ability to space sleeves at optimal distances as dictated by reservoir conditions

I

Post-stimulation intervention not required

I Single, continuous operation I

Maximized stimulation coverage in horizontal wells I Reliable isolation in open hole I

Rigless operations during fracturing

I

Sleeves that can be shifted to assist with reservoir management

Maximize reservoir drainage

The StageFRAC*†multistage fracturing service provides effective reservoir drainage through multistage fracturing of open-

hole wellbores and reduces completion times from days to hours.

The mechanical openhole packer with tandem elements is rated to 68.9 MPa [10,000 psi] and 218 degC [425 degF].

/reservoircontact

†Incorporating Packers Plus ®

technology

*Mark of Schlumberger

Copyright © 2007 Schlumberger. All rights reserved. 07-ST-028

StageFRAC

The Galaxie stimulation vessel mobilizing to treat the first StageFRAC job performed offshore West Africa.。