AS-300A焊台说明书

- 格式:doc

- 大小:49.50 KB

- 文档页数:1

ASCO A200系列自动转换开关--30~1200A型目录第一部份安装 (3)组装与接线 (3)辅助电路与导线 (4)发电机启动触头 (4)输入/输出标签 (4)功能试验 (5)第二部份操作程序 (7)第三部份试验与维护 (8)预防性维护 (8)转换试验 (8)拆卸控制板 (8)手动转换负载 (99)故障检查与解决方法 (100)第四部份调节 (111)延时调节与传感器调节 (111)怎样更改设定 (122)第五部份控制部件 (133)发电机周期试验(标准式与可选式) (133)发电机负载转换 (155)断载与远程控制 (155)电热丝加热器 (166)安装开关的人员必须是有经验且持有许可证的专业技术人员,并接受过所有规范的安全培训。

危险:在本手册里,该标志用于高压可能导致触电、烧伤甚至死亡的警告。

警告:在本手册里,该标志用于可能导致身体伤害的警告。

小心:在本手册里,该标志用于可能导致装置损坏的警告。

ASCOA200/300系列开关设备是根据UL1008标准中有关自动转换开关的安全标准而设计,已通过加拿大标准协会(CSA)之认证。

此外,所有通常使用附件均经过UL检验,以保障ASCO自动转换开关的附件符合OSHA安全要求,并能够为电气质检员接受。

ASCOA200/300开关系列装置适用于应急系统和备用系统,符合美国国家电气规程(NEC)第700条款和UL 1008标准规定。

同时,也符合NEC条款第517条--安全保障设施(Health Care Facilities)、第701条--备用系统的合法要求(Legally Required Standby Systems)、第702条--备选的备用系统(Optional Standby Systems) 以及NFPA第99条--安全保障设施(Health Care Facilities)和NFPA第110条--应急和备用供电系统(Emergency and Standby Power Systems)的规定。

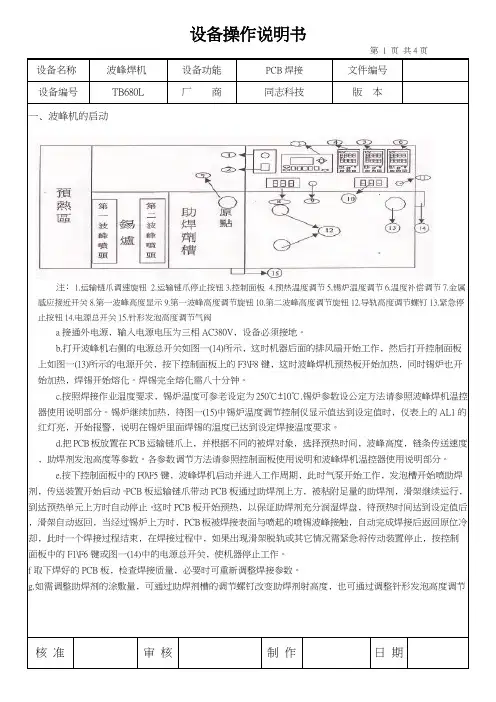

第 1 页共4页设备名称波峰焊机设备功能PCB焊接文件编号设备编号TB680L 厂商同志科技版本一﹑波峰机的启动图一波峰焊机平面示意图注﹕1.运输链爪调速旋钮 2.运输链爪停止按钮3.控制面板 4.预热温度调节5.锡炉温度调节6.温度补偿调节7.金属感应接近开关8.第一波峰高度显示9.第一波峰高度调节旋钮10.第二波峰高度调节旋钮12.导轨高度调节螺钉13.紧急停止按钮14.电源总开关15.针形发泡高度调节气阀a接通外电源﹐输入电源电压为三相AC380V﹐设备必须接地。

b.打开波峰机右侧的电源总开关如图一(14)所示﹐这时机器后面的排风扇开始工作﹐然后打开控制面板上如图一(13)所示的电源开关﹐按下控制面板上的F3\F8键﹐这时波峰焊机预热板开始加热﹐同时锡炉也开始加热﹐焊锡开始熔化。

焊锡完全熔化需八十分钟。

c.按照焊接作业温度要求﹐锡炉温度可参老设定为250℃±10℃.锡炉参数设公定方法请参照波峰焊机温控器使用说明部分。

锡炉继续加热﹐待图一(15)中锡炉温度调节控制仪显示值达到设定值时﹐仪表上的AL1的红灯亮﹐开始报警﹐说明在锡炉里面焊锡的温度已达到设定焊接温度要求。

d.把PCB板放置在PCB运输链爪上﹐并根据不同的被焊对象﹐选择预热时间﹐波峰高度﹐链条传送速度﹐助焊剂发泡高度等参数。

各参数调节方法请参照控制面板使用说明和波峰焊机温控器使用说明部分。

e.按下控制面板中的F0\F5键﹐波峰焊机启动并进入工作周期﹐此时气泵开始工作﹐发泡槽开始喷助焊剂﹐传送装置开始启动。

PCB板运输链爪带动PCB板通过助焊剂上方﹐被粘附足量的助焊剂﹐滑架继续运行﹐到达预热单元上方时自动停止。

这时PCB板开始预热﹐以保证助焊剂充分润湿焊盘﹐待预热时间达到设定值后﹐滑架自动返回﹐当经过锡炉上方时﹐PCB板被焊接表面与喷起的喷锡波峰接触﹐自动完成焊接后返回原位冷却﹐此时一个焊接过程结束﹐在焊接过程中﹐如果出现滑架脱轨或其它情况需紧急将传动装置停止﹐按控制面板中的F1\F6键或图一(14)中的电源总开关﹐使机器停止工作。

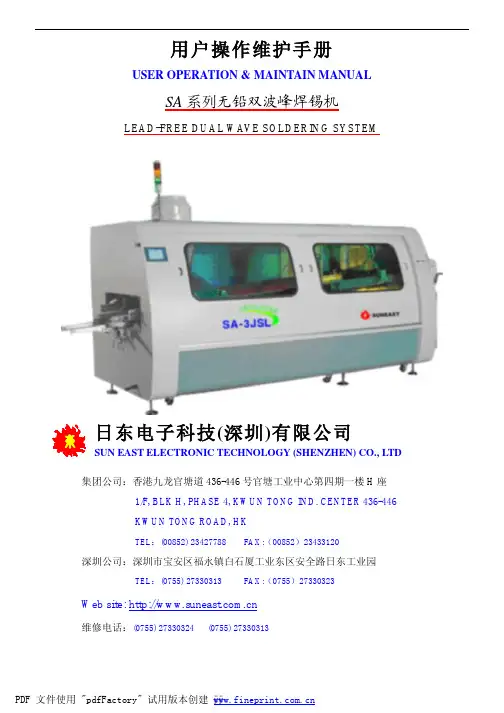

用户操作维护手册USER OPERATION & MAINTAIN MANUALSA系列无铅双波峰焊锡机LEAD-FREE DUAL WA VE SOLDERING SYSTEM日东电子科技(深圳)有限公司SUN EAST ELECTRONIC TECHNOLOGY (SHENZHEN) CO., LTD 集团公司:香港九龙官塘道436-446号官塘工业中心第四期一楼H座1/F, BLK H, PHASE 4, KWUN TONG IND. CENTER 436-446KWUN TONG ROAD, HKTEL:(00852) 23427788 FAX:(00852)23433120深圳公司:深圳市宝安区福永镇白石厦工业东区安全路日东工业园TEL:(0755) 27330313 FAX:(0755)27330323Web site: 维修电话:(0755) 27330324 (0755) 27330313PDF 文件使用 "pdfFactory" 试用版本创建ÿÿ警告:★.非本设备维护、维修人员或未经培训合格人员切勿随意操作机器。

★.通电之前,应再次确认电源电压是否与设备工作电压相符。

★.本设备属于高温加热及传动设备,操作时应注意人身安全。

warnings:★.Only staffs concerned is allowed to operate the machine.★.Make sure the voltage supplied suits the rated voltage beforeelectrifying.★.Heating and moving part involved, special cautions should bemade.注意:1. 当您使用或操作本设备之前,请仔细阅读此手册。

2. 请保存此手册,以便日后保养、维护和检修时使用。

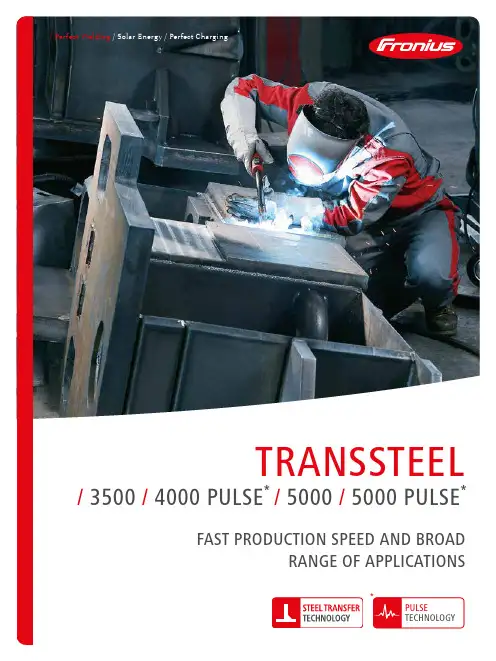

/ Perfect Welding / Solar Energy / Perfect Charging/ 2Yet the power source remains versatile: The TransSteel versions with the Pulse function make child's play of applications involving aluminium and stainless steel. SMEs can benefit from this variety of materials, as just one device is all they need to cover a wide range of applications. The underlying philosophy – stay on top of things. The function spectrum of the TransSteel has therefore been deliberately reduced to the essentials in all areas according to the motto - as much as necessary, with the best possible overview and ease of handling.HIGH-POWER WELDING AND A BROAD RANGE OF APPLICATIONS.WHETHER CONTAINER CONSTRUCTION, BRIDGE CONTRUCTION OR YELLOW GOODS:WITH NEARLY 170 OPTIMISED CHARACTERISTICS, THE TRANSSTEEL SERIES FEATURES THECHARACTERISTICS DEMANDED BY THE HEAVY-DUTY STEEL CONSTRUCTION SECTOR.Let’s get connec ted.What´s your welding challenge?70% LESS40%DUTY CYCLE/The Pulse function of the TransSteel 4000 and 5000 Pulse CUSTOMER BENEFITSREADY TO WELDIN THREE STEPS /The intuitive operating concept enables welders to start work straight away – no prior knowledge of the device is required. All the essential welding parameters can be viewed and adjusted on the front panel. The only parameters that have to be selected before welding begins are the gas, wire diameter and material thickness.167CHARACTERISTICS */Steel, CrNi, AlMg, AlSi, Metal Cored, Rutil FCW, Basic FCW, Self-shielded /0.8 – 1.6mm wire diameter /Eight different gas mixturesFour minutes of continuous welding at maximum output power, in other words, one minute more of productive output compared with the average in this power range.123ED40%/ 4THE TRANSSTEEL SERIESFUNCTIONS TransSteel3500TransSteel4000 PULSETransSteel5000TransSteel5000 PULSEPulseSynchroPulseData documentationMains operation3-phase3-phase3-phase3-phase Cooling Water-cooled Water-cooled Water-cooled Water-cooled Wire speed4R4R4R4REasy Jobs5555VERSATILE: FOR A BROAD RANGE OFAPPLICATIONS!/ 5To run repetitive welding tasks quickly and easily, five sets of welding parameters canbe saved – these are known as EasyJobs.THE REQUIRED WELDING PARAMETERS CAN THEN BE ACCESSED AT THE TOUCH OF A BUTTON.Entering a particular button combination locks the TransSteel control panel, MAKING UNINTENTIONAL MODIFICATIONS TO THE WELDING PARAMETERS IMPOSSIBLE. An optional keylock switch is also available for all the control panels in the TransSteel series (with the exception of TransSteel 2200 & 2700 C).CONTROL PANEL LOCKEASY JOBS/ 6The “SynchroPulse” option is recommended for the weldingof aluminium alloys when a rippled seam appearance isrequired. This effect is achieved by modifying the weldingSYNCHROPULSE works inSTANDARD SYNERGIC AND PULSE SYNERGIC MODE –but only on the TransSteel 4000 and 5000 Pulse./ 7CORRECTIONS / ARC LENGTH CORRECTION ARC-FORCE DYNAMIC / ARC LENGTH CORRECTIONTO CHANGE THE ARC CHARACTERISTICshorter arc, reduced welding voltage neutral arclonger arc, increased welding voltage/ ARC-FORCE DYNAMICsoft, low-spatter arc/ PULSE CORRECTIONhigher droplet detachment forceSuchen Sie nach den Icons in diesem Folder und erhalten Sie mit ihrer Magic Folder App weitere interessante Inhalte./ 8WELDING DATA DOCUMENTATIONWelding data documentation is essential, particularly in steel construction. Load-bearing steel structures, mass-produced products or sensitive parts often have to be traceable down to the final welding parameters. The Easy Documentation option enables TransSteel to record welding data extremely easily.USBTHUMB DRIVEEXPORT FUNCTIONA USB thumb drive can be connected to the rear of the device (the stick is included as part of the scope of supply with the Easy Documentation option). The drive can then be used to export a CSV file containing welding data.Easy Documentation records the following welding parameters:/Power source ID /Firmware version /Serial number/Process (Manual, Standard, Pulse, TIG, MMA)/Current / voltage / wire speed in the main process phase /Power from instantaneous values “IP” (Instantaneous Power) - energy / time (in the main process phase) /Energy from instantaneous values “IE” (Instantaneous Energy) over the entire welding operation /Motor current (in the main process phase)/Time stamp hh:mm:ss when current starts to flow /Counter/Welding duration/Error no. when welding is terminated /Wire speed (metric and imperial) /Characteristic number/Operating mode (2T, S2T, 4T, S4T, spot welding, stitch welding, SynchroPulse)/Signature for each weld seam number /Template for .csv file/Easy Job numberEASYDOCUMENTATIONRECORDING OF WELDING PARAMETERSThe Fronius central connector for all media and enables a variety of connected.FSCFRONIUS SYSTEM CONNECTORMORE THAN MULTILOCK:30 VERSIONS45°Suitable for all splitdevices in the TransSteel series.TU CAR 4TROLLEYBASIC, STANDARD & PROOPTIONS AVAILABLE IN THREEVERSIONSREMOTE CONTROLTR 1300/ 11The cooling unit is filled as standard with FCL10 coolant and is equipped with a coolant filter (and a flow temperature sensor as an option).COOLING UNITFK 5000A 4-roller wirefeeder with optional control unit for pulse or standardapplications that is perfectlyadapted to the systemVR 5000 REMOTETOOL BOXHANDY TOOL BOXSuitable for all split devices in the TransSteel series./ Perfect Welding / Solar Energy / Perfect ChargingT e x t a n d i m a g e s c o r r e s p o n d t o t h e c u r r e n t s t a t e o f t e c h n o l o g y a t t h e t i m e o f p r i n t i n g . S u b j e c t t o m o d i f i c a t i o n s .A l l i n f o r m a t i o n i s w i t h o u t g u a r a n t e e i n s p i t e o f c a r e f u l e d i t i n g - l i a b i l i t y e x c l u d e d . C o p y r i g h t © 2011 F r o n i u s ™. All r i g h t s r e s e r v e d .Further information about all Fronius products and our global sales partners and representatives can be found at THREE BUSINESS UNITS, ONE GOAL: TO SET THE STANDARD THROUGH TECHNOLOGICAL ADVANCEMENT.What began in 1945 as a one-man operation now sets technological standards in the fields of welding technology, photovoltaics and battery charging. Today, the company has around 5,440 employees worldwide and 1,264 patents for product development show the innovative spirit within the company. Sustainable development means for us to implement environmentally relevant and social aspects equally with economic factors. Our goal has remained constant throughout:to be the innovation leader.a w 21Fronius International GmbH Froniusplatz 14600 Wels AustriaTelephone +43 7242 241-0Fax +43 7242 241-953940*****************Fronius UK LimitedMaidstone Road, Kingston Milton Keynes, MK10 0BD United KingdomTelephone +44 1908 512 300Fax +44 1908 512 329*******************www.fronius.co.thE N v 01 A u g2020FOR MORE INFORMATIONabout TransSteel, visitREGISTER YOURPOWER SOURCEto extend your warrantyhttps:///pw/product-registrationTECHNICAL DATA。

![Emc300A说明书V4[1].0](https://uimg.taocdn.com/87da0df0f90f76c661371a17.webp)

前言感谢您购买伏达仪器,在您使用本仪器之前,请首先确认下一页“装箱清单”中所列的所有配件是否齐全,若发现配件不齐,或有错误,请尽快与我公司或我们的代理商联系,以维护您的权益。

本仪器为精密电子仪器,为确保正确使用,以免使仪器遭到不必要的损坏,在操作仪器之前请详细阅读本使用手册;请妥善保存本手册,以便遇到问题时能及时查阅。

公司声明:1.对于本手册的内容如有不同理解,以本公司技术部门为准。

2.本手册所描述的内容可能并非仪器的所有内容,本公司有权对本产品的性能、功能、外观、附件、包装物等进行改进或改变,而不另行通知。

3.若有疑问请与我们联系。

装箱清单EMC300A 接收机1台同轴电缆1根通讯线1根电源线1根使用手册1份(电子档) 保修卡1份合格证1份0.5A保险丝1只目录前言1装箱清单2第一章概述 61.1引言61.2术语解释 61.3 功能及技术指标 8 第二章系统的安装 102.1系统的组成 102.2测试环境要求 102.3安装112.3.1地线安装 112.3.2仪器安装 112.3.3软件安装 132.4几种典型被测器件的布置142.4.1节能灯的布置 142.4.2电子镇流器的布置 142.4.3电子变压器的布置 152.4.4灯具的布置 162.4.5家用电器、电热器具及电动工具的布置 162.4.5.1台式设备的布置162.4.5.2落地式设备的布置182.4.5.3 无接地连接的手持设备布置 19第三章操作步骤入门 223.1操作步骤简述 223.2参数设置233.3特别注意25 第四章操作说明 264.1测试前的准备264.2进入主页264.2.1进入主页 264.2.2串行口选择 264.3图标概述284.4测试294.4.1选择标准 294.4.2扫频参数设置 324.4.3扫频测试334.4.4单点测试334.4.5终测 344.4.5.1自动终测 344.4.5.2手动终测 364.5放大扫频图 374.6保存测试结果 374.7打开测试结果 384.8打印报告 384.8.1打印扫频图384.8.2打印终测数据384.9 计量检定38第五章系统故障 395.1使用简单的对比方法 395.2 常见故障及处理方法 39第六章使用环境及保修 416.1使用环境 416.2更换保险丝 416.3保修 42第七章包装储运 437.1标志 437.2 包装 437.3 运输 437.4 储存 43第一章概述1.1引言当今,电子、电器产品的电磁兼容性越来越受到各国的重视,尤其是欧美等发达国家,更是强制执行。

AT8586多功能一体化集成拆焊维修系统型号:AT8586 品牌:安泰信(ATTEN)应用范围1.工业生产进行电子产品装配2.科研部门进行产品开发3.维修行业进行电子产品检修4.各企事业单位电工进行锡焊操作5.电子技术爱好者进行电子装配6.各类院校电类学生进行技能实训功能特点●传感器闭合回路,微电脑PID控制,控温精确。

LED数码显示各种状态,按键切换,方便直观。

●热风枪功率大,升温迅速,出风柔和,风量大,非常适合无铅拆焊作业。

●焊台发热体采用低压电源供电,能有效的保护敏感器件及工作人员安全。

●完美的二合一组合,采用塑料外壳,机身小巧,占用工作台面积小。

●故障自我检测报警功能。

技术参数总机额定电压:AC 220V±10% 50Hz整机功率:750W±10%(最大)工作环境:0~40℃ 相对湿度<80%储存温度:-20~80℃ 相对湿度<80%热风枪部分工作电压:AC 220V±10% 50Hz输出功率:700W±10%温度范围:100℃~500℃ 气流量120L/min(最大)温度稳定度:±2℃ (静态)设置方式:按键调节显示方式:LED数显校温方式:数字校准温度锁定方式:数字式喷咀:A1130、A1170、A1110发热丝:700W 220V AT858发热丝电焊台部分工作电压:AC 26V±10% 50Hz输出功率:50W±10%温度范围:200℃~480℃温度稳定度:±2℃ (静态)设置方式:按键调节显示方式:LED数显校温方式:数字校准温度锁定方式:数字式焊咀对地阻抗:<2Ω焊咀对地电压:<2mV烙铁头:AT-02-SI发热芯:50W四芯陶瓷发热芯包装清单(购买时请检查包装,以证实所列清单项目正确无误。

)●设备主机连热风枪手柄:1台●热风枪手柄支架:1套●电焊铁:1支●烙铁座:1个●电源线:1条●清洁海绵:1份●说明书:1本●保修卡:1份使用指南1.安装新机器第一次使用时,必须安装热风枪手柄支架,如下图。

焊接设备操作说明书1. 简介焊接是一种常见的金属加工方法,通过高温熔化金属并使其沿接触面融合,从而实现金属材料的连接。

本操作说明书旨在向操作人员提供使用焊接设备的详细指导,确保操作的安全性和效率。

2. 设备准备在使用焊接设备之前,请确保以下准备工作已完成:- 检查设备是否完好,如有损坏请立即维修或更换;- 确认设备连接正确并处于稳定状态;- 准备好所需焊接材料和辅助设备,如焊条、电极等。

3. 安全注意事项焊接过程涉及高温和电流,因此在操作时务必遵循以下安全注意事项:- 戴上防护手套、面罩和防火服,确保人身安全;- 在操作环境内安装灭火器,以应对可能的火灾风险;- 在操作结束后,断开电源并冷却设备及焊接表面,避免烫伤。

4. 操作步骤4.1 准备工作- 将焊接设备连接到电源并打开电源开关;- 将焊接材料放在合适的位置,并确保其与设备的连接牢固。

4.2 调整设备参数- 根据所需焊接材料的特性,调整设备上的参数,如电流、电压、焊接速度等;- 注意根据焊接材料的厚度和类型进行合理的调整。

4.3 开始焊接- 将焊接材料端面对接,并将焊接设备的电极或焊条与材料接触;- 按下设备上的焊接按钮或扳手,启动焊接过程;- 在焊接过程中保持稳定的手持姿势,确保焊接线路的畅通。

4.4 结束焊接- 在焊接完成后,松开焊接按钮或扳手,停止焊接过程;- 断开电源,并在设备冷却后将其存放在安全位置。

5. 故障排除在使用焊接设备时,可能会出现一些常见的故障情况,如焊接不牢固、电源中断等。

以下是一些常见问题的排除方法:- 焊接不牢固:检查焊接设备参数是否正确设置,检查焊接材料的质量;- 电源中断:检查电源线是否连接松动或被损坏。

6. 维护保养为了延长焊接设备的使用寿命并确保操作的稳定性,定期进行维护保养是必要的。

以下是一些常见的维护保养工作:- 清洁设备表面和连接器,确保无积尘和腐蚀;- 定期检查电源线和焊接电极的连接状态,确保稳定;- 更换损坏或老化的零部件,确保设备的正常运行。

本文部分内容来自网络整理,本司不为其真实性负责,如有异议或侵权请及时联系,本司将立即删除!== 本文为word格式,下载后可方便编辑和修改! ==神牛说明书篇一:程控气动点(凸)焊机使用说明书 (数控)江阴市神牛自动化焊接设备有限公司D(T)N系列交流气动式点(凸)焊机使用说明书□ 感谢您购买了神牛焊接产品□ 为了安全正确使用焊机敬请详细阅读使用说明书地址:江阴市周庄镇东林村工业园区168号销售部电话:0510—80129913 技术咨询电话:0510—80129923 售后服务电话:0510—801299130510-80129923 传真:0510-********目录原理及用途;主要技术参数;设备的安装;控制器主要功能和特点;使用前的一般检查及准备;操作方法及调试;注意事项;常见焊接质量问题及处理;焊机的维护与保养;运输及保修;一.原理及用途DN/D(T)N系列交流气动程控电阻点(凸)焊机,是将工频交流电经阻焊变压器,转换成低压、大电流,在电极对工件施加一定压力下进行通电焊接的设备。

焊接电流大小及通电时间长短,由单片机程序控制可控硅的导通角及开通时间来实现,电极对工件加压由气动部分组成。

该设备具有操作简便,性能可靠和焊接生产效率高等特点,具有电阻点焊、凸焊,钎焊等多种功能,广泛应用在五金电器,汽车制造,机械制造等行业。

二.主要技术参数三.设备的安装使用环境:设备的使用环境必须通风良好,避免在易爆、易燃气体,多尘、多潮及高温等场地使用。

连接电源线:接380伏两相交流电源,要求电源线每平方毫米通过的电流不大于10安培,选择电源线的截面和空气开关的额定电流,根据焊机正常使用时的工作电流来确定。

为确保人身安全,设备外壳要良好接地。

连接压缩空气:要求压缩空气的额定压力大于0.4MPa,气路安装滤水器过滤,并要按时排水,以保证压缩空气无积水。

安装冷却水,焊机在长期使用时需通水冷却,并要保证水质纯净。

在每分钟的流量不小于1.0升,并要检查各管道有无堵塞,各接头有无漏水现象。

HT-46This compact heater is designed for many different applications including electrical and electronic enclosures, display panels, access and parking control systems and personnel booths. To determine the required heater size follow this equation:PH = (A x ∆T x k) - Pv P H = Required heating power for your application in Watts (W) P v = Heating power generated byexisting components (e.g. a transformer) in Watts (W) A = Exposed enclosure surface area square meters (m²) ∆T = Temperature differentialbetween the desired minimum interior temperature and lowest possible external temperature of the enclosure in Kelvin (K), 1.8°F = 1°C = 1K k = Heat transmission coefficient of the enclosure material used: Stainless Steel: 3.7 W/m²K Painted Steel: 5.5 W/m²K Aluminum: 12 W/m²K Polyester/Plastic: 3.5 W/m²K For outdoor applications it is recommended to double the heating power. Specifications Operating Voltage: 120 Vac Wattage: HVL02900: 100 W HVL03900: 150 WHVL13900: 200 WHVL14900: 300 W HVL15900: 400 WU Small, Compact Size Fan HeaterU Built-In Overheat ProtectionU DIN Rail MountableU M aintains MinimumOperating Temperatures in EnclosuresU H elps to Prevent Failure of Electronic Components Caused by Condensation and Corrosion Ordering Examples: HVL02900, fan heater, 100 W, 120 Vac.HVL14900, fan heater, 300 W, 120 Vac.Dimensions: mm (inch)200/300/400 W Heater HVL02900shown smaller than actual size.Heating Element: Resistance type cartridge heater Heat Sink: Die-cast aluminum, glass bead finish Required Fan Size (Included): 100/150 W: 80 x 80 x 25 mm(3.1 x 3.1 x 0.98") Min Air Flow: 35 m³/h (115 ft3/h) (20 cfm) 200/300/400 W: 120 x 120 x 25 mm (4.7 x 4.7 x 0.98") Min Air Flow: 108 m³/h (354 ft3/h) (63 cfm)Overheat Protection: Built-in temperature limiter Air Exit Temperature: Approx. 45°C (113°F) 50 mm (2") above heater Wiring Compartment: Plastic UL 94V-O Connection (Heater): 3-pole terminal,AWG 14 max [2.5 mm² (0.10 in 2)]Connection (Axial Fan): 2-poleterminal (L2/N2), AWG 14 max [2.5 mm² (0.10 in 2)]Mounting:Clip for 35 mm (1.4") DIN rail (EN 50022)Protection Class: I (grounded)Protection Type: NEMA 2 (IP20)Weight (with Fan): 100/150 W: 600 g (1.3 lb) 200/300/400 W: 900 g (2.0 lb)ø = diameterCOMPACT FAN HEATER。

SOFTA-300S的使用说明

打开电源仪器自检出现自检完成后,这是仪器处于待机状态按电源键仪器进入工作状态。

主屏幕:

1 仪器屏幕上滚动显示操作条件DT,SC,和GAS 等

2 如果在右上角看到一个*,按POWER键可以看到错误提示界面。

3 按POWER键到主采单用上下键选择需要调节的参数

DT 漂移管(室温---120度)

SC 雾化室(室温---80度)

ET 排气管(室温---120度)

OC 光学池(室温—120度)

BLN 基线状态

GAS 气体压力(50PSI左右)

FIT 基线过滤(默认关闭可设定1---10)

CL 校正(20---200)

FS 全量程(5V或10MV)

使用:开机正常后调节雾化室和漂移管的温度,打开气源调节气体压力,当雾化室和漂移管的温度达到射定值时,开泵进入流动相,等待基线稳定。

如基线噪音大可调节基线过滤器直到基线平稳即可进样。

2 关机前先断开流动相用气体吹扫5分钟左右然后关气源关检测器

3在仪器的使用中排气管要有气体排出,热裂解管中不能有气体排出只能有液体流出。