激光红外补光灯产品介绍

- 格式:pdf

- 大小:1.13 MB

- 文档页数:8

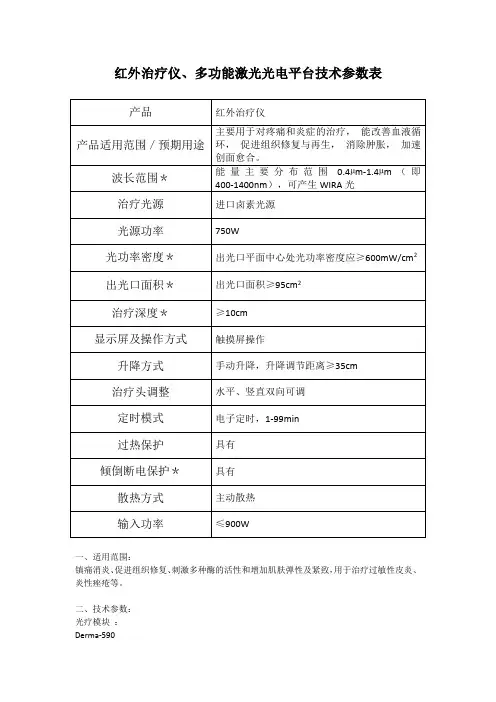

红外治疗仪、多功能激光光电平台技术参数表

一、适用范围:

镇痛消炎、促进组织修复、刺激多种酶的活性和增加肌肤弹性及紧致,用于治疗过敏性皮炎、炎性痤疮等。

二、技术参数:

光疗模块:

Derma-590

1. 光源类型:LED/可见光

2. 输出波长:590nm±5nm

3. 光源组成:400颗

4. 输出强度:25mW/cm²±25%

5. 光照面积:750 cm2,治疗头有5个发光瓣,可根据患处调节光源角度

6. 治疗时间:1~99min可调,步长1min

7. 工作模式:连续/脉冲模式

电疗模块:

Derma-CR

1、输出强度:0-15档

2、脉冲频率:4×(1±5%)MHz

3、治疗时间:1~60min可调,步长1min

4、输出方式:连续输出

主机平台

1、电源:~220V / 50Hz

2、显示屏:8寸液晶显示屏

3、脚轮配置:4个万向轮

4、操作控制系统:全电脑触摸屏操作控制

5、抬升动力系统配置:360°四关节旋转臂

6、有治疗头温度指示功能。

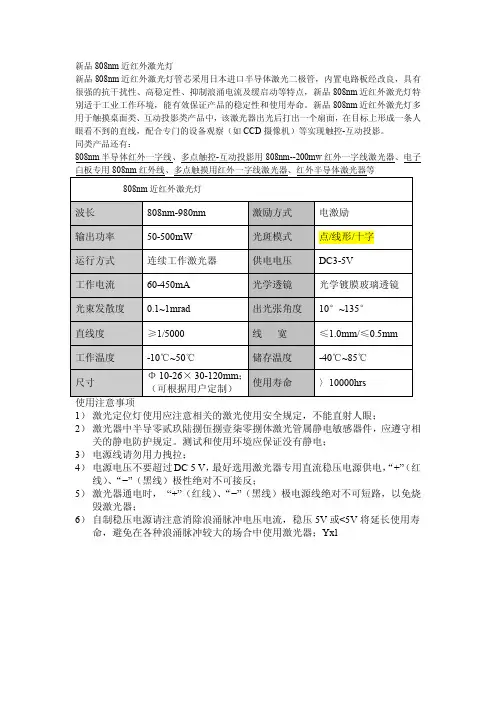

新品808nm近红外激光灯

新品808nm近红外激光灯管芯采用日本进口半导体激光二极管,内置电路板经改良,具有很强的抗干扰性、高稳定性、抑制浪涌电流及缓启动等特点,新品808nm近红外激光灯特别适于工业工作环境,能有效保证产品的稳定性和使用寿命。

新品808nm近红外激光灯多用于触摸桌面类、互动投影类产品中,该激光器出光后打出一个扇面,在目标上形成一条人眼看不到的直线,配合专门的设备观察(如CCD摄像机)等实现触控-互动投影。

同类产品还有:

808nm半导体红外一字线、多点触控-互动投影用808nm--200mw红外一字线激光器、电子

波长激励方式

输出功率光斑模式

运行方式供电电压

工作电流光学透镜

光束发散度出光张角度

直线度线宽

工作温度储存温度

尺寸;

使用寿命

1)激光定位灯使用应注意相关的激光使用安全规定,不能直射人眼;

2)激光器中半导零贰玖陆捌伍捌壹柒零捌体激光管属静电敏感器件,应遵守相关的静电防护规定。

测试和使用环境应保证没有静电;

3)电源线请勿用力拽拉;

4)电源电压不要超过DC5V,最好选用激光器专用直流稳压电源供电,“+”(红线)、“−”(黑线)极性绝对不可接反;

5)激光器通电时,“+”(红线)、“−”(黑线)极电源线绝对不可短路,以免烧毁激光器;

6)自制稳压电源请注意消除浪涌脉冲电压电流,稳压5V或<5V将延长使用寿命,避免在各种浪涌脉冲较大的场合中使用激光器;Yxl。

定焦系列VCSEL红外激光灯使用说明书(型号:IR-850-1W-D45)深圳市三千米光电科技有限公司2018-04-02一、 三千米激光照明产品简介三千米凭借自主研发的激光器封装工艺的独特优势,专注于激光技术与应用的研发、制造,产品跨控几大新兴高科技行业,在夜视照明、无人机、VR/AR/MR、汽车辅助驾驶、激光测距、激光雷达、颜色鉴别等应用领域有着异常广泛的应用。

在夜视照明行业,是目前唯一拥有全系列红外激光照明产品制造商,主要应用于夜间视频监控辅助照明,与摄像监控设备配合使用,组成夜视监控系统,用于全天候条件下,特别是夜间的远距离连续监控摄像,以便在全黑无光的极端条件下也能获得清晰准确的监控画面。

它适用于各类安防监控系统,夜视照明距离与角度完美的适配市面上所有的安防监控系统。

●定焦系列——从50米到500米;照明角度3.0°、8.0°、15.0°、30.0°、45.0°、65.0°、特殊角度需求定制。

●变焦系列——从300米到5公里;远近角度从0.3°到70.0°。

可满足不同应用场合的应用要求:家用监控设备、无人机、飞行时间测距(TOF)、平安城市、智能交通、车载系统、监狱、边防海防、森林防火、油田油库、大型厂区、安全部门、生态保护区、能源采矿、水利电力、机场港口、行政执法、渔政海监等。

二、 IR-850-1W-D45产品特点1、行业应用●安防夜视照明;●无人机;●飞行时间测距(TOF):3D成像、人脸识别、手势识别、体感识别、激光雷达等。

2、产品特点●固定角度:45.0°。

●集成了激光测距模块。

●专利封装技术,光电转化功率较高。

●体积小,比LED红外小三分一以上,完全兼容主流的产品结构。

●有效距离远,亮度高。

3、品质特点● -40.0℃~+85.0℃工业级工作温度范围。

●整机连续使用寿命50000小时以上。

1.ED红蓝光治疗机什么是1.EDiI宣光治疔机?红蓝光光动力治疗仪选用窄谱1.ED光源所发出的是一种冷光,不产生高热,不会灼伤皮肤,它将光能转为细胞内能盘,加速细胞生长过程循环,刺激纤维细胞产生胶原蛋白。

对修复老化皮肤、瘗疮皮肤、斑性皮肤、皱纹皮肤、过敏症状、日晒灼伤皮肤都能带来意想不到的功效,并且不会对皮肤造成任何损害和不适感,光动力是治疗座疮和嫩肤最,F安而且效果显著的仪器之一。

光治疗机各■光的应用一、红光:波长为635nm的红光具行纯度高、光源强、能最密度匀称的特点,在皮肤护理、保健治疗中效果显若,被称为生物活性光。

红光能让细胞的活性提高,促进细胞的新陈代谢,使皮肤大量分泌胶原蛋白与纤维组织来自身填充。

加速血液循环,增加肌肤弛性,改善皮肤姜黄、暗哑的状况,从而达到抗苍老、抗氧化、修史的功效,有着传统护肤无法达到的效果。

主要功效:美白淡斑、嫩肤祛皱、修复受损皮肤、抚平细小皱纹、缩小毛孔、增生胶原蛋白。

窄普红光(630nm±10nm):1、红光能让细胞的活性提高,促进细胞的新陈代谢,使皮肤大最分泌胶原蛋白与纤维组织来自沙填充,加速血液循环,增加肌肤弹性,改善皮肤萎黄、暗哑的状况,从而达到抗苍老、抗氧化、修复的功效。

2、被纤维原细胞充分汲取,促进细胞生长过过程。

3、增加新胶原质弹性蛋白和胶原蛋白的生长。

4、加厚和重组真皮结构C5、形成红润、细致又弹性的肌肤。

二、篮光:波长为415nm的蓝光具有快速抑制炎症的功效,在座疮的形成过程中,主要是丙酸杆菌在起作用所致,而蓝光可以在对皮肤组织至无损伤的状况下,高效的破坏这种细曲,最大限度削减座疮的形成,并且在很短时间内使炎症期的痒疮明显削减至愈合。

窄普蓝光(470nm±IOnm):1、激活座疮内的内源内吓噂IX的产生生成毒性单态氧基2、杀死座疮内的丙酸杆的3、快速消退座疮脓包,改善红色难看的肌肤三、紫光:是红光和绿光的双频光,其结合了两种光的功效,尤其在治疗瘁疮和祛瘁疮印痕方面有着特殊好的效果和修复作用。

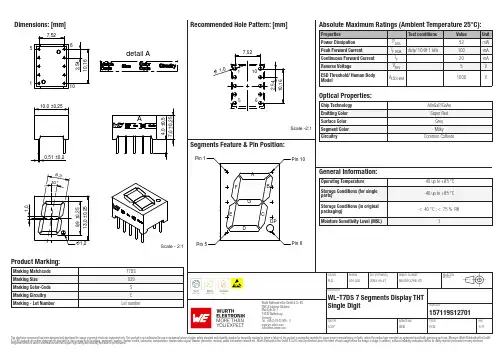

Dimensions: [mm]15detail AScale - 2:1157119S12701Schematic:157119S12701157119S12701157119S12701157119S12701157119S12701157119S12701T e m p e r a t u r eT T T 157119S12701Cautions and Warnings:The following conditions apply to all goods within the product series of Optoelectronic Components of Würth Elektronik eiSos GmbH & Co. KG:General:•This optoelectronic component is designed and manufactured for use in general electronic equipment.•Würth Elektronik must be asked for written approval (following the PPAP procedure) before incorporating the components into any equipment in fields such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network, etc. where higher safety and reliability are especially required and/or if there is the possibility of direct damage or human injury.•Optoelectronic components that will be used in safety-critical or high-reliability applications, should be pre-evaluated by the customer. •The optoelectronic component is designed and manufactured to be used within the datasheet specified values. If the usage and operation conditions specified in the datasheet are not met, the wire insulation may be damaged or dissolved.•Do not drop or impact the components, the component may be damaged•Würth Elektronik products are qualified according to international standards, which are listed in each product reliability report. Würth Elektronik does not warrant any customer qualified product characteristics beyond Würth Elektroniks’ specifications, for its validity and sustainability over time.•The responsibility for the applicability of the customer specific products and use in a particular customer design is always within the authority of the customer. All technical specifications for standard products also apply to customer specific products.Product specific:Soldering:•The solder profile must comply with the technical product specifications. All other profiles will void the warranty.•All other soldering methods are at the customers’ own risk.Cleaning and Washing:•Washing agents used during the production to clean the customer application might damage or change the characteristics of the optoelectronic component body, marking or plating. Washing agents may have a negative effect on the long-term functionality of the product.•Using a brush during the cleaning process may break the optoelectronic component body. Therefore, we do not recommend using a brush during the PCB cleaning process.Potting:•If the product is potted in the customer application, the potting material might shrink or expand during and after hardening. Shrinking could lead to an incomplete seal, allowing contaminants into the optoelectronic component body, pins or termination. Expansion could damage the components. We recommend a manual inspection after potting to avoid these effects.Storage Conditions:• A storage of Würth Elektronik products for longer than 12 months is not recommended. Within other effects, the terminals may suffer degradation, resulting in bad solderability. Therefore, all products shall be used within the period of 12 months based on the day of shipment.•Do not expose the optoelectronic component to direct sunlight.•The storage conditions in the original packaging are defined according to DIN EN 61760-2.•For a moisture sensitive component, the storage condition in the original packaging is defined according to IPC/JEDEC-J-STD-033. It is also recommended to return the optoelectronic component to the original moisture proof bag and reseal the moisture proof bag again. •The storage conditions stated in the original packaging apply to the storage time and not to the transportation time of the components. Packaging:•The packaging specifications apply only to purchase orders comprising whole packaging units. If the ordered quantity exceeds or is lower than the specified packaging unit, packaging in accordance with the packaging specifications cannot be ensured. Handling:•Violation of the technical product specifications such as exceeding the nominal rated current, will void the warranty.•The product design may influence the automatic optical inspection.•Certain optoelectronic component surfaces consist of soft material. Pressure on the top surface has to be handled carefully to prevent negative influence to the function and reliability of the optoelectronic components.•ESD prevention methods need to be applied for manual handling and processing by machinery.•Resistors for protection are obligatory.•Luminaires in operation may harm human vision or skin on a photo-biological level. Therefore direct light impact shall be avoided. All products are additionally certified as risk groups 0 to 2 according to DIN EN 62471:2008.•In addition to optoelectronic components testing, products incorporating these devices have to comply with the safety precautions given in IEC 60825-1, IEC 62471 and IEC 62778•Please be aware that Products provided in bulk packaging may get bent and might lead to derivations from the mechanical manufacturing tolerances mentioned in our datasheet, which is not considered to be a material defect.Technical specification:•The typical and/or calculated values and graphics of technical parameters can only reflect statistical figures. The actual parameters of each single product, may differ from the typical and/or calculated values or the typical characteristic line.•On each reel, only one bin is sorted and taped. The bin is defined on intensity, chromaticity coordinate or wavelength and forwardWürth Elektronik eiSos GmbH & Co. KGEMC & Inductive SolutionsMax-Eyth-Str. 174638 WaldenburgGermanyCHECKED REVISION DATE (YYYY-MM-DD)GENERAL TOLERANCE PROJECTIONMETHODPLD001.0022023-05-27DIN ISO 2768-1mDESCRIPTIONWL-T7DS 7 Segments Display THTSingle Digit ORDER CODE157119S12701SIZE/TYPE BUSINESS UNIT STATUS PAGEvoltage.•In order to ensure highest availability, the reel binning of standard deliveries can vary. A single bin cannot be ordered. Please contact us in advance, if you need a particular bin sorting before placing your order.•Test conditions are measured at the typical current with pulse duration < 30ms. •Wavelength tolerance under measurement conditions ± 2nm. •Optical intensity tolerance under measurement conditions ±15%. •Forward voltage tolerance under measurement conditions ± 0.2V.These cautions and warnings comply with the state of the scientific and technical knowledge and are believed to be accurate and reliable.However, no responsibility is assumed for inaccuracies or incompleteness.Würth Elektronik eiSos GmbH & Co. KG EMC & Inductive Solutions Max-Eyth-Str. 174638 Waldenburg GermanyCHECKED REVISION DATE (YYYY-MM-DD)GENERAL TOLERANCEPROJECTION METHODPLD001.0022023-05-27DIN ISO 2768-1mDESCRIPTIONWL-T7DS 7 Segments Display THT Single DigitORDER CODE157119S12701SIZE/TYPEBUSINESS UNITSTATUSPAGEImportant NotesThe following conditions apply to all goods within the product range of Würth Elektronik eiSos GmbH & Co. KG:1. General Customer ResponsibilitySome goods within the product range of Würth Elektronik eiSos GmbH & Co. KG contain statements regarding general suitability for certain application areas. These statements about suitability are based on our knowledge and experience of typical requirements concerning the areas, serve as general guidance and cannot be estimated as binding statements about the suitability for a customer application. The responsibility for the applicability and use in a particular customer design is always solely within the authority of the customer. Due to this fact it is up to the customer to evaluate, where appropriate to investigate and decide whether the device with the specific product characteristics described in the product specification is valid and suitable for the respective customer application or not.2. Customer Responsibility related to Specific, in particular Safety-Relevant ApplicationsIt has to be clearly pointed out that the possibility of a malfunction of electronic components or failure before the end of the usual lifetime cannot be completely eliminated in the current state of the art, even if the products are operated within the range of the specifications.In certain customer applications requiring a very high level of safety and especially in customer applications in which the malfunction or failure of an electronic component could endanger human life or health it must be ensured by most advanced technological aid of suitable design of the customer application that no injury or damage is caused to third parties in the event of malfunction or failure of an electronic component. Therefore, customer is cautioned to verify that data sheets are current before placing orders. The current data sheets can be downloaded at .3. Best Care and AttentionAny product-specific notes, cautions and warnings must be strictly observed. Any disregard will result in the loss of warranty.4. Customer Support for Product SpecificationsSome products within the product range may contain substances which are subject to restrictions in certain jurisdictions in order to serve specific technical requirements. Necessary information is available on request. In this case the field sales engineer or the internal sales person in charge should be contacted who will be happy to support in this matter.5. Product R&DDue to constant product improvement product specifications may change from time to time. As a standard reporting procedure of the Product Change Notification (PCN) according to the JEDEC-Standard inform about minor and major changes. In case of further queries regarding the PCN, the field sales engineer or the internal sales person in charge should be contacted. The basic responsibility of the customer as per Section 1 and 2 remains unaffected.6. Product Life CycleDue to technical progress and economical evaluation we also reserve the right to discontinue production and delivery of products. As a standard reporting procedure of the Product Termination Notification (PTN) according to the JEDEC-Standard we will inform at an early stage about inevitable product discontinuance. According to this we cannot guarantee that all products within our product range will always be available. Therefore it needs to be verified with the field sales engineer or the internal sales person in charge about the current product availability expectancy before or when the product for application design-in disposal is considered. The approach named above does not apply in the case of individual agreements deviating from the foregoing for customer-specific products.7. Property RightsAll the rights for contractual products produced by Würth Elektronik eiSos GmbH & Co. KG on the basis of ideas, development contracts as well as models or templates that are subject to copyright, patent or commercial protection supplied to the customer will remain with Würth Elektronik eiSos GmbH & Co. KG. Würth Elektronik eiSos GmbH & Co. KG does not warrant or represent that any license, either expressed or implied, is granted under any patent right, copyright, mask work right, or other intellectual property right relating to any combination, application, or process in which Würth Elektronik eiSos GmbH & Co. KG components or services are used.8. General Terms and ConditionsUnless otherwise agreed in individual contracts, all orders are subject to the current version of the “General Terms and Conditions of Würth Elektronik eiSos Group”, last version available at .Würth Elektronik eiSos GmbH & Co. KGEMC & Inductive SolutionsMax-Eyth-Str. 174638 WaldenburgGermanyTel. +49 (0) 79 42 945 - 0*******************CHECKED REVISION DATE (YYYY-MM-DD)GENERAL TOLERANCE PROJECTIONMETHODPLD001.0022023-05-27DIN ISO 2768-1mDESCRIPTIONWL-T7DS 7 Segments Display THTSingle Digit ORDER CODE157119S12701SIZE/TYPE BUSINESS UNIT STATUS PAGE0.39"eiPal PCN11/11This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation, transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.。

补光灯技术参数-概述说明以及解释1.引言1.1 概述补光灯技术参数是指在不同拍摄或摄影环境下,补光灯的功率、亮度、色温等技术参数的设定和调整。

补光灯在摄影、摄像等领域中扮演着重要的角色,它能够提供额外的光源,补充主光源不足的地方,以获得更好的拍摄效果。

因此,了解和掌握补光灯技术参数对于提升拍摄质量至关重要。

本文将系统地介绍补光灯技术参数的重要性、影响因素、不同场景下的选择,以及对其未来发展趋势和应用前景的展望,旨在为读者提供全面的补光灯技术参数知识,帮助其更好地应用于实际工作中。

1.2 文章结构文章结构部分的内容可以写为:文章结构包括引言、正文和结论三部分。

引言部分将概述补光灯技术参数的重要性、影响因素以及不同场景下的选择,同时介绍本文结构和目的。

正文部分将会详细讨论补光灯技术参数的重要性、影响因素以及在不同场景下的选择,结合实际案例和数据进行分析。

结论部分将对前文进行总结,并展望补光灯技术参数的发展趋势和应用前景。

整篇文章将在逻辑严谨的基础上,对补光灯技术参数进行深入剖析,为读者提供全面的专业知识和指导。

1.3 目的:本文旨在深入探讨补光灯技术参数在摄影和摄像领域中的重要性以及其对照明效果的影响因素。

通过对不同场景下补光灯技术参数的选择进行分析,希望能够为摄影师和摄像师提供实用的技术指导,使他们能够更好地根据具体需求选择合适的补光灯技术参数。

同时,本文也将展望补光灯技术参数的发展趋势,并探讨其在未来的应用前景,为行业和技术发展提供一定的参考和借鉴。

2.正文2.1 补光灯技术参数的重要性补光灯技术参数的重要性在于它直接影响着照明效果和拍摄质量。

首先,补光灯的亮度参数是其最基本的技术参数之一,它决定了照射物体的亮度和清晰度。

其次,色温参数也是补光灯技术参数中至关重要的一个,不同的色温会带来不同的照明效果,影响到拍摄物体的色彩还原度。

此外,补光灯的光束角度、光源稳定性、调光方式等参数也都直接影响着照明效果的实际表现。

ED白光补光灯与红外补光灯的区别?cmkeji88|创建时间:2015年05月18日10:12|浏览:1764|评论:0标签:LED白光灯LED补光灯LED红外灯红外灯的原理及应用(一)红外灯的选择和使用红外灯的选择最重要的问题是红外灯与摄像机、镜头、防护罩、供电电源等的成套性。

有的人买完了摄像机、镜头、防护罩、电源,甚至安装之後才考虑购买红外灯,这是不正确的,应在设计方案时就对所有器材综合考虑,将它视为一个红外低照度夜视监控系统工程来进行设计(二)红外发光二极管(LED)原理红外灯发光体是由红外发光二极管(LED)矩阵组成。

红外发光射二极管由红外辐射效率高的材料制成PN结,外加正向偏压向PN结注入电流激发红外光。

光谱功率分布为中心波长830 -- 950nm,半峰带宽约40nm左右,如图1(850nm、940nm红外发光二极管的光谱分布图)所示。

它是窄带分布,为普通CCD黑白摄像机可感受的范围。

其最大的优点是可以完全无红暴,(采用940~950nm波长红外管)或仅有微弱红暴(采用850nm 波长红外管);还具有寿命长的特点。

(三)光控软开关电路电路本红外灯采用了光控软开关电路,以减少其工作状态转换的冲击,延长红外灯的使用寿命。

(四)稳压恒流电路为补偿红外灯冬季与夏季红外光辐射功率的差异,本红外灯采用了稳压恒流电路,使红外发光二极管光功率稳定,从而提高了红外灯的使用效果,延长了使用寿命。

区别:红外灯工作时温度很高(LED管正常工作温度要求不高于30度,否则将影响投射距离和使用寿命),使用寿命很短。

这主要是因为LED管过流产生的,LED管如果供电电流过大散热又不好,随着温度不断升高电流也逐渐加大,光衰越来越严重甚至烧毁LED管;很多厂家为了提高出厂时灯的投射效果,把电流设得太大,用户购买时感觉效果还不错,可是安装没多久投射效果就不行了红外灯的发光转换功率是固定的,如果想发光角度大,那自然会牺牲照射距离,相反,如果保证照射距离就会牺牲角度!选择红外灯的角度是一个十分重要的问题。

激光植物补光灯的原理

激光植物补光灯是依照植物生长的自然规律,利用灯光代替太阳光来提供植物生长发育所需光源的一种灯具。

它可以根据植物利用太阳光进行光合作用的原理,模拟自然阳光中的红光和蓝光,为植物提供充足的光照,从而促进植物的生长和发育。

在光合作用中,植物利用光能将二氧化碳和水合成有机物质,并释放出氧气。

红光和蓝光是光合作用中重要的两种光线,红光可以促进植物的开花和结果,蓝光则可以促进植物的生长和发育。

因此,植物补光灯可以模拟自然阳光中的红光和蓝光,为植物提供充足的光照。

除此之外,激光植物补光灯还有其他优点。

例如,它可以解决光照不足的问题,让室内植物也能健康成长。

尤其在冬季或阴雨天,太阳光照不足,使用补光灯可以有效促进植物生长,保证植物正常发育。

以上内容仅供参考,如需更多专业信息,建议查阅植物补光灯相关文献或咨询农业专家。

红外激光照明:顾名思义就是采用红外波长的激光器作为光源,通过一定的光学变换而达到的一种照明效果。

一、原理简介:在自然光照明被动成像测量条件下,由于各种背景辐射的影响,限制了成像系统对远距离目标成像测量和精确跟踪能力。

采用激光主动照明的方式,对远、小、暗目标或其局部进行照明,可以减小背景辐射的影响,提高系统对远距离、小、暗目标的精确跟踪和高质量成像测量能力。

激光主动照明监视系统的工作原理与激光雷达基本相同。

通过调节发射激光束的聚焦状态(发散角),将目标全部或目标的关键特征部位照亮,满足接收系统探测要求,实现对目标的成像和精确跟踪的目的。

照明发射激光和回波信号在大气路径中传输,大气背景辐射、透过率、散射和吸收以及湍流等因素都将对主动照明成像产生影响。

红外激光照明是目前安防领域的新技术,尤其在长距离目标和精确跟踪领域具有独特的优势,是其他照明方式无法达到的。

目前,由深圳市量子通科技有限公司自主研发的红外激光照明器,就是采用光源自动或手动变焦、光强整形均匀化等红外激光夜视技术,通过将高功率半导体激光器和特有技术的光学系统结合,能够达到最高效率的光输出,同时具有优质的光斑,使照明范围内,光强分布均匀,有利于监控摄像头成优质的图象,可以很好地克服因为光强分布不均匀导致的成像忽明忽暗或者导致摄像头的饱和,无法实现监控。

该产品采用了多项独有关键技术,外壳进行加固密封处理,可广泛应用于需要在夜间、恶劣环境、远距离、大范围实时监控的场合。

同时由于采用了全球最好的激光二极管,所以同时这种红外激光器具有高可靠性,高稳定性以及寿命长的优点。

该产品配合红外摄像机、黑白CCD摄像机或微光夜视设备使用,组成夜视监测系统,用于全天候条件下、特别是夜间的远距离连续监视摄像,以便在全黑无光的条件下也能获得清晰准确的监控画面。

代替传统的红外灯,成为更加优良的夜视仪器红外照明装置。

二.产品特点:◆智能化同步变焦,与镜头变倍达到同步,操作简单,使用方便。

红蓝光治疗仪(LED光谱治疗仪)主要技术参数及商务要求主要技术参数:★1.设备要求:五片弧型扇面治疗头、并可伸展2.工作电压:AC220V-240V,50HZ或60HZ土2%。

3.额定功率:500VA□4.输出波长:红光633nm土IOnm;蓝光417nm土10nm;黄光590nm÷10nm;5.功率密度:红光4200mW/cm2±20%;蓝光4120mW∕cm2±20%;黄光≤42mW∕cm2±20%;6.定时范围:0〜99min连续可调7.照射强度:光源强度ITo(W可调★8.有效辐照面积:≥850cm29.光源类型:集红蓝黄三光源于同一治疗头,多种波长可供选择,无须更换治疗头;★10.光源选择:三种光源(红光、蓝光、黄光)一体,任意光源可同时开启,可单开,亦可复合光;★11•采用大功率SMD矩阵光源,排列密度大,使辐照强度更高、光斑更均匀:12.显示方式:采用8"全触屏辅以人性化的GUl设计,可旋转的触摸屏设计,13.照射方式:具有连续照射或脉冲照射两种工作模式,满足临床不同需求;★14.具有剂量和时间两种工作模式,更加适合光动力治疗,精准治疗;15.配备辐照强度校准系统,实时监测光源强度及使用情况,确保精准治疗:16.温馨的语音提醒,提醒患者及医护人员治疗情况,为患者带来轻松舒适的治疗体验;17.预存治疗方案,一键选择,操作更加便捷:18.自由升降阻尼悬寓设计,充分考虑人体工程学要求,方便操作,使光源可以在任意位置角度停留最大程度满足各种临床治疗环境;配置要求序号名称数量单位1主机1台2护目镜 3 副3液晶屏 1 个4底座 1 个5治疗头 1 个商务要求一、合同签订期:成交通知书发出之日起7个工作R。

二、交货期:自合同签订之日起30个日(自然日)内安装且调试完成并验收合格。

逾期交付的,采购人有权拒绝验收并取消成交供应商资格,所造成的一切损失由成交供应商负责。

红外线激光定位灯产品可广泛应用于各类工业加工机械,能起辅助标线与定位作用,如:轮胎成型机、木工机械、钢板划线定位、五金剪压机械、成衣加工、裁床裁剪对格与对条、纺织印染标示、制鞋机定位、运动器材加工、玻璃加工机械、电子SMT定位定格、印刷电路板标示定位、印刷机标示定位及建筑装潢等行业。

特点:红外线激光定位灯产品的安装机使用简单方便,可安装在使用机械的垂直或水平面上,提供一条可见的激光标线,使得在整个生产过程中有一条可见的、非接触的定位线指导操作过程。

具有方便生产操作和提高生产效率的优点。

激光线可在三维空间任意微调,已达到最佳使用效果。

应用领域红外线激光定位灯安装使用简单方便,通电即可使用,可广泛应用于轮胎成型机、纸张裁切机、金属锯床、pcb电路板切割机等工业机械的辅助定位,能较大幅度的提高工作效率。

一字线激光器线条清晰,小巧,易于安装。

参数光斑形状:一字线型波长:532nm 635nm 650nm可定制管芯功率:0~200mw(按要求定制工作电流:0~2000mA(可定制工作电压:5V 12V 24V 36V外形尺寸:①16X 55mm①16X 80mm①22x 85mm①26x 110mm选择光束发散度:0.3~1.5mrad出光张角:10(~135o光线直径:< 0.5mm @0.5m ; < 1.0mm @3.0m ; < 1.5mm @6.直线度:< 1.0mm@3.0m光学透镜:光学镀膜玻璃或塑胶透镜工作温度:-10~75C储存温度:-40~85C工作介质:半导体等级:川b可选配:专用支架、电源yxl。

红外补光灯的工作原理红外补光灯是一种广泛应用于夜间监控和安防领域的设备,它通过发射红外光来提供照明,以实现夜间监控的需求。

红外补光灯的工作原理可以简单描述为:利用红外光源发射红外光,红外光照射到物体上后,被物体表面吸收或反射,然后被摄像机接收和转化成电信号,从而实现夜间监控的目的。

红外补光灯的核心部件是红外光源,它通常采用发光二极管(LED)作为发光元件。

红外LED发射的光波长一般在850nm到940nm 之间,这是人眼无法直接看到的红外光。

红外光源的选择和性能对于红外补光灯的照明效果至关重要。

当红外补光灯工作时,红外LED会发射出红外光,这种光能够在夜间提供足够的照明。

红外光照射到物体上后,会被物体吸收或反射。

在监控领域,红外光主要被用于照亮被监控的区域,以提供摄像机所需的照明条件。

由于红外光的特殊性质,它能够穿透一些透明或半透明的材料,如玻璃、塑料等,因此在一些需要透过物体进行监控的场景中,红外光具有一定的优势。

红外补光灯的照明效果与红外光的功率、角度、距离等因素有关。

红外光功率的大小直接影响到照明的亮度,功率越大,照明亮度越高。

红外光的角度决定了照射范围的大小,角度越大,照射范围越广。

红外光与被照射物体的距离越近,照明效果越好。

因此,在选择和布置红外补光灯时,需要根据实际需求确定合适的功率、角度和距离。

除了红外光源,红外补光灯还包括一些其他的组成部分,如光学透镜、散热器、电源等。

光学透镜用于控制红外光的发射角度和照射范围,使其更加集中或扩散。

散热器用于散发红外光源产生的热量,以保证红外光源的稳定工作。

电源则提供电能支持红外光源的正常工作。

红外补光灯的工作原理简单明了,通过发射红外光,照亮被监控区域,为摄像机提供足够的照明条件。

它在夜间监控和安防领域具有重要的作用,在保障人们生命财产安全方面发挥着不可替代的作用。

随着科技的不断进步,红外补光灯的性能也在不断提高,将来有望在更多的领域得到应用。

激光夜视红外灯的作用原理

激光夜视红外灯的作用原理是利用激光和红外辐射技术,增强或补充低光或无光环境下的图像捕捉和观察能力。

具体原理如下:

1. 激光照明:激光夜视红外灯会发射一束高能激光光束,用于照亮低光或无光环境下的目标物体。

激光的定向性和高能量可以使目标物体易于被摄像设备捕捉和分析。

2. 红外辐射:激光夜视红外灯使用红外辐射技术,发射红外光,也称为红外线。

红外线光谱的特点是其波长较长,无法被人眼肉眼可见。

红外线的发射和接收可以帮助摄像设备在低光或无光环境中获取目标物体的图像。

3. 触发器和控制系统:激光夜视红外灯通常配备有触发器和控制系统,以精确控制光源的启动和停止时间,以及调整光源的亮度和照射角度等参数。

这有助于适应不同的拍摄场景和要求。

总的来说,激光夜视红外灯的作用原理是通过发射激光和红外线,使摄像设备能够在低光或无光环境下捕捉和观察目标物体,以提高图像质量和识别能力。

红外补光灯测试方法

红外补光灯是一种常见的安防监控设备,它能够在夜间或低光环境下提供红外光源,帮助摄像头获取更清晰的图像。

为了确保红外补光灯的正常工作和监控系统的稳定运行,需要对其进行定期的测试和维护。

下面我们将介绍一种常见的红外补光灯测试方法。

首先,需要准备一台红外感应摄像头和一台红外补光灯。

将两者连接到监控系统中,并确保其正常工作。

接下来,选择一个夜间或低光环境,确保周围没有其他光源干扰。

然后打开监控系统,观察红外补光灯是否能够正常工作。

可以通过监控系统的图像来检查红外补光灯的照射范围和亮度是否符合要求。

另外,还可以使用红外感应摄像头对红外补光灯进行测试。

在夜间或低光环境下,利用移动物体或人员来测试红外感应摄像头是否能够正常捕捉到目标,并触发红外补光灯的工作。

在测试过程中,需要注意观察红外补光灯的照射范围和亮度是否均匀,是否存在死角或盲区。

同时还需要检查红外补光灯是否存

在漏光或过度照射的情况。

在测试完成后,及时对红外补光灯进行清洁和维护,确保其长期稳定工作。

同时,也可以根据测试结果对监控系统进行调整和优化,提高整体的监控效果和安全性。

总之,红外补光灯是安防监控系统中不可或缺的重要设备,通过定期的测试和维护,可以保证其正常工作,提高监控系统的可靠性和稳定性。

希望以上介绍的红外补光灯测试方法能够对大家有所帮助。