个人防护用品PPE管理程序(中英文版本)

- 格式:doc

- 大小:81.00 KB

- 文档页数:9

PPE ManagementPPE管理程序1. Introduction介绍Personal protective equipment (PPE) is minimum protection to personnel in an event ofincident. This procedure outlines the general requirements for managing the PPE andprovides site wide standard on PPE related system. All areas and all DSPC staff shallfollow this procedure to ensure the realization of company safety objectives.个人防护用品是在事件发生时对人员的最起码防护。

本程序概述了个人防护用品管理的一般要求,并提出了涉及人个防护用品相关体系上的全厂标准。

所有区域和所有DSPC员工都要遵守本程序,以保证公司安全目标的实现。

2. Purpose目的PPE is a secondary protection for employees when engineering or administrative controls are not sufficient to protect employees. This procedure provides general concept on therequirements for hazard assessments in the workplace, selection of PPE, training on PPE, proper use of PPE, store and maintenance of PPE, certification and data records.在工程或管理控制不能充分保护员工时,个人防护用品作为员工的第二保护用品。

StandardMust ensure that all employees are protected from overexposures to regulated chemicals that could affect their respiratory system.Must provide respirators that are applicable and suitable for the purpose intendedWhere respirators are necessary to protect the health of the employee or whenever the requires respirators, must establish and implement a written respiratory protection programMore restrictive Country standard of potentially hazardous substances may not be accomplished using respirators except:•During the period necessary to install engineering controls•In situations where engineering controls are either not feasible or are insufficient to reduce the airborne concentration of a potentially hazardous substance below the specified permissible exposure limit or threshold limit value•In emergency situationsMinimum Requirements1. If respirators are to be used to reduce the exposure of employees to hazardous air contaminants, must develop and implement a written respiratory protection program with worksite-specific procedures. The plan must include the following elements:a. Designation of a qualified program administrator to oversee programb. Evaluation of job assignments to determine the need for respiratory protectioni. Jobs in which employees may be exposed to breathing air contaminated with harmful levels of dusts, fumes, sprays, mists, fogs, smokes, vapors, gases or radioactive material must be identified as potential situations for need of respiratory protection.c. Determination of eligibility and medical evaluation requirements to wear a respirator2. Selection of respiratorsa. Must select a respirator certified by the National Institute for Occupational Safety and Health that must be used in compliance with the conditions of its certifications.b. Must identify and evaluate the respiratory hazards in the workplace, including a reasonable estimate of employee exposures and identification of the contaminant’s chemical state and physical form.c. Where exposure cannot be identified or reasonably estimated, the atmosphere must be considered immediately dangerous to life or health (IDLH).3. Medical Evaluationa. Must provide a medical evaluation to determine employee’s ability to use a respirator before fit testing and use.b. Must identify a physician or other licensed/certified health care professional (PLHCP) to perform medical evaluationsusing a medical questionnaire or an initial medical examination that obtains the same information as the medical questionnaire.c. Must obtain a written recommendation regarding the employee’s ability to use the respirator from the PLHCP.d. Additional medical evaluations are required under certain circumstances such as:i. Employee reports medical signs or symptoms related to ability to use respiratorii. PLHCP, program administrator, or supervisor recommends reevaluationiii. Information from the respirator program, including observations made during fit testing and program evaluation, indicates a neediv. Change occurs in workplace conditions that may substantially increase the physiological burden on an employeev. Annual review of medical status is not required.4. Fit Testinga. All employees using a negative or positive pressure tight-fitting facepiece respirator must pass an appropriate qualitative fit test (QLFT) or quantitative fit test (QNFT).b. Fit testing is required before initial use, whenever a different respirator facepiece is used, and at least annually thereafter.5. Use of Respiratorsa. Employees who have facial hair or any condition that interferes with the face-to-facepiece seal or valve function must not wear tight-fitting respirators.b. Personal protective equipment must be worn in a manner that does not interfere with the seal of thefacepiece to the face of the user.c. Employees must perform a user seal check each time they put on a tight-fitting respirator.6. Maintenance and Care of Respiratorsa. Must clean and disinfect respirators at the following intervals.i. As often as necessary to maintain a sanitary condition for exclusive-use respiratorsii. Before being worn by different individuals when issued to more than one employeeiii. After each use for emergency-use respirators and those used in fit testing and training7. Identification of Filters, Cartridges, and Canistersa. All filters, cartridges, and canisters used in the workplace must be labeled and color-coded with the NIOSH approval label.b. The label must not be removed and must remain legible.8. Training and Informationa. Must provide effective training to respirator users, including:i. Why the respirator is necessary and how improper fit, use, or maintenance can compromise the protective effect of the respirator limitations and capabilities of the respiratorii. Limitations and capabilities of the respiratoriii. Use in emergency situationsiv. How to inspect, put on and remove, use and check the sealsv. Procedures for maintenance and storagevi. Recognition of medical signs and symptoms that may limit or prevent effective usevii. General requirements of this standard9. Training is required before initial use, unless another contractor has provided acceptable training within the past12 months.10. Retraining is required annually and when:a. Workplace conditions change, new types of respirator are usedb. Inadequacies in the employee’s knowledge or use indicate needi. Program Evaluation(i) Must conduct evaluations of the workplace as necessary to ensure proper implementation of the program, and consult with employees to ensure proper use.ii. Recordkeeping11. Records of medical evaluations must be retained and made available.12. A record of fit tests must be established and retained until the next fit test.13. A written copy of the current program must be retained.14. Must keep all records for the duration of employment.标准:应确保所有雇员在过度或者控制性的暴露于影响呼吸系统的化学物质时,安全健康得到保护。

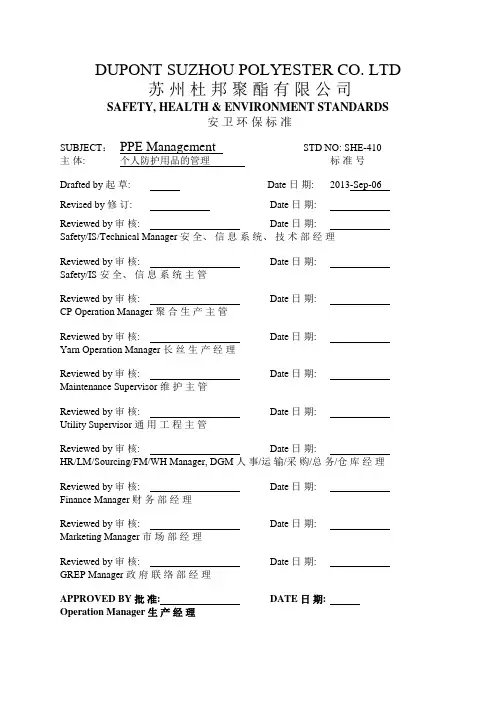

DUPONT SUZHOU POLYESTER CO. LTD苏州杜邦聚酯有限公司SAFETY, HEALTH & ENVIRONMENT STANDARDS安卫环保标准SUBJECT:PPE Management STD NO: SHE-410主体: 个人防护用品的管理标准号Drafted by 起草: Date 日期: 2013-Sep-06 Revised by 修订: Date 日期:Reviewed by 审核: Date 日期:Safety/IS/Technical Manager 安全、信息系统、技术部经理Reviewed by 审核: Date 日期:Safety/IS 安全、信息系统主管Reviewed by 审核: Date 日期:CP Operation Manager 聚合生产主管Reviewed by 审核: Date 日期:Yarn Operation Manager 长丝生产经理Reviewed by 审核: Date 日期:Maintenance Supervisor 维护主管Reviewed by 审核: Date 日期:Utility Supervisor 通用工程主管Reviewed by 审核: Date 日期:HR/LM/Sourcing/FM/WH Manager, DGM 人事/运输/采购/总务/仓库经理Reviewed by 审核: Date 日期:Finance Manager 财务部经理Reviewed by 审核: Date 日期:Marketing Manager 市场部经理Reviewed by 审核: Date 日期:GREP Manager 政府联络部经理APPROVED BY 批准: DATE 日期:Operation Manager 生产经理DSPC SHE STANDARDS STD NO 标准号: SHE-410 苏州杜邦安卫环保标准 Page 页数: Page 2 of 10 E f ective Date 生效日201 3Next Scheduled Review To Be Completed By: 2002-Sep-30下次复审完成时间PPE Management1. Introduction介绍Personal protective equipment (PPE) is minimum protection to personnel in an event ofincident. This procedure outlines the general requirements for managing the PPE andprovides site wide standard on PPE related system. All areas and all DSPC staff shallfollow this procedure to ensure the realization of company safety objectives.个人防护用品是在事件发生时对人员的最起码防护。

PPE ManagementPPE管理程序1. Introduction介绍Personal protective equipment (PPE) is minimum protection to personnel in an event ofincident. This procedure outlines the general requirements for managing the PPE andprovides site wide standard on PPE related system. All areas and all DSPC staff shallfollow this procedure to ensure the realization of company safety objectives.个人防护用品是在事件发生时对人员的最起码防护。

本程序概述了个人防护用品管理的一般要求,并提出了涉及人个防护用品相关体系上的全厂标准。

所有区域和所有DSPC员工都要遵守本程序,以保证公司安全目标的实现。

2. Purpose目的PPE is a secondary protection for employees when engineering or administrative controls are not sufficient to protect employees. This procedure provides general concept on therequirements for hazard assessments in the workplace, selection of PPE, training on PPE, proper use of PPE, store and maintenance of PPE, certification and data records.在工程或管理控制不能充分保护员工时,个人防护用品作为员工的第二保护用品。

个人防护用品(PPE)管理程序1.介绍个人防护用品是在事件发生时对人员的最起码防护。

本程序概述了个人防护用品管理的一般要求,并提出了涉及人个防护用品相关体系上的全厂标准。

所有区域和所有员工都要遵守本程序,以保证公司安全目标的实现。

2.目的在工程或管理控制不能充分保护员工时,个人防护用品作为员工的第二保护用品。

本程序提出的基本概念要求,有工作场所危害评定、如何选择PPE、PPE的培训、正确使用PPE、PPE 的储存和维护。

3.程序3.1危害评定3.1.1每一区域每年要对工作场所的危害进行评定,文档要经生产经理的批准并存档。

评定或复审要适用于所有工作区域。

应有以下几点。

a.区域/部门名字b.区域内哪种潜在危害c.是否要求PPE,如果是,每项工作或每位员工应穿戴哪种PPE。

若评定断定没有危害需要PPE,在文档中仍要保留。

3.1.2危害的评定可参考标准操作程序、工作检查表等等。

3.1.3PPE的需求或危害评定结果要张贴在区域内和/或写入具体的工作程序内。

3.2适用于区域/任务的PPE品种的选择3.2.1在危害评定的完成中,要选择正确的PPE。

需考虑下列基本危害种类,这些可能在危害评定期间已有所陈述:• 影响• 穿透力• 压缩• 化学制品• 高温• 有害粉尘• 轻度辐射(视力)3.2.2以下条例列出了PPE种类及其适用的工作任务或区域:• 带有边罩的安全眼镜所有实验室和工作区域,除被免除的特定区域。

• 面罩飞扬的微粒、切片、化学品飞溅物(如料桶的倒进倒出)对眼睛或脸部存在危害的任何操作。

腐蚀化学品的配制混合和带压管线的拆离。

• 防溅眼镜化学品可能飞溅而对眼睛有危害的任何操作。

危险液体的配制和混合。

在利用防溅眼镜防护被腐蚀时,同时要配戴面罩。

• 防毒气眼镜毒气或蒸气直接危害到眼睛的任何一项工作。

• 实验室外套提供保护人体部位免受化学品较小危险的最低防护。

不适用于防护腐蚀物。

包括放射性元素处理的所有操作。

对于某些危险化学品需备特种用途的外套。

护理职业防护物品配置与使用流程Personal protective equipment (PPE) is essential for healthcare professionals, especially those working in high-risk environments such as hospitals and clinics. 护理人员在工作过程中需要使用个人防护装备(PPE),特别是在高风险环境下工作的医院和诊所工作人员。

The proper selection and use of PPE can help prevent the spread of infectious diseases and protect both healthcare workers and patients. 正确选择和使用个人防护装备可以帮助防止传染疾病的传播,保护医护人员和患者。

It is crucial for healthcare facilities to provide adequate training on the proper use of PPE to their staff. 医疗机构有必要为员工提供关于正确使用PPE的充分培训。

Staff should receive training on how to properly don, doff, and dispose of PPE to ensure effectiveness and minimize the risk of contamination. 员工应该接受有关如何正确穿着、脱掉和处理PPE的培训,以确保有效性并减少污染的风险。

Regular assessments and audits should be conducted to ensure that healthcare workers are following proper protocols for PPE use. 需要定期评估和审计,以确保医护人员遵循PPE使用的正确程序。

PPE ManagementPPE管理程序1. Introduction介绍Personal protective equipment (PPE) is minimum protection to personnel in an event of incident. This procedure outlines the general requirements for managing the PPE and provides site wide standard on PPE related system. All areas and all DSPC staff shall follow this procedure to ensure the realization of company safety objectives.个人防护用品是在事件发生时对人员的最起码防护。

本程序概述了个人防护用品管理的一般要求,并提出了涉及人个防护用品相关体系上的全厂标准。

所有区域和所有DSPC员工都要遵守本程序,以保证公司安全目标的实现。

2. Purpose目的PPE is a secondary protection for employees when engineering or administrative controls are not sufficient to protect employees. This procedure provides general concept on the requirements for hazard assessments in the workplace, selection of PPE, training on PPE, proper use of PPE, store and maintenance of PPE, certification and data records.在工程或管理控制不能充分保护员工时,个人防护用品作为员工的第二保护用品。

个人防护用品(PPE)管理规定第一章总则第一条目的和依据为了保障企业员工的安全和健康,维护生产秩序,依据国家相关法律法规和企业管理制度,订立本规定。

第二条适用范围本规定适用于企业全体员工,包含办公区域、生产车间、仓库等各个工作场合。

第三条定义1.个人防护用品(PPE):指为了保护员工免受工作场合潜在的不安全因素侵害,防止事故发生或减少事故造成的损害而使用的各类安全防护用品。

2.个人防护用品管理人员:指负责个人防护用品采购、发放、维护和培训等相关工作的专职人员。

3.工作场合:指企业内员工从事工作的各个区域,包含办公区域、生产车间、仓库等。

第二章个人防护用品管理职责第四条企业管理层的职责1.将个人防护用品管理纳入企业生产运营管理的紧要内容,并投入充分的人力、物力和财力资源。

2.设立个人防护用品管理岗位,配备专职管理人员,负责个人防护用品采购、发放、维护和培训等工作。

3.编制个人防护用品管理制度,定期进行培训,提高员工对个人防护用品的认得和使用本领。

4.监督和检查个人防护用品的装备和使用情况,及时解决工作场合中存在的问题,确保员工使用合格的个人防护用品。

5.对个人防护用品管理人员进行考核,确保其履行职责。

第五条个人防护用品管理人员的职责1.负责个人防护用品的采购工作,确保采购的个人防护用品符合国家相关标准。

2.订立个人防护用品的发放方案,并依据工作场合的实际情况进行合理调配。

3.负责个人防护用品的发放工作,确保员工能够及时获得合适的个人防护用品。

4.对个人防护用品进行定期检查和维护,确保其功能完好。

5.组织个人防护用品的培训和宣传工作,提高员工的安全意识和使用本领。

第六条员工的职责1.遵守个人防护用品管理制度,正确佩戴和使用个人防护用品。

2.参加个人防护用品的培训和教育,提高对个人防护用品的认知和使用本领。

3.及时向管理人员报告个人防护用品损坏或失效的情况。

4.不得私自拆卸、更换个人防护用品,发现问题及时向管理人员反馈。

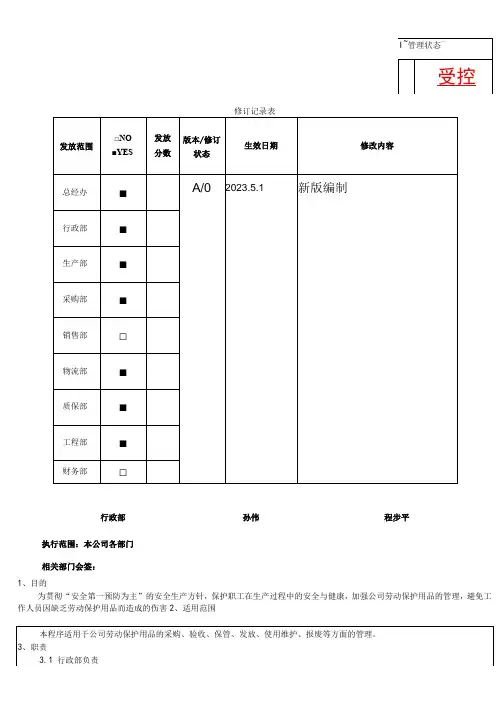

行政部孙伟程步平执行范围:本公司各部门

相关部门会签:

1、目的

为贯彻“安全第一预防为主”的安全生产方针,保护职工在生产过程中的安全与健康,加强公司劳动保护用品的管理,避免工作人员因缺乏劳动保护用品而造成的伤害2、适用范围

4.6.1员工所提出的有关劳动保护用品的意见和建议,应作为对供方评价的依据;

4.6.2行政部应对劳动保护用品的供应商组织资格、质量评定,经评定合格的供方才可签订供货合同。

4.7各部门在进行安全生产检查时,应对现场作业人员劳动防护用品佩戴使用情况进行检查。

5、相关文件

5.1《劳动保护用品配置基准》6、相关记录

5.2《采购申请单》

5.3《劳动保护用品发放记录》

5.4《劳保用品佩戴检查表》附件1:

劳动保护用品发放记录

附件2

劳保用品佩戴检查表。

个人防护用品(PPE)管理规定1. 什么是个人防护用品(PPE)?个人防护用品(Personal Protective Equipment, PPE)通常是指佩戴在人体上,可以提高工作安全性和健康保护效果的装备。

PPE包括头部、眼部、面部、耳部、呼吸道、手部、身体和脚部等部位的防护装备。

在某些行业领域,需要使用PPE来保护工人免受特定工作场所和活动中的危险物质和物理性因素的损伤。

2. PPE管理的必要性在现代生产和劳动过程中,机器、设备和材料的复杂性不断提高。

随着企业规模的扩大和生产活动的细化,PPE的使用也变得日益重要。

PPE管理是企业提供必要安全保障的重要措施之一,目的是保护工人免受劳动过程中的危害。

如果管理得当,PPE可以有效地控制工伤事故的发生,保护劳动者身体健康,提高安全生产的水平。

因此,为了保护工人的生命安全和身体健康,企业必须注意PPE的管理。

3. PPE管理规定3.1 选择适当的PPE选择适当的PPE,是PPE管理的首要原则。

针对特定的工作环境和作业内容,根据危险评估结果选择相应的PPE。

对于不同类型的PPE,应该根据其防护性能、舒适性、适用性和可接受程度等因素进行评估。

3.2 质量标准和检验选择合格的PPE产品,是确保有效防护的前提。

切勿使用未经质量检验或不符合安全使用要求的产品。

在使用PPE之前,必须对其进行质量检验,检查是否存在破损、老化、劣化等现象。

所有检验结果应记录并及时处理。

3.3 PPE的储存和保养在储存PPE时,应采取有效的措施防止污染和损坏。

所有PPE在使用前都应洗净和消毒。

对于不同类型的PPE,应严格按照生产厂家要求进行保养,包括但不限于清洗、消毒和维修等工作。

使用过的PPE应进行清洗、消毒和检验,看是否需要修理或替换。

3.4 PPE的颁发和佩戴PPE的颁发应按照具体工作环境和作业内容,向需要用到PPE的工人进行颁发。

工人必须检查所颁发的PPE,确保其符合自己的尺码和人体结构。

确保安全生产,保护本公司雇员在生产过程中的安全和健康,符合中国政府/地方法规和XXXX要求。

To ensure safety operation & safety and healthy of employees when working to comply with the requirements of relevant national/local government regulations and Celestica corporation.本程序适用本公司雇员。

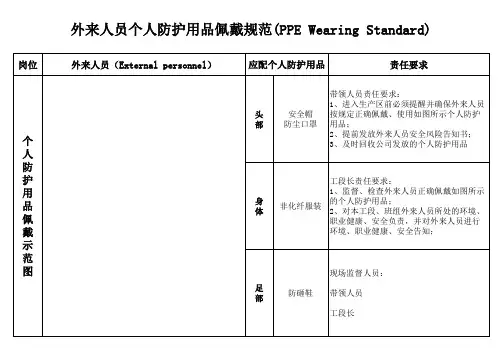

The procedure applies to employees of Celestica (Dongguan-SSL) Technology Ltd.外来人员的个人防护用品自理,如需进入生产区域,则仅提供防静电服和防静电拖鞋。

Visitors' PPE should be prepared by themselves. Celestica (Dongguan-SSL) Technology Ltd. just provides ESD smocks and slippers for those visitors who need to enter into production area. 3.1 EHS委员会负责根据法规和MSDS的要求,确认工作岗位的《个人防护用品清单》(见7.0 Appendix),并定期对个人防护用品清单进行评审以确认其有效性,确定个人防护用品使用/检验期限。

EHS Committee is responsible for confirming PPE List (See below 7.0Appendics) in relevant working station according to the requirement of the relevant laws/regulations and MSDS, and reviewing the list periodically to make sure the effectiveness. Also, EHS Committee should define the valid/checkup periodof PPE.3.2 人力资源部和货仓部负责日常消耗类个人防护用品,如防静电用品以及口罩/手套等一次性用品的日常购买/管理/分发;各个部门负责特殊消耗类个人防护用品的日常管理/分发,各个部门将每季度将特殊消耗类个人防护用品需求量汇总至EHS委员会,由EHS委员会统一填写PRF单请购.HR department and Warehouse department are responsible for the daily purchasing/ management/ distribution of daily consumable PPE, such as ESD /one-off equipment(glove/general respirator, etc). Each department is responsible for the dailymanagement/distribution of special PPE, and each department should sum up the quantity of special PPE consumption quarterly to EHS Committee; and EHS Committee is responsible for filling out PRF to Purchasing department.3.3 请购部门或者采购部需向有资质的供应商购买合格的个人劳动防护用品,要求供应商提交其劳保用品的生产许可证、安全鉴定证和特种劳动防护用品标志证书;请购部门确认后,需保留相关资质证明的复印件。

个体防护用品/劳保用品 Personal protective equipment PPE 正确使用和维护PPE Proper use and care of PPE提供合适的PPE Provide appropriate PPEPPE类型 Types of PPE损坏的 worn or damaged眼镜面部保护 Eye protection安全眼镜 Safety Goggles激光防护眼镜 Laser safety goggles焊工面罩 welding face-shield头部保护 head protection安全帽 hard hat protective helmets脚部和腿部保护 Foot and Leg Protection安全鞋 safety shoes protective footwears防酸靴 Acid-proof boots防静电鞋 static-proof shoes长裤 Full length trousers绑腿 Leggings脚面罩 Metatarsal guards护脚板 Toe guards导电鞋 Electrically conductive shoes钢板安全鞋 safety-toe shoes手臂保护 Hand and Arm Protection长袖T恤 Long sleeve shirt化学品防护手套 Chemicals Protective Glvoes绝缘手套 Insulaiting Glvoes身体保护 Body Protection工作服 uniform防化服 Chemicals Protective clothing防火服 Fire Protective clothing隔热服 Heat Protective clothing听力保护 Hearing Protection一次性耳塞 Single-use earplugs耳罩 Earmuffs呼吸保护 Respiratory protection净化式空气呼吸器 air-purifying respirator补给式空气呼吸器 atmosphere-supplying respirator 口罩 mask全面 full face半面 half face滤盒 Filter cartridge其他安全带 harness洗眼器 eye-washing equipment。

1.1个人防护用品(PPE)Personal Protective Equipment1.1.1一般服装General Apparel1.1.1.1每个员工都必须穿着防护服保护身体和手足。

下列典型人员伤害可以按照下面的方法进行防护:Every employee will at all times wear clothing that protects the body and extremities.The typical personnel hazards listed below can be prevented as follows:1.1.1.2由于接触热管导致热烫伤,可以穿长袖衣服佩戴手套进行防护。

Thermal burns resulting from contact with hot pipes, can be prevented by using Arraylong sleeve shirts and cloth gloves.1.1.1.3化学烧伤和/或皮肤吸入过敏原和霉素,可以穿着合适的化学防护服(CPC)加以防护或者将伤害降到最低。

Chemical burns and/or skin absorption of allergens and toxins can be prevented or minimized by use of appropriate chemical protective clothing (CPC).1.1.1.4在可以与通电导体,移动部件,设备或者其他此类危险接触时,不得穿着宽松的衣服。

Loose clothing will not be worn where it can contact or catch on energized conductors, moving parts, equipment, or other hazards of this type.1.1.1.5最好穿着自然纤维衣料的衣服。

Personal Protect Equipments Procedure个人防护用品管理程序1. RESPONSIBILITIES职责1.1 Department Manager/Supervisor部门主管、经理:1.1.1Communicate the contents of the Personal Protective Equipment Program to all affectedemployees, and ensure compliance of the contents of this program.对本部门受危害影响的员工进行沟通,让员工了解本程序的内容1.1.2 Provide adequate resources to administer the program.提供一定资源,对PPE进行管理1.1.3 Provide training to all employees new to the team, whenever new PPE items are introduced, andwhenever refresher training is required.对新加入本部门的员工进行培训,在有新的PPE使用于本部门的同时,为员工提供培训。

1.1.4 Maintain a list of PPE that has been approved for use, and modify the list as required by changesin PPE needs.维护PPE使用清单,在PPE使用情况发生变化时,应修改使用清单。

1.1.5. Coach, monitor how about the worker PPE wearing situation, aperiodicity’s to check and record.指导,监督操作工PPE的佩戴情况,不定期的检查并纪录。

PPE ManagementPPE管理程序1. Introduction介绍Personal protective equipment (PPE) is minimum protection to personnel in an event ofincident. This procedure outlines the general requirements for managing the PPE andprovides site wide standard on PPE related system. All areas and all DSPC staff shall follow this procedure to ensure the realization of company safety objectives.个人防护用品是在事件发生时对人员的最起码防护。

本程序概述了个人防护用品管理的一般要求,并提出了涉及人个防护用品相关体系上的全厂标准。

所有区域和所有DSPC 员工都要遵守本程序,以保证公司安全目标的实现。

2. Purpose目的PPE is a secondary protection for employees when engineering or administrative controls are not sufficient to protect employees. This procedure provides general concept on therequirements for hazard assessments in the workplace, selection of PPE, training on PPE, proper use of PPE, store and maintenance of PPE, certification and data records.在工程或管理控制不能充分保护员工时,个人防护用品作为员工的第二保护用品。

本程序提出的基本概念要求,有工作场所危害评定、如何选择PPE、PPE的培训、正确使用PPE、PPE的储存和维护。

3. Procedure程序3.1 Hazards Assessments危害评定3.1.1 Each area shall conduct a workplace hazards assessment every year, thedocument shall be approved by Plant Manager and kept in file. Assessmentsor reviews must be applied to all work areas. It shall address following items每一区域每年要对工作场所的危害进行评定,文档要经生产经理的批准并存档。

评定或复审要适用于所有工作区域。

应有以下几点。

∙Area/section name区域/部门名字∙What kind of potential hazards will have in the area区域内哪种潜在危害Whether PPE is required, and if so what kind of PPE is required for each job or each employee. If the assessment concludes that there are nohazards requiring PPE, it still shall be kept in document.是否要求PPE,如果是,每项工作或每位员工应穿戴哪种PPE。

若评定断定没有危害需要PPE,在文档中仍要保留。

3.1.2The hazard assessment can take the form of a process hazards review (PHR),standard operating procedure (SOP), checklist of tasks, etc.危害的评定可参考PHR、标准操作程序、工作检查表等等。

3.1.3The PPE requirement or the result of the Hazard assessments shall be postedin the area and/or written in specific job procedure.PPE的需求或危害评定结果要张贴在区域内和/或写入具体的工作程序内。

3.2Selection of PPE type for area/task适用于区域/任务的PPE品种的选择3.2.1On completion of the hazard assessment, the correct PPE should be chosen.Consideration should be given to following the basic hazard categories, someor all of which may have been discovered during the hazards assessment:在危害评定的完成中,要选择正确的PPE。

需考虑下列基本危害种类,这些可能在危害评定期间已有所陈述:• Impact影响• Penetration穿透力• Compression (roll-over)压缩• Chemical化学制品• Heat高温• Harmful dust有害粉尘• Light (optical) radiation轻度辐射(视力)3.2.2The following guide lists PPE and the activities or areas for which it isrequired:以下条例列出了PPE种类及其适用的工作任务或区域:• Safety Glasses with Side Shields带有边罩的安全眼镜All laboratories and work areas, unless specifically exempted bymanagement.所有实验室和工作区域,除被免除的特定区域。

• Face Shield面罩Any operation that presents an expected hazard to eyes or face from flyingparticles, chips, splash of chemicals (i.e., dispensing into or out of drums).Dispensing and mixing corrosive chemicals and disconnecting lines thatmay be under pressure.飞扬的微粒、切片、化学品飞溅物(如料桶的倒进倒出)对眼睛或脸部存在危害的任何操作。

腐蚀化学品的配制混合和带压管线的拆离。

• Splash Goggles防溅眼镜Any operation that presents an expected hazard to eyes from chemical splash.Dispensing and mixing of hazardous liquids. When using goggles to protectfrom corrosives, face shield should also be used.化学品可能飞溅而对眼睛有危害的任何操作。

危险液体的配制和混合。

在利用防溅眼镜防护被腐蚀时,同时要配戴面罩。

• Gas-tight Goggles防毒气眼镜Any work with gases or vapors that present an immediate hazard to the eyes.毒气或蒸气直接危害到眼睛的任何一项工作。

• Lab Coats:实验室外套Provide minimum protection for torso and arms from less hazardous chemicals. Not to be used for protection from corrosives. All operations involving radioisotope handling. Special purpose lab coats are available for protection from some hazardous chemicals.提供保护人体部位免受化学品较小危险的最低防护。

不适用于防护腐蚀物。

包括放射性元素处理的所有操作。

对于某些危险化学品需备特种用途的外套。

• Aprons:围裙Minimum splash protection for torso while handling corrosive or highly toxic materials.在处理腐蚀物或剧毒物料时,对于人体躯体部位的最低飞溅防护。

• Protective Sleev es, Arm Covers, Gauntlets:防护袖套、手臂套、长手套:Minimum protection for arms while handling corrosive or highly toxic materials. Can be used in lieu of lab coat in some situations.在处理腐蚀物或剧毒物料时,对手臂的最低防护。

在某些情况下可代替实验室外套。

• Safety Shoes安全鞋All material handling operations including moving gas cylinders and other objects on hand trucks. Any work involving routine lifting and carrying of objects weighing 20lb or more. Any activity or area that presents a foot puncture hazard (construction, demolition, and shop areas).适用于所有物料处理的操作,包括气瓶搬动和手推车上的其他物件的搬运。

任何涉及到日常提起或搬运重或超过20磅的操作。

任何对脚部有刺伤危害的行为或区域(建筑、拆除、车间区域)。